3D Printed Posterior Connector Dimensions’ Effect on Fracture Properties of Provisional Two-Unit Fixed Dental Prostheses

Abstract

1. Introduction

2. Materials and Methods

2.1. Master Model Design

2.2. Master Model Manufacturing

2.3. FPDs Design

2.4. FPDs Manufacturing

2.5. Specimens Testing

2.6. Specimens Evaluation

2.7. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ELsyad, M.A.; Elgamal, M.; Mohammed Askar, O.; Youssef Al-Tonbary, G. Patient satisfaction and oral health-related quality of life (OHRQoL) of conventional denture, fixed prosthesis and milled bar overdenture for All-on-4 implant rehabilitation. A crossover study. Clin. Oral Implant. Res. 2019, 30, 1107–1117. [Google Scholar] [CrossRef]

- The Glossary of Prosthodontic Terms 2023: Tenth Edition. J. Prosthet. Dent. 2023, 130 (Suppl. S1), e1–e3. [CrossRef] [PubMed]

- Rosenstiel, S.F.; Land, M.F.; Fujimoto, J. Contemporary Fixed Prosthodontics; Mosby/Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Saeed, F.; Muhammad, N.; Khan, A.S.; Sharif, F.; Rahim, A.; Ahmad, P.; Irfan, M. Prosthodontics dental materials: From conventional to unconventional. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 106, 110167. [Google Scholar] [CrossRef] [PubMed]

- Goodacre, C.J.; Naylor, W.P. Single implant and crown versus fixed partial denture: A cost-benefit, patient-centred analysis. Eur. J. Oral Implantol. 2016, 9 (Suppl. S1), S59–S68. [Google Scholar] [PubMed]

- Kullar, A.S.; Miller, C.S. Are There Contraindications for Placing Dental Implants? Dent. Clin. N. Am. 2019, 63, 345–362. [Google Scholar] [CrossRef]

- Park, S.M.; Park, J.M.; Kim, S.K.; Heo, S.J.; Koak, J.Y. Flexural Strength of 3D-Printing Resin Materials for Provisional Fixed Dental Prostheses. Materials 2020, 13, 3970. [Google Scholar] [CrossRef]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef]

- Dawood, A.; Marti Marti, B.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Liu, Q.; Leu, M.C.; Schmitt, S.M. Rapid prototyping in dentistry: Technology and application. Int. J. Adv. Manuf. Technol. 2005, 29, 317–335. [Google Scholar] [CrossRef]

- Barazanchi, A.; Li, K.C.; Al-Amleh, B.; Lyons, K.; Waddell, J.N. Additive Technology: Update on Current Materials and Applications in Dentistry. J. Prosthodont. 2017, 26, 156–163. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Fang, Y.; Liao, Y.; Chen, G.; Gao, C.; Zhu, P. 3D Printing and Digital Processing Techniques in Dentistry: A Review of Literature. Adv. Eng. Mater. 2019, 21, 1801013. [Google Scholar] [CrossRef]

- Zanetti, E.M.; Aldieri, A.; Terzini, M.; Calì, M.; Franceschini, G.; Bignardi, C. Additively Manufactured Custom Load-Bearing Implantable Devices. Australas. Med. J. 2017, 10, 694. [Google Scholar] [CrossRef]

- Alharbi, N.; Alharbi, S.; Cuijpers, V.; Osman, R.B.; Wismeijer, D. Three-dimensional evaluation of marginal and internal fit of 3D-printed interim restorations fabricated on different finish line designs. J. Prosthodont. Res. 2018, 62, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Ambre, M.J.; Aschan, F.; Vult von Steyern, P. Fracture strength of yttria-stabilized zirconium-dioxide (Y-TZP) fixed dental prostheses (FDPs) with different abutment core thicknesses and connector dimensions. J. Prosthodont. 2013, 22, 377–382. [Google Scholar] [CrossRef]

- Peñate, L.; Basilio, J.; Roig, M.; Mercadé, M. Comparative study of interim materials for direct fixed dental prostheses and their fabrication with CAD/CAM technique. J. Prosthet. Dent. 2015, 114, 248–253. [Google Scholar] [CrossRef]

- Motta, A.B.; Pereira, L.C.; da Cunha, A.R.; Duda, F.P. The influence of the loading mode on the stress distribution on the connector region of metal-ceramic and all-ceramic fixed partial denture. Artif. Organs 2008, 32, 283–291. [Google Scholar] [CrossRef]

- Oh, W.S.; Anusavice, K.J. Effect of connector design on the fracture resistance of all-ceramic fixed partial dentures. J. Prosthet. Dent. 2002, 87, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Astudillo-Rubio, D.; Delgado-Gaete, A.; Bellot-Arcis, C.; Montiel-Company, J.M.; Pascual-Moscardo, A.; Almerich-Silla, J.M. Mechanical properties of provisional dental materials: A systematic review and meta-analysis. PLoS ONE 2018, 13, e0193162. [Google Scholar] [CrossRef]

- Orthodontic Applications of Biomaterials; Elsevier: Amsterdam, The Netherlands, 2017. [CrossRef]

- Shillingburg, H.T. Fundamentals of Fixed Prosthodontics; Quintessence Pub. Co.: New Malden, UK, 1997. [Google Scholar]

- Scheid, R.C.; Woelfel, J.B. Woelfel’s Dental Anatomy; Wolters Kluwer/Lippincott Williams & Wilkins Health: Philadelphia, PA, USA, 2012. [Google Scholar]

- Junker, R.; Holler, M.; Yoshida-Anastasova, Y.; Frank, W.; Nothdurft, F.P. Influence of Connector Diameter on Fracture Load of CAD/CAM-Processed Monolithic Lithium Disilicate Fixed Partial Dentures. Int. J. Prosthodont. 2019, 32, 68–70. [Google Scholar] [CrossRef]

- Rezaei, S.M.; Heidarifar, H.; Arezodar, F.F.; Azary, A.; Mokhtarykhoee, S. Influence of Connector Width on the Stress Distribution of Posterior Bridges under Loading. J. Dent. 2011, 8, 67–74. [Google Scholar]

- Larsson, C.; Holm, L.; Lovgren, N.; Kokubo, Y.; Vult von Steyern, P. Fracture strength of four-unit Y-TZP FPD cores designed with varying connector diameter. An in-vitro study. J. Oral Rehabil. 2007, 34, 702–709. [Google Scholar] [CrossRef] [PubMed]

- Hoaglin, D.C.; Mosteller, F.; Tukey, J.W. Understanding Robust and Exploratory Data Analysis; Wiley: Hoboken, NJ, USA, 1983. [Google Scholar]

- Hoaglin, D.C.; Mosteller, F.; Tukey, J.W. Exploring Data Tables, Trends, and Shapes; Wiley: Hoboken, NJ, USA, 1985. [Google Scholar]

- Tukey, J.W. Exploratory Data Analysis; Addison-Wesley Pub. Co.: Princeton, NJ, USA, 1977. [Google Scholar]

- Hampel, F.R. Robust Statistics: The Approach Based on Influence Functions; Wiley: Hoboken, NJ, USA, 1986. [Google Scholar]

- Rousseeuw, P.J.; Leroy, A.M. Robust Regression and Outlier Detection; Wiley: Hoboken, NJ, USA, 1987. [Google Scholar]

- Masri, R.; Driscoll, C.F. Clinical Applications of Digital Dental Technology; Wiley-Blackwell: Hoboken, NJ, USA, 2023. [Google Scholar]

- Modi, R.; Kohli, S.; Rajeshwari, K.; Bhatia, S. A three-dimension finite element analysis to evaluate the stress distribution in tooth supported 5-unit intermediate abutment prosthesis with rigid and nonrigid connector. Eur. J. Dent. 2015, 9, 255–261. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Harshitha Gowda, B.H.; Satish Babu, C.L. Connector design in a long-span-fixed dental prosthesis: A three-dimensional finite element analysis. Indian J. Dent. Res. 2013, 24, 178–182. [Google Scholar] [CrossRef]

- Shen, C. Phillips’ Science of Dental Materials; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Luthy, H.; Filser, F.; Loeffel, O.; Schumacher, M.; Gauckler, L.; Hammerle, C. Strength and reliability of four-unit all-ceramic posterior bridges. Dent. Mater. 2005, 21, 930–937. [Google Scholar] [CrossRef]

| Group | Width (mm) | Height (mm) | Cross-Sectional Area (mm2) |

|---|---|---|---|

| A | 2 | 3 | 8.16 |

| B | 3 | 3 | 10.30 |

| C | 3 | 4 | 13.33 |

| D | 4 | 4 | 15.08 |

| Crown Fracture | ||||

|---|---|---|---|---|

| Type | First (Mesial) | Second (Distal) | Fracture Direction | Connector Fracture |

| 1 | Yes | No | One direction (mesial to distal) | No |

| 2 | Yes | No | Multiple directions | No |

| 3 | Yes | No | One direction (mesial to distal) | Yes |

| 4 | Yes | No | Multiple directions | Yes |

| 5 | No | Yes | One direction (mesial to distal) | No |

| 6 | No | Yes | Multiple directions | No |

| 7 | No | Yes | One direction (mesial to distal) | Yes |

| 8 | No | Yes | Multiple directions | Yes |

| 9 | Yes | Yes | One direction (mesial to distal) | No |

| 10 | Yes | Yes | Multiple directions | No |

| 11 | Yes | Yes | One direction (mesial to distal) | Yes |

| 12 | Yes | Yes | Multiple directions | Yes |

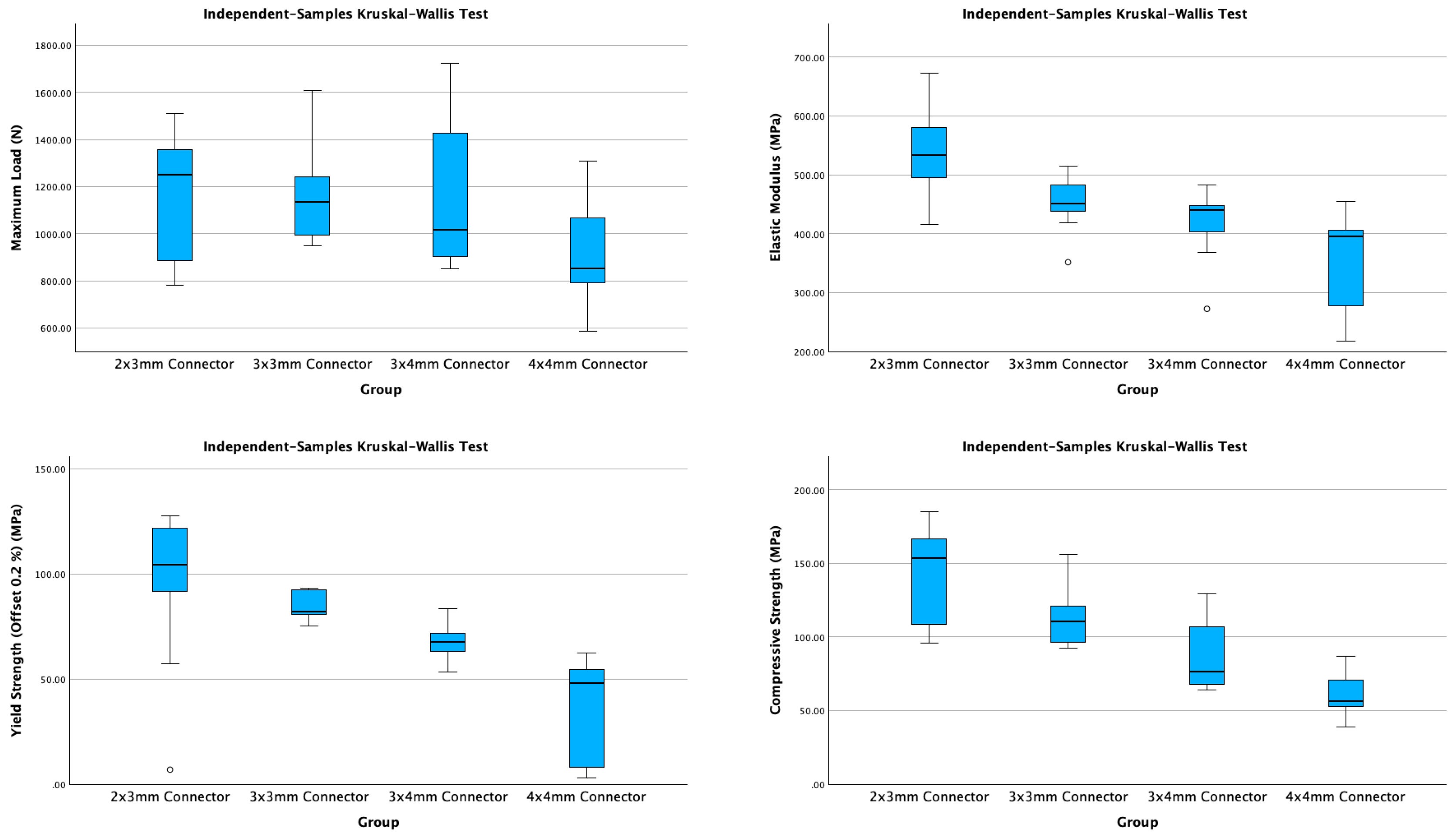

| Group | A | B | C | D | |

|---|---|---|---|---|---|

| n | 10 | 10 | 10 | 10 | |

| Maximum Load (N) | Median | 1251.32 | 1136.06 | 1016.78 | 853.59 |

| Mean | 1176.9 | 1159.6 | 1161 | 904.7 | |

| 95% Confidence Interval for Mean | 989.22–1364.64 | 1021.50–1297.71 | 920.50–1401.48 | 742.61–1066.85 | |

| SD | 262.4 | 193.06 | 336.19 | 226.6 | |

| Elastic Modulus (MPa) | Median | 533.92 | 451.09 | 440.57 | 394.83 |

| Mean | 537.62 | 451.9 | 421.79 | 359.5 | |

| 95% Confidence Interval for Mean | 488.91–586.34 | 418.79–485.01 | 377.27–466.32 | 302.09–416.91 | |

| SD | 68.1 | 46.28 | 62.24 | 80.25 | |

| Yield Strength (Offset 0.2%) (MPa) | Median | 104.44 | 82.21 | 67.48 | 48.00 |

| Mean | 94.14 | 84.78 | 67.77 | 37.98 | |

| 95% Confidence Interval for Mean | 67.98–120.29 | 79.72–89.85 | 61.89–73.65 | 20.81–55.15 | |

| SD | 36.56 | 7.08 | 8.22 | 24 | |

| Compressive Strength (MPa) | Median | 153.35 | 110.30 | 76.28 | 56.61 |

| Mean | 144.23 | 112.58 | 87.09 | 60 | |

| 95% Confidence Interval for Mean | 121.23–167.24 | 99.17–125.99 | 69.05–105.14 | 49.25–70.75 | |

| SD | 32.16 | 18.74 | 25.22 | 15.03 |

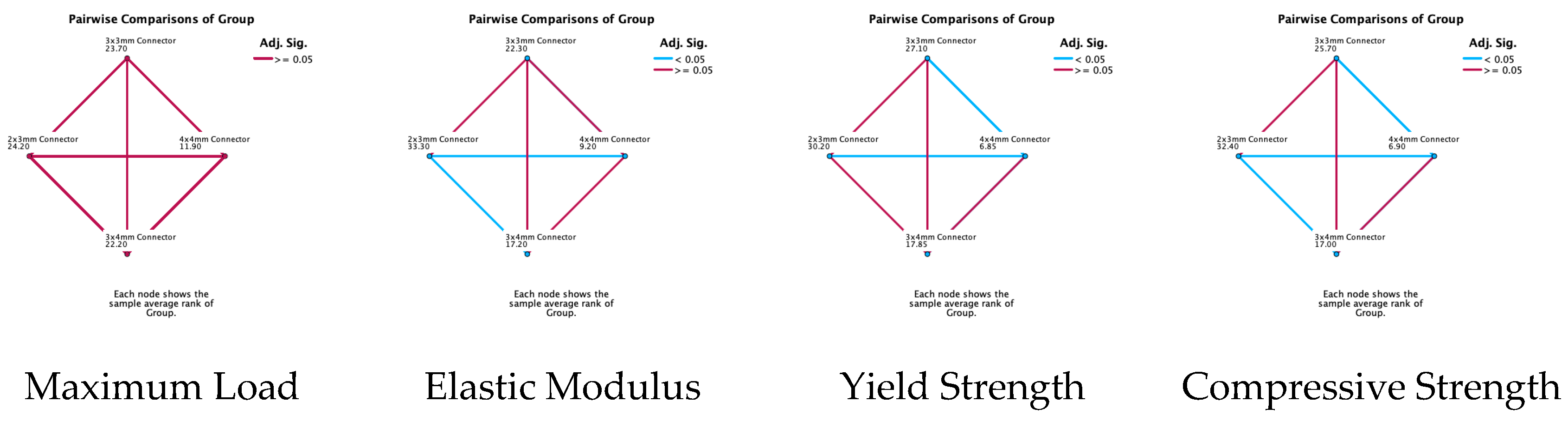

| Test Statistic | Sig. | Adj. Sig. a | |

|---|---|---|---|

| Maximum Load (N) across Group | |||

| Group D-Group C | 10.30 | 0.05 | 0.29 |

| Group D-Group B | 11.80 | 0.02 * | 0.14 |

| Group D-Group A | 12.30 | 0.02 * | 0.11 |

| Group C-Group B | 1.50 | 0.77 | 1.00 |

| Group C-Group A | 2.00 | 0.70 | 1.00 |

| Group B-Group A | 0.50 | 0.92 | 1.00 |

| Elastic Modulus (MPa) across Group | |||

| Group D-Group C | 8.00 | 0.13 | 0.76 |

| Group D-Group B | 13.10 | 0.01 * | 0.07 |

| Group D-Group A | 24.10 | <0.001 * | 0.00 |

| Group C-Group B | 5.10 | 0.33 | 1.00 |

| Group C-Group A | 16.10 | 0.00 * | 0.01 |

| Group B-Group A | 11.00 | 0.04 * | 0.21 |

| Yield Strength (Offset 0.2%) (MPa) across Group | |||

| Group D-Group C | 11.00 | 0.04 * | 0.21 |

| Group D-Group B | 20.25 | <0.001 * | 0.00 |

| Group D-Group A | 23.35 | <0.001 * | 0.00 |

| Group C-Group B | 9.25 | 0.08 | 0.46 |

| Group C-Group A | 12.35 | 0.02 * | 0.11 |

| Group B-Group A | 3.10 | 0.55 | 1.00 |

| Compressive Strength (MPa) across Group | |||

| Group D-Group C | 10.10 | 0.05 | 0.32 |

| Group D-Group B | 18.80 | <0.001 * | 0.00 |

| Group D-Group A | 25.50 | <0.001 * | 0.00 |

| Group C-Group B | 8.70 | 0.10 | 0.58 |

| Group C-Group A | 15.40 | 0.00 * | 0.02 |

| Group B-Group A | 6.70 | 0.20 | 1.00 |

| Maximum Load (N) | Elastic Modulus (MPa) | Yield Strength (Offset 0.2%) (MPa) | Compressive Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Group | Fracture Types | Count | Mean | SD | Mean | SD | Mean | SD | Mean | SD |

| A | 6 | 2 | 1378.65 | 56.36 | 543.74 | 181.68 | 49.31 | 59.98 | 168.95 | 6.91 |

| 8 | 1 | 1509.82 | . | 536.94 | . | 122.54 | . | 185.03 | . | |

| 11 | 3 | 918.70 | 206.29 | 548.47 | 35.82 | 86.59 | 25.45 | 112.59 | 25.28 | |

| 12 | 4 | 1186.52 | 215.08 | 526.60 | 41.82 | 115.11 | 11.31 | 145.41 | 26.36 | |

| B | 4 | 1 | 1241.98 | . | 448.84 | . | 93.25 | . | 120.58 | . |

| 10 | 1 | 1606.83 | . | 462.14 | . | 82.46 | . | 156.00 | . | |

| 12 | 8 | 1093.41 | 115.64 | 451.00 | 52.32 | 84.02 | 7.26 | 106.16 | 11.23 | |

| C | 9 | 1 | 961.81 | . | 368.82 | . | 71.59 | . | 72.15 | . |

| 10 | 1 | 849.49 | . | 447.29 | . | 62.87 | . | 63.73 | . | |

| 11 | 2 | 1016.78 | 76.13 | 360.07 | 123.99 | 60.72 | 10.35 | 76.28 | 5.71 | |

| 12 | 6 | 1294.17 | 381.23 | 446.95 | 30.40 | 70.30 | 8.05 | 97.09 | 28.60 | |

| D | 1 | 5 | 779.57 | 113.26 | 368.12 | 66.82 | 40.19 | 21.78 | 51.70 | 7.51 |

| 11 | 2 | 783.20 | 147.54 | 308.17 | 128.34 | 23.76 | 28.93 | 51.94 | 9.79 | |

| 12 | 3 | 1194.35 | 121.81 | 379.34 | 91.69 | 43.77 | 30.99 | 79.20 | 8.08 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkhallagi, T.S.; Alqahtani, M.A.; Marghalani, T.Y. 3D Printed Posterior Connector Dimensions’ Effect on Fracture Properties of Provisional Two-Unit Fixed Dental Prostheses. Appl. Sci. 2025, 15, 7171. https://doi.org/10.3390/app15137171

Alkhallagi TS, Alqahtani MA, Marghalani TY. 3D Printed Posterior Connector Dimensions’ Effect on Fracture Properties of Provisional Two-Unit Fixed Dental Prostheses. Applied Sciences. 2025; 15(13):7171. https://doi.org/10.3390/app15137171

Chicago/Turabian StyleAlkhallagi, Turki S., Manal A. Alqahtani, and Thamer Y. Marghalani. 2025. "3D Printed Posterior Connector Dimensions’ Effect on Fracture Properties of Provisional Two-Unit Fixed Dental Prostheses" Applied Sciences 15, no. 13: 7171. https://doi.org/10.3390/app15137171

APA StyleAlkhallagi, T. S., Alqahtani, M. A., & Marghalani, T. Y. (2025). 3D Printed Posterior Connector Dimensions’ Effect on Fracture Properties of Provisional Two-Unit Fixed Dental Prostheses. Applied Sciences, 15(13), 7171. https://doi.org/10.3390/app15137171