Drag Reduction in Compressible Channel Turbulence with Periodic Interval Blowing and Suction

Abstract

1. Introduction

2. Computational Details

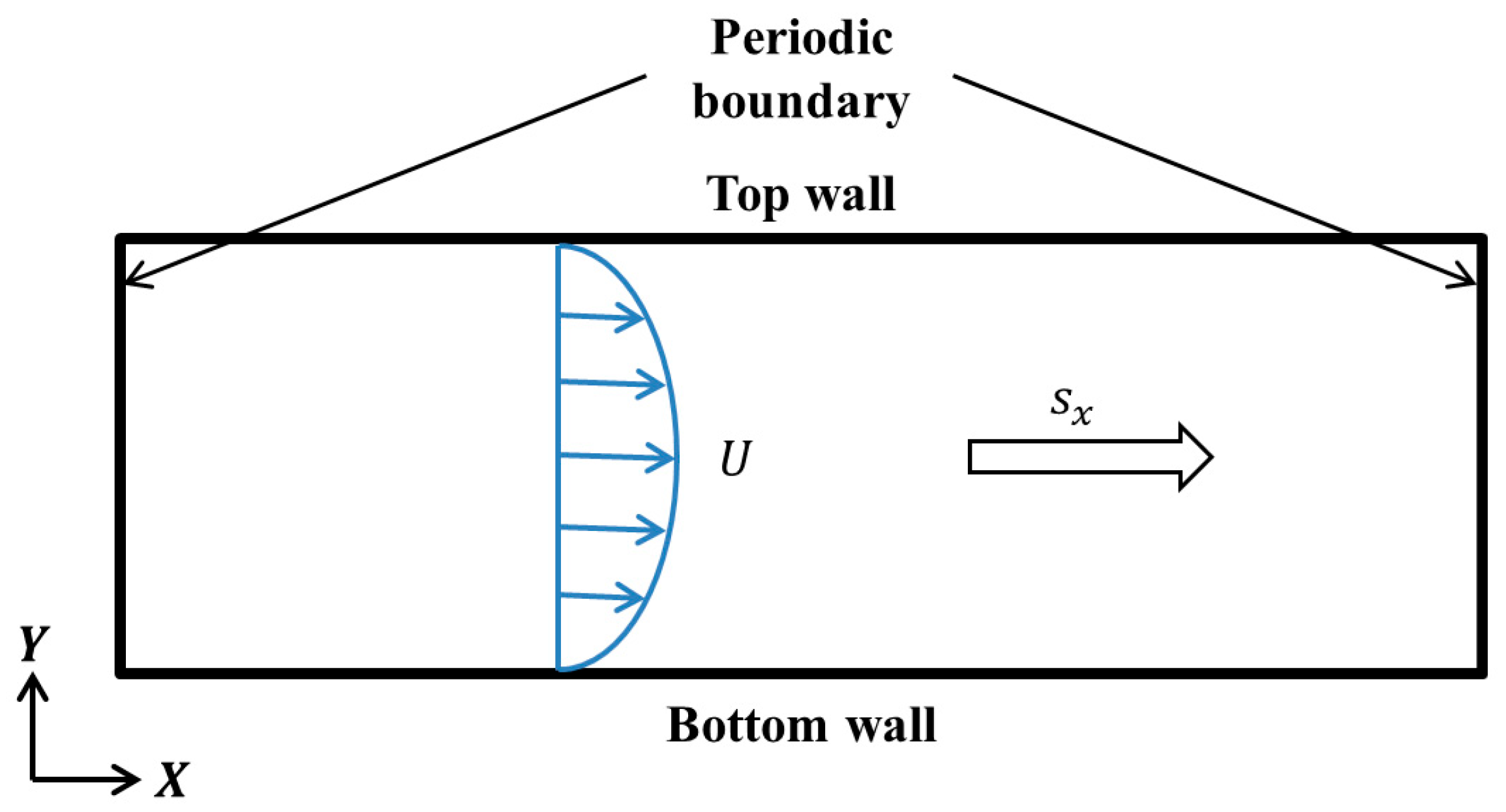

2.1. DNS Method and Physical Model

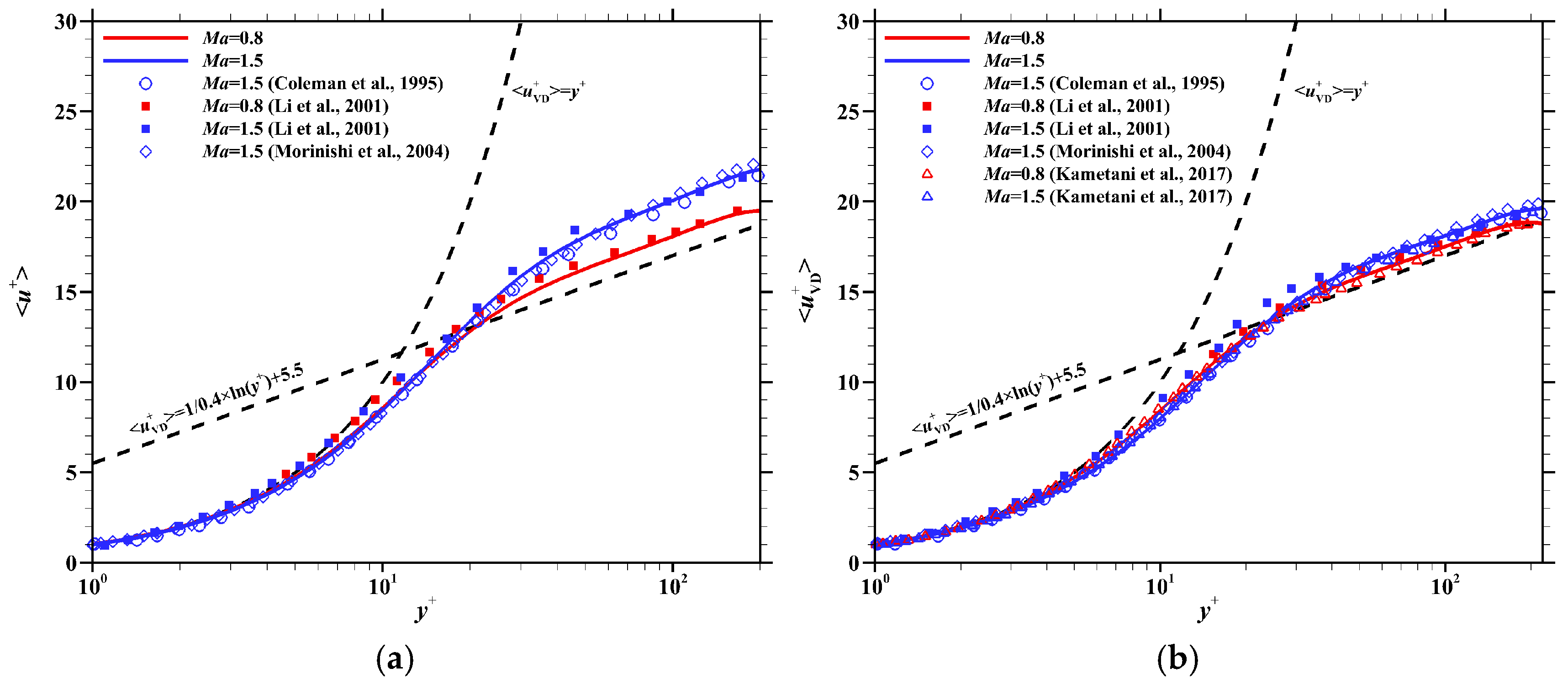

2.2. Basic Flow and Verification

3. Results and Discussions

3.1. Controlled Cases

| Case Number | (×10−2) | (%) | (%) | (%) | (%) | (×104) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.8 | 0 | × | 1.14 | 197 | × | × | × | × | × |

| C2 | 0.8 | 0.1% | 1 | 0.99 | 184 | 12.7 | −12.3 | 0.20 | 12.7 | 207.32 |

| C3 | 0.8 | 0.2% | 1/2 | 1.00 | 185 | 11.8 | −14.3 | −1.25 | 11.8 | 48.24 |

| C4 | 0.8 | 0.3% | 1/3 | 1.00 | 185 | 12.0 | −13.9 | −0.97 | 12.0 | 21.80 |

| C5 | 0.8 | 0.5% | 1/5 | 1.00 | 185 | 12.0 | −13.2 | −0.64 | 12.0 | 7.82 |

| C6 | 1.5 | 0 | × | 0.98 | 220 | × | × | × | × | × |

| C7 | 1.5 | 0.1% | 1 | 0.85 | 205 | 13.7 | −16.7 | −1.51 | 13.7 | 152.66 |

| C8 | 1.5 | 0.2% | 1/2 | 0.84 | 203 | 15.1 | −19.1 | −2.01 | 15.1 | 41.99 |

| C9 | 1.5 | 0.3% | 1/3 | 0.84 | 203 | 15.1 | −19.2 | −2.08 | 15.1 | 18.60 |

| C10 | 1.5 | 0.5% | 1/5 | 0.84 | 203 | 14.7 | −18.6 | −1.93 | 14.7 | 6.52 |

3.2. Effect of Injected Mass Flow Rate and Kinetic Energy

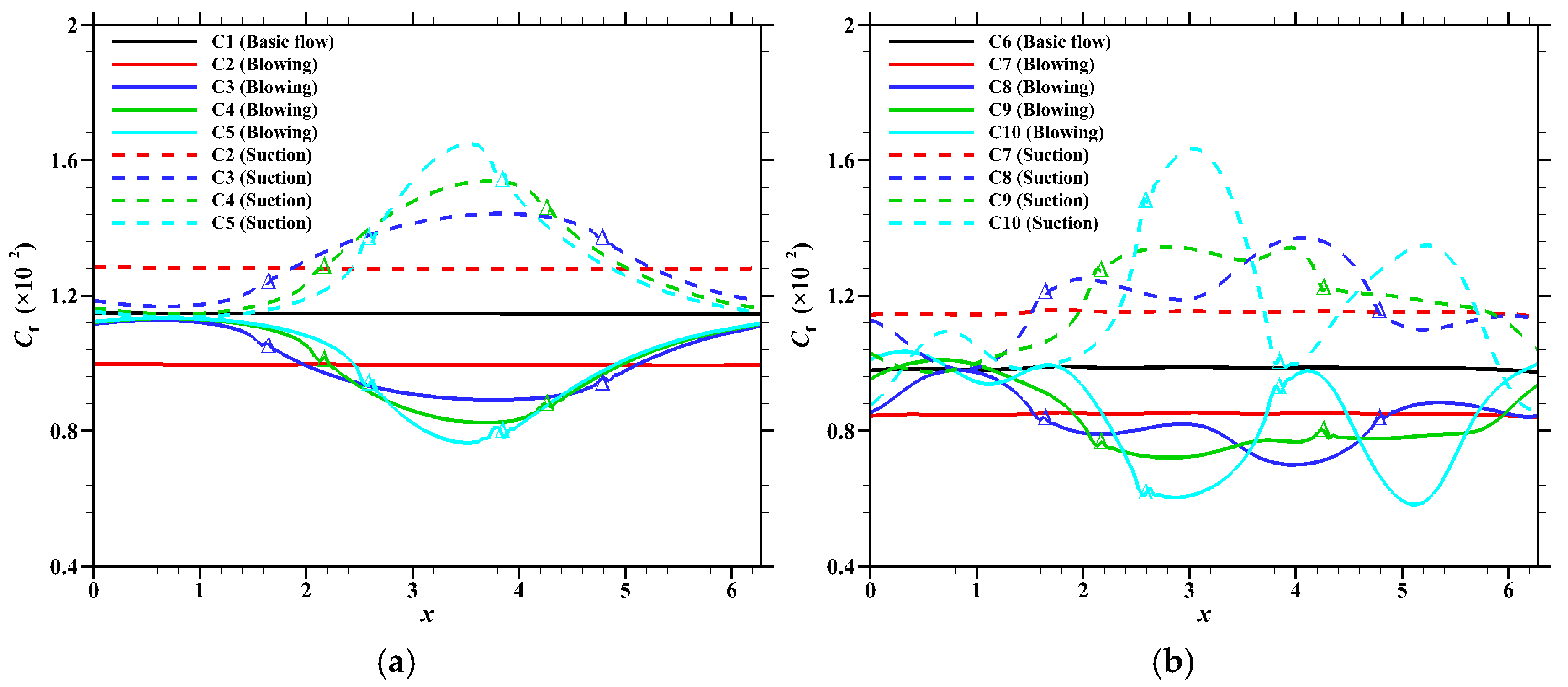

3.3. Skin Friction Distribution

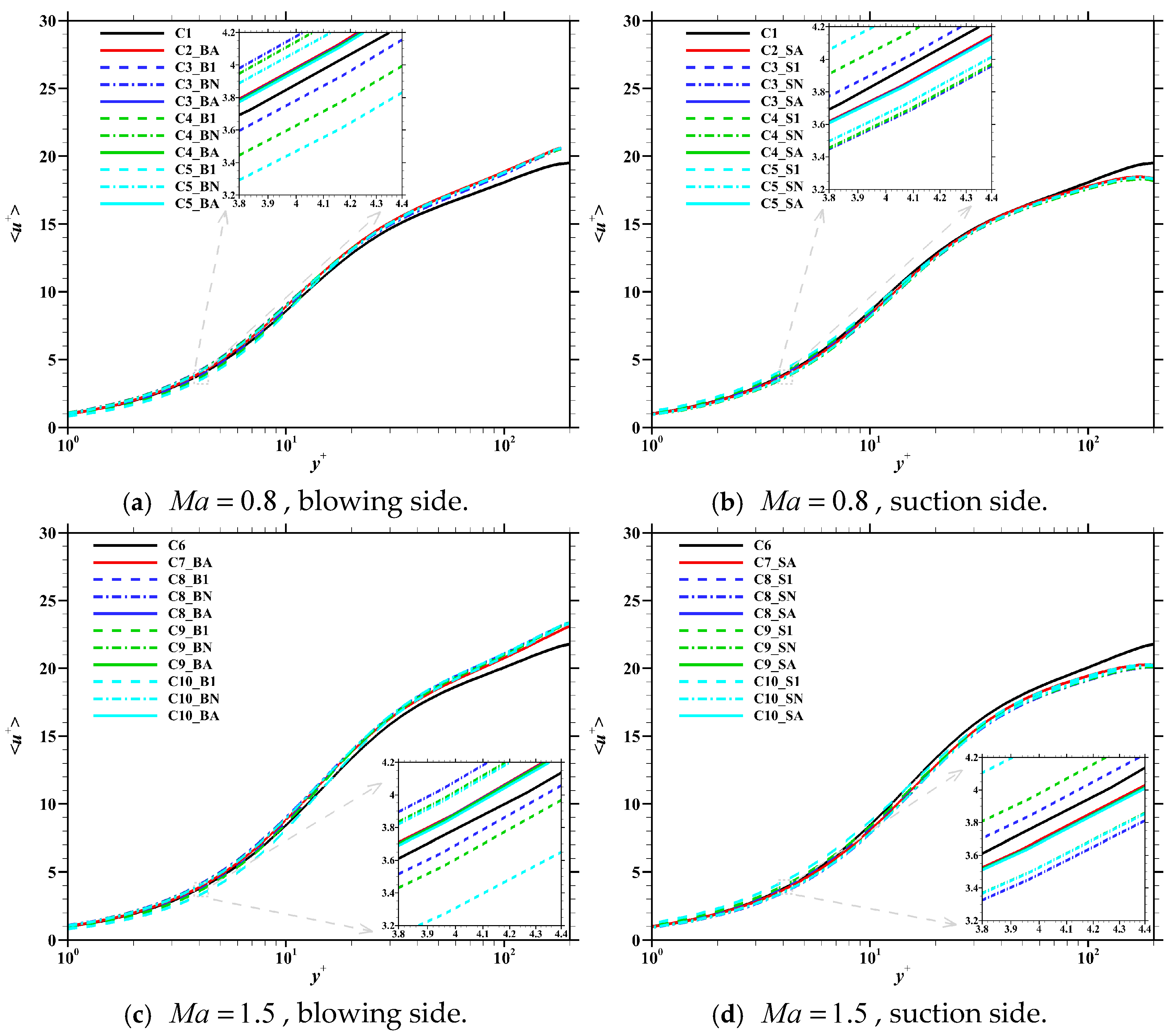

3.4. Averaged Velocity Profile

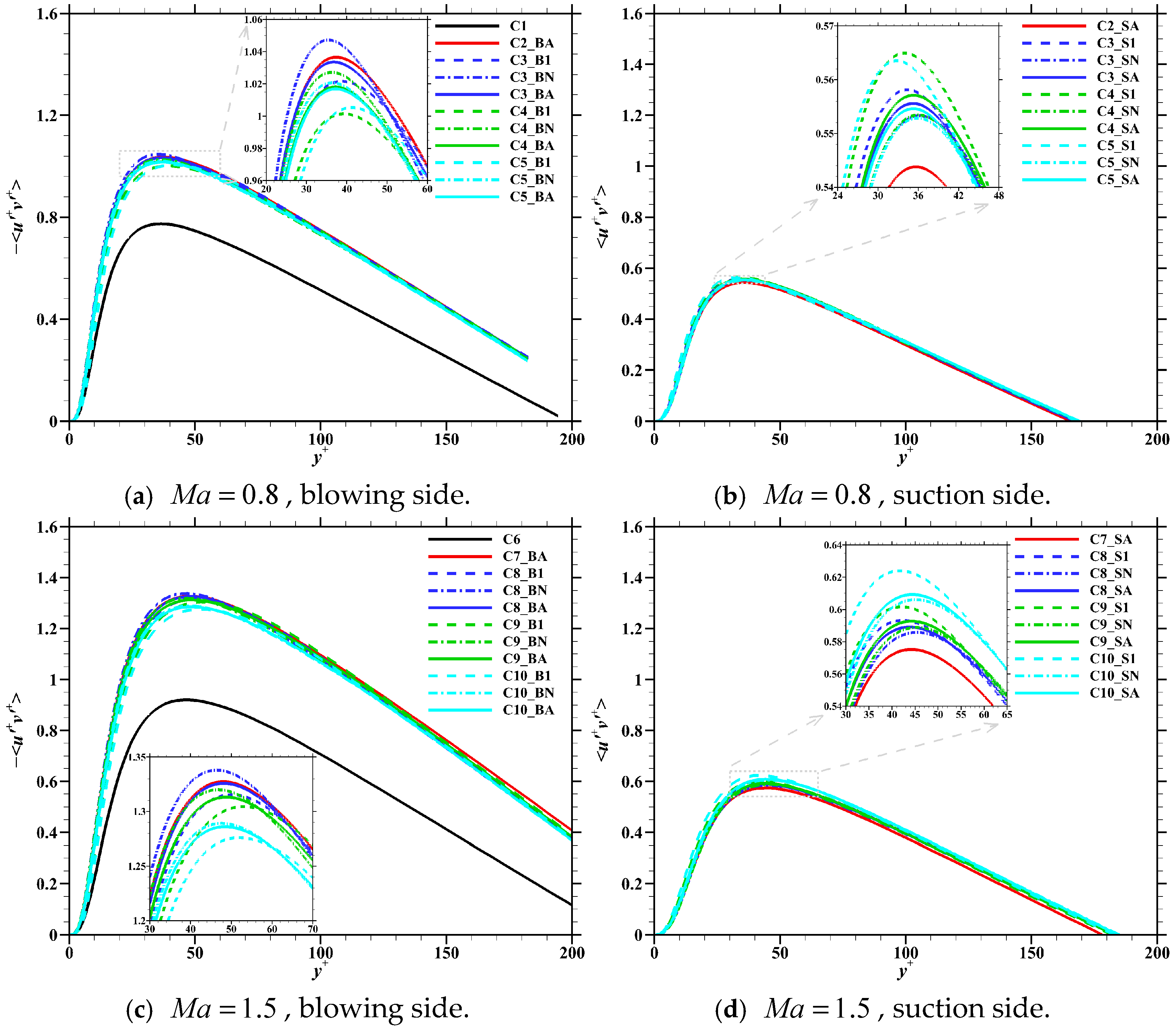

3.5. Reynolds Stress

4. Conclusions

- (1)

- The global drag reduction is strongly related to the wall mass flow rate, instead of the injected energy or blowing/suction intensity. Although the increasing blowing/suction intensity leads to a more significant control effect in the controlled region, the reduced controlled area will weaken the effect on the entire wall. In conclusion, when the Mach number and wall mass flow rate are identical, the velocity gradient within the viscous sublayer remains constant.

- (2)

- At the subsonic speed, the skin friction coefficient increases in the blowing region and decreases in the suction region. The variation in the controlled region rises with the blowing/suction intensity. At the supersonic speed, the curve oscillates in the controlled region. Generally, decreases in the blowing region and increases in the suction region, but this phenomenon becomes pronounced when the blowing/suction intensity reaches 0.5%.

- (3)

- In the controlled region, blowing will result in the peak position of the Reynolds stress shifting upward, whereas suction will cause the peak position to move closer to the wall. Within the controlled region, the variation in the peak position caused by blowing/suction will progressively diminish. When the wall mass flow rate is constant, the spatially averaged peak position of the Reynolds stress on the entire wall remains nearly the same.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ricco, P.; Skote, M.; Leschziner, M.A. A review of turbulent skin-friction drag reduction by near-wall transverse forcing. Prog. Aerosp. Sci. 2021, 123, 100713. [Google Scholar] [CrossRef]

- Kornilov, V. Combined blowing/suction flow control on low-speed airfoils. Flow Turbul. Combust. 2021, 106, 81–108. [Google Scholar] [CrossRef]

- Abbas, A.; De Vicente, J.; Valero, E. Aerodynamic technologies to improve aircraft performance. Aerosp. Sci. Technol. 2013, 28, 100–132. [Google Scholar] [CrossRef]

- Aabid, A.; Khan, S.A.; Baig, M. A critical review of supersonic flow control for high-speed applications. Appl. Sci. 2021, 11, 6899. [Google Scholar] [CrossRef]

- Mele, B. Riblet drag reduction modeling and simulation. Fluids 2022, 7, 249. [Google Scholar] [CrossRef]

- Pakatchian, M.R.; Rocha, J.; Li, L. Advances in riblets design. Appl. Sci. 2023, 13, 10893. [Google Scholar] [CrossRef]

- Kumar, S.; Kulkarni, V. An effective means of drag reduction in high enthalpy flow through unsteady energy deposition. Acta Astronaut. 2021, 186, 533–543. [Google Scholar] [CrossRef]

- Knight, D.; Kianvashrad, N. Review of energy deposition for high-speed flow control. Energies 2022, 15, 9645. [Google Scholar] [CrossRef]

- Kametani, Y.; Fukagata, K. Direct numerical simulation of spatially developing turbulent boundary layers with uniform blowing or suction. J. Fluid Mech. 2011, 681, 154–172. [Google Scholar] [CrossRef]

- Kametani, Y.; Kotake, A.; Fukagata, K.; Tokugawa, N. Drag reduction capability of uniform blowing in supersonic wall-bounded turbulent flows. Phys. Rev. Fluids 2017, 2, 123904. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Fu, S. Drag reduction in turbulent channel flows by a spanwise traveling wave of wall blowing and suction. Phys. Fluids 2021, 33, 095111. [Google Scholar] [CrossRef]

- Yao, J.; Hussain, F. Drag reduction via opposition control in a compressible turbulent channel. Phys. Rev. Fluids 2021, 6, 114602. [Google Scholar] [CrossRef]

- Niu, J.; Wang, J.; Liu, X.; Gong, J.; Dong, L. Micro-suction and micro-blowing on channel flow: Large eddy simulation of velocity normalization, root-mean-square velocity fluctuations, and Reynolds stress. Int. J. Green Energy 2025, 1–18. [Google Scholar] [CrossRef]

- Okochi, Y.; Nabae, Y.; Fukagata, K. Direct numerical simulations of a bump-installed turbulent channel flow for drag reduction by blowing and suction. J. Fluid Mech. 2025, 1010, A69. [Google Scholar] [CrossRef]

- Kornilov, V.I.; Boiko, A.V. Efficiency of air microblowing through microperforated wall for flat plate drag reduction. AIAA J. 2012, 50, 724–732. [Google Scholar] [CrossRef]

- Kornilov, V.I.; Boiko, A.V. Flat-plate drag reduction with streamwise noncontinuous microblowing. AIAA J. 2014, 52, 93–103. [Google Scholar] [CrossRef]

- Kametani, Y.; Fukagata, K.; Örlü, R.; Schlatter, P. Drag reduction in spatially developing turbulent boundary layers by spatially intermittent blowing at constant mass-flux. J. Turbul. 2016, 17, 913–929. [Google Scholar] [CrossRef]

- Xie, L.; Zheng, Y.; Zhang, Y.; Ye, Z.; Zou, J. Effects of localized micro-blowing on a spatially developing flat turbulent boundary layer. Flow Turbul. Combust. 2020, 107, 51–79. [Google Scholar] [CrossRef]

- Zeng, F.; Qiu, Y.; Jiang, Z.; Tong, C.; Hu, C.; Chen, W. Direct numerical simulation of skin friction drag reduction on supersonic turbulent boundary layers with micro-blowing. Phys. Fluids 2024, 36, 095165. [Google Scholar] [CrossRef]

- Lee, S.; Zhang, Y.; Zhao, Y.; Luo, J.; Zheng, Y. Effects of interval blowing on drag reduction incompressible channel turbulent flows. Phys. Fluids 2025, 37, 045136. [Google Scholar] [CrossRef]

- Hirokawa, S.; Ohashi, M.; Eto, K.; Fukagata, K.; Tokugawa, N. Turbulent friction drag reduction on Clark-Y airfoil by passive uniform blowing. AIAA J. 2020, 58, 4178–4180. [Google Scholar] [CrossRef]

- Miura, S.; Ohashi, M.; Fukagata, K.; Tokugawa, N. Drag reduction by uniform blowing on the pressure surface of an airfoil. AIAA J. 2022, 60, 2241–2250. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Lim, D.C.; Kurnia, J.C. Large eddy simulation of near-wall turbulent flow over streamlined riblet-structured surface for drag reduction in a rectangular channel. Therm. Sci. 2020, 24, 2793–2808. [Google Scholar] [CrossRef]

- Sharma, V.; Dutta, S. Experimental and Numerical Investigation of Bio-Inspired Riblet for Drag Reduction. J. Fluids Eng. 2022, 145, 021207. [Google Scholar] [CrossRef]

- Ma, R.; Gao, Z.H.; Lu, L.S.; Chen, S.S. Skin-friction drag reduction by local porous uniform blowing in spatially developing compressible turbulent boundary layers. Phys. Fluids 2022, 34, 125130. [Google Scholar] [CrossRef]

- Kong, W.; Dong, H.; Wu, J.; Yang, L.; Gao, S. Control of frictional and total drag by porous media at high Reynolds number wall turbulence conditions. Phys. Fluids 2025, 37, 035205. [Google Scholar] [CrossRef]

- Li, X.; Fu, D.; Ma, Y.; Liang, X. Direct numerical simulation of compressible turbulent flows. Acta Mech. Sin. 2010, 26, 795–806. [Google Scholar] [CrossRef]

- Li, X.; Ma, Y.; Fu, D. DNS and scaling law analysis of compressible turbulent channel flow. Sci. China Ser. A Math. 2001, 44, 645–654. [Google Scholar] [CrossRef]

- Coleman, G.N.; Kim, J.; Moser, R.D. A numerical study of turbulent supersonic isothermal-wall channel flow. J. Fluid Mech. 1995, 305, 159–183. [Google Scholar] [CrossRef]

- Morinishi, Y.; Tamano, S.; Nakabayashi, K. Direct numerical simulation of compressible turbulent channel flow between adiabatic and isothermal walls. J. Fluid Mech. 2004, 502, 273–308. [Google Scholar] [CrossRef]

| Case | ||||||

|---|---|---|---|---|---|---|

| Ma0.8 | ||||||

| Ma1.5 | ||||||

| Li et al. [28] | ||||||

| Kametani et al. [10] | ||||||

| Coleman et al. [29] | ||||||

| Morinishi et al. [30] |

| Case Number | (×10−2) | (%) | (%) | (%) | (%) | (×104) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| C2 | 0.8 | 0.1% | 1 | 0.99 | 184 | 12.7 | −12.3 | 0.20 | 12.7 | 207.32 |

| C11 | 0.8 | 0.4% | 1/8 | 1.07 | 190 | 6.16 | −6.11 | 0.02 | 6.16 | 12.57 |

| C7 | 1.5 | 0.1% | 1 | 0.85 | 205 | 13.7 | −16.7 | −1.51 | 13.7 | 152.66 |

| C12 | 1.5 | 0.4% | 1/8 | 0.91 | 211 | 7.28 | −8.38 | −0.55 | 7.28 | 10.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Zhou, C.; Zhang, Y.; Zhao, Y.; Luo, J.; Zheng, Y. Drag Reduction in Compressible Channel Turbulence with Periodic Interval Blowing and Suction. Appl. Sci. 2025, 15, 7117. https://doi.org/10.3390/app15137117

Lee S, Zhou C, Zhang Y, Zhao Y, Luo J, Zheng Y. Drag Reduction in Compressible Channel Turbulence with Periodic Interval Blowing and Suction. Applied Sciences. 2025; 15(13):7117. https://doi.org/10.3390/app15137117

Chicago/Turabian StyleLee, Shibo, Chenglin Zhou, Yang Zhang, Yunlong Zhao, Jiaqi Luo, and Yao Zheng. 2025. "Drag Reduction in Compressible Channel Turbulence with Periodic Interval Blowing and Suction" Applied Sciences 15, no. 13: 7117. https://doi.org/10.3390/app15137117

APA StyleLee, S., Zhou, C., Zhang, Y., Zhao, Y., Luo, J., & Zheng, Y. (2025). Drag Reduction in Compressible Channel Turbulence with Periodic Interval Blowing and Suction. Applied Sciences, 15(13), 7117. https://doi.org/10.3390/app15137117