Towards a Digital Twin for Open-Frame Underwater Vehicles Using Evolutionary Algorithms

Abstract

1. Introduction

2. Related Work

3. Methodology Description

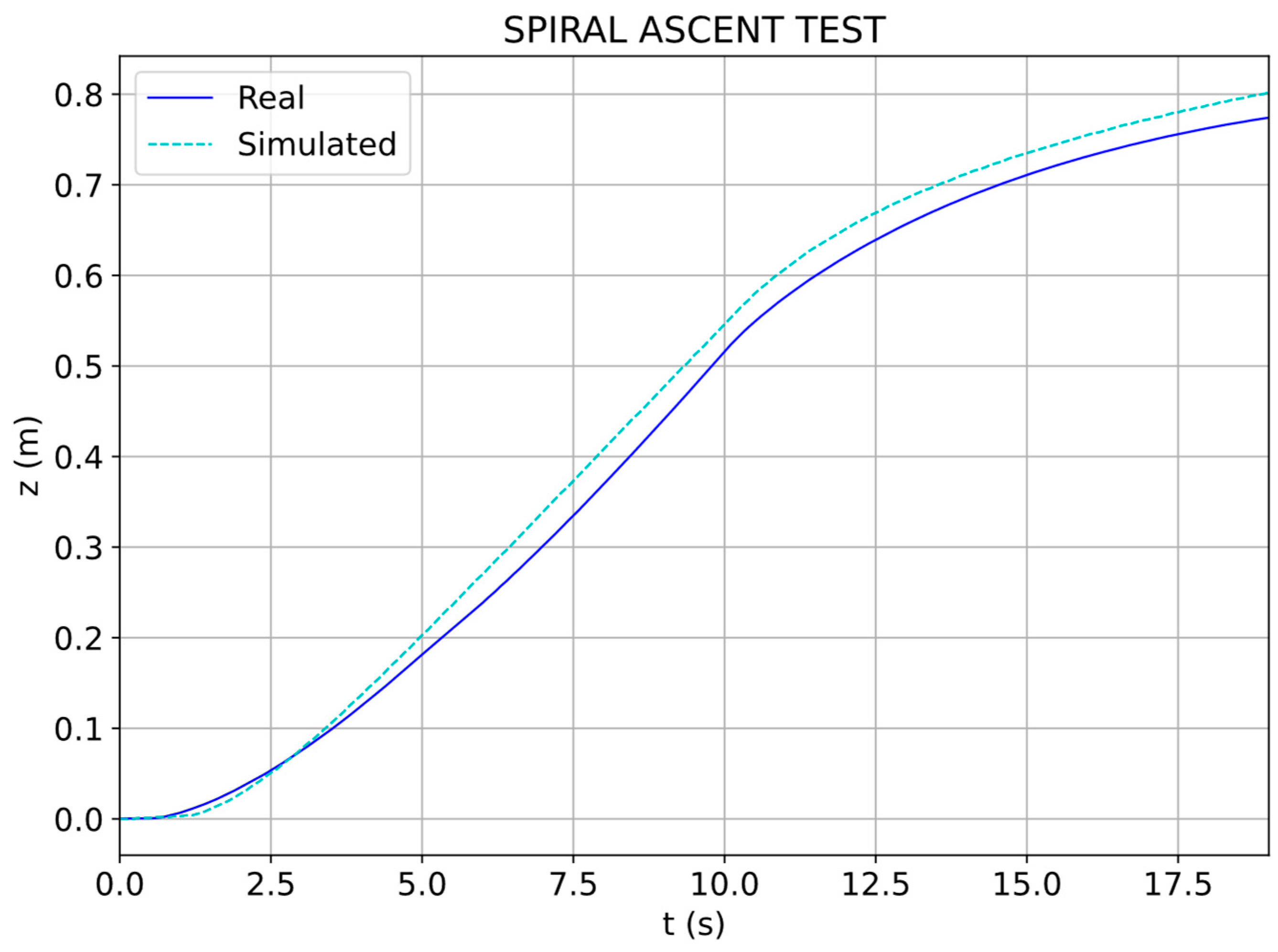

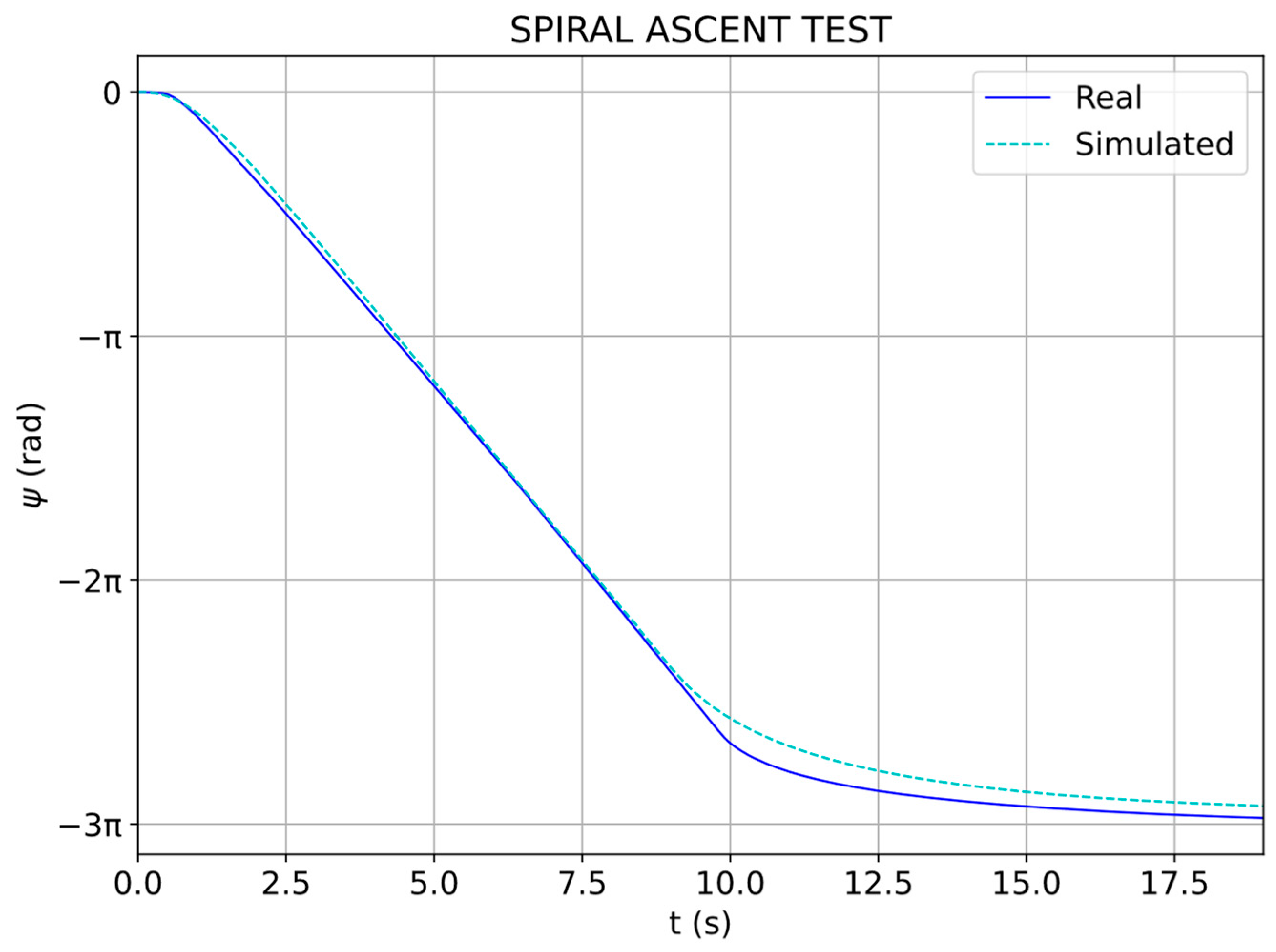

3.1. Digital Twin Setup

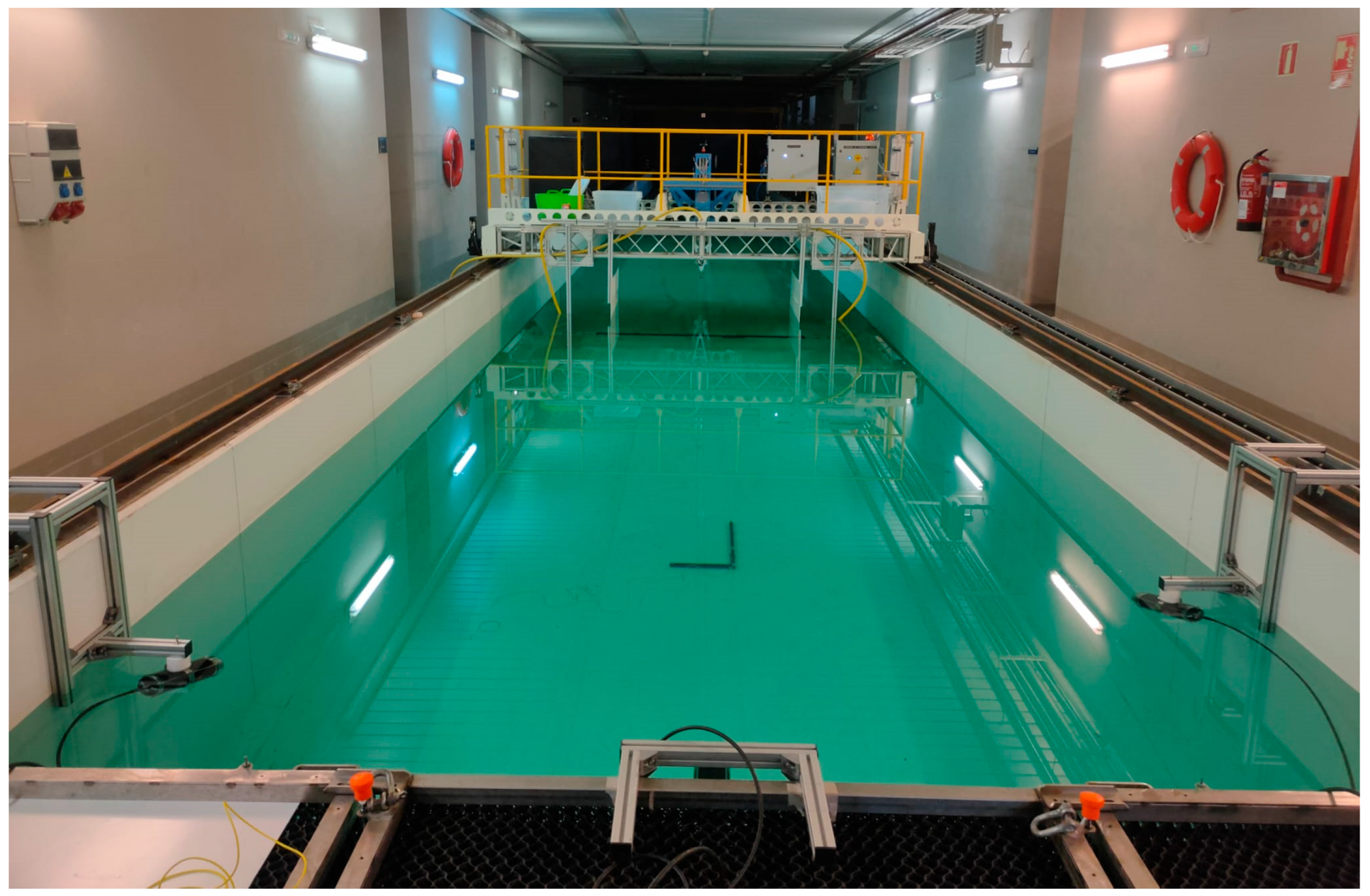

3.2. Real Tests and Measurements

3.3. Hydrodynamic Model

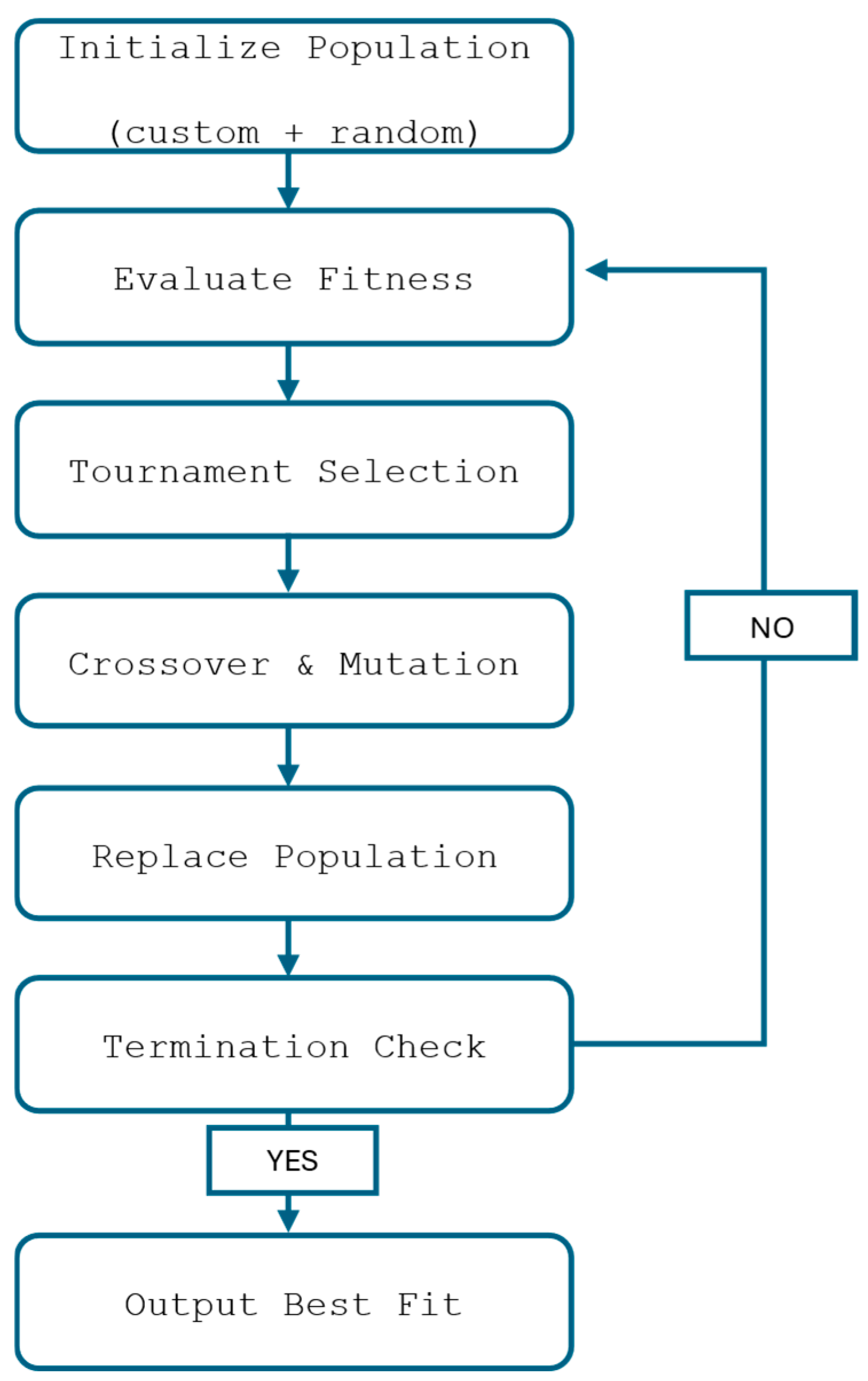

3.4. Optimization Algorithm

3.5. Analysis of the Results

3.6. Model Validation

3.7. Digital Twin Operation

4. BlueROV2 Case

4.1. Digital Twin Setup

- Assumption 1. The vehicle is assumed to be rigid, and 6 degrees of freedom (DOF) are considered.

- Assumption 2. The ROV is assumed symmetric around the front–back, port–starboard, and the top–bottom axes.

- Assumption 3. The body axes coincide with the main axes of inertia.

- Assumption 4. The origin of the b-frame is located at the center of mass of the vehicle.

- Assumption 5. The ocean current is modeled as a constant irrotational flow in the n-frame. Waves are neglected.

- Assumption 6. The movements for each DOF are assumed to be decoupled as they are performed at low speeds (less than 1 m/s).

- as the mass of the vehicle in kg.

- as the vertical distance of the gravity center from the CO.

- , and as the moments of inertia for each axis.

- as the added mass coefficients for each degree of freedom (DOF).

4.2. Real Tests

4.2.1. Propeller Modeling

4.2.2. Position and Orientation Tests

4.3. Hydrodynamic Model

4.4. Genetic Algorithm

- i.

- Initialization

- ii.

- Evaluation

- iii.

- Selection

- iv.

- Crossover

- v.

- Mutation

- vi.

- Replacement

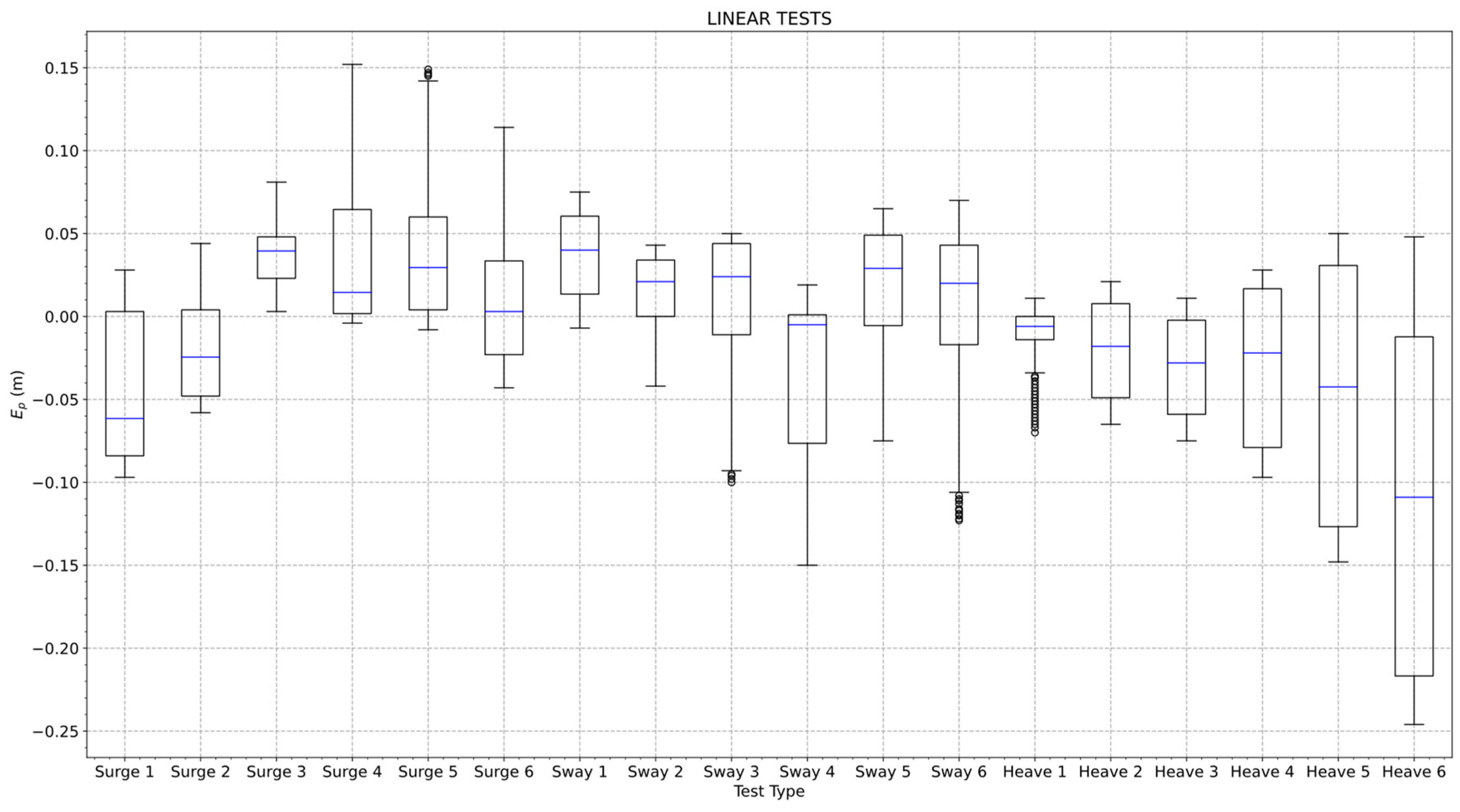

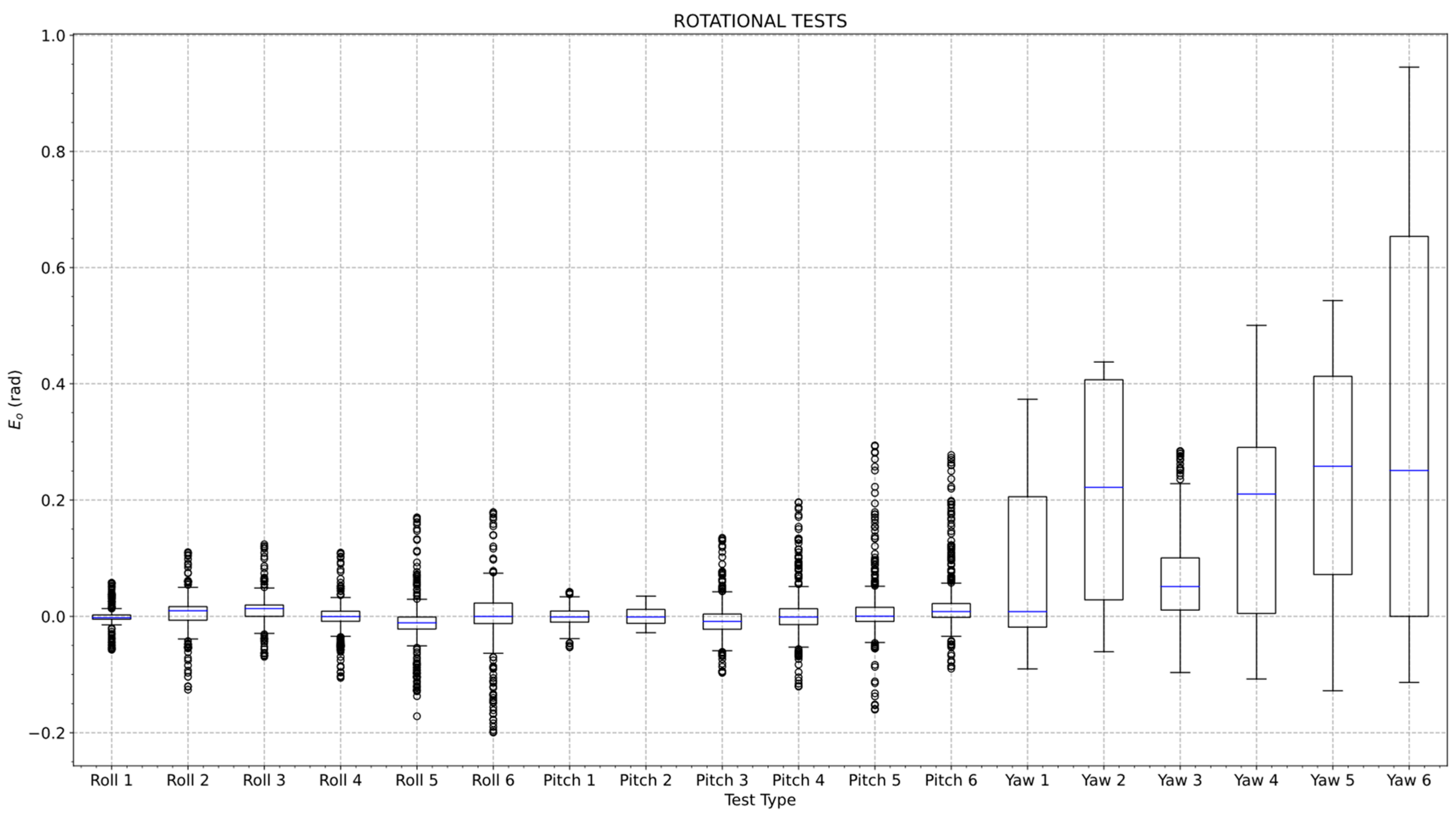

4.5. Analysis of the Results

5. Digital Twin Model Validation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, G.M.; Park, J.Y.; Kim, B.; Baek, H.; Park, S.; Shim, H.; Choi, G.; Kim, B.R.; Kang, H.G.; Jun, B.H.; et al. Development of an autonomous underwater vehicle ISiMI6000 for deep-sea observation. Indian. J. Mar. Sci. 2013, 42, 8. [Google Scholar]

- Rumson, A.G. The application of fully unmanned robotic systems for inspection of subsea pipelines. Ocean Eng. 2021, 235, 109214. [Google Scholar] [CrossRef]

- Albiez, J.; Joyeux, S.; Gaudig, C.; Hilljegerdes, J.; Kroffke, S.; Schoo, C.; Arnold, S.; Mimoso, G.; Alcantara, P.; Saback, R.; et al. FlatFish—A compact subsea-resident inspection AUV. In Proceedings of the OCEANS 2015—MTS/IEEE, Washington, DC, USA, 19–22 October 2015. [Google Scholar] [CrossRef]

- Wright, M.; Gorma, W.; Luo, Y.; Post, M.; Xiao, Q.; Durrant, A. Multi-actuated AUV Body for Windfarm Inspection: Lessons from the Bio-inspired RoboFish Field Trials. In Proceedings of the 2020 IEEE/OES Autonomous Underwater Vehicles Symposium, AUV 2020, St. Johns, NL, Canada, 30 September–2 October 2020. [Google Scholar] [CrossRef]

- Martins, A.; Almeida, J.; Almeida, C.; Matias, B.; Kapusniak, S.; Silva, E. EVA a hybrid ROV/AUV for underwater mining operations support. In Proceedings of the 2018 OCEANS—MTS/IEEE Kobe Techno-Oceans, Kobe, Japan, 28–31 May 2018. [Google Scholar] [CrossRef]

- AMartins, A.; Almeida, J.; Almeida, C.; Pereira, R.; Sytnyk, D.; Soares, E.; Matias, B.; Pereira, T.; Silva, E. MARA—A modular underwater robot for confined spaces exploration. In Proceedings of the 2020 Global Oceans 2020: Singapore—U.S. Gulf Coast, Biloxi, MS, USA, 5–30 October 2020. [Google Scholar] [CrossRef]

- Kutzke, D.T.; Carter, J.B.; Hartman, B.T. Subsystem selection for digital twin development: A case study on an unmanned underwater vehicle. Ocean Eng. 2021, 223, 108629. [Google Scholar] [CrossRef]

- Matsebe, O.; Kumile, C.M.; Tlale, N.S. A Review of Virtual Simulators for Autonomous Underwater Vehicles (AUVs). IFAC Proc. Vol. 2008, 41, 31–37. [Google Scholar] [CrossRef]

- Cho, H.-S.; Sohn, J.-H.; Han, J.-B.; Yeu, T.-K. Development of a Real-Time Track Solver for Digital Twin of the Underwater Tracked Vehicle. Int. J. Precis. Eng. Manuf.-Green Technol. 2025, 12, 1023–1036. [Google Scholar] [CrossRef]

- Ciuccoli, N.; Screpanti, L.; Scaradozzi, D. Underwater Simulators Analysis for Digital Twinning. IEEE Access 2024, 12, 34306–34324. [Google Scholar] [CrossRef]

- Manhães, M.M.M.; Scherer, S.A.; Voss, M.; Douat, L.R.; Rauschenbach, T. UUV Simulator: A Gazebo-based package for underwater intervention and multi-robot simulation. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, OCE 2016, Monterey, CA, USA, 19–23 September 2016. [Google Scholar] [CrossRef]

- Scaradozzi, D.; Gioiello, F.; Ciuccoli, N.; Drap, P. A Digital Twin Infrastructure for NGC of ROV during Inspection. Robotics 2024, 13, 96. [Google Scholar] [CrossRef]

- Adetunji, F.O.; Ellis, N.; Koskinopoulou, M.; Carlucho, I.; Petillot, Y.R. Digital Twins Below the Surface: Enhancing Underwater Teleoperation. In Proceedings of the OCEANS 2024, Singapore, 15–18 April 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Wang, W.; Clark, C.M. Modeling and Simulation of the VideoRay Pro III Underwater Vehicle. In Proceedings of the OCEANS 2006—Asia Pacific, Singapore, 16–19 May 2006; pp. 1–7. [Google Scholar] [CrossRef]

- Valeriano-Medina, Y.; Martínez, A.; Hernández, L.; Sahli, H.; Rodríguez, Y.; Cañizares, J.R. Dynamic model for an autonomous underwater vehicle based on experimental data. Math. Comput. Model. Dyn. Syst. 2013, 19, 175–200. [Google Scholar] [CrossRef]

- Eidsvik, O.A.; Schjølberg, I. Time Domain Modeling of ROV Umbilical using Beam Equations. IFAC-PapersOnLine 2016, 49, 452–457. [Google Scholar] [CrossRef]

- Satria, D.; Wiryadinata, R.; A Esiswitoyo, D.P.; I Adji, M.; Rosyadi, I.; Listijorini, E. Hydrodynamic analysis of Remotely Operated Vehicle (ROV) Observation Class using CFD. IOP Conf. Ser. Mater. Sci. Eng. 2019, 645, 012014. [Google Scholar] [CrossRef]

- Zarei, A.; Ashouri, A.; Hashemi, S.M.J.; Bushehri, S.A.S.F.; Izadpanah, E.; Amini, Y. Experimental and numerical study of hydrodynamic performance of remotely operated vehicle. Ocean Eng. 2020, 212, 107612. [Google Scholar] [CrossRef]

- Li, Q.; Cao, Y.; Li, B.; Ingram, D.M.; Kiprakis, A. Numerical Modelling and Experimental Testing of the Hydrodynamic Characteristics for an Open-Frame Remotely Operated Vehicle. J. Mar. Sci. Eng. 2020, 8, 688. [Google Scholar] [CrossRef]

- Evans, J.; Nahon, M. Dynamics modeling and performance evaluation of an autonomous underwater vehicle. Ocean Eng. 2004, 31, 1835–1858. [Google Scholar] [CrossRef]

- Kim, J.; Chung, W.K. Accurate and practical thruster modeling for underwater vehicles. Ocean Eng. 2006, 33, 566–586. [Google Scholar] [CrossRef]

- Geisbert, J.S. Hydrodynamic Modeling for Autonomous Underwater Vehicles Using Computational and Semi-Empirical Methods. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2007. [Google Scholar]

- Avila, J.P.J.; Adamowski, J.C. Experimental evaluation of the hydrodynamic coefficients of a ROV through Morison’s equation. Ocean Eng. 2011, 38, 2162–2170. [Google Scholar] [CrossRef]

- Gabl, R.; Davey, T.; Cao, Y.; Li, Q.; Li, B.; Walker, K.L.; Giorgio-Serchi, F.; Aracri, S.; Kiprakis, A.; Stokes, A.A.; et al. Hydrodynamic loads on a restrained ROV under waves and current. Ocean Eng. 2021, 234, 109279. [Google Scholar] [CrossRef]

- Fossen, T.I.; Fjellstad, O.-E. Nonlinear modelling of marine vehicles in 6 degrees of freedom. Math. Model. Syst. 1995, 1, 17–27. [Google Scholar] [CrossRef]

- Lau, W.; Low, E.; Seet, G.; Chin, C. Estimation of the hydrodynamic coefficients of an ROV using free decay pendulum motion. Eng. Lett. 2008, 16, 326–331. [Google Scholar]

- Avila, J.J.; Nishimoto, K.; Sampaio, C.M.; Adamowski, J.C. Experimental investigation of the hydrodynamic coefficients of a remotely operated vehicle using a planar motion mechanism. J. Offshore Mech. Arct. Eng. 2011, 134, 021601. [Google Scholar] [CrossRef]

- Avila, J.P.J.; Donha, D.C.; Adamowski, J.C. Experimental model identification of open-frame underwater vehicles. Ocean Eng. 2013, 60, 81–94. [Google Scholar] [CrossRef]

- Xie, S.; Li, Q.; Wu, P.; Luo, J.; Li, F.; Gu, J. Hydrodynamic coefficients identification and experimental investigation for an underwater vehicle. Sens. Transducers 2014, 164, 81–94. [Google Scholar]

- Eidsvik, O.A. Identification of Hydrodynamic Parameters for Remotely Operated Vehicles. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2015. [Google Scholar]

- Eidsvik, O.A.; Schjølberg, I. Determination of hydrodynamic parameters for remotely operated vehicles. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, Y.; Chae, J.; Choi, H.T.; Yeu, T.K. Preliminary Experiments to Determine Hydrodynamic Coefficients of Remotely Operated Vehicle. In Proceedings of the OCEANS 2019—Marseille, Marseille, France, 17–20 June 2019. [Google Scholar] [CrossRef]

- Hammoud, A.; Sahili, J.; Madi, M.; Maalouf, E. Design and dynamic modeling of ROVs: Estimating the damping and added mass parameters. Ocean Eng. 2021, 239, 109818. [Google Scholar] [CrossRef]

- Rojas, J.; Eichhorn, M.; Baatar, G.; Matz, S.; Glotzbach, T. Parameter Identification and Optimization of an Oceanographic Monitoring Remotely Operated Vehicle. In Proceedings of the 2018 OCEANS—MTS/IEEE Kobe Techno-Oceans, Kobe, Japan, 28–31 May 2018. [Google Scholar] [CrossRef]

- Soliman, M.A. Estimation of the ROV hydrodynamic coefficients using CFD. Int. Undergrad. Res. Conf. 2022, 6, 1–8. [Google Scholar]

- Panda, J.P.; Mitra, A.; Warrior, H.V. A review on the hydrodynamic characteristics of autonomous underwater vehicles. J. Eng. Marit. Environ. 2020, 235, 15–29. [Google Scholar] [CrossRef]

- Lack, S.; Rentzow, E.; Jeinsch, T. Experimental Parameter Identification for an open-frame ROV: Comparison of towing tank tests and open water self-propelled tests. IFAC-Pap. 2019, 52, 271–276. [Google Scholar] [CrossRef]

- Busse, C.; Reich, J.E.; Renner, B.C. In Situ Damping Parameter Estimation for an Underwater Vehicle Using Onboard Sensors. In Proceedings of the 2022 IEEE/OES Autonomous Underwater Vehicles Symposium, Singapore, 19–21 September 2022. [Google Scholar] [CrossRef]

- von Benzon, M.; Sørensen, F.F.; Uth, E.; Jouffroy, J.; Liniger, J.; Pedersen, S. An Open-Source Benchmark Simulator: Control of a BlueROV2 Underwater Robot. J. Mar. Sci. Eng. 2022, 10, 1898. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic and Evolutionary Algorithms Come of Age. Commun. ACM 1994, 37, 113–119. [Google Scholar] [CrossRef]

- Rodriguez-Cortegoso, J.; Romero, A.; Orjales, F.; Deibe, A.; Diaz-Casas, V. Improving the Hydrodynamic Characterization of Autonomous Underwater Vehicles Through Deep Learning. In Proceedings of the The 33rd International Ocean and Polar Engineering Conference, Ottawa, ON, Canada, 19–23 June 2023; pp. 1764–1769. [Google Scholar]

- Koenig, N.; Howard, A. Design and use paradigms for Gazebo, an Open-Source Multi-Robot Simulator. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Sendai, Japan, 28 September–2 October 2004. [Google Scholar] [CrossRef]

- Fossen, T.I. Handbook of Marine Craft Hydrodynamics and Motion Control; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Hydromechanics Subcommittee of the Technical and Research Committee of the Society of Naval Architects and Marine Engineers. SNAME, Nomenclature for Treating the Motion of a Submerged Body Through a Fluid; The Society of Naval Architects and Marine Engineers: New York, NY, USA, 1950; pp. 1–5. [Google Scholar]

- Antonelli, G. Underwater Robots; Springer International Publishing: Cham, Switzerland, 2014; Volume 96. [Google Scholar] [CrossRef]

- Lam, J.; Chen, A.; Bennett, A.; Triantafyllou, M. Propeller Characterization Testing of a Blue Robotics T200 Thruster. In Proceedings of the OCEANS 2023—Limerick, Limerick, Ireland, 5–8 June 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Fortin, F.A.; De Rainville, F.M.; Gardner, M.A.; Parizeau, M.; Gagńe, C. DEAP: Evolutionary algorithms made easy. J. Mach. Learn. Res. 2012, 13, 2171–2175. [Google Scholar]

| Position and Angles | Linear and Angular Velocities | Forces and Moments | |

|---|---|---|---|

| Movements | NED-frame | B-frame | B-frame |

| Surge | x | u | X |

| Sway | y | v | Y |

| Heave | z | w | Z |

| Roll | φ | p | K |

| Pitch | θ | q | M |

| Yaw | ψ | r | N |

| Parameters | Value | Units |

|---|---|---|

| 13.17 | kg | |

| 132.537 | N | |

| ) | (0.0, 0.0, 0.0) | m |

| (0.0, 0.0, −0.024) | m | |

| 0.344 | Kg·m2 | |

| 0.316 | Kg·m2 | |

| 0.389 | Kg·m2 | |

| 13.272 | Kg | |

| 13.123 | Kg | |

| 14.508 | Kg | |

| 0.207 | Kg·m2 | |

| 0.211 | Kg·m2 | |

| 0.109 | Kg·m2 | |

| −0.161 | Kg/s | |

| −0.17 | Kg/s | |

| −0.254 | Kg/s | |

| −0.349 | Kg·m2/s | |

| −0.221 | Kg·m2/s | |

| −0.141 | Kg·m2/s | |

| −33.346 | Kg/m | |

| −45.731 | Kg/m | |

| −72.668 | Kg/m | |

| −0.356 | Kg·m2 | |

| −0.461 | Kg·m2 | |

| −0.471 | Kg·m2 |

| Type of Movement | Inertia | Added Mass | Linear Damping | Quadratic Damping | |

|---|---|---|---|---|---|

| Linear Movements | Surge | - | Xu | Xu|u| | |

| Sway | - | Yv | Yv|v| | ||

| Heave | - | Zw | Zw|w| | ||

| Rotational Movements | Roll | Ixx | Kp | Kp|p| | |

| Pitch | Iyy | Mq | Mq|q| | ||

| Yaw | Izz | Nr | Nr|r| | ||

| Stage | Description | Parameter Values |

|---|---|---|

| Initialization | Custom initialization for the first generation; standard initialization for subsequent generations | Specific parameter values; random parameter values within predefined ranges Population size: 60 |

| Fitness Function | Sum of absolute differences between ground truth and simulated data | - |

| Selection | Tournament selection strategy | Tournament size: 5 |

| Crossover | Two-point crossover strategy | Cross rate: 0.5 |

| Mutation | Gaussian mutation operator | Mutation rate: 0.25 |

| Termination | Maximum number of generations | Generations: 30 |

| Parameter | Initial Value | Optimized Value | Difference (%) |

|---|---|---|---|

| 0.344 | 0.371 | 7.85 | |

| 0.316 | 0.352 | 11.39 | |

| 0.389 | 0.426 | 9.51 | |

| 13.272 | 15.638 | 17.83 | |

| 13.123 | 16.477 | 25.56 | |

| 14.508 | 16.751 | 15.46 | |

| 0.207 | 0.157 | −24.15 | |

| 0.211 | 0.165 | −21.8 | |

| 0.109 | 0.133 | 22.02 | |

| −0.161 | −0.153 | −4.97 | |

| −0.17 | −0.176 | 3.53 | |

| −0.254 | −0.242 | −4.72 | |

| −0.349 | −0.377 | 8.02 | |

| −0.221 | −0.201 | −9.05 | |

| −0.141 | −0.127 | −9.93 | |

| −33.346 | −34.972 | 4.88 | |

| −45.731 | −43.118 | −5.71 | |

| −72.668 | −70.209 | −3.38 | |

| −0.356 | −0.389 | 9.27 | |

| −0.461 | −0.427 | −7.38 | |

| −0.471 | −0.425 | −9.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orjales, F.; Rodríguez-Cortegoso, J.; Fernández-Pérez, E.; Romero, A.; Diaz-Casas, V. Towards a Digital Twin for Open-Frame Underwater Vehicles Using Evolutionary Algorithms. Appl. Sci. 2025, 15, 7085. https://doi.org/10.3390/app15137085

Orjales F, Rodríguez-Cortegoso J, Fernández-Pérez E, Romero A, Diaz-Casas V. Towards a Digital Twin for Open-Frame Underwater Vehicles Using Evolutionary Algorithms. Applied Sciences. 2025; 15(13):7085. https://doi.org/10.3390/app15137085

Chicago/Turabian StyleOrjales, Félix, Julián Rodríguez-Cortegoso, Enrique Fernández-Pérez, Alejandro Romero, and Vicente Diaz-Casas. 2025. "Towards a Digital Twin for Open-Frame Underwater Vehicles Using Evolutionary Algorithms" Applied Sciences 15, no. 13: 7085. https://doi.org/10.3390/app15137085

APA StyleOrjales, F., Rodríguez-Cortegoso, J., Fernández-Pérez, E., Romero, A., & Diaz-Casas, V. (2025). Towards a Digital Twin for Open-Frame Underwater Vehicles Using Evolutionary Algorithms. Applied Sciences, 15(13), 7085. https://doi.org/10.3390/app15137085