1. Overview of Wine Production

Although global wine production and consumption show a declining trend, 237.3 million hectoliters were produced in 2023, with 144.5 million hectoliters originating from the European Union alone [

1]. Annual wine industry operations consequently involve not only harvesting, transporting, and processing millions of tonnes of grapes but also managing large amounts of liquid effluents and biowastes, including grape stalks, grape marc (pomace), wine lees, and winery waste-activated sludge. The proper disposal of these by-products represents a technical challenge and a significant financial investment. However, if untreated, these residues pose a serious environmental risk [

2].

In the European Union, which for decades has included five of the world’s top ten wine-producing countries, regulatory measures promote the valorization of grape pomace (GP) and wine lees [

3,

4,

5]. These policies offer financial incentives for wineries to deliver such by-products to authorized distilleries, where valuable compounds, such as grape pigments for the food industry, ethanol used as bioethanol or a raw material in fortified wines and spirits, and calcium tartrate for tartaric acid production, can be recovered [

6].

Although estimates of the volume of GP generated as a by-product of winemaking vary depending on grape variety, vineyard practices, and processing techniques [

7], there is general agreement that it accounts for 15 to 25% of the total processed grape weight [

8,

9], corresponding to approximately 4.7 to 7.9 million tonnes worldwide in 2023.

1.1. Definition and Composition of GP

Fresh grape pomace (GP) can be broadly defined as the solid residue composed of skins, seeds, and occasionally stems, resulting from grape pressing, which may or may not contain unfermented sugars [

7].

This complex and heterogeneous bio-waste consists of approximately 425 kg of grape skins, 225 kg of grape seeds, and 249 kg of grape stalks (GS) per tonne, with a high and variable moisture content ranging from 50% to 72% [

7]. Among the structural and bioactive compounds present, lignin, pectic substances, sugars, proteins, minerals, and phenolic compounds were quantified [

8,

10,

11,

12,

13,

14] (

Table 1).

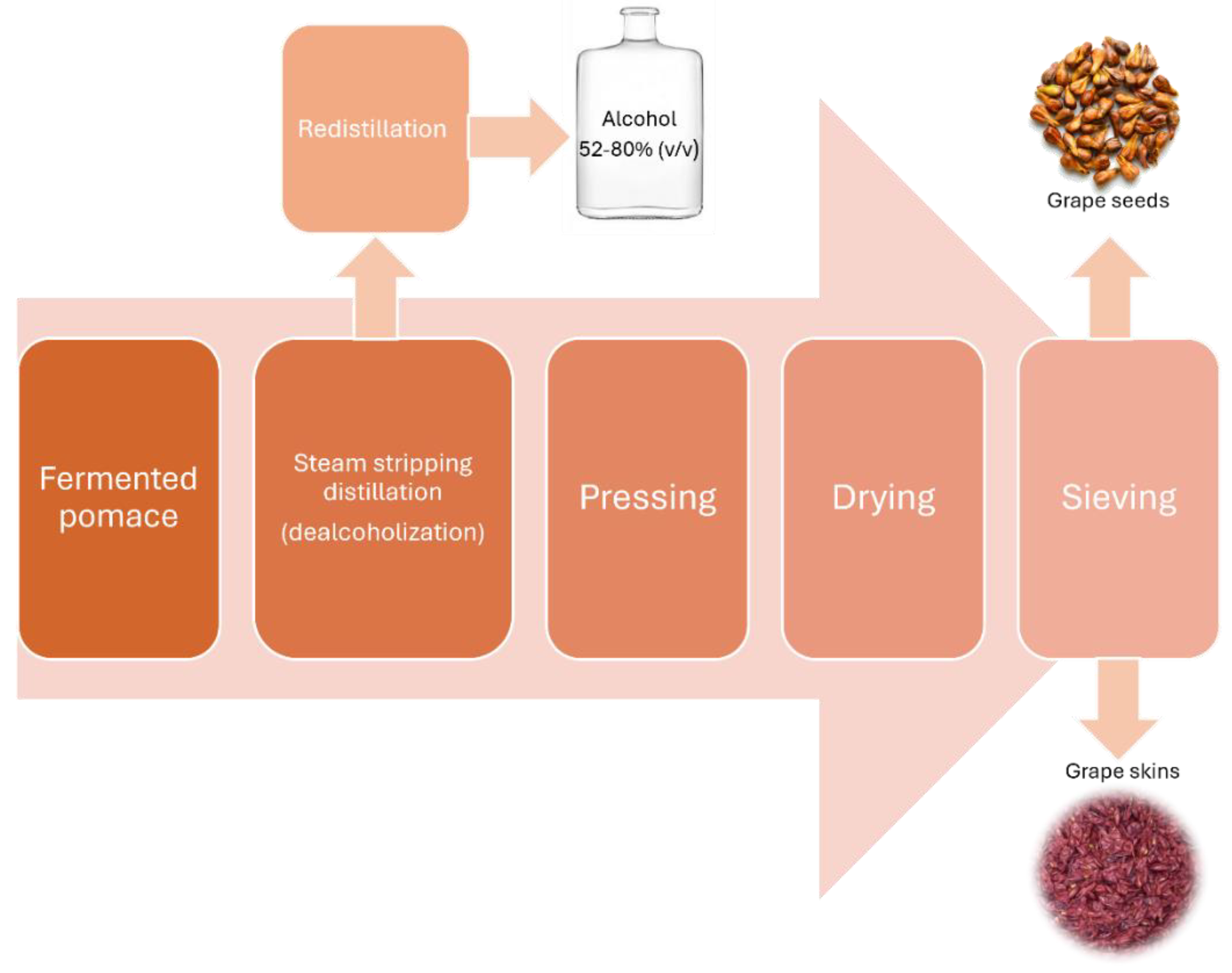

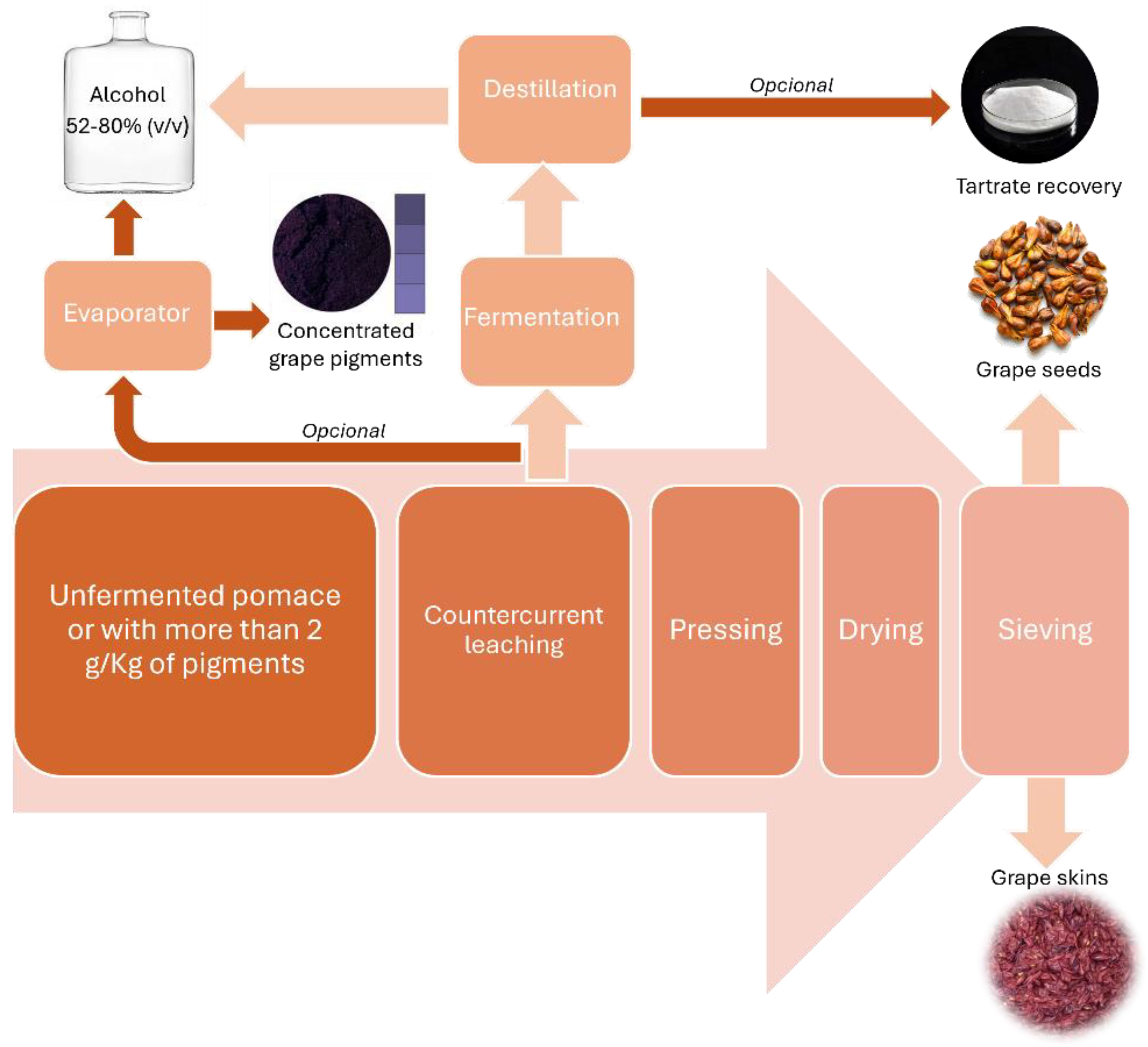

Traditionally, GP undergoes two distinct unit operations for recovering valuable substances. The choice of extraction process hinges on the unfermented sugar content and the levels of tartrate and grape pigments.

Fermented pomace from red wine production, which has low residual sugar, can be directly subjected to steam stripping distillation if ethanol recovery is the only desired outcome. The resulting product is a hydroalcoholic solution containing between 20 and 35% alcohol by volume (

v/

v), along with small amounts of ethyl acetate, methanol, and acetic acid. This solution is subsequently redistilled in appropriate columns to yield an alcohol with a concentration of 52–80% (

v/

v). This process is known in the wine industry as pomace “dealcoholization” (

Figure 1).

Conversely, pomace from white or fortified wine production, still rich in unfermented sugars, is subjected to a countercurrent leaching process. This yields a dilute hydroalcoholic solution (approximately 3% (

v/

v) alcohol and 30–50 g/L sugars), which is then fermented to increase its alcohol content before distillation. Similarly, if red pomace contains sufficient grape pigments or tartrates to warrant extraction, the same leaching process is applied, followed by concentration of the heat-sensitive dilute pigment solution at low temperatures using a multiple-effect evaporator (

Figure 2).

In the case of dealcoholized grape pomace (DGP), large-scale industrial applications typically involve partial dehydration by pressing, followed by drying in rotary furnaces to a final moisture content of approximately 5%. This process stabilizes the material microbiologically, enabling sieving to separate grape skins from seeds. Industrially, the recovered seeds can be used for grape seed oil extraction, as a component in animal feed, or as an efficient solid biomass fuel [

15].

If no viable market exists for the seeds, or if the distillery lacks steam generators powered by solid fuels, the DGP may be used as soil mulch, as an organic amendment, or be composted—often in combination with other bio-wastes that offer a complementary C/N ratio [

16,

17].

While the recovery of specific bioactive compounds is affected by the dealcoholization processes mentioned earlier [

18], structural compounds are largely unaffected by the conditions used due to their high thermal stability and low water solubility [

19].

1.2. Rationale for Upcycling in the Context of the Circular Economy and Bioeconomy

As a result of seed separation after drying dealcoholized grape pomace, a new lignocellulosic material composed mainly of grape skins is now produced. This material is sometimes known as spent seedless grape pomace (SSGP).

In recent years, beyond its traditional uses, there has been growing interest in applying circular economy principles to enhance the value of SSGP [

20]. Initial research has identified several valuable classes of compounds present in SSGP [

21,

22], including dietary fibers [

23] and bioactive compounds with antioxidant, anticancer, cardioprotective, and anti-inflammatory activities [

24,

25,

26].

Additionally, SSGP contains components with functional properties such as food colorants, texturizing agents, and natural antioxidants [

27].

More recent studies have shifted focus toward developing sustainable extraction methods and optimizing conditions to maximize the recovery of these compounds [

28,

29]. Researchers have also begun exploring the use of SSGP as a second-generation feedstock for synthesizing polymer building blocks or as a reinforcing filler in composite materials [

30].

Within the framework of the circular economy, the upcycling of SSGP contributes directly to reducing biomass waste and greenhouse gas emissions, extending material life cycles, and improving resource efficiency across the agri-food sector. Although dealcoholization may slightly reduce the levels of specific bioactive compounds, SSGP still retains a significant portion of its original composition, making it a versatile input for the development of secondary products. This makes it a valuable and versatile input for the development of secondary products. Its composition supports a wide range of applications, including food ingredients, dietary supplements, cosmetics, and biodegradable materials, which reduce our reliance on synthetic additives and non-renewable resources [

31]. Furthermore, the removal of alcohol enhances the safety and regulatory compliance of these applications, particularly in food and nutraceutical products, by lowering ethanol content to acceptable or negligible levels [

32].

From a bioeconomy perspective, valorizing SSGP supports a regenerative model in which biomass is repurposed efficiently and repeatedly across different sectors. This approach aligns with EU and global bioeconomy strategies by fostering local value chains and promoting rural development, especially in wine-producing regions where large volumes of pomace are generated annually [

33,

34]. When combined with green extraction technologies, such as supercritical CO

2 or subcritical water extraction, or when integrated into biopolymer systems based on polylactic acid (PLA), poly(butylene succinate), or starch derived from agri-food by-products, SSGP enables the sustainable recovery of high-value compounds. These innovations offer a low environmental impact and reinforce the role of bio-based solutions in accelerating the transition to a more sustainable industry [

35].

3. Pretreatment and Processing Technologies

Efficient processing and extraction of DGP and SSGP necessitate appropriate pretreatment methods to disrupt the complex plant cell wall matrix and enhance the accessibility and recovery of target molecules such as bioactive polyphenols and dietary fibers. These pretreatments can be broadly categorized into mechanical, chemical, and enzymatic approaches, often used in combination to maximize yields and product quality.

Mechanical pretreatments are fundamental first steps, primarily involving drying, milling, and size reduction. Drying is crucial for reducing moisture content, preventing microbial spoilage, concentrating compounds, and preparing the material for subsequent processing. Methods such as convective air drying, freeze-drying, and microwave-assisted drying are employed, with the choice influencing energy consumption and the preservation of thermolabile compounds, including certain polyphenols [

40]. Following drying, milling or grinding reduces particle size, significantly increasing the surface area available for solvent penetration and interaction. This enhanced surface area is directly correlated with improved extraction efficiency of both polyphenols and the subsequent accessibility of dietary fiber components [

41].

Chemical pretreatments predominantly involve the use of solvents for extraction, but they can also include treatments to modify fiber structure. For the extraction of phenolic compounds, solvents such as water, ethanol, methanol, acetone, and their aqueous mixtures have been investigated. Ethanol–water mixtures are particularly favored due to their Generally Recognized as Safe (GRAS) status and their ability to efficiently extract a broad range of substances. The choice of solvent, temperature, and extraction time is a critical parameter influencing yield and selectivity [

42]. Emerging green solvents, such as deep eutectic solvents (DES), are also gaining attention for their efficacy and environmental benefits. For dietary fiber modification or isolation, mild acid or alkaline treatments can be used to hydrolyze hemicellulose or delignify the material, making cellulose more accessible. However, this process must be carefully controlled to preserve other valuable components.

Enzymatic pretreatments provide a more targeted and gentle approach to deconstructing the plant cell wall, thereby releasing entrapped bioactive compounds and modifying the characteristics of dietary fiber. Enzymes such as cellulases, hemicellulases, pectinases, and tannases can be used individually or in combinations. These enzymes catalyze the hydrolysis of specific polysaccharides, including cellulose, hemicellulose, and pectin, which form the structural backbone of the cell wall. This process improves the release of polyphenols and increases the soluble dietary fiber fraction. Enzyme-assisted extraction (EAE) often yields higher polyphenol concentrations under gentler conditions, such as lower temperatures and less organic solvent, compared to conventional methods, thereby preserving their bioactivity [

43]. Furthermore, enzymatic treatment can enhance the functional properties of dietary fibers, such as their water-holding capacity and fermentability.

8. Industrial and Market Perspectives

8.1. Current Commercial Initiatives and Case Studies

The valorization of winemaking by-products and waste presents significant economic, social, and environmental advantages, often yielding higher financial returns than wine production. Grape pomace, in particular, has proven economically efficient for valorization. Rising waste disposal costs in the EU emphasize the need for viable recycling solutions. Economically, waste valorization can reduce management costs, sustain jobs, and enhance productivity by leveraging by-products like anthocyanins for use in food, pharmaceuticals, and cosmetics. This boosts income for wine producers and promotes high-performance products. Socially, benefits include improved agricultural management, adherence to European labor standards, job creation, and enhanced quality of life in rural areas. Environmentally, it promotes responsible management of emissions and resource use, reduces waste, and enables the utilization of by-products as fertilizers, which in turn protects the environment and creates job opportunities [

84].

In the article “The Exploitation of By-Products in a Waste Management Process”, the authors address the universal contemporary challenge of sustainability within the global economic, social, cultural, and physical environment. They highlight the critical role of interdisciplinary Supply Chain Management (SCM) and its evolution into Sustainable SCM (SSCM) and Green SCM. The wine industry is identified as a fertile ground for developing multidisciplinary collaborations and applying innovative entrepreneurship practices in both forward and reverse agrifood chains [

85]. The paper explicitly studies the exploitation of opportunities arising from wine production and waste management in this new environment. It presents a start-up business plan developed through a collaboration between the Agricultural University and the Harokopio University of Athens, Greece. The focus is on a wine waste management company located on the island of Crete, Greece, demonstrating how challenges can be transformed into opportunities for innovation and more efficient use of by-products and wastes.

The study’s methodology involved an action research framework and a business plan goal. The location, Kissamos province in Crete, was chosen due to its tradition in viticultural farming, wine production, and historical innovative capability. Data were collected through interviews with managers of potential supplier wineries and potential customer pharmaceutical and food companies. Secondary data provided technical information for the company’s setup and costs. Analytical tools used included PESTEL and SWOT analyses. A technical and financial analysis, including profit and loss (P/L) evaluation and economic performance indicators, was also conducted.

The start-up company in Kissamos, West Crete, will focus on elaborating wineries’ by-products, specifically pomace, to produce polyphenols. Pomace is a significant by-product of Greek wineries. The company’s potential suppliers are seven large wineries identified as having medium-level sustainable orientation (“unexploiters”) with potential for future adoption of sustainable practices. Potential customers are from the food, cosmetics, and pharmaceutical industries, with an interest in polyphenols derived from grapes. The SWOT analysis revealed key factors (

Table 7).

The financial evaluation of the start-up project yields positive results, with initial infrastructure costs estimated at over EUR 1.9 million and annual operational costs projected to exceed EUR 1.58 million. By utilizing pomace from suppliers, the company can produce 656.25 tons of polyphenols annually, with a forecasted first-year revenue of EUR 1,968,750, potentially increasing to over EUR 2 million within five years. Key financial indicators suggest that the investment is sustainable. The study highlights that entrepreneurship is driven by innovative behavior, appropriate infrastructure, and collaboration between academia and industry, which can enhance sustainability in the wine sector. Partnerships among local stakeholders are essential for developing sustainable solutions and creating job opportunities. The role of universities and authorities in promoting sustainable practices is crucial for overall well-being.

8.2. Market Potential for GP-Derived Materials

Although most grape pomace could be composted and returned to vineyards to help close the carbon cycle, this practice is not widely implemented. At the same time, there is growing consumer demand for natural compounds over synthetic alternatives, as well as an increasing focus on the sustainability of agricultural practices. This context highlights a vast array of potential applications for the bioactives found in grape pomace. Despite this potential, no prior assessment of the market potential for value-added uses of grape pomace had been conducted (

Table 8) [

86,

87].

The article by Dwyer et al. [

86] assesses the market potential of red grape pomace alternatives, highlighting existing products. The estimated market potential for red grape skins produced in Ontario and British Columbia (B.C.) in 2011 was approximately CAD 499 million for Ontario and CAD 185 million for B.C., assuming 100% utilization as supplements. For grape seed oil, the potential was over CAD 5 million combined from both provinces. These numbers reflect theoretical market values based on complete utilization and do not account for factors such as composting or extraction costs, meaning the actual potential would likely be lower. Despite this, they indicate significant annual production of pomace and potential commercial uses. Current primary uses involve composting, but there are opportunities in functional foods and supplements. Further research is necessary to assess economic viability and explore alternative applications, as grape pomace is expected to remain primarily composted until proven otherwise.

Recently, innovative uses have been found for grape pomace, indicating its increasing market potential. Dos Santos Silva et al. [

87] discuss the technological potential of grape pomace for use in the meat industry. The text addresses the compounds of interest within grape pomace and elucidates the challenges associated with their application in meat products. The adoption of nano- and microencapsulation technologies, along with the implementation of active packaging as carriers for grape pomace extracts, significantly enhances their application in meat and meat products. These technologies, whether applied individually or in combination, facilitate the controlled release of bioactive compounds during storage while also masking undesirable flavors associated with phenolic compounds.

In addition to the technological advancements, the incorporation of grape pomace within the meat industry aligns with the growing demand for natural additives. It aligns with the United Nations’ Sustainable Development Goals. This practice mitigates environmental impacts and enables the extraction of high-value molecules from industrial waste.

The work of Manso et al. [

88] examines an integrated biorefinery approach that aims to maximize the utilization of white grape pomace (WGP) through a combination of hydrothermal and organosolv treatments, followed by solid-state fermentation (SSF). The hydrothermal pretreatment process was optimized to enhance sugar extraction, achieving a concentration of up to 80.94 g L

−1 of reducing sugars, which can be utilized as a substrate for microalgae cultivation. The organosolv treatment facilitated the selective recovery of polyphenols and lignin, with the highest yield of polyphenols (2.27 g kg

−1 dry weight) being obtained at a temperature of 150 °C. Additionally, a lignin yield of 34.72% was achieved at 200 °C. The residual solid fractions were subsequently subjected to solid-state fermentation using the fungi

Aspergillus oryzae,

Neurospora intermedia, and

Rhizopus oryzae, resulting in a noteworthy increase in protein content, with

A. oryzae achieving a protein content of 17.6% on a dry weight basis. This multi-step integrated approach demonstrates a scalable and sustainable strategy for converting WGP into multiple high-value bio-products, thereby advancing the principles of the circular economy within the food sector.

As previously mentioned, the main solid by-products and waste from winemaking are grape pomace (GP), wine lees, and grape solids (GSs). Regulations in Spain require industrial waste to be recycled, valorized, or properly disposed of to prevent environmental contamination. Traditionally, wineries have opted for disposal and paid a “polluter pays” fee. However, a significant rise in disposal fees—along with fines for unauthorized discharges that can reach EUR 30,000 to EUR 40,000—has made waste valorization a more attractive and economically viable alternative. Penalties can also include mandatory decontamination of affected areas or even prison sentences.

In this context, valorization emerges as both an environmentally responsible and cost-effective strategy. Although it mentions data from 2011, the work of Devesa-Rey et al. [

89], which highlights several approaches for valorizing different winery wastes, including trimming residues, grape pomace, and wine lees, remains relevant. Their findings suggest that these strategies not only reduce the costs associated with biotechnological processes but also contribute to sustainable waste management.

Table 9 summarizes the valorization strategies proposed by Devesa-Rey et al. [

89] for DGP.

10. Final Remarks

The incorporation of DGP as a filler or additive in polymer matrices provides a substantial enhancement of mechanical characteristics, including increased tensile strength, elasticity, and flexibility, along with notable antioxidant properties. These enhancements render the resultant composites particularly appealing for sustainable packaging applications and other functional uses.

Integrating grape pomace into polymer systems has proven to be a proficient strategy for elevating the thermal properties of biocomposites. This method not only enhances heat resistance and thermal stability but also promotes sustainability by valorizing agricultural by-products, thereby reducing overall polymer consumption.

DGP in its various processed forms can be effectively utilized in the development of biodegradable plastics, enhancing their environmental credentials, mechanical robustness, and antioxidant efficacy. Such biocomposite materials show significant promise for applications in single-use items and food packaging; however, further research and development efforts are necessary to overcome commercial production hurdles and optimize the performance characteristics of these materials.

The employment of DGP in bio-based materials presents distinct environmental advantages by minimizing waste, reducing carbon emissions, and facilitating the transition to biodegradable and renewable products. This approach not only addresses the challenges associated with waste management but also contributes to the establishment of more sustainable material cycles.

Valorizing FLW presents a significant opportunity to mitigate environmental impacts. However, standardization and quality control are essential for scalable processes, which combine FLW valorization with efficient food production and emerging technologies to meet global needs.

Sustainable wine production is vital for the industry’s future, benefiting environmental, social, and economic sustainability. The sector can significantly contribute to various Sustainable Development Goals (SDGs), such as SDG 2 (Zero Hunger) through sustainable farming practices, SDG 3 (Good Health) by promoting responsible drinking, and SDG 12 (Responsible Consumption) through sustainable production and consumption. Academic literature can guide the industry in addressing sustainability challenges effectively.

11. Future Directions and Opportunities

11.1. Multidisciplinary Approaches for Material Development

Effective waste management faces challenges like inadequate funding, poor infrastructure, and limited public awareness. Traditional landfills harm the environment, while advanced thermal conversion technologies, such as gasification and pyrolysis, can be costly. Circular economy principles prioritize composting and anaerobic digestion over incineration and landfilling, as they enhance soil properties and support sustainable food systems [

90].

Proposals suggest integrating multiple disciplines to tackle global food waste challenges, specifically through anaerobic digestion. Key areas include (i) techniques such as metagenomics and proteomics, which enhance the understanding of microbial processes in biogas production; (ii) utilization of nanomaterials to enhance waste treatment efficiency, reduce costs, and improve biogas output through conductive materials; (iii) optimizes anaerobic digestion processes for better efficiency; and (iv) analyzing data and predict digester performance using methods like artificial neural networks [

91].

A collaborative and multidisciplinary approach, supported by robust policies, is essential for effective and sustainable food waste management worldwide. More integrated research is needed to explore these methodologies.

11.2. Advanced Functionalization and Hybrid Materials

The article by Otoni et al. [

92] explores the potential of using agri-food residues, specifically food losses and waste (FLW), to develop next-generation bioplastics and advanced materials within the context of a circular bioeconomy. It highlights the environmental impacts of food side streams, emphasizing the importance of reducing food loss and waste (FLW). The distinction is made between food loss, which occurs before retail, and food waste, often resulting from consumer behavior. Approximately 14% of food is lost before retail, particularly in cereals and pulses. The valorization of FLW involves transforming these residues into high-value materials, rather than returning them to food, by utilizing methods such as polymerization and biosynthesis to produce bioplastics and other materials.

Various building blocks derived from food loss and waste (FLW) are explored: (i) Monomers and modified molecules, which include hydroxy acids, epoxides, fatty acids, and lactic acid sourced from fruits, vegetables, and oils, are usable for producing polymers such as polyesters and polyurethanes. D-Limonene from citrus peels is a notable monomer, although challenges remain in its polymerization. (ii) Soluble biopolymers (pectin, starch) and insoluble ones (lignin) can be extracted for applications in films, coatings, and medical devices. Lignin enhances cellulose’s wet strength, enabling the creation of bioplastics, while proteins like gelatin are functional in medical wearables. Additionally, nanocelluloses from plant waste and chitin nanocrystals from crustacean shells can be utilized, along with biogenic silica microparticles obtained from pineapple peels.

FLW composition influences film formation, with each component contributing unique properties. Films made from carrots, parsley, and cauliflower show potential but may require reinforcement to achieve optimal strength.

Manufacturing processes significantly affect material properties. Utilizing FLW can lower production costs through methods such as spinning, casting, and 3D printing. Mycelium-based products are also emerging.

11.3. Integration into Local Circular Economy Models

The growing interest in sustainability within the wine industry highlights the increasing consensus that circular economy solutions are essential for achieving the United Nations’ Sustainable Development Goals (SDGs). By implementing circular economy strategies, wine production processes can improve both environmental and economic sustainability. Key components of these strategies include waste valorization and industrial symbiosis.

However, a gap exists between theoretical sustainability strategies and their practical implementation in the wine industry. This gap can be attributed to several factors, including the substantial investments of time, resources, and technology required, financial constraints faced by smaller producers, a lack of knowledge, and difficulties in coordinating practices throughout the entire supply chain.

The review by Abbate et al. [

20] identifies two main thematic areas: (i) Attitudes towards sustainability in the wine industry include drivers and barriers to adopting sustainable practices, the development of circular business models, the integration of technologies, and performance indicators. Drivers include internal values, stakeholder expectations, marketing, innovation, and competitiveness. Consumers are increasingly willing to pay more for sustainably produced wines. (ii) Wine waste valorization focuses on transforming by-products into valuable resources. This includes bioenergy from grape marc and cheese whey, biorefineries, and the extraction of bioactives from vine pruning. Other applications include grape seed oil for packaging and anthocyanins for food, cosmetics, and pharmaceuticals. Wine waste can also be processed into compost and organic fertilizer for functional foods.

Practical applications include integrating grape residues into consumer products, new extraction methods, and innovations such as WineLeather and antioxidant-rich asphalt. Economic and environmental benefits include reduced disposal costs and new revenue streams. Future research should explore technologies in vineyards, partnerships for by-product exchange, waste prevention, and the evaluation of sustainability through cost–benefit and life cycle analyses.

11.4. Alignment with UN Sustainable Development Goals (SDGs)

Sustainability is vital for the long-term survival of the wine industry. Embracing sustainable practices protects natural resources, ensures fair employment, and leverages technology to improve production quality while minimizing environmental impacts. These practices enhance wine quality by reducing chemical use, conserving water, and improving waste management. Additionally, sustainability enhances the industry’s image and tourism while lowering production costs through improved resource management.

The wine industry makes a significant contribution to the economy, culture, and local employment, while also having a positive impact on ecosystems and promoting the use of renewable energy. It engages in practices that reduce pesticide and fertilizer use, improve water quality, and enhance biodiversity.

Recognized as a key partner in the United Nations’ Sustainable Development Goals (SDGs), the wine industry supports economic growth, promotes employment and social justice, and fosters environmental preservation. It creates jobs, invests in education, and removes gender barriers, ultimately improving farmers’ incomes and quality of life. However, unsustainable wine production can harm development goals, including the use of pesticides, loss of biodiversity, excessive water use, and greenhouse gas emissions from transportation, packaging, and processing. Vineyard expansion can also lead to deforestation, soil erosion, and reduced land availability.

The study by Martínez-Falcó et al. [

93] used a bibliometric analysis of the Web of Science (WoS) database. A specific search equation, incorporating Boolean operators and wildcards, identified relevant articles published between 1997 and 2022. The PRISMA statement guided article selection, narrowing 114 initial records to 107 after removing duplicates and irrelevant items. Bibliometric reviews provide a comprehensive overview, highlighting research trends, priorities, and connections between authors.

Key findings include (i) a 633.33% increase in SDG-related wine research from 2015 (3 articles) to 2022 (22 articles), mainly due to the UN’s 2015 adoption of the SDGs; (ii) main research areas such as Environmental Sciences, Green Sustainable Science, and Food Science Technology, with contributions from Horticulture and Agriculture, underscoring the multidisciplinary focus.

11.5. A Roadmap for the Valorization of Dealcoholized Grape Pomace in Bio-Based Materials: Opportunities, Challenges, and Pathways for Industrial Uptake

DGP has emerged as a promising bio-based material for biocomposites and biodegradable plastics, particularly in applications such as food packaging, agricultural tools, and single-use items. Existing studies consistently demonstrate that DGP improves mechanical performance, thermal stability, and antioxidant activity when used as a filler or functional additive. These performance gains, along with DGP’s abundant availability and compatibility with circular economy principles, position it as an attractive candidate for developing sustainable materials.

Nevertheless, despite encouraging results, the field remains in a relatively early stage and would benefit from a more application-oriented research strategy. To support industrial uptake and advance scientific development, the following roadmap identifies key research priorities.

First, DGP’s role as a sustainable filler has been demonstrated, but its practical relevance could be significantly enhanced by focusing on application-specific performance metrics. For example, researchers should evaluate barrier properties for food packaging applications, investigate aging resistance for outdoor or agricultural uses, assess biodegradability under both industrial and home composting conditions, and examine shelf-life stability for active packaging systems.

Second, greater attention must be given to the optimization of processing parameters. This includes understanding the influence of drying methods and particle size on DGP’s reinforcing capabilities, fine-tuning compatibilizer formulations to enhance interfacial adhesion within different polymer matrices, and examining how extraction or purification methods affect the final material properties.

Third, while the environmental advantages of DGP valorization are well-articulated, the economic dimension requires stronger support. We consider that conducting a robust economic feasibility analysis—factoring in drying costs, energy demands, and market competitiveness—is essential to substantiate claims of sustainable valorization and to guide investment decisions.

Fourth, the path to industrial scale-up will benefit from standardization and integration into existing manufacturing frameworks. Establishing common protocols for the collection, drying, and storage of DGP will help ensure uniform quality. Moreover, defining key performance indicators and developing scalable, industry-aligned processing techniques are critical for consistent and widespread application.

Despite its potential, several scaling challenges must be addressed to ensure the successful commercial deployment of DGP-based materials. One significant barrier is supply chain variability, as the volume and composition of DGP can vary considerably depending on grape variety, regional practices, and vintage conditions, thereby complicating efforts toward consistent sourcing and standardization. Another significant hurdle is the energy-intensive and logistically complex process of drying wet pomace, especially for small and medium-sized wineries that may lack the infrastructure for in situ valorization. Regulatory issues also pose obstacles, particularly concerning approvals for food-contact materials or classification of DGP composites under national biodegradability standards. Ultimately, a significant gap remains in market readiness and industry awareness. Many potential users are still unaware of DGP’s functional benefits, highlighting the need for demonstration projects, stakeholder outreach, and more transparent communication of performance advantages.

DGP offers strong potential as a high-performing, sustainable, and circular filler for bio-based materials. To fully realize its value, the field must evolve beyond proof-of-concept work and pursue targeted application testing, economic and environmental validation, and the resolution of technical and regulatory bottlenecks. Coordinated efforts among researchers, industry partners, and policymakers will be essential. With the proper support, DGP-based materials can make a significant contribution to the development of a circular and bio-based economy, particularly in wine-producing regions where this resource is both abundant and underutilized.