Influence of Coal Bottom Ash as Fine Aggregate Replacement on the Mechanical Properties of Stone Mastic Asphalt

Abstract

1. Introduction

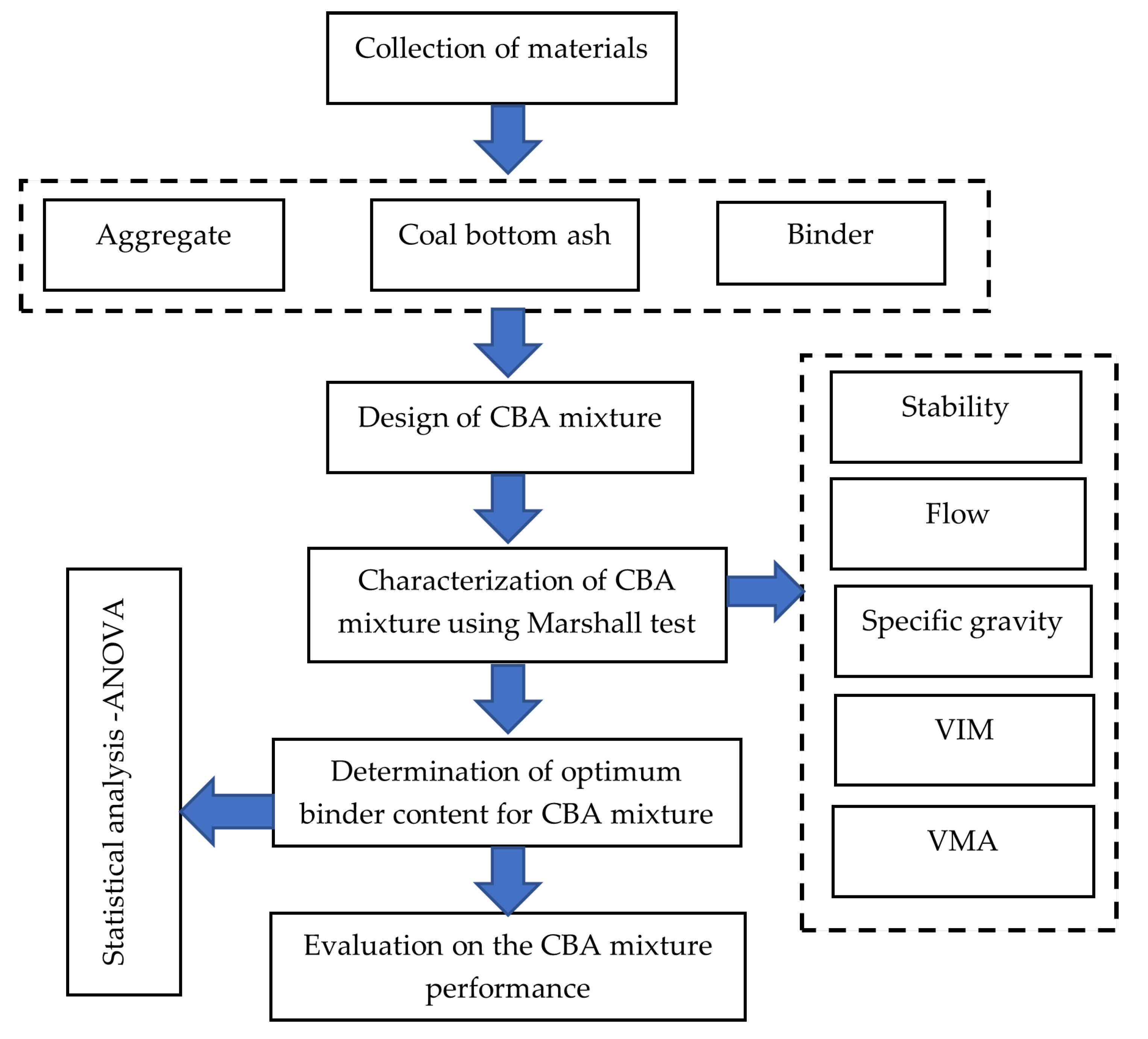

2. Materials and Methods

2.1. Bitumen, Aggregates, Coal Bottom Ash

| Properties | Binder Grade 80/100 | Standard Requirement |

|---|---|---|

| Penetration (25 °C, 100 g, 5 s) (0.01 mm) [46] | 89 | 80–100 |

| Softening point (ring and ball) (°C) [47] | 46 | 45–52 |

| Viscosity at 135 °C (mPa s) [48] | 263 | Max 3000 |

| Viscosity at 165 °C (mPa s) [48] | 151 | Max 3000 |

| Properties | Coal Bottom Ash | Aggregate |

|---|---|---|

| Specific gravity (ASTM C128 [51]) | 1.76 | - |

| Water absorption (%) (ASTM C128) | 22.9 | Max 2 |

| Parameter (s) | Unit (mg/kg) | Maximum Level | Status |

|---|---|---|---|

| Antimony, Sb | Nd (<1.5) | 500 | Pass |

| Arsenic, As | Nd (<1.5) | 500 | Pass |

| Barium, Ba | 242 | 10,000 | Pass |

| Beryllium, Be | Nd (<1.5) | 75 | Pass |

| Cadmium, Cd | 2.2 | 100 | Pass |

| Chromium, Cr | 5.2 | 2500 | Pass |

| Chromium-VI (CrVI) | Nd (<1.5) | 500 | Pass |

| Cobalt, Co | 6.0 | 8000 | Pass |

| Copper, Cu | 10.1 | 2500 | Pass |

| Lead, Pb | 4.1 | 1000 | Pass |

| Mercury, Hg | Nd (<0.1) | 20 | Pass |

| Molybdenum, Mo | Nd (<1.5) | 3500 | Pass |

| Nickel, Ni | 11.4 | 2000 | Pass |

| Selenium, Se | Nd (<0.1) | 1.0 | Pass |

| Silver, Ag | Nd (<0.1) | 5.0 | Pass |

| Thallium (Tl) | Nd (<1.5) | 700 | Pass |

| Vanadium (V) | 11.1 | 2400 | Pass |

| Zinc | 12.0 | 5000 | Pass |

2.2. Experimental Design

2.3. Mix Design

2.3.1. Preparation of Mixture

2.3.2. Optimum Binder Content

2.4. Microstructural Analysis (FESEM and EDS)

2.5. Pavement Performance

2.5.1. Cantabro Test

2.5.2. Resilient Modulus Test

2.5.3. Dynamic Creep Test

2.5.4. Moisture Susceptibility Test

2.6. Statistical Analysis (ANOVA)

3. Results

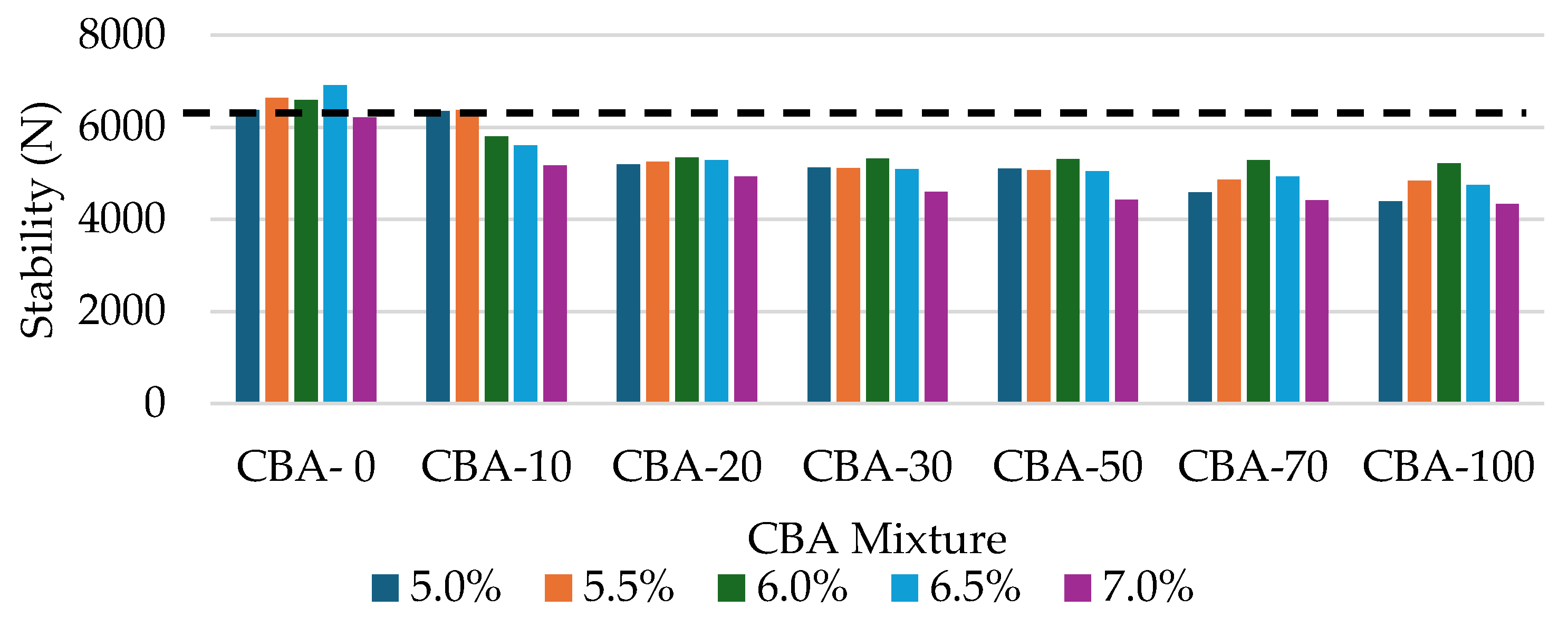

3.1. Marshall Stability vs. CBA Mixture

3.2. Flow

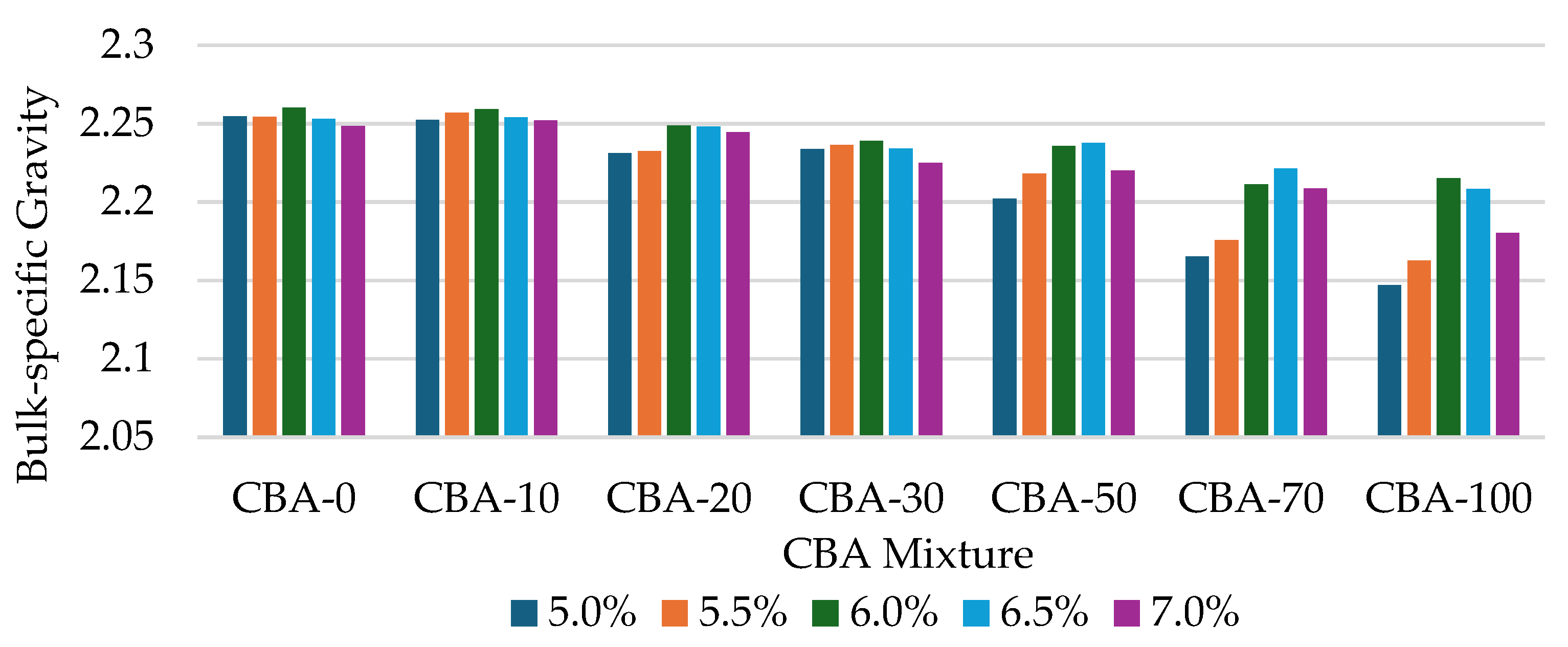

3.3. Bulk-Specific Gravity vs. CBA Mixture

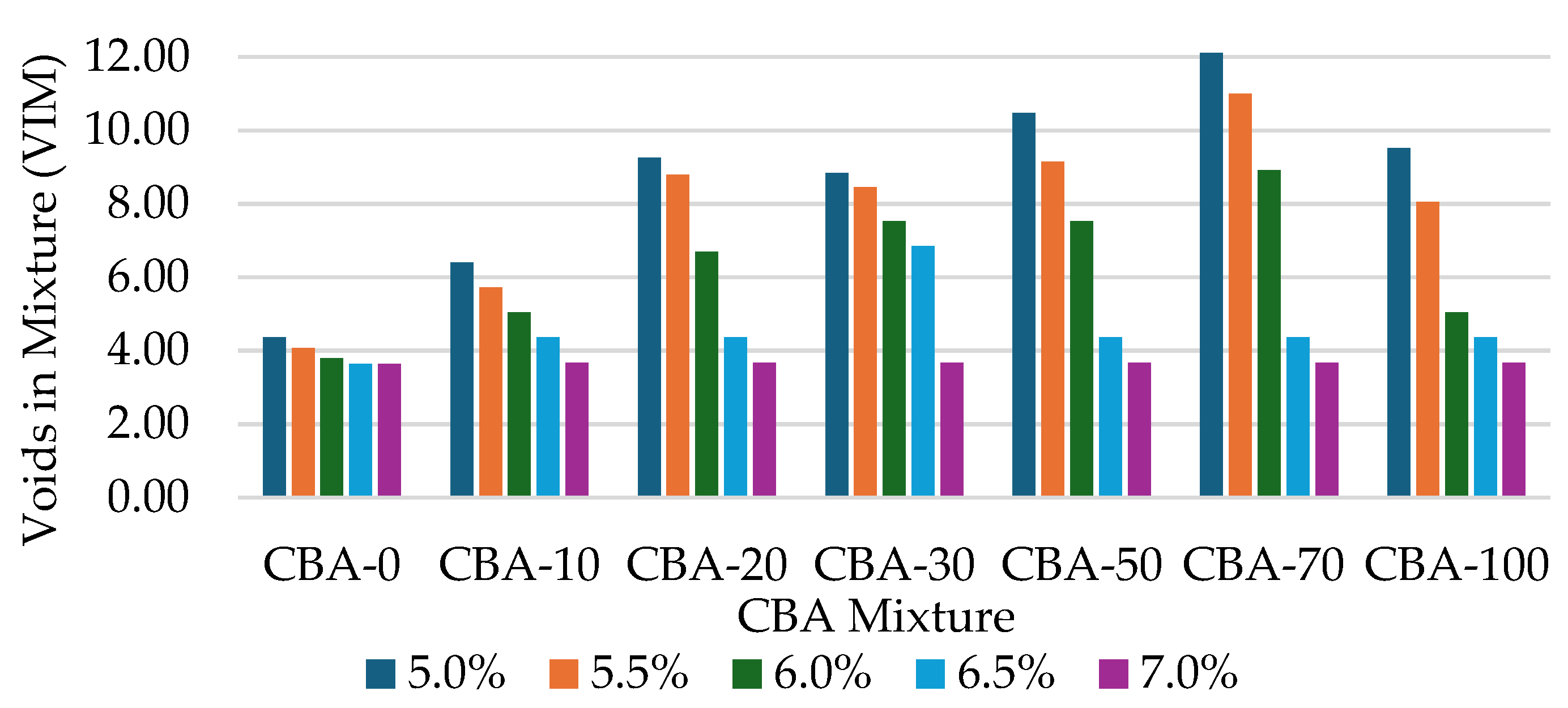

3.4. Voids in Mixture (VIM) vs. CBA Mixture

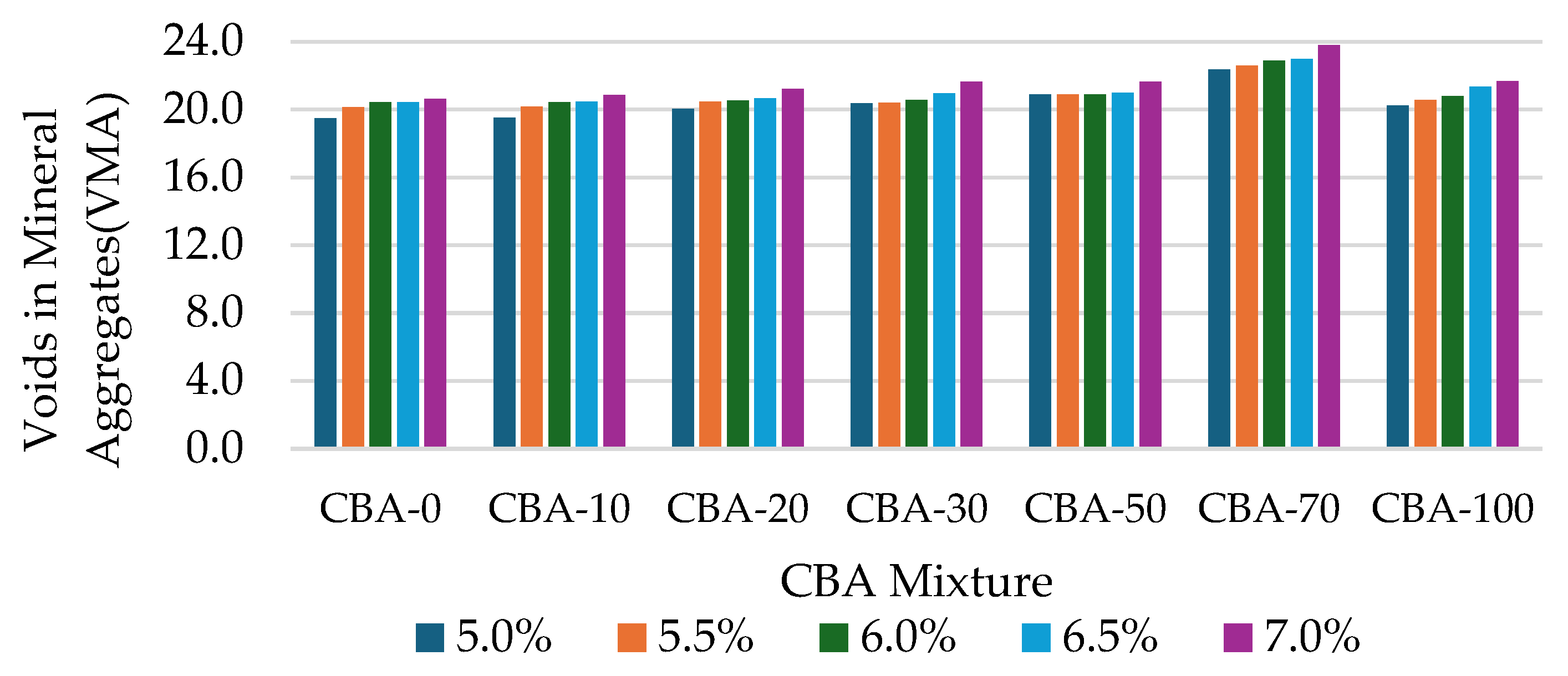

3.5. Void in Mineral Aggregate (VMA)

3.6. Determination of Optimum Binder Content

- Maximum Marshall stability;

- Maximum bulk-specific gravity;

- Median air void (4% for SMA).

3.7. Microstructural Characterisation

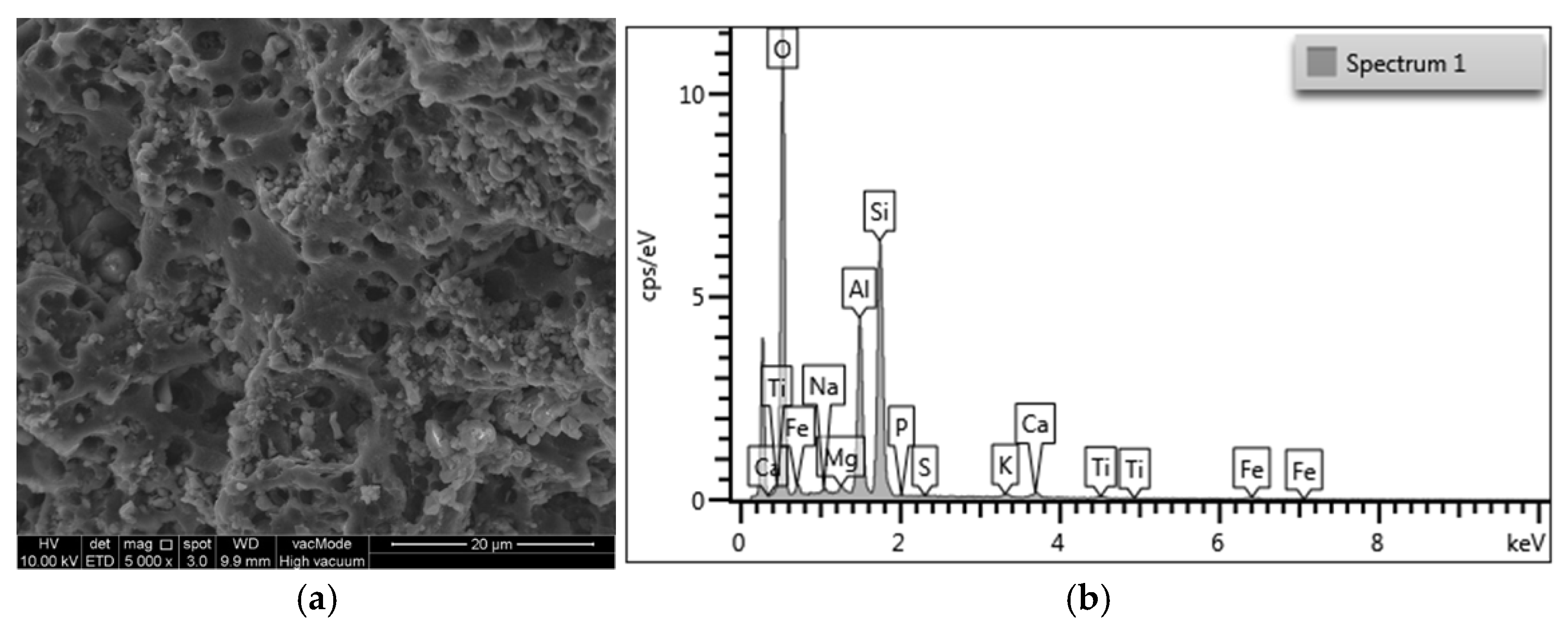

3.7.1. Raw Coal Bottom Ash

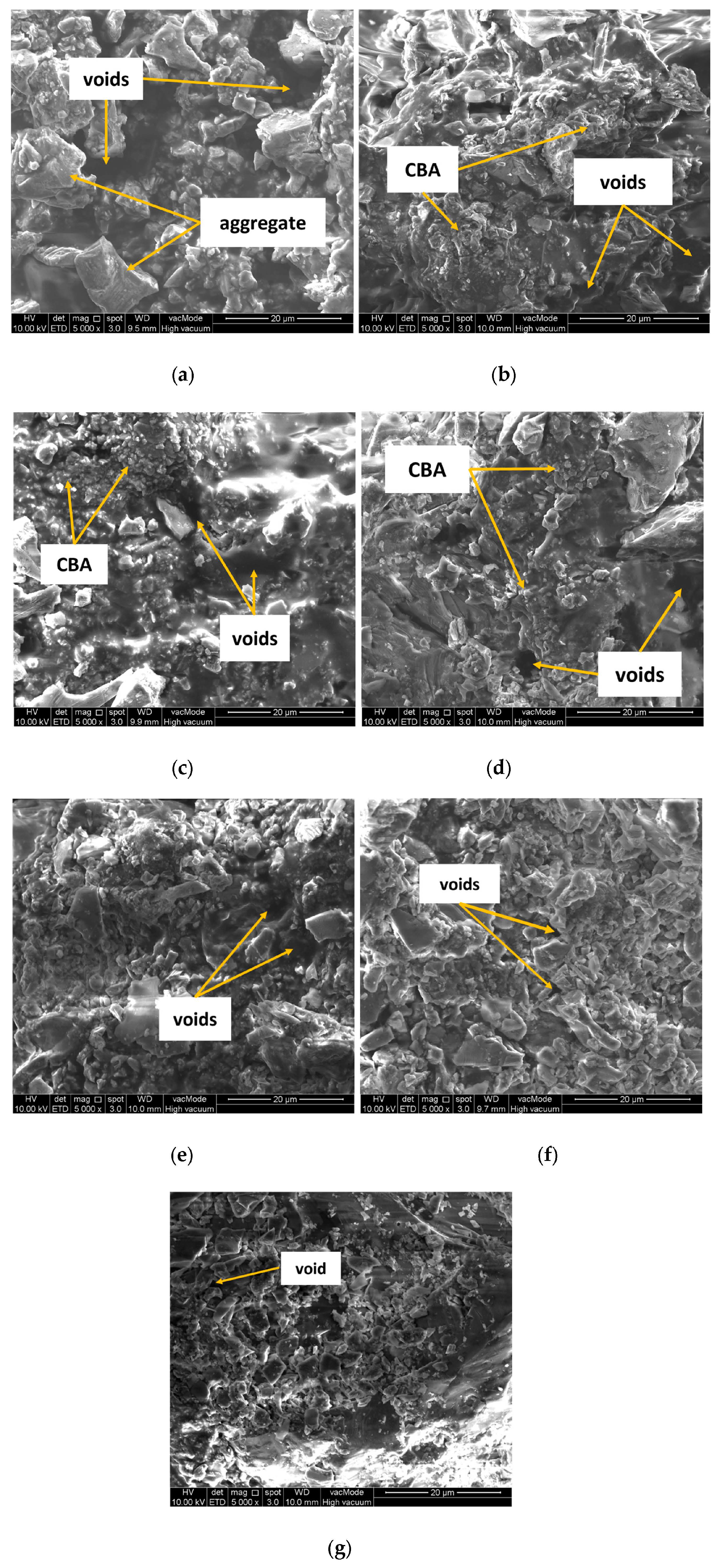

3.7.2. Asphalt Mixture with CBA

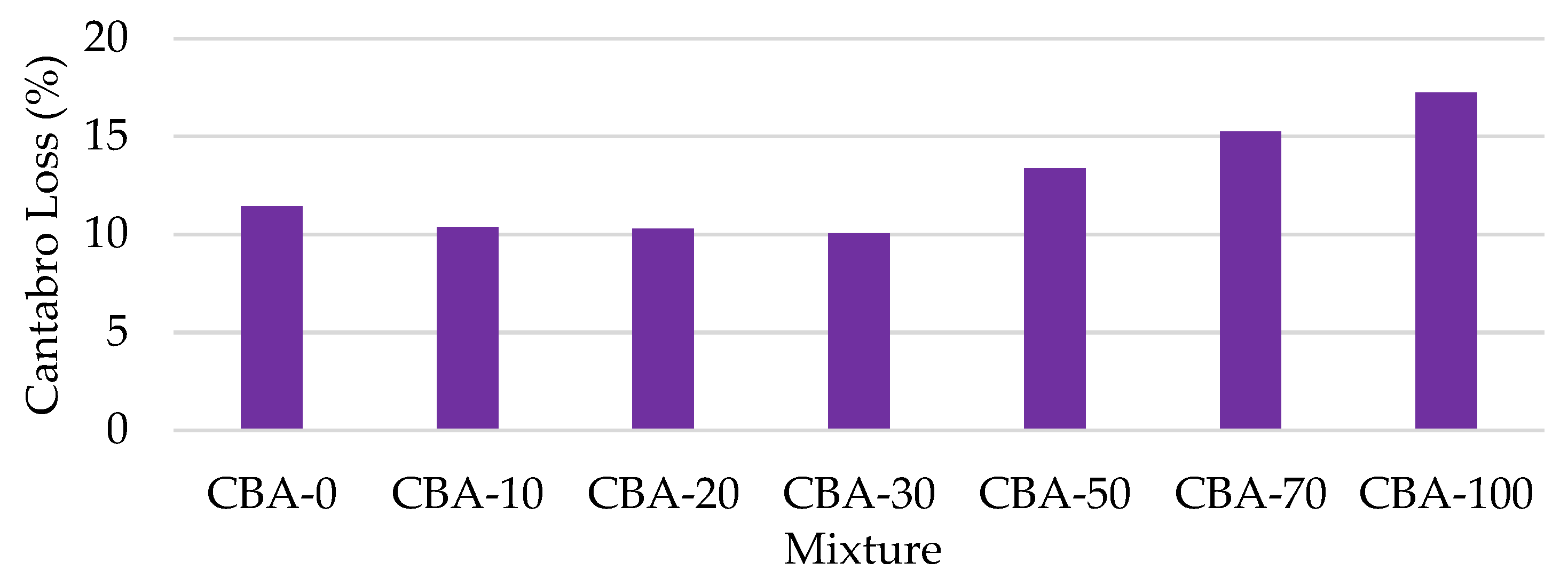

3.8. Cantabro Test Results

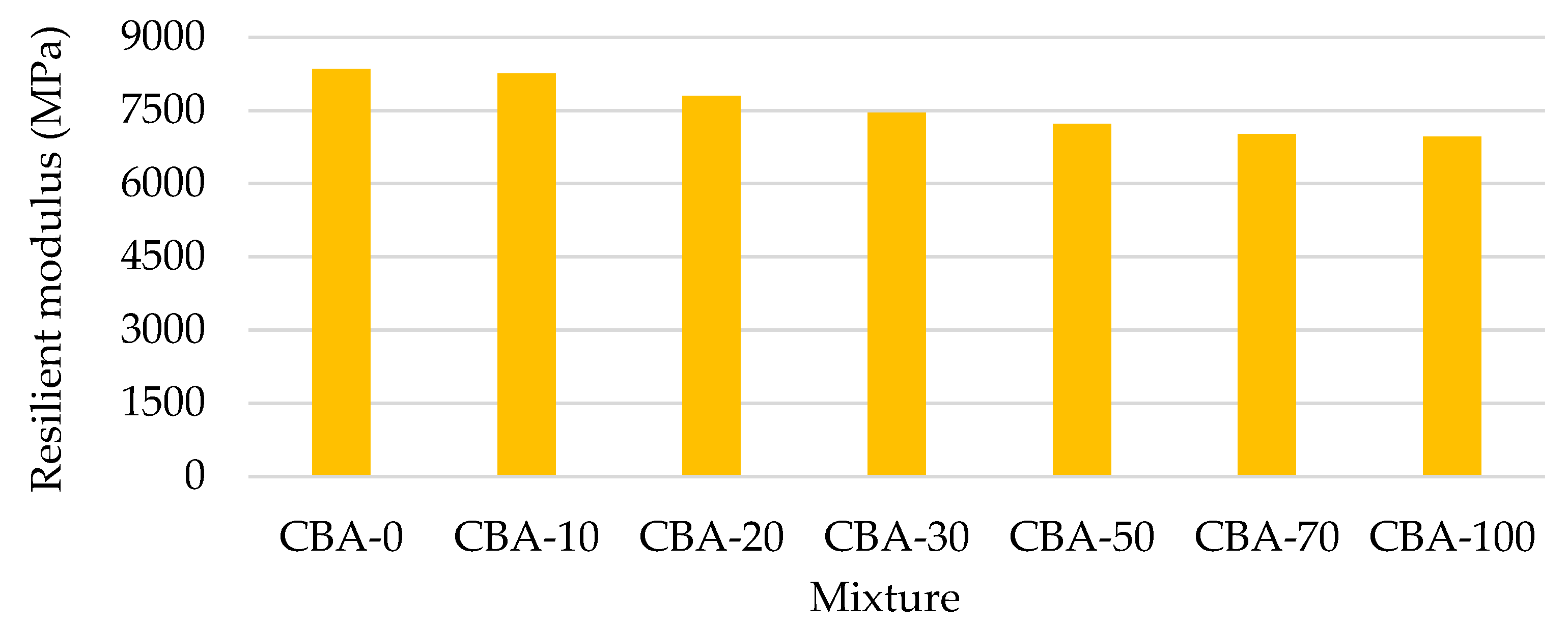

3.9. Resilient Modulus Test Results

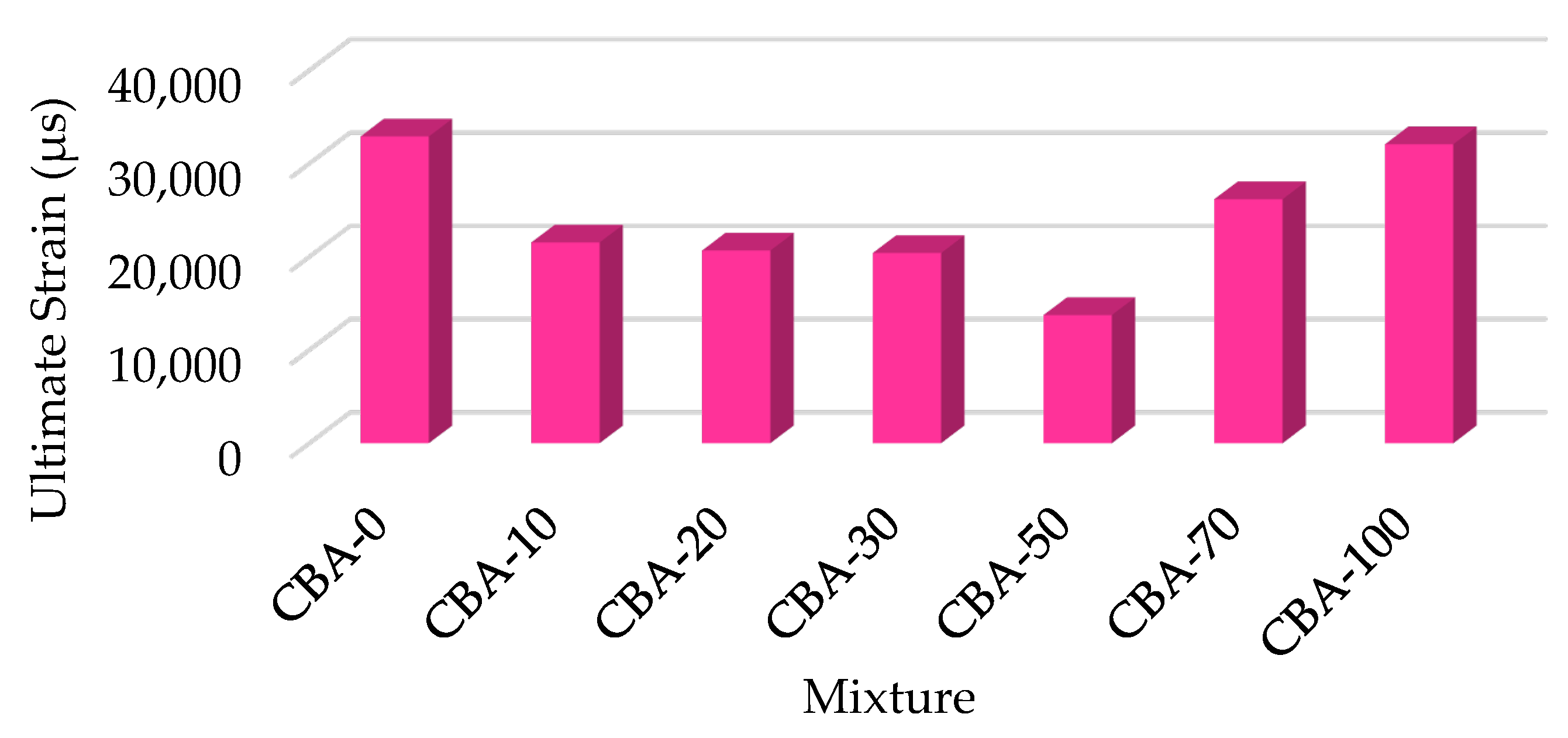

3.10. Dynamic Creep Curve and Ultimate Strain

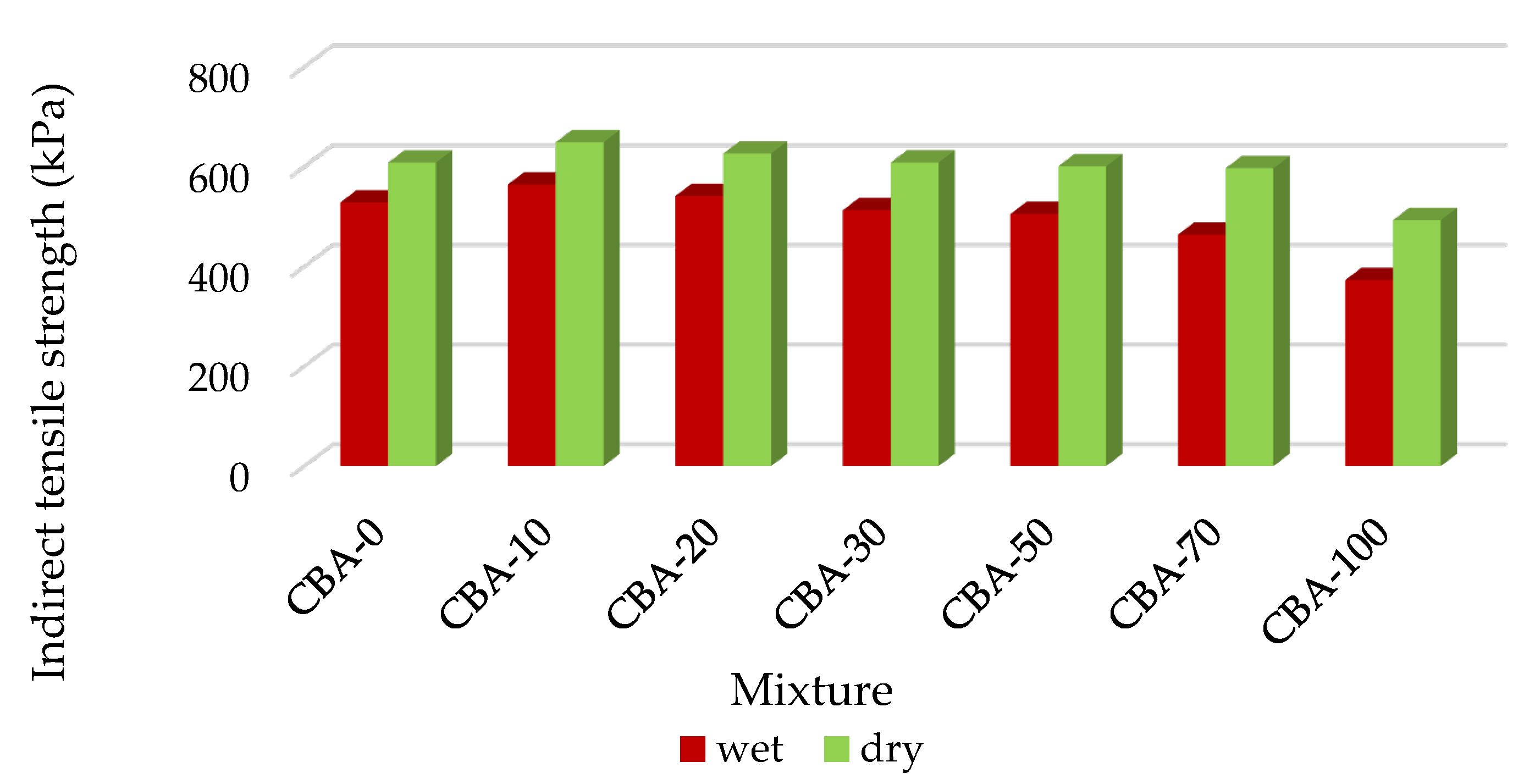

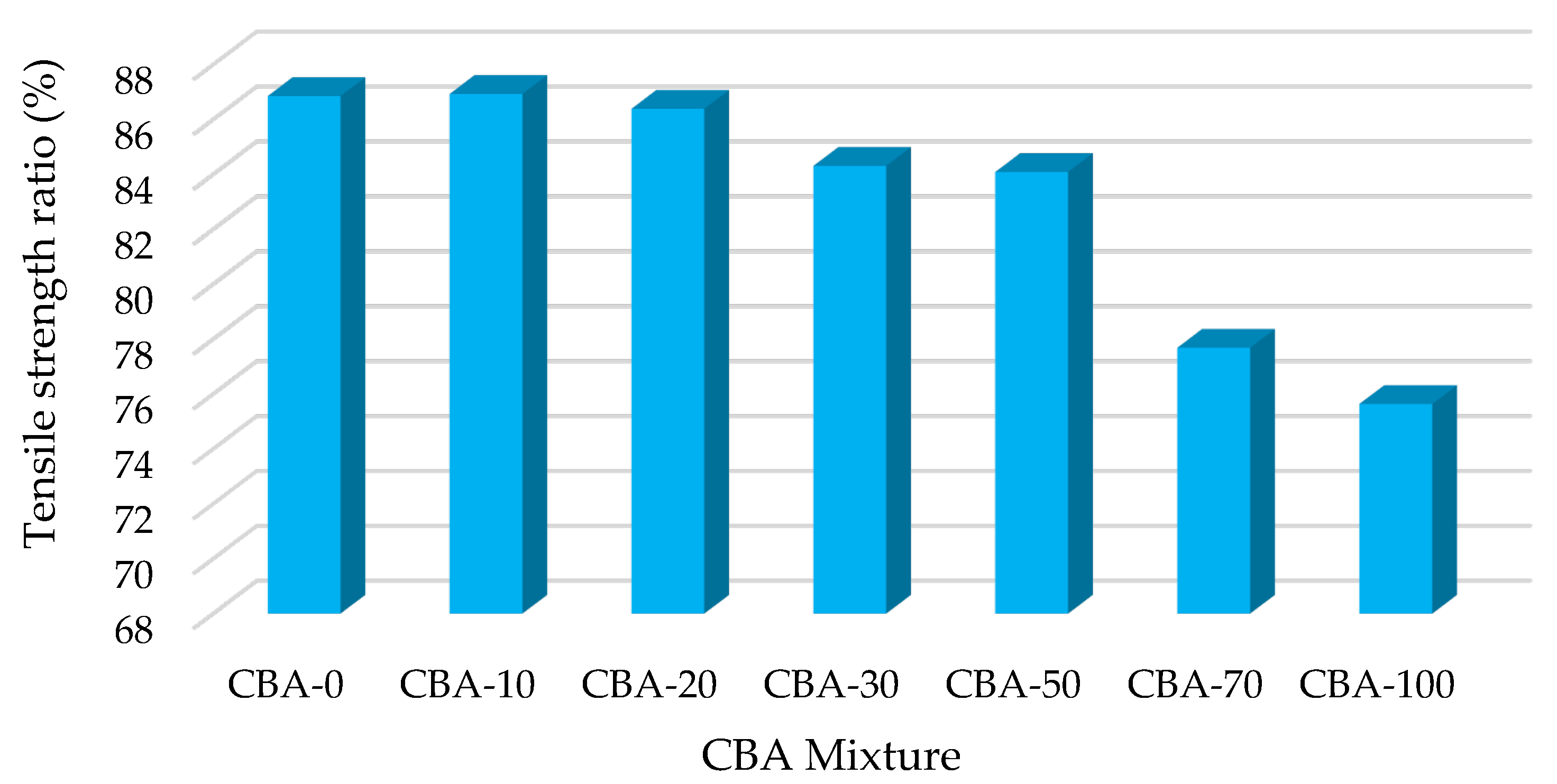

3.11. Moisture Susceptibility Test Results

4. Conclusions

- 1.

- Moderate CBA content enhances durability, as a 30% CBA replacement reduces the Cantabro mass loss. However, a higher CBA content weakens the structure and increases the mass loss;

- 2.

- The resilient modulus of the CBA mixtures decreased as the content of CBA increased. The reduction was minimal, less than 10%, with up to 20% CBA replacement. An increased CBA content resulted in a reduced modulus, which decreased the elastic stiffness of the mixture;

- 3.

- The permanent deformation increased up to 50% CBA replacement. This characteristic of CBA enhances interparticle friction, stabilizing the mixture and diminishing the strain under sustained loading, resulting in improved permanent deformation resistance;

- 4.

- CBA improved the tensile strength of asphalt mixtures in both wet and dry conditions. Up to 50% CBA satisfied the minimum TSR requirement of 80%, but higher CBA contents reduced the moisture resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, R.G.; Li, D.; Jeon, C.H. Experimental investigation of ignition behavior for coal rank using a flat flame burner at a high heating rate. Exp. Therm. Fluid Sci. 2014, 54, 212–218. [Google Scholar] [CrossRef]

- Gooi, S.; Mousa, A.A.; Kong, D. A critical review and gap analysis on the use of coal bottom ash as a substitute constituent in concrete. J. Clean. Prod. 2020, 268, 121752. [Google Scholar] [CrossRef]

- Antoni; Klarens, K.; Indranata, M.; Al Jamali, L.; Hardjito, D. The use of bottom ash for replacing fine aggregate in concrete paving blocks. MATEC Web Conf. 2017, 138, 01005. [Google Scholar] [CrossRef]

- Hower, J.C.; Granite, E.J.; Mayfield, D.B.; Lewis, A.S.; Finkelman, R.B. Notes on contributions to the science of rare earth element enrichment in coal and coal combustion byproducts. Minerals 2016, 6, 32. [Google Scholar] [CrossRef]

- Szatyłowicz, E.; Walendziuk, W. Analysis of polycyclic aromatic hydrocarbon content in ash from solid fuel combustion in low-power boilers. Energies 2021, 14, 6801. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Adesina, A. Sustainable application of coal bottom ash as fine aggregates in concrete: A comprehensive review. Case Stud. Constr. Mater. 2022, 16, e01109. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. Earth-Science Reviews A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Hashemi, S.S.G.; Mahmud, H.B.; Ghuan, T.C.; Chin, A.B.; Kuenzel, C.; Ranjbar, N. Safe disposal of coal bottom ash by solidification and stabilization techniques. Constr. Build. Mater. 2019, 197, 705–715. [Google Scholar] [CrossRef]

- Marto, A.; Hassan, M.A.; Makhtar, A.M.; Othman, B.A. Shear Strength Improvement of Soft Clay Mixed with Tanjung Bin Coal Ash. APCBEE Procedia 2013, 5, 116–122. [Google Scholar] [CrossRef]

- Topçu, I.B.; Bilir, T. Effect of bottom ash as fine aggregate on shrinkage cracking of mortars. ACI Mater. J. 2010, 107, 48–56. [Google Scholar]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- Lior, N. Sustainable energy development: The present (2009) situation and possible paths to the future. Energy 2010, 35, 3976–3994. [Google Scholar] [CrossRef]

- Mokhtar, M.M.; Hassim, M.H.; Taib, R.M. Health risk assessment of emissions from a coal-fired power plant using AERMOD modelling. Process Saf. Environ. Prot. 2014, 92, 476–485. [Google Scholar] [CrossRef]

- Abubakar, A.U.; Baharudin, K.S. Tanjung Bin Coal Bottom Ash: From Waste to Concrete Material. Adv. Mater. Res. 2013, 705, 163–168. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Heidrich, C.; Feuerborn, H.; Weir, A. Coal Combustion Products: A Global Perspective. World Coal Ash Conf. 2013, 22, 25. [Google Scholar]

- Sutcu, M.; Erdogmus, E.; Gencel, O.; Gholampour, A.; Atan, E.; Ozbakkaloglu, T. Recycling of bottom ash and fly ash wastes in eco-friendly clay brick production. J. Clean. Prod. 2019, 233, 753–764. [Google Scholar] [CrossRef]

- Pahroraji, M.; Hafez, M.E.; Saman, H.M.; Rahmat, M.N.; Kamaruddin, K. Properties of coal ash foamed brick stabilised with hydrated lime-activated ground granulated blastfurnace slag. Constr. Build. Mater. 2020, 235, 117568. [Google Scholar] [CrossRef]

- Rathnayake, M.; Julnipitawong, P.; Tangtermsirikul, S.; Toochinda, P. Utilization of coal fly ash and bottom ash as solid sorbents for sulfur dioxide reduction from coal fired power plant: Life cycle assessment and applications. J. Clean. Prod. 2018, 202, 934–945. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Clean. Prod. 2016, 112, 620–630. [Google Scholar] [CrossRef]

- Singh, N.; Mithulraj, M.; Arya, S. Influence of coal bottom ash as fine aggregates replacement on various properties of concretes: A review. Resour. Conserv. Recycl. 2018, 138, 257–271. [Google Scholar] [CrossRef]

- Jayaranjan, M.L.D.; van Hullebusch, E.D.; Annachhatre, A.P. Reuse options for coal fired power plant bottom ash and fly ash. Rev. Environ. Sci. Biotechnol. 2014, 13, 467–486. [Google Scholar] [CrossRef]

- Pandey, V.C.; Singh, J.S.; Singh, R.P.; Singh, N.; Yunus, M. Arsenic hazards in coal fly ash and its fate in Indian scenario. Resour. Conserv. Recycl. 2011, 55, 819–835. [Google Scholar] [CrossRef]

- Su, T.; Wang, J. Modeling batch leaching behavior of arsenic and selenium from bituminous coal fly ashes. Chemosphere 2011, 85, 1368–1374. [Google Scholar] [CrossRef] [PubMed]

- Bashkin, V.N.; Wongyai, K. Environmental fluxes of arsenic from lignite mining and power generation in northern Thailand. Environ. Geol. 2002, 41, 883–888. [Google Scholar]

- Jang, J.G.; Ahn, Y.B.; Souri, H.; Lee, H.K. A novel eco-friendly porous concrete fabricated with coal ash and geopolymeric binder: Heavy metal leaching characteristics and compressive strength. Constr. Build. Mater. 2015, 79, 173–181. [Google Scholar] [CrossRef]

- Chakraborty, R.; Mukherjee, A. Mutagenicity and genotoxicity of coal fly ash water leachate. Ecotoxicol. Environ. Saf. 2009, 72, 838–842. [Google Scholar] [CrossRef]

- Thi, N.N.; Hong, T.P.; Truong, S.B. Utilizing Coal Bottom Ash from Thermal Power Plants in Vietnam as Partial Replacement of Aggregates in Concrete Pavement. J. Eng. 2019, 2019, 3903097. [Google Scholar]

- Argiz, C.; Sanjuán, M.Á.; Menéndez, E. Coal Bottom Ash for Portland Cement Production. Adv. Mater. Sci. Eng. 2017, 2017, 6068286. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of Glass Powder-Based Geopolymer Stabilized Road Bases Containing Recycled Waste Glass Aggregate. Transp. Res. Rec. 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Costa, J.O.; Borges, P.H.R.; Santos, F.A.D.; Bezerra, A.C.S.; Van den bergh, W.; Blom, J. Cementitious binders and reclaimed asphalt aggregates for sustainable pavement base layers: Potential, challenges and research needs. Constr. Build. Mater. 2020, 265, 120325. [Google Scholar] [CrossRef]

- Simões, F.; Rios-Davila, F.J.; Paiva, H.; Morais, M.; Ferreira, V.M. Sustainability Evaluation of a Paper and Pulp Industrial Waste Incorporation in Bituminous Pavements. Appl. Sci. 2024, 14, 4846. [Google Scholar] [CrossRef]

- Mallick, R.B.; Radzicki, M.; Nanagiri, Y.V.; Veeraragavan, A. The impact of road construction on depletion of natural aggregates and consequence of delay in recycling pavement-key factors in sustainable road construction. Indian Highw. 2013, 41, 61–71. [Google Scholar]

- Gorakhki, M.H.; Bareither, C.A. Sustainable reuse of mine tailings and waste rock as water-balance covers. Minerals 2017, 7, 128. [Google Scholar] [CrossRef]

- Ramírez-Vargas, J.R.; Zamora-Castro, S.A.; Herrera-May, A.L.; Sandoval-Herazo, L.C.; Salgado-Estrada, R.; Diaz-Vega, M.E. A Review of Sustainable Pavement Aggregates. Appl. Sci. 2024, 14, 16. [Google Scholar] [CrossRef]

- Huang, Q.; Qian, Z.; Hu, J.; Zheng, D. Evaluation of Stone Mastic Asphalt Containing Ceramic Waste Aggregate for Cooling Asphalt Pavement. Materials 2020, 13, 2964. [Google Scholar] [CrossRef]

- Gautam, P.K.; Kalla, P.; Nagar, R.; Agrawal, R.; Jethoo, A.S. Laboratory investigations on hot mix asphalt containing mining waste as aggregates. Constr. Build. Mater. 2018, 168, 143–152. [Google Scholar] [CrossRef]

- Nwakaire, C.M.; Yap, S.P.; Yuen, C.W.; Onn, C.C.; Koting, S.; Babalghaith, A.M. Laboratory study on recycled concrete aggregate based asphalt mixtures for sustainable flexible pavement surfacing. J. Clean. Prod. 2020, 262, 121462. [Google Scholar] [CrossRef]

- Omrane, M.; Kenai, S.; Kadri, E.H.; Aït-Mokhtar, A. Performance and durability of self compacting concrete using recycled concrete aggregates and natural pozzolan. J. Clean. Prod. 2017, 165, 415–430. [Google Scholar] [CrossRef]

- Alinezhad, M.; Sahaf, A. Investigation of the fatigue characteristics of warm stone matrix asphalt (WSMA) containing electric arc furnace (EAF) steel slag as coarse aggregate and Sasobit as warm mix additive. Case Stud. Constr. Mater. 2019, 11, e00265. [Google Scholar] [CrossRef]

- Zawawi, M.N.A.A.; Muthusamy, K.; Majeed, A.P.P.A.; Musa, R.M.; Budiea, A.M.A. Mechanical properties of oil palm waste lightweight aggregate concrete with fly ash as fine aggregate replacement. J. Build. Eng. 2020, 27, 100924. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Koting, S.; Sulong, N.H.R.; Karim, M.R.; AlMashjary, B.M. Performance evaluation of stone mastic asphalt (SMA) mixtures with palm oil clinker (POC) as fine aggregate replacement. Constr. Build. Mater. 2020, 262, 120546. [Google Scholar] [CrossRef]

- Yoo, B.S.; Park, D.W.; Vo, H.V. Evaluation of Asphalt Mixture Containing Coal Ash. Transp. Res. Procedia 2016, 14, 797–803. [Google Scholar] [CrossRef]

- Colonna, P.; Berloco, N.; Ranieri, V.; Shuler, S.T. Application of Bottom Ash for Pavement Binder Course. Procedia-Soc. Behav. Sci. 2012, 53, 961–971. [Google Scholar] [CrossRef]

- Modarres, A.; Ayar, P. Coal waste application in recycled asphalt mixtures with bitumen emulsion. J. Clean. Prod. 2014, 83, 263–272. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2015.

- Jabatan Kerja Raya (JKR) Malaysia. Standard Specification for Road Work, Section 4: Flexible Pavement; Malaysian Public Works Department: Kuala Lumpur, Malaysia, 2008. [Google Scholar]

- Environmental Quality Council. Environmental Quality (Scheduled Wastes) Regulations 2005; P.U.A 294-2005; Minister of Natural Resources and Environment: Putrajaya, Malaysia, 2005; pp. 2–6. [Google Scholar]

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D1559-89; Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 1995.

- Sangiorgi, C.; Tataranni, P.; Simone, A.; Vignali, V.; Lantieri, C.; Dondi, G. Stone mastic asphalt (SMA) with crumb rubber according to a new dry-hybrid technology: A laboratory and trial field evaluation. Constr. Build. Mater. 2018, 182, 200–209. [Google Scholar] [CrossRef]

- ASTM C131; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D4123; Standard Test Method for Indirect Tension Test for Resilient Modulus of Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 1995.

- AS 2891.12.1; Methods of Sampling and Testing Asphalt Standards Australia, Method 12.1: Determination of the Permanent Compressive Strain Characteristics of Asphalt-Dynamic Creep Test. ASTM International: West Conshohocken, PA, USA, 1995.

- AASHTO T283; Resistance of Compacted Bituminous Mixture to Moisture Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007.

- NAPA. Designing and Constructing SMA Mixtures—State-of-the-Practice; National Asphalt Pavement Association (NAPA): Lanham, MD, USA, 2002; p. 43. [Google Scholar]

- Panda, M.; Suchismita, A.; Giri, J. Utilization of Ripe Coconut Fiber in Stone Matrix Asphalt Mixes. Int. J. Transp. Sci. Technol. 2013, 2, 289–302. [Google Scholar] [CrossRef]

- Vasudevan, G. Performance on Coal Bottom Ash in Hot Mix Asphalt. Int. J. Res. Eng. Technol. 2013, 2, 24–33. [Google Scholar]

- Mashaan, N.S. Use of Waste Tyre Rubber in Enhancing the Mechanical Properties of Stone Mastic Asphalt Mix. Ph.D. Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2016. [Google Scholar]

- Babalghaith, A.M.; Koting, S.; Sulong, N.H.R.; Karim, M.R.; Mohammed, S.A.; Ibrahim, M.R. Effect of palm oil clinker (POC) aggregate on the mechanical properties of stone mastic asphalt (SMA) mixtures. Sustainability 2020, 12, 2716. [Google Scholar] [CrossRef]

- Wakefield, A. Four Tips for Controlling Asphalt Mix Designs in the Lab and Field; Asphalt Magazine: Lexington, KY, USA, 2020. [Google Scholar]

- Ahmadinia, E. Waste Plastic Bottles as Additive for Stone Mastic Asphalt. Master’s Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2012. [Google Scholar]

- Muhardi, A.; Marto, A.; Kassim, K.A.; Makhtar, A.M.; Wei, L.F.; Lim, Y.S. Engineering characteristics of Tanjung Bin coal ash. Electron. J. Geotech. Eng. 2010, 15, 1117–1129. [Google Scholar]

- Ali, A.H. Influence of Crumb Rubber Modifier on Performance Characteristics of Stone Mastic Asphalt. Master’s Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2013. [Google Scholar]

- Gokhale, S.; Choubane, B.; Byron, T.; Tia, M. Rut Initiation Mechanisms in Asphalt Mixtures as Generated Under Accelerated Pavement Testing. Transp. Res. Rec. J. Transp. Res. Board 2008, 1940, 136–145. [Google Scholar] [CrossRef]

- Katman, H.Y.; Ibrahim, M.R.; Karim, M.R.; Koting, S.; Mashaan, N.S. Effect of Rubberized Bitumen Blending Methods on Permanent Deformation of SMA Rubberized Asphalt Mixtures. Adv. Mater. Sci. Eng. 2016, 2016, 4395063. [Google Scholar] [CrossRef]

- Katman, H.Y.; Ibrahim, M.R.; Karim, M.R.; Mashaan, N.S.; Koting, S. Evaluation of permanent deformation of unmodified and rubber-reinforced SMA asphalt mixtures using dynamic creep test. Adv. Mater. Sci. Eng. 2015, 2015, 247149. [Google Scholar] [CrossRef]

- Do, H.S.; Mun, P.H.; Suk keun, R. A study on engineering characteristics of asphalt concrete using filler with recycled waste lime. Waste Manag. 2008, 28, 191–199. [Google Scholar]

- Jattak, Z.A.; Hassan, N.A.; Satar, M.K.I.M. Moisture susceptibility and environmental impact of warm mix asphalt containing bottom ash. Case Stud. Constr. Mater. 2021, 15, e00636. [Google Scholar] [CrossRef]

- Zeng, M.; Ksaibati, K. Evaluation of moisture susceptibility of asphalt mixtures containing bottom ash. In Proceedings of the Transportation Research Board 82nd Annual Meeting, Washington, DC, USA, 12–16 January 2003; pp. 1–21. [Google Scholar]

| CBA Content (%) | CBA Mixtures | CBA Content (%) |

|---|---|---|

| 0 | CBA-0 | 0 |

| 10 | CBA-10 | 10 |

| 20 | CBA-20 | 20 |

| 30 | CBA-30 | 30 |

| 50 | CBA-50 | 50 |

| 70 | CBA-70 | 70 |

| 100 | CBA-100 | 100 |

| Mixture | Maximum Stability (%) | 4% of Air Void, VIM (%) | Maximum Bulk-Specific Gravity (%) | Optimum Binder Content(%) |

|---|---|---|---|---|

| CBA-10 | 4.95 | 5.95 | 6.79 | 5.90 |

| CBA-20 | 5.89 | 5.47 | 6.86 | 6.07 |

| CBA-30 | 5.35 | 5.36 | 7.52 | 6.08 |

| CBA-50 | 5.07 | 6.25 | 6.92 | 6.08 |

| CBA-70 | 5.48 | 6.12 | 6.80 | 6.13 |

| CBA-100 | 5.95 | 5.81 | 6.55 | 6.10 |

| Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between Groups | 0.174 | 6 | 0.029 | 2.615 | 0.065 |

| Within Groups | 0.156 | 14 | 0.011 | ||

| Total | 0.330 | 20 |

| CBA Content (%) | CBA Mixture | Normalized |

|---|---|---|

| Control | 11.43 | 1.00 |

| CBA-10 | 10.37 | 0.91 |

| CBA-20 | 10.30 | 0.90 |

| CBA-30 | 10.06 | 0.88 |

| CBA-50 | 13.37 | 1.17 |

| CBA-70 | 15.26 | 1.33 |

| CBA-100 | 17.23 | 1.51 |

| Mixture | CBA | Normalized |

|---|---|---|

| CBA-0 | 8351 | 1.00 |

| CBA-10 | 8262 | 0.99 |

| CBA-20 | 7803 | 0.93 |

| CBA-30 | 7458 | 0.89 |

| CBA-50 | 7219 | 0.86 |

| CBA-70 | 7019 | 0.84 |

| CBA-100 | 6959 | 0.83 |

| Mixture | Ultimate Strain (µs) | Normalized |

|---|---|---|

| CBA-0 | 32,906 | 1.00 |

| CBA-10 | 21,535 | 0.65 |

| CBA-20 | 20,667 | 0.63 |

| CBA-30 | 20,400 | 0.62 |

| CBA-50 | 13,747 | 0.42 |

| CBA-70 | 26,170 | 0.80 |

| CBA-100 | 32,070 | 0.97 |

| Mixture | TSR (%) | Normalized |

|---|---|---|

| CBA-0 | 86.9 | 1.00 |

| CBA-10 | 86.9 | 1.00 |

| CBA-20 | 86.4 | 0.99 |

| CBA-30 | 84.3 | 0.97 |

| CBA-50 | 84.1 | 0.97 |

| CBA-70 | 77.7 | 0.89 |

| CBA-100 | 75.6 | 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, S.A.; Koting, S.; Babalghaith, A.M.; Isa, M.H.M.; Khairuddin, F.H. Influence of Coal Bottom Ash as Fine Aggregate Replacement on the Mechanical Properties of Stone Mastic Asphalt. Appl. Sci. 2025, 15, 6826. https://doi.org/10.3390/app15126826

Mohammed SA, Koting S, Babalghaith AM, Isa MHM, Khairuddin FH. Influence of Coal Bottom Ash as Fine Aggregate Replacement on the Mechanical Properties of Stone Mastic Asphalt. Applied Sciences. 2025; 15(12):6826. https://doi.org/10.3390/app15126826

Chicago/Turabian StyleMohammed, Syakirah Afiza, Suhana Koting, Ali Mohammed Babalghaith, Mohd Hafizan Md. Isa, and Faridah Hanim Khairuddin. 2025. "Influence of Coal Bottom Ash as Fine Aggregate Replacement on the Mechanical Properties of Stone Mastic Asphalt" Applied Sciences 15, no. 12: 6826. https://doi.org/10.3390/app15126826

APA StyleMohammed, S. A., Koting, S., Babalghaith, A. M., Isa, M. H. M., & Khairuddin, F. H. (2025). Influence of Coal Bottom Ash as Fine Aggregate Replacement on the Mechanical Properties of Stone Mastic Asphalt. Applied Sciences, 15(12), 6826. https://doi.org/10.3390/app15126826