Radiation Hardness of Oxide Thin Films Prepared by Magnetron Sputtering Deposition

Abstract

1. Introduction

2. Experiment Details

3. Experiment Results and Discussion

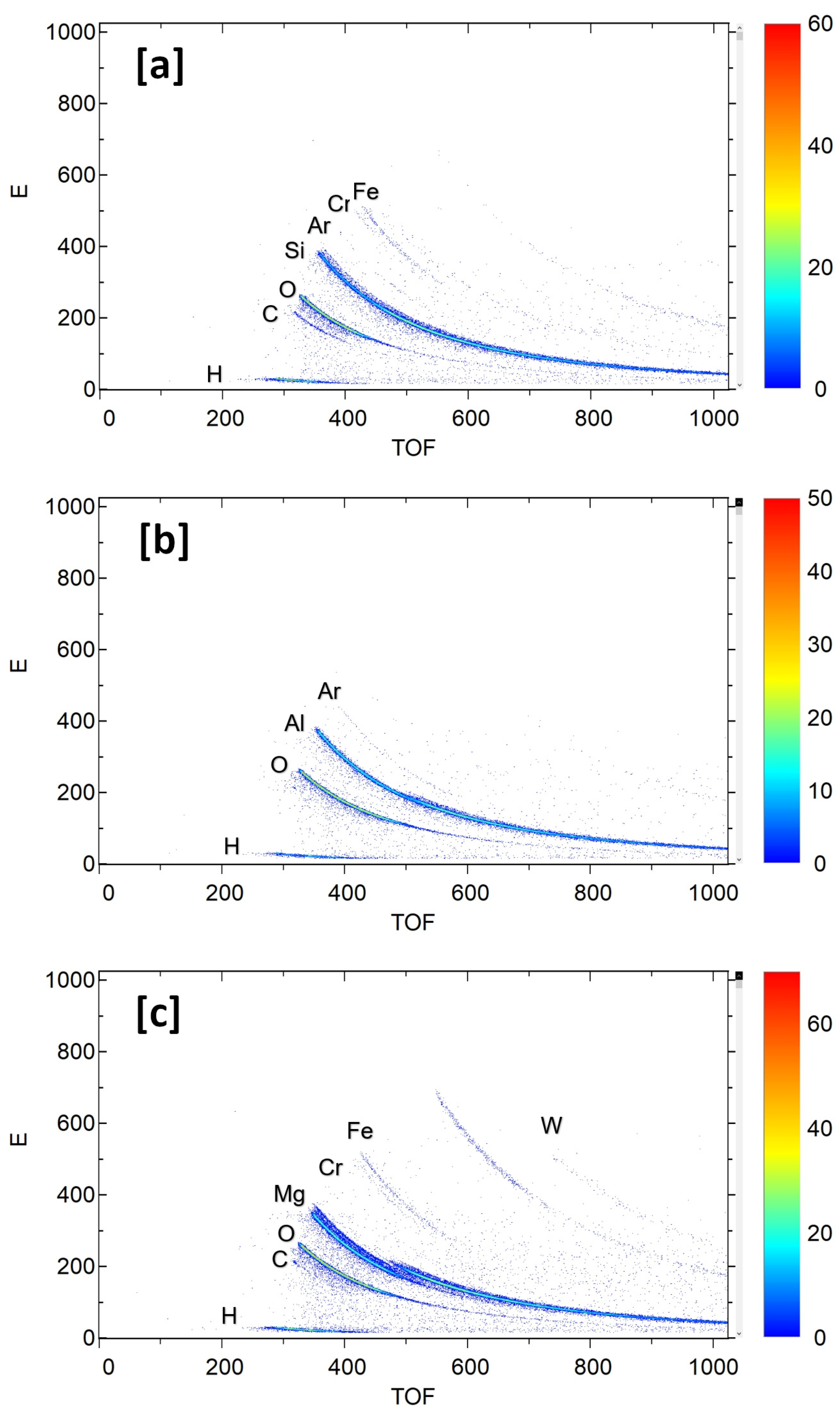

3.1. Elastic Recoil Detection Analysis of Magnetron-Sputtering-Deposited Oxides

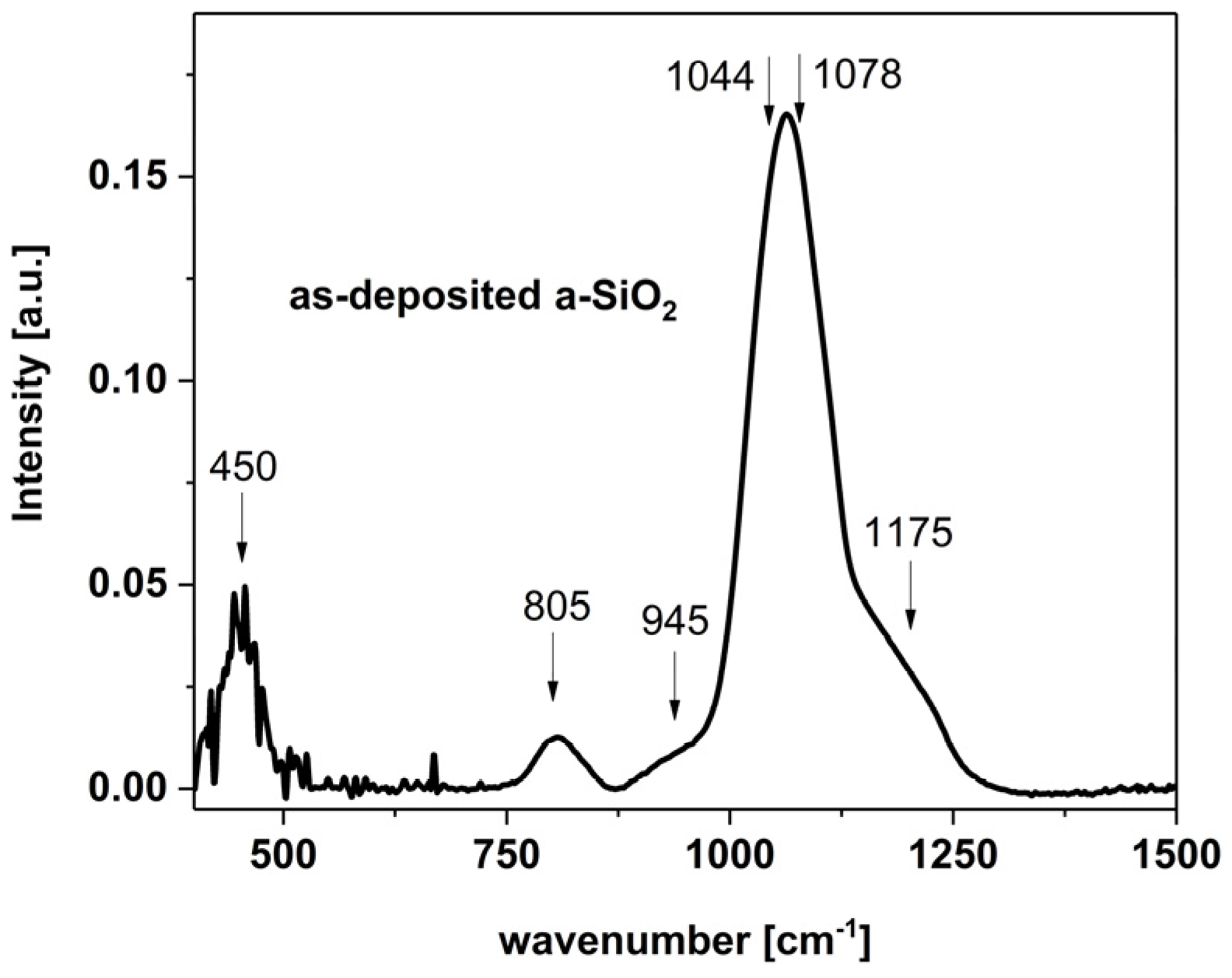

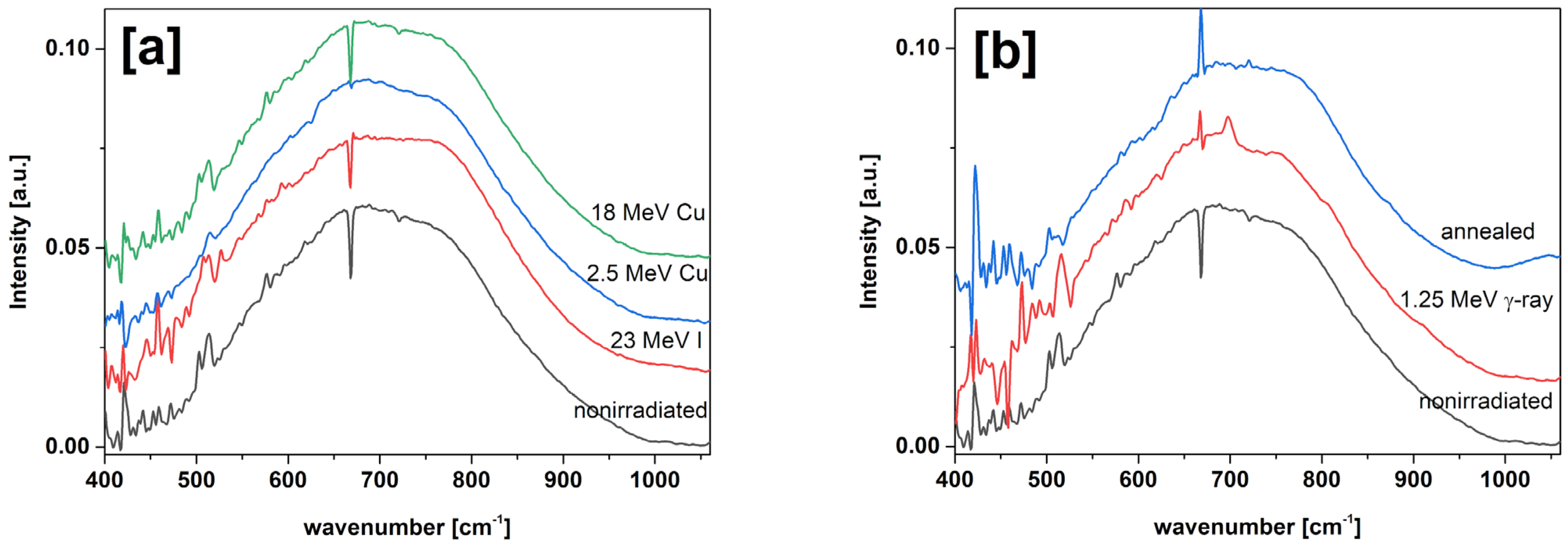

3.2. Comparing Thermally Grown a-SiO2 with Magnetron-Sputtering-Deposited a-SiO2

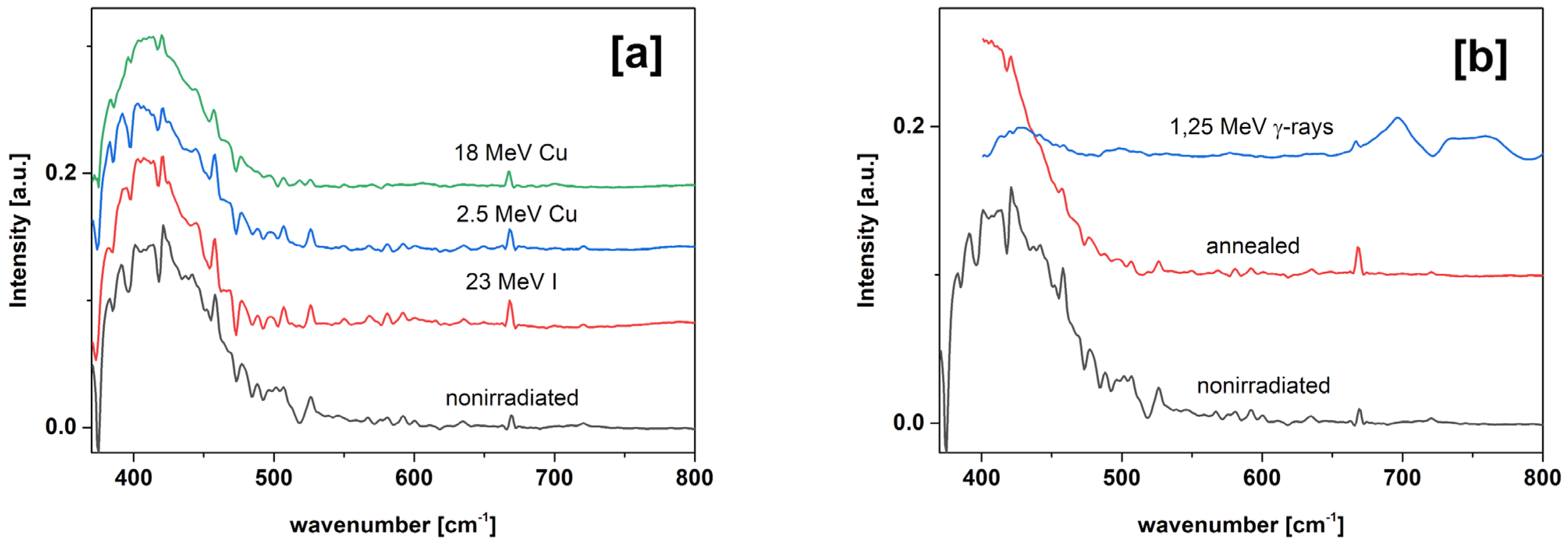

3.3. Radiation Hardness of Magnetron-Sputtering-Deposited a-Al2O3 and a-MgO

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Toulemonde, M.; Assmann, W.; Dufour, C.; Meftah, A.; Trautmann, C. Nanometric transformation of the matter by short and intense electronic excitation: Experimental data versus inelastic thermal spike model. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2012, 277, 28. [Google Scholar] [CrossRef]

- Agulló-López, F.; Climent-Font, A.; Muñoz-Martín, Á.; Olivares, J.; Zucchiatti, A. Ion beam modification of dielectric materials in the electronic excitation regime: Cumulative and exciton models. Prog. Mater. Sci. 2016, 76, 1. [Google Scholar] [CrossRef]

- Klaumünzer, S. Ion Tracks in quartz and vitreous silica. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2004, 225, 136. [Google Scholar] [CrossRef]

- Aumayr, F.; Facsko, S.; El-Said, A.S.; Trautmann, C.; Schleberger, M. Single ion induced surface nanostructures: A comparison between slow highly charged and swift heavy ions. J. Phys. Condens. Matter. 2011, 23, 393001. [Google Scholar] [CrossRef]

- Weber, W.J.; Ewing, R.C.; Catlow, C.R.A.; de la Rubia, T.D.; Hobbs, L.W.; Kinoshita, C.; Matzke, H.J.; Motta, A.T.; Nastasi, M.; Salje, E.K.H.; et al. Radiation effects in crystalline ceramics for the immobilization of high-level nuclear waste and plutonium. J. Mater. Res. 1998, 13, 1434. [Google Scholar] [CrossRef]

- Mir, A.H.; Peuget, S. Using external ion irradiations for simulating self-irradiation damage in nuclear waste glasses. State of the art, recommendations and prospects. J. Nucl. Mater. 2020, 539, 152246. [Google Scholar] [CrossRef]

- Akcöltekin, S.; Akcöltekin, E.; Roll, T.; Lebius, H.; Schleberger, M. Patterning of insulating surfaces by electronic excitation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2009, 267, 1386. [Google Scholar] [CrossRef]

- Meftah, A.; Brisard, F.; Constantini, J.M.; Dooryhee, E.; Hage-Ali, M.; Hervieu, M.; Stoquert, J.P.; Studer, F.; Toulemonde, M. Track formation in SiO2 quartz and the thermal-spike mechanism. Phys. Rev. B 1994, 49, 12457. [Google Scholar] [CrossRef]

- Toulemonde, M.; Ramos, S.M.M.; Bernas, H.; Clerc, C.; Canut, B.; Chaumont, J.; Trautmann, C. MeV gold irradiation induced damage in a quartz: Competition between nuclear and electronic stopping. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2001, 178, 331. [Google Scholar] [CrossRef]

- Peña-Rodríguez, O.; Manzano-Santamaría, J.; Rivera, A.; García, G.; Olivares, J.; Agulló-López, F. Kinetics of amorphization induced by swift heavy ions in alpha-quartz. J. Nucl. Mater. 2012, 430, 125. [Google Scholar] [CrossRef]

- Luketić, K.T.; Hanžek, J.; Mihalcea, C.G.; Dubček, P.; Gajović, A.; Siketić, Z.; Jakšić, M.; Ghica, C.; Karlušić, M. Charge State Effects in Swift-Heavy-Ion-Irradiated Nanomaterials. Crystals 2022, 12, 865. [Google Scholar] [CrossRef]

- Karlušić, M.; Rymzhanov, R.A.; O’Connell, J.H.; Bröckers, L.; Luketić, K.T.; Siketić, Z.; Fazinić, S.; Dubček, P.; Jakšić, M.; Provatas, G.; et al. Mechanisms of surface nanostructuring of Al2O3 and MgO by grazing incidence irradiation with swift heavy ions. Surf. Interf. 2021, 27, 101508. [Google Scholar] [CrossRef]

- Hanžek, J.; Dubček, P.; Fazinić, S.; Luketić, K.T.; Karlušić, M. High-Energy Heavy Ion Irradiation of Al2O3, MgO and CaF2. Materials 2022, 15, 2110. [Google Scholar] [CrossRef] [PubMed]

- Toulemonde, M.; Dufour, C.; Paumier, E. Transient thermal process after a high-energy heavy-ion irradiation of amorphous metals and semiconductors. Phys. Rev. B 1992, 46, 14362. [Google Scholar] [CrossRef]

- Awazu, K.; Ishii, S.; Shima, K.; Roorda, S.; Brebner, J.L. Structure of latent tracks created by swift heavy-ion bombardment of amorphous SiO2. Phys. Rev. 2000, 62, 3689. [Google Scholar] [CrossRef]

- Kluth, P.; Schnohr, C.S.; Pakarinen, O.H.; Djurabekova, F.; Sprouster, D.J.; Giulian, R.; Ridgway, M.C.; Byrne, A.P.; Trautmann, C.; Cookson, D.J.; et al. Fine Structure in Swift Heavy Ion Tracks in Amorphous SiO2. Phys. Rev. Lett. 2008, 101, 175503. [Google Scholar] [CrossRef]

- Toulemonde, M.; Weber, W.J.; Li, G.; Shutthanandan, V.; Kluth, P.; Yang, T.; Wang, Y.; Zhang, Y. Synergy of nuclear and electronic energy losses in ion-irradiation processes: The case of vitreous silicon dioxide. Phys. Rev. B 2011, 83, 054106. [Google Scholar] [CrossRef]

- Kluth, P.; Pakarinen, O.H.; Djurabekova, F.; Giulian, R.; Ridgway, M.C.; Byrne, A.P.; Nordlund, K. Nanoscale density fluctuations in swift heavy ion irradiated amorphous SiO2. J. Appl. Phys. 2011, 110, 123520. [Google Scholar] [CrossRef]

- Rotaru, C.; Pawlak, F.; Khalfaoui, N.; Dufour, C.; Perrière, J.; Laurent, A.; Stoquert, J.P.; Lebius, H.; Toulemonde, M. Track formation in two amorphous insulators, vitreous silica and diamond like carbon: Experimental observations and description by the inelastic thermal spike model. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2012, 272, 9. [Google Scholar] [CrossRef]

- Benyagoub, A.; Toulemonde, M. Ion tracks in amorphous silica. J. Mater. Res. 2015, 30, 1529. [Google Scholar] [CrossRef]

- Karlušić, M.; Škrabić, M.; Majer, M.; Buljan, M.; Skuratov, V.A.; Jung, H.K.; Gamulin, O.; Jakšić, M. Infrared spectroscopy of ion tracks in amorphous SiO2 and comparison to gamma irradiation induced changes. J. Nucl. Mater. 2019, 514, 74. [Google Scholar] [CrossRef]

- Buljan, M.; Karlušić, M.; Bogdanović-Radović, I.; Jakšić, M.; Salamon, K.; Bernstorff, S.; Radić, N. Determination of ion track radii in amorphous matrices via formation of nano-clusters by ion-beam irradiation. Appl. Phys. Lett. 2012, 101, 103112. [Google Scholar] [CrossRef]

- Carvalho, A.M.J.F.; Marinoni, M.; Touboul, A.D.; Guasch, C.; Lebius, H.; Ramonda, M.; Bonnet, J.; Saigne, F. Discontinuous ion tracks on silicon oxide on silicon surfaces after grazing-angle heavy ion irradiation. Appl. Phys. Lett. 2007, 90, 073116. [Google Scholar] [CrossRef]

- Carvalho, A.M.J.F.; Touboul, A.D.; Marinoni, M.; Ramonda, M.; Guasch, C.; Saigne, F.; Bonnet, J.; Gasiot, J. Oxide thickness dependence of swift heavy ion-induced surface tracks formation in silicon dioxide on silicon structures at grazing incidence. J. Appl. Phys. 2007, 102, 124306. [Google Scholar] [CrossRef]

- Carvalho, A.M.J.F.; Touboul, A.D.; Marinoni, M.; Carlotti, J.-F.; Guasch, C.; Ramonda, M.; Lebius, H.; Saigne, F.; Bonnet, J. SiO2–Si under swift heavy ion irradiation: A comparison between normal and grazing incidence features. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2008, 266, 2981. [Google Scholar] [CrossRef]

- Karlušić, M.; Mičetić, M.; Kresić, M.; Jakšić, M.; Šantić, B.; Bogdanović-Radović, I.; Bernstorff, S.; Lebius, H.; Ban-d’Etat, B.; Rožman, K.Ž.; et al. Nanopatterning surfaces by grazing incidence swift heavy ion irradiation. Appl. Surf. Sci. 2021, 541, 148467. [Google Scholar] [CrossRef]

- Arstila, K.; Julin, J.; Laitinen, M.I.; Aalto, J.; Konu, T.; Kärkkäinen, S.; Rahkonen, S.; Raunio, M.; Itkonen, J.; Santanen, J.P.; et al. Potku—New analysis software for heavy ion elastic recoil detection analysis. Nucl. Instr. Meth. Phys. Res. Sect. B Beam Interact. Mater. At. 2014, 331, 34. [Google Scholar] [CrossRef]

- Siketić, Z.; Bogdanović-Radović, I.; Jakšić, M. Development of a time-of-flight spectrometer at the Ruđer Bošković Institute in Zagreb. Nucl. Instr. Meth. Phys. Res. B Beam Interact. Mater. At. 2008, 266, 1328. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—the stopping and range of ions in the matter (2010). Nucl. Instr. Meth. Phys. Res. B Beam Interact. Mater. At. 2010, 268, 1818. [Google Scholar] [CrossRef]

- Majer, M.; Pasariček, L.; Knežević, Ž. Dose mapping of the 60Co gamma irradiation facility and a real irradiated product—Measurements and Monte Carlo simulation. Radiat. Phys. Chem. 2024, 214, 111280. [Google Scholar] [CrossRef]

- Ishikawa, N.; Fujimura, Y.; Kondo, K.; Szabo, G.L.; Wilhelm, R.A.; Ogawa, H.; Taguchi, T. Surface nanostructures on Nb-doped SrTiO3 irradiated with swift heavy ions at grazing incidence. Nanotechnology 2022, 33, 235303. [Google Scholar] [CrossRef] [PubMed]

- Pai, P.G.; Chao, S.S.; Takagi, Y.; Lucovsky, G. Infrared spectroscopic study of SiOx films produced by plasma enhanced chemical vapor deposition. J. Vac. Sci. Techn. A 1986, 4, 689. [Google Scholar] [CrossRef]

- Herth, E.; Zeggari, R.; Rauch, J.-Y.; Remy-Martin, F.; Boireau, W. Investigation of amorphous SiOx layer on gold surface for Surface Plasmon Resonance measurements. Microel. Eng. 2016, 163, 43. [Google Scholar] [CrossRef]

- Sanaeishoar, H.; Sabbaghan, M.; Mohave, F. Synthesis and characterization of micro-mesoporous MCM-41 using various ionic liquids as co-templates. Micropor. Mesopor. Mater. 2015, 217, 219. [Google Scholar] [CrossRef]

- Ellerbrock, R.; Stein, M.; Schaller, J. Comparing amorphous silica, short-range-ordered silicates and silicic acid species by FTIR. Sci. Rep. 2022, 12, 11708. [Google Scholar] [CrossRef] [PubMed]

- Innocenzi, P. Infrared spectroscopy of sol–gel derived silica-based films: A spectra-microstructure overview. J. Non Cryst. Solids 2003, 316, 309. [Google Scholar] [CrossRef]

- Giacomazzi, L.; Shcheblanov, N.S.; Povarnitsyn, M.E.; Li, Y.; Mavrič, A.; Zupančić, B.; Grdadolnik, J.; Pasquarello, A. Infrared spectra in amorphous alumina: A combined ab initio and experimental study. Phys. Rev. Mater. 2023, 7, 045604. [Google Scholar] [CrossRef]

- Rutkowska, I.; Marchewka, J.; Jeleń, P.; Odziomek, M.; Korpyś, M.; Paczkowska, J.; Sitarz, M. Chemical and Structural Characterization of Amorphous and Crystalline Alumina Obtained by Alternative Sol–Gel Preparation Routes. Materials 2021, 14, 1761. [Google Scholar] [CrossRef]

- Colomban, P. Structure of oxide gels and glasses by infrared and Rarnan scattering. J. Mater. Sci. 1989, 24, 3002. [Google Scholar] [CrossRef]

- Dasgupta, A.; Chowdhuri, A.R.; Takoudis, C.G. Metalorganic chemical vapor deposition of aluminum oxide on silicon nitride. Mat. Res. Soc. Symp. Proc. 2003, 751, Z3–Z45. [Google Scholar] [CrossRef]

- Aruga, T.; Katano, Y.; Ohmichi, T.; Okayasu, S.; Kazumata, Y. Amorphization behaviors in polycrystalline alumina irradiated with energetic iodine ions. Nucl. Instr. Meth. Phys. Res. B Beam Interact. Mater. At. 2000, 166, 913. [Google Scholar] [CrossRef]

- Szenes, G. Ion-induced amorphization in ceramic materials. J. Nucl. Mater. 2005, 336, 81. [Google Scholar] [CrossRef]

- Mohandes, F.; Davar, F.; Salavati-Niasari, M. Magnesium oxide nanocrystals via thermal decomposition of magnesium oxalate. J. Phys. Chem. Solids 2010, 71, 1623. [Google Scholar] [CrossRef]

- Thoms, H.; Epple, M.; Reller, A. The thermal decomposition of magnesium alcoholates to magnesia (MgO): Studies by IR and thermal analysis. Solid State Ion. 1997, 101, 79–84. [Google Scholar] [CrossRef]

- Arnoldbik, W.M.; Tomozeiu, N.; van Hattum, E.D.; Lof, R.W.; Vredenberg, A.M.; Habraken, F.H.P.M. High-energy ion-beam-induced phase separation in SiOx films. Phys. Rev. B 2005, 71, 125329. [Google Scholar] [CrossRef]

- Wong, M.-S.; Lin, Y.-J.; Pylnev, M.; Kang, W.-Z. Processing, structure and properties of reactively sputtered films of titanium dioxide and suboxides. Thin Solid Film. 2019, 688, 137351. [Google Scholar] [CrossRef]

- Politano, G.G. Optical Properties of Graphene Nanoplatelets on Amorphous Germanium Substrates. Molecules 2024, 29, 4089. [Google Scholar] [CrossRef]

| Material | Power (W) | Time (s) | Nominal Thickness (nm) |

|---|---|---|---|

| SiO2 | 150 | 6.000 | 150 |

| Al2O3 | 190 | 14.400 | 150 |

| MgO | 140 | 36.000 | 180 |

| SiO2 + Al2O3 | 63 + 190 | 7.200 | 150 |

| Material | Ion Beam | Electronic Stopping (keV/µg/cm2) | Nuclear Stopping (keV/µg/cm2) |

|---|---|---|---|

| SiO2 | 23 MeV I | 23.70 | 1.17 |

| 18 MeV Cu | 23.53 | 0.28 | |

| 2.5 MeV Cu | 5.74 | 1.19 | |

| Al2O3 | 23 MeV I | 22.73 | 1.13 |

| 18 MeV Cu | 22.73 | 0.27 | |

| 2.5 MeV Cu | 5.58 | 1.16 | |

| MgO | 23 MeV I | 23.00 | 1.16 |

| 18 MeV Cu | 23.54 | 0.28 | |

| 2.5 MeV Cu | 5.74 | 1.18 |

| Nominal Composition | A-SiO2 | A-Al2O3 | A-MgO |

| Measured composition | H 8.7 ± 0.6 C 2.0 ± 0.2 O 60 ± 4 Si 27 ± 1 Ar 0.05 ± 0.02 Cr(?) 0.18 ± 0.03 Fe(?) 0.68 ± 0.07 | H 3.9 ± 0.3 O 59 ± 4 Al 36 ± 2 Ar 0.23 ± 0.03 | H 6.7 ± 0.5 O 50 ± 3 Mg 42 ± 2 Cr(?) 0.16 ± 0.02 Fe(?) 0.4 ± 0.04 W(?) 0.083 ± 0.007 |

| Thickness (1015 at/cm2) | 1413 | 1857 | 1750 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Škrabić, M.; Majer, M.; Siketić, Z.; Mičetić, M.; Knežević, Ž.; Karlušić, M. Radiation Hardness of Oxide Thin Films Prepared by Magnetron Sputtering Deposition. Appl. Sci. 2025, 15, 7067. https://doi.org/10.3390/app15137067

Škrabić M, Majer M, Siketić Z, Mičetić M, Knežević Ž, Karlušić M. Radiation Hardness of Oxide Thin Films Prepared by Magnetron Sputtering Deposition. Applied Sciences. 2025; 15(13):7067. https://doi.org/10.3390/app15137067

Chicago/Turabian StyleŠkrabić, Marko, Marija Majer, Zdravko Siketić, Maja Mičetić, Željka Knežević, and Marko Karlušić. 2025. "Radiation Hardness of Oxide Thin Films Prepared by Magnetron Sputtering Deposition" Applied Sciences 15, no. 13: 7067. https://doi.org/10.3390/app15137067

APA StyleŠkrabić, M., Majer, M., Siketić, Z., Mičetić, M., Knežević, Ž., & Karlušić, M. (2025). Radiation Hardness of Oxide Thin Films Prepared by Magnetron Sputtering Deposition. Applied Sciences, 15(13), 7067. https://doi.org/10.3390/app15137067