Abstract

This paper presents the development of fleet management software for mobile robots, including AGV and AMR technologies, within the scope of a case study from the GreenAuto project. The system was designed to integrate position and status data from different robots, unifying this information into a single map. To achieve this, a web-based platform was developed to allow the simultaneous, real-time visualization of all robots in operation. However, the main challenge of this research lies in the heterogeneity of the fleet, which comprises robots of different makes and models from various manufacturers, each using distinct data formats. The proposed approach addresses this by facilitating fleet monitoring and management, ensuring a greater efficiency and coordination in the robot movement. The results demonstrate that the platform improves the traceability and operational supervision, promoting the optimized management of mobile robots. It is concluded that the proposed solution contributes to industrial automation by providing an intuitive and centralized interface, enabling future expansions for new functionalities and the integration with other emerging technologies. The proposed system demonstrated efficiency in updating and supervising operations, with an average latency of 120 ms for task status updates and an interface refresh rate of less than 1 s, enabling near real-time supervision and facilitating operational decision-making.

Keywords:

fleet management; mobile robots; AGV; AMR; Industry 4.0; web-based fleet management system 1. Introduction

Industry 4.0 represents a paradigm shift in the way products are designed, manufactured, and distributed. This transformation is primarily driven by the integration of advanced technologies, including automation, data analytics, and machine-to-machine communication [1]. The ability to integrate machines, systems, and humans into a single intelligent and logical network distinguishes Industry 4.0 from its predecessors, enabling more flexible and efficient production [2,3]. Furthermore, digital interconnectivity enables real-time communication and cooperation between operators, machines, and products, thereby optimizing workflows and significantly increasing the efficiency of industrial processes. The Industry 4.0 concept introduces multiple advantages, notably operational efficiency, flexibility, improved product quality, and sustainability. However, the transition to this paradigm can be challenging, as it requires substantial investments in both technology and workforce training [2,4].

One of the main goals of Industry 4.0 is the automation of production and distribution lines, aiming to enhance flexibility and optimize manufacturing processes. Achieving this objective requires the integration of technological solutions that align with these goals. One such approach is the deployment of mobile robots to distribute materials and tools within factories [5]. Thanks to their high level of autonomy and adaptability, the use of mobile robots is pervasive in different industries, supporting production systems and warehouse logistics [6]. Thus, mobile robots have become increasingly important in smart factories due to their viability, high precision, and efficiency in industrial applications. As a result, fleet and mobile robot management becomes a key factor in the performance of industrial processes, positioning fleet management systems as critical and valuable assets [7].

According to the MarketsandMarkets report (December 2024), the global mobile robot market is expected to grow from EUR 2.07 billion in 2025 to EUR 4.20 billion by 2030, representing a Compound Annual Growth Rate (CAGR) of 15.1%. This growth reflects the rapid adoption of autonomous mobile solutions in sectors such as logistics, retail, healthcare, and manufacturing, driven by factors such as labor shortages, efficiency demands, and advancements in AI and autonomous navigation [8].

Thus, this paper presents the development of a software system for managing fleets of mobile robots, allowing the real-time visualization of the status of the mobile robot fleet and its activity. This visualization includes the status of each robot (e.g., position, battery, route, etc.), presented through a color-coded system and real-time information about the direction of their movement. The information collected by the system is presented visually using an intuitive user interface to alert operators about the different statuses of robots. A key development challenge is the integration of two types of mobile robot technologies, namely Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), from distinct manufacturers and with varying characteristics.

The methodology used and the benefits that fleet management software can bring to the automotive industry are demonstrated, as well as its potential for future scalability. The main contributions of this paper are as follows:

- The Development of a Fleet Management System: The creation of a platform that integrates different types of mobile robots, enabling real-time monitoring and the efficient management of operations.

- The Integration of Diverse Technologies: The implementation of a system that unifies data from AGVs and AMRs from different manufacturers, overcoming compatibility and data standardization challenges.

- The Improvement in Operational Efficiency: A demonstration of how the proposed platform can optimize workflows and reduce robot downtime.

- An Intuitive and Centralized Interface: The development of a web interface that facilitates the supervision and control of robots, promoting a simplified and intuitive user experience.

- Scalability and Adaptability: A discussion on the potential for expanding the system to include new functionalities and integrate emerging Industry 4.0 technologies.

The structure of this article is organized as follows:

Section 1 introduces the motivation behind this paper. Section 2 presents the context of the case study addressed in this paper. Section 3 presents the state of the art, divided into three aspects: a comparison between AGVs and AMRs, the widespread use of AGVs and AMRs in industry, and the current state of the literature regarding fleet management systems. Section 4 presents the robotic systems being used for the case study under analysis. Section 5 demonstrates the proposed methodology for developing a fleet management system. Section 6 shows the results and functionalities of the developed system. Section 7 presents a discussion of the work carried out, framed within the challenges in the industry. Finally, Section 8 discusses the results obtained, the contributions made, and suggestions for future work.

2. A Brief Description of the Case Study

The project “GreenAuto: Green Innovation for the Automotive Industry” aims to strengthen the automotive industry by promoting the production of low-emission vehicles and optimizing their respective production processes. Within this project, there is a Work Package (WP) dedicated to automated logistics for the automotive industry, which seeks to improve the operational efficiency of the Stellantis manufacturing unit, located in Mangualde, Portugal. To achieve this, solutions for supervision and navigation systems of mobile robots have been developed. Currently, the company lacks a functional fleet management system that allows the monitoring of the location and operational status of mobile robots. This situation is further complicated by the fact that several models and brands are used, making data collection and standardization difficult.

The type of robots used in the company follows AGV technology, as shown in Figure 1. The AGVs are distributed across the assembly and production lines, encompassing both older models and the latest generation ones. The challenge arises from the differences between the software of the various existing models, as it is necessary to ensure that all AGVs communicate with a server in a standardized way to ensure a smooth operation and efficiency.

Figure 1.

One example of an AGV currently in use at the Stellantis factory—ASTI EasyBot AGV.

Thus, the approach used aims to develop and implement an efficient and scalable tool to monitor and supervise all mobile robots on the factory floor, ensuring continuous and reliable communication through a mesh network with multiple access points.

3. Related Work

This section presents the state of the art regarding the integration of AGVs and AMRs in the automotive industry, as well as the current literature review related to the fleet management of mobile robots in the industry in general.

3.1. AGVs Versus AMRs

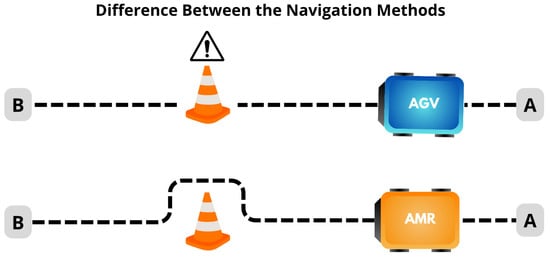

Due to the increase in consumption and the greater availability of products worldwide, industries face pressures that force them to be in constant development and in search of new technologies to meet production needs [9]. To this end, mobile robots such as AGVs and AMRs are used. These continue to revolutionize the industry, offering a higher efficiency, error reductions, and safety improvements. Their main difference lies in their navigation mode, as illustrated in Figure 2, where AGVs follow fixed paths and AMRs are more advanced and autonomous, using sensors and software for navigation [10], allowing for advanced capabilities such as obstacle-avoidance, as shown in Figure 2.

AGVs are highly versatile and flexible and are suitable for a variety of industrial and logistical tasks, from warehouse management to the optimization of logistical processes. In the industry, AGVs play a crucial role in applications involving the movement, handling, and loading of materials [10,11].

As for AMRs, they have a higher level of intelligence through the use of advanced sensors, cameras, and artificial intelligence algorithms to navigate dynamically through the environment, offering a greater flexibility in navigation, versatility in tasks, increased efficiency, and safety, although their cost is higher [10,12].

Figure 2.

The difference between the navigation methods of AGVs and AMRs (adapted from [13]).

3.2. General Applications of AGVs and AMRs in Industry

The use of AGVs and AMRs in the automotive industry has optimized logistics and production. AGVs are widely used for material transport, ensuring accurate deliveries and reducing human errors [14]. AMRs offer greater flexibility by navigating autonomously and adjusting routes in real-time [15].

Additionally, the integration with Manufacturing Execution Systems (MESs) improves the coordination between warehouses and assembly lines, reducing waste and increasing efficiency [16]. Studies indicate that the implementation of these technologies reduces operational costs and improves safety by minimizing the need for human intervention in repetitive tasks [17].

3.3. Fleet Management Systems

The fleet management of mobile robots has increasingly become a crucial factor in optimizing processes in industrial and logistical environments. With technological advancements, different approaches have been developed to enhance the task distribution, movement coordination, and efficient communication between robots, making systems more effective and adaptable [18].

Regarding planning and coordination, the use of search and optimization algorithms, combined with machine learning techniques, has enabled a better performance in the dynamic allocation of tasks and collision avoidance. Recent studies show that these approaches lead to a significant increase in the efficiency of multi-robot systems, allowing the devices to respond more quickly and effectively to environmental conditions [19].

The communication between robots also plays a crucial role in fleet coordination. Instead of relying on complex networks and fixed infrastructures, decentralized systems based on a consensus have been adopted, offering a greater scalability and resilience in fleet management [20]. The integration of mobile robots with smart infrastructures represents another key aspect in the development of these systems. The incorporation of sensors in warehouses and factories enables better environmental awareness, allowing for optimized trajectories and the prevention of congestion. These advancements have proven essential for increasing efficiency and reducing resource consumption in logistical processes [21].

Regarding the applicability of fleet management systems, the current literature shows that research has been conducted on applying this methodology in different fields. For example, in [22] the authors developed a fleet management system (FMS) to manage logistics tasks performed by mobile robots in hospital environments, through an architecture that integrates several tools to support dynamic route planning and fleet management. Alexandru M. et al. discuss digital transformation in the management of Automated Guided Vehicle (AGV) fleets using Digital Twins. To this end, they propose upgrading traditional AGV management systems to incorporate Digital Twin capabilities, highlighting the benefits of this change [23]. Finally, in [24] the authors propose a linear programming-based algorithm for task scheduling and charging for fleets of AMRs that operate continuously. The focus is on minimizing the downtime and battery degradation and integrating preventive maintenance into the planning.

Unlike many existing fleet management systems, both academic and commercial, the proposed solution was specifically developed to integrate AGVs and AMRs from different brands and manufacturers into a unified interface. In this way, the proposed system enables native interoperability through data abstraction layers and protocol translation, allowing for the continuous monitoring of heterogeneous robots. Furthermore, few existing systems combine, in a single real-time interface, SLAM-based localization and RFID detection—functionalities that are fully integrated into the system presented in this article. One of the most distinctive aspects of the proposed approach is the real-time web interface, which allows for the visual fusion of data into a single map, simplifying supervision and facilitating decision-making.

4. Robot System Description

Three mobile robots were considered for the development of the fleet management system, consisting of two AMRs and one AGV, from different brands. For this case study, the AGV used is an ASTI TriBot (with specifications listed in Table 1), as shown in Figure 3. Developed by ABB, it is designed for industrial and logistical applications. The AGV is characterized by its flexibility and navigation capabilities, making it ideal for material transport tasks within factories and warehouses [25].

Table 1.

Specifications of the ASTI TriBot AGV [25].

Figure 3.

AGV ABB ASTI TriBot.

This AGV is equipped with a datalogger and an access point (AP), which allow for the collection and transmission of data to a central server, ensuring real-time monitoring.

Regarding the AMRs, one of them is an Aiten MP10 (with the specifications listed in Table 2), as shown in Figure 4. The Aiten MP10 is a forklift robot from the MP series by AiTEN Robotics, designed to optimize material handling in industrial environments. This model stands out due to its compact and modular design, integrating a differential wheel system and a forklift chassis with AiTEN’s advanced Simultaneous Localization and Mapping (SLAM) laser navigation technology [26].

Table 2.

Specifications of AMR AiTEN MP10 [26].

Figure 4.

AMR AiTEN MP10.

This robot is equipped with a 3D laser sensor at the top of the structure, as shown in Figure 4, to ensure a 360° perception of the surrounding environment, as well as a sensor at the bottom front, which is essential for mapping and navigation.

Finally, the last robot used in this case study was the AMB-1000JS from Seer (with the specifications listed in Table 3), as illustrated in Figure 5. It is an AMR designed for safe lifting operations and handling heavy loads in industrial environments [27]. This robot is equipped with two SICK nanoscan3 Core safety sensors, providing an omnidirectional 360° perception.

Table 3.

Specifications of AMR SEER AMB100-JS [27].

Figure 5.

AMR SEER AMB100-JS.

These two AMRs support two types of communication, which are as follows:

- HTTP (Server): The HyperText Transfer Protocol (HTTP) is the foundation of web communication, enabling the exchange of information between clients and servers. It operates on a request–response model, where the client requests a resource, and the server processes the request and sends a corresponding response. Among the most commonly used HTTP methods are GET and POST, each with specific characteristics and objectives [28]. However, this communication requires an additional server, provided by the manufacturer, and the data collection is more limited.

- TCP/IP: The Transmission Control Protocol/Internet Protocol (TCP/IP) is the foundation of communication in computer networks and servers, enabling reliable data transmission between devices. In the context of mobile robots, this protocol is used to collect information, ensuring the integrity of data packets and the correct sequence of the transmission [29]. In this case, each robot is identified by a unique IP address within the local network, and the communication occurs through TCP sockets. The messages sent follow a structured format, ensuring the correct interpretation of commands and responses. Compared to HTTP communication, more data can be collected from the robot.

5. Proposed Fleet Management System

This section aims to present the proposed methodology for the development of the fleet management system. The methodology is divided into four steps:

- Local communication with the robots;

- Global communication with the robots;

- The mapping and interconnection of the robots;

- Software development.

5.1. Local Communication with the Robots

Local communication refers to the direct interaction with a single robot at a time, to understand how the data from each robot is processed. In this step, the focus was on studying the methods of communication with the robots individually, in order to collect their data.

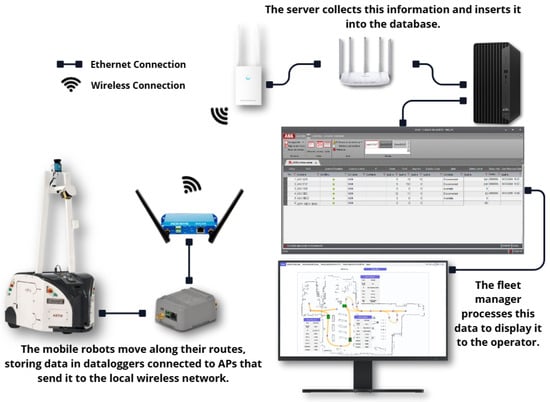

For the AGV ABB TriBot, this process is carried out through a datalogger that records real-time information about the vehicle’s state and position. To ensure a stable connection during the development phase, the AGV was initially connected to a computer via Ethernet, configuring the computer’s IP address to match the robot’s address range. Access to the data is made through a web page of the datalogger, where information such as the position, system status, and recorded events can be viewed. However, for more efficient communication, the datalogger is connected to a router, allowing remote data collection without the need for a direct physical connection, as shown in Figure 6.

Figure 6.

The local communication method with the AGV ABB TriBot.

Automated data collection was implemented using Python 3.10 and Selenium 4.10.0, enabling the continuous extraction of information directly from the datalogger’s interface without human intervention. After the data is collected, it is filtered to remove irrelevant information before being stored for later analysis.

This approach ensures efficient communication with the AGV individually, allowing the continuous monitoring of the vehicle and optimizing its integration into the fleet management system.

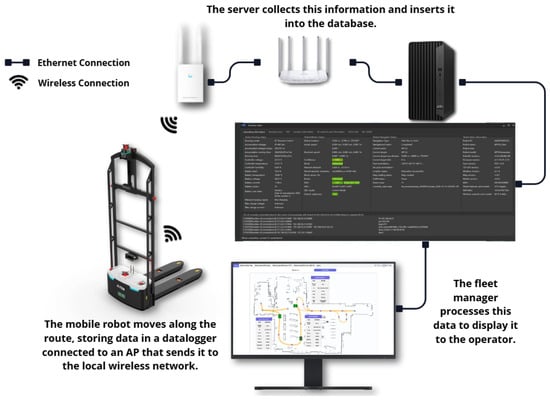

In terms of communication for the Aiten MP10S and SEER AMB-1000JS AMRs, this is achieved through the TCP/IP, where the robot acts as a server, accepting and responding to requests from an external client. This method ensures efficient communication, allowing for data collection and the remote control of the robots, as shown in Figure 7 and Figure 8.

Figure 7.

The local communication method with the AMR Aiten MP10S.

Figure 8.

The local communication method with the AMR AMB-1000JS.

The API used follows a TCP request–response model, where each message sent contains a fixed header and a data area in a serialized JSON format. The header identifies the basic packet information, such as the length and data type, while the data area contains the specific information of the request or response.

Communication with these AMRs allows for detailed control and efficient data collection, facilitating the integration into the global fleet management system.

5.2. Global Communication with the Robots

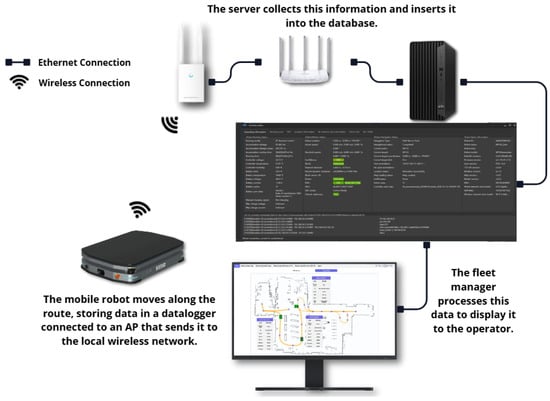

Global communication refers to the interconnection of all robots with the fleet management system, allowing for the efficient coordination of operations. In this model, the different AGVs and AMRs continuously transmit information to a central server, which processes the data and distributes commands to optimize the fleet operation. Figure 9 thus illustrates the global communication with all robots.

Figure 9.

Global communication method.

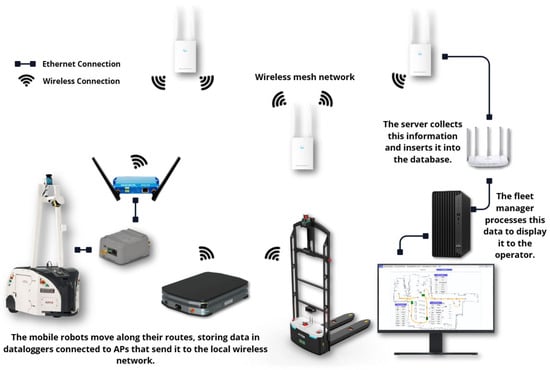

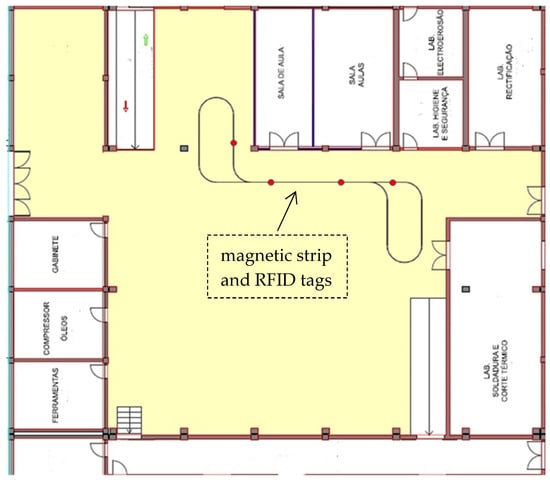

Figure 10 presents the architecture of the fleet management system runtime environment, highlighting its modular structure and its capacity for integration with the Industrial Internet of Things (IIoT). Although the communication with IIoT systems is not yet active in the current implementation, the architecture was designed to allow for this expansion in a seamless manner. The lower layer of the diagram represents this future capability, including two main mechanisms: a REST API, which exposes structured data (such as robot positions, statuses, and events) to systems like MES and ERP, and an MQTT broker, intended to enable real-time event publishing from the AMRs. This approach ensures compatibility with IIoT platforms such as Node-RED, Grafana, and other industrial solutions. Additionally, the architecture has been designed to support the future integration with the VDA 5050 protocol, promoting interoperability with fleet control systems from multiple manufacturers in a standardized production environment, in line with the principles of Industry 4.0.

Figure 10.

System architecture—runtime environment and Industrial IOT integration.

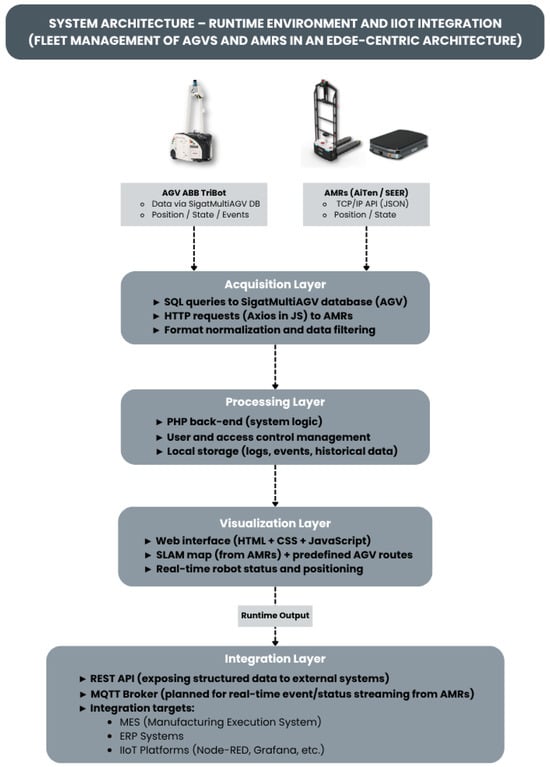

5.3. Mapping and Interconnection of Robots

The tests involving the AGV and AMRs were conducted in the Mechanical Engineering Department of the Coimbra Institute of Engineering, within a laboratory covering an area of approximately 500 m2, which has machines and furniture of different sizes and with different forms of organization, as well as some wide movement corridors. Figure 10 shows the laboratory in question, where it is possible to see the circuit created with the magnetic strip to move the AGV. This space is the most suitable for carrying out experimental tests, as it roughly simulates the conditions found in the factory where the final prototype is to be installed.

To allow all robots to be viewed in a single monitoring window, an AMR with SLAM technology was used to create a map of the entire operating area.

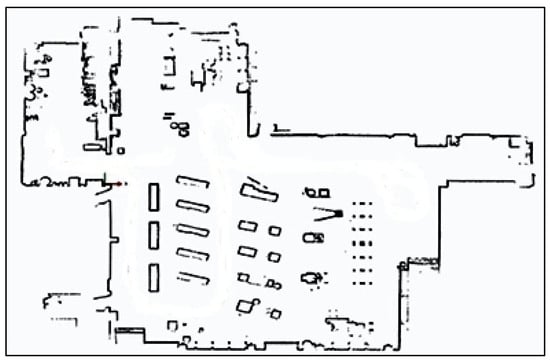

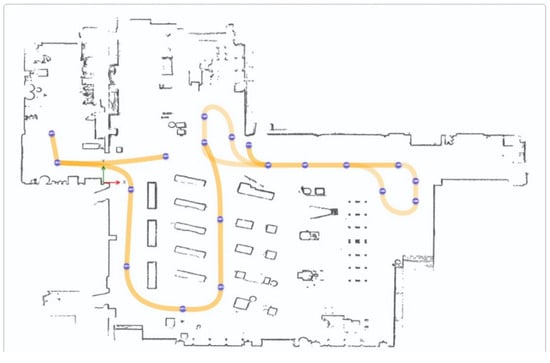

Figure 11 shows the layout of the laboratory where the yellow shaded area represents the space where the mobile robot with SLAM technology moved to carry out the mapping. Figure 12 shows the map created where you can see the location of the machines and furniture in the laboratory.

Figure 11.

The laboratory where the AGV and AMRs conducted experimental tests.

Figure 12.

The area of the laboratory where the mapping was carried out.

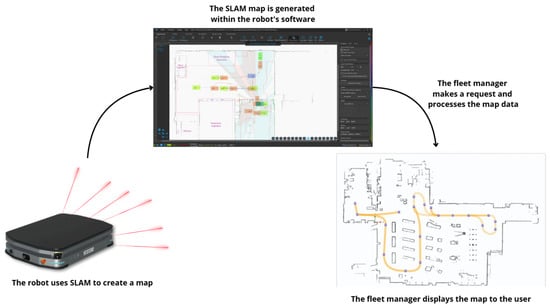

After the map is created using SLAM, the fleet management system makes a request the AMR to obtain the map and present it to the operator, as shown in Figure 13.

Figure 13.

The layout of the laboratory obtained after mapping with SLAM technology.

With this process, it is possible to view, in real-time, all the robots moving along their respective routes through a single web page. The AMRs, by utilizing SLAM technology, are capable of creating their maps, which gives them greater flexibility and autonomy in navigation. On the other hand, the AGVs, which operate with technology based on magnetic strips and tags placed on the ground, lack mapping capabilities.

Therefore, by overlaying the tags on the map created by SLAM, as shown in Figure 14, it becomes possible to visualize the predefined routes of the AGVs within the same dynamically mapped environment created by the AMRs. This approach enables a centralized view of all robots in operation, regardless of the navigation technology used, facilitating the monitoring and supervision by the operator.

Figure 14.

The mapping of the work area.

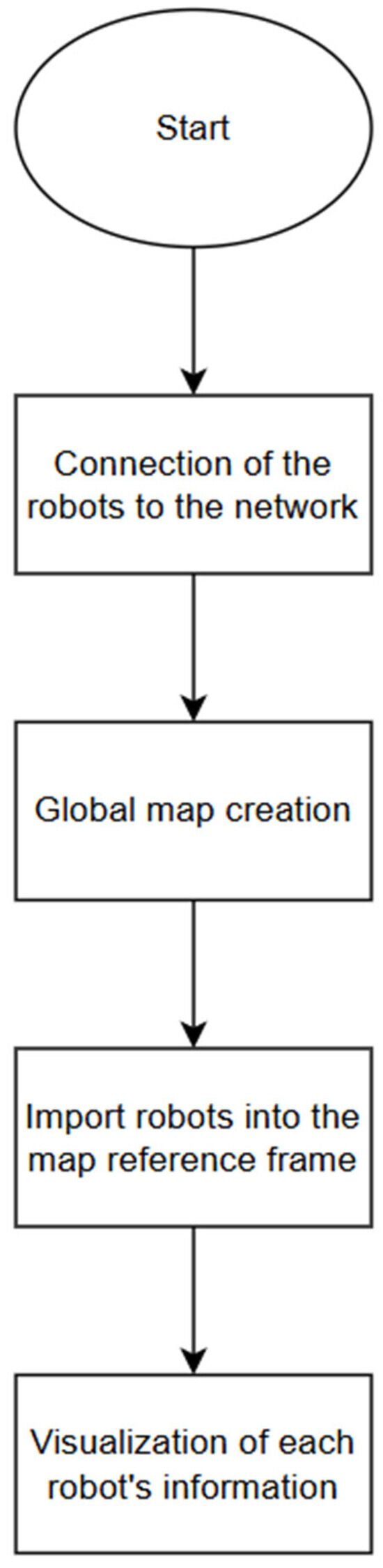

Figure 15 presents a flowchart developed to improve the understanding of the fleet management software functionality.

Figure 15.

A flowchart of the fleet management software operation.

The SLAM-based map used in the system was generated through the native capabilities of the AMR. The map is created during an initial exploration phase and remains static during routine operations, being accessed by the fleet manager for visualization purposes only. Real-time map updates are not currently implemented, and the robots navigate using onboard localization relative to this static SLAM map.

5.4. Software Development

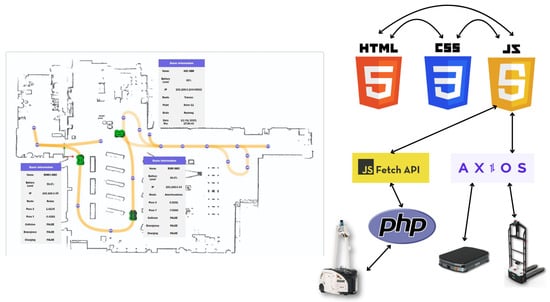

For the development of the fleet management software, several programming languages were used, including the HTML, CSS, JS, and PHP, as shown in Figure 16. The combination of these tools allowed for the creation of an interactive and functional web application capable of managing and monitoring different models of mobile robots.

Figure 16.

The interconnection of the different technologies used.

The HyperText Markup Language (HTML) is the programming language responsible for structuring the content of the web page, serving as the foundation for creating the interface that the user interacts with. Cascading Style Sheets (CCSs) are used to apply visual styles to the content of the web page, making the interface more intuitive and organized for the operator. JavaScript (JS), a client-side interpreted programming language, allows interactivity to be added to the web page, consisting of various small functions that are executed when the user interacts with the elements defined on the web page through the HTML.

For the communication between JavaScript and PHP, the FetchAPI was used, a native JavaScript interface that allows asynchronous HTTP requests. This API acts as an intermediary between the client-side code JS and the server-side code (PHP). Through the API, it is possible to send data to PHP scripts, which can then query, add, or remove information from the AGV databases or the fleet manager’s access control database. All of this is achieved dynamically without the need to reload the web page.

Additionally, the Axios library in JS was used to make HTTP requests. In the project, Axios was particularly useful in the communication with the AMRs, allowing real-time data to be retrieved through HTTP or TCP/IP interfaces.

The correct integration of all these technologies—the HTML, CSS, JavaScript, Fetch API, PHP, and Axios—is essential to ensure the proper functioning of the entire system, enabling the centralized and efficient management of the fleet of mobile robots.

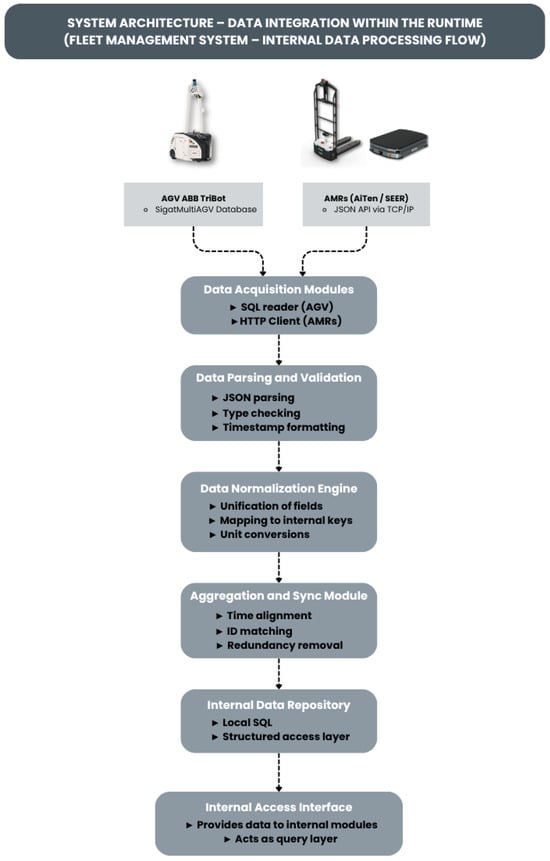

Figure 17 presents the internal data integration architecture within the runtime environment of the fleet management system. The data from mobile robots is acquired, analyzed, normalized, synchronized, and stored in a structured local repository. The internal access interface provides these processed data to other system modules, enabling a modular, scalable, and reliable operation in the context of industrial automation.

Figure 17.

The system architecture—data integration within the runtime.

6. Functionalities and Results

6.1. Fleet Management System Functionalities

The fleet manager allows for the efficient monitoring and management of both AGVs and AMRs. Among its main features is the protection of system integrity through an authentication system, in which each user is assigned a specific access level, thereby enabling operators to perform actions with a greater or lesser impact on the system, according to their permissions.

The adoption of static facility maps to reference the position of mobile robots in fleet management systems is not ideal. Considering that a factory environment can undergo occasional and temporary changes, the use of static maps would result in outdated layouts. Furthermore, it would hinder the system’s adoption in other environments where updated maps are not available. An additional challenge includes managing the identifiers that define AGV routes. These can occasionally be repositioned, either due to route redefinition or simply the replacement of damaged identifiers.

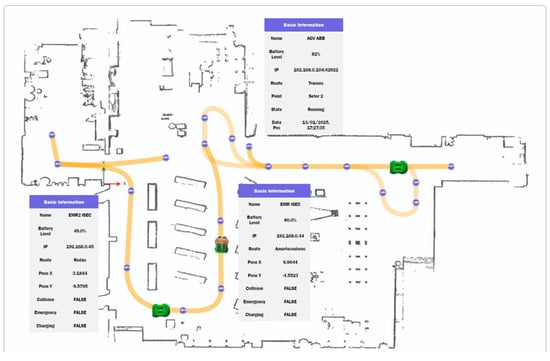

Taking this into account, an important feature is the visualization of predefined routes for both types of robots, as shown in Figure 18. In the case of AGVs, it is possible to edit the position of the tags directly in the fleet manager, providing greater flexibility in managing the trajectories. Regarding the AMRs, they use the SLAM-generated map complemented by a topological map with lines that define the zones through which they will navigate.

Figure 18.

Routes page.

The fleet manager also allows for the real-time consultation (as Figure 19 demonstrates) of various data related to AGVs and AMRs, including the name, IP address, battery level, current route, and operational status. The current position of each mobile robot is also available for viewing. In AMRs, the X, and Y coordinates and orientation angle are displayed, while in AGVs, it is possible to view the tag on which it is located, and from there, consult the X and Y position of the respective tag.

Figure 19.

A map with all robots imported into the system.

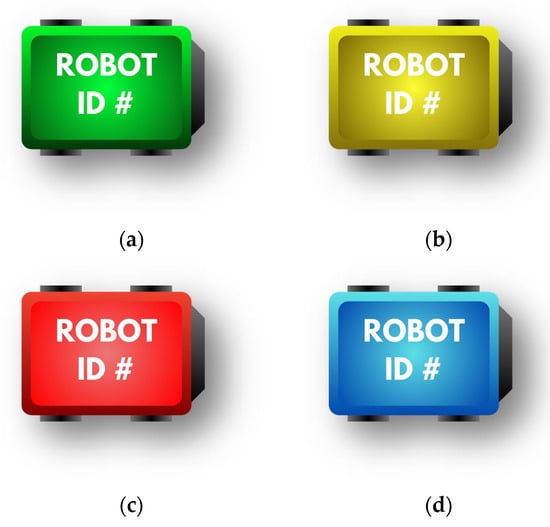

To facilitate the supervision of the mobile robots’ status, the fleet manager offers a visual indication through a color synoptic, as illustrated in Figure 20. This system allows operators to quickly and intuitively monitor the navigation status of each robot at a glance.

Figure 20.

The color code corresponding to the navigation status of the robots: (a) green—the AGV is functioning correctly; (b) yellow—the AGV is stopped due to an obstacle; (c) red—the AGV is stopped due to a failure or malfunction; and (d) blue—the AGV is charging its batteries.

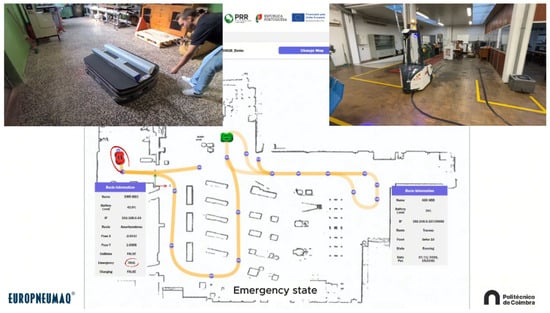

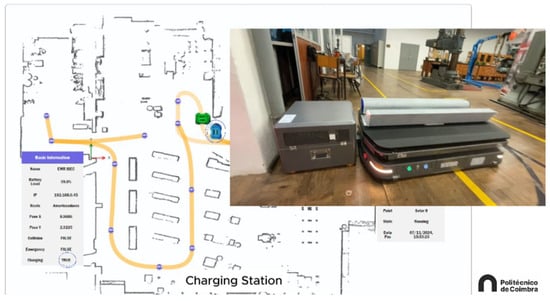

Based on the information regarding the robot states (presented in Figure 18), the following are real photographic records that illustrate the robot’s different operational states. Each state is identified by a distinct color, making it easier to visually recognize during the operation, as shown in Figure 21, Figure 22 and Figure 23.

Figure 21.

Obstacle detection, robot’s icon changes to yellow.

Figure 22.

Emergency state, robot’s icon changes to red.

Figure 23.

Charging battery state, robot’s icon changes to blue.

6.2. Quantitative Performance Evaluation

The proposed platform demonstrated a strong performance in the updating and supervision of mobile robot operations. The average update interval for the robot status was approximately 120 ms, allowing for the efficient visualization of tasks in progress. The user interface (UI) exhibited a latency below 1 s, ensuring near real-time supervision, which is essential for operational decision-making in dynamic environments.

During experimental tests, it was possible to simultaneously monitor up to 20 robots, including AMRs (Autonomous Mobile Robots) and AGVs (Automated Guided Vehicles), without a significant degradation in either the interface or server performance. The server uptime remained above 99.5% throughout the testing period, highlighting the robustness of the infrastructure. Minor positioning inaccuracies were observed, with variations of up to 10–15 cm in AMRs, mainly attributed to the environmental interference with the LiDAR signal. In AGVs, deviations occurred due to the wear or displacement of magnetic strips and RFID tags. The communication between the robots and the server showed minimal delays, remaining under 200 ms, depending on the quality of the available WiFi network. The real-time data fusion required an efficient synchronization, which was achieved through the use of temporal buffers and periodic queries via TCP/IP sockets.

In terms of the throughput, the system was able to process up to 150 messages per second in high-density robot scenarios, without compromising the platform stability or responsiveness.

7. Discussion

The development of the fleet management system proved to be an effective solution for monitoring and supervising mobile robots from different brands and technologies, namely AGVs and AMRs, within a single software platform. The main challenge addressed was the difference between the various communication and data collection methods of the mobile robots.

In this context, the integration of the robot location and status data onto a single map, with the overlay of predefined AGV routes and SLAM for AMRs, demonstrated an efficient approach for the simultaneous monitoring of different devices. The use of an intuitive web interface contributed to the practicality of the fleet manager, allowing operators to immediately and effectively monitor and supervise the status of mobile robots in operation. To reinforce the security and reliability of the system, an authentication mechanism with different access levels was implemented, ensuring the proper management of each user. Furthermore, the software is extensible, which represents a significant advantage for constantly evolving industrial environments, since it is possible to add new robots by simply adapting the data extracted from the new robot’s API and standardizing it for the display in the software.

It is important to clarify that the fleet management system developed in the scope of this work operates primarily at the level of the centralized monitoring and supervision of AGVs and AMRs, based on the position, status, and task progress data collected through the APIs provided by each robot manufacturer. The low-level control—namely path planning, the SLAM execution, and collision or obstacle management—is handled internally by each robot via the manufacturer’s proprietary systems. The proposed system operates at a high level of abstraction, focusing exclusively on the monitoring of the location and operational status data from robots of different brands. This data is collected, translated, and standardized to be presented through a single, integrated interface, thereby facilitating supervision by human operators.

Considering the results achieved, it is important to discuss the main contributions of the proposed solution to the current industrial context, as well as recognize its limitations and envision future technological developments. Firstly, the fleet management system presented in this manuscript constitutes a relevant advancement in the monitoring and coordination of diverse mobile robots in industrial environments. Its ability to centralize operational information from AGVs and AMRs—regardless of their brands or technologies—into a single point translates into more efficient management, with a direct impact on productivity and the reduction in operational failures. Additionally, by enabling the interoperability between devices from different manufacturers, the system significantly contributes to overcoming limitations, increasing operational flexibility, and facilitating the integration with other industrial automation systems.

The real-time visualization of predefined routes and dynamic maps, through the overlay of information on the same graphical interface, is a valuable resource for operators. This approach, combined with an intuitive web interface, ensures a simplified user experience, favoring the rapid detection of anomalies and informed decision-making on time. From a cybersecurity and user management perspective, the implementation of different access levels offers granular and secure control over information and assigned permissions. The scalability of the system, in turn, makes it particularly suitable for constantly changing industrial environments, allowing it to keep pace with the growth of operations and the introduction of new robots or functionalities.

Thus, the contributions presented demonstrate that the developed system effectively meets the current needs of the industry regarding the integrated management of diverse robotic fleets. Its flexibility, scalability, and focus on usability make it a robust solution, prepared to keep pace with the evolution of modern industrial environments.

8. Conclusions

This research presented a practical and functional solution for the management of mobile robot fleets in an industrial environment, with a special focus on the reality of the Stellantis factory. The developed fleet manager demonstrated the ability to integrate different types of robots, collect and process data in real-time, and make this information available to operators in a clear and accessible way, through a visual synoptic based on color coding. This approach significantly improved operational visibility and timely decision-making.

In addition to the practical implementation, this study demonstrated the great potential of decentralization and the integration with smart infrastructures, which are affirmed as key elements for the scalability, adaptability, and resilience of modern logistics systems. The proposed flexible and modular architecture positions the platform as a robust foundation for the gradual adoption of innovative solutions, fully aligned with the principles of Industry 4.0, promoting a continuous and sustainable digital transformation in industrial environments.

For future work, the following is proposed:

- The creation of dashboards for the robot performance analysis (e.g., energy consumption, average operating time, and downtime).

- The integration of artificial intelligence algorithms for fault prediction and route optimization.

- To enhance the interoperability of the platform with other emerging Industry 4.0 technologies.

It is believed that this platform can serve as a basis for future developments and adaptations in diverse industrial environments, significantly contributing to the digitalization and automation of logistics and production processes. The continuity of this research will not only refine the performance of the solution but also expand its impact to different sectors of the industry, fostering innovation and competitiveness in the context of advanced manufacturing.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app15137235/s1.

Author Contributions

Conceptualization, F.S.; Methodology, D.L., T.P., A.G., F.C. (Francisco Cunha) and F.S.; Software, D.L.; Validation, T.P., A.G., F.C. (Francisco Cunha), F.L., V.S., J.D., P.S., P.F. and J.P.F.T.; Formal analysis, F.L., V.S., J.B., F.S. and J.P.F.T.; Investigation, D.L., T.P., A.G., F.C. (Francisco Cunha), J.A. and E.D.C.d.F.; Data curation, F.C. (Francisco Cunha), J.B. and J.P.F.; Writing—original draft, D.L.; Writing—review & editing, T.P., A.G., J.A., V.S., F.C. (Fernanda Coutinho), J.B., J.D., P.S., P.F., E.D.C.d.F., J.P.F. and N.M.F.F.; Visualization, F.L., J.A., V.S., F.C. (Fernanda Coutinho), F.S., P.F. and N.M.F.F.; Supervision, N.M.F.F.; Project administration, N.M.F.F.; Funding acquisition, N.M.F.F. All authors have read and agreed to the published version of the manuscript.

Funding

The present work was funded under the project AGENDA GREENAUTO—GREEN INNOVATION FOR THE AUTOMOTIVE INDUSTRY, project investment No. 54, AAC No. 02/C05-i01/2022, co-financed by European Funds, the Recovery and Resilience Plan (PRR), and the Portuguese Republic.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article/Supplementary Material.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Vinitha, K.; Ambrose Prabhu, R.; Bhaskar, R.; Hariharan, R. Review on industrial mathematics and materials at Industry 1.0 to Industry 4.0. Mater. Today: Proc. 2020, 33, 3956–3960. [Google Scholar] [CrossRef]

- Gonçalves, A.; Pereira, T.; Lopes, D.; Cunha, F.; Lopes, F.; Coutinho, F.; Barreiros, J.; Durães, J.; Santos, P.; Simões, F.; et al. Enhancing Nut-Tightening Processes in the Automotive Industry: Integration of 3D Vision Systems with Collaborative Robots. Automation 2025, 6, 8. [Google Scholar] [CrossRef]

- Eriksson, S.; Bengtsson, L.; Samen, L.; Haartman, R.V. Visual management in the era of industry 4.0: Perceived advantages and disadvantages of digital boards. Int. J. Adv. Oper. Manag. 2023, 15, 1. [Google Scholar] [CrossRef]

- Grau, A.; Indri, M.; Lo Bello, L.; Sauter, T. Robots in Industry: The Past, Present, and Future of a Growing Collaboration With Humans. EEE Ind. Electron. Mag. 2021, 15, 50–61. [Google Scholar] [CrossRef]

- Hu, H.; Jia, X.; He, Q.; Fu, S.; Liu, K. Deep reinforcement learning based AGVs real-time scheduling with mixed rule for flexible shop floor in industry 4.0. Comput. Ind. Eng. 2020, 149, 106749. [Google Scholar] [CrossRef]

- Bai, Y.; Lv, Y.; Zhang, J. Smart mobile robot fleet management based on hierarchical multi-agent deep Q network towards intelligent manufacturing. Eng. Appl. Artif. Intell. 2023, 124, 106534. [Google Scholar] [CrossRef]

- Autonomous Mobile Robot Market Size|Industry Report 2030. Available online: https://www.grandviewresearch.com/industry-analysis/autonomous-mobile-robots-market (accessed on 12 June 2025).

- Silesian University of Technology, Organization and Management Department, Economics and Informatics Institute; Wolniak, R. Innovations in Industry 4.0 conditions. Sci. Pap. Silesian Univ. Technol. Organ. Manag. Ser. 2023, 2023, 725–741. [Google Scholar] [CrossRef]

- Silva, R.T.; Brilhante, M.; Sobreira, H.; Matos, D.; Costa, P. AGVs vs AMRs: A Comparative Study of Fleet Performance and Flexibility. In Proceedings of the 2024 7th Iberian Robotics Conference (ROBOT), Madrid, Spain, 6–8 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Moshayedi, A.J.; Li, J.; Liao, L. AGV (automated guided vehicle) robot: Mission and obstacles in design and performance. J. Simul. 2019, 12, 5–18. [Google Scholar]

- Zhao, X.; Chidambareswaran, T. Autonomous Mobile Robots in Manufacturing Operations. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7. [Google Scholar]

- AMR vs. AGV. Available online: https://www.vecnarobotics.com/amr-vs-agv/ (accessed on 8 April 2025).

- Kubasakova, I.; Kubanova, J.; Benco, D.; Kadlecová, D. Implementation of Automated Guided Vehicles for the Automation of Selected Processes and Elimination of Collisions between Handling Equipment and Humans in the Warehouse. Sensors 2024, 24, 1029. [Google Scholar] [CrossRef] [PubMed]

- Cservenák, Á.; Husár, J. A Multidisciplinary Learning Model Using AGV and AMR for Industry 4.0/5.0 Laboratory Courses: A Study. Appl. Sci. 2024, 14, 7965. [Google Scholar] [CrossRef]

- Sousa, N.; Oliveira, N.; Praça, I. A Multi-Agent System for Autonomous Mobile Robot Coordination. arXiv 2021, arXiv:2109.12386. [Google Scholar]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Gago, R.M.; Galassi, M.; Silveira, F.; Freitas, G.M. A survey on robot fleet management systems for industrial processes. In Proceedings of the 2024 Latin American Robotics Symposium (LARS), Arequipa, Peru, 11–14 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Chakraa, H.; Guérin, F.; Leclercq, E.; Lefebvre, D. Optimization techniques for Multi-Robot Task Allocation problems: Review on the state-of-the-art. Robot. Auton. Syst. 2023, 168, 104492. [Google Scholar] [CrossRef]

- Li, Q.; Gama, F.; Ribeiro, A.; Prorok, A. Graph Neural Networks for Decentralized Multi-Robot Path Planning. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020. [Google Scholar]

- Dai, Y.; Kim, D.; Lee, K. Navigation Based on Hybrid Decentralized and Centralized Training and Execution Strategy for Multiple Mobile Robots Reinforcement Learning. Electronics 2024, 13, 2927. [Google Scholar] [CrossRef]

- Guzmán Ortiz, E.; Andres, B.; Fraile, F.; Poler, R.; Ortiz Bas, Á. Fleet management system for mobile robots in healthcare environments. J. Ind. Eng. Manag. 2021, 14, 55. [Google Scholar] [CrossRef]

- Alexandru, M.; Dragoș, C.; Bălă-Constantin, Z. Digital Twin for automated guided vehicles fleet management. Procedia Comput. Sci. 2022, 199, 1363–1369. [Google Scholar] [CrossRef]

- Atik, S.T.; Chavan, A.S.; Grosu, D.; Brocanelli, M. A Maintenance-Aware Approach for Sustainable Autonomous Mobile Robot Fleet Management. IEEE Trans. Mob. Comput. 2024, 23, 7394–7407. [Google Scholar] [CrossRef]

- ASTI—TriBOT 10000-Tow Tractor. Available online: https://www.agvnetwork.com/robot-showroom-2/ad/tow-tractor,11/asti-tribot-10000-tow-tractor,118 (accessed on 8 April 2025).

- AiTEN—MP Series Products. Available online: https://www.aitenrobot.com/series/mp-2 (accessed on 8 April 2025).

- SEER Robotics-Build Your Own Robot Fleet Within Days. Available online: https://www.seer-robotics.ai/agvs/amr-robots/AMB-1000JS (accessed on 8 April 2025).

- Tedyyana, A.; Ghazali, O.; Purbo, O.W. A real-time hypertext transfer protocol intrusion detection system on web server. TELKOMNIKA Telecommun. Comput. Electron. Control 2023, 21, 566. [Google Scholar] [CrossRef]

- Wang, S.; Xu, D.; Yan, S. Analysis and application of Wireshark in TCP/IP protocol teaching. In Proceedings of the 2010 International Conference on E-Health Networking Digital Ecosystems and Technologies (EDT), Shenzhen, China, 17–18 April 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 269–272. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).