Surface Quality of CNC Face-Milled Maple (Acer pseudoplatanus) and Oak (Quercus robur) Using Two End-Mill Tool Types and Varying Processing Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Samples

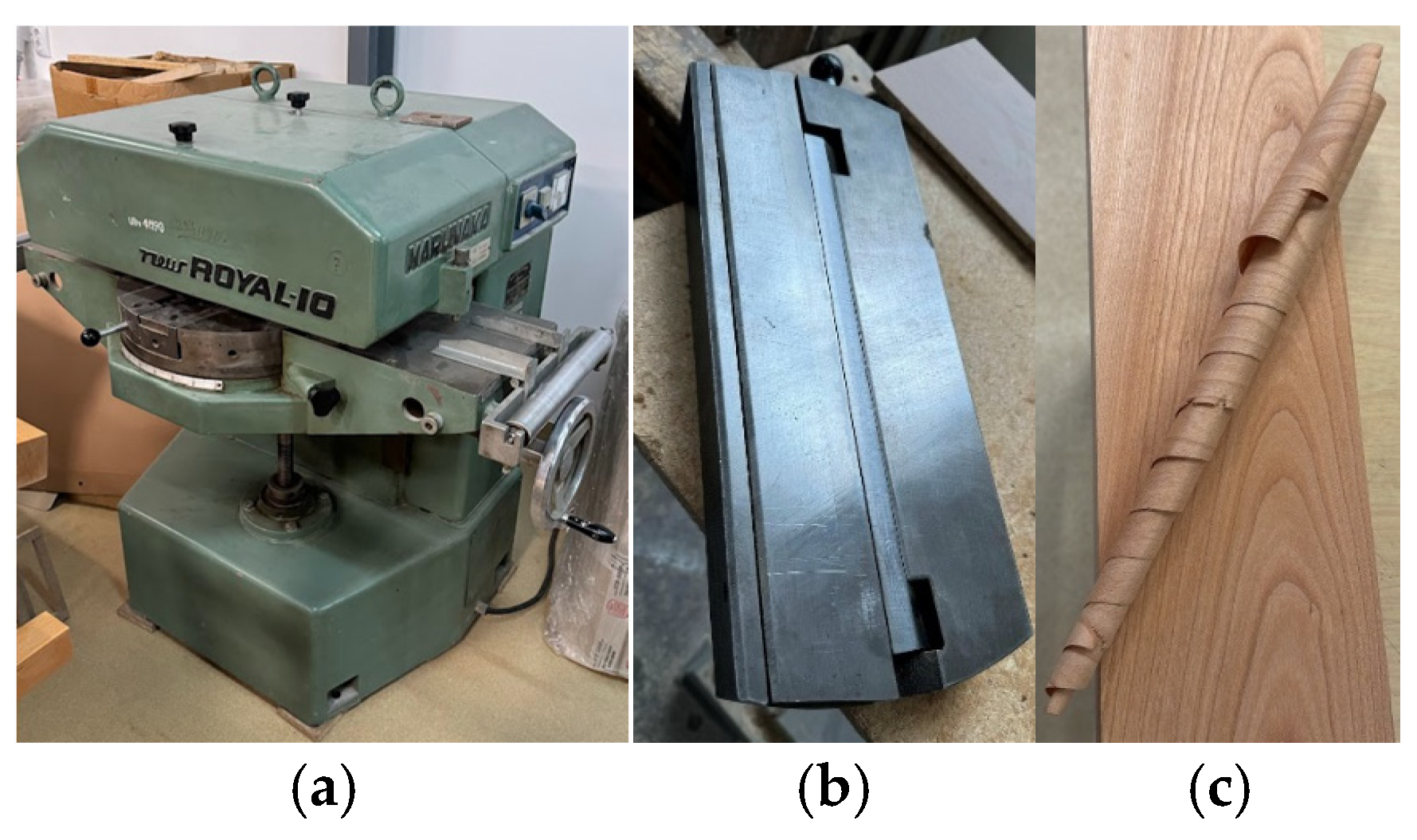

2.2. Processing by CNC

2.3. Processing by Super Surfacing (Shaving Operation)

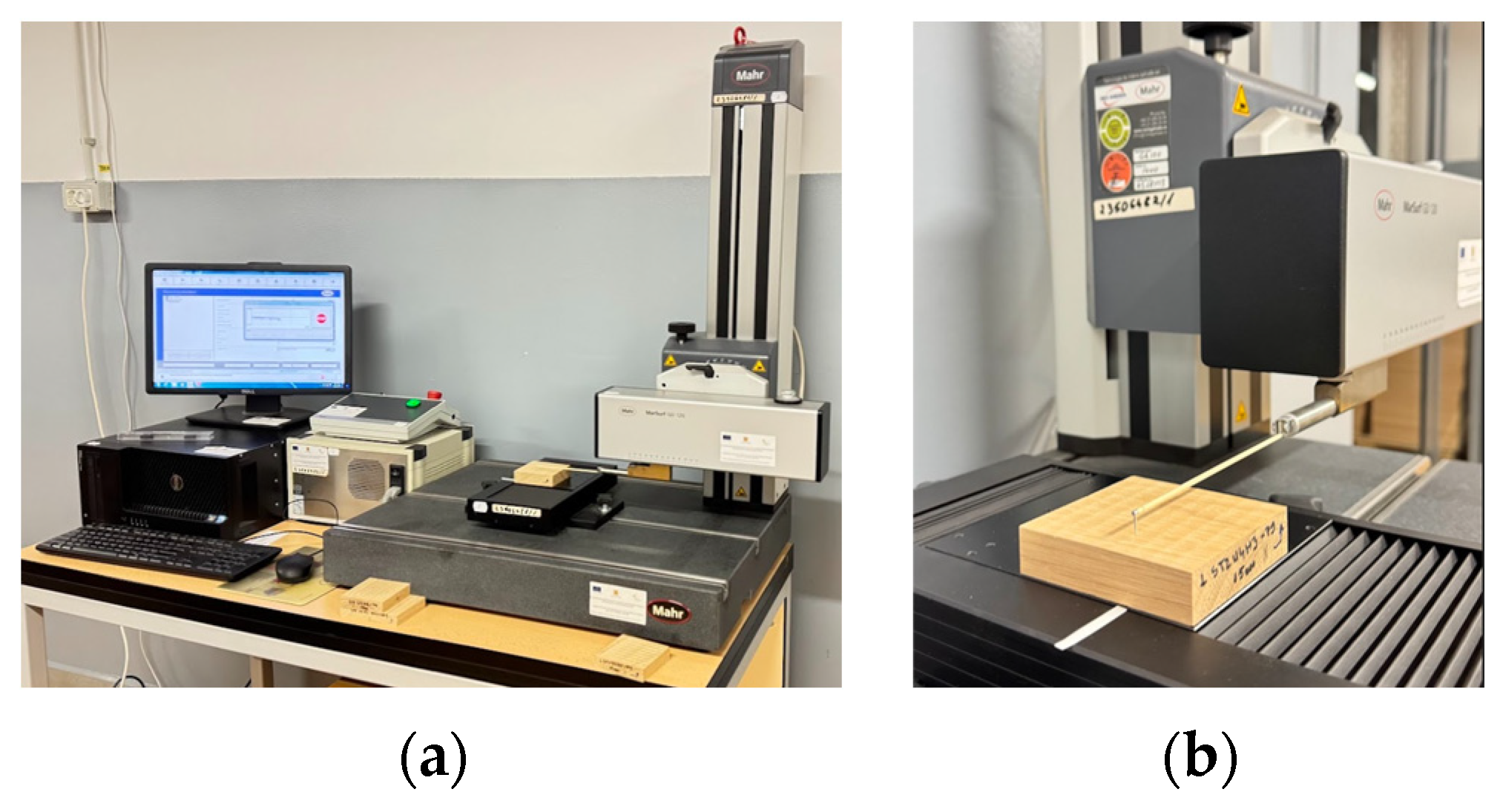

2.4. Surface Quality Measurements

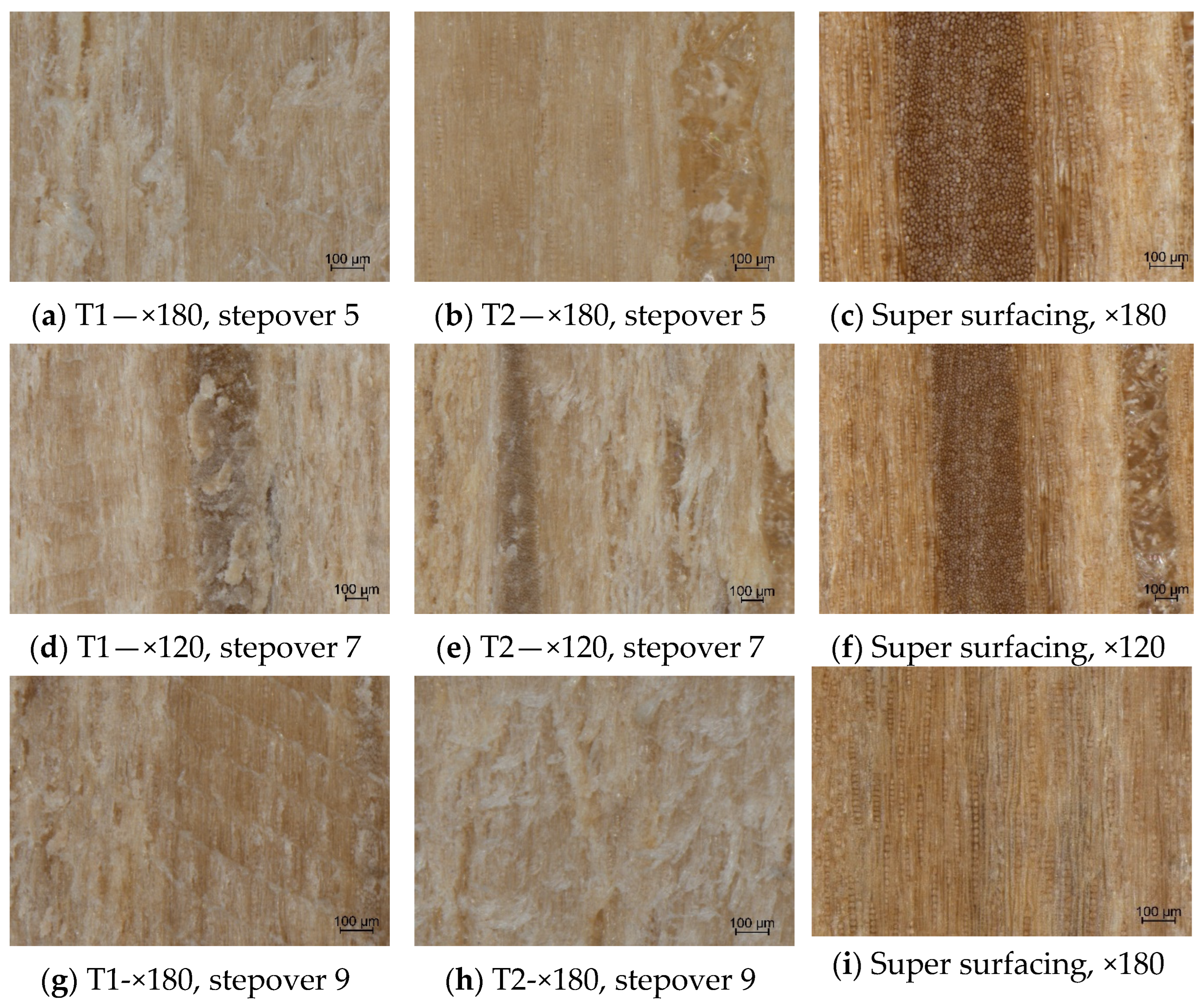

2.5. Stereomicroscopy Analysis

3. Results

3.1. Quality Evaluation of the Shaved Surfaces

3.2. Quality Evaluation of the CNC Milled Surfaces

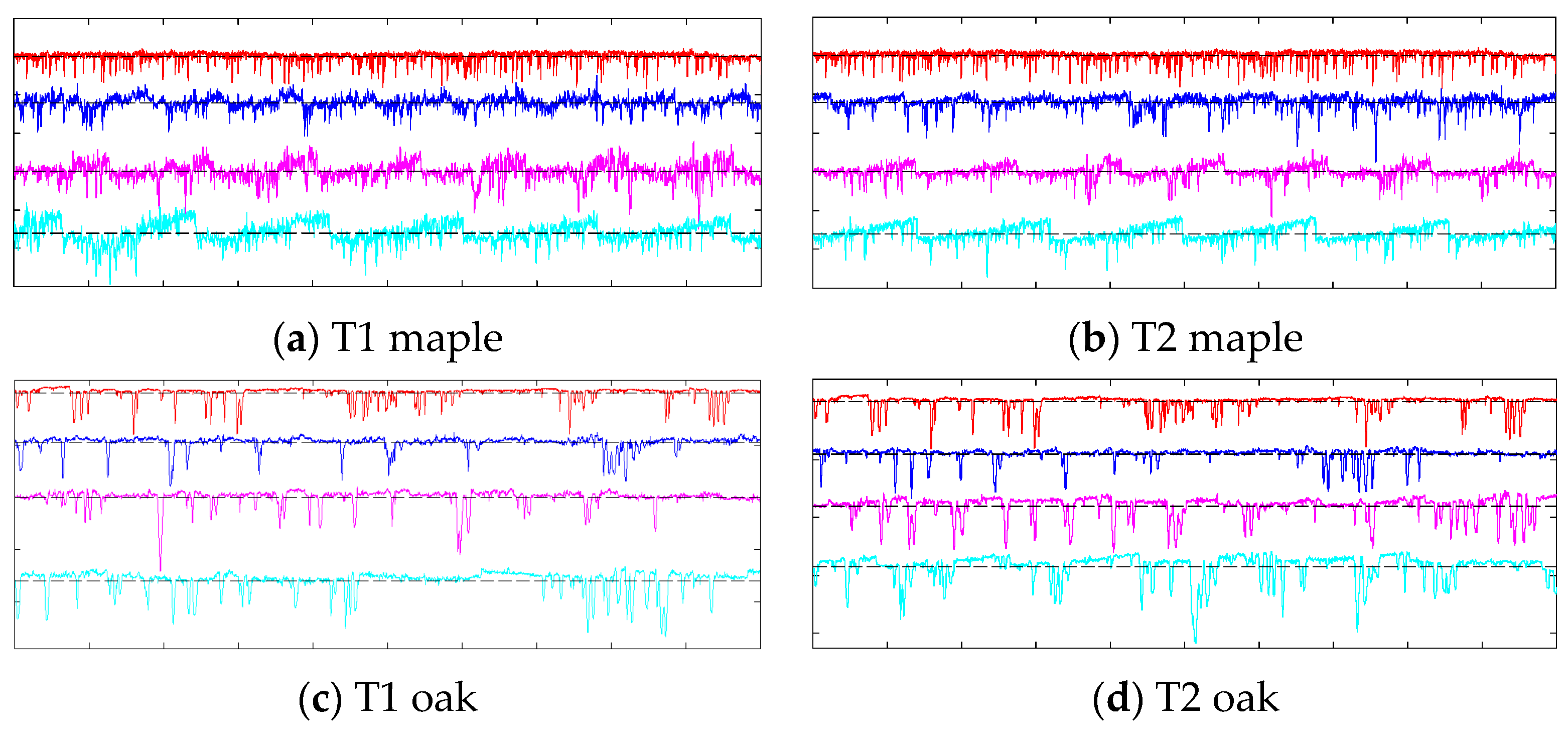

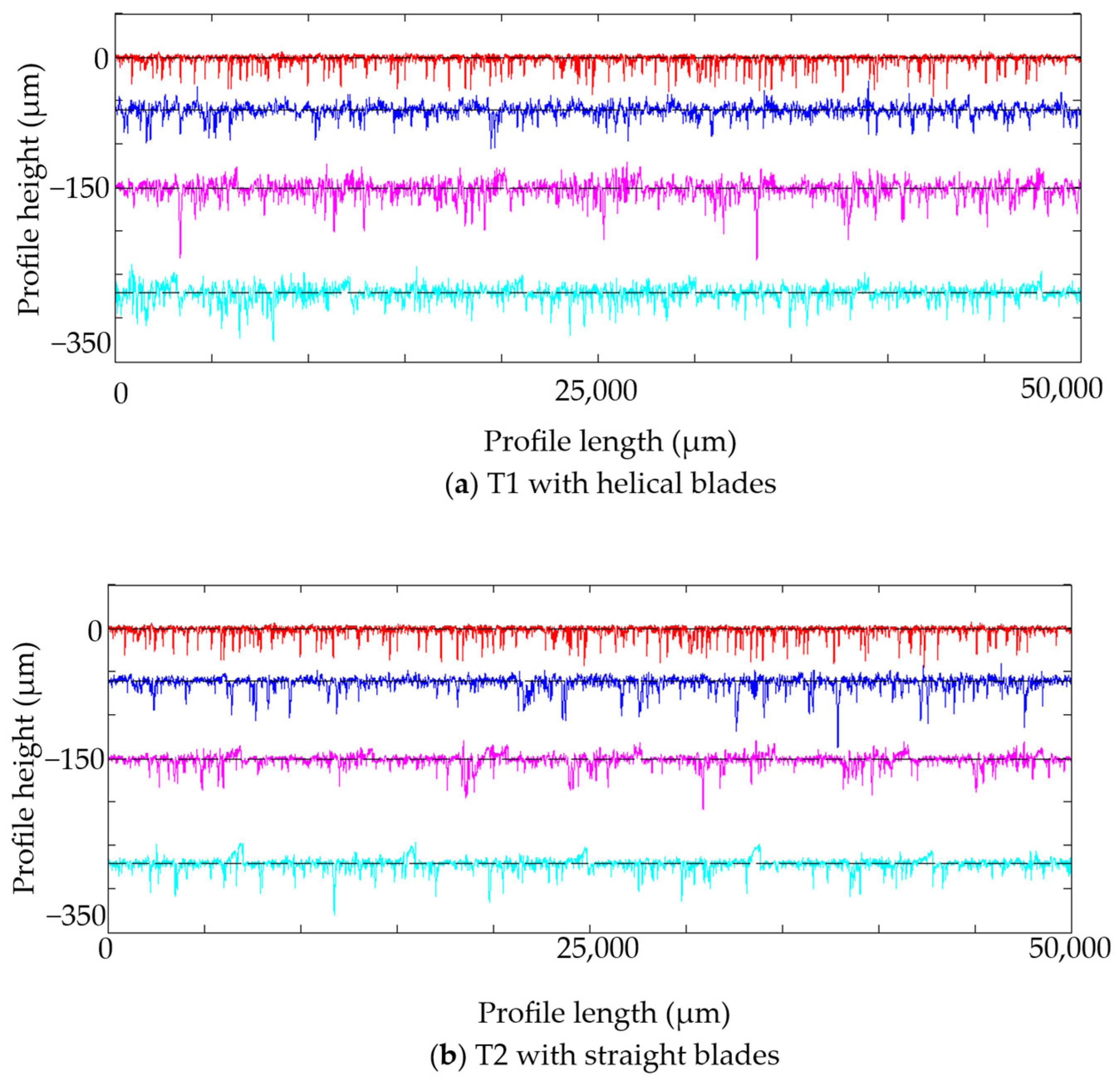

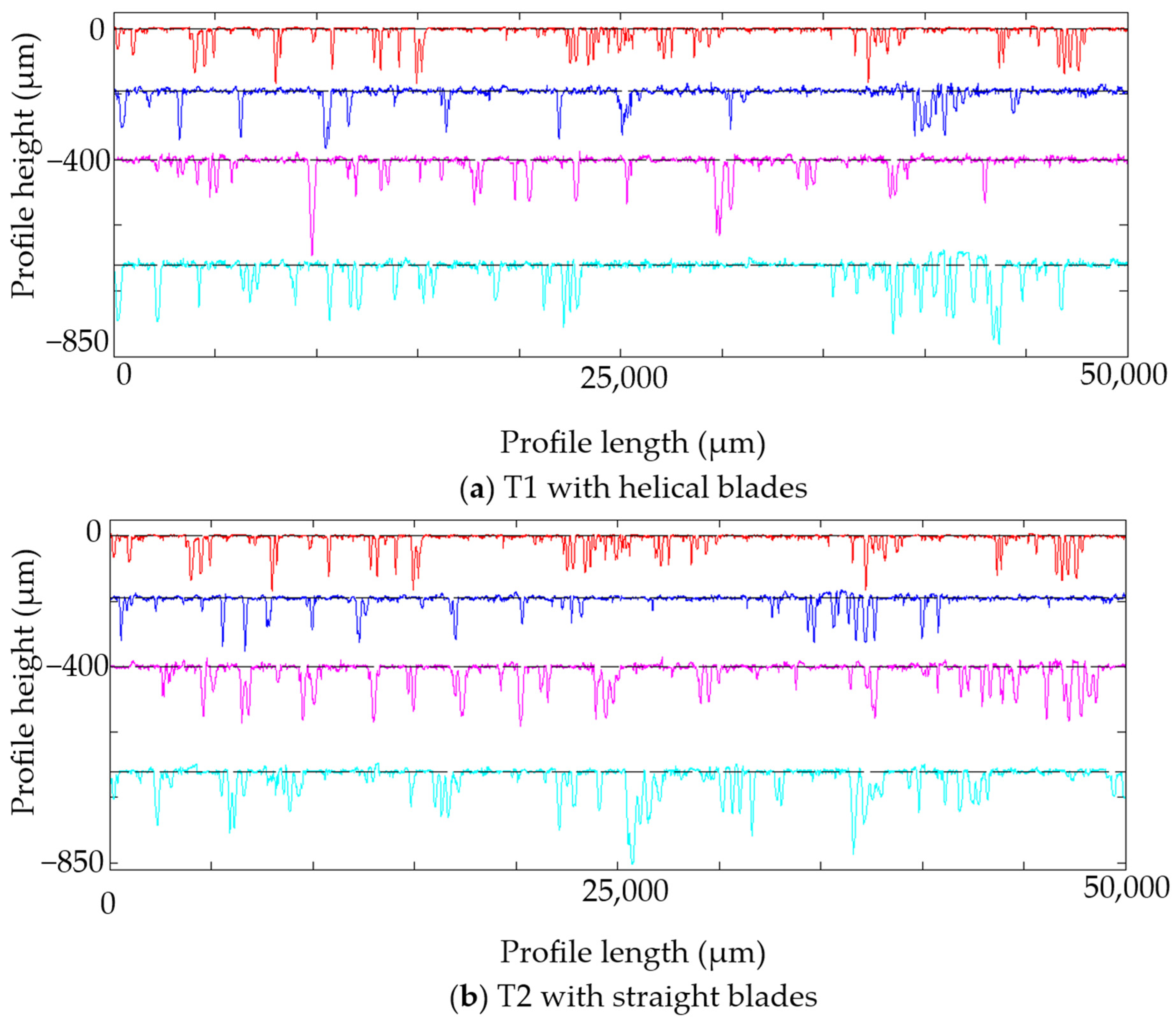

3.2.1. Analysis of the Primary Profiles

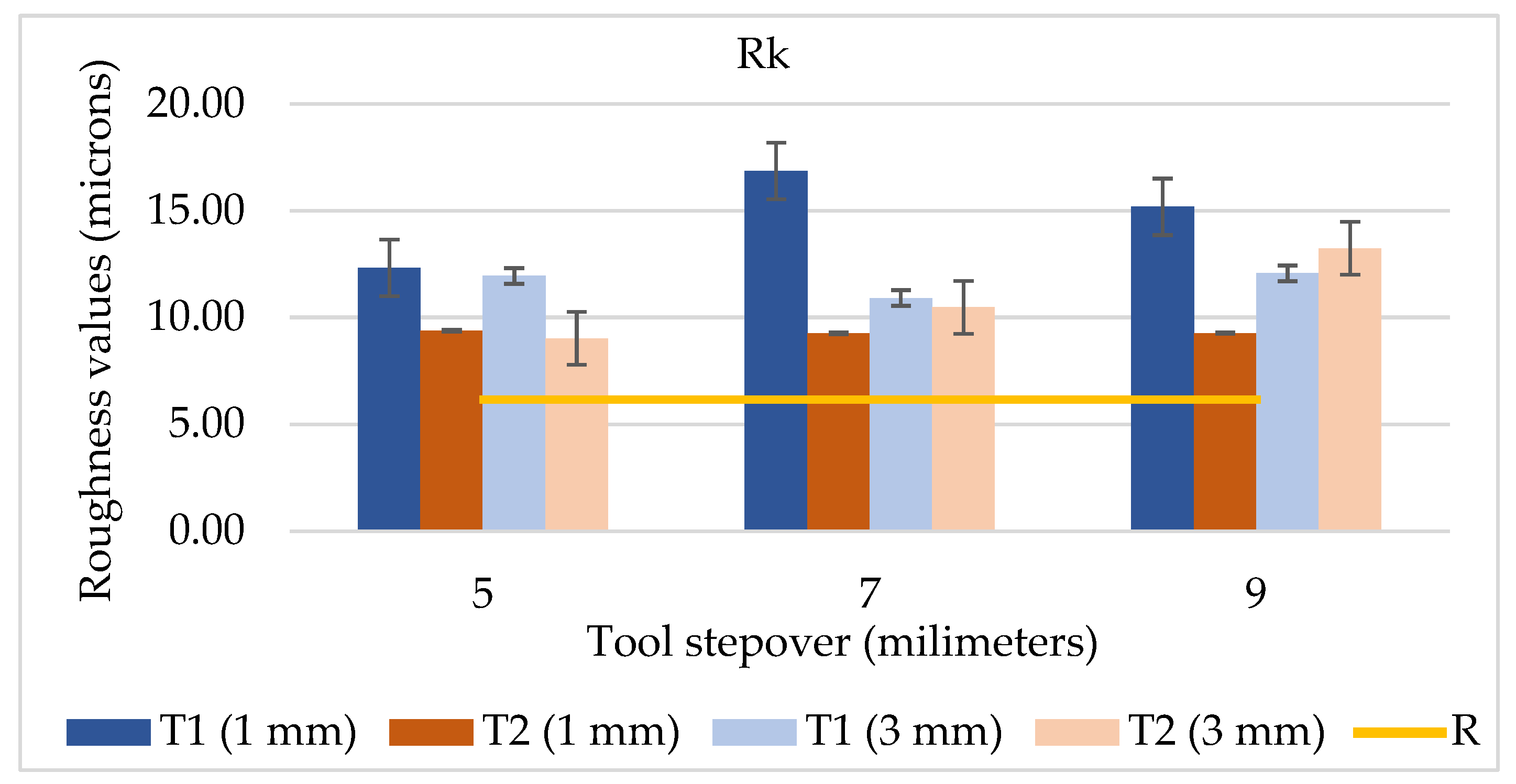

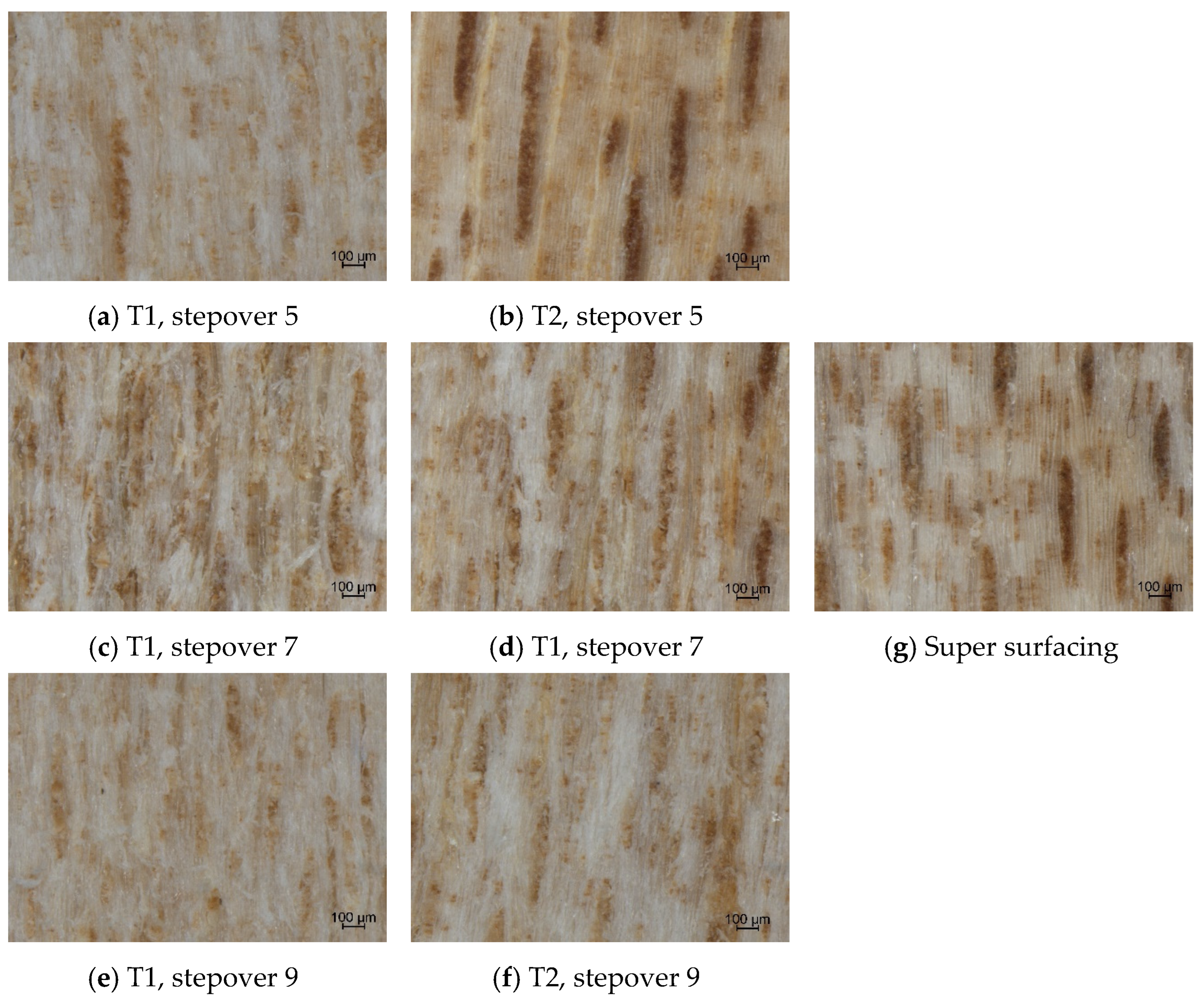

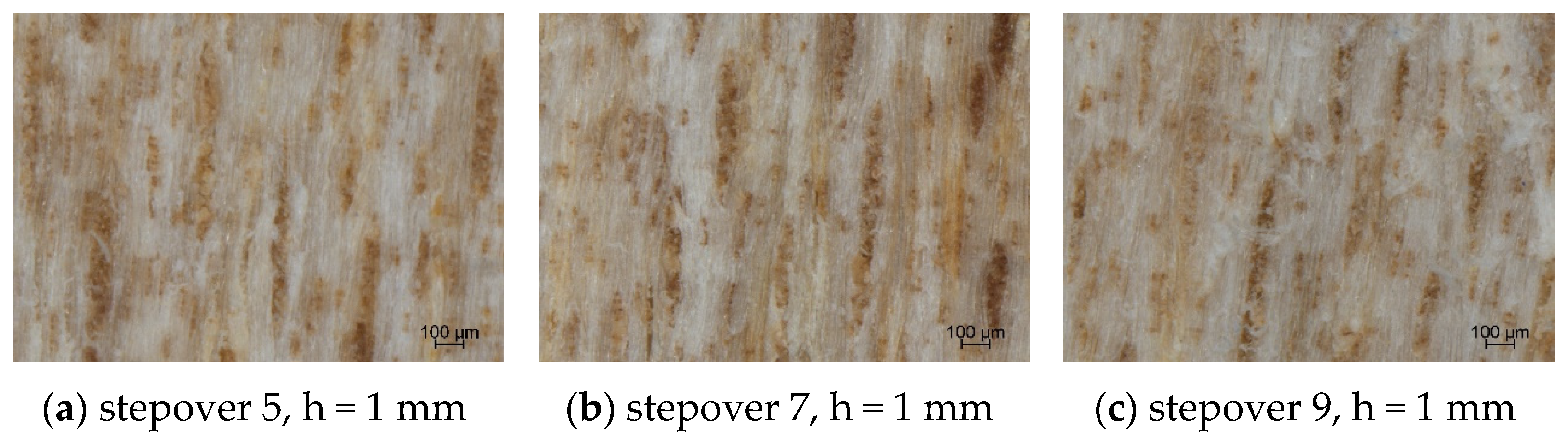

3.2.2. Surface Roughness and Stereomicroscopy Analysis of CNC-Processed Maple

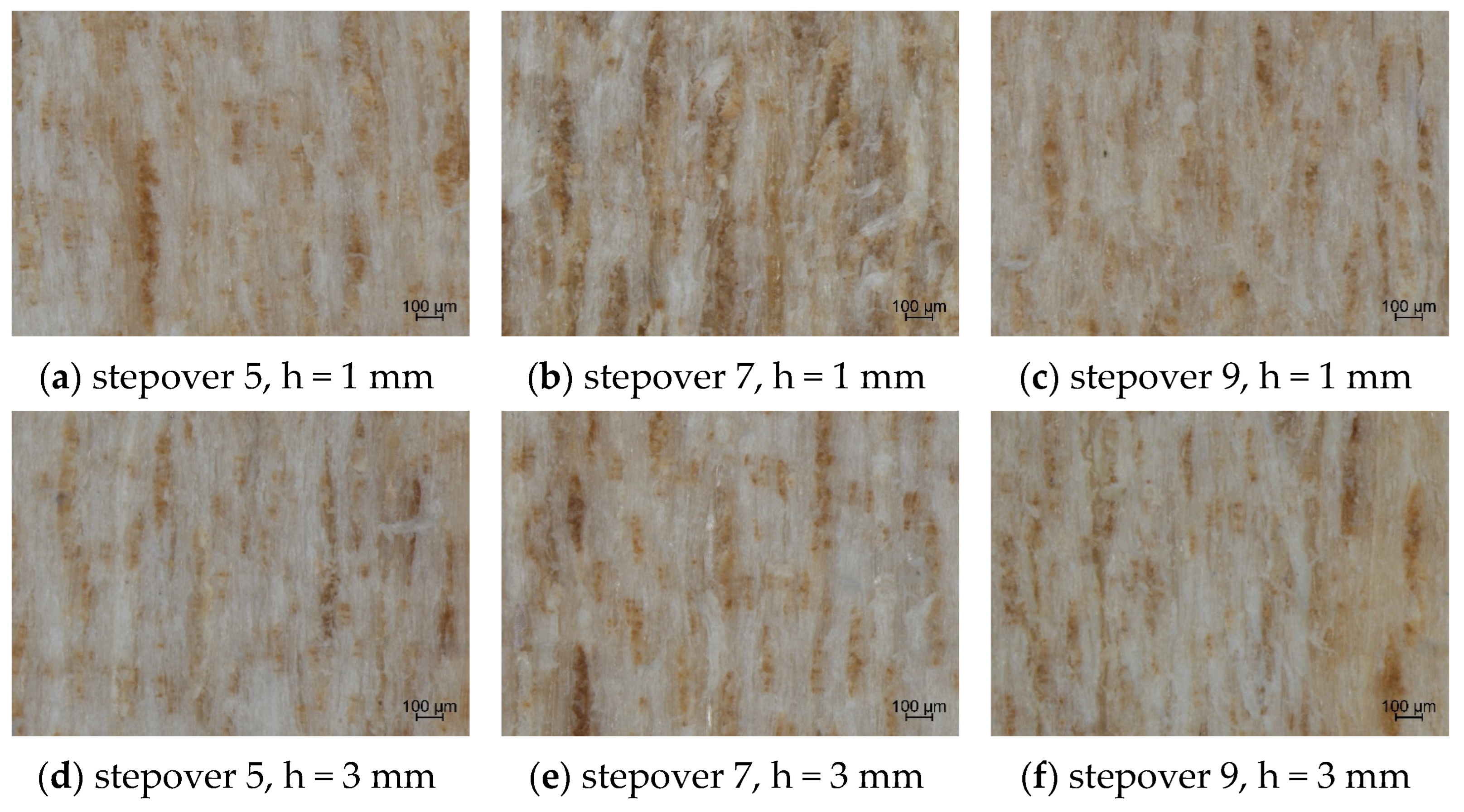

3.2.3. Surface Roughness and Stereomicroscopy Analysis for CNC-Processed Oak

3.2.4. Influence of Wood Anatomy on Surface Roughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Moura, L.F.; Cool, J.; Hernández, R.E. Anatomical Evaluation of Wood Surfaces Produced by Oblique Cutting and Face Milling. IAWA J. 2010, 31, 77–88. [Google Scholar] [CrossRef]

- Hernández, R.E.; Cool, J. Effects of Cutting Parameters on Surface Quality of Paper Birch Wood Machined across the Grain with Two Planing Techniques. Holz Roh Werkst. 2008, 66, 147–154. [Google Scholar] [CrossRef]

- Aras, O.; Sofuoğlu, S.D. Analyze the Effects of CNC Machining Parameters on the Surface Roughness (Rz) of Anatolian Chestnut. Ağaç ve Orman 2024, 5, 42–50. [Google Scholar] [CrossRef]

- Yaghoubi, S.; Rabiei, F. A Profound Evaluation of Different Strategies to Improve Surface Roughness of Manufactured Part in Wood-CNC Machining Process. J. Eng. Res. 2024; in press. [Google Scholar] [CrossRef]

- Kilic, M.; Hiziroglu, S.; Burdurlu, E. Effect of Machining on Surface Roughness of Wood. Build. Environ. 2006, 41, 1074–1078. [Google Scholar] [CrossRef]

- Dündar Sofuoğlu, S.; Kurtoğlu, A. Effects of Machining Conditions on Surface Roughness in Planing and Sanding of Solid Wood. Drv. Ind. 2015, 66, 265–272. [Google Scholar] [CrossRef]

- Jankowska, A. Understanding of Surface Roughness of Wood Based on Analysis Its Structure Anddensity. Ann. WULS-SGGW. For. Wood Technol. 2020, 111, 27–31. [Google Scholar] [CrossRef]

- Rawangwong, S.; Chatthong, J.; Rodjananugoon, J.; Boonchouytan, W. A Study of Proper Conditions in Face Milling Palmyra Palm Wood by Computer Numerical Controlled Milling Machine. Silpakorn Univ. Sci. Technol. J. 2011, 5, 33–39. [Google Scholar] [CrossRef]

- Smajic, S.; Jovanovic, J. Influence of Different Machining on the Roughness of Oak Wood. FWIAFE 2021, 14, 101–108. [Google Scholar] [CrossRef]

- Hänsel, A.; Tröger, J.; Rößler, M.; Brachhold, N.; Niemz, P. Influence of Surface Treatment on the Bonding Quality of Wood for Load-Bearing Purposes. Wood Mater. Sci. Eng. 2023, 18, 2128–2139. [Google Scholar] [CrossRef]

- Kläusler, O.; Hass, P.; Amen, C.; Schlegel, S.; Niemz, P. Improvement of Tensile Shear Strength and Wood Failure Percentage of 1C PUR Bonded Wooden Joints at Wet Stage by Means of DMF Priming. Eur. J. Wood Prod. 2014, 72, 343–354. [Google Scholar] [CrossRef]

- Stewart, H.A. Result Force and Surface Quality from Some Facemilling Variables. For. Prod. J. 1984, 19, 21–24. [Google Scholar]

- Su, W.-C.; Wang, Y. Effect of the Helix Angle of Router Bits on Chip Formation and Energy Consumption during Milling of Solid Wood. J. Wood Sci. 2002, 48, 126–131. [Google Scholar] [CrossRef]

- Salcă, E. Contribuții La Optimizarea Prelucrării Lemnului de Arin Prin Frezare și Șlefuire în Vederea Valorificarii în Producție de Mobilă; Universitatea Transilvania din Brașov: Brasov, Romania, 2008. [Google Scholar]

- Doichinov, A. Optimization of the Cnc Milling Process Via Modifying Some Parameters of the Cutting Mode when Processing Mdf Workpieces. Acta Fac. Xylologiae Zvolen 2023, 65, 99–108. [Google Scholar] [CrossRef]

- Pinkowski, G.; Szymański, W.; Nosowski, T. Analyses of Surface Roughness in Selected Wood Species after Machining on a CNC Woodworking Centre. Ann. Wars. Univ. Life Sci.-SGGW For. Wood Technol. 2012, 79, 164–169. [Google Scholar]

- Deus, P.R.; Alves, M.C.S.; Vieira, F.H.A.; Bilesky, L.R. Analysis of the Cutting Parameters in Front Milling for Medium Density Fiberboard. BioResources 2018, 13, 3404–3410. [Google Scholar] [CrossRef]

- Deus, P.R.; Alves, M.C.D.S.; Vieira, F.H.A. The Quality of MDF Workpieces Machined in CNC Milling Machine in Cutting Speeds, Feedrate, and Depth of Cut. Meccanica 2015, 50, 2899–2906. [Google Scholar] [CrossRef]

- Keturakis, G.; Bendikiene, R.; Baltrusaitis, A. Tool Wear Evolution and Surface Formation in Milling Various Wood Species. BioResources 2017, 12, 7943–7954. [Google Scholar] [CrossRef]

- İşleyen, Ü.K.; Karamanoğlu, M. The Influence of Machining Parameters on Surface Roughness of MDF in Milling Operation. BioResources 2019, 14, 3266–3277. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- ISO 16610-31:2016; Geometrical Product Specifications (GPS)—Filtration Part 31: Robust Profile Filters: Gaussian Regression Filters. ISO: Geneva, Switzerland, 2016.

- Gurău, L. The Roughness of Sanded Wood Surfaces. Ph.D. Thesis, Forest Products Research Centre, Buckinghamshire Chilterns University College, High Wycombe, UK, 2004. [Google Scholar]

- Tan, P.L.; Sharif, S.; Sudin, I. Roughness Models for Sanded Wood Surfaces. Wood Sci. Technol. 2012, 46, 129–142. [Google Scholar] [CrossRef]

- Gurău, L.; Irle, M. Surface Roughness Evaluation Methods for Wood Products: A Review. Curr. For. Rep. 2017, 3, 119–131. [Google Scholar] [CrossRef]

- Magoss, E. General Regularities of Wood Surface Roughness. Acta Silv. Lignaria Hung. 2008, 4, 81–93. [Google Scholar] [CrossRef]

- Gurău, L.; Coşereanu, C.; Paiu, I. Comparative Surface Quality of Larch (Larix decidua Mill.) Fretwork Patterns Cut through by CNC Routing and by Laser. Appl. Sci. 2021, 11, 6875. [Google Scholar] [CrossRef]

- Iskra, P.; Hernández, R. The Influence of Cutting Parameters on the Surface Quality of Routed Paper Birch and Surface Roughness Prediction Modeling. Wood Fiber Sci. 2009, 41, 28–37. [Google Scholar]

- Aykaç, E.; Sofuoglu, S.D. Investigation of the Effect of Machining Parameters on Surface Quality in Bamboo. Teh. Vjesn. 2021, 28, 684–688. [Google Scholar] [CrossRef]

- Piernik, M.; Pinkowski, G.; Krauss, A. Effect of Chip Thickness, Wood Cross-Sections, and Cutting Speed on Surface Roughness and Cutting Power during up-Milling of Beech Wood. BioResources 2023, 18, 6784–6801. [Google Scholar] [CrossRef]

- Kudela, J.; Mrenica, L.; Javorek, L. The Influence of Milling and Sanding on Wood Surface Morphology. Acta Fac. Xylologiae Zvolen 2018, 60, 71–83. [Google Scholar] [CrossRef]

- Sütçü, A. Investigation of Parameters Affecting Surface Roughness in CNC Routing Operation on Wooden EGP. BioResources 2012, 8, 795–805. [Google Scholar] [CrossRef]

- Wagenführ, R. Holzatlas; 5., erg. und erw. Aufl.; Fachbuchverl. im Hanser Verl: Leipzig, Germany, 2000; ISBN 978-3-446-21390-6. [Google Scholar]

- Thoma, H.; Peri, L.; Lato, E. Evaluation of Wood Surface Roughness Depending on Species Characteristics. Maderas Cienc. Tecnol. 2015, 17, 285–292. [Google Scholar] [CrossRef]

- Sütçü, A.; Karagöz, Ü. The Influence of Process Parameters on the Surface Roughness in Aesthetic Machining of Wooden Edge-Glued Panels (EGPs). BioResources 2013, 8, 5435–5448. [Google Scholar] [CrossRef]

- Laina, R.; Sanz-Lobera, A.; Villasante, A.; López-Espí, P.; Martínez-Rojas, J.A.; Alpuente, J.; Sánchez-Montero, R.; Vignote, S. Effect of the Anatomical Structure, Wood Properties and Machining Conditions on Surface Roughness of Wood. Maderas Cienc. Tecnol. 2017, 19, 203–212. [Google Scholar] [CrossRef][Green Version]

- Vančo, M.; Korčok, M.; Barcík, Š.; Koleda, P.; Gochev, Z.B. Analysis of Factors Effecting on Qualitative Parameters of Surface When Planar Milling Heat–Treated Oak Wood. Innov. Woodwork. Ind. Eng. Des. 2020, 18, 15–28. [Google Scholar]

- Pelit, H.; Korkmaz, M.; Budakçı, M. Surface Roughness of Thermally Treated Wood Cut with Different Parameters in CNC Router Machine. BioResources 2021, 16, 5133–5147. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Rotation speed | 15,000 rpm (constant) |

| Feed speed | 4 m/min (constant) |

| Depth of cut | 1 and 3 mm |

| Stepover | 5 mm, 7 mm, and 9 mm |

| Tool characteristics | T1: D = 10 mm, Z = 2 (helical), L = 70 mm, active L = 25 mm |

| T2: D = 10 mm, Z = 2 (straight), L = 70 mm, active L = 23 mm |

| Reference Surface | Ra | Rk | Rpk | Rvk | Rk + Rpk | Rv |

|---|---|---|---|---|---|---|

| Maple | 3.83 (0.11) | 6.16 (0.21) | 1.27 (0.09) | 16.21 (0.64) | 7.43 (0.66) | 45.79 (3.19) |

| Oak | 9.96 (1.83) | 6.46 (0.62) | 2.37 (1.44) | 63.36 (10.80) | 8.83 (11.75) | 165.04 (8.98) |

| Roughness Parameter | Cutting Depth | T1 (5) | T1 (7) | T1 (9) | T2 (5) | T2 (7) | T2 (9) | R | |

|---|---|---|---|---|---|---|---|---|---|

| Ra | 1 | mean | 4.66 | 6.99 | 5.84 | 4.68 | 4.50 | 4.65 | 3.83 |

| ST. DEV | 0.31 | 0.27 | 0.28 | 0.21 | 0.13 | 0.36 | 0.11 | ||

| 3 | mean | 4.51 | 4.25 | 4.83 | 4.03 | 5.72 | 6.55 | 3.83 | |

| ST. DEV | 0.13 | 0.17 | 0.52 | 0.07 | 0.51 | 0.40 | 0.11 | ||

| Rk | 1 | mean | 12.32 | 16.86 | 15.19 | 9.39 | 9.26 | 9.27 | 6.16 |

| ST. DEV | 0.87 | 1.36 | 0.36 | 0.39 | 0.61 | 1.03 | 0.21 | ||

| 3 | mean | 11.95 | 10.92 | 12.08 | 9.03 | 10.48 | 13.24 | 6.16 | |

| ST. DEV | 0.41 | 0.59 | 1.13 | 0.45 | 0.42 | 1.25 | 0.21 | ||

| Rpk | 1 | mean | 5.82 | 8.51 | 7.42 | 4.05 | 5.86 | 9.61 | 1.27 |

| ST. DEV | 0.34 | 0.74 | 0.49 | 0.46 | 0.38 | 0.87 | 0.09 | ||

| 3 | mean | 5.96 | 6.03 | 7.07 | 3.66 | 7.17 | 7.04 | 1.27 | |

| ST. DEV | 0.62 | 0.80 | 0.81 | 0.21 | 0.52 | 1.19 | 0.09 | ||

| Rvk | 1 | mean | 13.08 | 20.59 | 24.33 | 18.74 | 16.06 | 15.65 | 16.21 |

| ST. DEV | 2.02 | 1.40 | 2.60 | 1.33 | 0.24 | 1.44 | 0.64 | ||

| 3 | mean | 12.14 | 11.52 | 14.02 | 14.92 | 21.99 | 23.85 | 16.21 | |

| ST. DEV | 0.89 | 0.99 | 2.66 | 1.37 | 2.32 | 2.13 | 0.64 | ||

| Rk + Rpk | 1 | mean | 18.14 | 25.38 | 22.61 | 13.43 | 15.12 | 18.89 | 7.42 |

| ST. DEV | 0.76 | 1.10 | 0.70 | 0.67 | 0.26 | 0.76 | 0.66 | ||

| 3 | mean | 17.91 | 16.95 | 19.15 | 12.69 | 17.65 | 20.28 | 7.42 | |

| ST. DEV | 0.08 | 1.39 | 1.72 | 0.47 | 0.74 | 2.27 | 0.66 | ||

| Rv | 1 | mean | 59.52 | 74.27 | 57.27 | 69.77 | 63.23 | 56.09 | 45.79 |

| ST. DEV | 19.44 | 10.12 | 2.77 | 11.60 | 7.14 | 3.30 | 3.19 | ||

| 3 | mean | 50.93 | 43.71 | 56.97 | 57.30 | 66.50 | 76.74 | 45.79 | |

| ST. DEV | 8.21 | 3.11 | 22.99 | 11.60 | 4.36 | 6.83 | 3.19 |

| ANOVA | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | SS | df | MS | F | p-Value | F crit |

| Rows | 0.062338 | 3 | 0.020779 | 0.055278 | 0.981819336 | 3.8625484 |

| Columns | 32.53002 | 3 | 10.84334 | 28.84625 | 6.00666 × 10−5 | 3.8625484 |

| Error | 3.383111 | 9 | 0.375901 | |||

| Total | 35.97547 | 15 |

| Roughness Parameter | Cutting Depth | T1 (5) | T1 (7) | T1 (9) | T2 (5) | T2 (7) | T2 (9) | R | |

|---|---|---|---|---|---|---|---|---|---|

| Ra | 1 | mean | 10.01 | 15.21 | 15.97 | 8.50 | 19.06 | 22.47 | 9.96 |

| ST. DEV | 1.10 | 1.56 | 3.90 | 1.47 | 1.52 | 1.80 | 1.83 | ||

| 3 | mean | 12.04 | 18.04 | 17.95 | 16.18 | 19.65 | 21.19 | 9.96 | |

| ST. DEV | 3.95 | 184.00 | 2.36 | 1.49 | 3.76 | 3.12 | 1.83 | ||

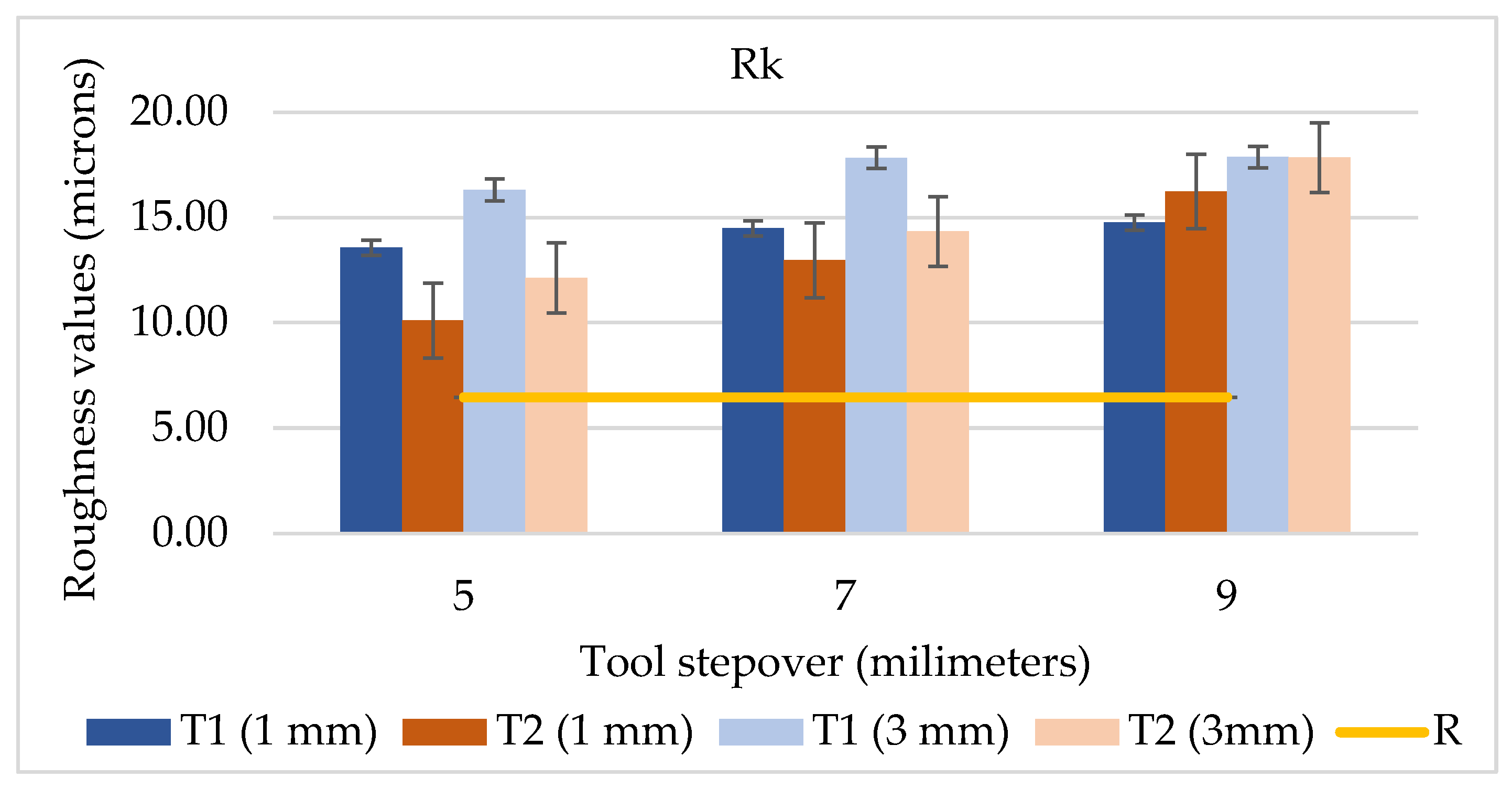

| Rk | 1 | mean | 13.57 | 14.49 | 14.76 | 10.10 | 12.97 | 16.23 | 6.46 |

| ST. DEV | 0.29 | 0.82 | 1.40 | 0.72 | 1.17 | 2.14 | 0.62 | ||

| 3 | mean | 16.31 | 17.83 | 17.86 | 12.14 | 14.33 | 17.85 | 6.46 | |

| ST. DEV | 2.70 | 0.99 | 0.87 | 0.72 | 0.97 | 2.04 | 0.62 | ||

| Rpk | 1 | mean | 9.17 | 7.49 | 11.20 | 5.50 | 9.39 | 18.14 | 2.37 |

| ST. DEV | 0.89 | 1.10 | 3.46 | 0.31 | 2.76 | 9.25 | 1.44 | ||

| 3 | mean | 9.01 | 9.45 | 8.95 | 6.60 | 13.27 | 6.95 | 2.37 | |

| ST. DEV | 1.18 | 1.42 | 0.92 | 0.79 | 9.37 | 0.85 | 1.44 | ||

| Rvk | 1 | mean | 61.52 | 96.06 | 101.85 | 64.10 | 102.77 | 108.58 | 63.36 |

| ST. DEV | 10.94 | 8.25 | 16.95 | 11.17 | 5.24 | 6.40 | 10.80 | ||

| 3 | mean | 65.02 | 91.68 | 92.10 | 103.53 | 106.91 | 104.17 | 63.36 | |

| ST. DEV | 22.99 | 10.05 | 9.83 | 7.12 | 17.37 | 5.40 | 10.80 | ||

| Rk + Rpk | 1 | mean | 22.74 | 21.98 | 25.96 | 15.61 | 22.35 | 34.37 | 8.83 |

| ST. DEV | 0.93 | 1.68 | 3.86 | 0.58 | 2.60 | 9.45 | 1.90 | ||

| 3 | mean | 25.32 | 27.29 | 26.82 | 18.74 | 27.60 | 24.80 | 8.83 | |

| ST. DEV | 3.04 | 1.88 | 0.78 | 1.30 | 10.02 | 1.78 | 1.90 | ||

| Rv | 1 | mean | 172.50 | 252.21 | 203.70 | 173.00 | 219.93 | 264.37 | 165.04 |

| ST. DEV | 12.22 | 33.74 | 245.71 | 8.16 | 22.54 | 25.39 | 8.98 | ||

| 3 | mean | 171.69 | 196.71 | 191.80 | 219.15 | 225.89 | 238.48 | 165.04 | |

| ST. DEV | 21.31 | 8.16 | 8.25 | 20.69 | 25.85 | 17.13 | 8.98 |

| ANOVA | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | SS | df | MS | F | p-Value | F crit |

| Rows | 4.826416 | 3 | 1.608805 | 0.70846801 | 0.5708396 | 3.862548 |

| Columns | 81.74111 | 3 | 27.24704 | 11.99875198 | 0.0016932 | 3.862548 |

| Error | 20.4374 | 9 | 2.270823 | |||

| Total | 107.0049 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angelescu, A.-M.; Gurau, L.; Ispas, M. Surface Quality of CNC Face-Milled Maple (Acer pseudoplatanus) and Oak (Quercus robur) Using Two End-Mill Tool Types and Varying Processing Parameters. Appl. Sci. 2025, 15, 6975. https://doi.org/10.3390/app15136975

Angelescu A-M, Gurau L, Ispas M. Surface Quality of CNC Face-Milled Maple (Acer pseudoplatanus) and Oak (Quercus robur) Using Two End-Mill Tool Types and Varying Processing Parameters. Applied Sciences. 2025; 15(13):6975. https://doi.org/10.3390/app15136975

Chicago/Turabian StyleAngelescu, Ana-Maria, Lidia Gurau, and Mihai Ispas. 2025. "Surface Quality of CNC Face-Milled Maple (Acer pseudoplatanus) and Oak (Quercus robur) Using Two End-Mill Tool Types and Varying Processing Parameters" Applied Sciences 15, no. 13: 6975. https://doi.org/10.3390/app15136975

APA StyleAngelescu, A.-M., Gurau, L., & Ispas, M. (2025). Surface Quality of CNC Face-Milled Maple (Acer pseudoplatanus) and Oak (Quercus robur) Using Two End-Mill Tool Types and Varying Processing Parameters. Applied Sciences, 15(13), 6975. https://doi.org/10.3390/app15136975