Hybrid Wind–Redox Flow Battery System for Decarbonizing Off-Grid Mining Operations

Abstract

1. Introduction

- What is the optimal configuration of wind energy and redox flow storage to maximize diesel savings at the Raglan mining site?

- What are the economic implications of integrating large-scale redox flow batteries, particularly in Arctic conditions?

- How does energy storage improve grid stability, and what policy incentives could enhance financial feasibility?

- Economic indicators: capital and operating expenditures, energy price, payback period, and net present value (NPV);

- Technical indicators: installed capacity and power, number of wind turbines, wind penetration rate, number of generators in operation or removed, redox battery capacity, and greenhouse gas (GHG) emission reduction.

2. System Description

3. Methodology

3.1. Assumptions

- Energy demand: The mine’s annual electricity consumption is 145,195 MWh, requiring 34.2 million liters of diesel. The daily average electricity consumption of the site is shown in Figure 5.

- Wind resource: Wind speed data from 2020 indicates monthly average speeds between 6 and 9 m/s (see Figure 6) with an annual average of 8.5 m/s at the wind turbine hub height (92 m).

- Ambient temperature: The average temperature on site is −15 °C, which affects air density (1.367 kg/m3 instead of the standard 1.225 kg/m3).

- Wind farm expansion: The existing two wind turbines (Enercon E-82) are expected to be supplemented with newer E-115 EP3 E4 turbines, each with a rated power of 4260 kW (92 m hub height) and a power curve illustrated in Figure 7.

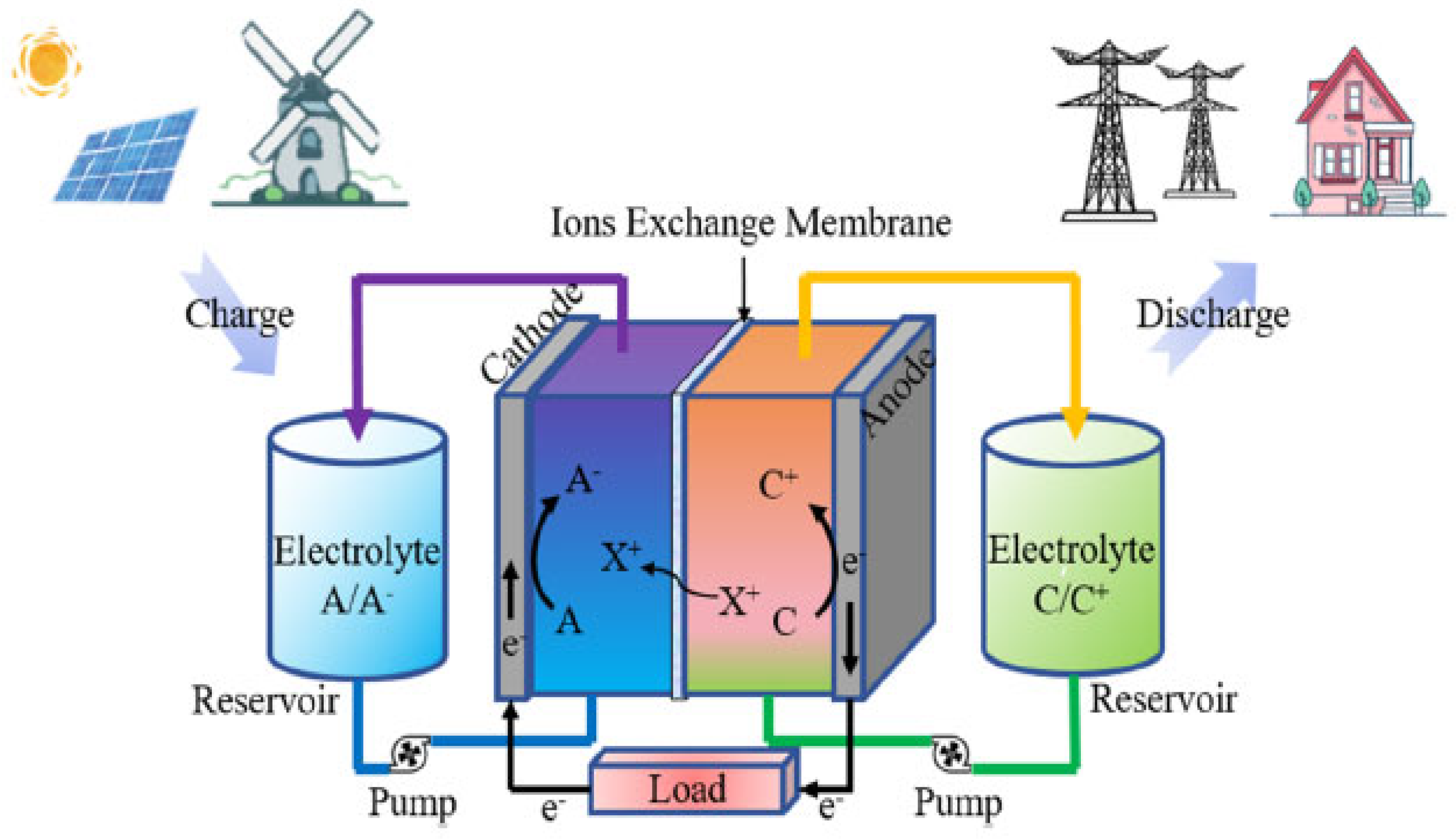

- Battery storage: The selected VRB ENERGY all-vanadium flow battery is installed in a heated facility to mitigate cold-related efficiency losses.

3.2. Wind Energy Production in Mining Sites: Forecasting, Optimization, and Utilization

3.3. Sizing of the Energy System

3.3.1. Sizing, Installation, and Cost of the Wind Farm

3.3.2. Sizing, Implementation, and Cost of the Storage System

- The footprint of the redox battery system;

- The required storage capacity.

4. Design, Sizing, and Modeling of the Wind Energy and Storage System

- Wind energy production;

- Electricity and heat generation based on generator operation;

- Diesel fuel consumption;

- Energy storage dynamics (charging and discharging cycles).

- Renewable energy penetration rate;

- Wind energy curtailment losses;

- Diesel fuel savings;

- Greenhouse gas (GHG) emissions reduction;

- Economic performance metrics (including financial feasibility analysis).

4.1. Model Input Data

- Number of wind turbines;

- Number of diesel generators in operation;

- Maximum battery power (maximum_battery_power);

- Battery storage duration (battery_storage_time);

- Total battery storage capacity (max_battery_capacity).

- Hourly heat demand data (2021);

- Wind speed data at 15 min intervals (2020);

- Electricity consumption data from the 25 kV network (hourly, 2020);

- The power curve of the ENERCON E-115 wind turbine.

4.2. Sub-Model 1: Wind Speed Model

- Unfavorable: Wind speed decreases between −10% and −5%;

- Random: Wind speed fluctuates within a range of −5% to +5%;

- Favorable: Wind speed increases between +5% and +10%.

- a and b are the lower and upper bounds of the wind speed variation interval;

- N represents the random numbers within the interval (a,b);

- (N,1) is the MATLAB random function that generates values within the specified range.

- Wind turbine performance fluctuations;

- Energy storage system behavior under variable wind conditions;

- Grid stability under different wind penetration scenarios.

- The number of hours per year with no wind;

- Consecutive hours with zero wind generation;

- Consecutive hours without peak wind speeds.

4.3. Sub-Model 2: Wind Power Generation Model

- Estimation of the wind farm’s load factor;

- Calculation of total wind energy production (based on the number of new turbines installed);

- Computation of average hourly energy output per turbine.

4.4. Sub-Model 3: Model of the Response to Electrical Demand

- Battery management (state of charged and discharged energy);

- Unused surplus energy;

- Generator consumption.

- Electricity demand is satisfied:

- The energy supply exceeds demand, generating excess power.

- The surplus is directed toward charging storage batteries.

- If batteries are fully charged, the excess energy is curtailed (rejected).

- This is the ideal case for the Raglan mine, as it maximizes the utilization of renewable energy.

- Electricity demand is not satisfied:

- The 25 kV network draws from battery storage to cover the deficit.

- If battery reserves are insufficient, additional power must be generated.

- In this case, an emergency recourse to diesel generators is triggered.

- Each generator has an estimated power output of 2.88 MW.

4.5. Sub-Model 4: Thermal Demand Response Model

- Heat recovery from EMD engine blocks;

- Diesel-fired boilers.

- Exhaust gas recovery: 5.12 MWh;

- 31-HX-02 heat exchanger recovery: 12.35 MWh.

5. Validation of the Global Model

- Error-free execution;

- Optimized calculation times;

- Seamless operation with a single command.

6. Results and Discussion

6.1. Data

- Wind speed at Raglan: Monthly average wind speed is typically between 6 and 9 m/s.

- The overall efficiency of electricity production by generators is 3.78 kWh/L, corresponding to an electricity generation efficiency of 35.5%.

- Air density: Approximately 1.37 kg/m3, based on an average atmospheric temperature of −15 °C, a common condition at Raglan.

- Wind energy production data from 2020 was used as the baseline for modeling wind power generation.

- Electricity consumption data from 2020 was used to model the electrical demand of the mine.

- Thermal energy consumption data from 2021 was used to represent the mine’s heating requirements.

6.2. Model Results

- Reduce diesel consumption, lowering operational costs and reliance on fossil fuels;

- Decrease greenhouse gas (GHG) emissions, mitigating the environmental impact of mining activities.

6.2.1. General Trend Results

Scenario of Two Generators in Operation and 120 MWh Battery: Impact of Adding Wind Turbines to the 25 kV-G Network

Impact of the Number of Operating Generators and Additional Wind Turbines on the Diesel Savings

6.2.2. Results for the Most Economical Scenario

6.2.3. Scenarios with the Highest Diesel Savings

6.3. Discussion

7. Conclusions and Perspectives

- *

- Full or partial decommissioning of diesel generators;

- *

- The number of additional E-115 wind turbines to be added;

- *

- The ideal energy storage capacity of the redox flow battery.

- Detailed sensitivity and uncertainty analysis of key parameters (wind variability, energy demand, climate trends);

- Probabilistic modeling to assess long-term performance and reliability under varying environmental and operational conditions;

- Power system simulations to evaluate voltage and frequency stability under high-renewable-integration scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Equation | Equation Number | Variable | Observation | Meaning of Terms |

|---|---|---|---|---|

| (A1) | LCOE | Equation taken from the IRENA [43] report “Renewable power generation costs 2021” | | |

| (A2) | LCOS | The LCOS equation is taken from the work of Schmidt et al. [38]. | cost of electricity (or more broadly of energy) needed to power the system. either the dismantling cost or the value of the installation at the end of the system’s life (salvage value) annual amount of electricity discharged by the system | |

| (A3) | Amount of heat | The specific heat capacity of the exhaust gases is taken as 1066 J/kg.K | mass : The specific heat capacity of the exhaust gases Temperature variation | |

| (A4) | Wind speed | The simulation of wind speed variations | a and b are the lower and upper bounds of the wind speed variation interval N represents the random numbers within the interval (a,b) rand(N,1) is the MATLAB random function that generates values within the specified range. | |

| (A5) | The Weibull distribution | The Weibull distribution is used to estimate the annual mean wind speed at Raglan. | λ the scale factor, k the shape factor and; x the wind speed. | |

| (A6) | OPEX | LCOE corresponds to the addition of CAPEX and OPEX. | Fc: load factor | |

| (A7) | CAPEX | LCOE corresponds to the addition of CAPEX and OPEX. | Fc: load factor D: project lifespan | |

| (A8) | correction factor | The correction factor is applied to account for production inefficiencies. It takes into account the harsh environmental conditions in Raglan (cold, frost, storms, etc.). |

References

- United Nations. Framework convention on climate change. In Proceedings of the Report of the Conference of the Parties on Its Twenty-First Session, Paris, France, 30 November–11 December 2015; Part One: Proceedings. p. 42. [Google Scholar]

- Jahangiri, Z.; Hendriks, R.; McPherson, M. A Machine Learning Approach to Analysis of Canadian Provincial Power System Decarbonization. Energy Rep. 2024, 11, 4849–4861. [Google Scholar] [CrossRef]

- Government of Canada. Canada’s Official Greenhouse gas Inventory. Annex 13—Electricity in Canada. Available online: https://open.canada.ca/data/en/dataset/779c7bcf-4982-47eb-af1b-a33618a05e5b (accessed on 9 January 2025).

- Government of Canada. Canadian Net-Zero Emissions Accountability Act. Available online: https://www.canada.ca/en/services/environment/weather/climatechange/climate-plan/net-zero-emissions-2050/canadian-net-zero-emissions-accountability-act.html (accessed on 9 January 2025).

- Saffari, M.; McPherson, M. Assessment of Canada’s Electricity System Potential for Variable Renewable Energy Integration. Energy 2022, 250, 123757. [Google Scholar] [CrossRef]

- Nielsen, A.S.; Del Alamo Serrano, G.; Schanche, T.L.; Burheim, O.S. Reducing CO2 Emissions, Energy Consumption, and Decarbonization Costs in Manganese Production by Integrating Fuel-Assisted Solid Oxide Electrolysis Cells in Two-Stage Oxide Reduction. Appl. Energy 2025, 377, 124572. [Google Scholar] [CrossRef]

- Da Silva, F.T.F.; Garcez Lopes, M.S.; Asano, L.M.; Angelkorte, G.; Brambilla Costa, A.K.; Szklo, A.; Schaeffer, R.; Coutinho, P. Integrated Systems for the Production of Food, Energy and Materials as a Sustainable Strategy for Decarbonization and Land Use: The Case of Sugarcane in Brazil. Biomass Bioenergy 2024, 190, 107387. [Google Scholar] [CrossRef]

- Du, Y.; Shen, X.; Kammen, D.M.; Hong, C.; Nie, J.; Zheng, B.; Yao, S. A Generation and Transmission Expansion Planning Model for the Electricity Market with Decarbonization Policies. Adv. Appl. Energy 2024, 13, 100162. [Google Scholar] [CrossRef]

- Balaban, G.; Dumbrava, V.; Lazaroiu, A.C.; Kalogirou, S. Analysis of Urban Network Operation in Presence of Renewable Sources for Decarbonization of Energy System. Renew. Energy 2024, 230, 120870. [Google Scholar] [CrossRef]

- Dongsheng, C.; Ndifor, E.Z.; Temidayo Olayinka, A.-O.; Ukwuoma, C.C.; Shefik, A.; Hu, Y.; Bamisile, O.; Dagbasi, M.; Uzun Ozsahin, D.; Adun, H. An EnergyPlan Analysis of Electricity Decarbonization in the CEMAC Region. Energy Strategy Rev. 2024, 56, 101548. [Google Scholar] [CrossRef]

- Obiora, S.C.; Bamisile, O.; Hu, Y.; Ozsahin, D.U.; Adun, H. Assessing the Decarbonization of Electricity Generation in Major Emitting Countries by 2030 and 2050: Transition to a High Share Renewable Energy Mix. Heliyon 2024, 10, e28770. [Google Scholar] [CrossRef]

- Roshan Kumar, T.; Beiron, J.; Marthala, V.R.R.; Pettersson, L.; Harvey, S.; Thunman, H. Combining Exergy-Pinch and Techno-Economic Analyses for Identifying Feasible Decarbonization Opportunities in Carbon-Intensive Process Industry: Case Study of a Propylene Production Technology. Energy Convers. Manag. X 2025, 25, 100853. [Google Scholar] [CrossRef]

- Asri, L.I.M.; Ariffin, W.N.S.F.W.; Zain, A.S.M.; Nordin, J.; Saad, N.S. Comparative Study of Energy Storage Systems (ESSs). J. Phys. Conf. Ser. 2021, 1962, 012035. [Google Scholar] [CrossRef]

- Mahadevan, V.; S, S.R.; Rusho, M.A.; Yishak, S. Critical Review of Energy Storage Systems: A Comparative Assessment of Mechanisms, Advantages, Challenges, and Integration with Renewable Energy. Results Eng. 2025, 26, 105589. [Google Scholar] [CrossRef]

- Babaharra, O.; Choukairy, K.; Faraji, H.; Khallaki, K.; Hamdaoui, S.; Bahammou, Y. Thermal Performance Analysis of Hollow Bricks Integrated Phase Change Materials for Various Climate Zones. Heat Transf. 2024, 53, 2148–2172. [Google Scholar] [CrossRef]

- Liu, X.; Pan, L.; Rao, H.; Wang, Y. A Review of Transport Properties of Electrolytes in Redox Flow Batteries. Future Batter. 2025, 5, 100019. [Google Scholar] [CrossRef]

- Thamizhselvan, R.; Naresh, R.; Ulaganathan, M.; Pol, V.G.; Ragupathy, P. Achieving Exceptional Cell Voltage (2.34 V) through Tailoring pH of Aqueous Zn-Br2 Redox Flow Battery for Potential Large-Scale Energy Storage. Electrochim. Acta 2023, 441, 141799. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Zhang, S.; Wu, S.; Chen, F.; Xu, J. A Comparative Study of Iron-Vanadium and All-Vanadium Flow Battery for Large Scale Energy Storage. Chem. Eng. J. 2022, 429, 132403. [Google Scholar] [CrossRef]

- Sun, J.; Wu, M.; Jiang, H.; Fan, X.; Zhao, T. Advances in the Design and Fabrication of High-Performance Flow Battery Electrodes for Renewable Energy Storage. Adv. Appl. Energy 2021, 2, 100016. [Google Scholar] [CrossRef]

- Standard 34-2010; Designation and Safety Classification of Refrigerants. ANSI/ASHRAE: Atlanta, GA, USA, 2011.

- Huang, Z.; Mu, A.; Wu, L.; Wang, H.; Zhang, Y. Electrolyte Flow Optimization and Performance Metrics Analysis of Vanadium Redox Flow Battery for Large-Scale Stationary Energy Storage. Int. J. Hydrog. Energy 2021, 46, 31952–31962. [Google Scholar] [CrossRef]

- Loktionov, P.; Pichugov, R.; Konev, D. Neutralization Flow Batteries in Energy Harvesting and Storage. J. Energy Storage 2023, 72, 108467. [Google Scholar] [CrossRef]

- Ren, J.; Li, Y.; Wang, Z.; Sun, J.; Yue, Q.; Fan, X.; Zhao, T. Thermal Issues of Vanadium Redox Flow Batteries. Int. J. Heat Mass Transf. 2023, 203, 123818. [Google Scholar] [CrossRef]

- Zeng, D.; Mao, T.; Zhang, Z.; Dai, J.; Ouyang, J.; Xie, Z. A High-Performance Aqueous Eu/Ce Redox Flow Battery for Large-Scale Energy Storage Application. Int. J. Heat Mass Transf. 2024, 233, 125978. [Google Scholar] [CrossRef]

- Ouyang, T.; Zhang, M.; Qin, P.; Tan, X. Flow Battery Energy Storage System for Microgrid Peak Shaving Based on Predictive Control Algorithm. Appl. Energy 2024, 356, 122448. [Google Scholar] [CrossRef]

- Darling, R.M. Techno-Economic Analyses of Several Redox Flow Batteries Using Levelized Cost of Energy Storage. Curr. Opin. Chem. Eng. 2022, 37, 100855. [Google Scholar] [CrossRef]

- Lourenssen, K.; Williams, J.; Ahmadpour, F.; Clemmer, R.; Tasnim, S. Vanadium Redox Flow Batteries: A Comprehensive Review. J. Energy Storage 2019, 25, 100844. [Google Scholar] [CrossRef]

- CEA. RMN: Tout Savoir sur L’électrolyte Organique D’une Batterie à Flux Redox. Available online: https://www.cea.fr/drf/Pages/Actualites/En-direct-des-labos/2023/rmn--tout-savoir-sur-lelectrolyte-organique-dune-batterie-a-flux-redox.aspx#:~:text=Les%20batteries%20%C3%A0%20flux%20redox,de%20stocker%20des%20charges%20%C3%A9lectriques (accessed on 21 January 2025).

- Zheng, N.; Wang, Q.; Ding, X.; Zhang, H.; Duan, L.; Wang, X.; Zhou, Y.; Sun, M.; Desideri, U. Techno-Economic Analysis of a Novel Solar-Based Polygeneration System Integrated with Vanadium Redox Flow Battery and Thermal Energy Storage Considering Robust Source-Load Response. Appl. Energy 2024, 376, 124288. [Google Scholar] [CrossRef]

- Yesilyurt, M.S.; Ozcan, H.G.; Yavasoglu, H.A. Co-Simulation-Based Conventional Exergy Evaluation of a Hybrid Energy Generation-Vanadium Redox Flow Battery-Air Source Heat Pump System. Energy 2023, 281, 128301. [Google Scholar] [CrossRef]

- Oshnoei, S.; Oshnoei, A.; Mosallanejad, A.; Haghjoo, F. Novel Load Frequency Control Scheme for an Interconnected Two-Area Power System Including Wind Turbine Generation and Redox Flow Battery. Int. J. Electr. Power Energy Syst. 2021, 130, 107033. [Google Scholar] [CrossRef]

- Reynard, D.; Girault, H. Combined Hydrogen Production and Electricity Storage Using a Vanadium-Manganese Redox Dual-Flow Battery. Cell Rep. Phys. Sci. 2021, 2, 100556. [Google Scholar] [CrossRef]

- Huang, Z.; Mu, A.; Wu, L.; Wang, H. Vanadium Redox Flow Batteries: Flow Field Design and Flow Rate Optimization. J. Energy Storage 2022, 45, 103526. [Google Scholar] [CrossRef]

- Ulaganathan, M.; Aravindan, V.; Yan, Q.; Madhavi, S.; Skyllas-Kazacos, M.; Lim, T.M. Recent Advancements in All-Vanadium Redox Flow Batteries. Adv. Mater. Interfaces 2016, 3, 1500309. [Google Scholar] [CrossRef]

- Hosseiny, S.S.; Wessling, M. Ion Exchange Membranes for Vanadium Redox Flow Batteries. In Advanced Membrane Science and Technology for Sustainable Energy and Environmental Applications; Elsevier: Amsterdam, The Netherlands, 2011; pp. 413–434. ISBN 978-1-84569-969-7. [Google Scholar]

- Skyllas-Kazacos, M.; Menictas, C.; Lim, T. Redox Flow Batteries for Medium—to Large-Scale Energy Storage. In Electricity Transmission, Distribution and Storage Systems; Elsevier: Amsterdam, The Netherlands, 2013; pp. 398–441. ISBN 978-1-84569-784-6. [Google Scholar]

- Emrani, A.; Achour, Y.; Sanjari, M.J.; Berrada, A. Adaptive Energy Management Strategy for Optimal Integration of Wind/PV System with Hybrid Gravity/Battery Energy Storage Using Forecast Models. J. Energy Storage 2024, 96, 112613. [Google Scholar] [CrossRef]

- Cremoncini, D.; Di Lorenzo, G.; Frate, G.F.; Bischi, A.; Baccioli, A.; Ferrari, L. Techno-Economic Analysis of Aqueous Organic Redox Flow Batteries: Stochastic Investigation of Capital Cost and Levelized Cost of Storage. Appl. Energy 2024, 360, 122738. [Google Scholar] [CrossRef]

- IRENA. Electricity Storage and Renewables: Costs and Markets to 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017; p. 132. [Google Scholar]

- Schmidt, O.; Melchior, S.; Hawkes, A.; Staffell, I. Projecting the Future Levelized Cost of Electricity Storage Technologies. Joule 2019, 3, 81–100. [Google Scholar] [CrossRef]

- Minke, C.; Turek, T. Materials, System Designs and Modelling Approaches in Techno-Economic Assessment of All-Vanadium Redox Flow Batteries—A Review. J. Power Sources 2018, 376, 66–81. [Google Scholar] [CrossRef]

- Zheng, M.; Sun, J.; Meinrenken, C.J.; Wang, T. Pathways Toward Enhanced Techno-Economic Performance of Flow Battery Systems in Energy System Applications. J. Electrochem. Energy Convers. Storage 2019, 16, 021001. [Google Scholar] [CrossRef]

- Zhang, M.; Moore, M.; Watson, J.S.; Zawodzinski, T.A.; Counce, R.M. Capital Cost Sensitivity Analysis of an All-Vanadium Redox-Flow Battery. J. Electrochem. Soc. 2012, 159, A1183–A1188. [Google Scholar] [CrossRef]

- Noack, J.; Wietschel, L.; Roznyatovskaya, N.; Pinkwart, K.; Tübke, J. Techno-Economic Modeling and Analysis of Redox Flow Battery Systems. Energies 2016, 9, 627. [Google Scholar] [CrossRef]

- Viswanathan, V.; Crawford, A.; Stephenson, D.; Kim, S.; Wang, W.; Li, B.; Coffey, G.; Thomsen, E.; Graff, G.; Balducci, P.; et al. Cost and Performance Model for Redox Flow Batteries. J. Power Sources 2014, 247, 1040–1051. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2021; International Renewable Energy Agency: Abu Dhabi, The Emirates, 2022; p. 204. [Google Scholar]

- Tardy, A.; Rousse, D.R.; Mungyeko Bisulandu, B.-J.R.; Ilinca, A. Enhancing Energy Sustainability in Remote Mining Operations Through Wind and Pumped-Hydro Storage; Application to Raglan Mine, Canada. Energies 2025, 18, 2184. [Google Scholar] [CrossRef]

- Durand, S.; Turcotte, P.; Haillot, D.; Rousse, D.R.; Arasteh, H.; Kalivogui, S.; Zhang, K.; Izquierdo, R.; Merabtine, A.; Maref, W.; et al. Decarbonization Strategies for Northern Canada: A Review of Renewable Energy and Energy Storage in off-Grid Communities. Energy Convers. Manag. X 2025, 27, 101055. [Google Scholar] [CrossRef]

- VRB Energy. VRB Energy Announces UL1973 Certification for 1MW VRB-ESS. Available online: https://vrbenergy.com/vrb-energy-announces-ul1973-certification-for-1mw-vrb-ess/ (accessed on 12 June 2025).

- Stehly, T.; Duffy, P. 2020 Cost of Wind Energy Review; Renewable Energy: Golden, CO, USA, 2022; p. 77. [Google Scholar]

- Solar Huawei. Coût du Stockage D’énergie Solaire: Guide Pour les Propriétaires. Available online: https://solar.huawei.com/tn/blog/tn/2024/solar-energy-storage-cost (accessed on 22 January 2025).

| Storage System Type | Max Power Rating [MW] | Discharge Time | Max Cycles or Lifetime | Energy Density [Wh/L] | Efficiency |

|---|---|---|---|---|---|

| Pumped hydro | ~3000+ | 4 h–16 h | 30–60 years | 0.2–2 | 70–85% |

| Compressed air | ~1000 | 2 h–30 h | 20–40 years | 2–6 | 40–70% |

| Molten salt | 100–150 | Several hours | ~30 years | 70–210 | 80–90% |

| Li-ion battery | 1–100+ | 1 min–8 h | 1000–10,000 cycles | 200–400 | 85–95% |

| Lead–acid | 1–100 | 1 min–8 h | 6–40 years | 50–80 | 80–90% |

| Flow battery | 10–100+ | Several hours | 12,000–14,000 cycles | 20–70 | 60–85% |

| Hydrogen | ~100+ | Minutes–weeks | 5–30 years | ~600 (at 700 bar) | 25–45% |

| Flywheel | 1–20 | Seconds–minutes | 20,000–100,000+ cycles | 20–80 | 70–95% |

| References | Context-Application | Storage System | Results |

|---|---|---|---|

| Zheng et al. [29] | To address the intermittency of renewable energy sources To manage fluctuating energy demand | VRFB system | Exergy efficiency of 78.52% |

| Yesilyurt et al. [30] | Powering a hybrid air-source heat pump | VRFB system | Efficiency of wind turbine integration with VRFB |

| Oshnoei et al. [31] | Load frequency control model for a wind power system | VRFB system | Higher performance due to the use of frequency-based VRFB |

| Reynard and Girault [32] | Energy storage Clean hydrogen production, integrating VRFBs with catalytic reactors to enhance efficiency | VRFB system | Improving the efficiency of catalytic reactors |

| Ouyang et al. [25] | Performance of a VRFB within a microgrid integrating a biomass gasifier and a solid oxide fuel cell designed for electricity generation in rural environments | VRFB system | Battery performance is highly dependent on the flow of the electrolyte. An efficiency of 84% was achieved during peak shaving operations. |

| Types of Wind Turbine | Minimum Wind Speed for a Wind Turbine Operation | Wind Speed to Reach Maximum Power | Maximum Operating Wind Speed of the Wind Turbine |

|---|---|---|---|

| E-82 | 3 m/s | 17 m/s | 26 m/s |

| E-115 | 2 m/s | 14.5 m/s | 34 m/s |

| Localization | OPEX (CAD/kW·yr) | OPEX (CAD/MWh) | CAPEX (CAD/kW) | CAPEX (CAD/MWh) | LCOE (CAD/MWh) |

|---|---|---|---|---|---|

| Canada | 46.9 | 11.84 | 1833 | 23.15 | 35.0 |

| Raglan | 117.6 | 30.76 | 4857 | 84.69 | 115.5 |

| 10 MW, Raglan | |||

|---|---|---|---|

| Parameters | 4 h | 6 h | 8 h |

| Storage system | |||

| Storage unit and electrolyte | 118.1 | 105.2 | 98.3 |

| Storage balance | 23.6 | 21.0 | 19.8 |

| Energy system | |||

| Power supply equipment | 14.3 | 9.5 | 7.1 |

| Control and communication | 0.9 | 0.6 | 0.4 |

| System Integration | 21.9 | 19.3 | 18.0 |

| System balance | |||

| Engineering, transportation, and construction | 83.0 | 73.0 | 68.7 |

| Project development | 41.8 | 37.2 | 34.9 |

| Network Integration | 9.0 | 6.0 | 4.5 |

| Total CAPEX | 312.5 | 271.8 | 251.8 |

| Total OPEX | 35.3 | 33.9 | 33.3 |

| Total LCOS | 347.8 | 305.8 | 285.0 |

| 20 MW, Raglan | |||

|---|---|---|---|

| Parameters | 4 h | 6 h | 8 h |

| Electrochemical system (M CAD) | 117.0 | 152.7 | 188.6 |

| Area required (m2) | 4000 | 6000 | 8000 |

| Shed price (M CAD) | 32.5 | 48.8 | 65.0 |

| Total cost (M CAD) | 149.5 | 201.4 | 253.6 |

| Characteristics | Modeled Value | Real Value | Relative Error (%) |

|---|---|---|---|

| Diesel consumed by generators (L) | 37,979,558 | 37,141,356 | 2.26 |

| Diesel consumed by boilers (L) | 111,815 | 111,182 | 0.57 |

| Total diesel consumed by the 25 kV network (L) | 38,091,374 | 37,252,539 | 2.25 |

| Wind power production (MWh) | 16,286 | 16,871 | 3.59 |

| Data at the Entrance | Value |

|---|---|

| Exchange rate as of 21 September 2022 | 1.34 CAD/USD |

| Load factor (%) | 32% |

| Lifetime of project (yr) | 15.00 |

| IRENA Canada Wind OPEX (CAD/kW.yr) | 35.00 |

| IRENA Canada Wind CAPEX (CAD/kW.yr) | 1368 |

| Exits | Value |

| CAPEX (CAD/MWh) | 49.24 |

| OPEX (CAD/MWh) | 24.15 |

| LCOE (CAD/MWh) | 73.40 |

| Number of Wind Turbines | 160 MWh Redox Battery | 120 MWh Redox Battery | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 gen | 1 gen | 2 gen | 3 gen | 0 gen | 1 gen | 2 gen | 3 gen | |

| 12 | −63.98% | −58.66% | −51.98% | −41.84% | −62.72% | −57.43% | −50.82% | −40.88% |

| 11 | −62.83% | −57.69% | −51.27% | −41.28% | −61.56% | −56.44% | −50.08% | −40.37% |

| 10 | −61.45% | −56.59% | −50.35% | −40.79% | −60.20% | −55.34% | −49.12% | −39.76% |

| 9 | −59.82% | −55.34% | −49.33% | −40.13% | −58.63% | −54.10% | −48.15% | −39.08% |

| 8 | −57.85% | −53.71% | −48.14% | −39.32% | −56.71% | −52.58% | −46.95% | −38.23% |

| 7 | −55.19% | −51.75% | −46.75% | −38.29% | −54.20% | −50.68% | −45.61% | −37.17% |

| 6 | −51.24% | −49.12% | −44.79% | −37.13% | −50.51% | −47.99% | −43.78% | −36.02% |

| 5 | −45.15% | −44.70% | −42.17% | −35.43% | −44.82% | −44.12% | −41.11% | −34.44% |

| 4 | −37.87% | −37.96% | −37.46% | −32.95% | −37.79% | −37.70% | −36.86% | −32.18% |

| 3 | −30.06% | −29.83% | −29.52% | −27.95% | −29.96% | −29.86% | −29.46% | −27.49% |

| 2 | −20.62% | −20.62% | −20.34% | −19.21% | −20.65% | −20.59% | −20.29% | −19.20% |

| 1 | −10.14% | −10.20% | −10.07% | −9.23% | −10.19% | −10.17% | −10.17% | −9.21% |

| 0 | 0.73% | 0.74% | 0.61% | 0.96% | 0.71% | 0.66% | 0.68% | 1.09% |

| Number of Wind Turbines | 80 MWh Redox Battery | Without Redox Battery | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 gen | 1 gen | 2 gen | 3 gen | 0 gen | 1 gen | 2 gen | 3 gen | |

| 12 | −61.27% | −56.06% | −49.49% | −39.66% | −56.68% | −51.31% | −44.79% | −35.44% |

| 11 | −60.10% | −55.05% | −48.74% | −39.16% | −55.43% | −50.34% | −43.93% | −34.76% |

| 10 | −58.79% | −53.93% | −47.82% | −38.49% | −54.17% | −49.16% | −43.00% | −34.10% |

| 9 | −57.22% | −52.62% | −46.75% | −37.79% | −52.51% | −47.80% | −41.88% | −33.29% |

| 8 | −55.29% | −51.14% | −45.56% | −36.92% | −50.60% | −46.15% | −40.63% | −32.23% |

| 7 | −52.92% | −49.33% | −44.11% | −35.91% | −48.45% | −44.40% | −39.07% | −31.19% |

| 6 | −49.56% | −46.73% | −42.33% | −34.69% | −45.82% | −42.09% | −37.31% | −29.84% |

| 5 | −44.39% | −43.23% | −39.96% | −33.20% | −42.28% | −39.37% | −35.05% | −28.21% |

| 4 | −37.69% | −37.37% | −36.13% | −30.95% | −37.01% | −35.46% | −32.12% | −26.10% |

| 3 | −29.94% | −29.72% | −29.21% | −26.90% | −29.62% | −29.14% | −27.56% | −23.15% |

| 2 | −20.61% | −20.52% | −20.23% | −19.08% | −20.51% | −20.27% | −19.61% | −17.86% |

| 1 | −10.14% | −10.08% | −10.09% | −9.19% | −10.14% | −10.04% | −9.71% | −8.76% |

| 0 | 0.71% | 0.63% | 0.51% | 1.11% | 0.64% | 0.66% | 0.72% | 1.32% |

| Data Type | Value | Unit |

|---|---|---|

| Wind CAPEX (5 wind turbines) | 103.4 | M CAD |

| CAPEX redox (battery and hangar) | 149.5 | M CAD |

| TOTAL CAPEX | 253.0 | M CAD |

| CAPEX additional cost | 236.3 | M CAD |

| TOTAL Economy | 155.8 | M CAD |

| LCOE complete system | 460 | CAD/MWh |

| LCOS complete system | 7830 | CAD/MWh |

| Wind integration | 80.48 | % |

| Wind penetration | 48.71 | % |

| Diesel saved | 39.96 | % |

| Quantity of GHG avoided | 42,429 | tCO2 eq. |

| Data Type | Value | Unit |

|---|---|---|

| Wind CAPEX (12 wind turbines) | 248.3 | M CAD |

| CAPEX redox (battery and hangar) | 253.6 | M CAD |

| TOTAL CAPEX | 501.9 | M CAD |

| CAPEX additional cost | 485.2 | M CAD |

| TOTAL Economy | −16.3 | M CAD |

| LCOE complete system | 590 | CAD/MWh |

| LCOS complete system | 6110 | CAD/MWh |

| Wind integration | 45.81 | % |

| Wind penetration | 60.09 | % |

| Diesel saved | 51.98 | % |

| Quantity of GHG avoided | 55,203 | tCO2 eq. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robert, A.; Mungyeko Bisulandu, B.-J.R.; Ilinca, A.; Rousse, D.R. Hybrid Wind–Redox Flow Battery System for Decarbonizing Off-Grid Mining Operations. Appl. Sci. 2025, 15, 7147. https://doi.org/10.3390/app15137147

Robert A, Mungyeko Bisulandu B-JR, Ilinca A, Rousse DR. Hybrid Wind–Redox Flow Battery System for Decarbonizing Off-Grid Mining Operations. Applied Sciences. 2025; 15(13):7147. https://doi.org/10.3390/app15137147

Chicago/Turabian StyleRobert, Armel, Baby-Jean Robert Mungyeko Bisulandu, Adrian Ilinca, and Daniel R. Rousse. 2025. "Hybrid Wind–Redox Flow Battery System for Decarbonizing Off-Grid Mining Operations" Applied Sciences 15, no. 13: 7147. https://doi.org/10.3390/app15137147

APA StyleRobert, A., Mungyeko Bisulandu, B.-J. R., Ilinca, A., & Rousse, D. R. (2025). Hybrid Wind–Redox Flow Battery System for Decarbonizing Off-Grid Mining Operations. Applied Sciences, 15(13), 7147. https://doi.org/10.3390/app15137147