Abstract

Concrete and other cementitious materials are among the most widely used construction materials worldwide. However, their high embodied carbon emissions and energy-intensive manufacturing processes pose significant environmental challenges. This study assesses the carbon emissions, cost implications, and circularity potential of a novel concrete mix, Tex-crete, which incorporates recycled textile and cardboard fibres as sustainable alternatives to conventional reinforcement and cementitious materials in concrete. The study employs a cradle-to-gate life cycle assessment (LCA) approach to compare carbon emissions and costs across different mix designs, using two case studies: a temporary construction site compound and a footpath. Experimental results indicate that Tex-crete, particularly the KFT mix design (including 2.5% textile fibres with treated kraft fibres), achieves comparable compressive and tensile strength to traditional concrete while demonstrating a net reduction in both carbon emissions (3.38%) and production costs (2.56%). A newly introduced circularity index (CI) further evaluated the reuse, repair, and recycling potential of the novel mix, revealing that KFT exhibits the highest circularity score (0.44). Parametric analysis using Monte Carlo simulations highlighted transportation distance and energy consumption during fibre processing as key factors influencing emissions. The findings provide valuable insights for industry stakeholders seeking sustainable concrete solutions aligned with circular economy principles, offering an optimized balance between environmental performance, structural integrity, and cost-effectiveness.

1. Introduction

Products containing cementitious material including concrete and mortar are some of the most widely used materials in the global building construction industry [1]. Previous studies have discussed methods for the calculation of the primary energy and associated emissions in concrete and other cementitious products [2,3,4]. However, these studies often highlight inconsistencies in outputs due to lack of transparency, unavailability of local inventory data, differences in scope, assumptions, and system boundaries. Therefore, there has been limited adoption and application by decision makers and design engineers to compare the primary energy requirements and environmental impacts of different construction-related processes and products. Most variations observed in comparative studies have been shown to arise from differences in assumptions, system boundaries of assessment, and a lack of accurate input data [5].

Concrete, despite traditionally having high compressive strength characteristics, performs poorly under tensile forces and is highly energy intensive during the virgin material extraction [2]. Supplementary cementitious materials have been extensively researched across the globe in cement composites to replace virgin material extractions, mainly due to the recent sustainability advancements and drive towards greener applications. Replacing cement and steel from reinforced concrete is one of the most effective ways to reduce the embodied carbon emissions from construction materials [6]. Reinforcing the concrete mix with randomly distributed short fibre reinforcements (most typically steel, glass, or synthetic) can enhance the tensile strength of the matrix [7,8,9]. These fibres can be extracted from virgin sources that are extremely resource and energy intensive to manufacture, which, in turn, causes high pollution and carbon dioxide emission. Moreover, several cement replacement materials have been extensively researched in previous studies with highly satisfactory laboratory results [10,11]. However, the majority of the studies have focused only on laboratory scale development with limited comparative studies on industry implementations. This lack of studies and analyses often restricts the comparison options and decision making towards commercialization of the innovative products. Moreover, the majority of these studies have focused only on the recycling stage while neglecting the other “R” stages of the circular economy concept, which limits holistic comparison options [12].

Life cycle assessment (LCA) is a tool that allows architects and other building construction professionals to understand the energy use and other environmental impacts associated with all life cycle phases of the building construction materials, including concrete procurement, construction, operation, and decommissioning. The LCA methodology dates to the 1960s, when concerns over the limited availability of raw materials and energy resources led to new ways to account for energy use and the consequences of these uses considering the whole life cycle [5]. However, based on the objectives and the priorities, the scope and the system boundary for a study can fit to include only a few emission substances and environmental impacts [13,14,15]. Moreover, studies on manufacturing costs have seldom been considered while trying to benchmark characteristics strength and carbon emissions [16].

Thus, the current study aimed to assess and compare carbon emissions and costs associated with the manufacturing of a novel concrete mix, Tex-crete, incorporating textile fibres and carboard fibres. The textile fibres were processed fibres extracted from end-of-life Hi-Viz vests used as a fibre-reinforced material while converted cardboard fibre composite mix was used as a cement replacement material in the concrete matrix. Two case studies including a temporary compound at a construction site and foot path were used to compare the cradle-to-gate carbon emissions. A circularity index was also introduced to examine the recycle, reuse, and repair characteristics of the novel product. The study also examined the influence of other parameters on the total carbon emissions using a detailed parametric assessment. The findings of the study would be useful for stakeholders who are keen to benchmark the carbon emission and assist the market implementation of sustainable products with circular economy benefits.

2. Background

The environmental impact of various industries has come under increasing scrutiny due to globally recognized climate change reduction targets [17]. The building and construction (B&C) industry is responsible for nearly one-third of global greenhouse gas (GHG) emissions, making it one of the main sectors contributing to global warming [18]. Moreover, B&C activities consume approximately 60% of the worlds raw materials and produce nearly 40% of energy-related carbon dioxide (CO2) emissions [19]. Among the various B&C materials, steel and concrete remain the highest contributors to negative environmental impacts, accounting for approximately 7–11% and 9% of total CO2 emissions, respectively [20,21]. Research has been focused on trying to reduce the negative effects of concrete, due to the potential opportunity of material substitution [22,23,24,25]. Cement is one of the primary constituent materials in concrete that is responsible for 5–8% of total global CO2 emissions annually [26]. Therefore, researchers have searched for locally available alternative materials to replace energy-intensive virgin resources like cement [27]. This has become a widely adopted and effective strategy for creating sustainable products that support the circular economy framework [28,29]. Moreover, the use of abundant waste materials as substitutes for virgin resources can help address issues like excessive resource depletion and large-scale landfills resulting from excessive waste generation.

Research trends has focused on incorporating waste materials, such as masonry, plastics, glass, fly ash (FA), and ground granulated blast-furnace slag (GBFS), into concrete as partial substitutions for cement and aggregate materials [30,31,32,33,34]. Additionally, other materials such as metakaolin (MK) and silica fume (SF) are seen as a sustainable option to cement replacement [35,36]. However, researchers are still investigating the potential of using novel waste materials in concrete that would otherwise end up in landfill [37]. Additionally, integrating alternative waste materials into concrete can help ensure that the B&C industry aligns traditional construction methods with positive environmental outcomes. Common household waste is an abundant source and a constant supply stream of materials. With the endless supply of the various wastes, textile and cardboard waste provide a promising and novel alternative. Globally, 100 billion textile garments are produced annually, with 92 million tonnes ending up in landfill [38]. In Australia, between 2022 and 2023, textile waste recorded a 5% recycling rate. This was the lowest recycling rate of all waste materials, including plastics, hazardous waste, glass, organics, metals, paper, and cardboard [39]. Moreover, the textile waste stream has increased in 2022–2023 by 9.3%, compared to 2016–2017. This is mainly driven by the economic feasibility that encourages consumers to purchase new clothing. In addition to textile waste, 4.9 million tons (Mt) of paper and cardboard waste materials were generated in Australia between 2022 and 2023 [39]. Although paper and cardboard waste have a high recovery rate of 68%, 1.57 Mt still ended up in landfill.

Studies have focused on integrating the materials in concrete [2,40]. However, the research focus has often been to achieve specific mechanical targets to comparatively analyse if it is a viable option within the B&C industry. The utilisation of waste materials often requires additional processing requirements [41]. The processing systems are not often mainstream and can often lead to significant energy requirements. Therefore, a comprehensive assessment of the environmental impacts of B&C materials throughout their entire life cycle is an effective way to benchmark sustainability benefits. Life cycle assessment (LCA) studies can encourage the adoption of alternative methods that yield environmentally positive and sustainable results before substantial economic investments are made for further development. The combination of cardboard and textile waste in concrete materials has yet to be environmentally benchmarked. This study presents a novel circular economy index for benchmarking circular performance of construction materials. This research will aim is to identify an optimal concrete mix design using the waste materials and assess its environmental and cost impacts while comparing the circular economy benefits.

3. Research Methodology

3.1. Emission Scope

LCA is a holistic methodology that is used to collect and quantify resources, energy consumption, emissions, wastes, and environmental impacts associated with the entire life cycle stages of a product or process [42]. A comprehensive LCA must be carried out for products and processes according to the ISO 14040-14044 standards [43]. As per ISO 14040-14044 standards, there are four steps of an LCA; (1) goal and scope definition; (2) life cycle inventory (LCI); (3) life cycle impact assessment (LCIA); and (4) interpretation of results. Goal and scope definition includes the reason for conducting an LCA study, its objectives, data categories, description of the system boundary, and functional unit [44]. The focus of the study is to compare cradle-to-gate carbon emissions of construction case studies; predominantly, the construction stage emissions are due to fossil fuel combustion and electricity emissions [45]. Therefore, carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) are considered as equivalent carbon emissions in kgCO2-eq.

3.1.1. Goal and Scope Definition

This study aims to compare the carbon emissions and costs associated with four novel concrete mix designs, including a fibre mix of 7.5% by weight and a control mix design corresponding to 40 MPa. To conduct a comprehensive cradle-to-gate LCA, the manufacturing of concrete products was examined along with inputs and output flows. The functional unit of 1 m3 concrete product (control mix design and fibre mix design) to which all the inputs and output are referred were considered in the present study for analysing carbon emissions. The functional unit for the case studies was expressed as kgCO2-eq/m2 of the poured concrete area to maintain uniform comparison of emissions across the trial pours. The study expects to demonstrate the comparative carbon and cost benefits of Tex-crete and provide a streamlined assessment methodology for comparing the carbon emissions of low-carbon mixes.

3.1.2. Quantitative Approach

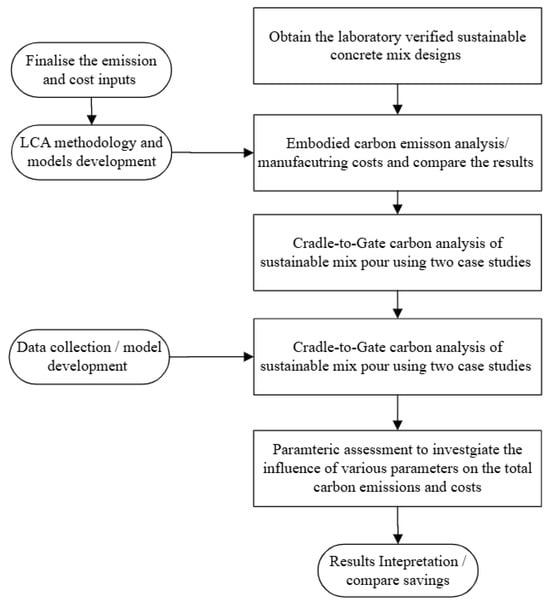

ISO 14040 and ISO 14044 specifies requirements and provides guidance of conducting a comprehensive life cycle assessment (LCA) study including the following key four steps: (1) goal and scope definition, (2) life cycle inventory analysis (LCI), (3) life cycle impact assessment (LCIA), and (4) life cycle interpretation. The main objective of an LCA study is to comprehensively assess wide range of environmental impacts associated with a product or process from cradle to grave [45]. Previous studies have restricted the scope to include only several emission sources and specific life cycle stages within the system boundary in order to cater specific objectives [46]. A typical LCA methodology can be three distinct methods, mainly input–output based, process-based, and hybrid approaches based on data availability and modelling aspects [47,48,49,50]. Since the study focuses on a comparative assessment, a process-based approach was used using the available data to develop the analysis model from cradle-to-gate. Figure 1 highlights the research methodology adopted in the current study.

Figure 1.

Research methodology.

3.1.3. System Boundary

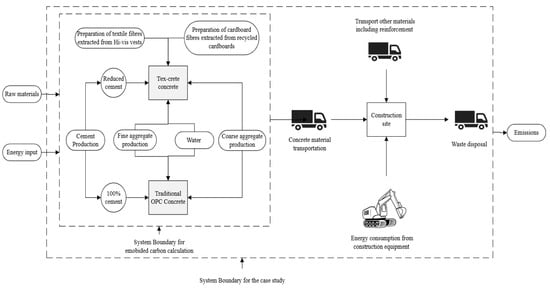

Since the study objective was to compare embodied carbon emissions from the concrete mix and the case studies, two system boundaries were considered. The first system boundary included emission processes involving the manufacture of traditional OPC concrete and sustainable Tex-crete concrete mixes. This system boundary includes energy consumption activities during material extraction and energy consumption during the conversion of waste materials to valuable raw material. The second system boundary included a cradle-to-gate boundary including carbon emissions from materials, equipment usage, and material transportation. Material transportation corresponds to the energy consumption during transportation of processed materials to the construction site, i.e., concrete and reinforcement.

Figure 2 illustrates the two system boundaries considered for the current study.

Figure 2.

System boundaries considered for the current study assessment models.

Total GHG emissions (kgCO2-eq) can be estimated from the following equation.

Et is the total GHG emissions and Ex,GHG is the GHG emissions from the xth emission source; m represents either materials, equipment usage, or transportation in the current study. Emissions from materials (Em) can be determined from Equation (2). Qi is the amount of ith raw material used in the concrete mix design in kg and eim is the carbon emission factor for ith raw material in kgCO2-eq/kg.

Equation (3) is used to determine GHG emissions from transportation. Etr is the total carbon emissions from transportation, EFj is the GHG emission factor for fuel type (j) in kgCO2-eq/Mega Joules (MJ), and fT is the energy content factor for the transport mode T in MJ/tonne-km. dm is the distance travelled by the vehicle in km, wi is the weight of the ith material in kg.

Previous studies have emphasized that the carbon emissions from construction equipment depends mainly on the fuel consumption [51]. Therefore, carbon emissions from construction (EEQ) equipment can be estimated from the following equation.

where EFeq is the GHG emission factor for equipment “eq” in kgCO2-eq/kL, feq is the fuel consumption in litres/hour, and heq is the usage in hours.

3.2. Laboratory Testing Procedure and Case Studies

3.2.1. Experimental Methodology

Concrete testing followed the methods outlined in AS/NZS 1012.8.2 [52], with both compressive and tensile tests conducted on cylindrical specimens measuring 100 mm diameter and 200 mm height. The compressive load rate was set to 20 MPa/min, in accordance with AS 1012.9 [53]. Indirect tensile testing was performed at a load rate of 1.5 MPa/min, as specified by AS 1012.10 [54]. Testing was conducted at 28 days, with three samples measured. Average values and standard deviation measurements were recorded. Mechanical tests were conducted using the Matest C088-11 N Servo-Plus Evolution testing machine, along with the Cyber-Plus Evolution data acquisition system.

Textile materials were sourced from pre-used high-visibility construction vests, from which polyester fibres were extracted. These vests were shredded and converted into a fibrous material for further laboratory analysis. The primary materials used to reduce the ordinary Portland cement (OPC) content in the mix designs include waste corrugated cardboard and metakaolin (MK). Waste cardboard was processed into a fibrous material through the addition of silica fume (SF), which served as a fibre modification technique. The process begins by immersing the waste cardboard in water and using rotating mixing methods to reduce it into a pulp. SF slurry is then applied to the cardboard fibres, resulting in silica fume kraft fibres (SFKFs). These SFKFs undergo a moisture removal process and are mixed further in a rotating mixer to form a fibrous material. The SF applied to the cardboard fibres (KFs) meets the Australian Standard AS/NZS 3582.3 [55] for silica fume in cementitious materials. MK, used as a partial cement substitute, adheres to the ASTM C-618 [56] Class N specification for natural and calcined pozzolans. OPC, conforming to AS/NZS 3972 [57], serves as the primary component for pozzolanic reactivity in the mix. Locally sourced aggregates (20 mm coarse and 0.6 mm fine) from Melbourne, Australia, were used in accordance with AS/NZS 1141.6.2 [58] and AS/NZS 1141.5 [59], respectively. Regular potable water was used for preparing the specimen designs.

Sample preparation followed the guidelines of AS/NZS 1012.2 [60], using a mortar mixer. The materials were dry mixed for five minutes, after which water was added, and mixing continued for another five minutes. Once the mix was ready, the concrete materials were placed into moulds in three layers. Each layer was compressed twenty times with a steel rod before the next layer was added. The moulds were kept at a room temperature of approximately 20 °C for 24 h before being transferred to curing baths. Slump tests were performed according to the procedures outlined in AS/NZS 1012.3.1 [61]. The mechanical and microstructure investigations for the mix designs including the % waste material addition as virgin material replacement was determined based on rigorous experimental investigations and these findings were published previously [2,7,8]. The experimental program included testing of at least 10 cylindrical specimens for each test.

The target compressive strength for all concrete specimens was 40 MPa. The experimental mechanical analysis included five different mix designs. The first design served as the control, with no fibre integration. The second design incorporated 2.5% textile (T2.5) materials for reinforcement. The third design used 5% SFKFs (SFKF5), replacing 5% of the cement. The fourth mix design (MKT) combined 5% MK and 5% SFKFs, partially replacing cement with 2.5% textile reinforcement. The fifth design (KFT) combined 2.5% textiles for reinforcement with 5% SFKFs to partially replace cement.

Detailed formulations of the mix designs can be found in Table 1. The optimum mix designs are obtained from several simulations and trail experimentation. The density of the fibre materials was adjusted based on their intended purpose. For instance, when supplementing cement with KFs, the weight of the KFs was adjusted to match the density of the cement. Similarly, textile materials were adjusted to act as a reinforcing agent based on the density of the concrete. The water content and the ratios of fine and coarse aggregates remained consistent with the control mix. Regardless of fibre integration, the workability of the fibre-reinforced concrete remained satisfactory throughout the mixing process.

Table 1.

Mix design ratios (kg/m3).

3.2.2. Case Studies

Two case studies corresponding to a temporary compound at a construction site and foot path were poured using KFT concrete mix. The temporary compound was a construction site of Eastern Freeway—Burke to Tram Alliance construction site in Bullen, Victoria, Australia (case study A) and the footpath was for a Meditation Monastery in Mount Evelyn, Victoria, Australia (case study B). The case study analyses were used to obtain a comparative assessment of carbon emissions at the material production stage, construction stage, and transportation stages.

The carbon emission factors for electricity, transportation, and equipment usage were derived from the Australian national greenhouse gas accounts published by the Department of Climate Change, Energy, the Environment and Water [62]. Table 2 highlights the major materials, energy consumption, and transportation details for the two current case studies used in the analysis.

Table 2.

Case study details.

3.3. Parametric Assessment

Carbon emissions and manufacturing cost is often influenced by several input parameters including conversion process, local availability, and transportation. The influence of these parameters can significantly impact the final carbon emissions and manufacturing cost. Therefore, the variables listed in Table 3 are considered in a detailed parametric assessment to investigate the impact on total carbon emissions and construction costs. A Monte Carlo simulation using 5000 iterations was utilised to identify the effect of input variables on carbon emissions and cost of material production. The Monte Carlo simulation was performed in Excel in conjunction with @Risk software (Version 7.0). These selected variables highlighted in Table 3 have no influence on the mechanical strength of concrete and are considered to have no significance on the concrete performance.

Table 3.

Variables considered in the parametric assessment.

3.4. Circularity Index (CI)

The circularity concept is often defined in R aspects, which include reduce, replace, reuse, repair, and recycle [63]. Many research studies have defined circularity of a material only in terms of the recycling aspect while neglecting other key focuses including reusability, repurpose, and repair [64]. However, the importance of each aspect within material circularity will depend on the project objectives, goals, and sustainability priorities. Especially in the case of novel products, achieving the short-term and long-term strength characteristics is critical towards the commercialization of the sustainable products [65,66]. Therefore, the current study proposes the following circularity index to evaluate the circularity of the proposed mix designs.

The “recycle” component in the circularity index is defined in terms of percentage of virgin material replaced in the sustainable mix, without significantly compromising the characteristic strength. is the characteristic strength ratio of the sustainable mix and the control mix considered. p is the percentage of virgin materials replaced in the sustainable mix. The “repair” component is defined in terms of durability results, assuming that higher durability results can delay the repair works of concrete. ratio in the repair component is the ratio of durability characteristic strengths of the novel and control mix designs, respectively. The “reuse” component is defined in terms the extent to which the end-of-life concrete can be reused in the same product production without compromising the characteristic strength of the new product. In the current index definition, is the characteristic strength ratio of the mix designs with reused aggregates and the control mix designs. is the material reuse ratio in the mix design with reused aggregates.

, , and are the prioritisation factors that are obtained from experts involved in a specific project. These factors are obtained from pairwise comparison of experts who can evaluate the circular economy performance of construction materials. The current study used an equal importance factor for all the three stages to maintain uniform comparison. A detailed sensitivity analysis is then conducted using Monte Carlo simulation to investigate the influence of the prioritisation factors on the total circularity performance.

4. Results and Discussions

4.1. Laboratory Testing Results

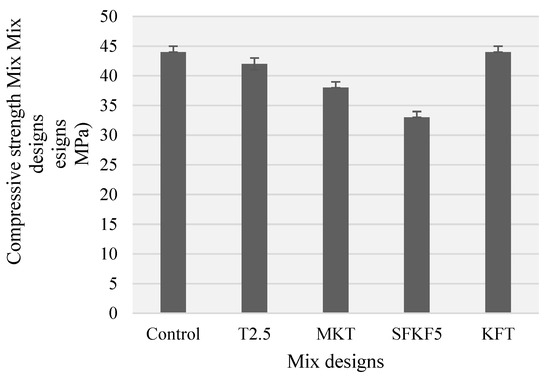

4.1.1. Compressive Strength Results

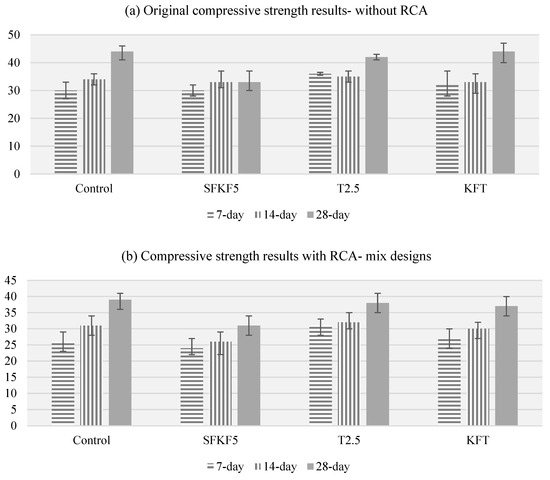

Figure 3 shows the variation in compressive strength across the different concrete mix designs with various fibre types and compositions. Error bars represent the standard deviation in strength between the samples. The control sample measured 44 MPa at the 28-day interval, with a target compressive strength of 40 MPa. Samples T2.5, MKT, and SFKF5 achieved compressive strengths of 42, 38, and 33 MPa, respectively. Notably, KFT also reached 44 MPa at 28 days. However, KFT exhibited greater variability in strength compared to the control, as indicated by a wider range of strength values, fluctuating by 1–2 MPa. Although this difference is marginal, it highlights the variability associated with the integration of fibres in concrete. The smaller surface area of the shredded textile materials allowed them to fill voids in the concrete matrix, contributing to the observed differences in compressive strength between T2.5, SFKF5, and KFT. SFKF5 showed the lowest compressive strength at 33 MPa, while T2.5 had the second highest at 42 MPa. Despite variations in cement content, these results suggest that fine fibrous textile materials can effectively fill voids, helping to maintain high compressive strength. It is worth noting that SFKF5 reduced cement content by 5% by incorporating SFKFs as a partial substitute. However, when textile fibres were combined with KFs, such as in KFT, there was an 11 MPa increase in compressive strength. This further demonstrates that the packing density of the concrete matrix plays a crucial role in achieving high compressive strength.

Figure 3.

Compressive strength results after 28 days.

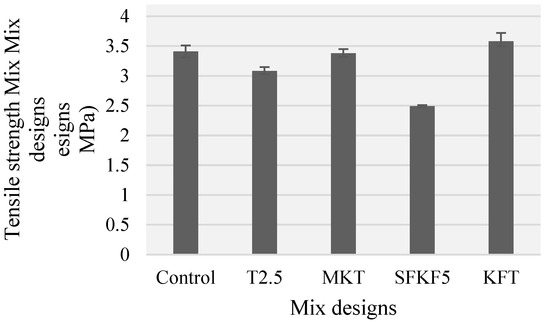

4.1.2. Tensile Strength Results

Figure 4 shows the variation in tensile strength across different concrete samples with various fibre types and compositions. Error bars indicate the standard deviation in strength between the samples. The addition of fibres led to an increase in tensile strength, with KFT reaching 3.58 MPa at 28 days, compared to the control, which measured 3.41 MPa at the same age. MKT also showed similar results, achieving 3.38 MPa at 28 days. The chemical composition of metakaolin (MK) in the concrete mix appears to influence tensile strength through several factors, such as pozzolanic reactivity, microstructural features, and the synergy between fibres. MK contains amorphous silica and alumina, both highly reactive within cementitious materials. This improved bonding capacity, which allows for better stress transfer between the two materials, reduces microcrack formation [67]. MK also helps improve particle packing by reducing the pore structure. However, it is worth noting that a 5% cement reduction with MK does not completely prevent the formation of calcium hydroxide that can degrade fibres within the matrix. This is shown in the lower tensile strength of MKT at 28 days.

Figure 4.

Tensile strength results after 28 days.

SFKF5 recorded the lowest tensile strength among the samples, which can be attributed to fibre degradation within the matrix. Natural fibres, in comparison to synthetic, are more susceptible to degradation in cementitious materials. These fibres absorb moisture from the matrix, leading to dimensional changes and weakening over time. This absorption and release of moisture contribute to physical degradation, reduced strength, and loss of structural integrity. Additionally, natural fibres are more susceptible to alkali attacks in a cementitious matrix, which further weakens the fibre structure and causes degradation. However, pairing SFKFs with textile fibres led to a notable strength increase. The fine surface area of textile fibres helped create a denser matrix by reducing the composite’s porosity. When both types of fibres are used together, the load transfer within the matrix can shift between fibre types, creating a stronger composite by distributing forces more evenly and minimizing strain on any one fibre type. The optimal cement replacement in this mix design is 5%, as demonstrated in KFT, but only when textile fibres are integrated into the mix.

The laboratory testing results are essential, as they will ensure the product is suitable for industry implementation and can be certified prior to benchmarking for economic or environmental performance.

4.2. Carbon Emission and Cost Results

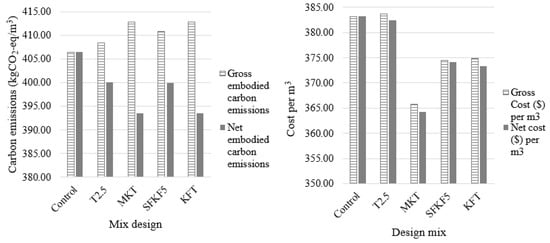

The resulting embodied carbon emissions and manufacturing costs per cubic meter (m3) for the control mix design and the four sustainable mix designs are highlighted in Figure 5. The gross emissions and costs refer to the total carbon emissions and production costs associated with producing 1 m3 of each mix design, while the net emissions and costs represent the amounts after subtracting the avoided landfill emissions and costs due to the use of waste materials in the mix.

Figure 5.

Embodied carbon emissions and production costs of 1 m3 of concrete.

According to the results, there is a 0.7% to 2% increase in carbon emissions caused by the additional energy consumption involved in processing textile and cardboard fibres. However, when considering the avoided landfill carbon emissions and costs, all the new sustainable mix designs demonstrate reductions in both cost and carbon emissions. The greatest reduction is seen in the KFT and MKT samples, with carbon emission reductions of 3.38%, while the lowest reduction is observed in the T2.5 samples at 1.57%.

In terms of net production cost reductions, the MKT samples recorded the highest percentage reduction at 4.94%, whereas the SFKF2.5 samples showed the lowest cost percentage reduction at 0.21%. The KFT samples achieved a net production cost reduction of 2.56%. Furthermore, the KFT samples showed the best comparable results to the control mix designs in terms of compressive and tensile strength.

Considering all three factors, strength, carbon emissions, and production costs, the KFT sample provided the most sustainable mix design. Therefore, it was selected for trial pours in the two case studies. Further optimization studies could focus on identifying the best kraft fibre and textile composite composition to maximize carbon and cost savings without compromising strength requirements.

4.3. Circularity Results

4.3.1. End-of-Life Usage of the Mix Designs

To determine the end-of-life use applications of the novel concrete mix designs, crushed and repurposed concrete were used as a recycled concrete aggregate (RCA) in the same concrete mix. The RCA was obtained at laboratory scale by crushing the tested concrete cylinder specimens and sieving the aggregate mixture as per the AS 1141.11. The comparative results highlighted in Figure 6b signify that traditional concrete mix with RCA aggregates achieve the desired strength as compared to the control mix. The T2.5 and KFT concrete mix designs with RCA and textile and kraft fibres achieve 80–90% of the required strength in comparison with the control mix. These results signify that RCA from crushed sustainable concrete mix at the end of the life cycle can be used as a coarse aggregate in a normal 40 MPa concrete mix, justifying the circularity of the product. Also, these RCA can be used as an aggregate in low-stress concrete applications including paving concretes for footpaths. This is due to the presence of fibre materials within the aggregates that can reduce the thermal cracking in paving concretes.

Figure 6.

Comparison of compressive strength results of normal vs. RCA concrete specimens.

4.3.2. Circularity Comparison Results

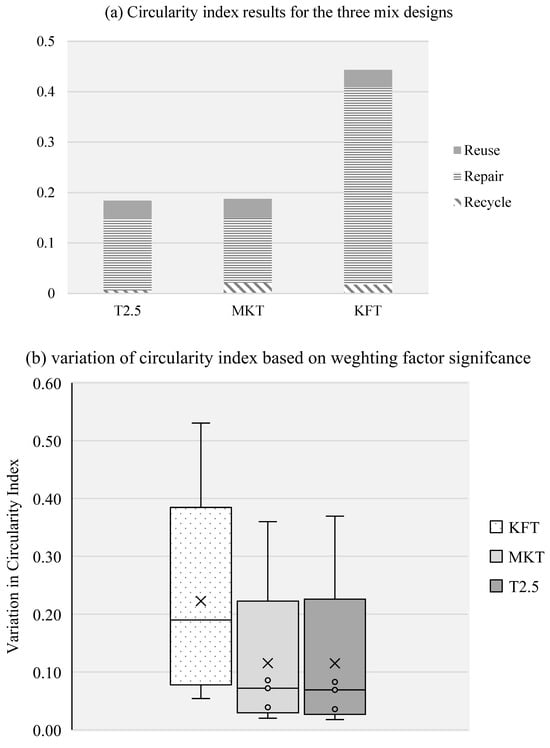

The three samples—T2.5, MKT, and KFT—were used for the circularity comparison mainly because the other sample (SFKF5) did not achieve the desired compressive and tensile strengths. The durability results for the proposed equation is obtained from previously published results [40]. The circularity index results for the three mix designs, giving equal importance to reuse, repair, and recycling, are shown in Figure 7a. A circularity index closer to 1.0 indicates a higher potential for circularity in the product mix. The results indicate that the KFT sample achieves the highest circularity score of 0.44, while both T2.5 and MKT have a circularity score of 0.184.

Figure 7.

Circularity index results for the three mix designs.

For all three samples, the repair stage contributed the most to the circularity index. This is primarily due to the significant durability improvements in the novel mixes compared to the control mix. This suggests that the novel mixes would last longer than conventional mixes, thereby reducing repair and maintenance costs.

A Monte Carlo simulation with 5000 iterations was performed to investigate the influence of weighting factors (the importance of each “R” stage within material circularity) on the circularity index. The corresponding results are presented in Figure 7b. These results further emphasize that the KFT mix can achieve better circularity performance compared to the other mix designs proposed in this study. Additionally, the findings highlight that, for the given mix designs, focusing on improving durability characteristics with an optimized high cement replacement ratio can lead to better circularity performance.

4.4. Parametric Assessment Results

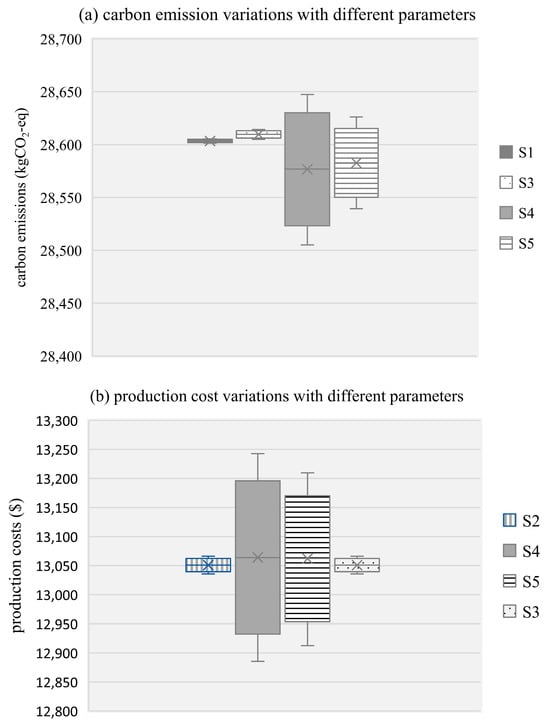

The resulting parametric results for carbon emissions and production cost variations are shown in Figure 8a,b. The results indicate that transportation distance (S4) and the power of the shredding machine used to process cardboard and textile fibres (S5) are the most significant variables influencing total carbon emissions. Electricity consumption for fibre processing and transportation capacity has little to no impact on total carbon emissions. At the scale of the current case study, optimizing the S4 and S5 parameters could reduce total carbon emissions by approximately 1%.

Figure 8.

Parametric assessment results for carbon emissions and production costs.

Production cost variations for the indicators considered are highlighted in Figure 8b. Similar to the carbon emission results, transportation distance (S4) and shredding machine power (S5) are the most influential factors affecting total production costs. Therefore, optimizing the textile fibre processing and reducing transportation distance can further decrease both carbon emissions and production costs of the sustainable mixes.

Further optimization studies are recommended for large-scale implementation of Tex-crete, focusing on the need for additional processing infrastructure and addressing potential regulatory barriers prior to widespread industry implementation.

5. Conclusions and Future Perspectives

This study explored the environmental and economic feasibility of incorporating recycled textile and cardboard fibres into concrete through a novel Tex-crete mix. The research focused on assessing carbon emissions, production costs, and circularity potential using a cradle-to-gate life cycle assessment (LCA) approach. The findings indicate that Tex-crete, particularly the KFT mix (2.5% textile fibres and 5% silica fume-treated kraft fibres), demonstrates a promising balance between sustainability, cost-effectiveness, and mechanical performance, making it a viable alternative to conventional concrete.

The study highlighted the environmental benefits of Tex-crete. The LCA carbon emission results show that although raw material processing introduced some additional emissions, the avoided landfill emissions associated with using recycled fibres led to an overall net reduction in embodied carbon. KFT recorded a 3.38% reduction in total carbon emissions compared to conventional concrete, while MKT and T2.5 also achieved lower emissions. Furthermore, cost analysis reveals that using waste-derived materials resulted in a net cost reduction of 2.56% for KFT, making it a cost-competitive sustainable alternative. A novel circularity index (CI) was introduced to assess the reuse, repair, and recycling potential of Tex-crete. The results indicate that KFT had the highest circularity score (0.44), outperforming other mix designs due to its balance between material substitution and structural durability. The reuse potential of Tex-crete was further validated through laboratory testing, where crushed Tex-crete aggregates were successfully reintegrated into new concrete mixes without significant strength loss. This highlights the feasibility of using end-of-life Tex-crete in secondary applications, contributing to a circular construction economy.

Despite the positive outcomes, several challenges remain for the large-scale implementation of Tex-crete. Variability in waste fibre properties, the need for additional processing infrastructure, and potential regulatory barriers must be addressed before widespread industry adoption. Further research should focus on optimizing fibre composition, refining processing techniques, and conducting long-term durability studies to ensure the structural reliability of Tex-crete in diverse applications. Additionally, expanding the LCA to include full life-cycle emissions beyond the cradle-to-gate scope would provide a more comprehensive understanding of Tex-crete’s long-term sustainability impact. Moreover, future studies can also focus on undertaking comparative assessment using machine learning to compare cost, environmental impact, and mechanical properties of similar sustainable concrete mixes to benchmark the overall sustainable performance. Overall, this study demonstrates that integrating recycled textile and cardboard fibres into concrete offers a viable strategy for reducing embodied carbon, lowering production costs, and enhancing circularity in the construction industry. The successful real-world case applications provide a foundation for the future commercialization of Tex-crete. With further optimization, this innovative concrete mix could serve as a sustainable alternative to conventional concrete, contributing to the broader goal of reducing environmental impacts in the built environment.

Author Contributions

Conceptualization, M.S.; Methodology, M.S. and R.H.; Software, M.S.; Validation, R.K.; Formal analysis, M.S.; Resources, R.K.; Data curation, R.H.; Writing—original draft, M.S. and R.H.; Writing—review & editing, R.K., E.Y. and Z.V.; Supervision, M.S., E.Y. and Z.V.; Project administration, M.S., E.Y. and Z.V.; Funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Sustainability Victoria, grant number C-13294.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Acknowledgments

The authors would like to acknowledge Assembled Threads, Textile Recyclers Australia for providing the textile (Hi-Viz vests) fibres and Sustainability Victoria for funding this project.

Conflicts of Interest

Author Ronja Kraus was employed by the company Eastern Freeway—Burke to Tram Alliance. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Habert, G.; De Lacaillerie, J.D.E.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Joseph, P.; Yaghoubi, E.; Vrcelj, Z. The mechanical and microstructural performance of waste textile and cardboard materials in concrete. Struct. Concr. 2024, 25, 4033–4047. [Google Scholar] [CrossRef]

- Hao, J.L.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach. J. Total Environ. 2020, 723, 137870. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Hobday, R. Energy Related Environmental Impact of Buildings; Technical Synthesis Report Annex 31: International Energy Agency Buildings and Community Systems; FaberMaunsell Ltd.: Hertfordshie, UK, 2006. [Google Scholar]

- Gunasekara, C.; Sandanayake, M.; Zhou, Z.; Law, D.W.; Setunge, S. Effect of nano-silica addition into high volume fly ash–hydrated lime blended concrete. Constr. Build. Mater. 2020, 253, 119205. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Joseph, P.; Arun, M.; Yaghoubi, E.; Vrcelj, Z.; Sasi, S. The Thermo-Phase Change Reactivity of Textile and Cardboard Fibres in Varied Concrete Composites. Sustainability 2024, 16, 3221. [Google Scholar] [CrossRef]

- Merta, I.; Mladenovič, A.; Turk, J.; Šajna, A.; Mauko Pranjić, A. Life cycle assessment of natural fibre reinforced cementitious composites. Key Eng. Mater. 2018, 761, 204–209. [Google Scholar] [CrossRef]

- Sopov, V.; Korkh, O.; Izbash, M.Y. A study of the alkali-silica reaction in recycled glass concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kharkiv, Ukraine, 21–22 May 2020; p. 012062. [Google Scholar]

- Dulsang, N.; Kasemsiri, P.; Posi, P.; Hiziroglu, S.; Chindaprasirt, P. Characterization of an environment friendly lightweight concrete containing ethyl vinyl acetate waste. Mater. Des. 2016, 96, 350–356. [Google Scholar] [CrossRef]

- Asante, R.; Faibil, D.; Agyemang, M.; Khan, S.A. Life cycle stage practices and strategies for circular economy: Assessment in construction and demolition industry of an emerging economy. Environ. Sci. Pollut. Res. 2022, 29, 82110–82121. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Dimoula, V.; Kehagia, F.; Tsakalidis, A.J.A.; Research, A.Q. A holistic approach for estimating carbon emissions of road and rail transport systems. Aerosol Air Qual. Res. 2016, 16, 61–68. [Google Scholar] [CrossRef]

- Kuruvachalil, L.; Sandanayake, M.; Kumanayake, R.; Radhakrishna. Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays & mdash; A Road Rehabilitation Feasibility Study. Future Transp. 2022, 2, 263–280. [Google Scholar]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Global Alliance for Buildings and Construction; Global Status Report for Buildings and Construction: Beyond Foundations—Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- Yılmaz, Y.; Seyis, S. Mapping the scientific research of the life cycle assessment in the construction industry: A scientometric analysis. Build. Environ. 2021, 204, 108086. [Google Scholar] [CrossRef]

- Dong, Y.; Ng, S.T.; Liu, P. Towards the principles of life cycle sustainability assessment: An integrative review for the construction and building industry. Sustain. Cities Soc. 2023, 95, 104604. [Google Scholar] [CrossRef]

- Sustainable Ships Sustainability on Demand. What Is the Carbon Footprint of Steel? 2024. Available online: https://www.sustainable-ships.org/stories/2022/carbon-footprint-steel (accessed on 1 February 2025).

- Leaf The Voice of Impact by Greenly. What Is the Environmental Impact of Concrete? 2024. Available online: https://greenly.earth/en-gb/blog/ecology-news/what-is-the-carbon-footprint-of-concrete (accessed on 1 February 2025).

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A Decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Hou, G.; Chen, J.; Lu, B.; Chen, S.; Cui, E.; Naguib, H.M.; Guo, M.-Z.; Zhang, Q. Composition design and pilot study of an advanced energy-saving and low-carbon rankinite clinker. Cem. Concr. Res. 2020, 127, 105926. [Google Scholar] [CrossRef]

- Huo, Z.; Lu, B.; Sun, J.; Jiang, R.; Hou, G.; Ji, S.; Naguib, H.M. Preparation of high flexural strength rankinite cement benefiting from formation of aragonite whisker during carbonation curing. J. Sustain. Cem.-Based Mater. 2024, 13, 738–753. [Google Scholar] [CrossRef]

- Hou, G.; Yan, Z.; Sun, J.; Naguib, H.M.; Lu, B.; Zhang, Z. Microstructure and mechanical properties of CO2-cured steel slag brick in pilot-scale. Constr. Build. Mater. 2021, 271, 121581. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H.; Lee, Y.Y. Fiber-reinforced alkali-activated concrete: A review. J. Build. Eng. 2022, 45, 103638. [Google Scholar] [CrossRef]

- Sargent, P.; Sandanayake, M.; Law, D.W.; Hughes, D.J.; Shifa, F.; Borthwick, B.; Scott, P. Strength, mineralogical, microstructural and CO2 emission assessment of waste mortars comprising excavated soil, scallop shells and blast furnace slag. Constr. Build. Mater. 2024, 411, 134425. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Rahmati, K.; Mohtasham Moein, A.; Rigby, S.E.; Saradar, A.; Karakouzian, M. Utilizing construction and demolition waste in concrete as a sustainable cement substitute: A comprehensive study on behavior under short-term dynamic and static loads via laboratory and numerical analysis. J. Build. Eng. 2024, 97, 110778. [Google Scholar] [CrossRef]

- Wu, H.; Gao, J.; Liu, C.; Guo, Z.; Luo, X. Reusing waste clay brick powder for low-carbon cement concrete and alkali-activated concrete: A critical review. J. Clean. Prod. 2024, 449, 141755. [Google Scholar] [CrossRef]

- Annalisa Franco, G.P.; Schiavi, L.; De Luca, G.; Bonati, A. Influence of displacement rate in the tensile testing of dry yarns for composite materials used in masonry strengthening. Struct. Integr. Procedia 2023, 44, 2246–2253. [Google Scholar] [CrossRef]

- Vinod Kumar, R.; Rupesh Kumar, D.D. Recycled plastic (HDPE) coarse aggregate manufacturing method and performance in concrete. Mater. Today Proc. 2023, 92, 1304–1309. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wang, Z. Void geometry analysis and multifaceted characterisation of cementitious mortar reinforced with short carbon and glass fibres—A comparative study. J. Build. Eng. 2024, 89, 109283. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, J.; Yan, C.; Liu, S.; Wang, X.; Jiang, Z. Waste rubber-modified sulfur-fly ash-sand composites as low CO2-emission cements. Mater. Chem. Phys. 2023, 306, 108060. [Google Scholar] [CrossRef]

- Boquera, L.; Castro, J.R.; Fernandez, A.G.; Navarro, A.; Pisello, A.L.; Cabeza, L.F. Thermo-mechanical stability of concrete containing steel slag as aggregate after high temperature thermal cycles. Sol. Energy 2022, 239, 59–73. [Google Scholar] [CrossRef]

- Kumar Gautam, C.; Alam, P. To study the effect of geopolymer concrete by using metakaolin & bottom ash. Mater. Today Proc. 2023, 74, 1028–1034. [Google Scholar]

- Vashistha, P.; Oinam, Y.; Pyo, S. Valorization of waste concrete powder (WCP) through silica fume incorporation to enhance the reactivity and hydration characteristics. Dev. Built Environ. 2023, 16, 100272. [Google Scholar] [CrossRef]

- Sabbrojjaman, M.; Liu, Y.; Tafsirojjaman, T. A comparative review on the utilisation of recycled waste glass, ceramic and rubber as fine aggregate on high performance concrete: Mechanical and durability properties. Dev. Built Environ. 2024, 17, 100371. [Google Scholar] [CrossRef]

- Igini, M. 10 Concerning Fast Fashion Waste Statistics 2023. Available online: https://earth.org/statistics-about-fast-fashion-waste/ (accessed on 14 January 2025).

- Joe Pickin, J.M. National Waste and Resource Recovery Report 2024; Blue Environment: Docklands, Australia, 2025. [Google Scholar]

- Haigh, R.; Sandanayake, M.; Yaghoubi, E.; Joseph, P.; Vrcelj, Z. The mechanical and microstructural investigations of concrete incorporating waste textile and cardboard fibers following thermal and freeze–thaw cycles. Struct. Concr. 2025, 26, 2757–2772. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A life cycle assessment of cardboard waste in low stress grade concrete applications. Environ. Manag. 2024, 354, 120428. [Google Scholar] [CrossRef]

- Rashedi, A.; Muhammadi, I.U.; Hadi, R.; Nadeem, S.G.; Khan, N.; Ibrahim, F.; Hassan, M.Z.; Khanam, T.; Jeong, B.; Hussain, M. Characterization and life cycle exergo-environmental analysis of wood pellet biofuel produced in Khyber Pakhtunkhwa, Pakistan. Sustainability 2022, 14, 2082. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. The International Organization for Standardization: Geneva, Switzerland, 1997.

- Hussain, M.; Malik, R.N.; Taylor, A. Environmental profile analysis of particleboard production: A study in a Pakistani technological condition. Int. J. Life Cycle Assess. 2018, 23, 1542–1561. [Google Scholar] [CrossRef]

- Sandanayake, M.; Law, D.; Sargent, P. A new framework for assessing the environmental impacts of circular economy friendly soil waste-based geopolymer cements. Build. Environ. 2022, 210, 108702. [Google Scholar] [CrossRef]

- Fernando, A.; Gunasekara, C.; Siriwardana, C.; Law, D.; Zhang, G.K.; Gamage, J.C.P.H. Evaluating the Environmental Performance of Blended Cement-Based Concrete: A Comparative Life-Cycle Analysis to Derive an Environmental Score. J. Mater. Civ. Eng. 2025, 37, 04025093. [Google Scholar] [CrossRef]

- Treloar, G.; Love, P.; Faniran, O.; Iyer-Raniga, U. A hybrid life cycle assessment method for construction. Constr. Manag. Econ. 2000, 18, 5–9. [Google Scholar] [CrossRef]

- Crawford, R.H. Validation of a hybrid life-cycle inventory analysis method. J. Environ. Manag. 2008, 88, 496–506. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Lei, S. The embodied energy and emissions of a high-rise education building: A quantification using process-based hybrid life cycle inventory model. Energy Build. 2012, 55, 790–798. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Wang, Y. The embodied energy and environmental emissions of construction projects in China: An economic input–output LCA model. Energy Policy 2010, 38, 6597–6603. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S. Environmental emissions at foundation construction stage of buildings—Two case studies. Build. Environ. 2016, 95, 189–198. [Google Scholar] [CrossRef]

- AS/NZS-1012.8.2; Methods of Testing Concrete. Method for Making and Curing Concrete-Flexure Test Specimens. Australian Standard: Sydney, Australia, 2014.

- AS/NZS-1012.9; Methods of Testing Concrete. Method 9: Compressive Strength Tests-Concrete, Mortar and Grout Specimens. Australian Standard: Sydney, Australia, 2014.

- AS/NZS-1012.10; Methods of Testing Concrete. Method 10: Determination of Indirect Tensile Strength of Concrete Cylinders (“Brazil” or Splitting Test). Australian Standard: Sydney, Australia, 2000.

- AS/NZS-3582; Supplementary Cementitious Materials. Part 3: Amorphous Silica. Australian Standard: Sydney, Australia, 2016.

- ASTM-C-618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- AS/NZS-3972; General Purpose and Blended Cements. Australian Standard: Sydney, Australia, 2010.

- AS/NZS-1141.6.2; Methods for Sampling and Testing Aggregates—Particle Density and Water Absorption of Coarse Aggregate—Pycnometer Method. Australian Standard: Sydney, Australia, 2016.

- AS/NZS-1141.5; Methods for Sampling and Testing Aggregates-Particle Density and Water Absorption of Fine Aggregate. Australian Standard: Sydney, Australia, 2000.

- AS/NZS-1012.2; Methods of Testing Concrete. Preparing Concrete Mixes in the Laboratory. Australian Standard: Sydney, Australia, 2014.

- AS/NZS-1012.3.1; Methods of Testing Concrete. Determination of Properties Related to the Consistency of Concrete—Slump Test. Australian Standard: Sydney, Australia, 2014.

- AGGA. Australian National Greenhouse Gas Accounts 2023. Available online: https://www.dcceew.gov.au/sites/default/files/documents/national-greenhouse-account-factors-2023.pdf (accessed on 6 March 2025).

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Mhatre, P.; Gedam, V.V.; Unnikrishnan, S. Material circularity potential for construction materials—The case of transportation infrastructure in India. Resour. Policy 2021, 74, 102446. [Google Scholar] [CrossRef]

- Yatim, F.E.; Boumanchar, I.; Srhir, B.; Chhiti, Y.; Jama, C.; Alaoui, F.E.M.H. Waste-to-energy as a tool of circular economy: Prediction of higher heating value of biomass by artificial neural network (ANN) and multivariate linear regression (MLR). Waste Manag. 2022, 153, 293–303. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Narule, G.N.; Ulape, Y.B. Performance on steel fiber reinforced concrete using metakaolin. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).