Simulation and Experimental Study on the Shrub-Cutting Performance of Quasi-Planetary Cutter

Abstract

1. Introduction

2. Materials and Equipment

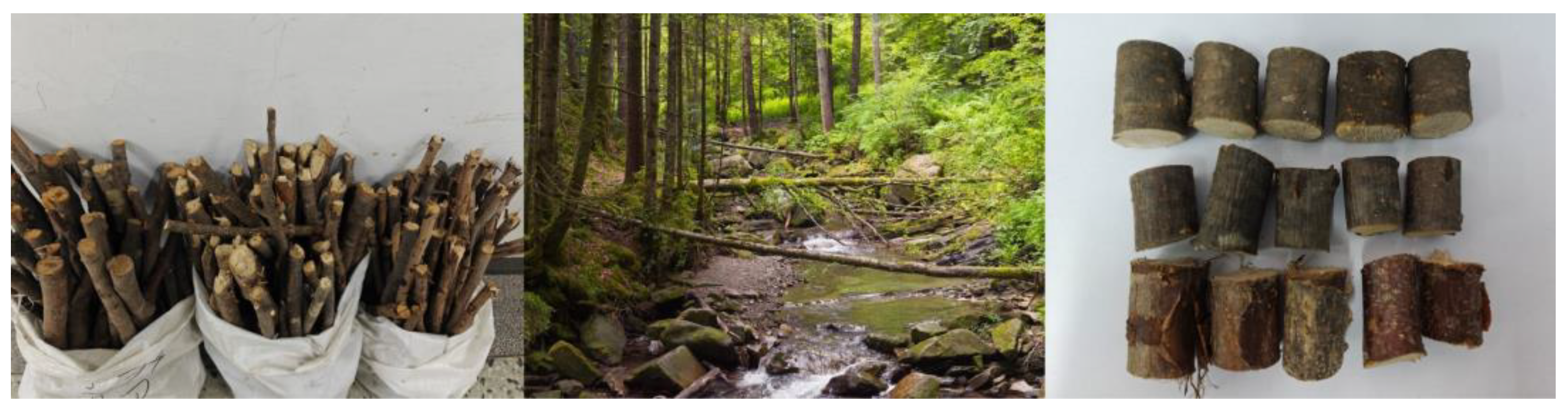

2.1. Materials

2.1.1. Preparation

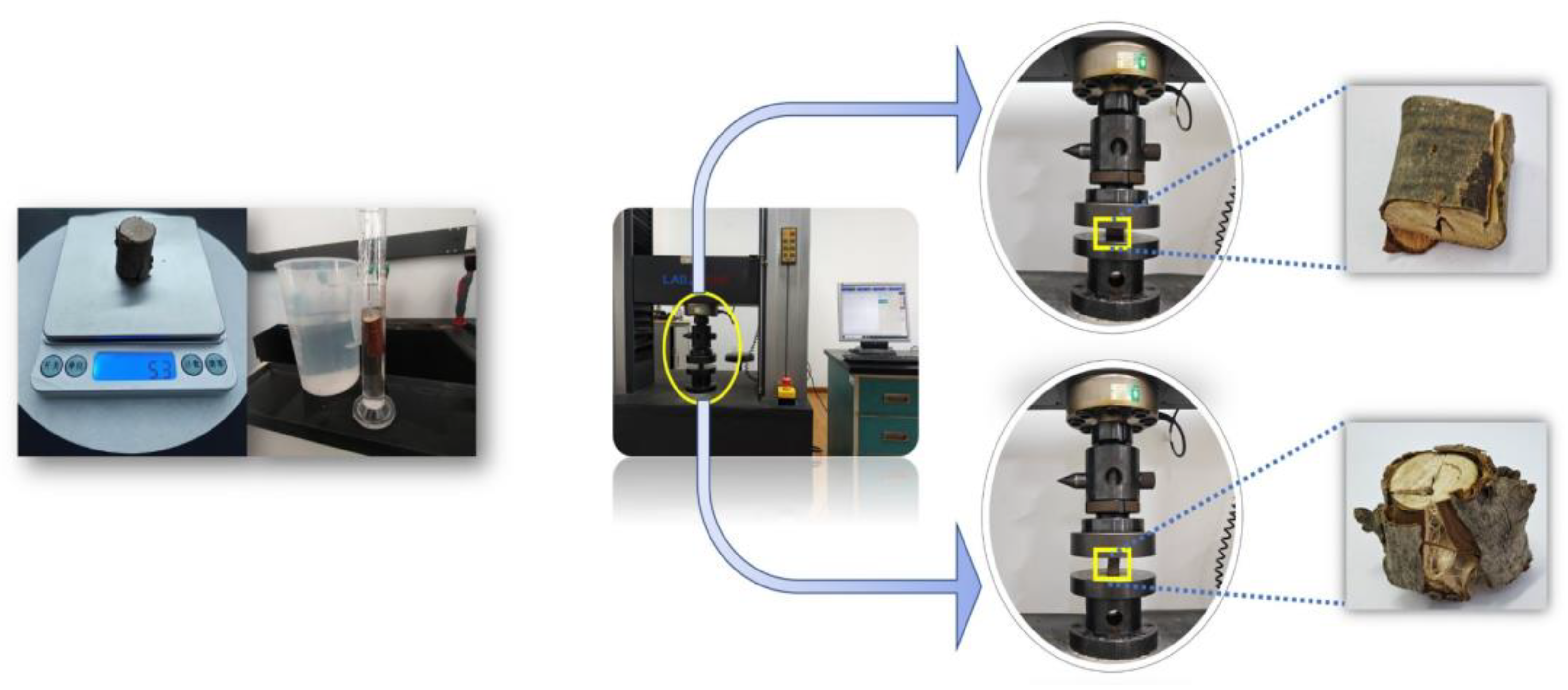

2.1.2. Physical and Mechanical Properties

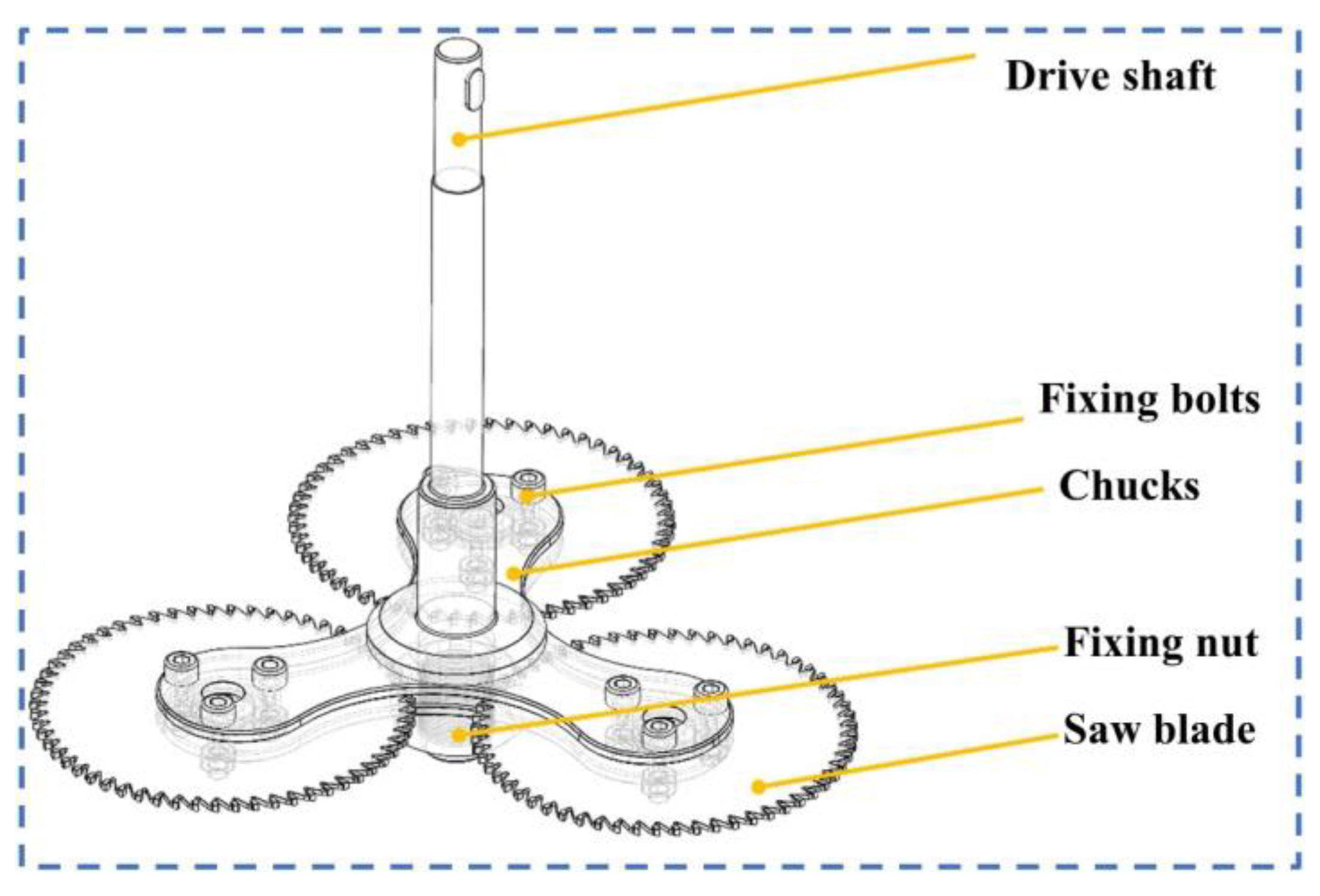

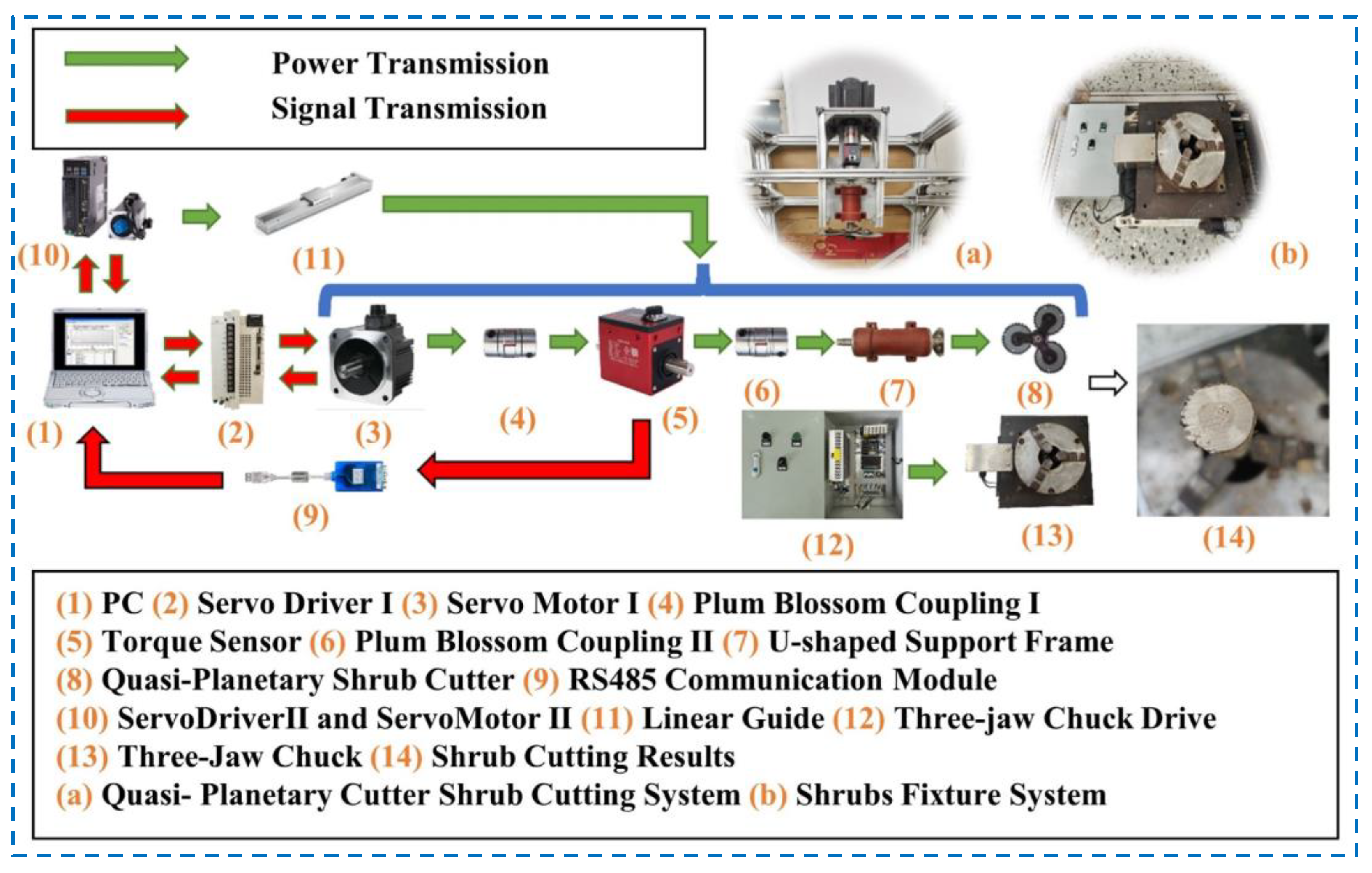

2.2. Equipment

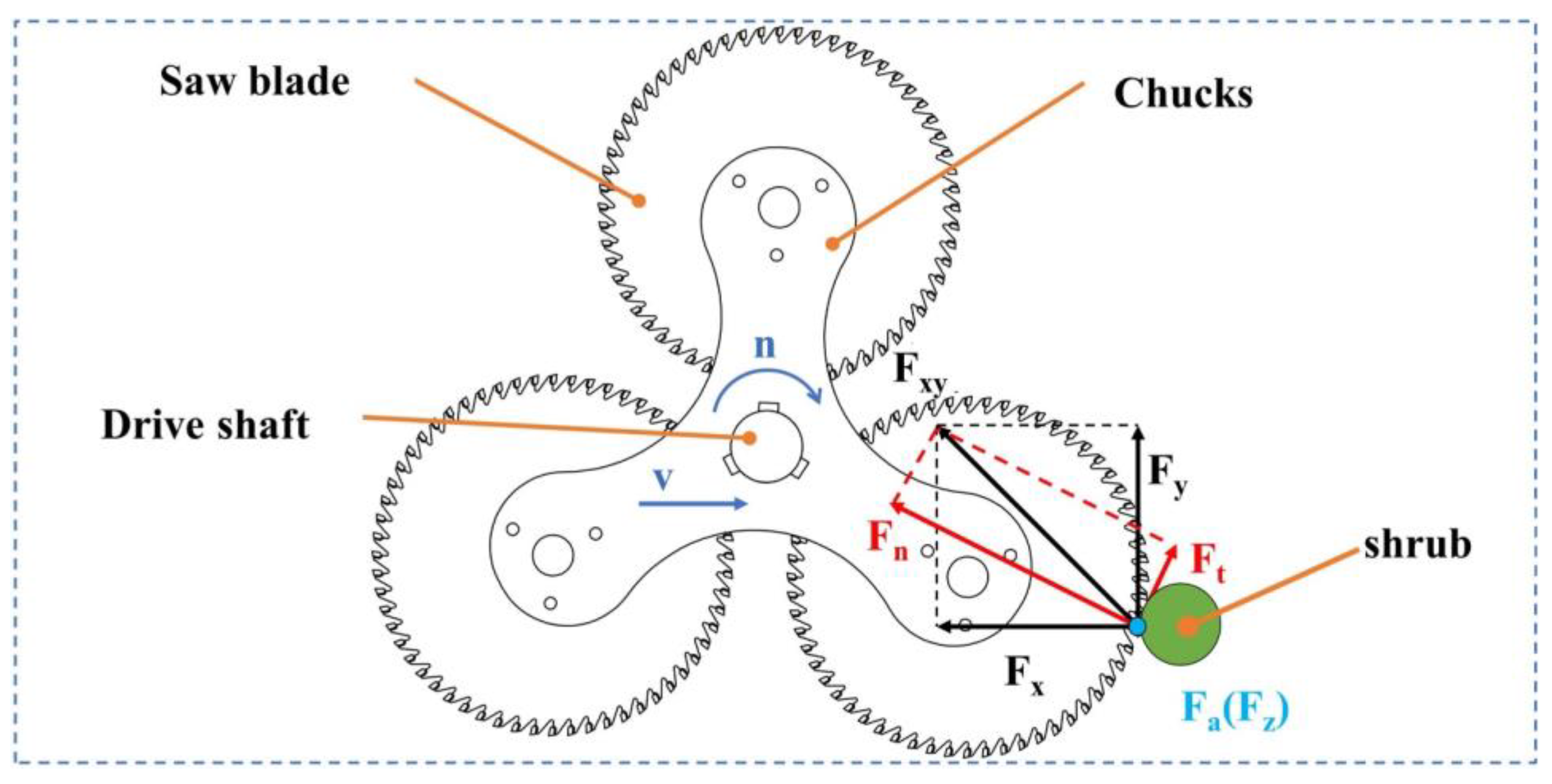

2.2.1. Quasi-Planetary Shrub Cutter

2.2.2. Cutting Test Device

3. Methods and Experimental Design

3.1. Finite-Element Single-Factor Simulation Experiment

3.1.1. Indicators and Factors

3.1.2. Finite-Element Modelling

3.2. Orthography Experimental Design

4. Results and Discussion

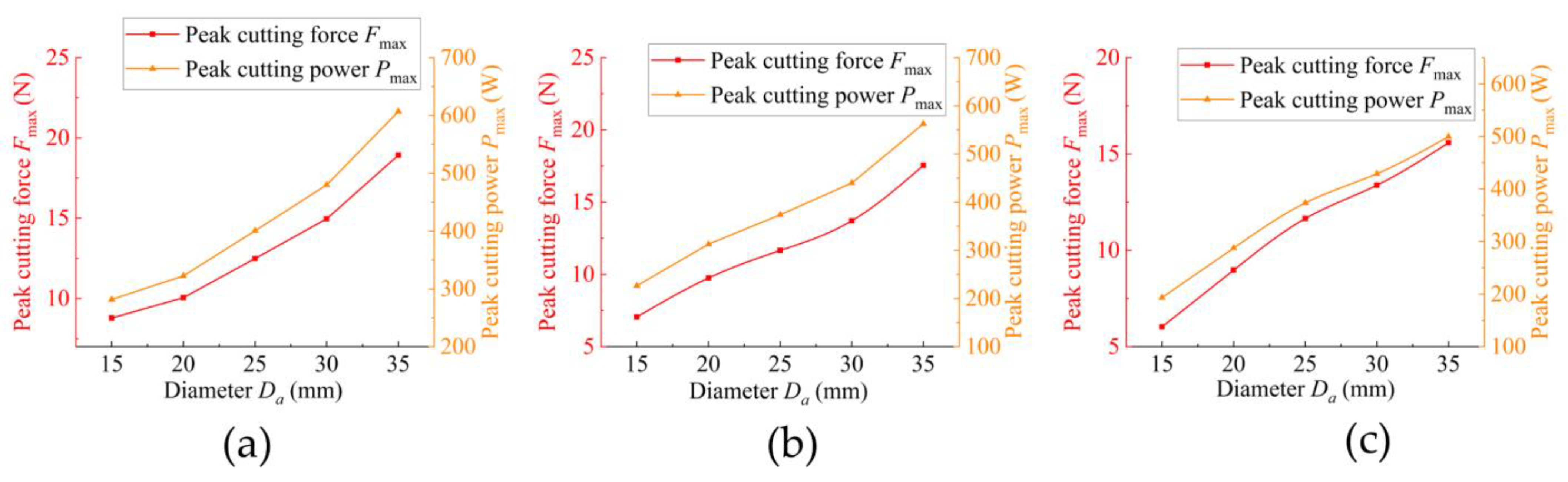

4.1. Single Experiment Simulation Results and Analysis

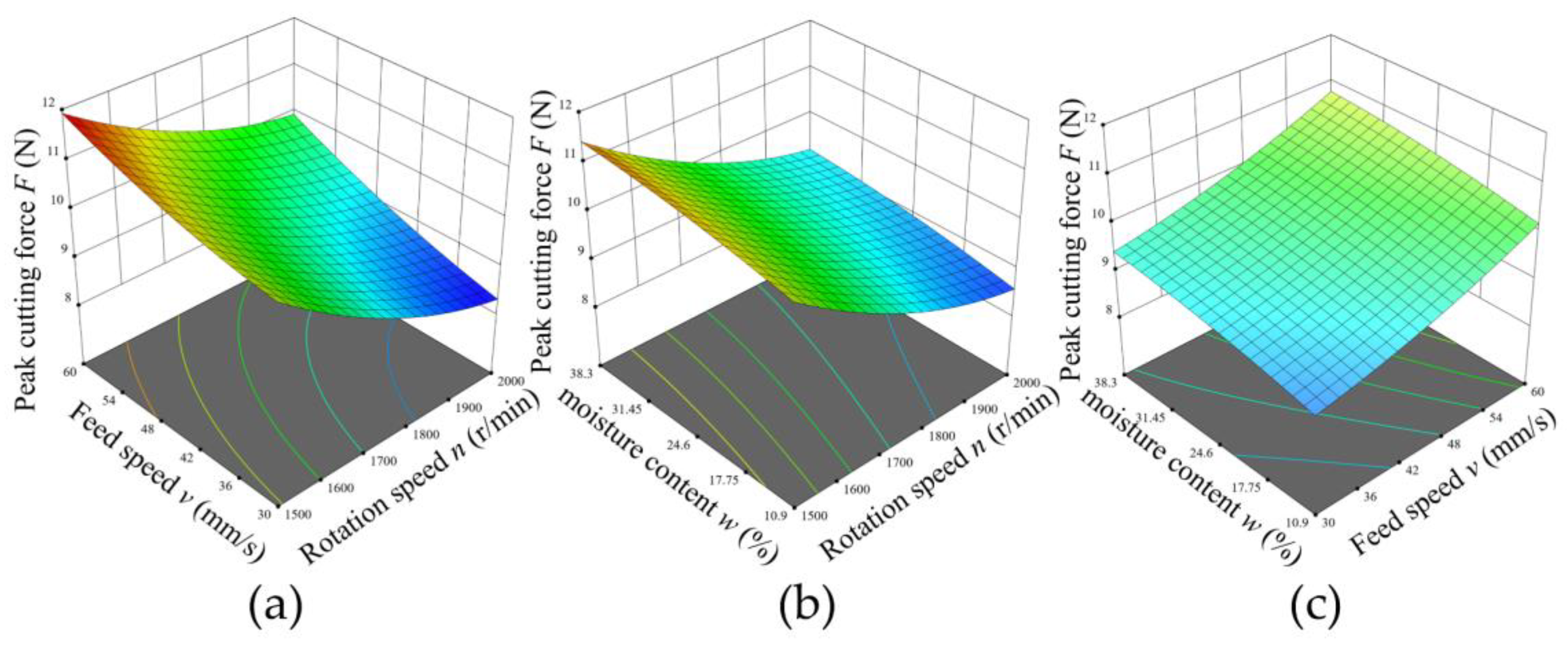

4.2. Orthogonal Experiment Results and Analysis

4.2.1. Orthogonal Experiment Results

4.2.2. Analysis

4.3. Optimization and Test Verification

5. Conclusions

- Using material mechanics methods and a universal mechanical testing machine, the material constitutive models of three types of shrubs were derived based on their transverse isotropy. Based on these constitutive models, a finite-element model of the planetary tool cutting shrubs was established. Single-factor simulation tests showed that as the tool rotation speed increases, the peak cutting force tends to decrease, while the peak cutting power initially decreases and then gradually increases. As the feed rate increases, both the peak cutting force and peak cutting power increase. Additionally, as the shrub diameter increases, both peak cutting force and peak cutting power also increase;

- A three-factor, three-level orthogonal experiment was designed based on the constructed test bench. Regression and variance analyses were performed on the results, and a single-factor experiment was conducted with shrub moisture content as the variable. The experimental results showed that as moisture content increases, both peak cutting force and peak cutting power initially decrease and then increase. The results of the multi-factor experiment are consistent with those of the single-factor experiment;

- With the optimisation objective of minimising both peak cutting force and peak cutting power, optimisation and experimental validation were performed. The results indicated that when the tool rotation speed is 1813 rpm, the feed rate is 30 mm/s, and the shrub moisture content is 10.9%, the peak cutting force reaches 8.42 N, and the peak cutting power reaches 282.99 W, both achieving their optimal values. The errors between the predicted values and the validation test results are 2.68% and 1.56%, respectively [13].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A.H. | Alnus hirsuta |

| S.A. | Syringa amurensis |

| C.H. | Corylus heterophylla |

References

- Mao, P.; Qin, L.; Hao, M.; Zhao, W.; Luo, J.; Qiu, X.; Xu, L.; Xiong, Y.; Ran, Y.; Yan, C.; et al. An Improved Approach to Estimate Above-Ground Volume and Biomass of Desert Shrub Communities Based on UAV RGB Images. Ecol. Indic. 2021, 125, 107494. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Mei, C.; Li, Y.; Duan, G.; Agarwal, S.; Greiner, A.; Ma, C.; Jiang, S. Wood-Inspired Anisotropic Cellulose Nanofibril Composite Sponges for Multifunctional Applications. ACS Appl. Mater. Interfaces 2020, 12, 35513–35522. [Google Scholar] [CrossRef] [PubMed]

- Sun, F. Comparison Analysis of Moisture-Dependent Orthotropic Elasticity between Earlywood and Latewood in Chinese Fir Using Digital Image Correlation. Ind. Crops Prod. 2024, 220, 119185. [Google Scholar] [CrossRef]

- Igathinathane, C.; Womac, A.; Sokhansanj, S. Corn stalk orientation effect on mechanical cutting. Biosyst. Eng. 2010, 107, 97–106. [Google Scholar] [CrossRef]

- Xie, L.; Wang, P.; Luo, J.; Yi, W.; Deng, J. Optimisation and Numerical Simulation of Shearing Blade Used for Citrus Seedling Grafting. Biosyst. Eng. 2022, 215, 67–79. [Google Scholar] [CrossRef]

- Li, M.; Xu, S.; Yang, Y.; Guo, L.; Tong, J. A 3D simulation model of corn stubble cutting using finite element method. Soil Tillage Res. 2017, 166, 43–51. [Google Scholar] [CrossRef]

- Wang, T.; Yan, X.; Mi, G.; Liu, S.; Zhang, Z.; Liu, Z. Research status of hard stem cutting device. J. Chin. Agric. Mech. 2023, 44, 34–39. [Google Scholar] [CrossRef]

- Luo, H.; Guo, S.; Zhi, Z.; Kan, J. Sliding Cutting and Cutting Parameters of Concentric Curvilineal Edge Sliding Cutter for Caragana Korshinskii (C.K.) Branches. Forests 2023, 14, 2379. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Y.; Qu, A.; Kan, J.; Kang, F.; Wang, Y. Study of Sawing Parameters for Caragana Korshinskii (C.K.) Branches. Forests 2022, 13, 327. [Google Scholar] [CrossRef]

- Sanchez-Espiga, J.; Fuerst, M.; Fernandez-del-Rincon, A.; Otto, M.; Viadero, F.; Stahl, K. On the Behaviour of N-Planets Planetary Gear Sets Influenced by Geometrical Design Factors. Mech. Mach. Theory 2025, 205, 105860. [Google Scholar] [CrossRef]

- Qiu, M.; Meng, Y.; Li, Y.; Shen, X. Sugarcane stem cut quality investigated by finite element simulation and experiment. Biosyst. Eng. 2021, 206, 135–149. [Google Scholar] [CrossRef]

- Meng, Y.; Wei, J.; Wei, J.; Chen, H.; Cui, Y. An ANSYS/LS-DYNA Simulation and Experimental Study of Circular Saw Blade Cutting System of Mulberry Cutting Machine. Comput. Electron. Agric. 2019, 157, 38–48. [Google Scholar] [CrossRef]

- Li, Z.; Lin, Z.; Li, S.; Zhang, H. Optimization Research on the Working Parameters of Sugarcane Harvester on the Cutting Time of Stalks Using Virtual Prototype Technology. Sugar Tech. 2023, 25, 41–56. [Google Scholar] [CrossRef]

- Luo, Y.; He, H.; Zhang, Z.; Liu, T.; Yu, Z.; Liu, Z.; Bao, G. Species composition and diversity under different stand densities in Zhangguangcailing. J. Cent. South Univ. For. Technol. 2023, 43, 131–141. [Google Scholar] [CrossRef]

- SAC/TC 41. GB/T 1927-2021; Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens. State Administration for Market Regulation. Standardization Administration of China: Beijing, China, 2021.

- Li, P.; Guo, Y.B.; Shim, V.P.W. A Constitutive Model for Transversely Isotropic Material with Anisotropic Hardening. Int. J. Solids Struct. 2018, 138, 40–49. [Google Scholar] [CrossRef]

- SAC/TC 41. GB/T 1935-2009; Dimensions of Wood Specimens for Physical and Mechanical Tests. General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China Standardization Administration of China: Beijing, China, 2009.

- Xie, Q.; Zhang, L.; Zhang, B.; Yang, G.; Yao, J. Dynamic Parallel-to-Grain Compressive Properties of Three Softwoods under Seismic Strain Rates: Tests and Constitutive Modeling. Holzforschung 2020, 74, 927–937. [Google Scholar] [CrossRef]

- Mascia, N.T. Evaluation of the Coefficients of Mutual Influence of Wood through Off-Axis Compression Tests. Constr. Build. Mater. 2012, 30, 522–528. [Google Scholar] [CrossRef]

- Svoreň, J.; Naščák, Ľ.; Barcík, Š.; Koleda, P.; Stehlík, Š. Influence of Circular Saw Blade Design on Reducing Energy Consumption of a Circular Saw in the Cutting Process. Appl. Sci. 2022, 12, 1276. [Google Scholar] [CrossRef]

- Elwakeel, A.E.; Mohamed, S.M.A.; Tantawy, A.A.; Okasha, A.M.; Elsayed, S.; Elsherbiny, O.; Farooque, A.A.; Yaseen, Z.M. Design, Construction and Field Testing of a Manually Feeding Semiautomatic Sugarcane Dud Chipper. Sci. Rep. 2024, 14, 5373. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, D.; Zhao, J. Study of the Cutting Mechanism of Oil Tree Peony Stem. Forests 2020, 11, 760. [Google Scholar] [CrossRef]

- Svrzic, S.; Djurkovic, M.; Danon, G.; Furtula, M.; Stanojevic, D. On Acoustic Emission Analysis in Circular Saw Cutting Beech Wood with Respect to Power Consumption and Surface Roughness. BioResources 2021, 16, 8239–8257. [Google Scholar] [CrossRef]

- Bukhtoyarov, L.; Kunickaya, O.; Urazova, A.; Perfiliev, P.; Druzyanov, V.; Egipko, S.; Burgonutdinov, A.; Tikhonov, E. Substantiating Optimum Parameters and Efficiency of Rotary Brush Cutters. J. Appl. Eng. Sci. 2022, 20, 788–797. [Google Scholar] [CrossRef]

- Ren, Y.; Teng, C.; Gao, T.; Zhang, Y.; Liu, H.; Dong, X. Frictional Properties of Red Pine Cones Harvested under Different Conditions. BioResources 2024, 19, 766–788. [Google Scholar] [CrossRef]

- Wang, W.; Ma, Y.; Fu, L.; Cui, Y.; Majeed, Y. Physical and Mechanical Properties of Hydroponic Lettuce for Automatic Harvesting. Inf. Process. Agric. 2021, 8, 550–559. [Google Scholar] [CrossRef]

- Warguła, Ł.; Wojtkowiak, D.; Kukla, M.; Talaśka, K. Modelling the Process of Splitting Wood and Chipless Cutting Pinus Sylvestris L. Wood in Terms of Designing the Geometry of the Tools and the Driving Force of the Machine. Eur. J. Wood Wood Prod. 2023, 81, 223–237. [Google Scholar] [CrossRef]

- Song, S.; Zhou, H.; Jia, Z.; Xu, L.; Zhang, C.; Shi, M.; Hu, G. Effects of Cutting Parameters on the Ultimate Shear Stress and Specific Cutting Energy of Sisal Leaves. Biosyst. Eng. 2022, 218, 189–199. [Google Scholar] [CrossRef]

- Tayisepi, N.; Svosve, R.; Tigere, G.; Mnkandla, A.N.; Mapindu, I. Comparative Optimisation of the Cutting Parameters for Surface Quality and Energy Efficiency during the Machining Manufacturing of Teak, Saligna and Pine Wood Materials. J. Eng. Res. Rep. 2023, 25, 73–87. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Z.; Xiao, M.; Bartos, P.; Bohata, A. Soil-Cutting Simulation and Parameter Optimization of Rotary Blade’s Three-Axis Resistances by Response Surface Method. Comput. Electron. Agric. 2019, 164, 104902. [Google Scholar] [CrossRef]

- Zhao, L.; Yuan, W.; Xu, L.; Jin, S.; Cui, W.; Xue, J.; Zhou, H. Linear Cutting Performance Tests and Parameter Optimization of Poplar Branches Based on RSM and NSGA-II. Forests 2024, 15, 146. [Google Scholar] [CrossRef]

| ID | Density (kg/m3) | EL (MPa) | ER (MPa) | ET (MPa) | GRT (MPa) | GLR (MPa) | GLT (MPa) | μRT | μLR | μLT |

|---|---|---|---|---|---|---|---|---|---|---|

| A.H. | 816.32 | 960.94 | 119.91 | 119.91 | 57.59 | 340.76 | 340.76 | 0.041 | 0.41 | 0.41 |

| S.R. | 768.41 | 917.16 | 107.12 | 107.12 | 51.50 | 327.56 | 327.56 | 0.040 | 0.40 | 0.40 |

| C.H. | 855.76 | 784.52 | 86.33 | 86.33 | 41.67 | 288.43 | 288.43 | 0.036 | 0.36 | 0.36 |

| Model | Structure | Symbol/Unit | Parameters |

|---|---|---|---|

| Saw blade | Outer diameter | D1/mm | 150 |

| Saw-tooth number | Z/T | 60 | |

| Thickness | s/mm | 1.8 | |

| Inner diameter | d/mm | 25.4 | |

| Tooth geometry | Alternate top bevel | ||

| Front angle | α/° | 15 | |

| Rear angle | β/° | 15 | |

| Chuck | Cylindrical diameters | D2/mm | 250 |

| Inner diameter | d1/mm | 30 | |

| Thickness | s1/mm | 10 |

| Level | n (r/min) | v (mm/s) | Da (mm) |

|---|---|---|---|

| 1 | 1000 | 30 | 15 |

| 2 | 1250 | 45 | 20 |

| 3 | 1500 | 60 | 25 |

| 4 | 1750 | 75 | 30 |

| 5 | 2000 | 90 | 35 |

| Material | Poisson’s Ratio | Density (kg/m3) | Elastic Modulus (Gpa) | Yield Limit (Gpa) | Shear Modulus (Gpa) |

|---|---|---|---|---|---|

| 65 Mn | 0.3 | 7850 | 206 | 0.44 | 78.5 |

| Level | n (r/min) | v (mm/s) | w (mm) |

|---|---|---|---|

| 1 | 1500 | 45 | 15 |

| 2 | 1750 | 60 | 20 |

| 3 | 2000 | 75 | 25 |

| Groups | n (r/min) | v (mm/s) | w (mm) | Fmax (N) | Pmax (W) |

|---|---|---|---|---|---|

| 1 | 1750 | 45 | 24.6 | 9.65 | 309.47 |

| 2 | 1500 | 60 | 24.6 | 11.83 | 325.09 |

| 3 | 1750 | 60 | 10.9 | 10.28 | 329.65 |

| 4 | 1750 | 45 | 24.6 | 9.71 | 311.37 |

| 5 | 1750 | 45 | 24.6 | 9.69 | 310.87 |

| 6 | 1750 | 45 | 24.6 | 9.75 | 312.59 |

| 7 | 1750 | 60 | 38.3 | 10.88 | 349.06 |

| 8 | 1750 | 30 | 38.3 | 9.33 | 299.29 |

| 9 | 1750 | 45 | 24.6 | 9.89 | 317.13 |

| 10 | 1500 | 45 | 10.9 | 10.84 | 297.86 |

| 11 | 2000 | 45 | 10.9 | 8.57 | 314.13 |

| 12 | 1750 | 30 | 10.9 | 8.70 | 279.09 |

| 13 | 1500 | 30 | 24.6 | 10.87 | 298.92 |

| 14 | 1500 | 45 | 38.3 | 11.43 | 314.22 |

| 15 | 2000 | 30 | 24.6 | 8.42 | 308.59 |

| 16 | 2000 | 45 | 38.3 | 9.22 | 338.11 |

| 17 | 2000 | 60 | 24.6 | 9.88 | 362.08 |

| Variance Source | Degree of Freedom | Fmax (N) | Pmax (W) | ||

|---|---|---|---|---|---|

| F-Values | p-Values | F-Values | p-Values | ||

| Model | 9 | 120.28 | <0.0001 | 52.66 | <0.0001 |

| n | 1 | 700.69 | <0.0001 | 70.8 | <0.0001 |

| v | 1 | 273.14 | <0.0001 | 304.38 | <0.0001 |

| w | 1 | 54.93 | 0.0001 | 60.04 | 0.0001 |

| n·v | 1 | 4.58 | 0.0696 | 14.03 | 0.0072 |

| n·w | 1 | 0.0612 | 0.8118 | 1.09 | 0.3319 |

| v·w | 1 | 0.0106 | 0.9209 | 0.0115 | 0.9176 |

| n2 | 1 | 39.74 | 0.0004 | 13.76 | 0.0076 |

| v2 | 1 | 6.57 | 0.0373 | 7.26 | 0.0309 |

| w2 | 1 | 2.22 | 0.1796 | 2.48 | 0.1591 |

| Lack of Fit | 3 | 2.59 | 0.1900 | 2.28 | 0.2211 |

| Number | Fmax (N) | Pmax (W) |

|---|---|---|

| 1 | 7.96 | 264.47 |

| 2 | 8.35 | 277.43 |

| 3 | 9.13 | 303.34 |

| 4 | 8.81 | 292.71 |

| 5 | 9.01 | 299.36 |

| Average value | 8.65 | 287.46 |

| Relative errors | 2.68% | 1.56% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.; Dong, X.; Teng, C.; Guo, B.; Zhang, J.; Zhang, Y. Simulation and Experimental Study on the Shrub-Cutting Performance of Quasi-Planetary Cutter. Appl. Sci. 2025, 15, 6937. https://doi.org/10.3390/app15126937

Song Z, Dong X, Teng C, Guo B, Zhang J, Zhang Y. Simulation and Experimental Study on the Shrub-Cutting Performance of Quasi-Planetary Cutter. Applied Sciences. 2025; 15(12):6937. https://doi.org/10.3390/app15126937

Chicago/Turabian StyleSong, Zikai, Xibin Dong, Chi Teng, Ben Guo, Jiawang Zhang, and Yuchen Zhang. 2025. "Simulation and Experimental Study on the Shrub-Cutting Performance of Quasi-Planetary Cutter" Applied Sciences 15, no. 12: 6937. https://doi.org/10.3390/app15126937

APA StyleSong, Z., Dong, X., Teng, C., Guo, B., Zhang, J., & Zhang, Y. (2025). Simulation and Experimental Study on the Shrub-Cutting Performance of Quasi-Planetary Cutter. Applied Sciences, 15(12), 6937. https://doi.org/10.3390/app15126937