Study on the Ash Deposition Characteristics for Co-Combustion of Zhundong Coal with Cotton Stalk

Abstract

1. Introduction

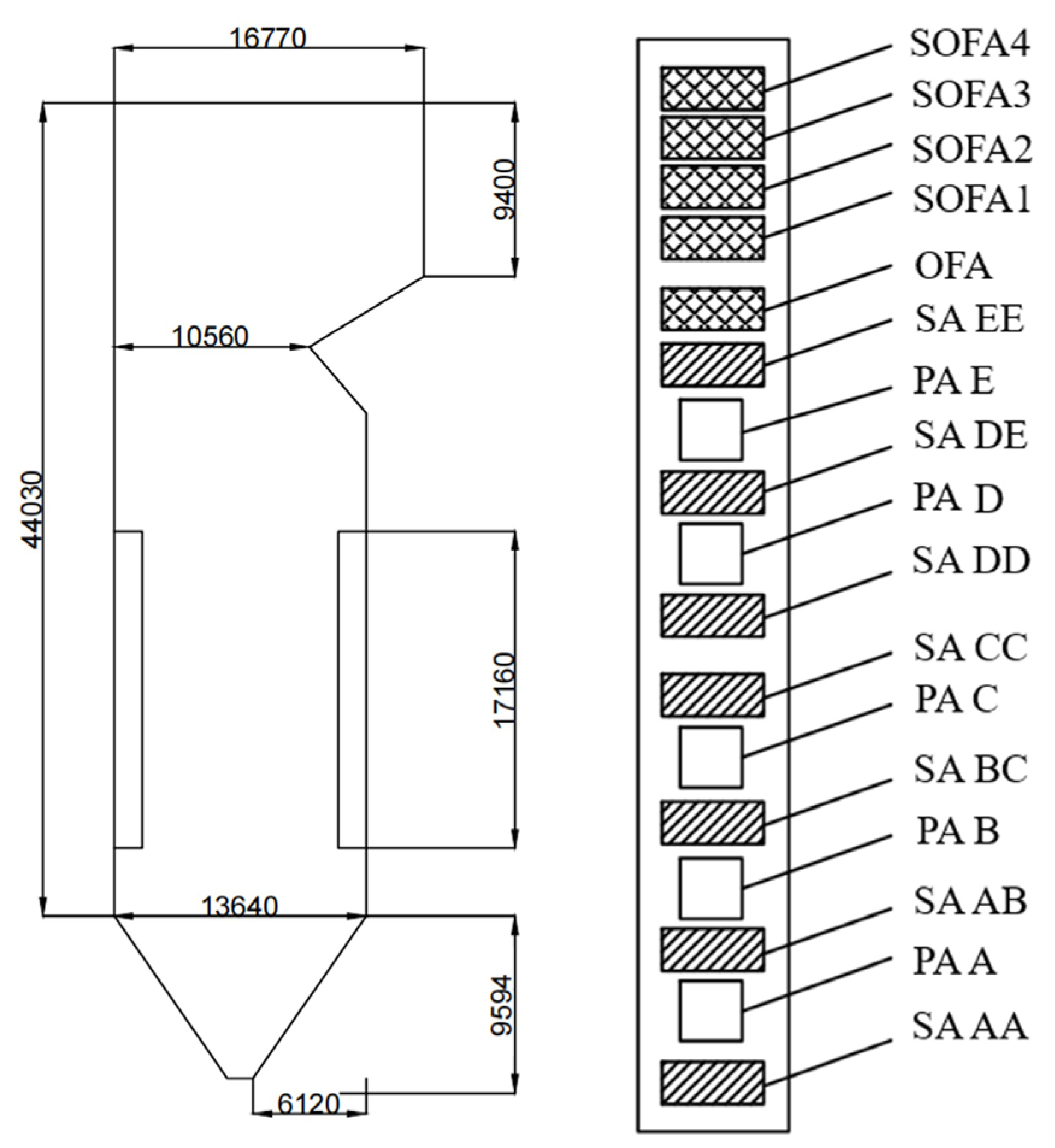

2. Structure of the Boiler and Computational Model

2.1. Overall Structure of the Boiler

2.2. Fuel Properties and Simulation Conditions

2.3. Mathematical Model

2.4. Ash Deposition Model Model

3. Results and Discussion

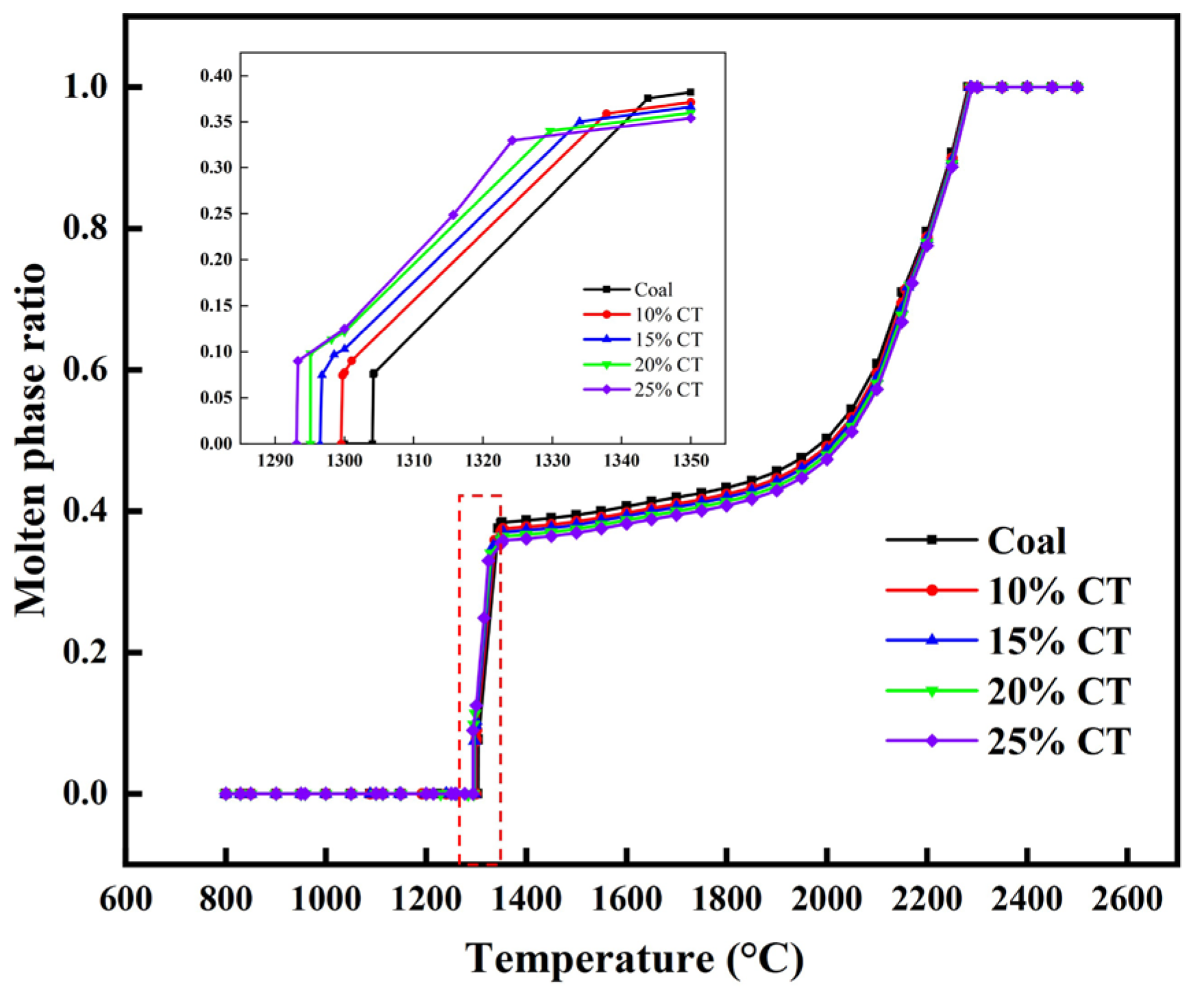

3.1. Effects of the Cotton Stalk Blending Ratio on the Ash Melting Ratio

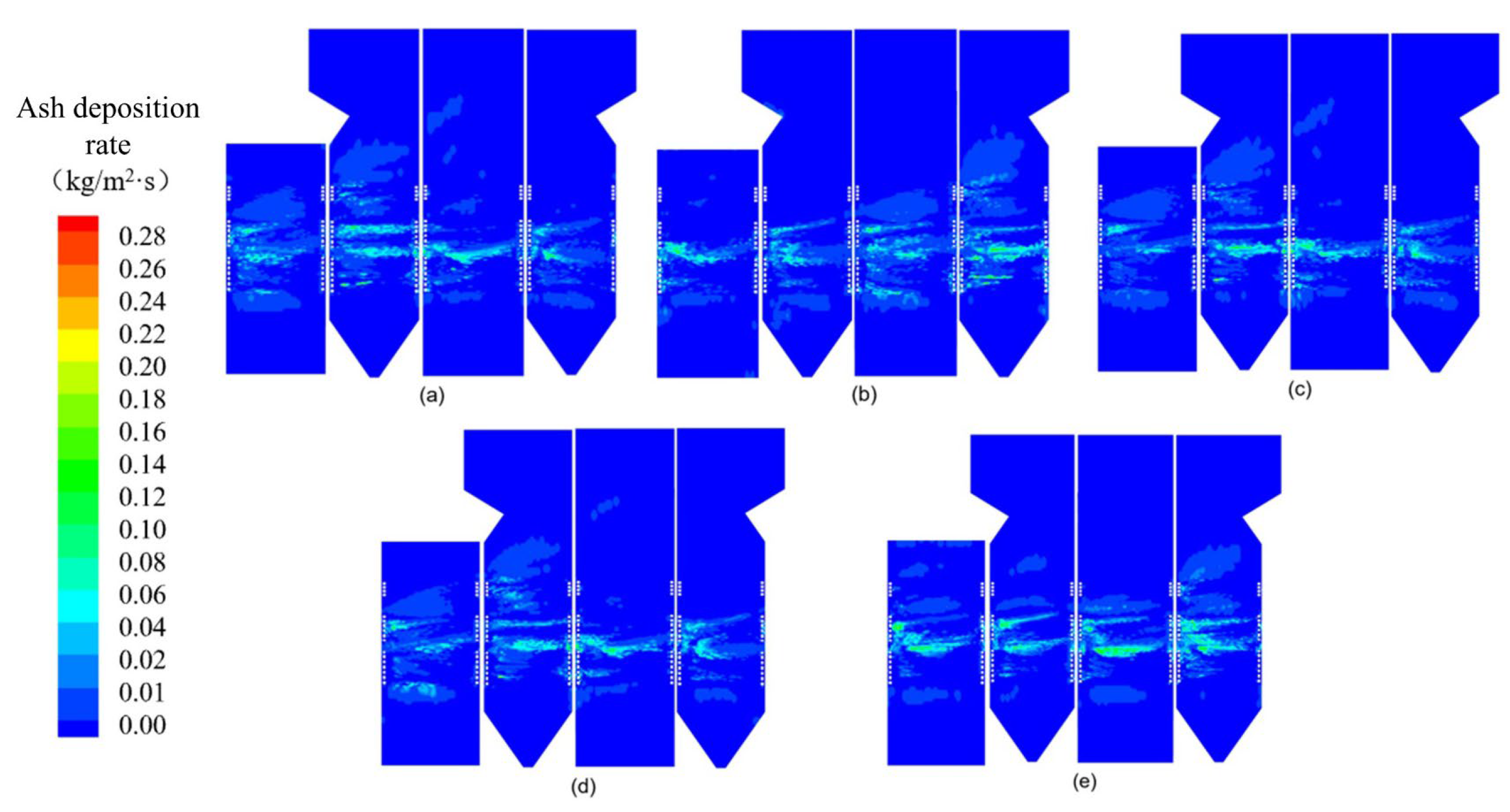

3.2. Effect of Cotton Stalk Blending Ratio on Ash Deposition Characteristics

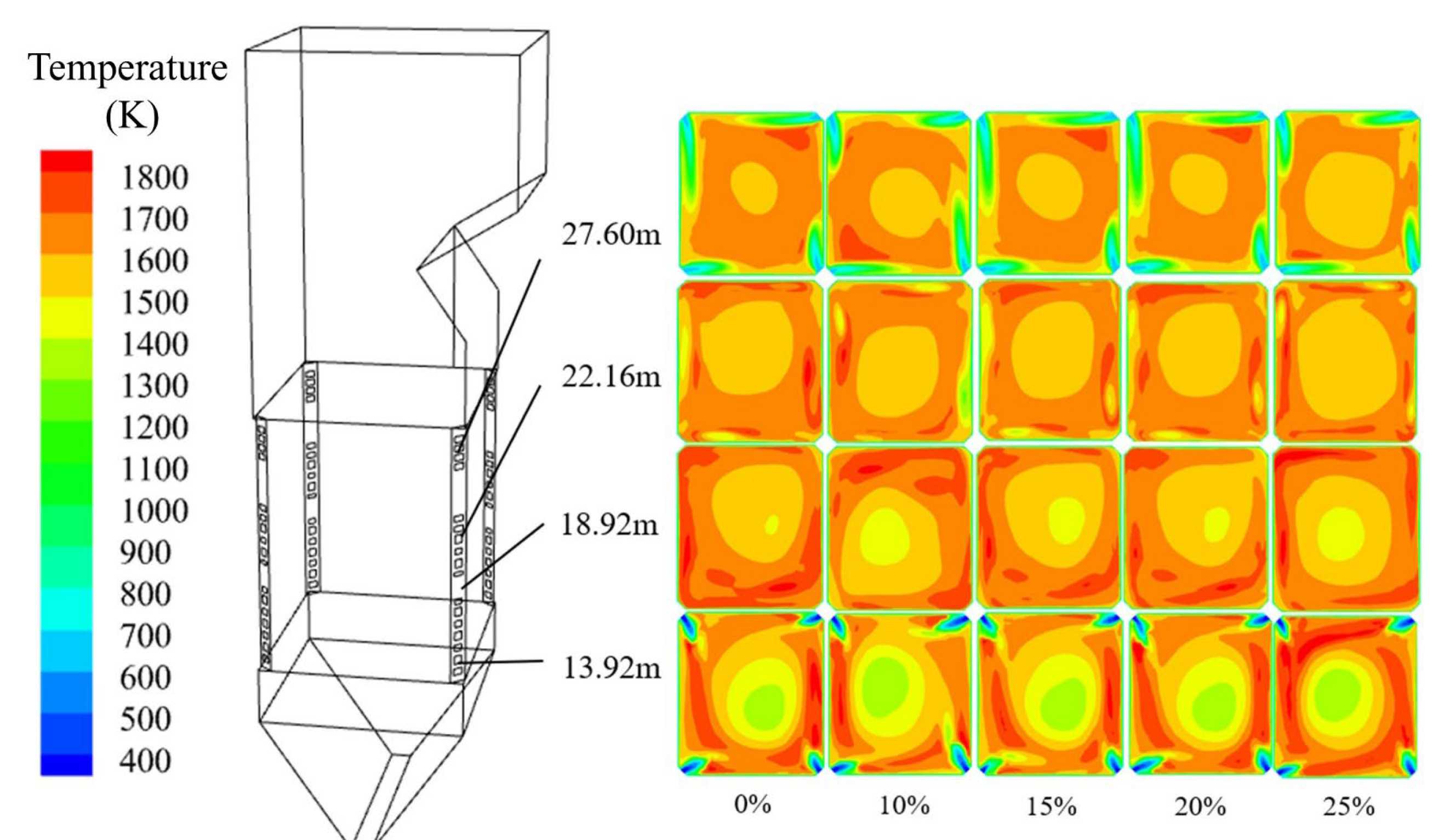

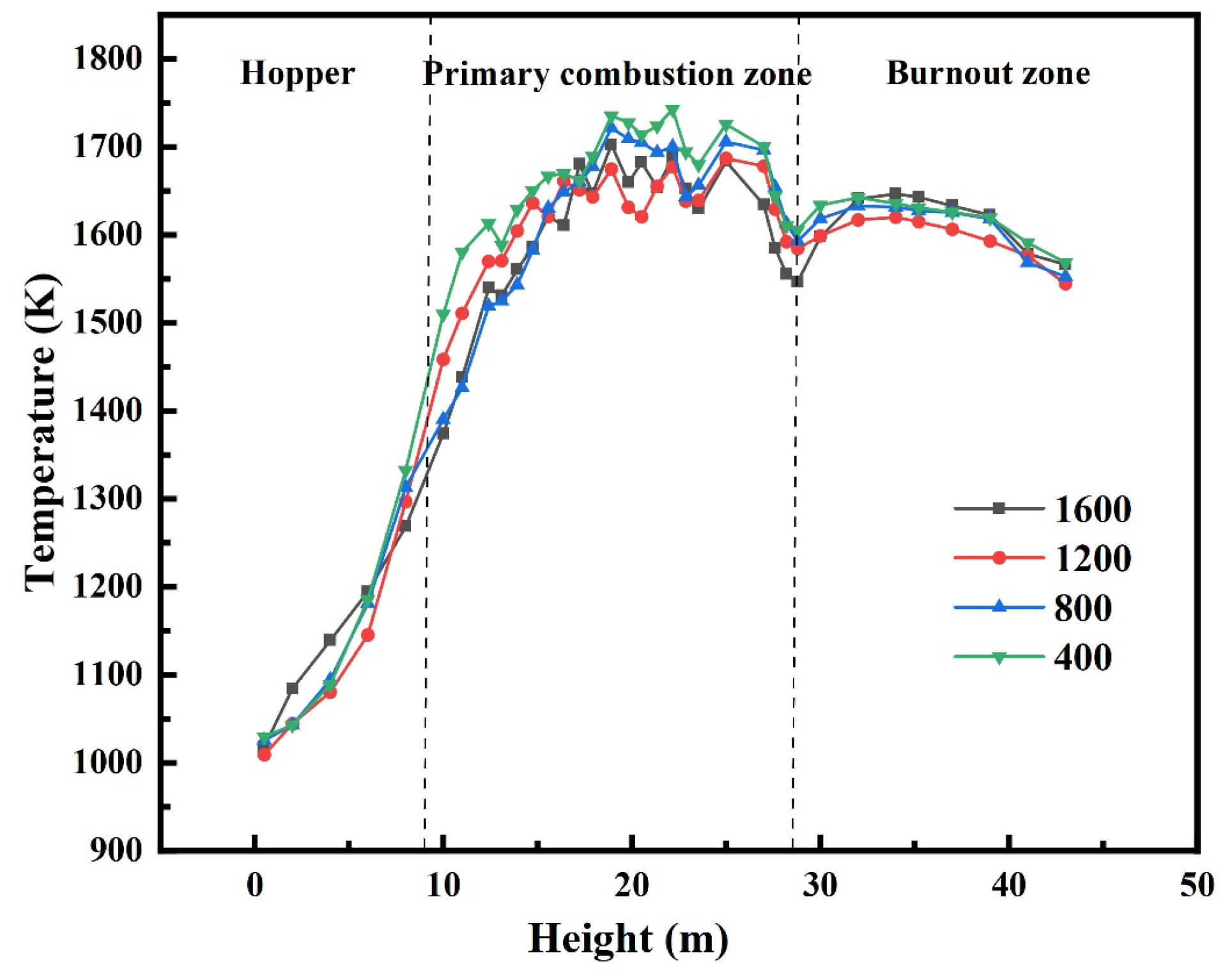

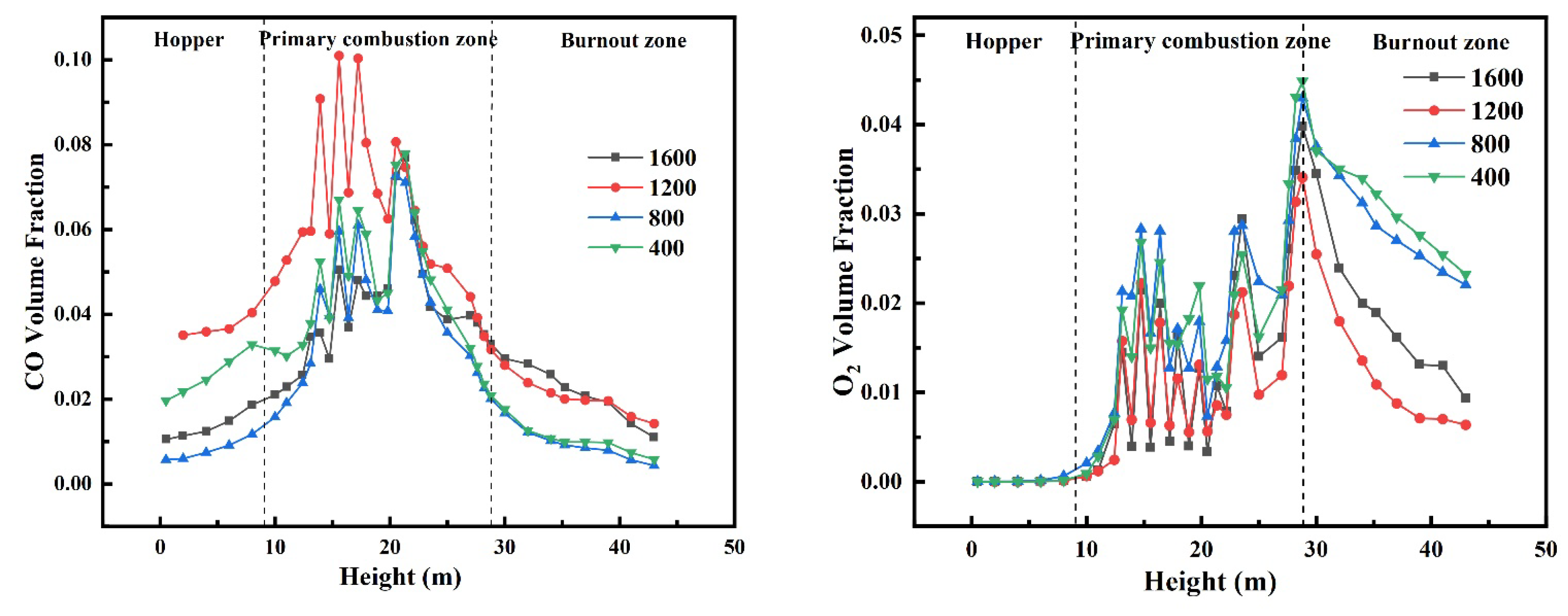

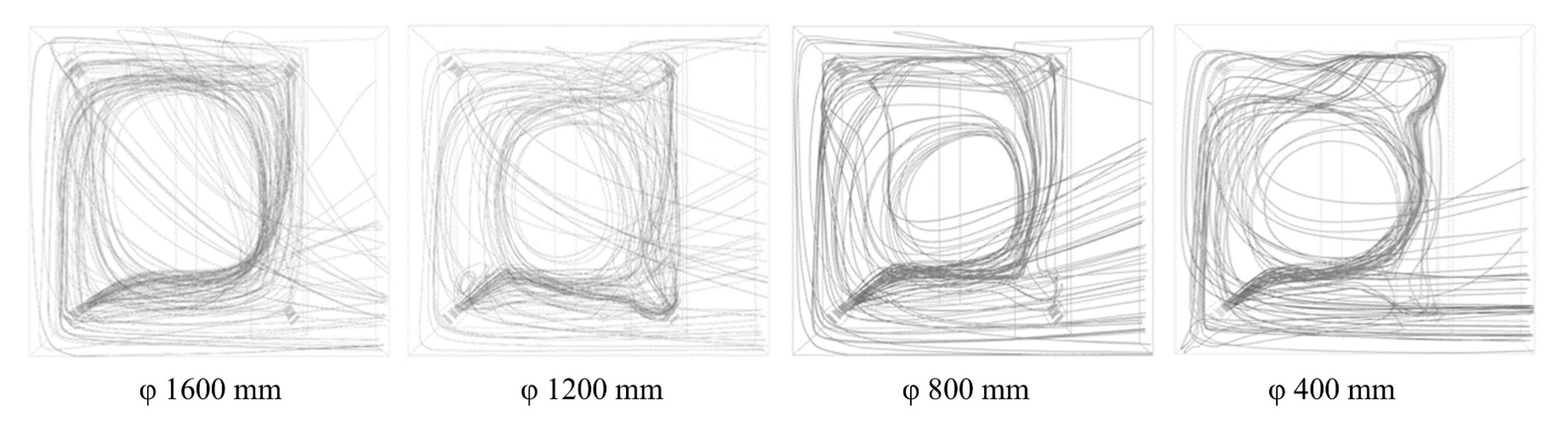

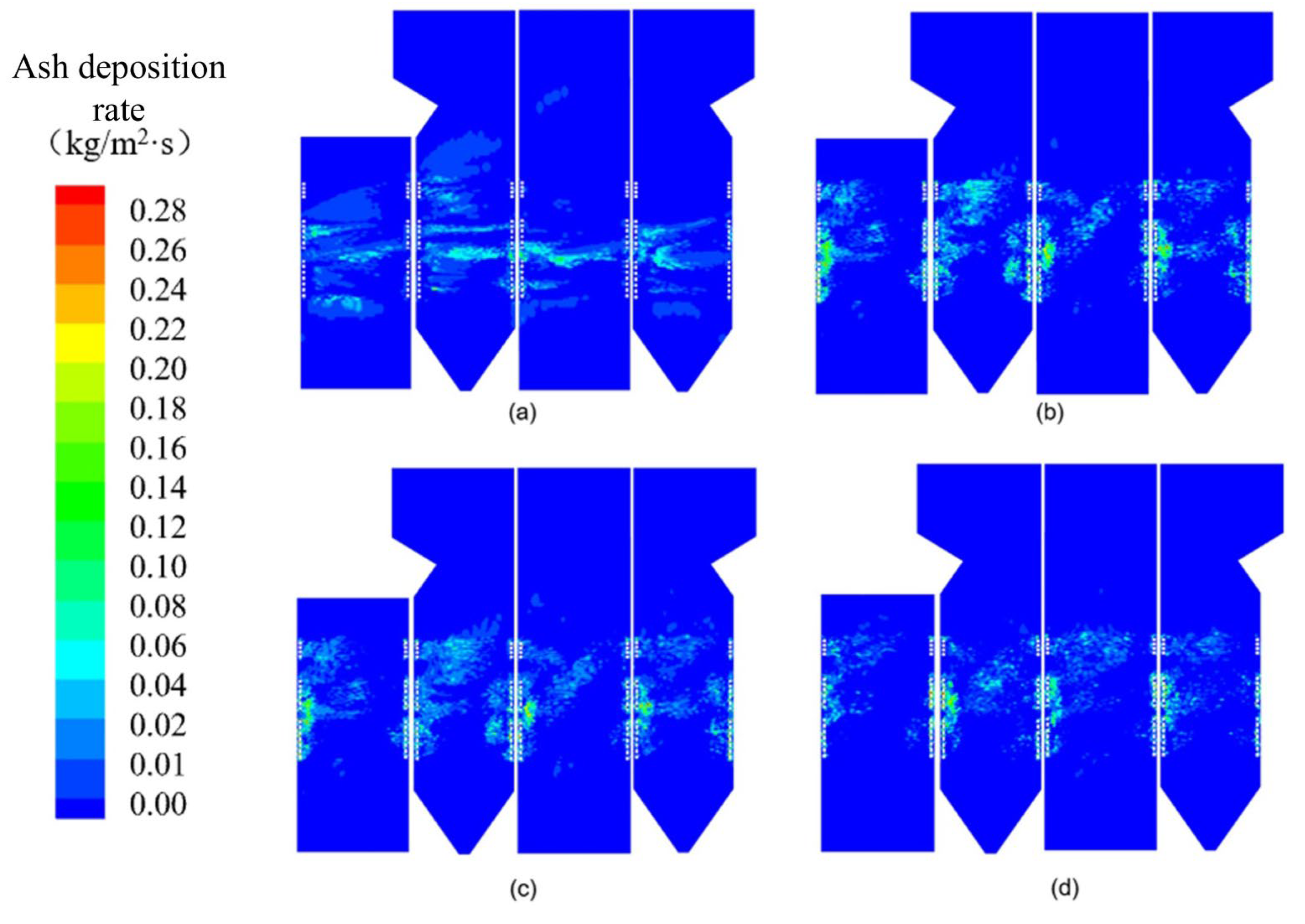

3.3. Effect of Tangential Circle Diameter on the Ash Fusion Process

4. Conclusions

- (1)

- With the increase in the blending ratio of cotton stalks, the content of K2O increased significantly, from 0.31% without mixing to 9.31% when the mixing ratio was 25%. While the contents of CaO, Fe2O3, and Al2O3 in the ash gradually decreased, the difference was not significant.

- (2)

- With the increase in the mixing ratio, the condition of wall ash deposition deteriorated gradually, and the average ash deposition rate increased significantly. The average ash deposition rate on the wall was 0.00327 kg/(m2·s) without mixing, and the average ash yield was 0.00581 kg/(m2·s) when the mixing ratio was 25%, which was 77.6% higher than that without mixing.

- (3)

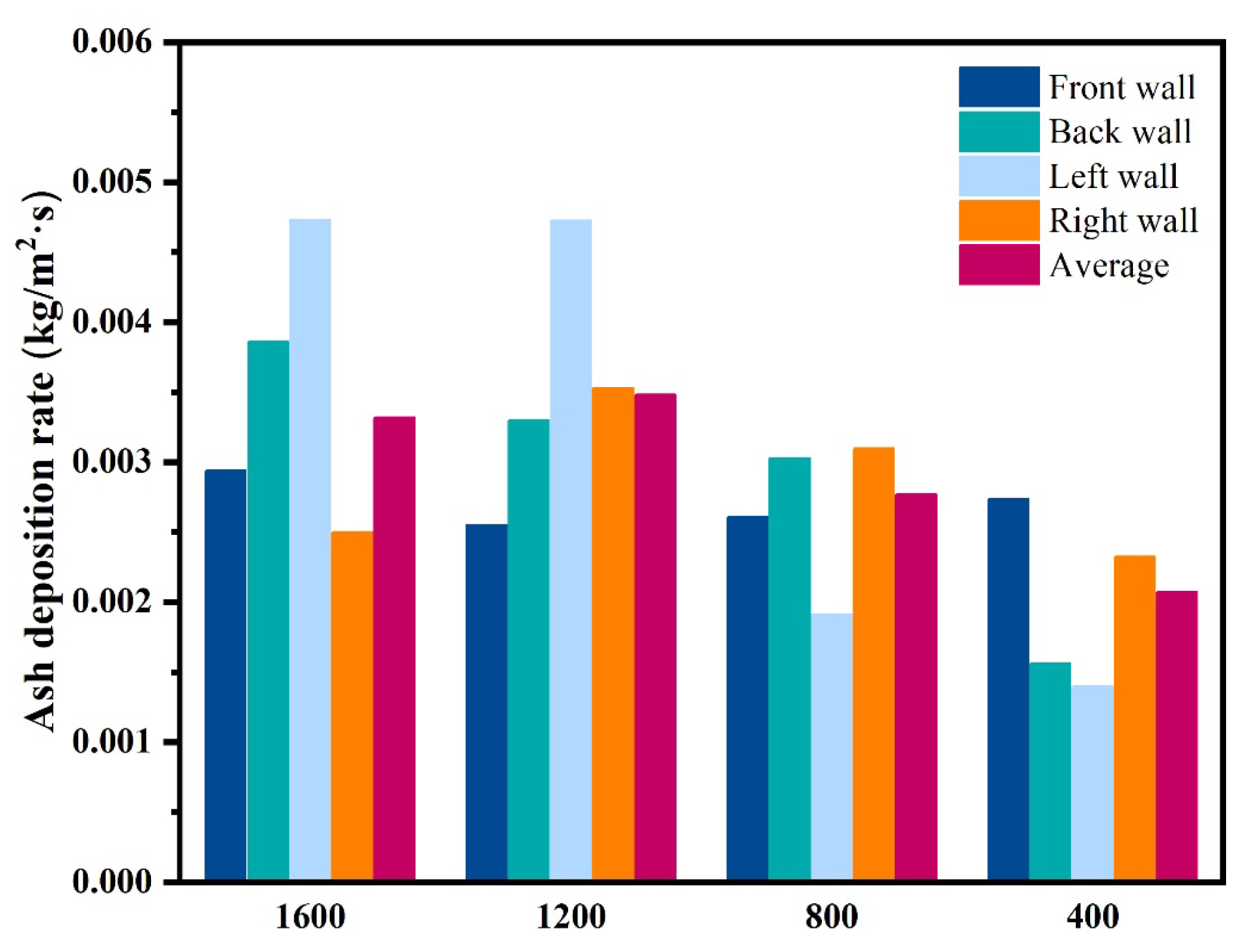

- Reducing the tangential circle diameter can alleviate the ash deposition on the wall. With the decrease in the tangential circle diameter, the ash deposition changed from a zonal distribution to a point-like distribution, and the ash deposition rate and distribution area both decreased significantly. When the tangential circle diameter was reduced to 400 mm, the average ash deposition rate on the wall was reduced to 0.00207 kg/(m2·s), which was 37.6% lower than the original condition. However, the influence of reducing the circumferential diameter on the combustion efficiency of the boiler needs to be further evaluated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.; Zhuang, X.; Alastuey, A.; Querol, X.; Li, J. Geochemistry and mineralogy of coal in the recently explored Zhundong large coal field in the Junggar basin, Xinjiang province, China. Int. J. Coal Geol. 2010, 82, 51–67. [Google Scholar] [CrossRef]

- Liu, K.; Wei, B.; Zhang, Y.; Wang, J.; Chen, L.; Wu, W.; Tan, H.; Yao, H. Fe occurrence form and slagging mechanism on water-wall during high iron Zhundong coal combustion process. Fuel 2022, 315, 123268. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Z.; Wei, B.; Zhang, L.; Tan, H.; Yang, T.; Mikulčić, H.; Duić, N. The ash deposition mechanism in boilers burning Zhundong coal with high contents of sodium and calcium: A study from ash evaporating to condensing. Appl. Therm. Eng. 2015, 80, 150–159. [Google Scholar] [CrossRef]

- Wei, B.; Wu, W.; Liu, K.; Wang, J.; Chen, L.; Ma, J.; Wang, F.; Li, X.; Yang, W.; Tan, H. Investigation of slagging characteristics on middle and low temperature heat transfers by burning high sodium and iron coal. Combust. Sci. Technol. 2022, 194, 1768–1787. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and opportunities in biomass ash management and its utilization in novel applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, W.; Shen, Y.; Luo, S.; Ren, D. Progress in the change of ash melting behavior and slagging characteristics of co-gasification of biomass and coal: A review. J. Energy Inst. 2023, 111, 101414. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, T.; Li, C.; Song, Q.; Zhang, M.; Yang, H. Development Status and Prospects of Biomass Energy in China. Energies 2024, 17, 4484. [Google Scholar] [CrossRef]

- Mularski, J.; Li, J. A review on biomass ignition: Fundamental characteristics, measurements, and predictions. Fuel 2023, 340, 127526. [Google Scholar] [CrossRef]

- Si, F.; Zhang, H.; Feng, X.; Xu, Y.; Zhang, L.; Zhao, L.; Li, L. Thermodynamics and synergistic effects on the co-combustion of coal and biomass blends. J. Therm. Anal. Calorim. 2024, 149, 7749–7761. [Google Scholar] [CrossRef]

- Toptas, A.; Yildirim, Y.; Duman, G.; Yanik, J. Combustion behavior of different kinds of torrefied biomass and their blends with lignite. Bioresour. Technol. 2015, 177, 328–336. [Google Scholar] [CrossRef]

- Liu, K.; Wei, B.; Wang, J.; Chen, L.; Kong, L.; Lu, H. Effect of atmosphere and chemical composition on ash fusion process of Zhundong high iron coal. Fuel 2025, 386, 134223. [Google Scholar] [CrossRef]

- Niu, Y.; Tan, H.; Hui, S. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Wang, X.; Cao, R.; Wei, B. The condensation and thermodynamic characteristics of alkali compound vapors on wall during wheat straw combustion. Fuel 2017, 187, 33–42. [Google Scholar] [CrossRef]

- Zhou, H.; Ma, W. An experimental study on the effects of adding biomass ashes on ash sintering behavior of Zhundong coal. Appl. Therm. Eng. 2017, 126, 689–701. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Y.; Matovic, M.D.; Whalen, J.K. Exploring switchgrass and hardwood combustion on excess air and ash fouling/slagging potential: Laboratory combustion test and thermogravimetric kinetic analysis. Energy Convers. Manag. 2015, 97, 409–419. [Google Scholar] [CrossRef]

- Wu, H.; Bashir, M.S.; Jensen, P.A.; Sander, B.; Glarborg, P. Impact of coal fly ash addition on ash transformation and deposition in a full-scale wood suspension-firing boiler. Fuel 2013, 113, 632–643. [Google Scholar] [CrossRef]

- Gao, R.; Yin, S.; Song, T.; Lu, P. Numerical simulation of co-combustion of pulverized coal and biomass in TTF precalciner. Fuel 2023, 334, 126515. [Google Scholar] [CrossRef]

- Deng, L.; Ma, S.; Jiang, J.; Tie, Y.; Zhang, Y.; Zhu, Z.; Belošević, S.; Tomanović, I.; Che, D. Numerical Investigation on Cofiring Characteristics of Biomass Syngas and Coal in a 660-MW Tower Boiler. J. Energy Eng. 2022, 148, 04022014. [Google Scholar] [CrossRef]

- Cai, Y.; Tay, K.; Zheng, Z.; Yang, W.; Wang, H.; Zeng, G.; Li, Z.; Keng Boon, S.; Subbaiah, P. Modeling of ash formation and deposition processes in coal and biomass fired boilers: A comprehensive review. Appl. Energy 2018, 230, 1447–1544. [Google Scholar] [CrossRef]

- Wieland, C.; Kreutzkam, B.; Balan, G.; Spliethoff, H. Evaluation, comparison and validation of deposition criteria for numerical simulation of slagging. Appl. Energy 2012, 93, 184–192. [Google Scholar] [CrossRef]

- Yang, X.; Ingham, D.; Ma, L.; Zhou, H.; Pourkashanian, M. Understanding the ash deposition formation in Zhundong lignite combustion through dynamic CFD modelling analysis. Fuel 2017, 194, 533–543. [Google Scholar] [CrossRef]

- Fan, J.; Zha, X.; Sun, P.; Cen, K. Simulation of ash deposit in a pulverized coal-fired boiler. Fuel 2001, 80, 645–654. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, H.; Wei, Y.; Lei, L.; Duan, X.; Zhou, H. Numerical simulations of the slagging characteristics in a down-fired, pulverized-coal boiler furnace. Fuel Process. Technol. 2010, 91, 88–96. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, W.; Yu, P.; Cai, Y.; Zhou, H.; Boon, S.K.; Subbaiah, P. Simulating growth of ash deposit in boiler heat exchanger tube based on CFD dynamic mesh technique. Fuel 2020, 259, 116083. [Google Scholar] [CrossRef]

- Zheng, S.; Zeng, X.; Qi, C.; Zhou, H. Modeling of ash deposition in a pulverized-coal boiler by direct simulation Monte Carlo method. Fuel 2016, 184, 604–612. [Google Scholar] [CrossRef]

- Yin, C.; Rosendahl, L.; Kær, S.K.; Condra, T.J. Use of numerical modeling in design for co-firing biomass in wall-fired burners. Chem. Eng. Sci. 2004, 59, 3281–3292. [Google Scholar] [CrossRef]

- Tang, C.; Pan, W.; Zhang, J.; Wang, W.; Sun, X. A comprehensive review on efficient utilization methods of High-alkali coals combustion in boilers. Fuel 2022, 316, 123269. [Google Scholar] [CrossRef]

- Akiyama, K.; Pak, H.; Tada, T.; Ueki, Y.; Yoshiie, R.; Naruse, I. Ash deposition behavior of upgraded brown coal and bituminous coal. Energy Fuels 2010, 24, 4138–4143. [Google Scholar] [CrossRef]

| Sample | Proximate Analysis/wt.% | Ultimate Analysis/wt.% | Qnet,ar/(kJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Vdaf | FCad | Car | Har | Oar | Nar | St,ar | ||

| ZD | 11.69 | 21.10 | 35.65 | 44.99 | 50.12 | 4.74 | 10.95 | 0.83 | 0.62 | 20,800.0 |

| CTs | 11.76 | 9.31 | 78.36 | 27.64 | 43.01 | 4.29 | 30.62 | 0.71 | 0.30 | 14,348.0 |

| Sample | Fe2O3 | Al2O3 | CaO | MgO | SiO2 | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| ZD | 8.95 | 4.58 | 40.46 | 11.09 | 0.28 | 27.92 | 0.31 | 6.41 |

| CTs | 0.40 | 0.42 | 19.63 | 9.44 | 1.43 | 7.31 | 51.50 | 9.87 |

| Items | Fe2O3 | Al2O3 | CaO | MgO | SiO2 | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| 0 | 8.95 | 4.58 | 40.46 | 11.09 | 0.28 | 27.92 | 0.31 | 6.41 |

| 10% | 8.38 | 4.30 | 39.08 | 10.98 | 0.36 | 26.55 | 3.71 | 6.64 |

| 15% | 8.08 | 4.16 | 38.35 | 10.92 | 0.40 | 25.83 | 5.50 | 6.76 |

| 20% | 7.77 | 4.01 | 37.58 | 10.86 | 0.44 | 25.08 | 7.37 | 6.89 |

| 25% | 7.45 | 3.85 | 36.79 | 10.80 | 0.48 | 24.30 | 9.31 | 7.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Liu, N.; Liu, K.; Wei, B.; Wang, J.; Wang, F.; Qi, Y.; Chen, N. Study on the Ash Deposition Characteristics for Co-Combustion of Zhundong Coal with Cotton Stalk. Appl. Sci. 2025, 15, 6963. https://doi.org/10.3390/app15136963

Li T, Liu N, Liu K, Wei B, Wang J, Wang F, Qi Y, Chen N. Study on the Ash Deposition Characteristics for Co-Combustion of Zhundong Coal with Cotton Stalk. Applied Sciences. 2025; 15(13):6963. https://doi.org/10.3390/app15136963

Chicago/Turabian StyleLi, Tianyou, Ning Liu, Kunpeng Liu, Bo Wei, Jianjiang Wang, Feng Wang, Yanjie Qi, and Ning Chen. 2025. "Study on the Ash Deposition Characteristics for Co-Combustion of Zhundong Coal with Cotton Stalk" Applied Sciences 15, no. 13: 6963. https://doi.org/10.3390/app15136963

APA StyleLi, T., Liu, N., Liu, K., Wei, B., Wang, J., Wang, F., Qi, Y., & Chen, N. (2025). Study on the Ash Deposition Characteristics for Co-Combustion of Zhundong Coal with Cotton Stalk. Applied Sciences, 15(13), 6963. https://doi.org/10.3390/app15136963