1. Introduction

Microcantilevers provide the basis for the simplest/fundamental device structure within the field of microelectromechanical systems (MEMSs) [

1,

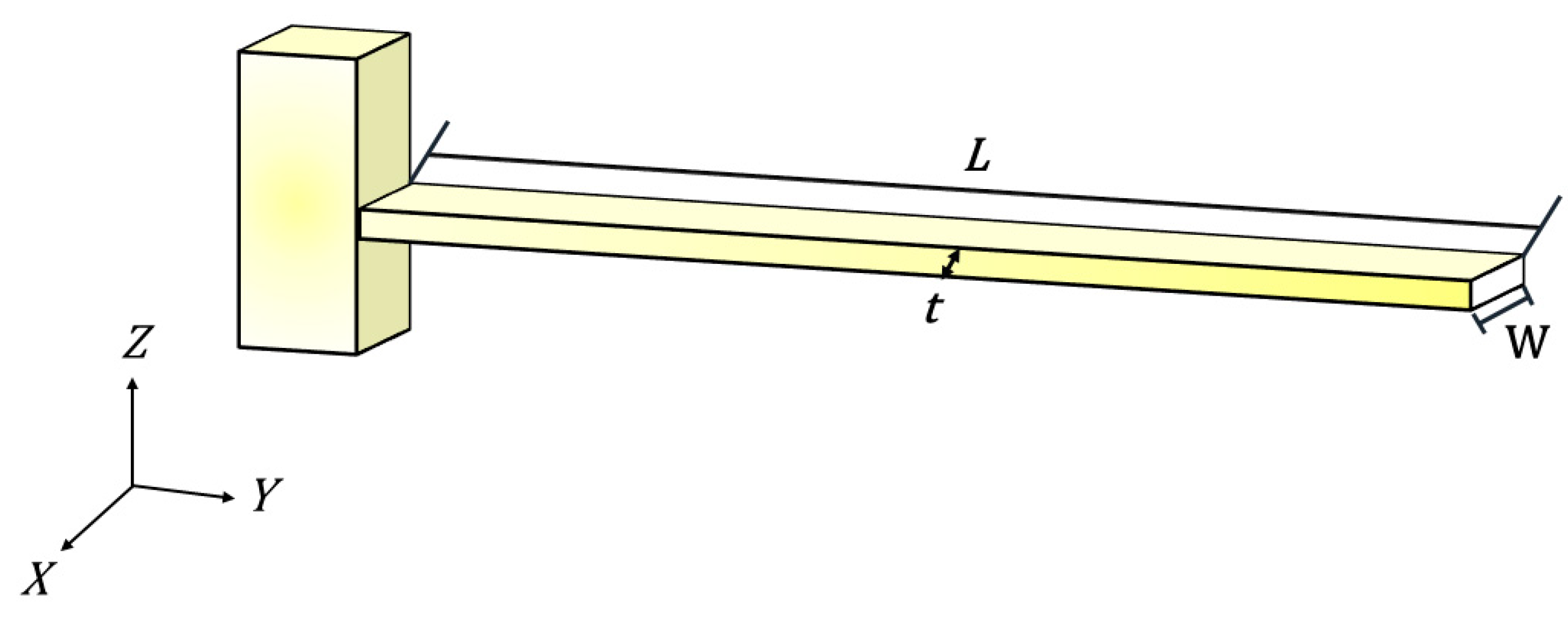

2]. Rectangular microcantilevers can be modeled as a planar beam that lies in a single plane (e.g., plane XY in

Figure 1). The microcantilever lies in a plane parallel to a substrate where films to produce the microcantilever were grown, with the free tip capable of moving perpendicular to the substrate, such that the lateral in-plane motion of the free end would encounter more resistance [

3].

Microcantilevers are extensively used as key components of physical, chemical, and biological sensors. The sensing application is based on the changes in bending (static mode) [

4] or in resonance frequency (dynamic mode) [

5] produced by the action induced by molecules or other materials adsorbed on the surface of the cantilever [

6].

Although microcantilevers have been extensively explored for biosensing applications, several limitations persist in the existing literature. Most conventional designs rely on silicon (Si) or silicon-based materials (see

Table 1), which, while widely available, exhibit moderate mechanical properties that constrain sensitivity—especially in dynamic operation modes. The relatively low Young’s modulus of Si limits the achievable resonant frequency, reducing the cantilever’s capacity to detect extremely small mass changes, such as those in the picogram range. Furthermore, many prior studies treat the actuator and cantilever design as separate entities, lacking a clear correlation between the piezoelectric actuator’s resonant frequency and the cantilever’s mechanical response. This disjointed approach leads to suboptimal energy transfer and reduced sensitivity. In addition, environmental damping and mechanical losses are often overlooked in simulation models, impacting predictive accuracy under real-world conditions.

This study introduces a unified and systematic design methodology that begins with optimizing the piezoelectric actuator and then designing the microcantilever based on the novel ultrananocrystalline diamond (UNCD) to match the actuator’s resonant frequency. This matching ensures efficient vibrational excitation. UNCD offers a higher Young’s modulus, shear modulus, and hardness and lower damping (characterized by Poisson’s ratio) compared to prior materials used for microcantilevers (

Table 1). The unique UNCD properties enable enhanced resonant frequencies and superior sensitivity. The simulation framework incorporates both frequency and time domain analyses, including thermoelastic damping, to realistically predict quality factors and oscillation amplitudes. This integrated approach directly addresses the key challenges found in previous designs and provides a robust foundation for next-generation, high-sensitivity MEMS biosensors.

Table 1 summarizes the key mechanical properties of the materials previously used as bases for producing MEMS microcantilevers [

7,

8]. These include ultrananocrystalline diamond (UNCD) films, as developed by Auciello and colleagues [

9,

10,

11,

12], grown on Si substrates. UNCD exhibits the highest Young’s modulus among the listed materials. This implies that microcantilevers fabricated with UNCD are expected to exhibit superior sensitivity and mass resolution, especially when operating in dynamic mode.

For a cantilever operating in static mode, the sensing method relies on the flexural single bending of the beam (static mode) [

4]. When a cantilever oscillates at its resonance frequency, induced by electrical or physical excitation, usually at its first resonance mode or eigenfrequency (dynamic mode) [

5], the change in mass produced by the absorption of particles or molecules on the cantilever’s surface induces a change in the natural frequency [

13].

Static mode is described by the Stoney Equation (1) [

14],

where

is the bending amplitude of the microcantilever,

is the surface stress change,

is the Poisson’s ratio,

L is the length of the microcantilever,

E is the Young’s modulus of the base material used to make the microcantilever, and

t is thickness of the microcantilever. Thus, in operation mode, the sensing is based on the differential stress produced by the addition of particles or molecules on the surface of the cantilever and the consequent amplitude of the bending.

On the other hand, in dynamic mode, the sensing is related to the resonance frequency shift produced by the addition of particles to the surface of the vibrating microcantilever [

9]. The resonance frequency, in terms of geometry and mechanical properties of the microcantilever, is given by Equation (2),

where

is the natural resonance frequency of the microcantilever, with no damping for the

n mode,

is a constant that appears during modal analysis,

ρ is the density of the base material, and

E,

L, and

t represent the same parameters as in Equation (1). For the first eigenfrequency,

is 1.875, which originates from the solution of the Euler–Bernoulli beam theory, as shown in Equation (2) [

3,

15].

Furthermore, the mass sensitivity per unit mass of load on a rectangular microcantilever is given by Equation (3) [

16],

where

mc is the total mass of the microcantilever. Equation (3) can be rewritten in terms of geometrical characteristics and material properties, replacing

in Equation (3) with the parameters shown in Equation (2), giving Equation (4).

Equation (4) enables the calculation of the shift in the microcantilever vibration frequency in the first resonance mode produced by the addition of mass on the microcantilever. The frequency shift increases with the squared root of E and decreases with an increased density ρ of the beam’s material and an increased width W and length L of the cantilever.

Another important aspect to consider is the mass resolution, which is given by Equation (5) [

14,

16],

where

is defined as the minimum mass detectable by the minimum frequency shift,

is the Boltzmann constant,

T is the absolute temperature,

B is the detection bandwidth,

is the spring constant of the microcantilever,

Q is the quality factor, and

A is the amplitude of the oscillation. Equation (5) is a general equation for micro-resonators for mass sensing. This equation shows that as the amplitude (

A) of the oscillations decreases, the mass resolution of the resonator increases. On the other hand, the increase in resonant frequency (

fn,0) increases the mass resolution.

As seen in Equations (4) and (5) the mechanical properties of the material play an important role in the mass sensitivity of microcantilevers. Both equations show that the Young’s modulus of a microcantilever’s material is a key factor for sensitivity and mass resolution, such that a large Young’s modulus increases the resonant frequency of the microcantilever, which, in turn, increases the mass resolution and sensitivity of a microcantilever-based biosensor.

Under dynamic mode operation, the actuation mechanism of the microcantilever plays a critical role. The most used methods include magnetic, electrostatic, thermoelectric, optothermal, and piezoelectric actuation [

17].

Piezoelectric actuation offers several advantages, including suitability for miniaturization, high efficiency, absence of electromagnetic noise generation, and non-flammability [

18]. Among piezoelectric materials, lead (Pb)–zirconium (Zr)–titanate (Ti) (PbZr

xTi

1-xO

3 (PZT)) films are commonly used because they exhibit some of the highest piezoelectric coefficients and strong electromechanical coupling factors [

19]. However, because of the toxicity of lead (Pb), alternative materials, such as aluminum nitride (AlN), zinc oxide (ZnO), and barium titanate (BaTiO

3), have been explored for use in MEMS piezoelectric film applications.

AlN presents an electromechanical coupling coefficient of ~0.23, a high breakdown voltage (>1.2 × 10

6 V∙cm

−1), a high resistivity (~10

12 Ω∙cm), a low loss tangent, and a high signal-to-noise ratio [

20,

21,

22,

23].

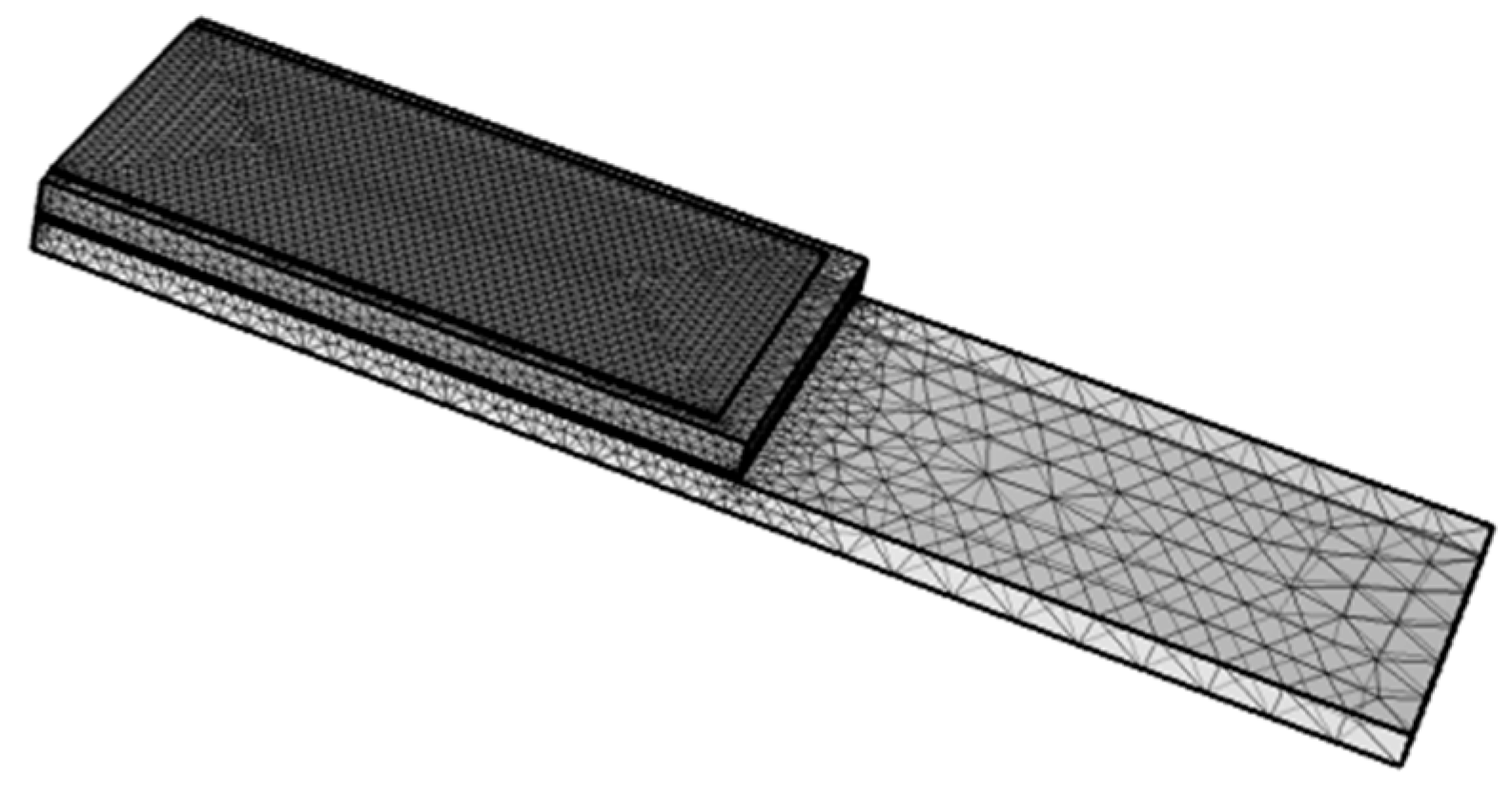

The purpose of the research presented in this article is to implement a methodology for studying the structural performance of UNCD microcantilevers actuated piezoelectrically, using AlN as the piezoelectric layer, for biosensing applications. The simulations were carried out using the commercially available software COMSOL Multiphysics Version 4. The results presented in this article provide valuable insight into the advantages of using UNCD-based microcantilevers for biosensing applications. The biosensor design is based on the structure proposed in reference [

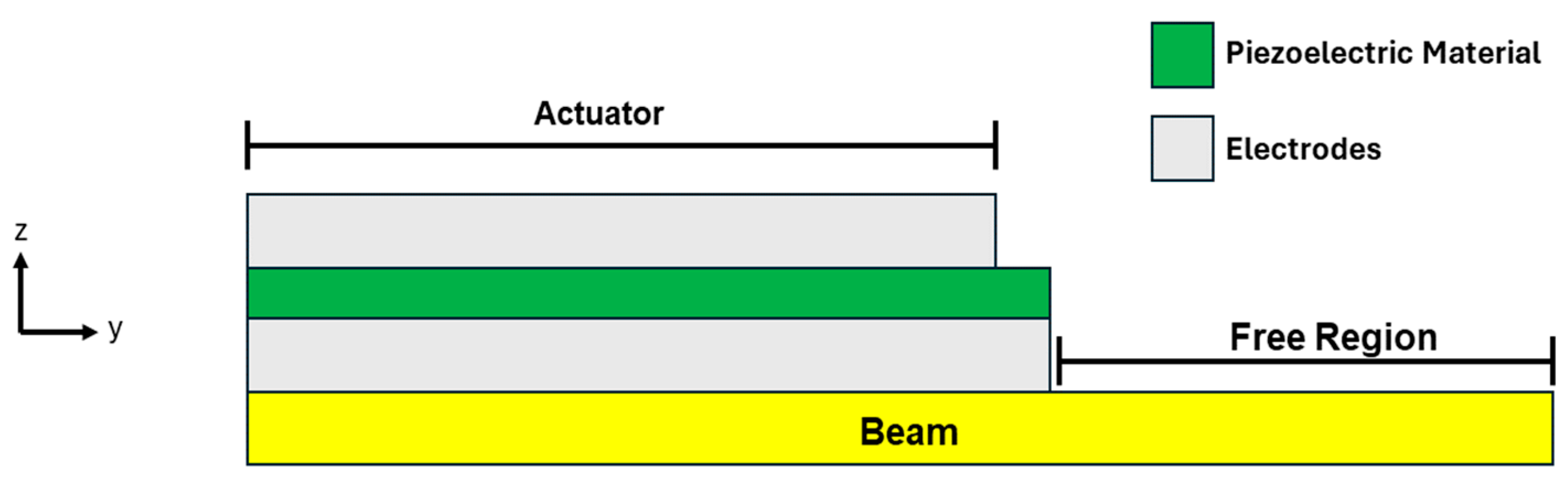

13], which features a stepped microcantilever with a portion of the beam left uncovered to allow particle adhesion on the UNCD surface, as shown in

Figure 2. This uncovered region, referred to as the active area, can be functionalized for the selective binding of specific biomolecules, taking advantage of the excellent biocompatibility of the UNCD surface—an attribute demonstrated in multiple chapters of a recently published book edited by O. Auciello [

24].

Additionally, a silicon (Si) microcantilever with the same design parameters was modeled to compare its performance with that of the UNCD-based microcantilevers.

2. Materials and Methods

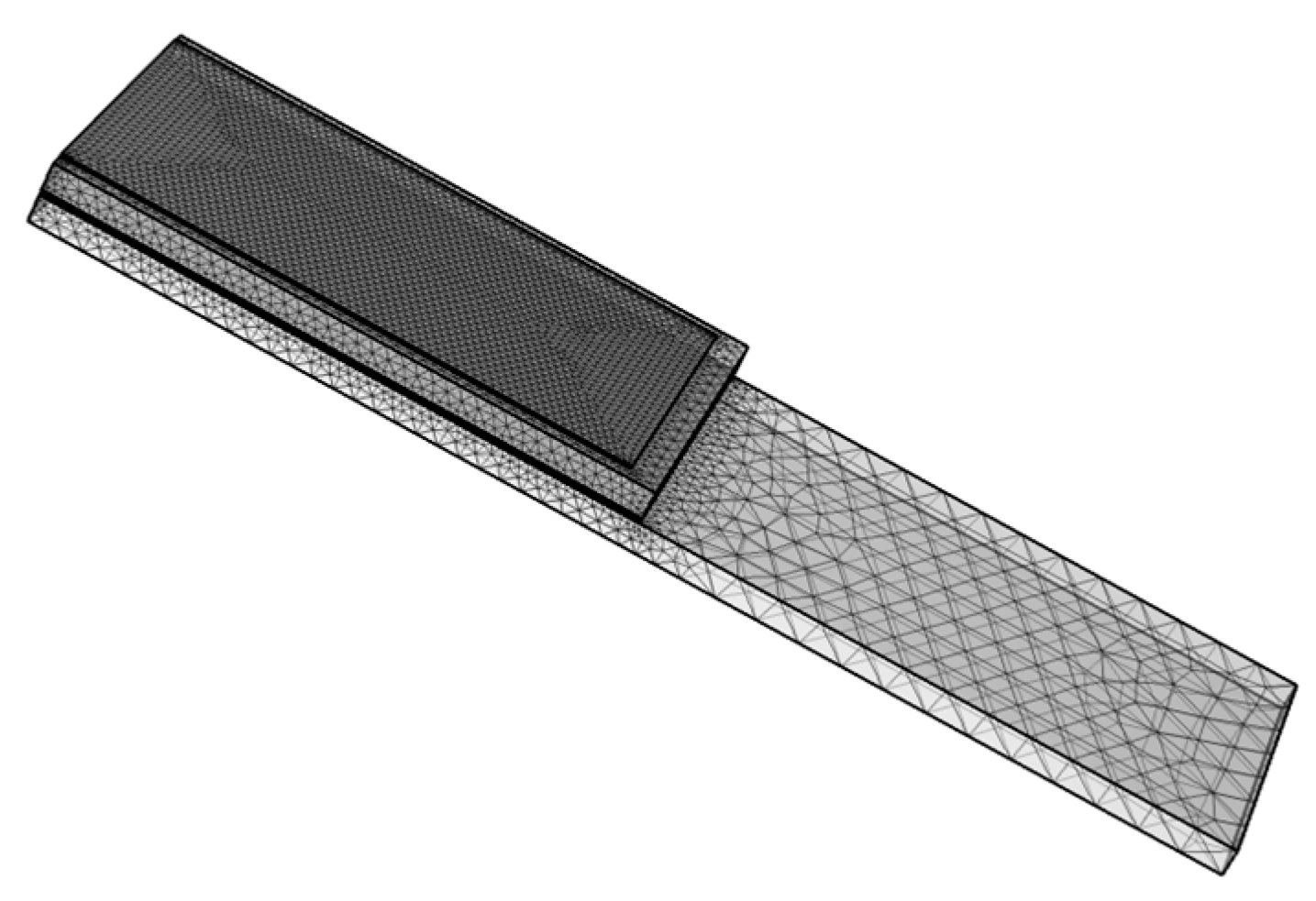

The structure of the UNCD-based microcantilever, shown in

Figure 2, was designed using COMSOL Multiphysics version 6.0. The design process was divided into two main stages. The first stage focused on analyzing the frequency response of the actuator alone. The second stage combined frequency and time domain analyses to determine the resonant frequency shift, oscillation amplitude (A), and quality factor (Q) of the integrated piezoelectric actuator–UNCD or Si beam system. The current model does not account for environmental damping or the influence of surrounding air. The simulations were conducted under vacuum conditions (≤10

−3 Torr), where gas damping is negligible and the fluid is in the molecular regime. This simplification corresponds to a first step, first approximation approach aimed at determining the intrinsic structural parameters of the microcantilever. While measurements in future work will be carried out at atmospheric pressure, this initial modeling framework establishes a baseline that can be refined and improved by incorporating experimental data, including damping effects from air or liquid environments. All simulations were conducted at a fixed temperature of 298.15 K.

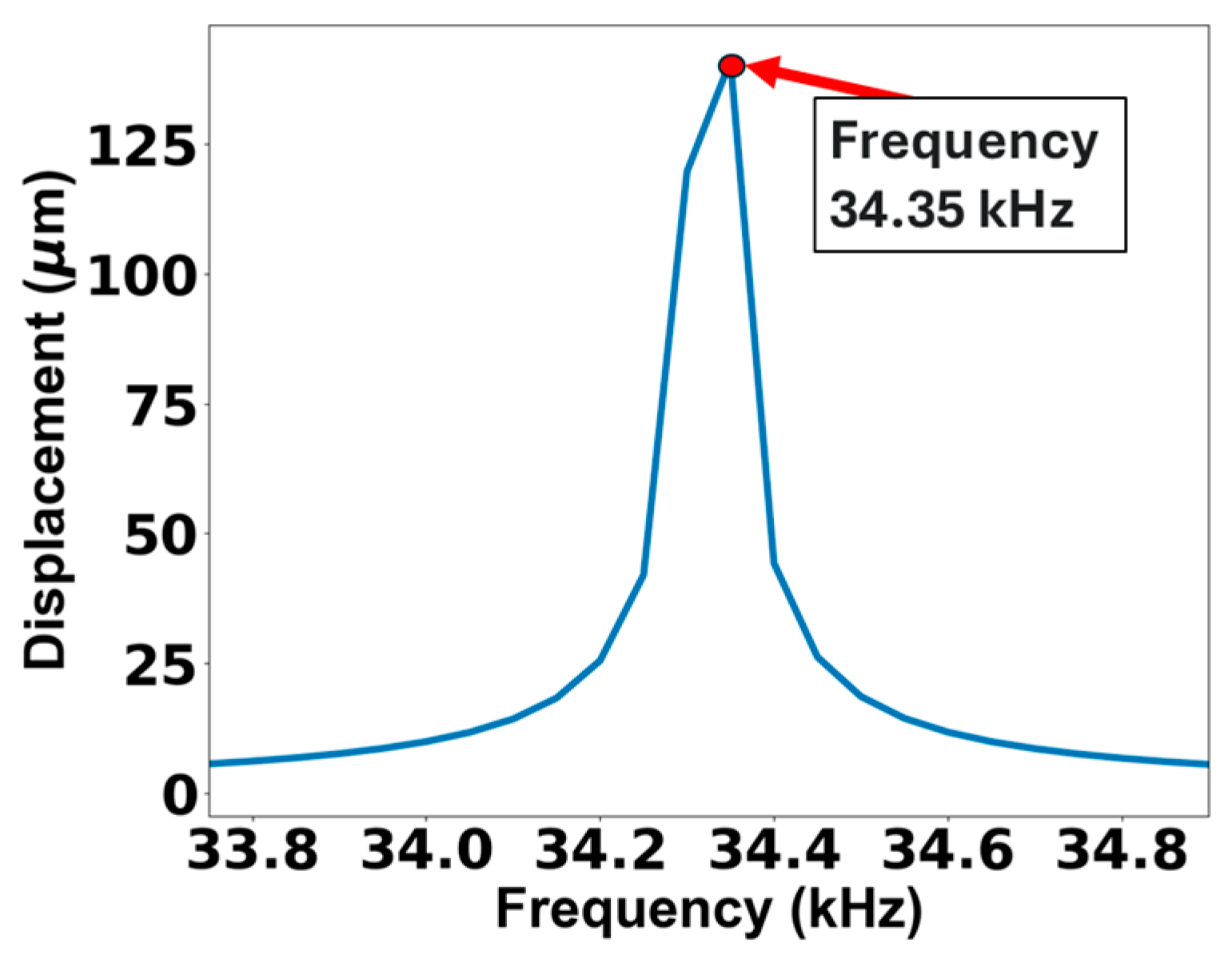

2.1. Design of the Actuator Structure

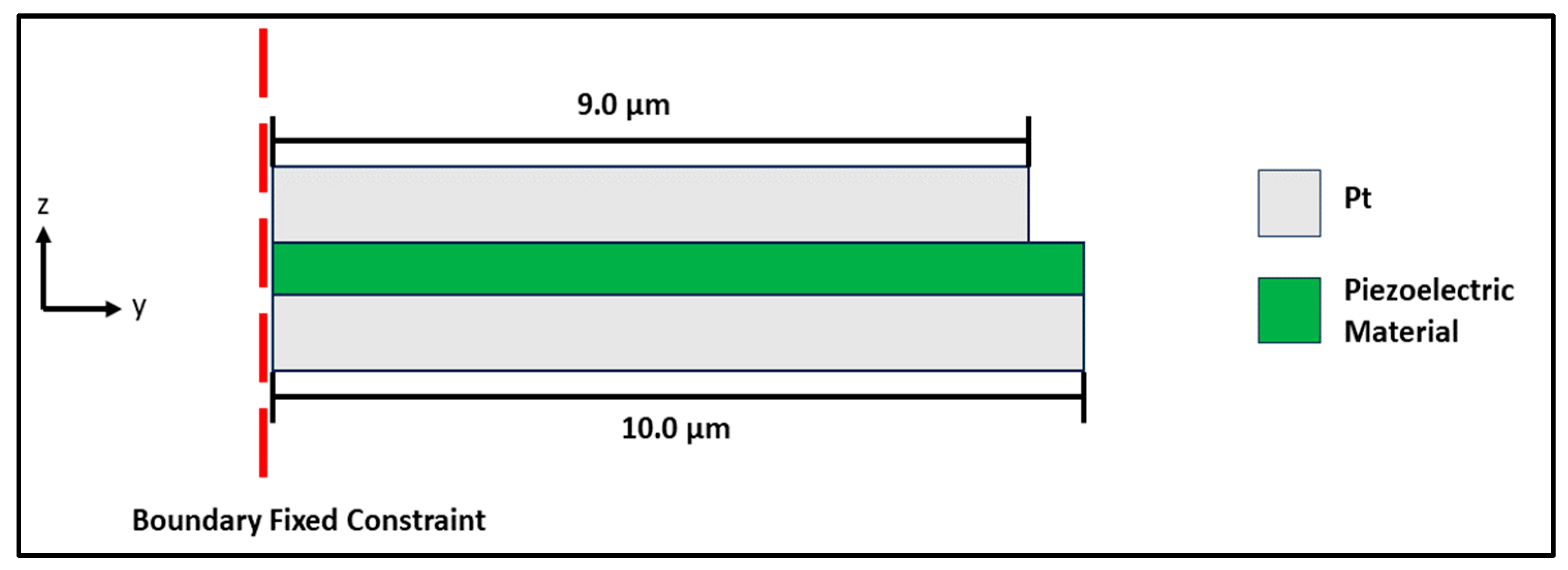

The metal/piezoelectric/metal actuation structure is designed as a capacitor-like configuration, consisting of an AlN film sandwiched between two platinum (Pt) electrodes, as shown in

Figure 3. The top electrode measures 9.0 µm in length and 20 µm in width, while the bottom electrode is 10.0 µm long and 20 µm wide. Both electrodes have a thickness of 100 nm. The thickness of the AlN layer varies between 300 nm and 1000 nm.

The simulations in COMSOL Version 4 employed the Solid Mechanics and Electrostatics modules, as the primary objective was to determine the resonant frequency of the actuator. Thermoelastic effects were not included since this study focused on structural performance under idealized conditions, and thermal influences were assumed negligible at this stage to simplify the model and reduce the computational cost.

One end of the microcantilever was fixed while the other remained free, as indicated by the dotted red line in

Figure 3. A relative tolerance of 0.001 was applied in the simulation. The generalized alpha solver of COMSOL Version 4 software was used, which operates similarly to the backward differentiation formula (BDF) solver but introduces a parameter called alpha to control numerical damping at higher frequencies. Displacement data were collected using an edge probe positioned at the tip of the actuator structure. The vertical displacement (in the

z-direction, as shown in

Figure 3) was used to estimate the resonant frequency.

It is important to acknowledge that the current model assumes a uniform mass distribution across the active surface of the microcantilever. While this simplification is useful for establishing baseline performance and sensitivity, it does not fully capture the localized nature of biomolecular adsorption that occurs in real biosensing applications. In practice, adsorbed mass is often concentrated near the tip of the cantilever, which can result in a more pronounced shift in resonant frequency. Modeling such non-uniform distributions would require additional assumptions about adsorption site, pattern, and density—parameters that depend on the specific biochemical environment and are not readily available without experimental input. Recognizing this limitation, future work will focus on incorporating spatially varying mass loads to improve the predictive accuracy of the simulations under more realistic sensing conditions.

2.2. Beam Eigenfrequency Matching

The purpose of optimizing the microcantilever beam is to standardize the design process. This step ensures that the initial beam length is determined using consistent criteria for both Si- and UNCD-based microcantilevers. The simulations involve an eigenfrequency optimization, where Equation (6) is used as the objective function [

15].

Equation (6) represents a user-defined objective function employed within the COMSOL Multiphysics Version 4 optimization module. Here, fr refers to the frequency used as a variable in the simulations. This objective function is commonly applied for eigenfrequency tuning.

This objective function (Equation (6)) represents the square of the relative error. The optimization was based on the minimization of the relative error using the BOBYQA (Bound Optimization By Quadratic Approximation) algorithm.

2.3. Coupled Simulation Actuator

Using the same methodology described in

Section 2.1, the resonant frequency of the integrated piezoelectric actuator structure combined with either a UNCD or Si microcantilever was estimated. A mass of 1 picogram (pg), uniformly distributed across the surface of the UNCD or Si microcantilever, was then modeled using the Added Mass node in the Solid Mechanics module. This approach allows for the evaluation of the resonant frequency shift resulting from surface mass loading.

If the resonant frequency does not shift by at least 2 kHz, the microcantilever structure is modified by reducing the beam length. Shortening the beam increases its resonant frequency due to the corresponding reduction in mass. Additionally, since the sensitivity of a rectangular microcantilever (as shown in Equation (4)) is inversely proportional to the cube of its length (1/L3), decreasing the beam length significantly enhances the frequency shift and, consequently, the overall sensitivity.

After the optimization was finished, a more realistic mass distribution model was implemented to test the frequency response of the microcantilever. In this case, the mass was simulated by using the Added Mass Node but using a Gaussian distribution function to constrain the mass distribution to a certain area on the microcantilever. Equation (7) was used as the mass distribution function.

where

x and

y represent the coordinates across the microcantilever beam,

x0 and

y0 are the coordinates where the center of the mass distribution is located,

r is the variance in the mass distribution, which constrains the distribution to a certain region, and exp represents the Euler number. The maximum value of the mass distribution is reached exactly at the center of the region and decreases as the function takes a value away from the center. The value of

r was set to 5 µm to evaluate the distribution at

y0 40 µm, 30 µm, and 20 µm. The value of

x0 was kept constant at 0 µm.

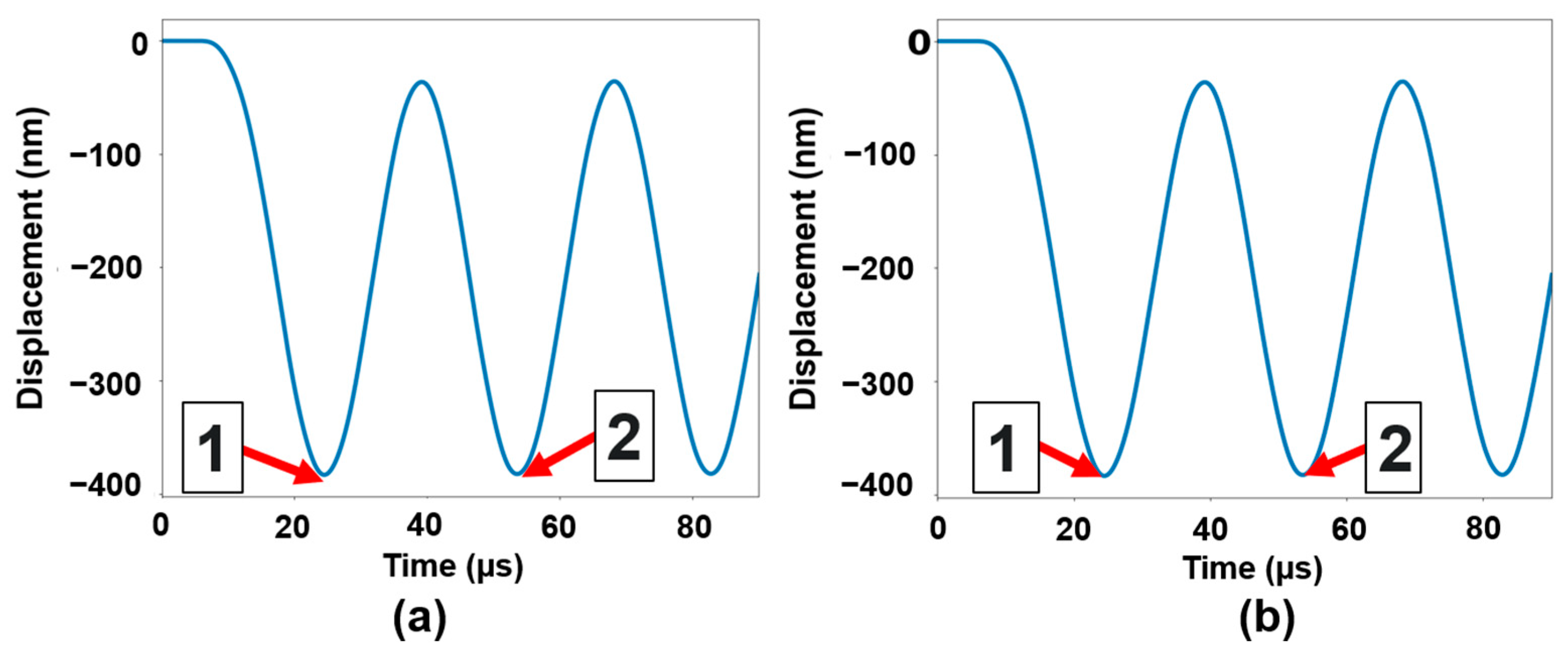

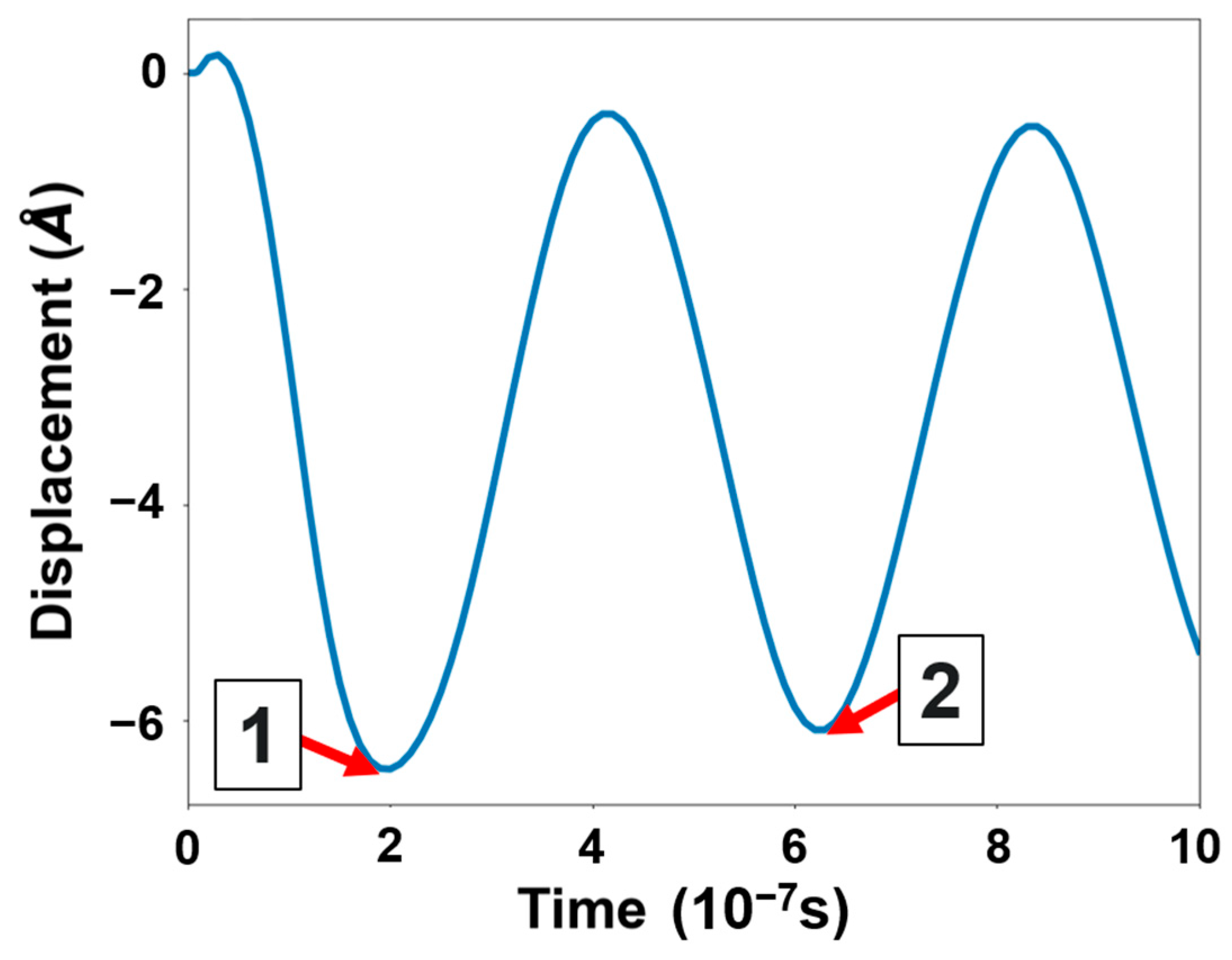

2.4. Time Domain Analysis

In the initial phase of the simulation, the frequency response of the microcantilever was determined. The next step involved estimating the quality factor (Q) and the oscillation amplitude. However, these parameters cannot be obtained directly from frequency domain analysis unless experimental data are incorporated into the numerical model to account for damping coefficients and mechanical losses.

In this section, the Heat Transfer in Solids module was implemented to account for thermoelastic damping, a critical effect in MEMS resonators. This module couples the heat transfer equations with the structural mechanics problem modeled using the Solid Mechanics module [

25].

To induce physical motion in the microcantilever, an electrical pulse was applied to the electrodes that sandwich the AlN piezoelectric layer. The duration of the pulse was set to 100 times the period corresponding to the first resonant frequency, which was found to reliably ensure excitation of the fundamental vibrational mode.

The time steps for the electrical pulses were maintained at 1 × 10−8 s, with a strict relative tolerance of 0.001. The simulations employed the BDF solver with fixed time steps. To assess the influence of numerical damping introduced by the solver, the maximum order was varied between 2 and 5.

To compute the quality factor (

Q), the general equation relating

Q to the damping ratio was used, as defined in reference [

26],

where

ζ represents the damping ratio, which quantifies how quickly oscillations decay between successive cycles. It is defined in terms of the logarithmic decrement

δ, as described in reference [

25],

The logarithmic decrement is defined as natural logarithm of the ratio between the amplitudes of two consecutive pulse peaks

separated by

n cycles of period

T [

25],

where

is the amplitude of the first pulse peak at

and

is the amplitude of the subsequent pulse peak, occurring after

n cycles of period

T.

The damping ratio was not directly inserted into the model; instead, it was estimated from the time-domain simulation by analyzing the decay of oscillation amplitude after a voltage pulse was applied. This indirect method allows for the calculation of Q without assuming arbitrary damping values, ensuring that the simulation reflects the natural damping behavior of the microcantilever under vacuum-like conditions.

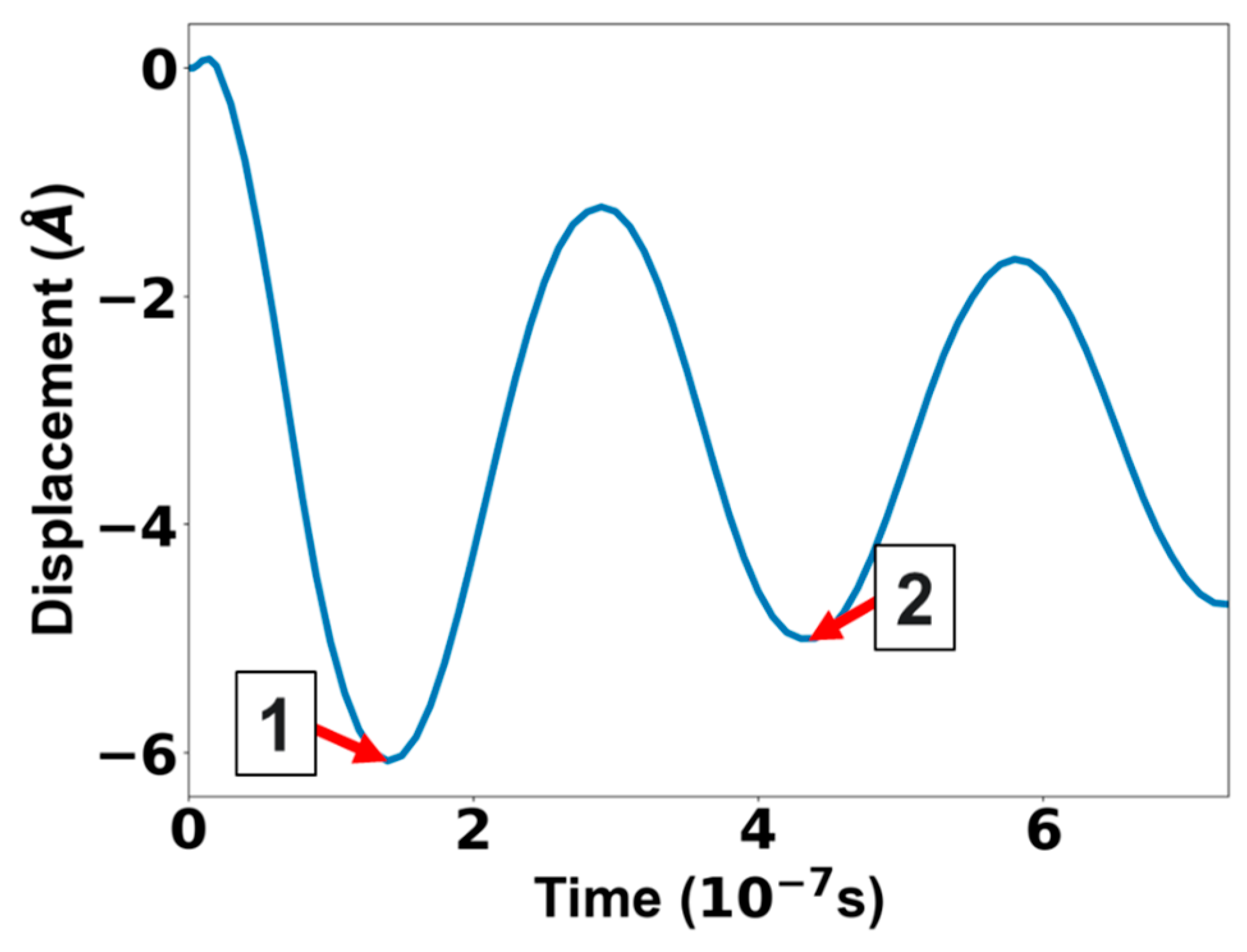

2.5. Validation of the Models

Initially, the model was validated to prove its effectiveness for designing and analyzing the mechanical response of microcantilevers. The condition for validation of the model was that the microcantilever under test operated in the molecular regime where the damping of the surrounding fluid can be neglected.

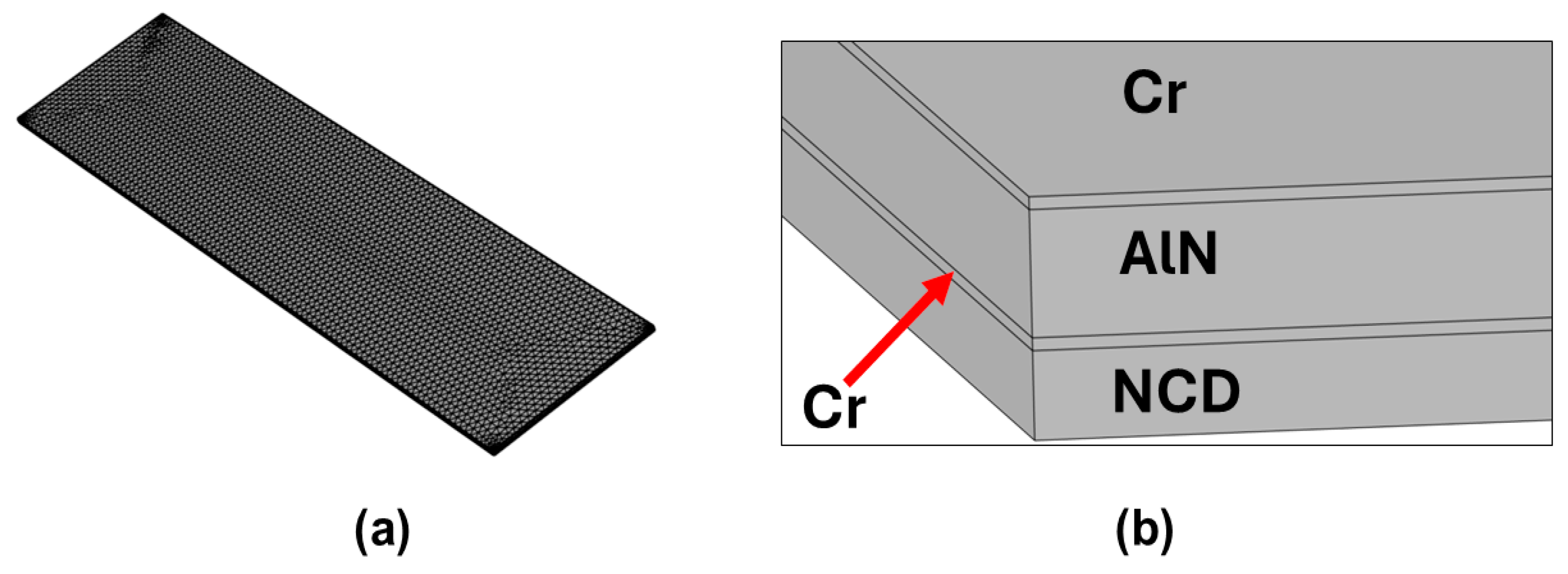

The integrated electrode/AlN/electrode layered structure on a nanocrystalline diamond (NCD) microcantilever, as reported in reference [

27], was selected for comparison to validate the model developed in this study for the UNCD-based microcantilever. This choice is justified by the similarity in grain size between NCD (~10–20 nm) and UNCD (~3–5 nm). In reference [

27], the characterization of the electrode/AlN/electrode/NCD microcantilever was performed using impedance analysis under relatively low vacuum conditions, specifically at a pressure of 200 mTorr.

Determining the first resonant frequency and its corresponding quality factor is essential for evaluating the accuracy and reliability of the models implemented in this study.

4. Conclusions

This work presented the theoretical design and modeling of high-sensitivity piezoelectrically actuated microcantilevers for biosensing applications. The modeling approach was validated against experimental data from nanocrystalline diamond (NCD) microcantilevers with integrated AlN piezoelectric actuators. Given the similarity in Young’s modulus between NCD and ultrananocrystalline diamond (UNCD), this system provided a suitable reference for validating both the frequency and time domain numerical models developed in this study. The simulated resonant frequencies and quality factors showed strong agreement with the experimental values, with deviations below 3%, likely due to numerical damping and microfabrication tolerances.

Following this validation, the models were applied to design UNCD-based and Si-based microcantilevers aimed at detecting an added mass of 1 picogram (pg) uniformly distributed over the cantilever’s active area. The design methodology centered on the integration of a Pt/AlN/Pt piezoelectric actuator, which served as the foundational component. The design process was standardized to enable scalability across different operational frequency ranges and target masses. By tuning the actuator’s resonant frequency and subsequently optimizing the beam length, the microcantilevers were tailored to exhibit measurable resonance frequency shifts in response to added mass.

Subsequently, a Gaussian distribution was used to confine the mass distribution to a certain area on the microcantilever. Three positions were used to observe the impact of the mass location on the resonant frequency shift of the UNCD and Si microcantilevers. It was observed that the resonant frequency shift decreases in comparison to when the mass is considered uniformly distributed on the surface. The resonant frequency shifts were reduced by 4 times.

Furthermore, the resonant frequency shift decreases as the mass distribution center is nearer the border of the piezoelectric actuator and increases as the mass distribution center moves towards the tip of the microcantilever. Both the UNCD and Si microcantilevers show slightly similar resonant frequency shifts upon positioning the mass distribution at the same points on the microcantilever (

Table 9 and

Table 12). Nonetheless, the relative trends between materials (UNCD vs. Si) and the overall design methodology remain valid. These results confirm the robustness of the modeling framework while acknowledging that precise mass distribution patterns would ultimately require experimental validation. Future work will further incorporate spatially resolved biomolecular adsorption data to improve accuracy.

Although environmental damping models, such as thermoacoustic effects, were not included in this phase of analysis, the structural response of the system was thoroughly characterized. This provided a critical first step in the design of reliable MEMS-based biosensors. Furthermore, the integration of COMSOL’s Heat Transfer in Solids module enabled the inclusion of thermoelastic damping, which allowed for physically realistic quality factor (Q) estimation through time domain simulations.

To evaluate biosensing performance, both the UNCD and Si microcantilevers were designed with identical geometries and actuator structures to isolate the impact of the base material. The results indicated that UNCD microcantilevers exhibit superior sensitivity and higher natural frequencies compared to their Si counterparts for the same active sensing area. This enhancement is attributed to the superior mechanical properties of UNCD, making it a strong candidate for next-generation biosensor platforms.

In terms of time domain analysis, simulations using a Backward Differentiation Formula (BDF) solver of orders 2 and 5 revealed that a lower solver order (2) produced results more consistent with the experimental

Q values reported in [

27]. This is likely due to the suppression of higher-order vibrational modes by the numerical damping introduced at lower solver orders. Attempts to implement the generalized alpha solver did not yield conclusive results, particularly for microcantilevers with natural frequencies approximately three orders of magnitude higher than the validation case. Further work is required to refine these damping models and improve simulation accuracy under high-frequency operation.

Table 13 summarizes studies of cantilever simulations found in the literature.

Compared to previously reported methodologies for modeling microcantilever biosensors, the approach presented in this work offers a more comprehensive and experimentally validated framework by integrating both frequency and time domain finite element simulations using COMSOL Multiphysics. While analytical models, such as those by Akcali et al. [

31] and Ansari and Cho [

35], provide useful insights for initial estimations or device optimization, they are limited in their ability to account for complex material stacks and damping mechanisms. Stochastic models, like those by Snyder et al. [

33] and Paul et al. [

34], focus on noise and thermal fluctuations, but they do not provide structural performance evaluation under piezoelectric actuation. In contrast, the study described in this article not only models a realistic multilayer actuator structure (Pt/AlN/Pt) integrated on ultrananocrystalline diamond (UNCD), but it also validates the model using published experimental data on nanocrystalline diamond (NCD) microcantilevers. This dual-domain, experimentally benchmarked simulation strategy allows for accurate estimation of key performance indicators, such as resonant frequency shifts and quality factor (

Q), making it more suitable for guiding the design of next-generation MEMS biosensors with picogram-level sensitivity.

In conclusion, this study demonstrates a robust simulation framework for designing and analyzing piezoelectrically actuated UNCD-based microcantilevers. The methodology is validated, scalable, and adaptable, laying a solid foundation for the development of MEMS biosensors capable of detecting extremely small mass changes with high precision. Future work will focus on the fabrication and experimental testing of the proposed devices to validate their biosensing performance under realistic conditions. One critical aspect will be the experimental investigation of how the mechanical properties of thin films—particularly UNCD and AlN—vary with thickness at the nanoscale, as such variations can significantly influence resonant behavior. Additionally, the effect of atmospheric pressure on the quality factor and sensitivity will be studied by simulating and testing device performance under different environmental damping conditions, including operation in air and vacuum. This next phase will not only verify the predictive accuracy of the numerical models but also provide insight into optimizing the microcantilever structure for real-world biochemical detection applications.