Data-Driven Prediction of Binder Rheological Performance in RAP/RAS-Containing Asphalt Mixtures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

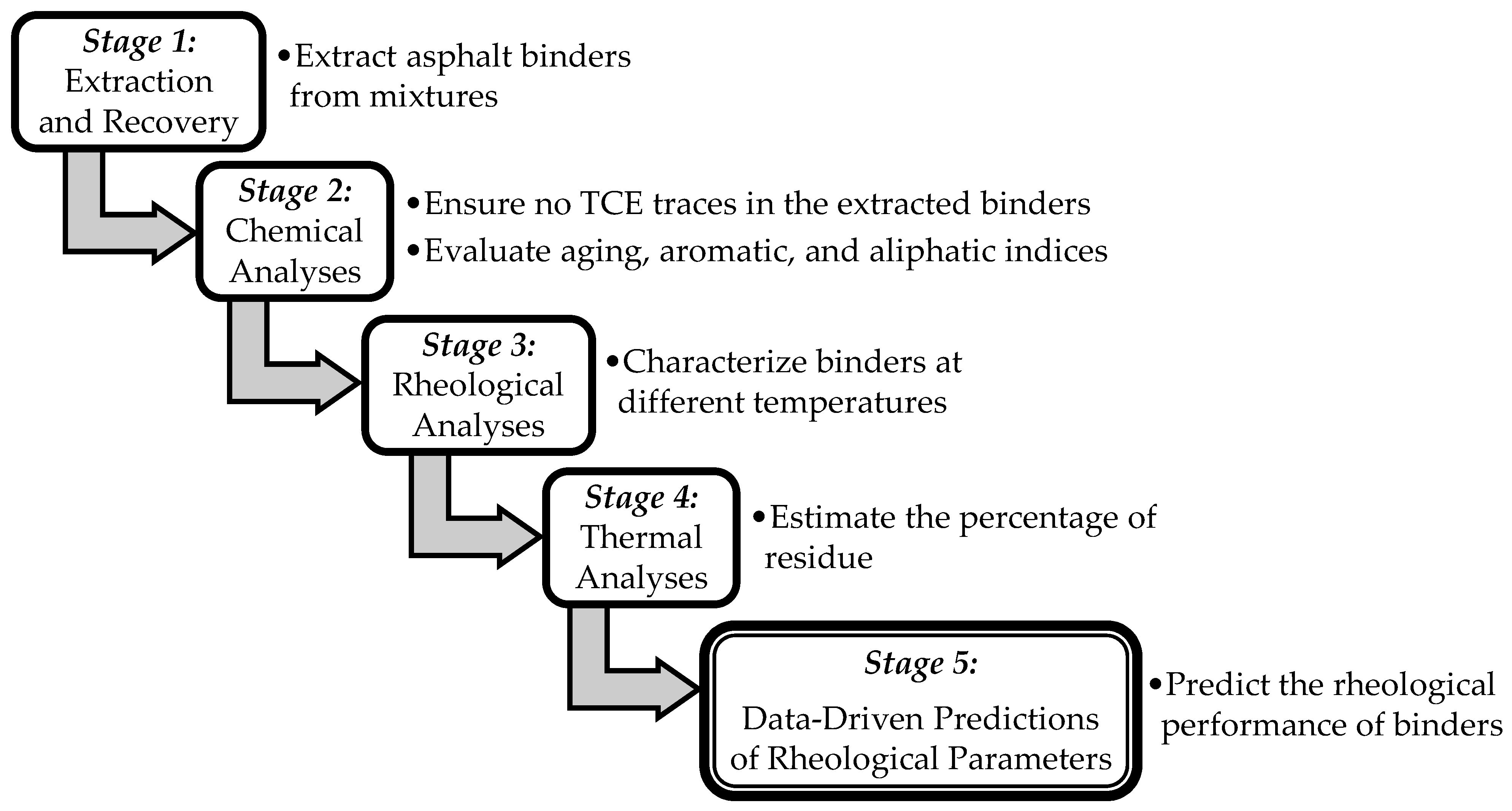

2.2. Methods

2.2.1. Extraction and Recovery

2.2.2. Chemical Analyses

2.2.3. Rheological Analyses

Rutting Parameter

Fatigue Cracking Parameter

Block Cracking Parameter

Thermal Cracking Parameter

2.2.4. Thermal Analyses

2.2.5. Data-Driven Predictions of Rheological Parameters

3. Results and Discussion

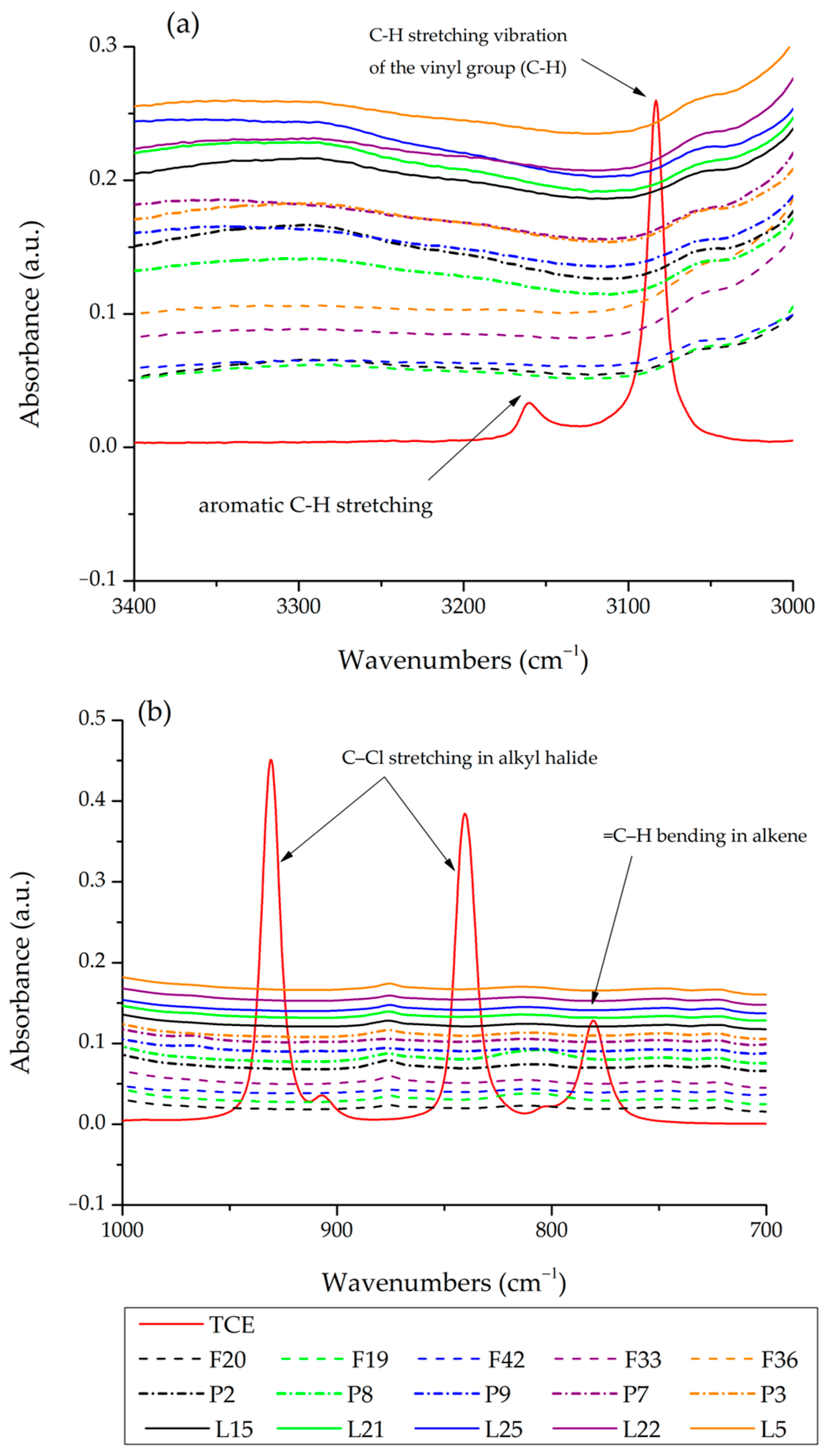

3.1. Ensuring No TCE Traces in the Extracted Binders

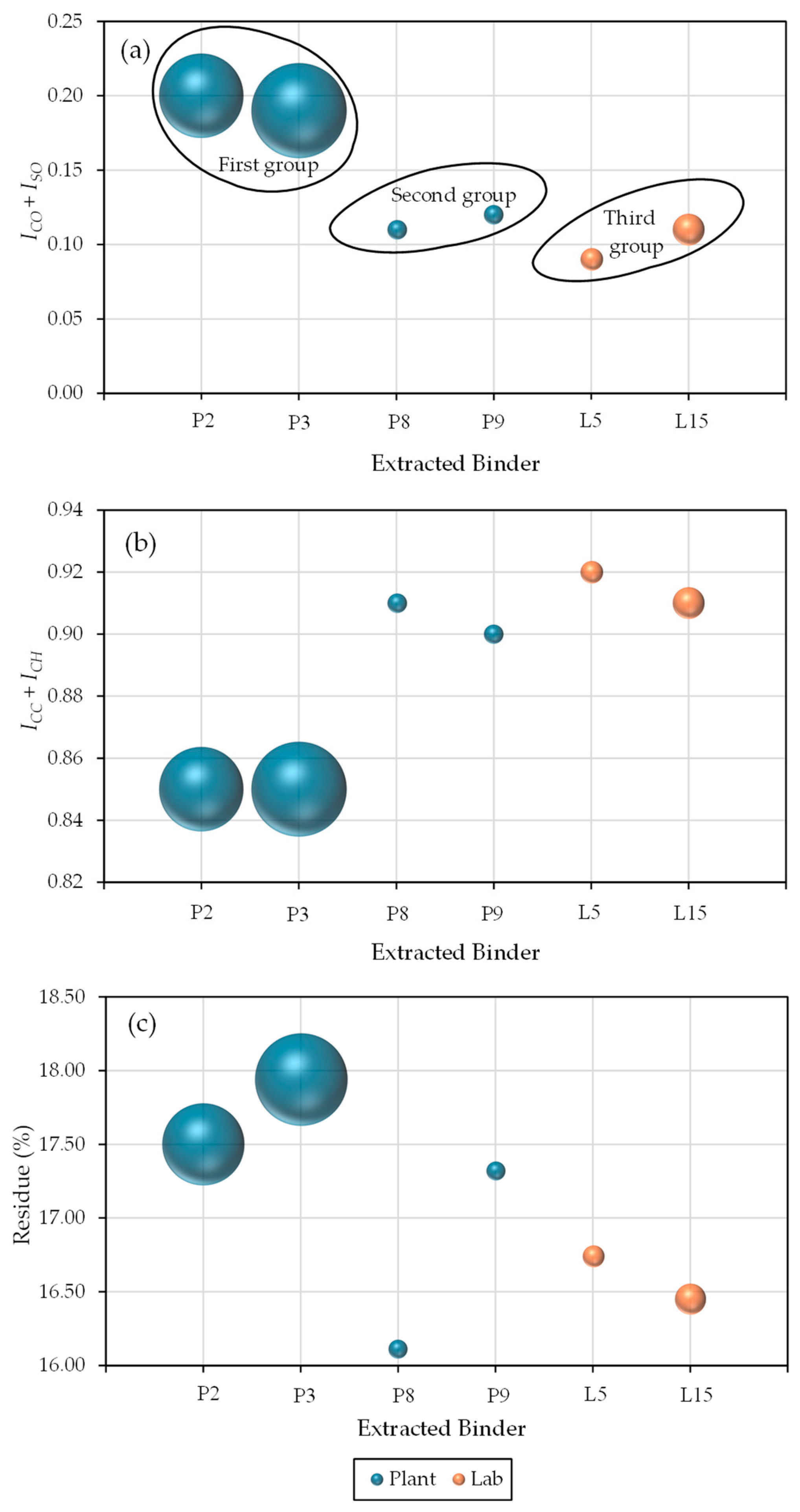

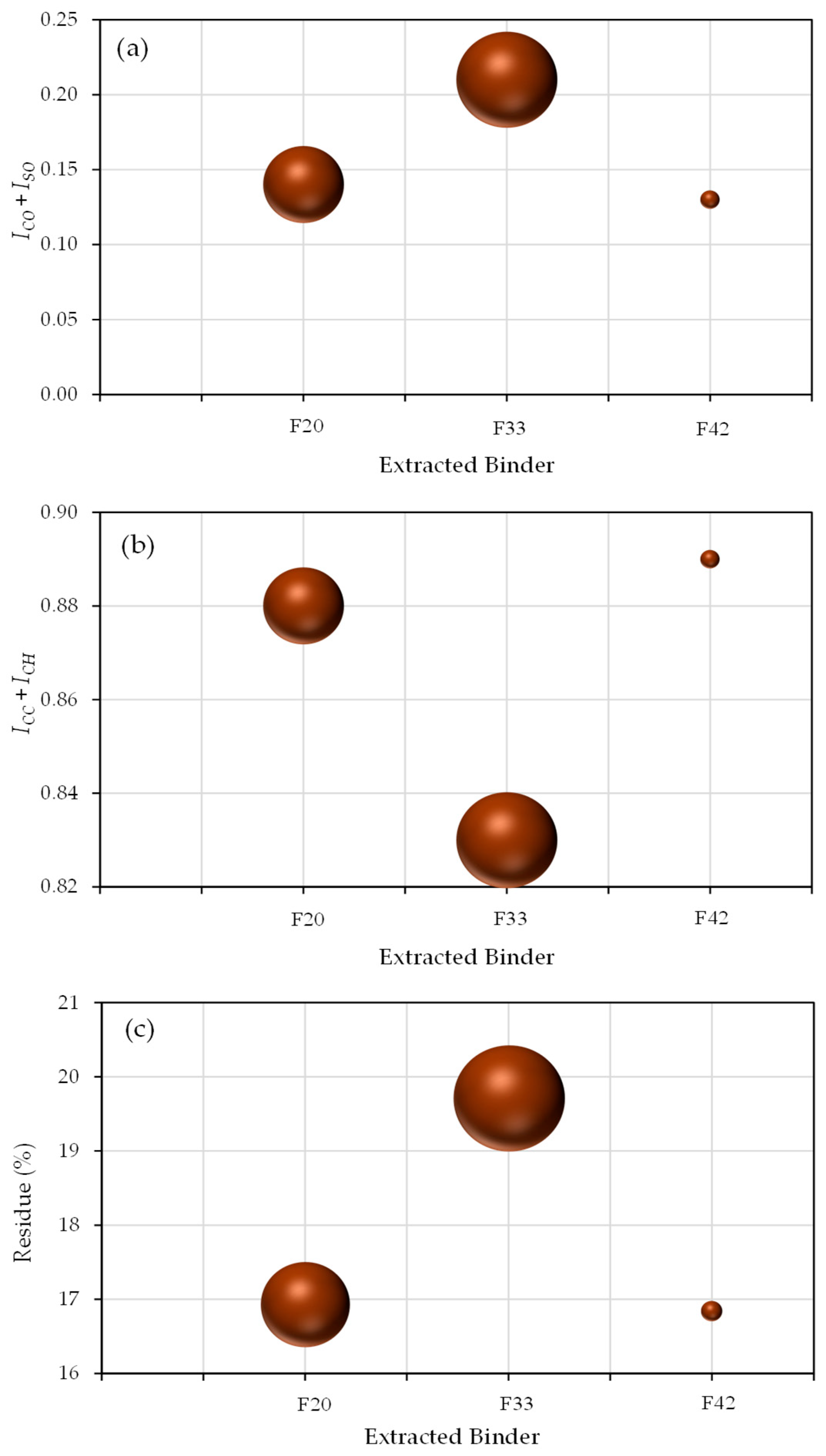

3.2. Rheological, Chemical, and Thermal Characterization of the Extracted Binders

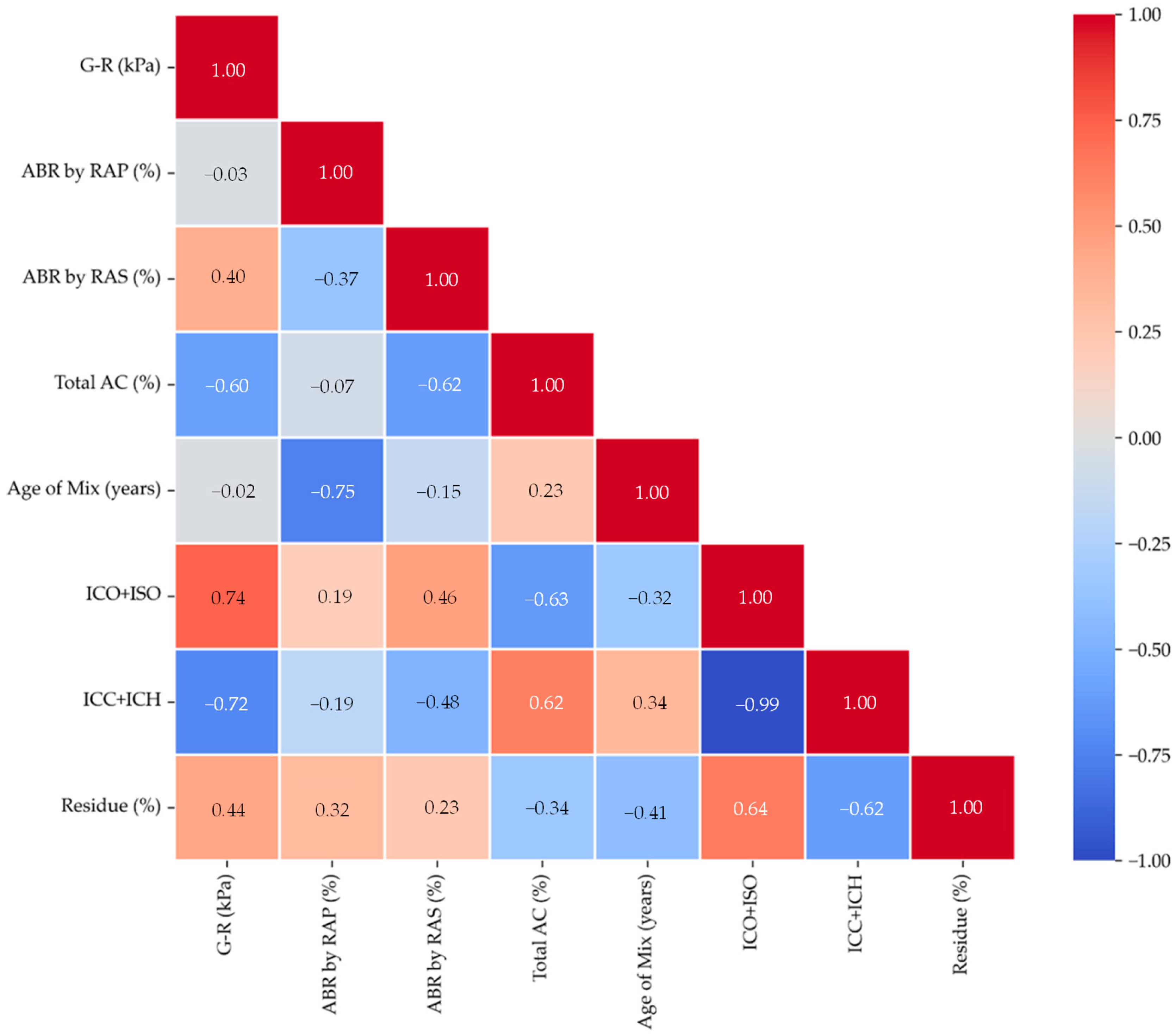

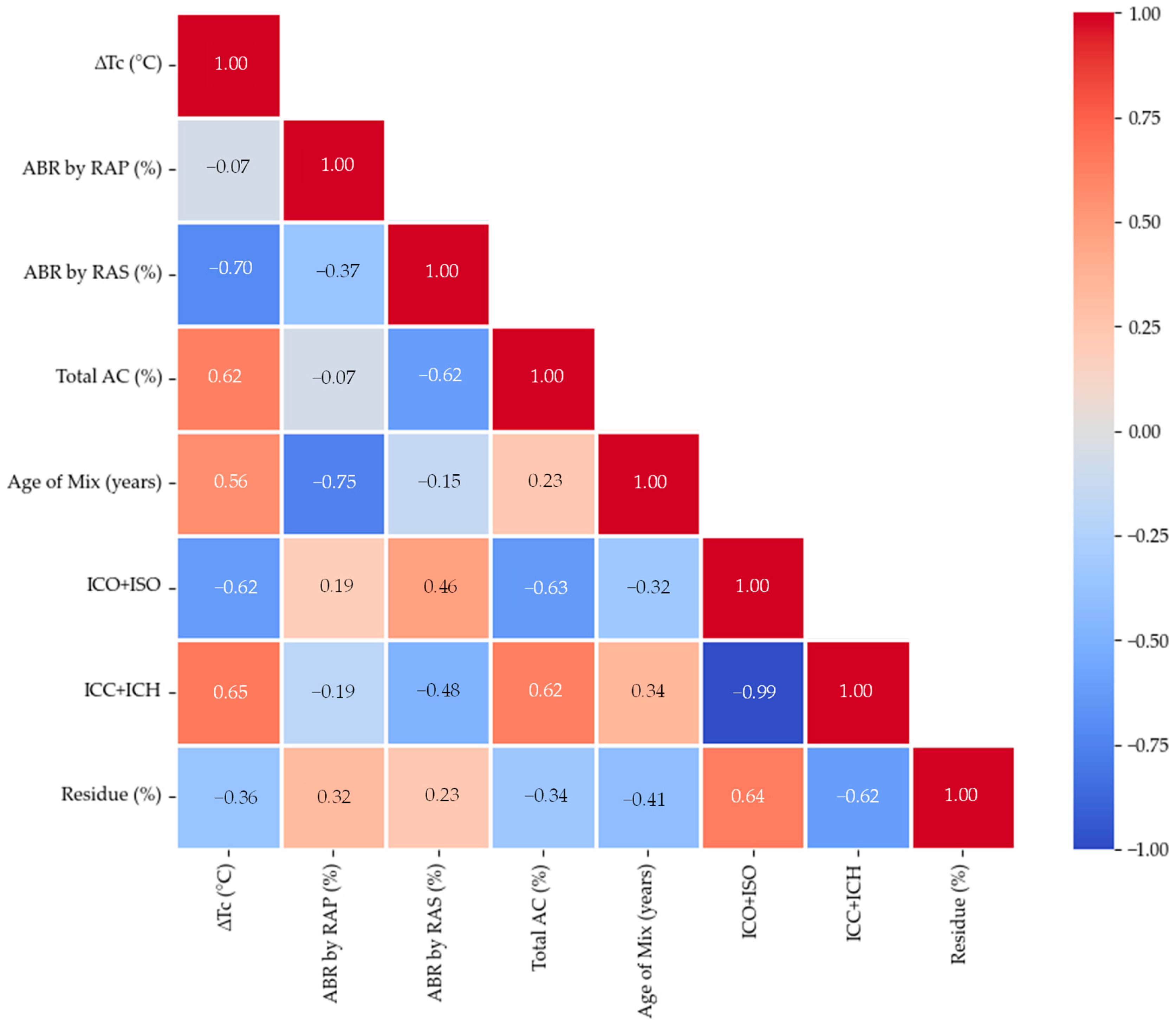

3.3. Correlations Between Rheology and Other Parameters

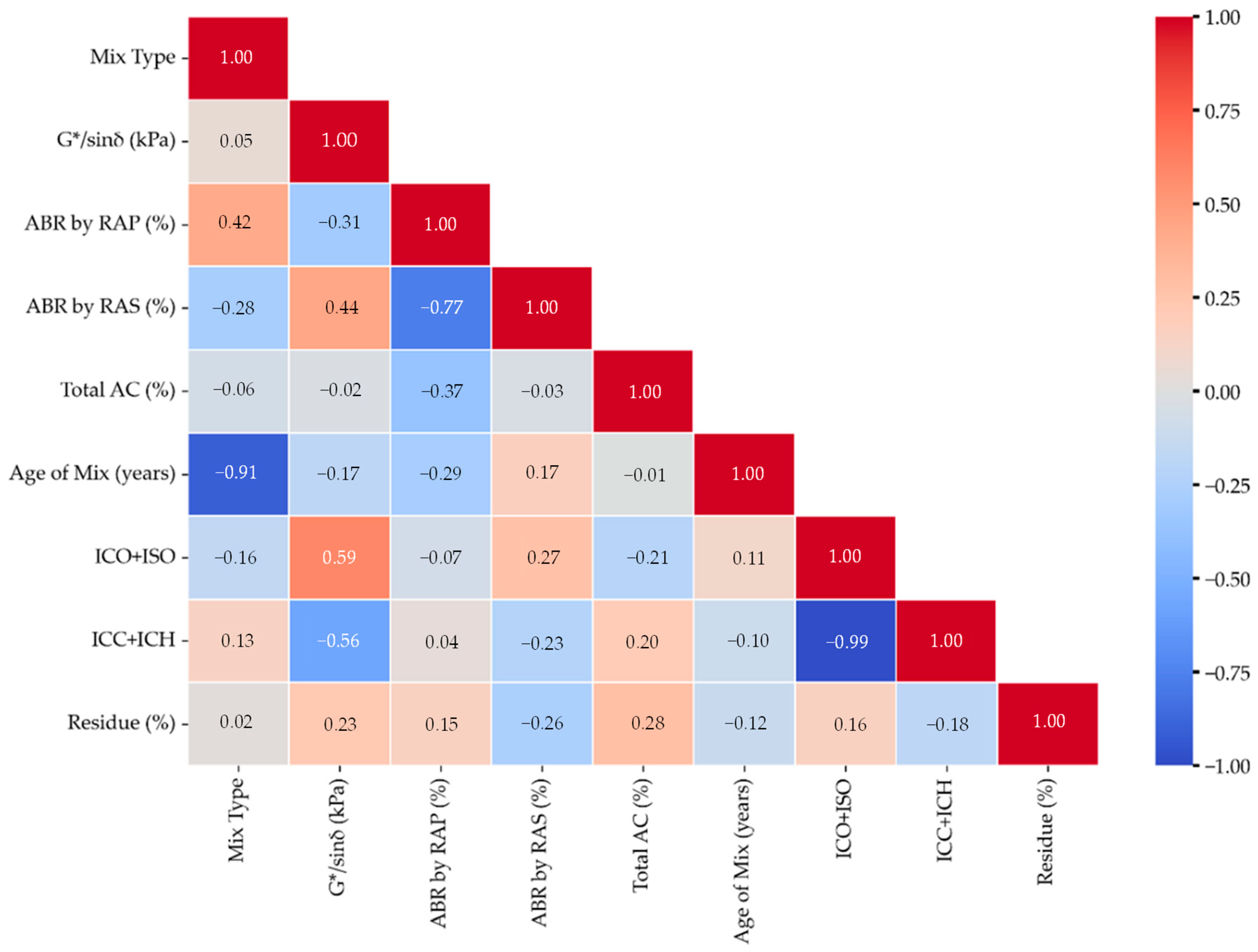

3.3.1. Rutting Correlations

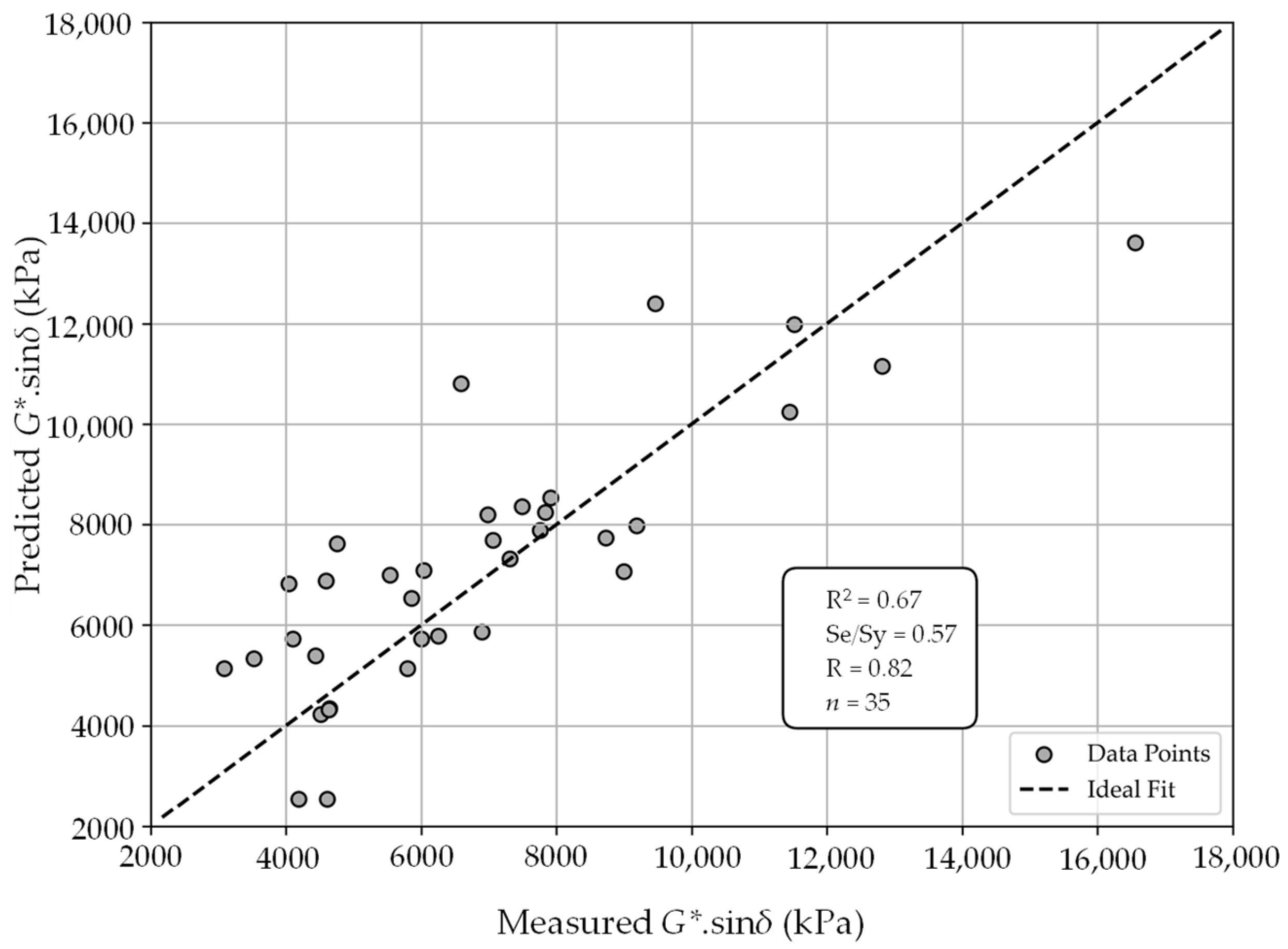

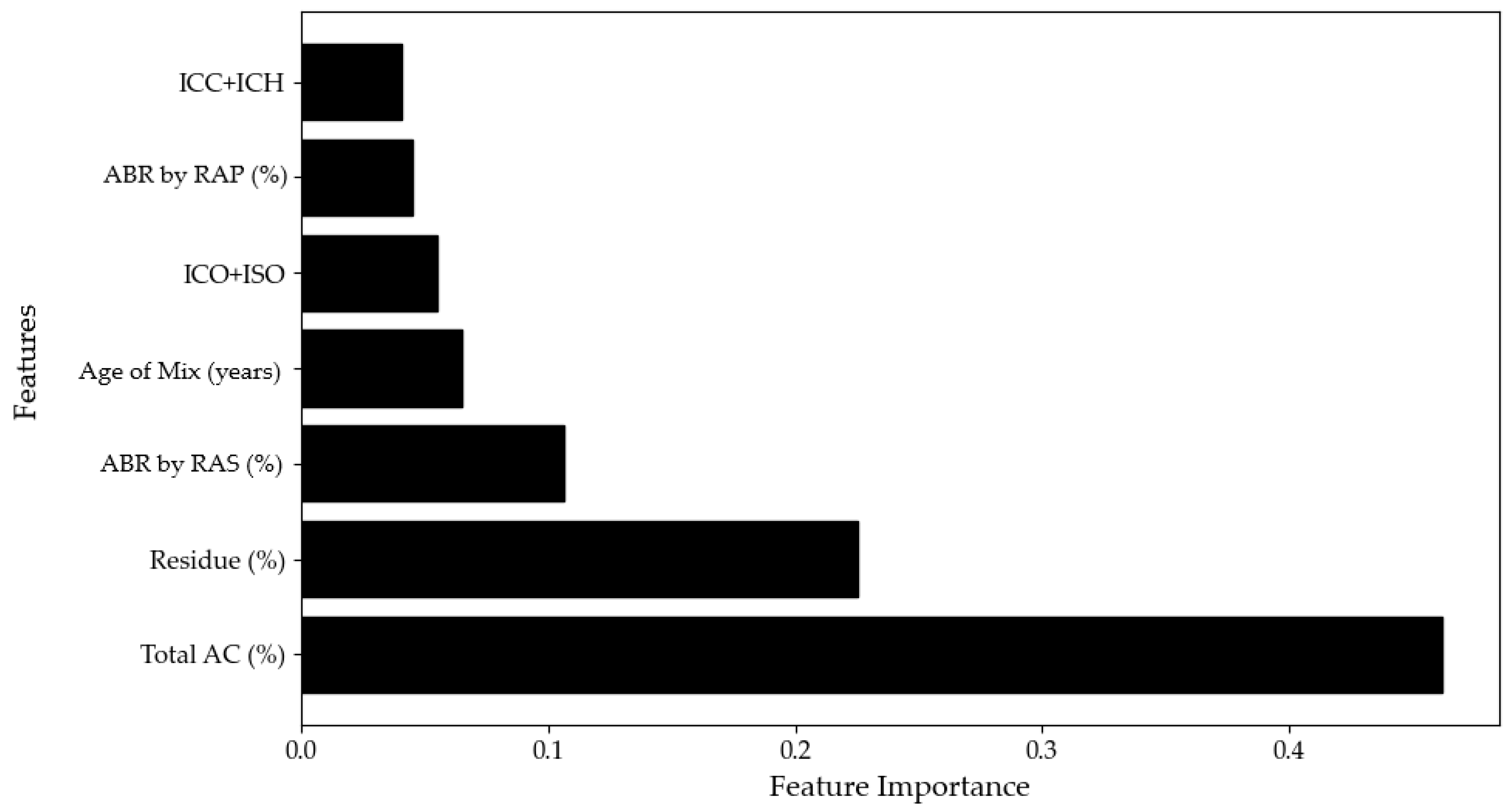

3.3.2. Fatigue Cracking Correlations

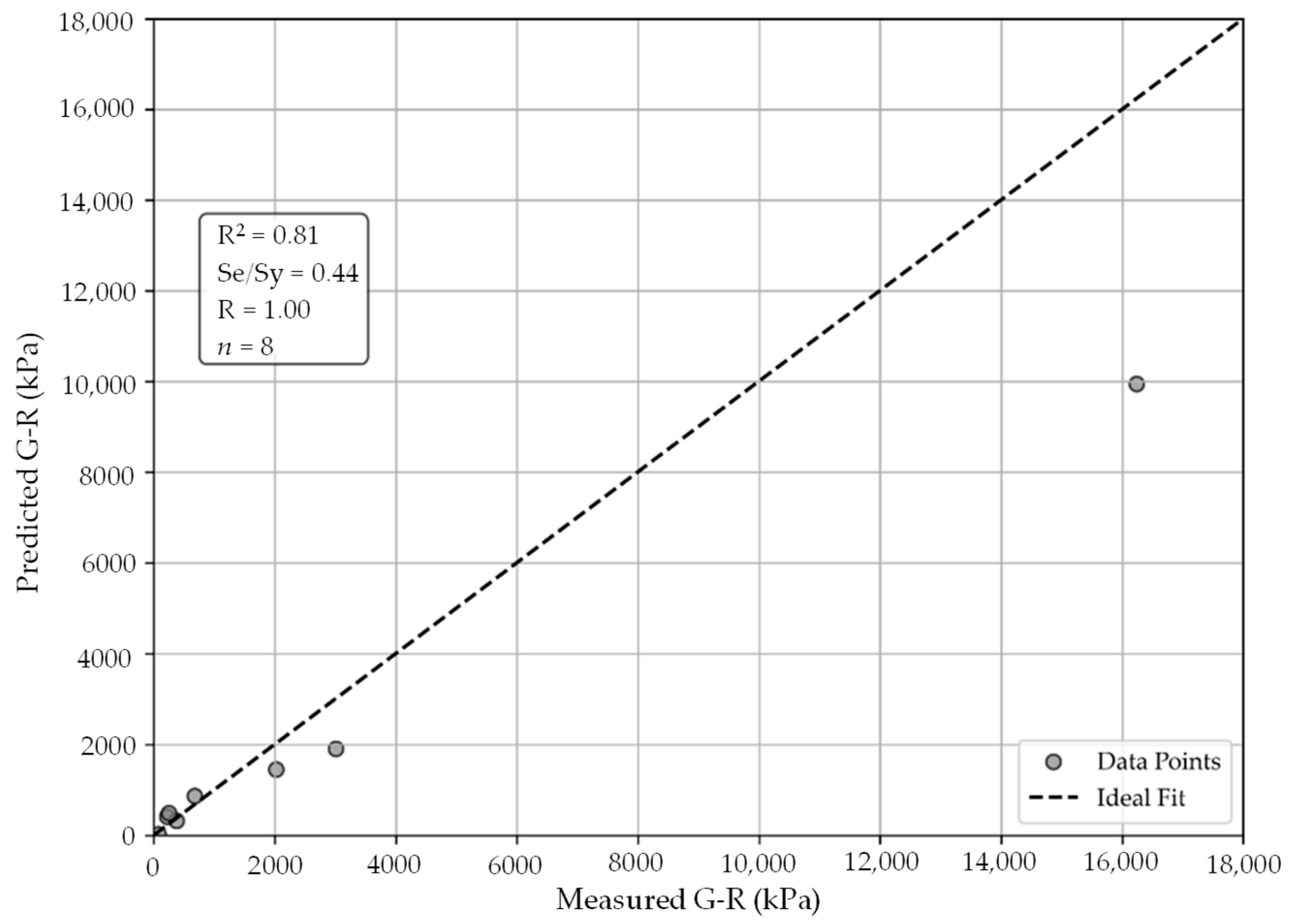

3.3.3. Block Cracking Correlations

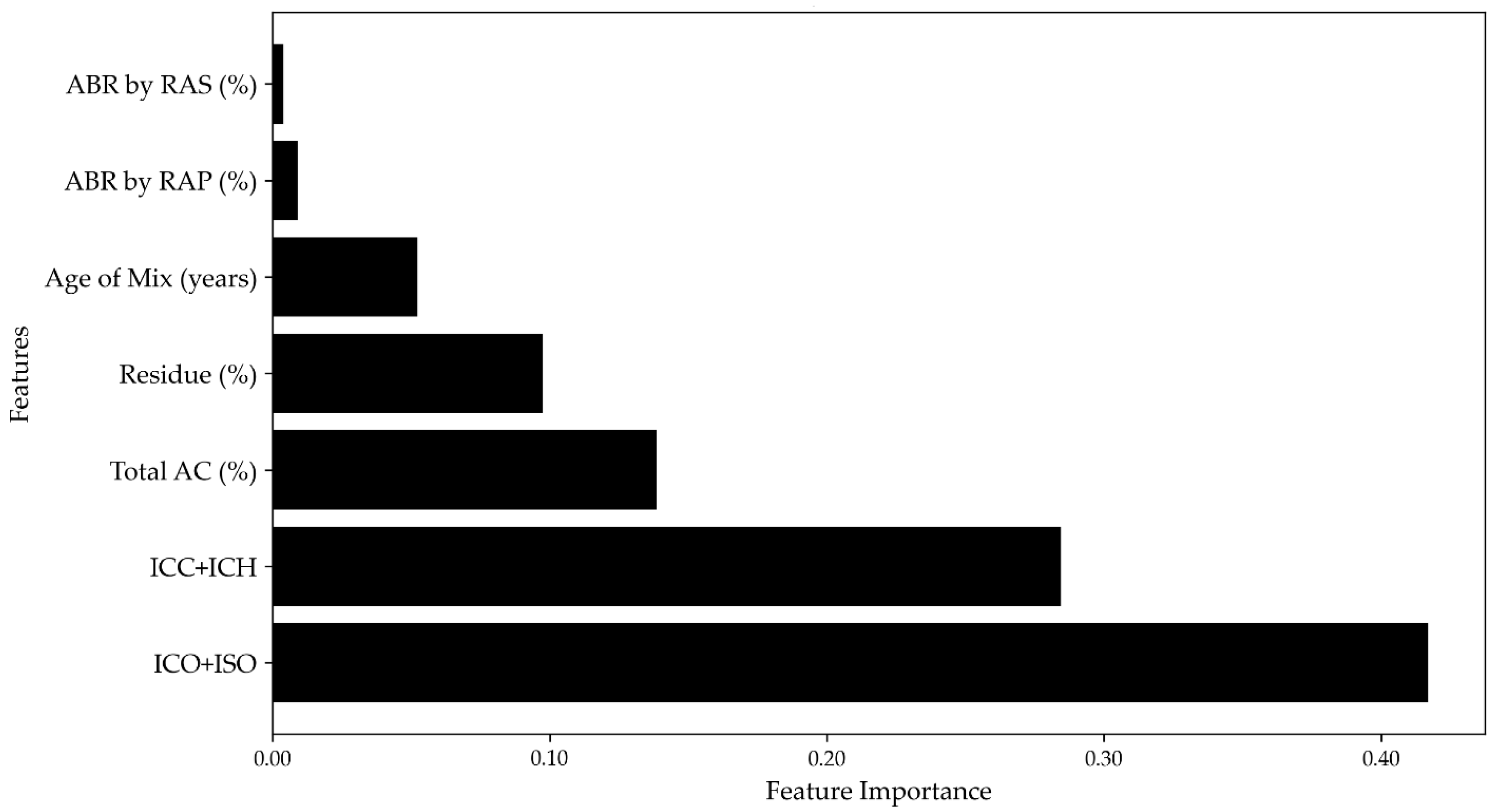

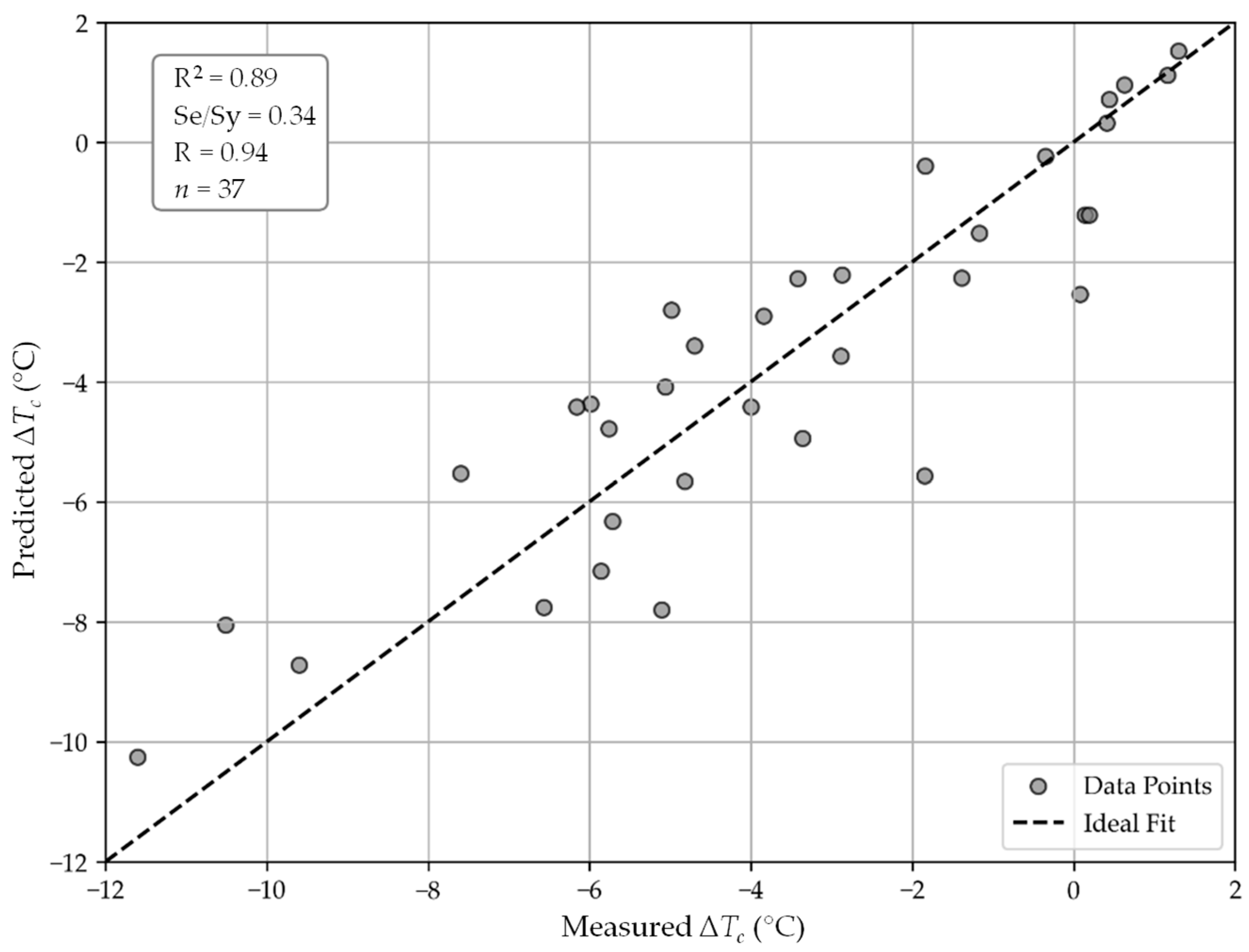

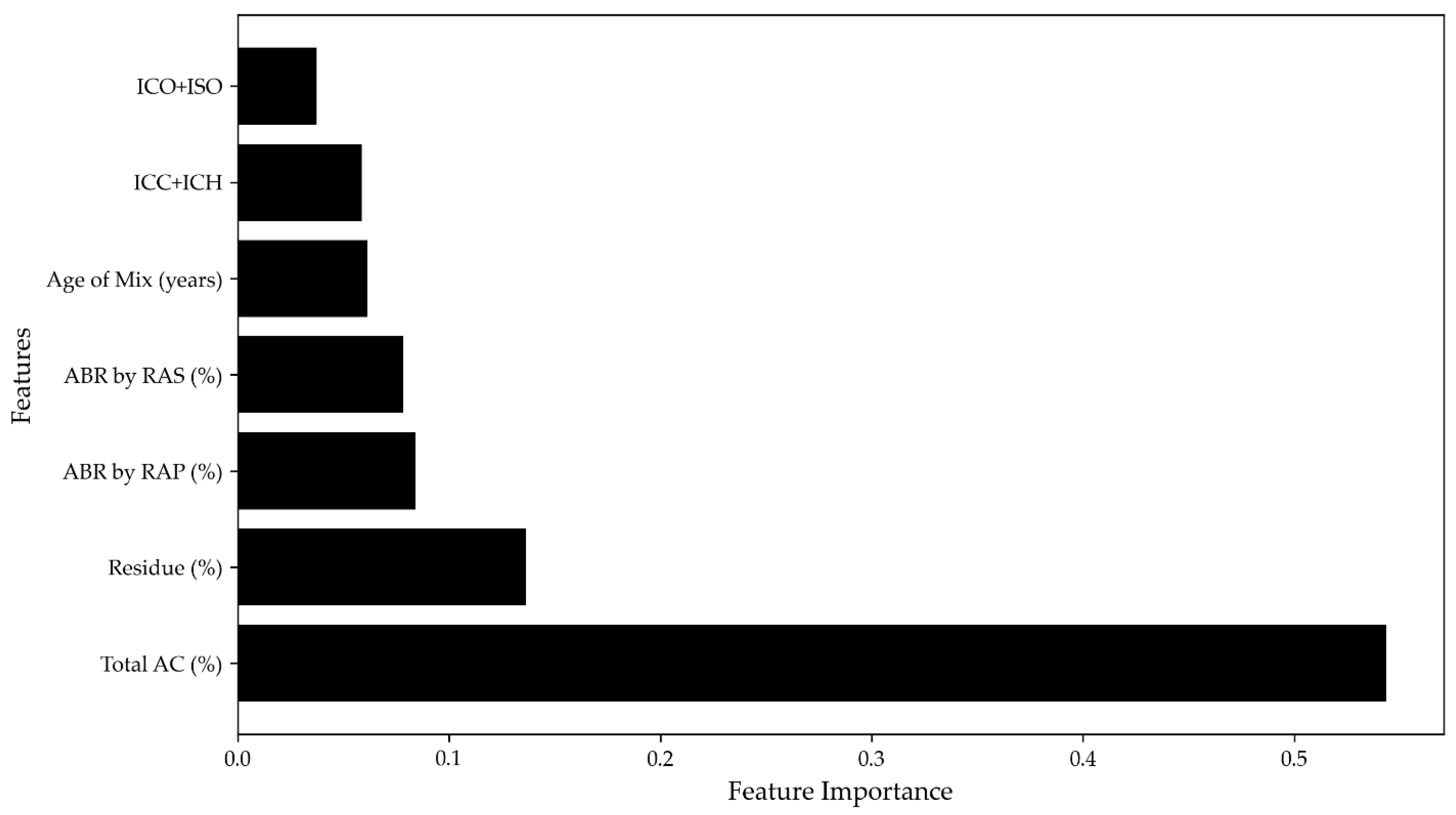

3.3.4. Thermal Cracking Correlations

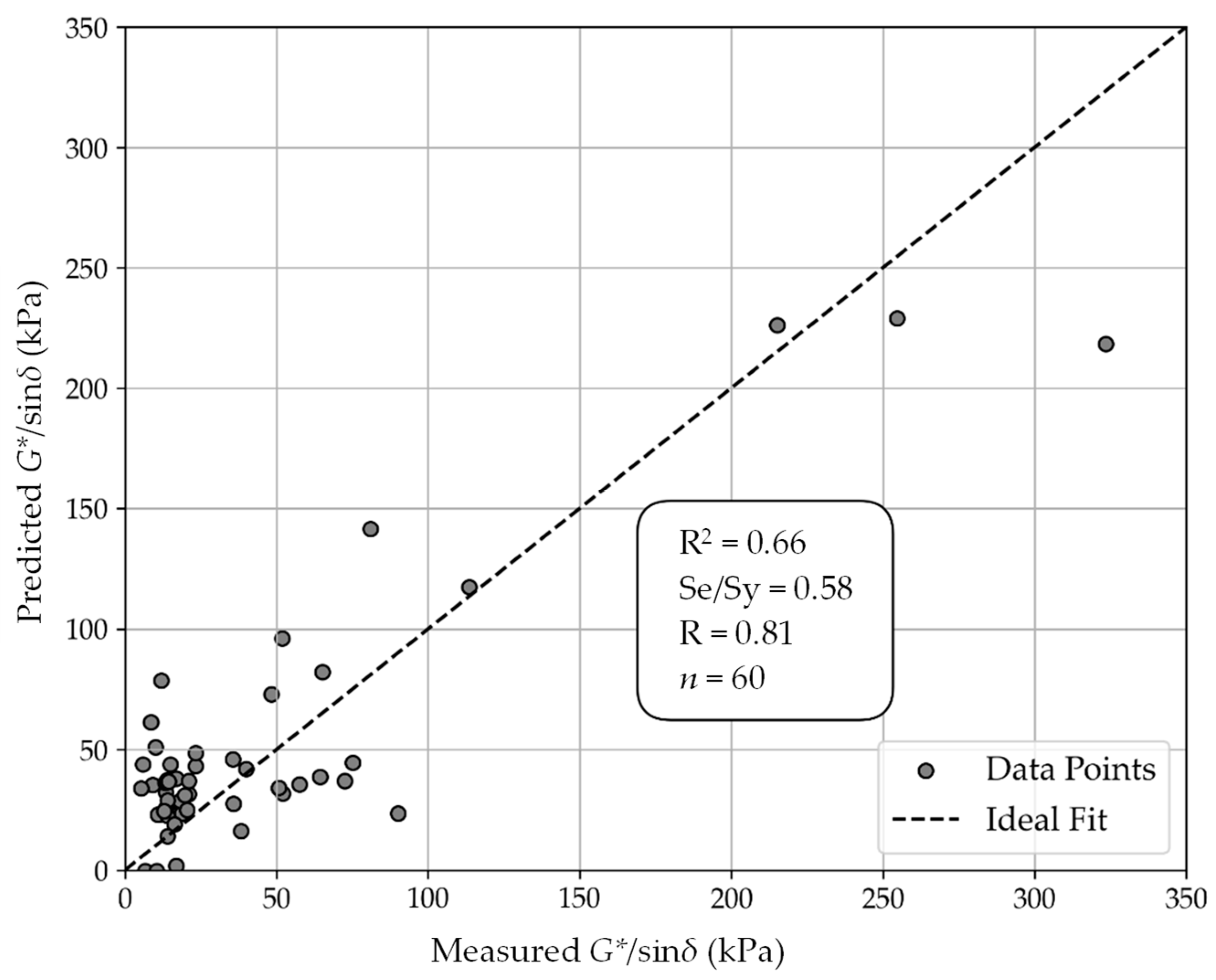

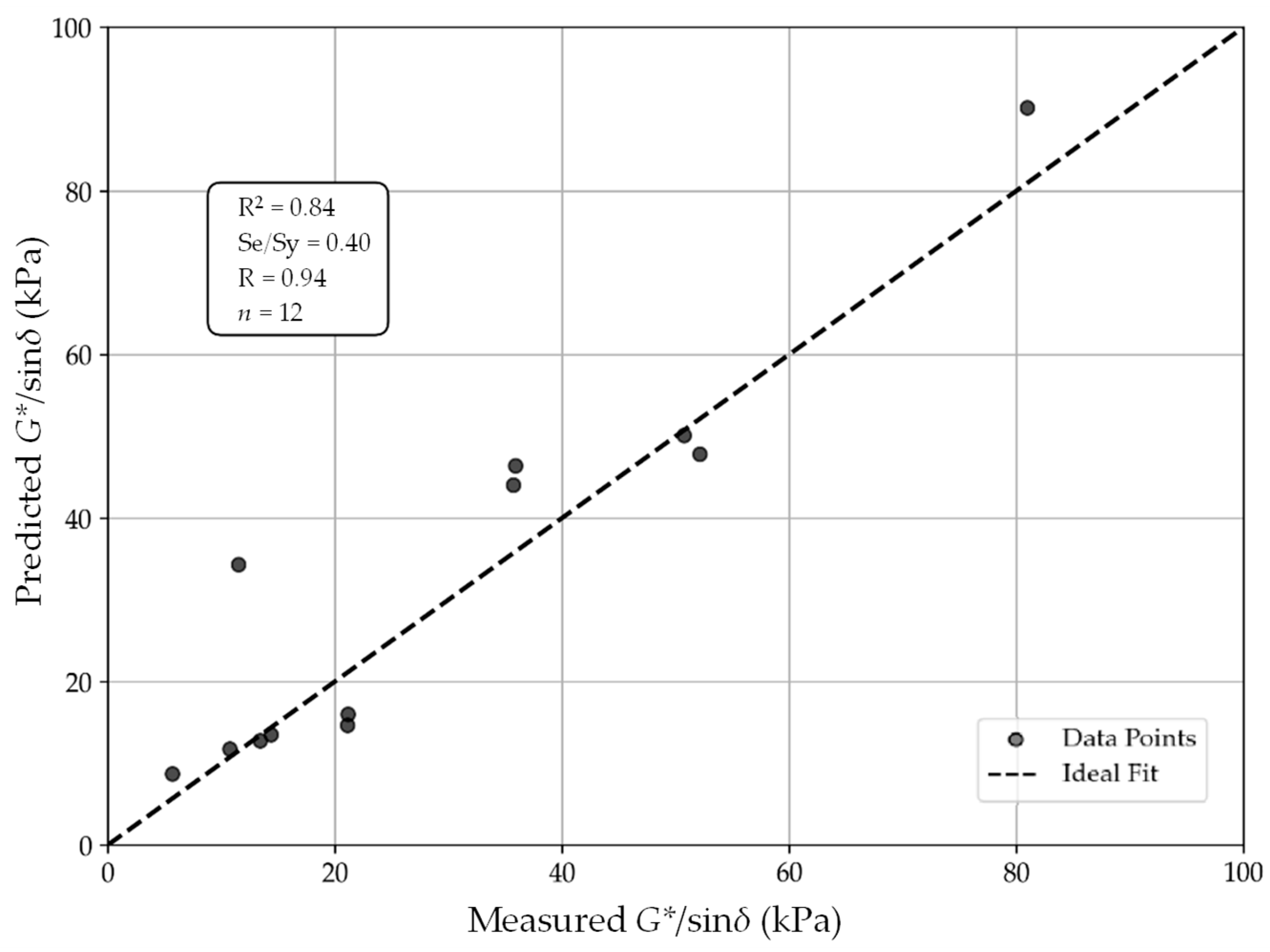

3.4. Statistical Evaluation of Model Predictions

4. Conclusions

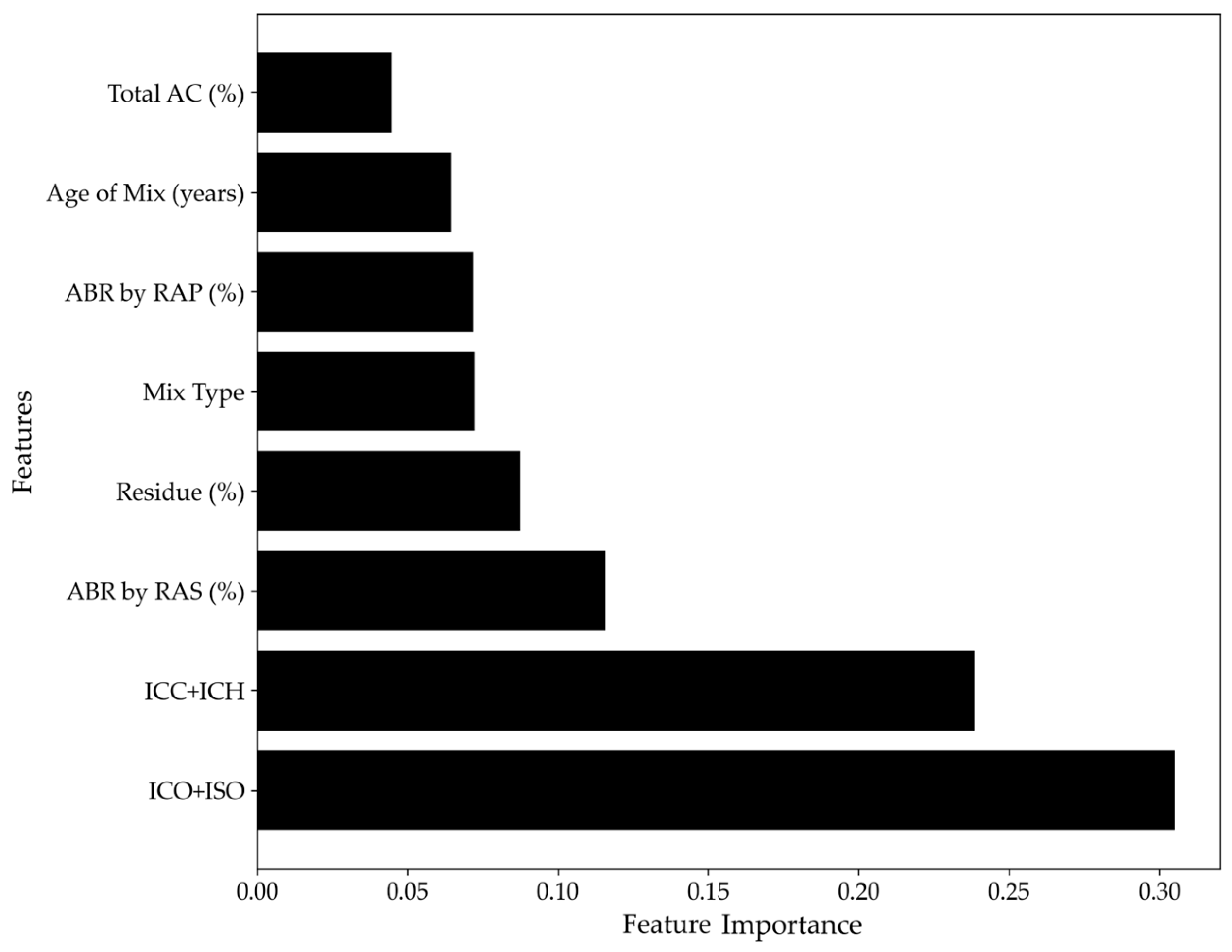

- Robust predictive capability: Machine learning, specifically RF regression, enabled accurate predictions of binder performance at high, intermediate, and low temperatures. The RF nonlinear models reduced RMSE by 69% for rutting resistance, 37% for fatigue cracking, and 21% for thermal cracking when compared to linear model performance. In terms of block cracking, the RF model had an R value of 1.00, but it overfitted the data, resulting in an RMSE that was 41% greater than that obtained using a linear model. While all of these results demonstrate the importance of combining metrics of accuracy with residuals to assess model robustness, they are of concern, especially with a dataset that had such variability.

- Practical for limited binder amounts: One advantage of the framework is its capability to provide reliable predictions using small amounts of extracted binder. This is beneficial in practice because field cores with high RAP/RAS contents usually yield limited amounts of extracted binders.

- Enhanced knowledge of binder performance: The combination of rheological and chemical analyses, such as aging, aromatic and aliphatic indices, and thermal residue characteristics, enables the understanding of binder development in recycled systems. This is a way to successfully break through some of the constraints of conventional methodologies based exclusively on rheological measurements.

- Feature importance emphasizes the dominance of chemical and thermal properties: Thermal residue, along with carbonyl, sulfoxide, aromatic, and aliphatic indices, consistently ranked among the top five most influential features affecting the rheological characteristics of the extracted binders.

- Promoting sustainable recycling: The framework allocates data-driven information on the use of RAP/RAS, thus ensuring that the utilization of RAP/RAS is more sustainable. The study establishes a benchmark for balancing sustainability and performance by evaluating RAP/RAS binder replacement up to 35%.

- Scalability, broader applications, and limitations: This study was conducted on mixtures with RAP/RAS; however, the framework can be applied to other recycled or modified binders. With further development, it could be expanded into a digital tool for quality control and mixture optimization in both research and field industries. Although the suggested framework offers accurate forecasts on binders extracted from mixtures with 0–35% RAP/RAS binder replacements, its application beyond this range requires recalibration and validation with expanded datasets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABR | Asphalt Binder Replacement |

| AC | Asphalt Content |

| DSR | Dynamic Shear Rheometer |

| FTIR | Fourier Transform Infrared |

| G-R | Glover-Rowe |

| RAP | Reclaimed Asphalt Pavement |

| RAS | Recycled Asphalt Shingles |

| RF | Random Forest |

| RMSE | Root Mean Square Error |

| STD | Standard Deviation |

| TCE | Trichloroethylene |

| TGA | Thermogravimetric Analysis |

References

- Pasetto, M.; Haider, S.; Pasquini, E. Circular economy for transport infrastructure: An overview of the sustainable use of recycled asphalt shingles in asphalt mixtures. Appl. Sci. 2024, 14, 10145. [Google Scholar] [CrossRef]

- Elnaml, I.; Mohammad, L.N.; Baumgardner, G.; Cooper, S.; Cooper, S. Sustainability of asphalt mixtures containing 50% RAP and recycling agents. Recycling 2024, 9, 85. [Google Scholar] [CrossRef]

- Mocelin, D.M.; Isied, M.M.; Castorena, C. Influence of reclaimed asphalt pavement (RAP) and recycled asphalt shingle (RAS) binder availability on the composition of asphalt mixtures. J. Clean. Prod. 2023, 426, 139156. [Google Scholar] [CrossRef]

- Yu, J.; Lin, Z.; Zou, G.; Yu, H.; Leng, Z.; Zhang, Y. Long-term performance of recycled asphalt mixtures containing high RAP and RAS. J. Road Eng. 2024, 4, 36–53. [Google Scholar] [CrossRef]

- Deef-Allah, E.; Abdelrahman, M. Correlating the compositional changes to the rheological properties of recovered asphalt binders from recycled asphalt mixtures: Insights from the thermogravimetric measurements. Metrology 2025, 5, 16. [Google Scholar] [CrossRef]

- Rahman, M.A.; Mateos, A.; Harvey, J.T.; Buscheck, J.; Brotschi, J.; Jones, D.J.; Deng, H. Fatigue and age-related cracking performance of asphalt mixes containing RAP, RAS and recycling agents (RA). Constr. Build. Mater. 2025, 466, 140302. [Google Scholar] [CrossRef]

- Deef-Allah, E.; Abdelrahman, M. Quality assurance framework for recovered binders and aggregates from asphalt mixtures incorporating recycled materials. Recycling 2025, 10, 71. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Katman, H.Y.; Mohd Satar, M.K.I.; Bilema, M.; Putra Jaya, R.; Eltwati, A.S.; Radeef, H.R. A review on the durability of recycled asphalt mixtures embraced with rejuvenators. Sustainability 2021, 13, 8970. [Google Scholar] [CrossRef]

- Sukhija, M.; Coleri, E. A systematic review on the role of reclaimed asphalt pavement materials: Insights into performance and sustainability. Clean. Mater. 2025, 16, 100316. [Google Scholar] [CrossRef]

- Li, H.; Xing, C.; Zhu, B.; Zhang, X.; Gao, Y.; Tang, S.; Cheng, H. Comparative analysis of four styrene-butadiene-styrene (SBS) structure repair agents in the rejuvenation of aged SBS-modified bitumen. Constr. Build. Mater. 2025, 476, 141232. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Deef-Allah, E.; Abdelrahman, M. Investigating the relationship between the fatigue cracking resistance and thermal characteristics of asphalt binders extracted from field mixes containing recycled materials. Transp. Eng. 2021, 4, 100055. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Jing, R.; Erkens, S. Toward the long-term aging influence and novel reaction kinetics models of bitumen. Int. J. Pavement Eng. 2023, 24, 2024188. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E. Thermal stability and evolved gas analysis of rejuvenated reclaimed asphalt pavement (RAP) bitumen using thermogravimetric analysis–Fourier transform infrared (TG–FTIR). J. Therm. Anal. Calorim. 2018, 131, 865–871. [Google Scholar] [CrossRef]

- Deef-Allah, E.; Abdelrahman, M. Thermal, chemical and rheological properties of asphalt binders extracted from field cores. Innov. Infrastruct. Solut. 2022, 7, 235. [Google Scholar] [CrossRef]

- Pipintakos, G.; Sreeram, A.; Mirwald, J.; Bhasin, A. Engineering bitumen for future asphalt pavements: A review of chemistry, structure and rheology. Mater. Des. 2024, 244, 113157. [Google Scholar] [CrossRef]

- Liu, F.; Wen, H. Prediction of rheological and damage properties of asphalt binders that result from oxidative aging. Transp. Res. Rec. 2015, 2505, 92–98. [Google Scholar] [CrossRef]

- Sarker, I.H. Machine learning: Algorithms, real-world applications and research directions. SN Comput. Sci. 2021, 2, 160. [Google Scholar] [CrossRef]

- Sarker, I.H.; Salah, K. AppsPred: Predicting context-aware smartphone apps using random forest learning. Internet Things 2019, 8, 100106. [Google Scholar] [CrossRef]

- Cappelli, F.; Castronuovo, G.; Grimaldi, S.; Telesca, V. Random Forest and feature importance measures for discriminating the most influential environmental factors in predicting cardiovascular and respiratory diseases. Int. J. Environ. Res. Public. Health 2024, 21, 867. [Google Scholar] [CrossRef]

- Liu, J.; Liu, F.; Zheng, C.; Fanijo, E.O.; Wang, L. Improving asphalt mix design considering international roughness index of asphalt pavement predicted using autoencoders and machine learning. Constr. Build. Mater. 2022, 360, 129439. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Tran, V.Q. Data-driven approach for investigating and predicting rutting depth of asphalt concrete containing reclaimed asphalt pavement. Constr. Build. Mater. 2023, 377, 131116. [Google Scholar] [CrossRef]

- Al-Ammari, M.; Dong, R.; Nasser, M.; Al-Maswari, A. Innovative machine learning approaches for predicting the asphalt content during Marshall design of asphalt mixtures. Materials 2025, 18, 1474. [Google Scholar] [CrossRef] [PubMed]

- Rondinella, F.; Oreto, C.; Abbondati, F.; Baldo, N. Laboratory investigation and machine learning modeling of road pavement asphalt mixtures prepared with construction and demolition waste and RAP. Sustainability 2023, 15, 16337. [Google Scholar] [CrossRef]

- Afshin, A.; Behnood, A. Prediction of moisture susceptibility of asphalt mixtures containing RAP materials using machine learning algorithms. Int. J. Pavement Eng. 2024, 25, 2431610. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; Liu, J.; Zhao, X. Using artificial neural networks to predict the dynamic modulus of asphalt mixtures containing recycled asphalt shingles. J. Mater. Civ. Eng. 2018, 30, 04018051. [Google Scholar] [CrossRef]

- Ghavami, S.; Alipour, Z.; Naseri, H.; Jahanbakhsh, H.; Karimi, M.M. A new ensemble prediction method for reclaimed asphalt pavement (RAP) mixtures containing different constituents. Buildings 2023, 13, 1787. [Google Scholar] [CrossRef]

- Mullapudi, R.S.; Sudhakar Reddy, K. An investigation on the relationship between FTIR indices and surface free energy of RAP binders. Road Mater. Pavement Des. 2020, 21, 1326–1340. [Google Scholar] [CrossRef]

- ASTM D2172/D2172M-24; Test Methods for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D5404/D5404M-24; Standard Practice for Recovery of Asphalt Binder from Solution Using the Rotary Evaporator. ASTM International: West Conshohocken, PA, USA, 2024.

- Van den Bergh, W. The Effect of Ageing on the Fatigue and Healing Properties of Bituminous Mortars. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2011. [Google Scholar]

- Singh, D.; Sawant, D. Understanding effects of RAP on rheological performance and chemical composition of SBS modified binder using series of laboratory tests. Int. J. Pavement Res. Technol. 2016, 9, 178–189. [Google Scholar] [CrossRef]

- De la Roche, C.; van de Ven, M.; Planche, J.-P.; van den Bergh, W.; Grenfell, J.; Gabet, T.; Mouillet, V.; Porot, L.; Farcas, F.; Ruot, C. Hot recycling of bituminous mixtures. In Advances in Interlaboratory Testing and Evaluation of Bituminous Materials; Partl, M.N., Bahia, H.U., Canestrari, F., de la Roche, C., di Benedetto, H., Piber, H., Sybilski, D., Eds.; Springer: Dordrecht, The Netherlands, 2013; Volume 9, pp. 361–428. [Google Scholar]

- Gong, M.; Yang, J.; Yao, H.; Wang, M.; Niu, X.; Haddock, J.E. Investigating the performance, chemical, and microstructure properties of carbon nanotube-modified asphalt binder. Road Mater. Pavement Des. 2018, 19, 1499–1522. [Google Scholar] [CrossRef]

- ASTM D7175-15; Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2023.

- Anderson, R.M.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 615–664. [Google Scholar]

- Deef-Allah, E.; Abdelrahman, M. Performance evaluation of extracted asphalt binders from field cores containing recycled components: Load-and non-load-associated cracking resistance. Adv. Mat. Res. 2023, 1175, 149–170. [Google Scholar] [CrossRef]

- Glover, C.J.; Davison, R.R.; Domke, C.H.; Ruan, Y.; Juristyarini, P.; Knorr, D.B.; Jung, S.H. Development of a New Method for Assessing Asphalt Binder Durability with Field Validation; Texas Department of Transportation: Austin, TX, USA, 2005. [Google Scholar]

- ASTM E1131-20; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2020.

- Nciri, N.; Shin, T.; Kim, N.; Caron, A.; ben Ismail, H.; Cho, N. Towards the use of waste pig fat as a novel potential bio-based rejuvenator for recycled asphalt pavement. Materials 2020, 13, 1002. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xu, T.; Shi, H.; Wang, L. Physicochemical and pyrolysis properties of SARA fractions separated from asphalt binder. J. Therm. Anal. Calorim. 2015, 122, 241–249. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Gao, Z. Thermal analysis on the component interaction of asphalt binders modified with crumb rubber and warm mix additives. Constr. Build. Mater. 2016, 125, 168–174. [Google Scholar] [CrossRef]

- Sugano, M.; Iwabuchi, Y.; Watanabe, T.; Kajita, J.; Iwai, S.; Hirano, K. Thermal degradation mechanism of polymer modified asphalt. Chem. Eng. Trans. 2009, 18, 839–844. [Google Scholar]

- Rogel, E.; Ovalles, C.; Moir, M. Asphaltene Chemical characterization as a function of solubility: Effects on stability and aggregation. Energy Fuels 2012, 26, 2655–2662. [Google Scholar] [CrossRef]

- Barneto, A.G.; Carmona, J.A.; Garrido, M.J.F. Thermogravimetric assessment of thermal degradation in asphaltenes. Thermochim. Acta 2016, 627–629, 1–8. [Google Scholar] [CrossRef]

- Salin, I.M.; Seferis, J.C. Kinetic Analysis of high-resolution TGA variable heating rate data. J. Appl. Polym. Sci. 1993, 47, 847–856. [Google Scholar] [CrossRef]

- Gill, P.S.; Sauerbrunn, S.R.; Crowe, B.S. High resolution thermogravimetry. J. Therm. Anal. 1992, 38, 255–266. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning, 2nd ed.; Springer New York: New York, NY, USA, 2009. [Google Scholar]

- Masis, S. Interpretable Machine Learning with Python: Build Explainable, Fair, and Robust High-Performance Models with Hands-On, Real-World Examples, 2nd ed.; Packt Publishing: Birmingham, UK, 2023. [Google Scholar]

- Nishikiori, H.; Hayashibe, M.; Fujii, T. Visible light-photocatalytic activity of sulfate-doped titanium dioxide prepared by the sol–gel method. Catalysts 2013, 3, 363–377. [Google Scholar] [CrossRef]

- Deef-Allah, E.; Abdelrahman, M.; Ragab, M. Components’ exchanges between recycled materials and asphalt binders in asphalt mixes. Adv. Civ. Eng. Mater. 2022, 11, 20210105. [Google Scholar] [CrossRef]

| Mixture Code | Type | Original Asphalt Grade | ABR by RAP-RAS (%) | Total AC (%) | Mix’s Age (Years) |

|---|---|---|---|---|---|

| F1, F2, and F3 | Field | 58–28 | 33-0 | 5.3 | 0.04 |

| F4, F5, and F6 | 31-0 | 5.1 | |||

| F7, F8, and F9 | 0-33 | 5.2 | |||

| F10, F11, and F12 | 18-15 | 5.2 | |||

| F13, F14, and F15 | 35-0 | 5.1 | |||

| F16, F17, F18, F19, and F20 | 30-0 | 5.9 | 4.00 | ||

| F21, F22, and F23 | 64–22 | 25-0 | 5.0 | 5.00 | |

| F24, F25, and F26 | 0-34 | 4.8 | 6.00 | ||

| F27, F28, and F29 | 20-10 | 5.6 | 8.00 | ||

| F30, F31, and F32 | 25-0 | 5.1 | |||

| F33, F34, F35, F36, and F37 | 16-15 | 4.7 | 9.00 | ||

| F38, F39, and F40 | 0-0 | 6.2 | 13.00 | ||

| F41, F42, and F43 | 0-0 | 5.6 | 14.00 | ||

| F44, F45, and F46 | 64–22H | 17-0 | 5.7 | 0.04 | |

| F47, F48, and F49 | 35-0 | 4.8 | |||

| F50 and F51 | 0-0 | 5.4 | |||

| F52, F53, and F54 | 30-0 | 5.3 | 6.00 | ||

| F55, F56, and F57 | 70–22 | 12-0 | 5.7 | 9.00 | |

| F58, F59, and F60 | 9-0 | 5.6 | 10.00 | ||

| P1, P2, and P3 | Plant | 58–28 | 0-33 | 5.2 | 0.00 |

| P4, P5, and P6 | 35-0 | 5.1 | |||

| P7, P8, and P9 | 31-0 | 5.1 | |||

| P10, P11, and P12 | 64–22H | 17-0 | 5.7 | ||

| L1, L2, L3, L4, and L5 | Lab | 58–28 | 31-0 | 5.1 | 0.00 |

| L6, L7, and L8 | 35-0 | ||||

| L9 and L10 | 46–34 | 31-0 | |||

| L11, L12, and L13 | 5.2 | ||||

| L14 and L15 | 5.5 | ||||

| L16, L17, L18, L19, L20, and L21 | 35-0 | 5.1 | |||

| L22 and L23 | 5.3 | ||||

| L24 and L25 | 5.5 |

| Rheological Parameter | Model | Goodness of Fit | Accuracy of Prediction | ||||

|---|---|---|---|---|---|---|---|

| R2 | R | Se/Sy | Mean of Residuals | STD of Residuals | RMSE | ||

| Rutting | Linear | 0.66 | 0.81 | 0.58 | 6.58 | 26.90 | 27.69 |

| RF Nonlinear | 0.84 | 0.94 | 0.40 | 3.08 | 8.03 | 8.60 | |

| Fatigue Cracking | Linear | 0.67 | 0.82 | 0.57 | 381.89 | 1599.87 | 1644.82 |

| RF Nonlinear | 0.75 | 0.86 | 0.50 | 449.27 | 936.70 | 1038.87 | |

| Block Cracking | Linear | 0.84 | 0.92 | 0.40 | 241.41 | 1542.36 | 1561.14 |

| RF Nonlinear | 0.81 | 1.00 | 0.44 | −882.72 | 2014.34 | 2199.26 | |

| Thermal Cracking | Linear | 0.89 | 0.94 | 0.34 | 0.04 | 1.58 | 1.58 |

| RF Nonlinear | 0.87 | 0.95 | 0.36 | −0.53 | 1.13 | 1.25 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deef-Allah, E.; Abdelrahman, M. Data-Driven Prediction of Binder Rheological Performance in RAP/RAS-Containing Asphalt Mixtures. Appl. Sci. 2025, 15, 6976. https://doi.org/10.3390/app15136976

Deef-Allah E, Abdelrahman M. Data-Driven Prediction of Binder Rheological Performance in RAP/RAS-Containing Asphalt Mixtures. Applied Sciences. 2025; 15(13):6976. https://doi.org/10.3390/app15136976

Chicago/Turabian StyleDeef-Allah, Eslam, and Magdy Abdelrahman. 2025. "Data-Driven Prediction of Binder Rheological Performance in RAP/RAS-Containing Asphalt Mixtures" Applied Sciences 15, no. 13: 6976. https://doi.org/10.3390/app15136976

APA StyleDeef-Allah, E., & Abdelrahman, M. (2025). Data-Driven Prediction of Binder Rheological Performance in RAP/RAS-Containing Asphalt Mixtures. Applied Sciences, 15(13), 6976. https://doi.org/10.3390/app15136976