Determination of the Social Contribution of Sustainable Additives for Asphalt Mixes Through Fuzzy Cognitive Mapping

Abstract

1. Introduction

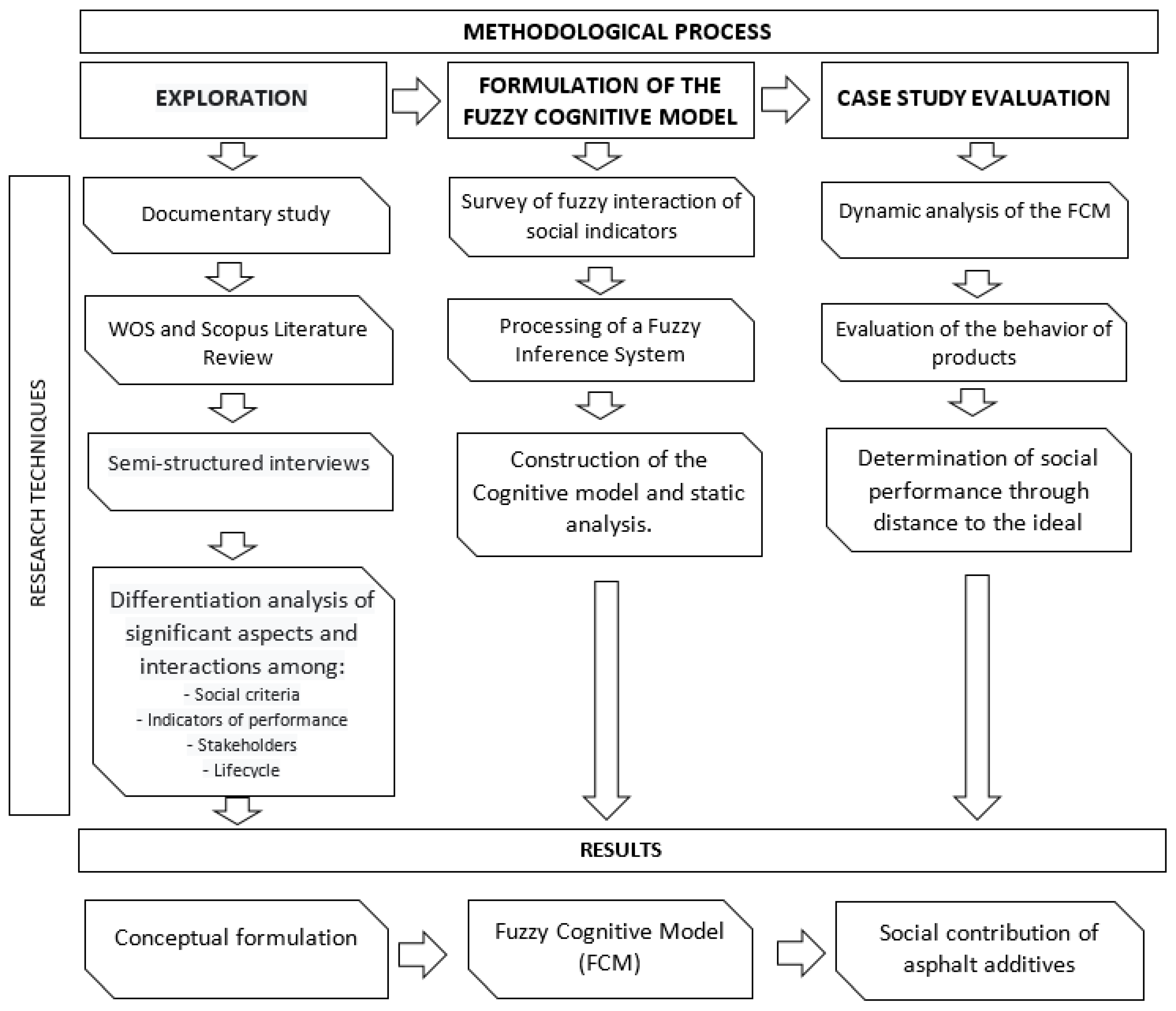

2. Research Methodology

2.1. Case Study

2.2. Research Method

2.2.1. Exploration of the Conceptual Model

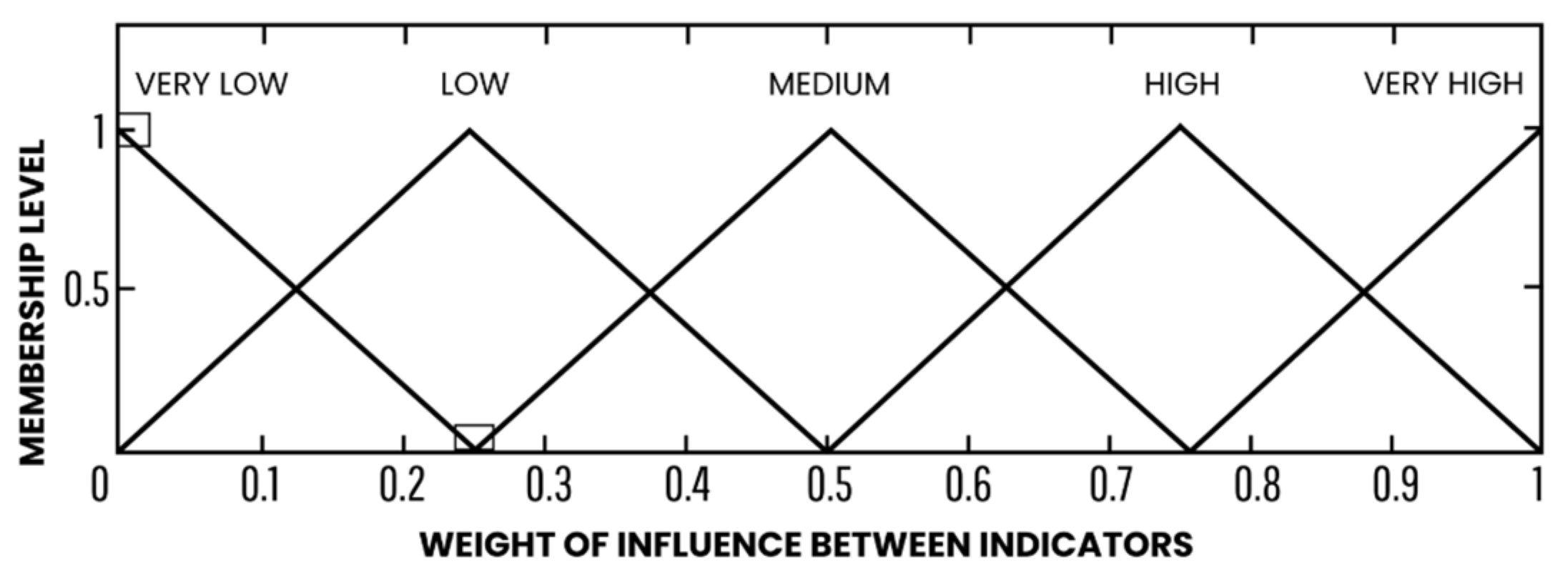

2.2.2. Formulation of the FCM

2.2.3. Case Study Evaluation

3. Results

3.1. Conceptual Formulation

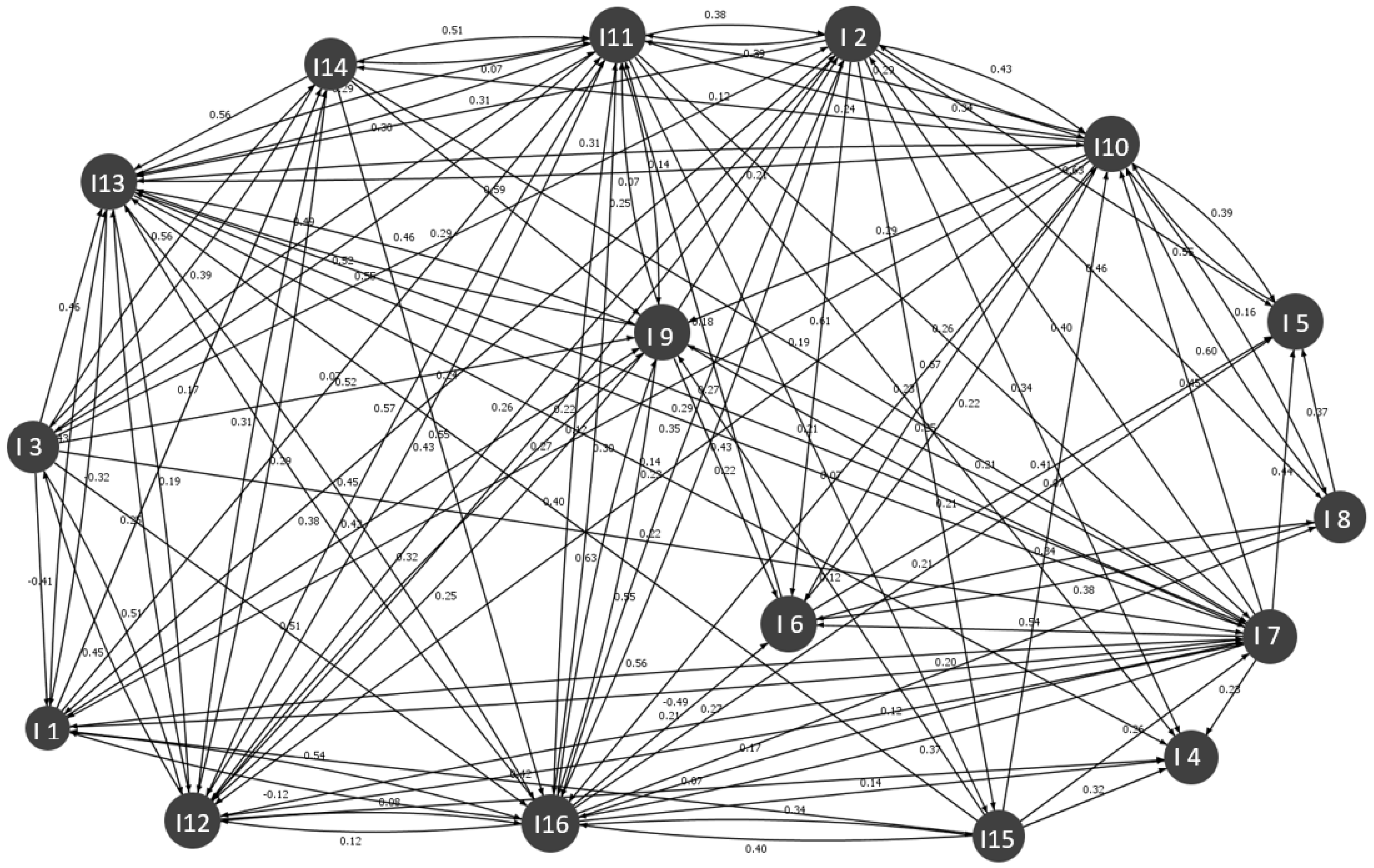

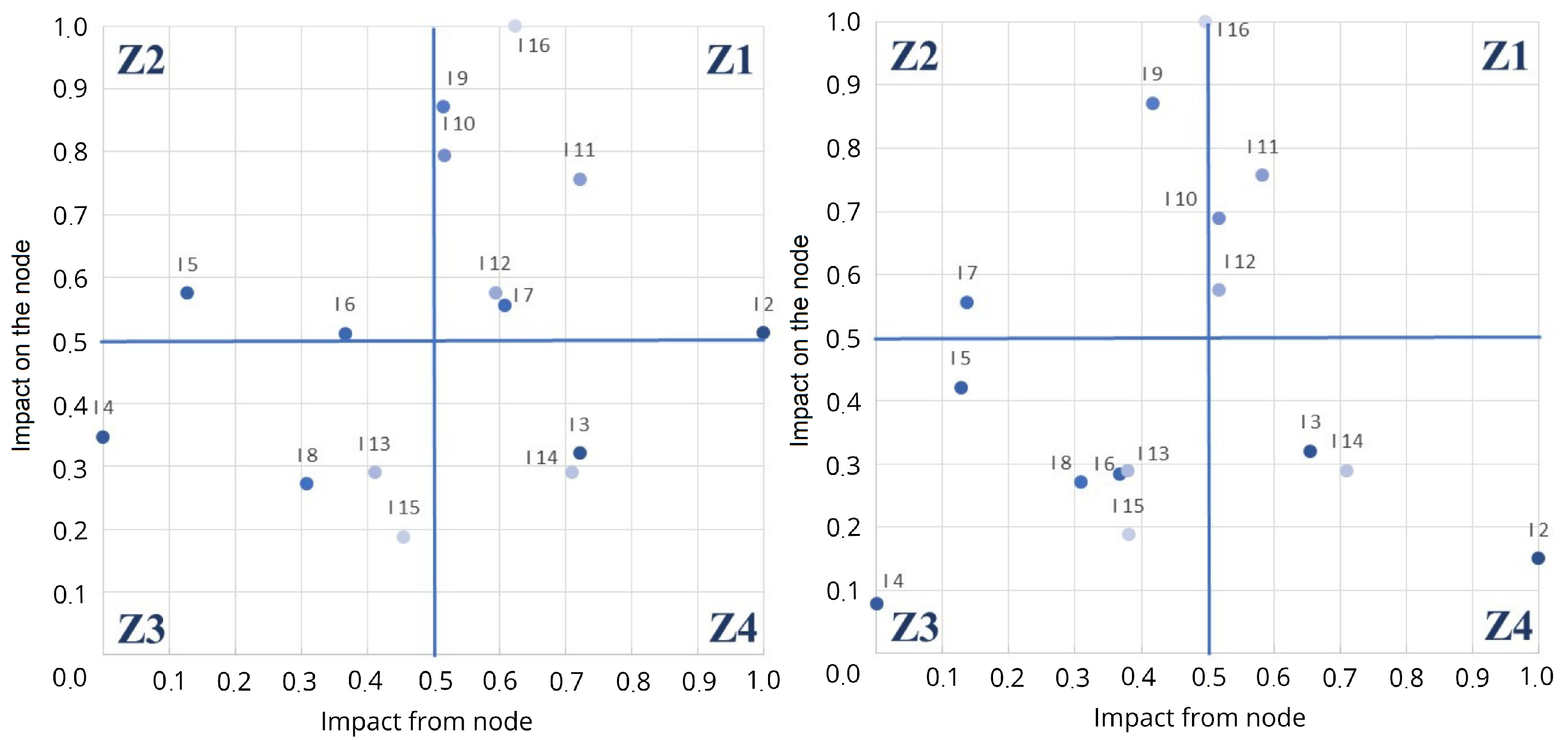

3.2. Fuzzy Cognitive Model (FCM)

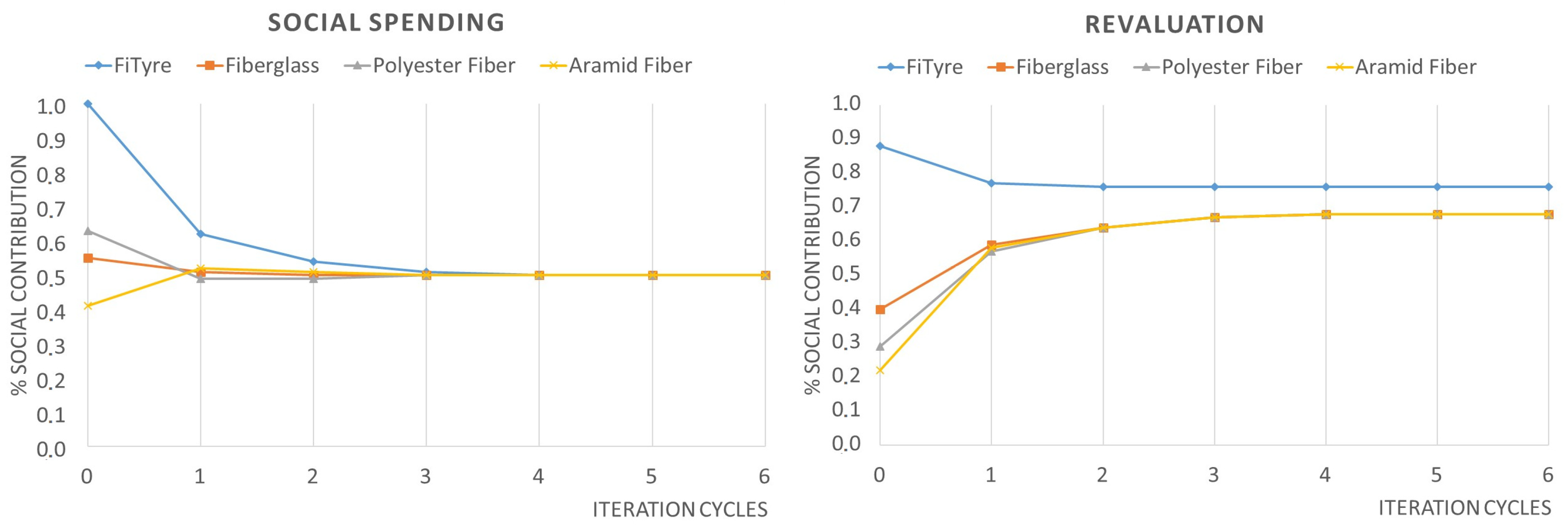

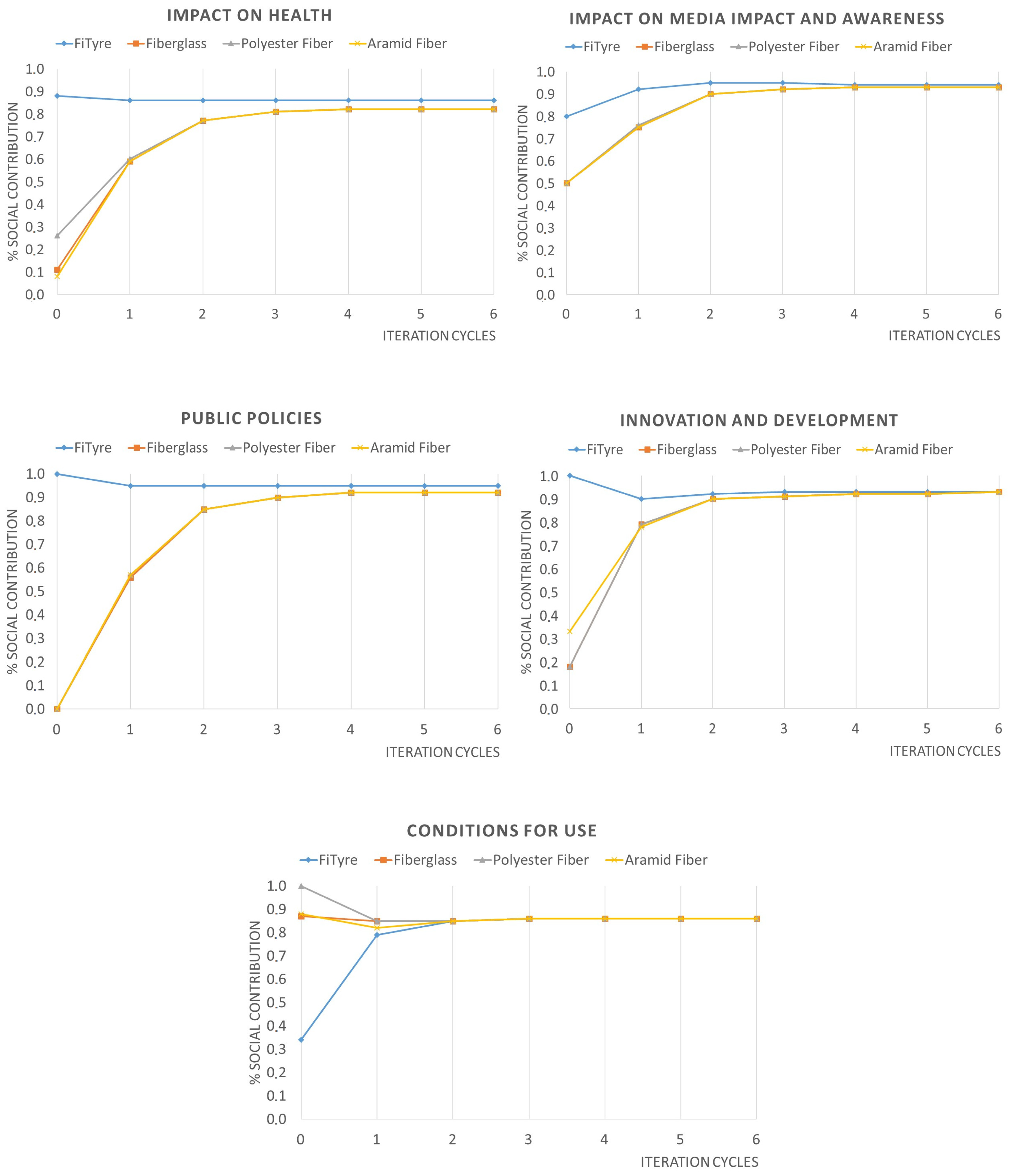

3.3. Social Contribution of the Study Case

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ONU. 17 Objetivos Para Transformar Nuestro Mundo. Naciones Unidas. 2015. Available online: https://www.un.org/sustainabledevelopment/es/ (accessed on 1 December 2024).

- Weiland, S.; Hickmann, T.; Lederer, M.; Marquardt, J.; Schwindenhammer, S. The 2030 agenda for sustainable development: Transformative change through the sustainable development goals? Politi. Gov. 2021, 9, 90–95. [Google Scholar] [CrossRef]

- Sierra-Varela, L.; Valdes-Vidal, G.; Calabi-Floody, A.; Lleuful-Cruz, L.; Villegas-Flores, N.; Filun-Santana, Á. Determination of the Social Contribution of Sustainable Asphalt Mixes. Sustainability 2023, 15, 15205. [Google Scholar] [CrossRef]

- Hossain, U.; Poon, C.S.; Dong, Y.H.; Lo, I.M.C.; Cheng, J.C.P. Development of social sustainability assessment method and a comparative case study on assessing recycled construction materials. Int. J. Life Cycle Assess. 2018, 23, 1654–1674. [Google Scholar] [CrossRef]

- Wang, K.; Ke, Y. Social sustainability of communities: A systematic literature review. Sustain. Prod. Consum. 2024, 47, 585–597. [Google Scholar] [CrossRef]

- Arroyo, P.; Herrera, R.; Salazar, L.; Giménez, Z.; Martínez, J.; Calahorra, M. A new approach for integrating environmental, social and economic factors to evaluate asphalt mixtures with and without waste tires. Rev. Ing. De Constr. 2018, 33, 301–314. [Google Scholar] [CrossRef]

- Azzini, I.; Munda, G. Sensitivity and Robustness Analyses in Social Multi-Criteria Evaluation of Public Policies. J. Multi-Criteria Decis. Anal. 2025, 32, e70006. [Google Scholar] [CrossRef]

- Vanclay, F.; Esteves, A.M. Setting the scene for good social impact assessment and management. In Handbook of Social Impact Assessment and Management; Edward Elgar Publishing Limited: Cheltenham, UK, 2024; pp. 2–15. [Google Scholar] [CrossRef]

- Vanclay, F. Reflections on Social Impact Assessment in the 21st Century. Soc. Impact Assess. 2020, 38, 126–131. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Klinsky, L.; Kaloush, K.; Faria, V.; Bardini, V. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef]

- Delafuente-Navarro, C.; Lastra-González, P.; Slebi-Acevedo, C.; Indacoechea-Vega, I.; Castro-Fresno, D. Multi-criteria analysis of porous asphalt mixtures with aramid fiber under adverse conditions. Constr. Build. Mater. 2024, 429, 136438. [Google Scholar] [CrossRef]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Ren, D.; Fan, S.; He, L.; Liu, Y.; Deng, S.; Luo, Y.; Wang, P.; Jin, X.; Li, J. Covalent Deposition of Diels–Alder Reaction on Polyester Fiber Surface and Its Enhancement Mechanism on SBS-Modified Asphalt. J. Appl. Polym. Sci. 2025, 142, e56712. [Google Scholar] [CrossRef]

- Romero Tellaeche, J.A. Los retos de la economía externa: Importaciones, exportaciones, inversión extranjera, tasa de interés, tipo de cambio. Econ. UNAM 2019, 16, 45–53. [Google Scholar]

- Bocci, E.; Prosperi, E. Recycling of reclaimed fibers from end-of-life tires in hot mix asphalt. J. Traffic Transp. Eng. 2020, 7, 678–687. [Google Scholar] [CrossRef]

- Cámara de la Industria del Neumático de Chile (CINC). Generación de Neumáticos Fuera de Uso; CINC: Santiago, Chile, 2020. [Google Scholar]

- MMA—Ministerio del Medio Ambiente Chile. Decreto Supremo N°8, de 20 de Enero de 2021, que Establece Metas de Recolección y Valorización y Otras Obligaciones Asociadas de Neumáticos; Biblioteca Nacional del Congreso de Chile: Santiago, Chile, 2021.

- Valdés-Vidal, G.; Calabi-Floody, A.; Duarte-Nass, C.; Mignolet, C.; Díaz, C. Development of a New Additive Based on Textile Fibers of End-of-Life Tires (ELT) for Sustainable Asphalt Mixtures with Improved Mechanical Properties. Polymers 2022, 14, 3250. [Google Scholar] [CrossRef]

- Valdes-Vidal, G.; Calabi-Floody, A.; Mignolet-Garrido, C.; Bravo-Espinoza, C. Enhancing Fatigue Resistance in Asphalt Mixtures with a Novel Additive Derived from Recycled Polymeric Fibers from End-of-Life Tyres (ELTs). Polymers 2024, 16, 385. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.R.M.; Chew, J.-W.; Jamshidi, A.; Yang, X.; Hamzah, M.O. Review of sustainability, pretreatment, and engineering considerations of asphalt modifiers from the industrial solid wastes. J. Traffic Transp. Eng. 2019, 6, 209–244. [Google Scholar] [CrossRef]

- Calabi-Floody, A.; Mignolet-Garrido, C.; Valdes-Vidal, G. Study of the effect of the use of asphalt binders modified with polymer fibres from end-of-life tyres (ELT) on the mechanical properties of hot mix asphalt at different operating temperatures. Materials 2022, 15, 7578. [Google Scholar] [CrossRef]

- Landi, D.; Gigli, S.; Germani, M.; Marconi, M. Investigating the feasibility of a reuse scenario for textile fibres recovered from end-of-life tyres. Waste Manag. 2018, 75, 187–204. [Google Scholar] [CrossRef]

- Sierra-Varela, L.; Filun-Santana, Á.; Araya, F.; Villegas-Flores, N.; Martinez-Soto, A. Rural Road Assessment Method for Sustainable Territorial Development. Appl. Sci. 2024, 14, 11021. [Google Scholar] [CrossRef]

- Papageorgiou, K.; Singh, P.K.; Papageorgiou, E.; Chudasama, H.; Bochtis, D.; Stamoulis, G. Fuzzy Cognitive Map-Based Sustainable Socio-Economic Development Planning for Rural Communities. Sustainability 2020, 12, 305. [Google Scholar] [CrossRef]

- Bakhtavar, E.; Valipour, M.; Yousefi, S.; Sadiq, R.; Hewage, K. Fuzzy cognitive maps in systems risk analysis: A comprehensive review. Complex Intell. Syst. 2021, 7, 621–637. [Google Scholar] [CrossRef]

- Olazabal, M.; Pascual, U. Use of fuzzy cognitive maps to study urban resilience and transformation. Environ. Innov. Soc. Transit. 2016, 18, 18–40. [Google Scholar] [CrossRef]

- Nasirzadeh, F.; Ghayoumian, M.; Khanzadi, M.; Cherati, M.R. Modelling the social dimension of sustainable development using fuzzy cognitive maps. Int. J. Constr. Manag. 2020, 20, 223–236. [Google Scholar] [CrossRef]

- Sun, F.; Li, L.; Bian, D.; Ji, H.; Li, N.; Wang, S. Short-term PV power data prediction based on improved FCM with WTEEMD and adaptive weather weights. J. Build. Eng. 2024, 90, 109408. [Google Scholar] [CrossRef]

- van Hulst, F.; Ellis, R.; Prager, K.; Msika, J. Using co-constructed mental models to understand stakeholder perspectives on agro-ecology. Int. J. Agric. Sustain. 2020, 18, 172–195. [Google Scholar] [CrossRef]

- Amirkhani, A.; Papageorgiou, E.I.; Mohseni, A.; Mosavi, M.R. A review of fuzzy cognitive maps in medicine: Taxonomy, methods, and applications. Comput. Methods Programs Biomed. 2017, 142, 129–145. [Google Scholar] [CrossRef]

- Vidal, R.; Salmeron, J.L.; Mena, A.; Chulvi, V. Fuzzy Cognitive Map-based selection of TRIZ (Theory of Inventive Problem Solving) trends for eco-innovation of ceramic industry products. J. Clean. Prod. 2015, 107, 202–214. [Google Scholar] [CrossRef]

- Lago, N.C.; Marcon, A.; Ribeiro, J.L.D.; de Medeiros, J.F.; Brião, V.B.; Antoni, V.L. Determinant attributes and the compensatory judgement rules applied by young consumers to purchase environmentally sustainable food products. Sustain. Prod. Consum. 2020, 23, 256–273. [Google Scholar] [CrossRef]

- Ziari, H.; Aliha, M.R.M.; Moniri, A.; Saghafi, Y. Crack resistance of hot mix asphalt containing different percentages of reclaimed asphalt pavement and glass fiber. Constr. Build. Mater. 2020, 230, 117015. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T.; Thom, N.; Grenfell, J. Microstructure and mechanical properties of fibre reinforced asphalt mixtures. Constr. Build. Mater. 2020, 240, 117932. [Google Scholar] [CrossRef]

- Dehghan, Z.; Modarres, A. Evaluating the fatigue properties of hot mix asphalt reinforced by recycled PET fibers using 4-point bending test. Constr. Build. Mater. 2017, 139, 384–393. [Google Scholar] [CrossRef]

- Qian, S.; Ma, H.; Feng, J.; Yang, R.; Huang, X. Fiber reinforcing effect on asphalt binder under low temperature. Constr. Build. Mater. 2014, 61, 120–124. [Google Scholar] [CrossRef]

- Hong, R.-B.; Wu, J.-R.; Cai, H.-B. Low-temperature crack resistance of coal gangue powder and polyester fibre asphalt mixture. Constr. Build. Mater. 2020, 238, 117678. [Google Scholar] [CrossRef]

- Gupta, A.; Castro-Fresno, D.; Lastra-Gonzalez, P.; Rodriguez-Hernandez, J. Selection of fibers to improve porous asphalt mixtures using multi-criteria analysis. Constr. Build. Mater. 2021, 266, 121198. [Google Scholar] [CrossRef]

- Gupta, A.; Lastra-Gonzalez, P.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Laboratory Characterization of Porous Asphalt Mixtures with Aramid Fibers. Materials 2021, 14, 1935. [Google Scholar] [CrossRef]

- Xing, X.; Liu, T.; Pei, J.; Huang, J.; Li, R.; Zhang, J.; Tian, Y. Effect of fiber length and surface treatment on the performance of fiber-modified binder. Constr. Build. Mater. 2020, 248, 118702. [Google Scholar] [CrossRef]

- Kim, M.-J.; Kim, S.; Yoo, D.-Y.; Shin, H.-O. Enhancing mechanical properties of asphalt concrete using synthetic fibers. Constr. Build. Mater. 2018, 178, 233–243. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Sadeghi, H.; Fazeli, A.; Mahdiyar, A.; Hosseini, M.R.; Arashpour, M.; Zayed, T. Causal analysis of accidents on construction sites: A hybrid fuzzy Delphi and DEMATEL approach. Saf. Sci. 2022, 151, 105730. [Google Scholar] [CrossRef]

- Mathern, A.; Penadés-Plà, V.; Barros, J.A.; Yepes, V. Practical metamodel-assisted multi-objective design optimization for improved sustainability and buildability of wind turbine foundations. Struct. Multidiscip. Optim. 2022, 65, 46. [Google Scholar] [CrossRef]

- Tüű-Szabó, B.; Kóczy, L.T. A highly accurate Mamdani fuzzy inference system for tennis match predictions. Fuzzy Optim. Decis. Mak. 2025, 1–29. [Google Scholar] [CrossRef]

- Felix, G.; Nápoles, G.; Falcon, R.; Froelich, W.; Vanhoof, K.; Bello, R. A review on methods and software for fuzzy cognitive maps. Artif. Intell. Rev. 2019, 52, 1707–1737. [Google Scholar] [CrossRef]

- Tola, M.; Georgopoulos, V.C.; Geronikou, E.; Plotas, P.; Stylios, C. Fuzzy Cognitive Maps for Decision Support in Post-COVID Syndrome with Speech-Language Pathology-Related Problems. Appl. Sci. 2024, 15, 13. [Google Scholar] [CrossRef]

- Hosmer, D.W., Jr.; Lemeshow, S.; Sturdivant, R.X. Applied Logistic Regression; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Ghaleenoei, N.K.; Saghatforoush, E.; Mansouri, T.; Zareravasan, A. An FCM-based dynamic modeling of operability and maintainability barriers in road projects. Int. J. Pavement Res. Technol. 2022, 15, 367–383. [Google Scholar] [CrossRef]

- Daimi, S.; Rebai, S. Sustainability performance assessment of Tunisian public transport companies: AHP and ANP approaches. Socio-Econ. Plan. Sci. 2023, 89, 101680. [Google Scholar] [CrossRef]

- Kumar, S.; Banerji, H. Bayesian network modeling for economic-socio-cultural sustainability of neighborhood-level urban communities: Reflections from Kolkata, an Indian megacity. Sustain. Cities Soc. 2022, 78, 103632. [Google Scholar] [CrossRef]

- Karami, S.; Karami, E.; Buys, L.; Drogemuller, R. System dynamic simulation: A new method in social impact assessment (SIA). Environ. Impact Assess. Rev. 2017, 62, 25–34. [Google Scholar] [CrossRef]

- Alavi, B.; Tavana, M.; Mina, H. A dynamic decision support system for sustainable supplier selection in circular economy. Sustain. Prod. Consum. 2021, 27, 905–920. [Google Scholar] [CrossRef]

- de Vialidad, D. Manual de Carreteras Volumen 9: Estudios y Criterios Ambientales en Proyectos Viales; Ministerio de Obras Públicas: Santiago de Chile, Chile, 2023. Available online: https://mc.mop.gob.cl/Inicio/Index/ (accessed on 2 March 2025).

- Prouty, C.; Koenig, E.S.; Wells, E.C.; Zarger, R.K.; Zhang, Q. Rapid assessment framework for modeling stakeholder involvement in infrastructure development. Sustain. Cities Soc. 2017, 29, 130–138. [Google Scholar] [CrossRef]

| Additive | Ref. | Density/Length/Diameter | Advantages | Disadvantages |

|---|---|---|---|---|

| Fiberglass | Mohammed et al. 2020 [35] | ρ: 2.58 g/cm3 L: 6–13 mm Ø: 0.012–0.02 mm | Increases in indirect tensile strength. High resistance to moisture damage. Improves resistance to low-temperature cracking. | Less resistance to fatigue with a content of 2%. |

| Ziari et al. 2020 [34] | ρ: 1.18 g/cm3 L: 12 mm Ø: 0.13 mm | Improves resistance to cracking with a content of 1% and 2%. The positive effect of the fibers outweighs the adverse impact of the reclaimed asphalt pavement material. | About 2% of the resistance to cracking of the mixtures is affected. However, better performance is maintained than in the control mixture. | |

| Aramid | Gupta et al. 2021 [39] | ρ: 1.44 g/cm3 L: 6 mm | Fiber positively influences abrasion resistance. | Decrease in the content of air voids. Lower resistance to indirect tensile strength (ITS). Increased moisture susceptibility. |

| Xing et al. 2020 [41] | ρ: 1.44 g/cm3 L: 1–6 mm Ø: 12 μm | Improves performance at high temperatures. Improves the viscosity of the modified asphalt cement, increasing the modulus of rigidity. | Agglomeration of 6 mm long fibers. Fibers do not have a promising effect on low-temperature crack resistance. | |

| Polyester | Dehghan and Modarres 2017 [36] | ρ: 1.35 g/cm3 L: 10–20 mm Ø: 30 μm | Improves fatigue resistance. | Due to the agglomeration generated in the mixture, the maximum fiber content is limited to 2%. |

| Kim et al. 2018 [42] | ρ: 1.40 g/cm3 L: 6 mm Ø: 41 μm | Improvement in the mechanical properties of the asphalt mix: Marshall stability, indirect tensile strength (ITS), permanent deformation, and bending capacity. | --- | |

| Hong et al. 2020 [38] | ρ: 1.4 g/cm3 L: 12 mm Ø: 20 μm | Improves resistance to low-temperature cracking. | The fiber distribution in the mix is affected by about 7%. | |

| Qian et al. 2014 [37] | ρ: 1.38 g/cm3 L: 4–24 mm Ø: 20 μm | Improves tensile deformation properties. Maintains tensile ductility, regardless of temperature change (low temperatures). | A fiber content of less than 1% and more than 8% has an unfavorable effect on tensile performance. The fiber length is crucial for good performance and distribution in the mix. Optimal length is 6 mm. | |

| Fityre | Valdés et al. 2022, 2024 [19,20] | ρ: 1.18 g/cm3 L: 4.8–12.1 mm Ø: 3.6–5.8 mm | Improves performance properties, especially up to 40% of permanent deformations, and can double the fatigue life of the material. | At the laboratory scale, increased compaction energy requirements have been proven to enable densification. |

| N° | Institution | Amount | Experience | Profession | Stakeholders | |

|---|---|---|---|---|---|---|

| 1 | Ministry of Public Works | 1 | 8 years | Civil Engineer | Regulator/ Asphalt Mix Consumer | |

| 2 | State Universities Specialty Departments | 4 | 10–20 years | Construction Engineers, Sociologist and Civil Engineer (PhDs) | Researchers | |

| 3 | Private asphalt company | 1 | 18 years | Civil Engineer | Asphalt mix producer | |

| 4 | Road dealership | 1 | 45 years | Civil Engineer (MSc) | Asphalt mix Consumer | |

| 5 | Private recycling companies | 3 | 10–41 years | Mechanical engineer, Economist, Environmental engineer | Recycler/Additive producer | |

| 6 | NGOs | 2 | 15–18 years | Industrial Engineer, Sociologist (PhDs) | Asphalt mix consumer- community | |

| 7 | Ministry of Environment | 1 | 20 years | Environmental engineer | Regulator | |

| Criterion | LC(St) 1 | ID | Indicator | Definition of the Indicator |

|---|---|---|---|---|

| Social Spending | F.Pr. (A, B, C) M.Pr. (A, B, C, F) | I1 | Reduction in additive cost per ton of mix 2 | The ratio between 1 ton of mix and the cost in USD of the required amount of additive. |

| Revaluation | Ext. (A, B, D, E) F.Pr. (A, B, E) | I2 | Extending the useful life of a reused product | Contribution of the additive to the circular economy (extension of the useful life of a waste product). |

| M.Pr. (A, B, C, E, F) | I3 | Technical input on existing additives | Documented improvements in the technical performance of asphalt mixes (sensitivity to the action of water, resistance to cracking, resistance to plastic deformation, and modulus of rigidity). | |

| Ext. (A, B, D) F.Pr. (A, B, C) | I4 | National jobs | No. of workers required to produce the additive in a production plant. | |

| Impact on health | Ext. (A, B, D, E) | I5 | Reduction in landfill fire risk | Reduced risk of landfill fires by preventing the waste from reaching the landfill. |

| Ext. (A, B, D, E) | I6 | Reduction in area of occupied land | Defines the area of land no longer allocated for landfill. | |

| Ext. (A, B, D, E) F.Pr. (A, B, C, E, F) M.Pr. (A, B, C, F) | I7 | Amount of additive required | The necessary weight of the additive is to produce one ton of mix. | |

| Ext. (A, B, D, E) | I8 | Reduced time spent in landfill | Defines the volume of the environmental load caused by the fiber reaching the landfill considering the degradation time of the waste. | |

| Media impact and awareness | F.Pr. (A, B) M.Pr. (C, F) | I9 | Degree of acceptance of change | Level of acceptance by those seeking a pavement composed of asphalt fibers, including the possible use of innovative raw materials that replace part or all of a conventional mixture. |

| Public policies | Ext. (A, B, D, E) F.Pr. (B, E) | I10 | Association to the REP 3 Law | Role of the additive in meeting the collection and revaluation goals established by the Extended Producer Responsibility Law. |

| Innovation and development | Ext. (A, D) F.Pr. (B, E) | I11 | Innovation and patented development in the domestic industry | Pertains to whether the product is a domestic innovation. |

| Ext. (A, D) F.Pr. (A, B, C, F) | I12 | Knowledge transfer | Stakeholders involved in product development (E = Enterprise, A = Academia, G = Government) | |

| Conditions for use | M.Pr. (A, B, C, F) | I13 | Interest from producers | Defines the % of interest asphalt mix producers have in these additives. |

| F.Pr. (A, B, C, E, F) M.Pr. (A, B, C, E, F) | I14 | Certifications | Additive status under evaluation. Defines the importance of product certification. | |

| Ext. (A, B, C, D, E, F) F.Pr. (A, B, C, E, F) | I15 | Current fiber supply | Fiber coverage to meet the demand for replacement of existing pavement. Assuming a 100 km stretch of pavement, the required fiber is calculated and compared with monthly availability. | |

| M.Pr. (A, B, C, F) | I16 | General consumer interest | Percentage of interest asphalt mix consumers have in these additives. |

| ID | Indicators | Unit of Measure | Response Status | FiTyre | Fiberglass | Polyester Fiber | Aramid Fiber |

|---|---|---|---|---|---|---|---|

| 1 | Cost of additive for one ton of mixture | Ton of mixture/USD of additive | 1Ton/USD | 1/5 | 1/9 | 1/8 | 1/12 |

| 2 | Extending the useful life of a reused product | Answer to question | YES/NO | YES | NO | NO | NO |

| 3 | Technical contribution | Level of improvement | N° of technical contributions (water resistance, cracking, deformation, fatigue) | 1 | 2 | 1 | 1 |

| 4 | National jobs | N° of employees | Estimated number of jobs. | 30 | 0 | 0 | 0 |

| 5 | Reduction in landfill fire risk | Kg of TfELT not reaching the landfill for each ton of mix produced | Kg of TfELTs not reaching the landfill for each ton of mix produced | 0.577 | 0 | 0 | 0 |

| 6 | Reduction in area of occupied land | (m2 released/ton of fiber) × (amount of fiber/ton of mixture) | (m2 released/ton of fiber) × (amount of fiber/ton of mixture) | 0.001 | 0 | 0 | 0 |

| 7 | Amount of fiber required | Kg of additive per ton of mixture | Kg of additive per ton of mixture | 1.06 | 1.06 | 2.12 | 0.583 |

| 8 | Reduced time spent in landfill | Volume per ton of mixture (cm3) | The lower the volume, the lower the environmental load | 3356 | 0 | 0 | 0 |

| 9 | Degree of acceptance of change | Reception level | Very high, high, medium, low, very low | Medium | Very high | Very high | Very high |

| 10 | Association with the REP Law | % of the total fiber produced by a unit of waste used in the production of 1 ton of mixture | Percentage | 0.63 | 0 | 0 | 0 |

| 11 | Innovation and patented development in national industry | Compliance | Complies; does not comply | Complies | Does not comply | Does not comply | Does not comply |

| 12 | Knowledge transfer | Link to knowledge transfer | E + A + G; E + A; E + G. 1 | E + A + G | E | E | E + A |

| 13 | Interest from producers | Level of interest in the product | Percentage | 51% | 61% | 75% | 50% |

| 14 | Certifications | State | Certified; not certified | Does not comply | Complies | Complies | Complies |

| 15 | Current fiber supply | Amount of fiber needed to supply 100 km of road in the short term/amount of fiber available | Meets the demand; does not meet the demand | Does not meet demand | Meets demand | Meets demand | Meets demand |

| 16 | Consumer interest | Level of interest in the product | Percentage | 56% | 51% | 83% | 66% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sierra-Varela, L.; Calabi-Floody, A.; Valdés-Vidal, G.; Yepes, V.; Filun-Santana, Á. Determination of the Social Contribution of Sustainable Additives for Asphalt Mixes Through Fuzzy Cognitive Mapping. Appl. Sci. 2025, 15, 3994. https://doi.org/10.3390/app15073994

Sierra-Varela L, Calabi-Floody A, Valdés-Vidal G, Yepes V, Filun-Santana Á. Determination of the Social Contribution of Sustainable Additives for Asphalt Mixes Through Fuzzy Cognitive Mapping. Applied Sciences. 2025; 15(7):3994. https://doi.org/10.3390/app15073994

Chicago/Turabian StyleSierra-Varela, Leonardo, Alejandra Calabi-Floody, Gonzalo Valdés-Vidal, Víctor Yepes, and Álvaro Filun-Santana. 2025. "Determination of the Social Contribution of Sustainable Additives for Asphalt Mixes Through Fuzzy Cognitive Mapping" Applied Sciences 15, no. 7: 3994. https://doi.org/10.3390/app15073994

APA StyleSierra-Varela, L., Calabi-Floody, A., Valdés-Vidal, G., Yepes, V., & Filun-Santana, Á. (2025). Determination of the Social Contribution of Sustainable Additives for Asphalt Mixes Through Fuzzy Cognitive Mapping. Applied Sciences, 15(7), 3994. https://doi.org/10.3390/app15073994