Double-Borehole Superimposed Effect of a New Non-Explosive Directional Rock-Breaking Method

Abstract

1. Introduction

2. Methodology

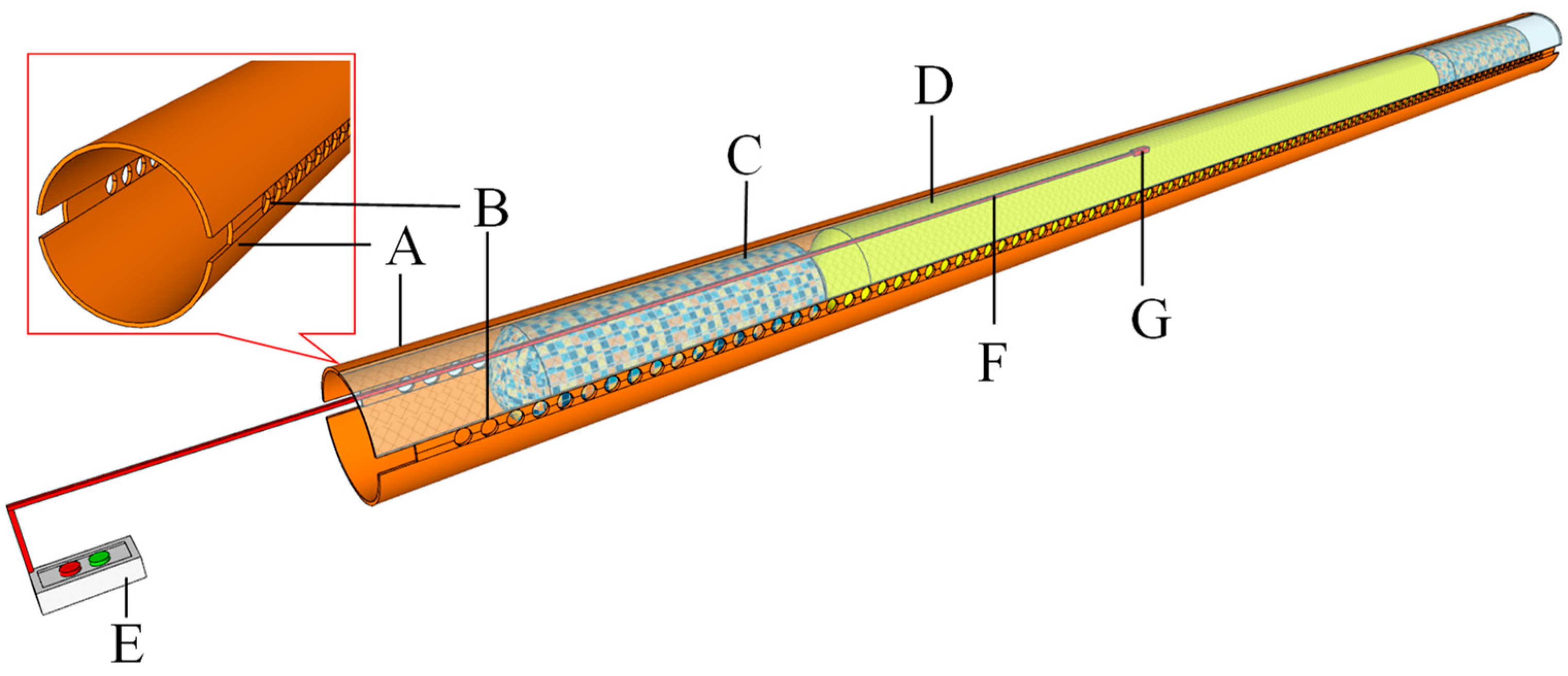

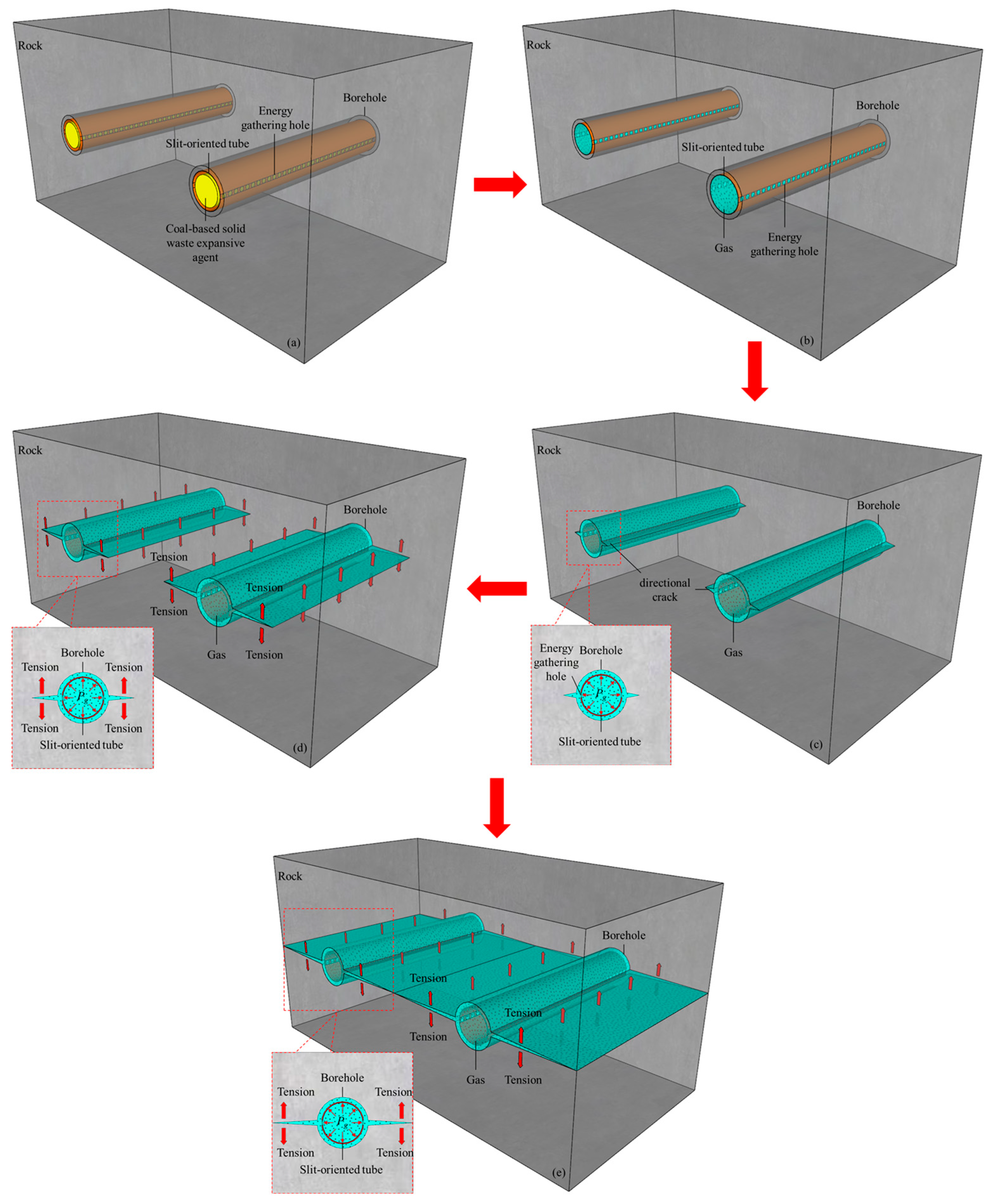

2.1. Structure and Working Principle of IESF

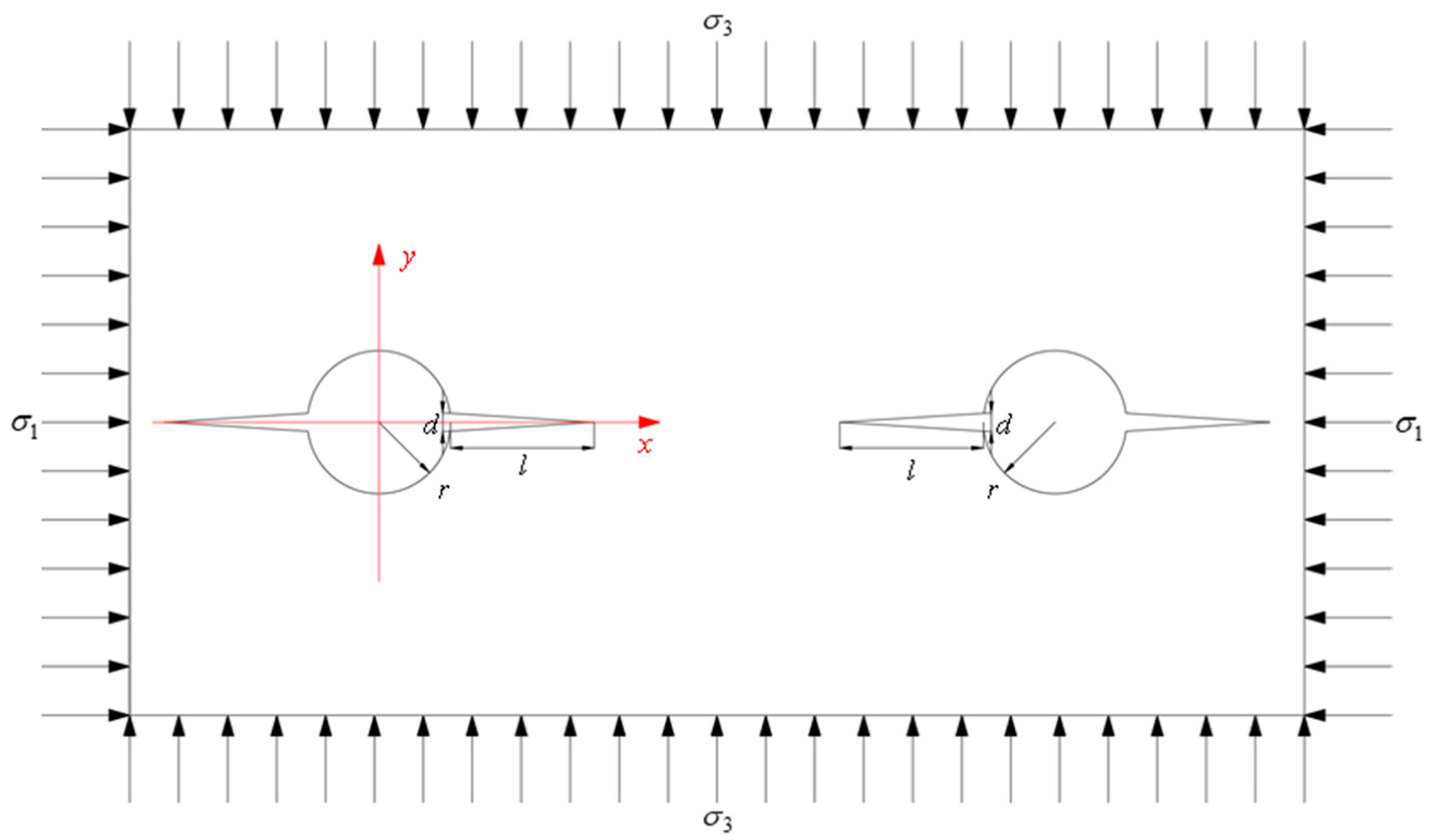

2.2. The Theoretical Model of Double-Borehole Directional Rock-Breaking by IESF

2.2.1. Spatial Distribution Pattern of High-Pressure Gas Pressure Generated by IESF

2.2.2. Crack Propagation Criterion of IESF

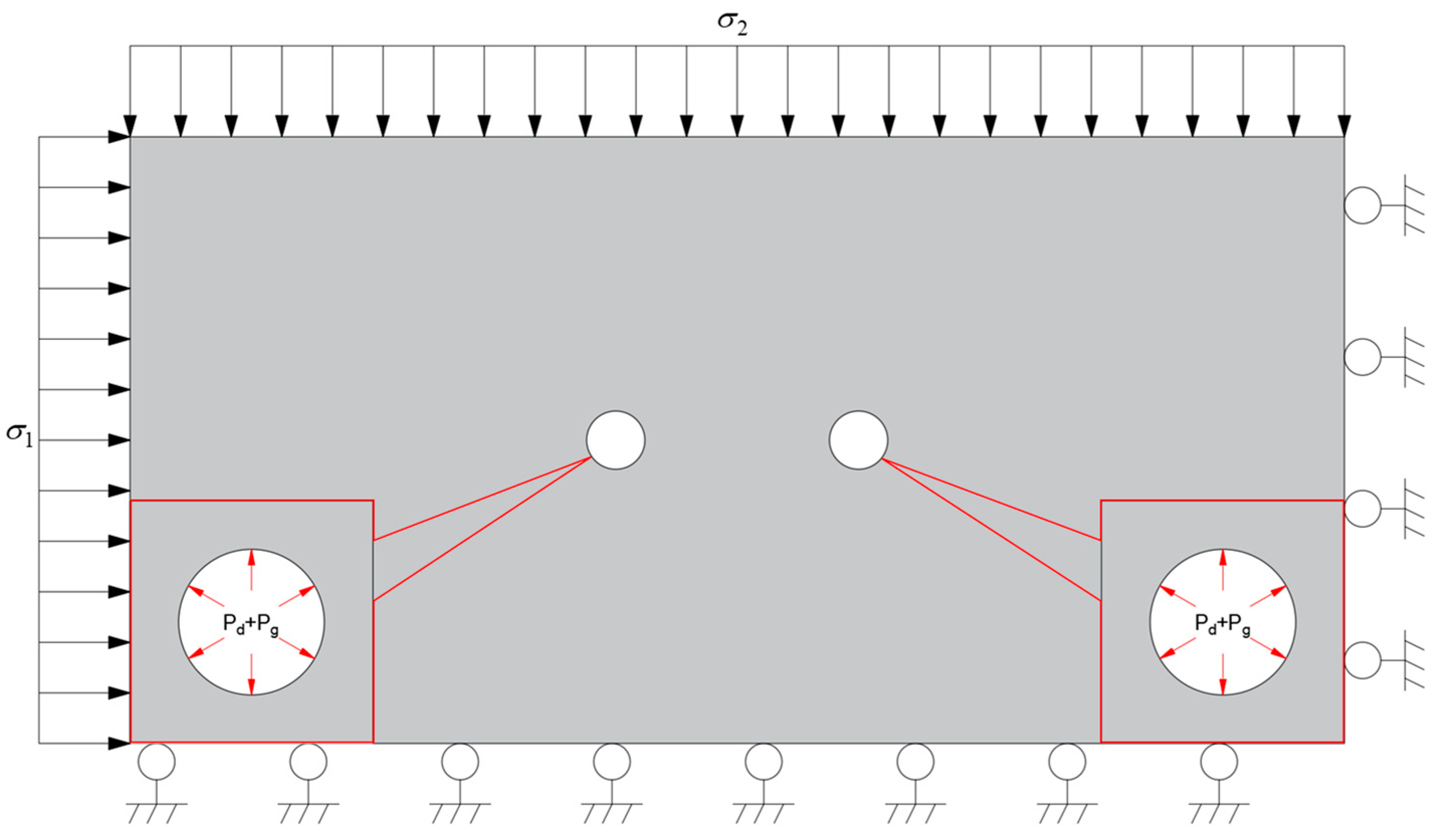

2.3. The Numerical Model Calculation Principle of IESF

2.3.1. The Numerical Calculation Theory of IESF

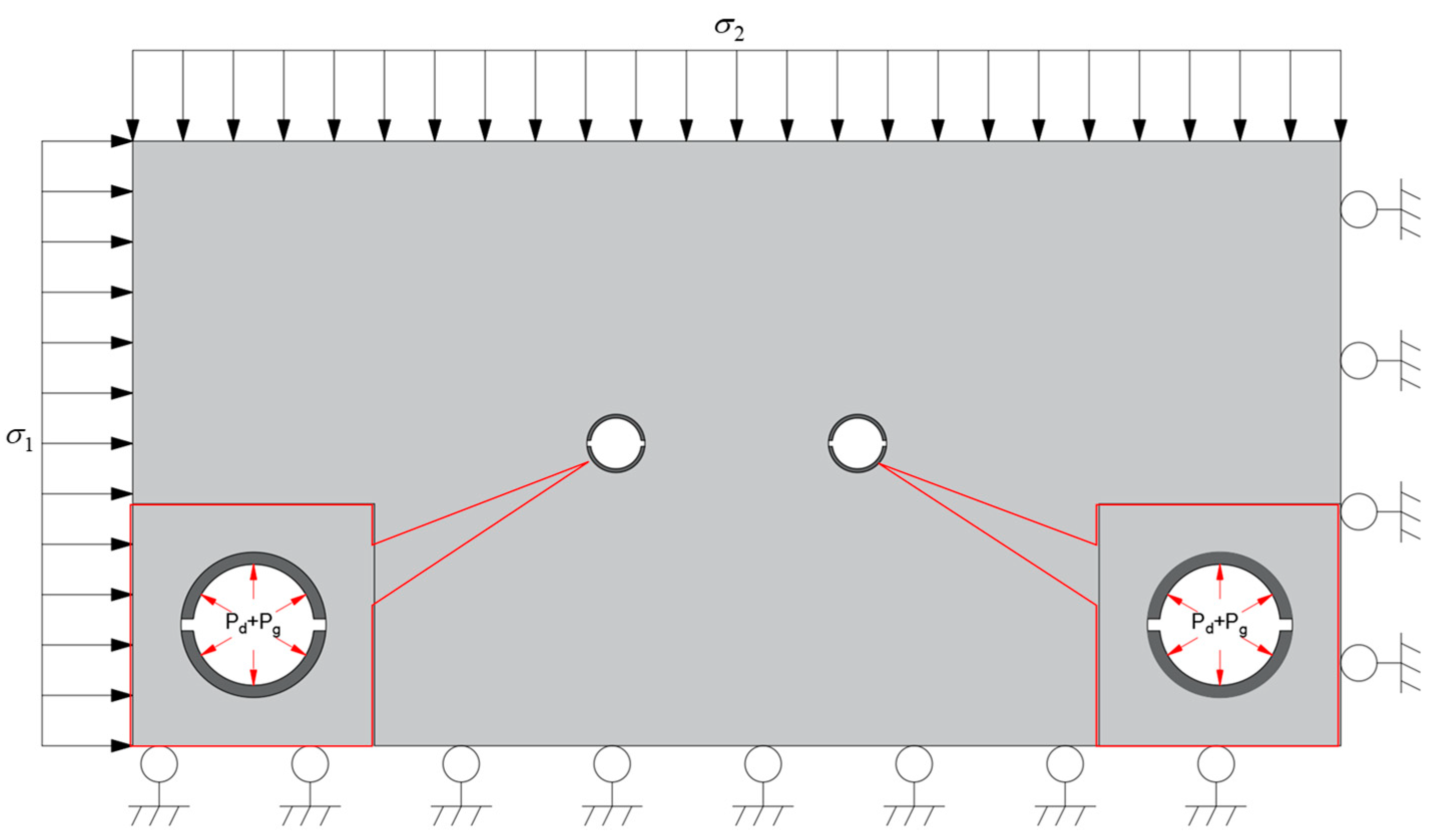

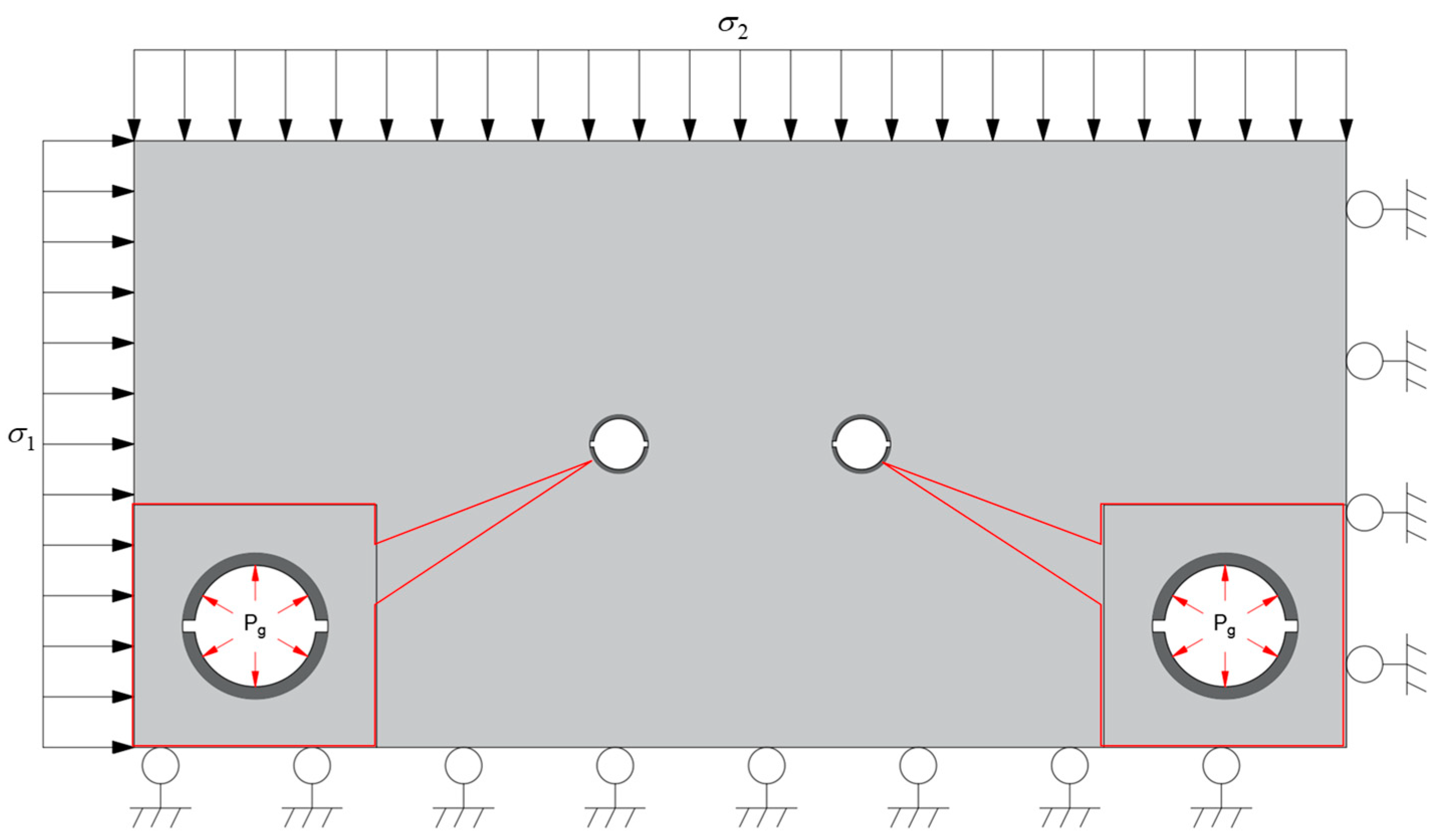

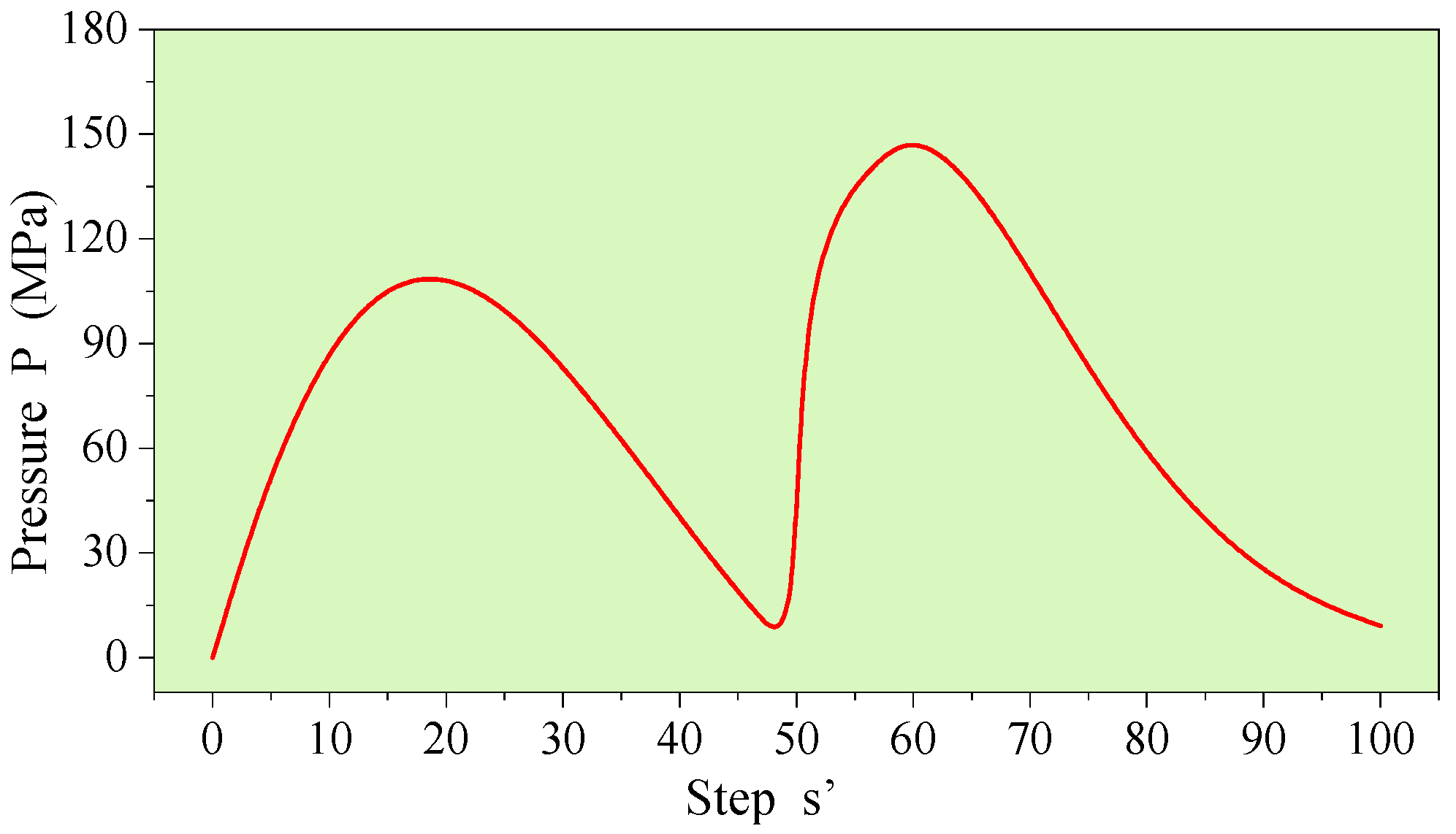

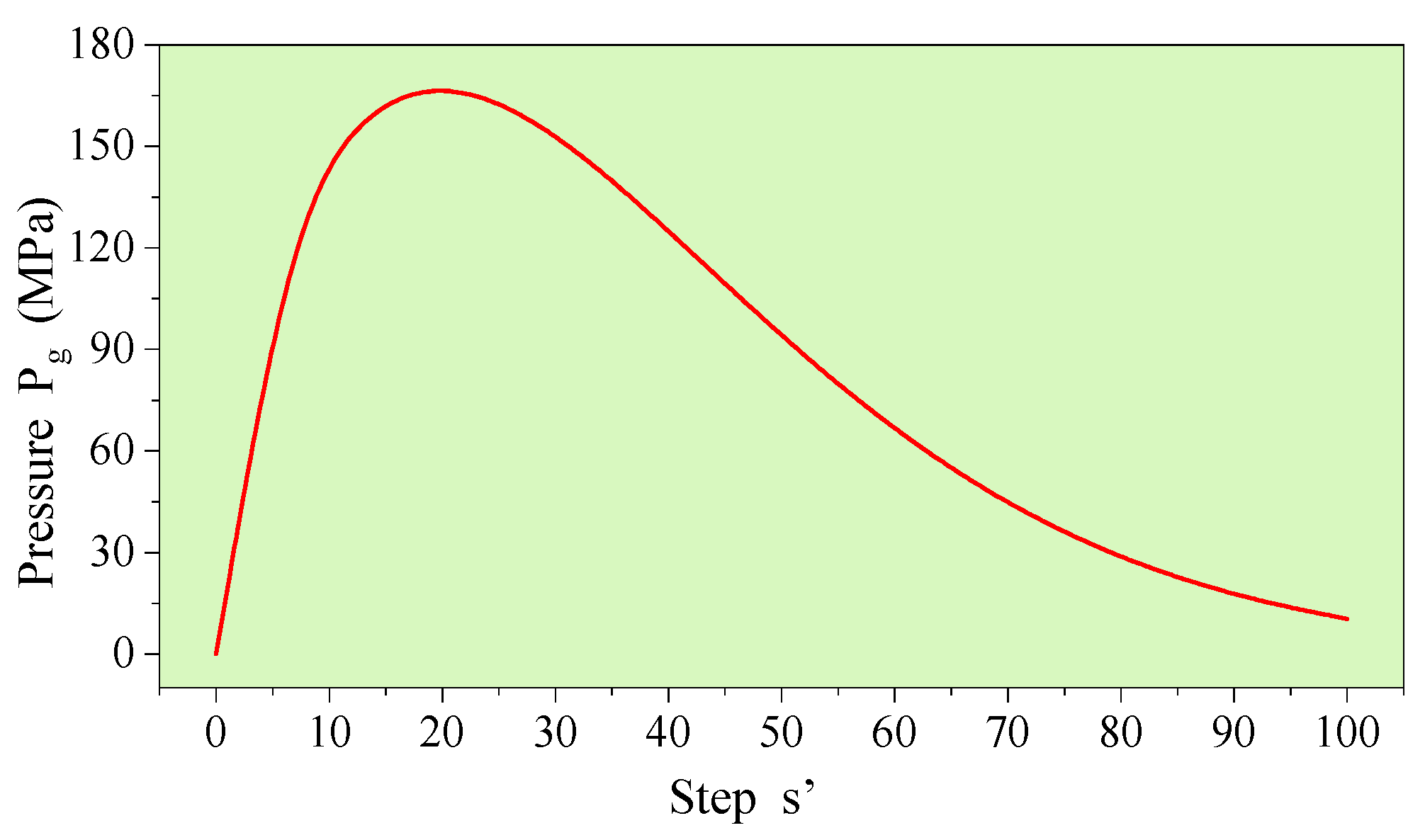

2.3.2. Numerical Model of Double-Hole Fracture

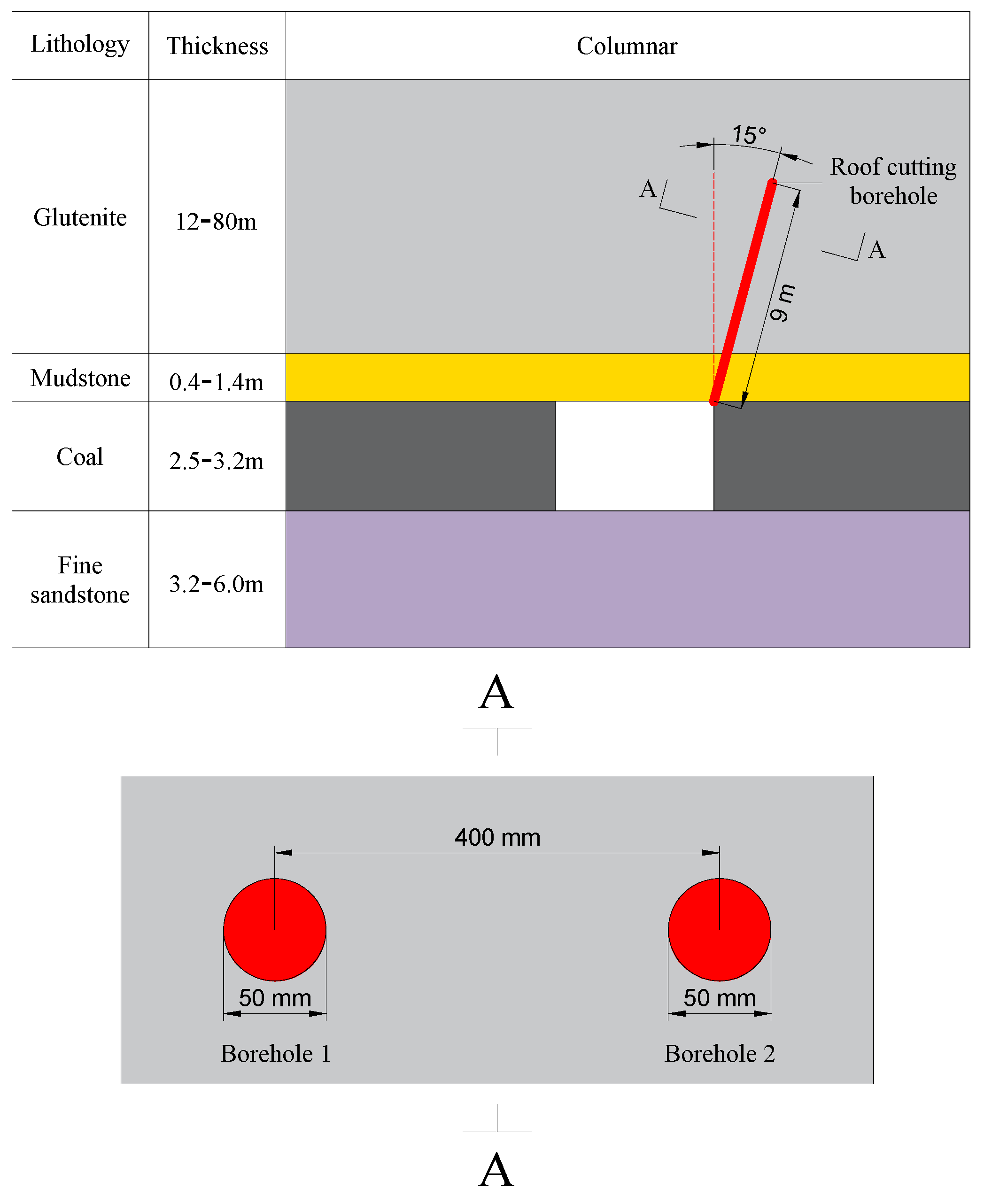

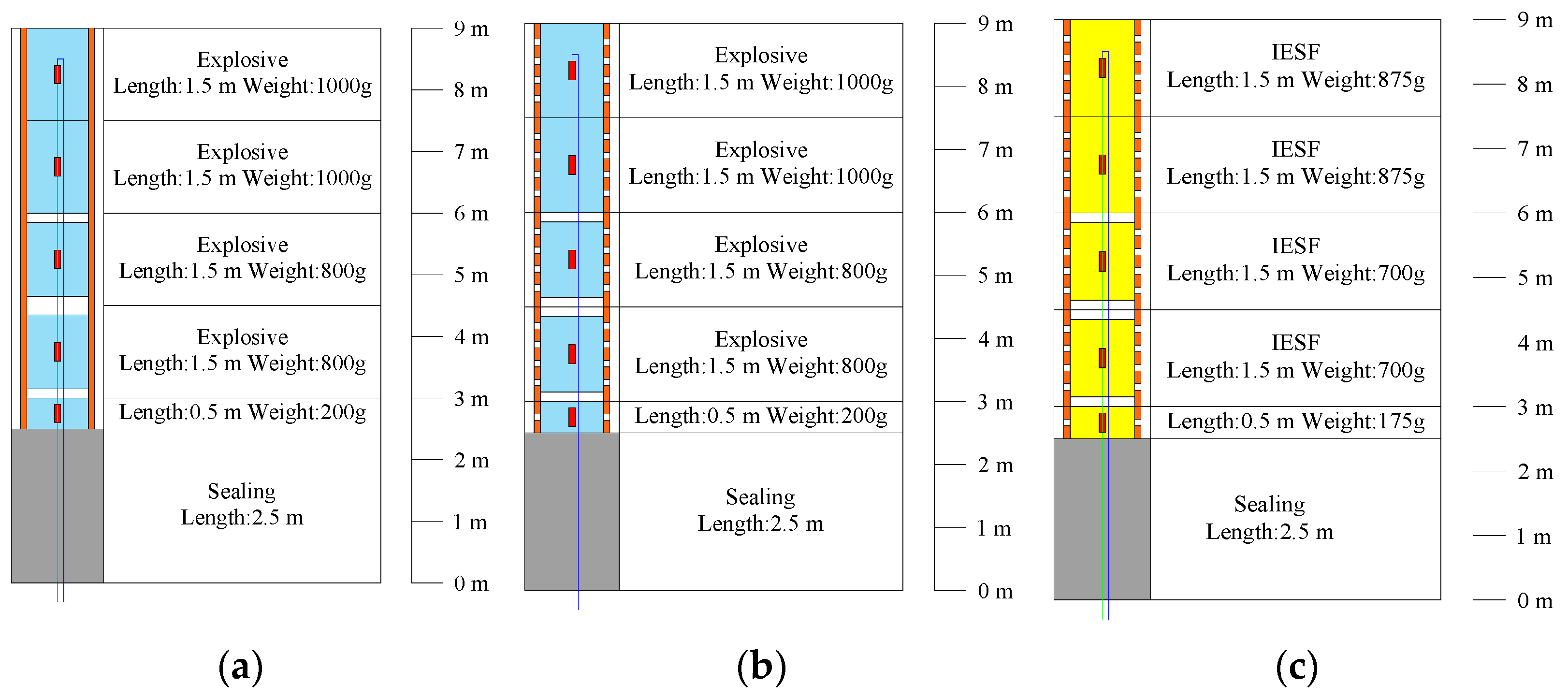

2.4. In Situ Test Scheme of IESF

3. Results

3.1. Numerical Simulation Results of IESF

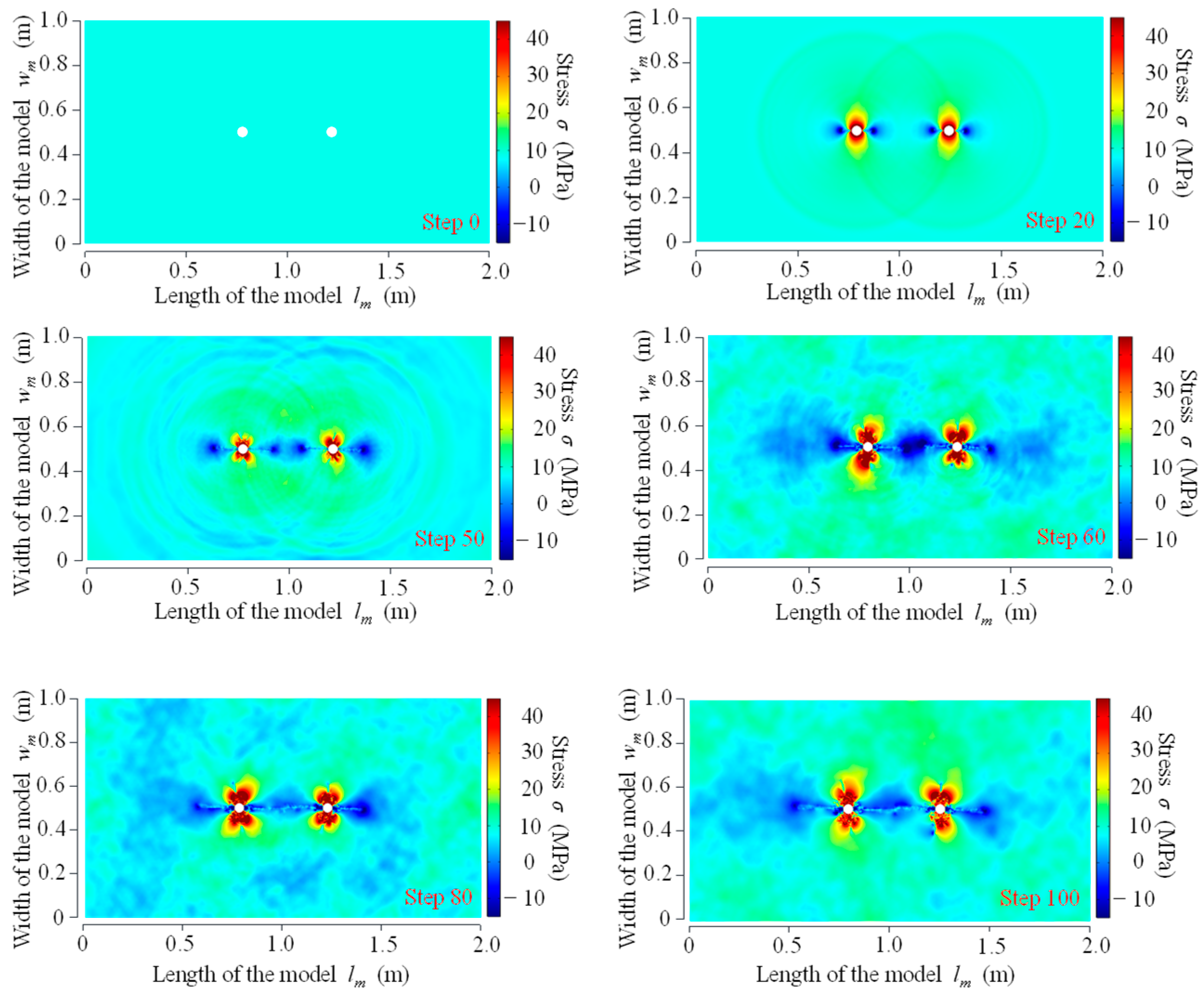

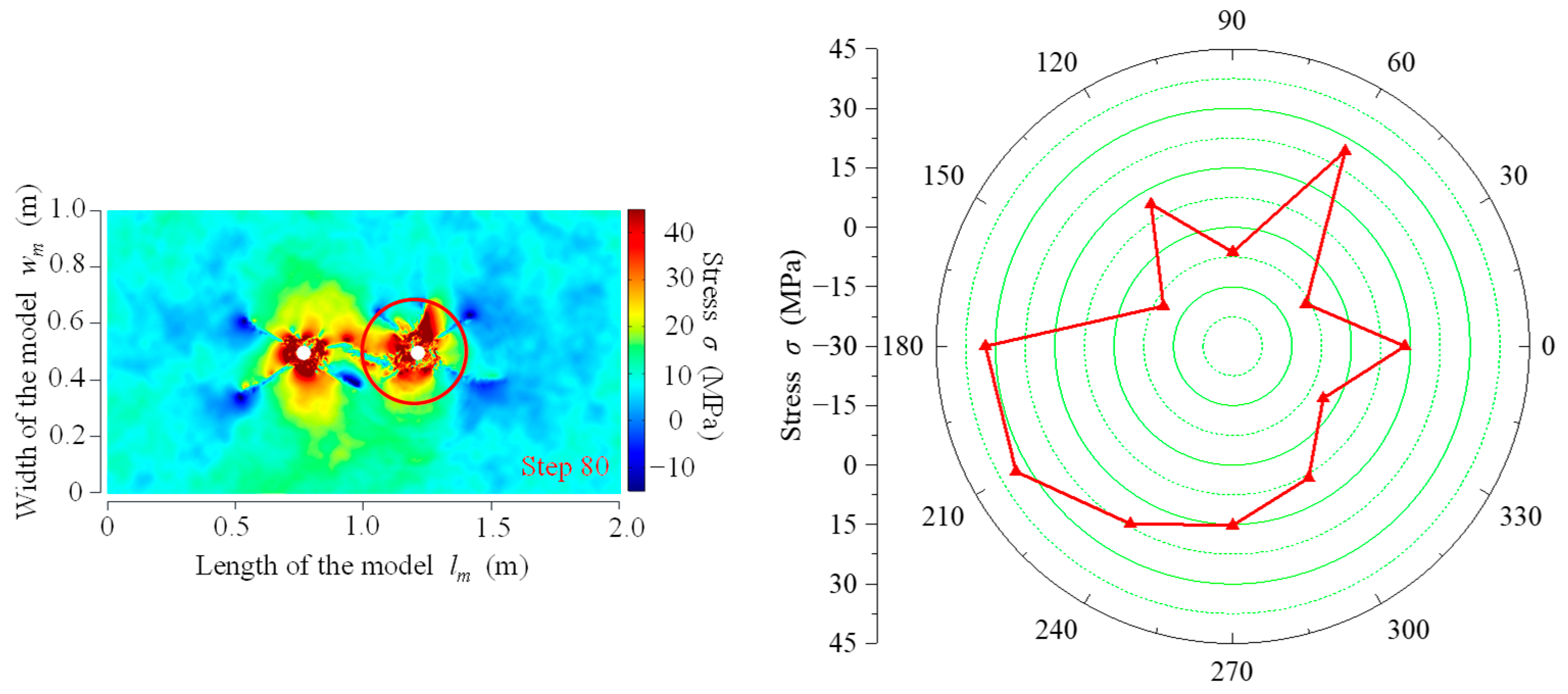

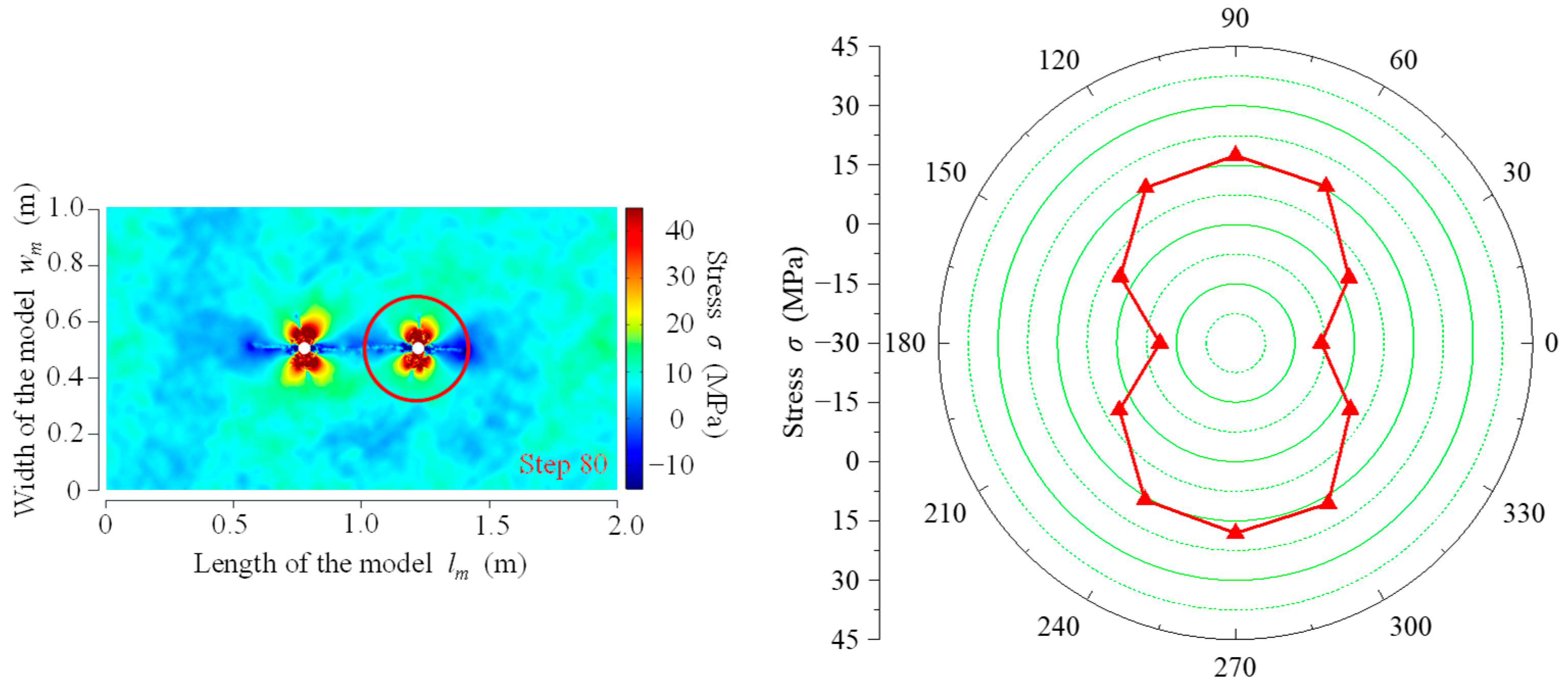

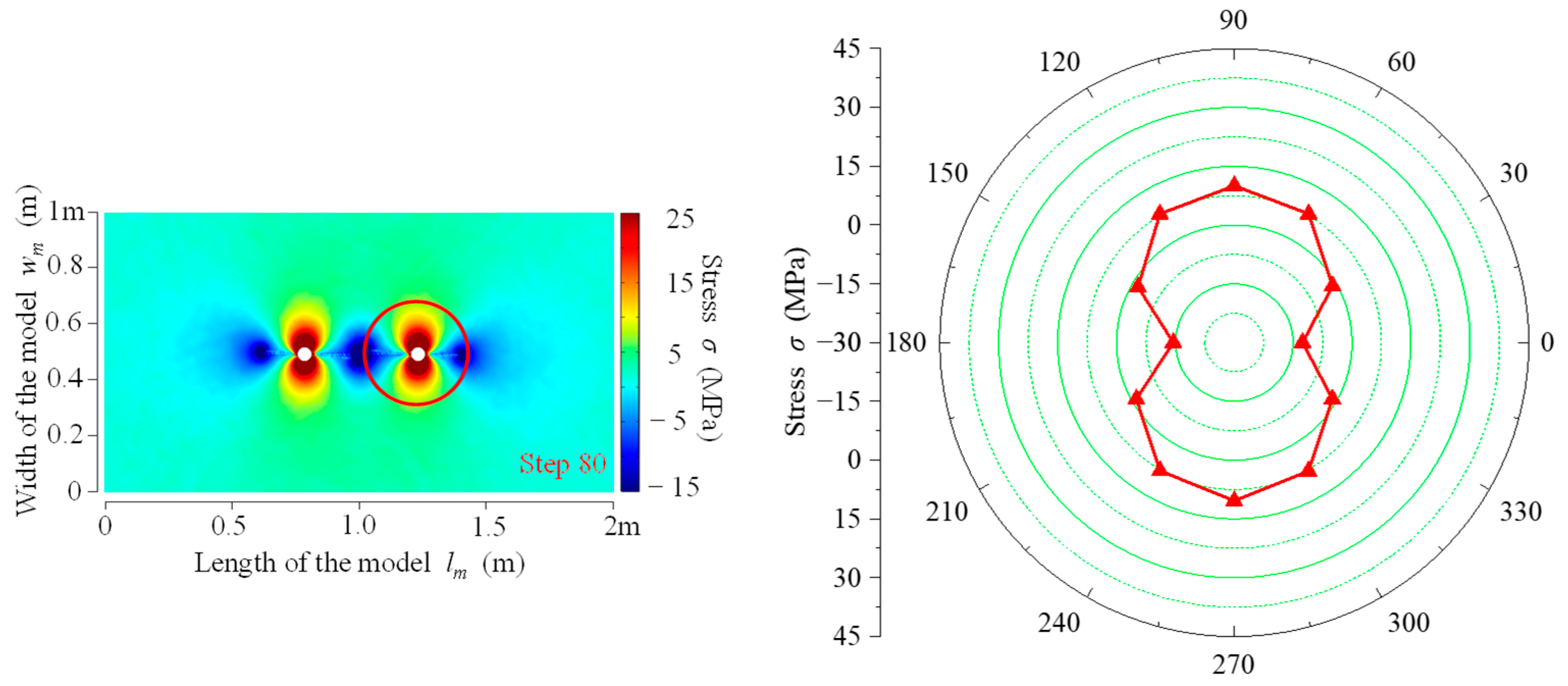

3.1.1. Stress Field Evolution Law for Double-Hole Fracture

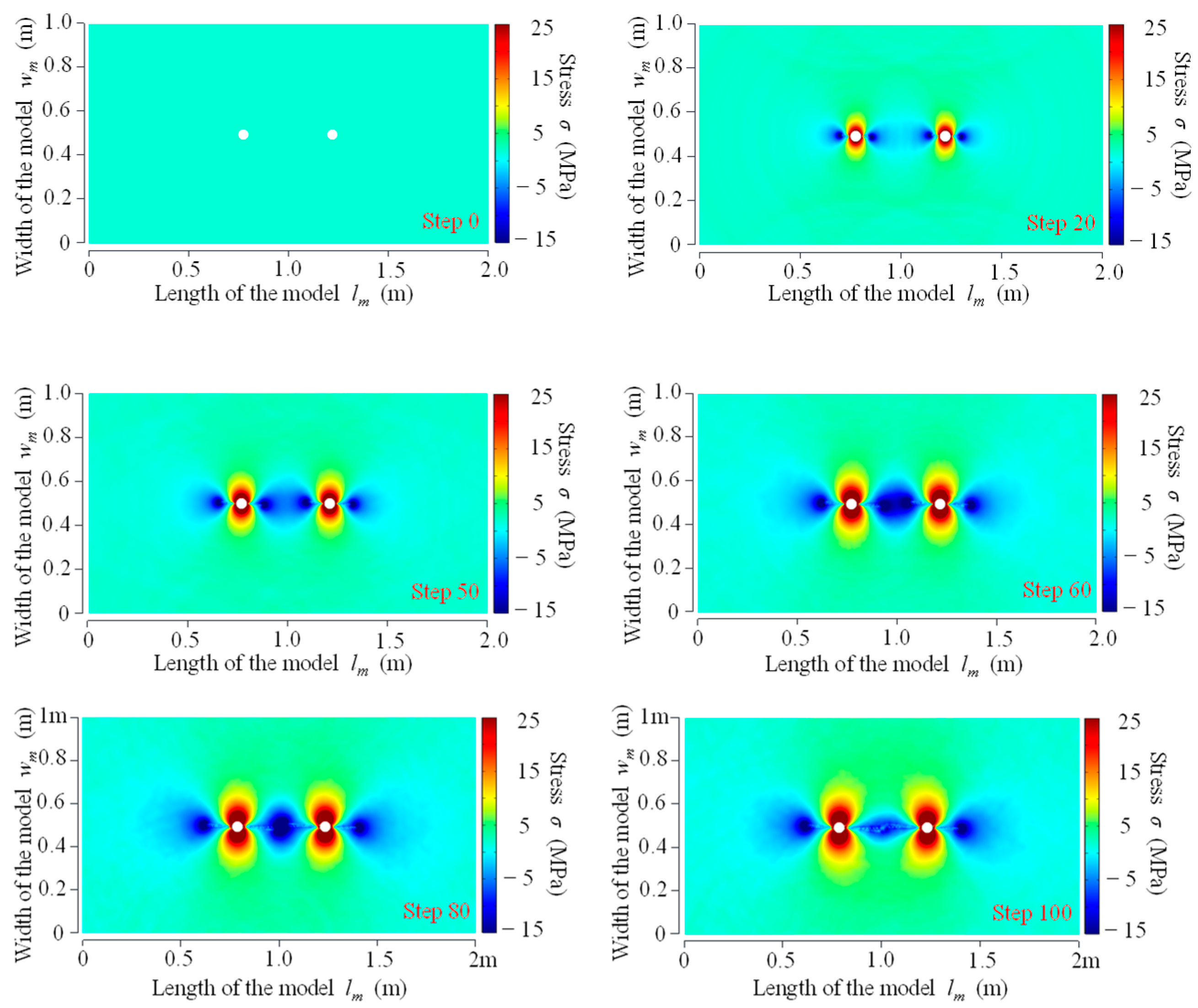

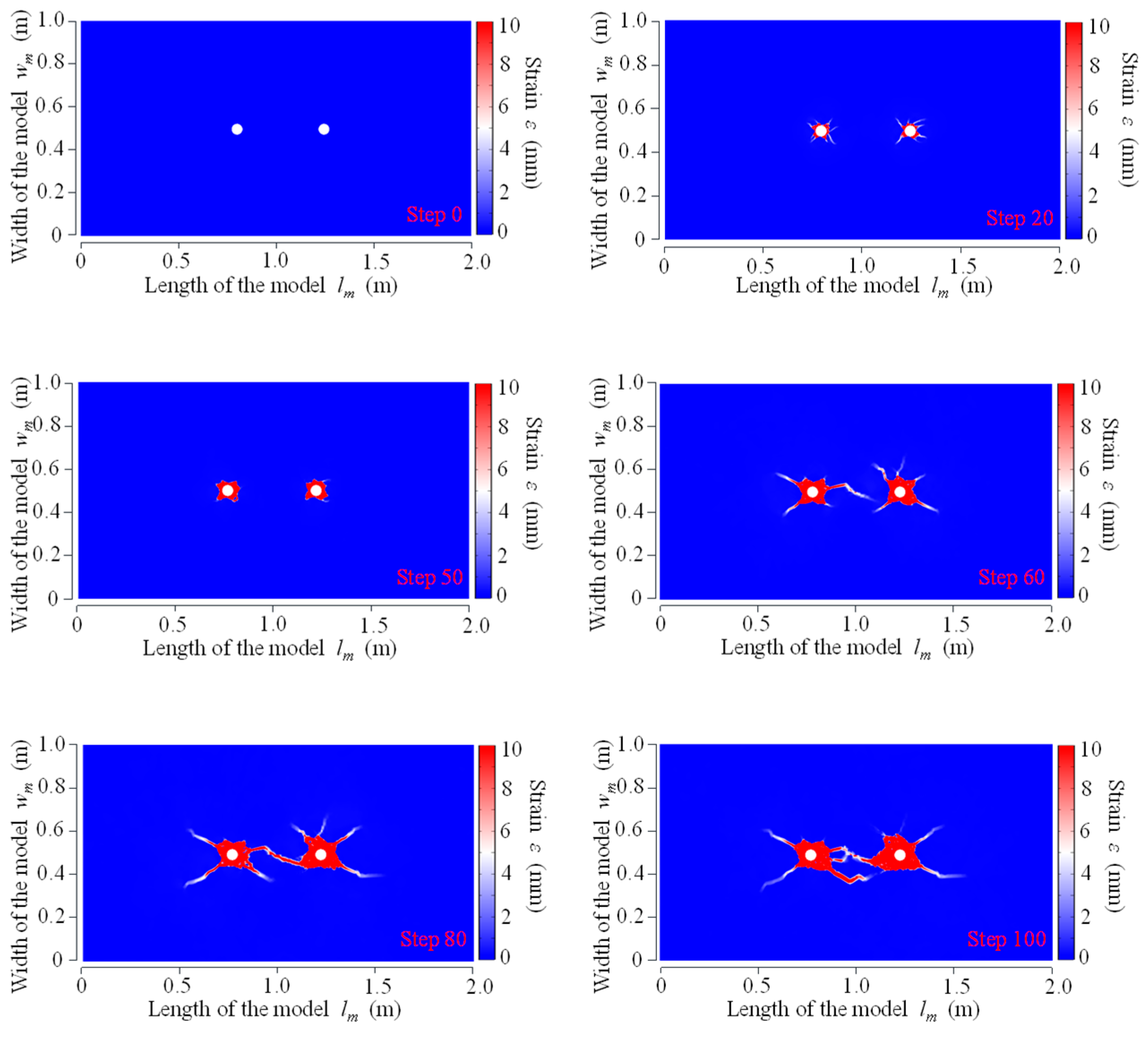

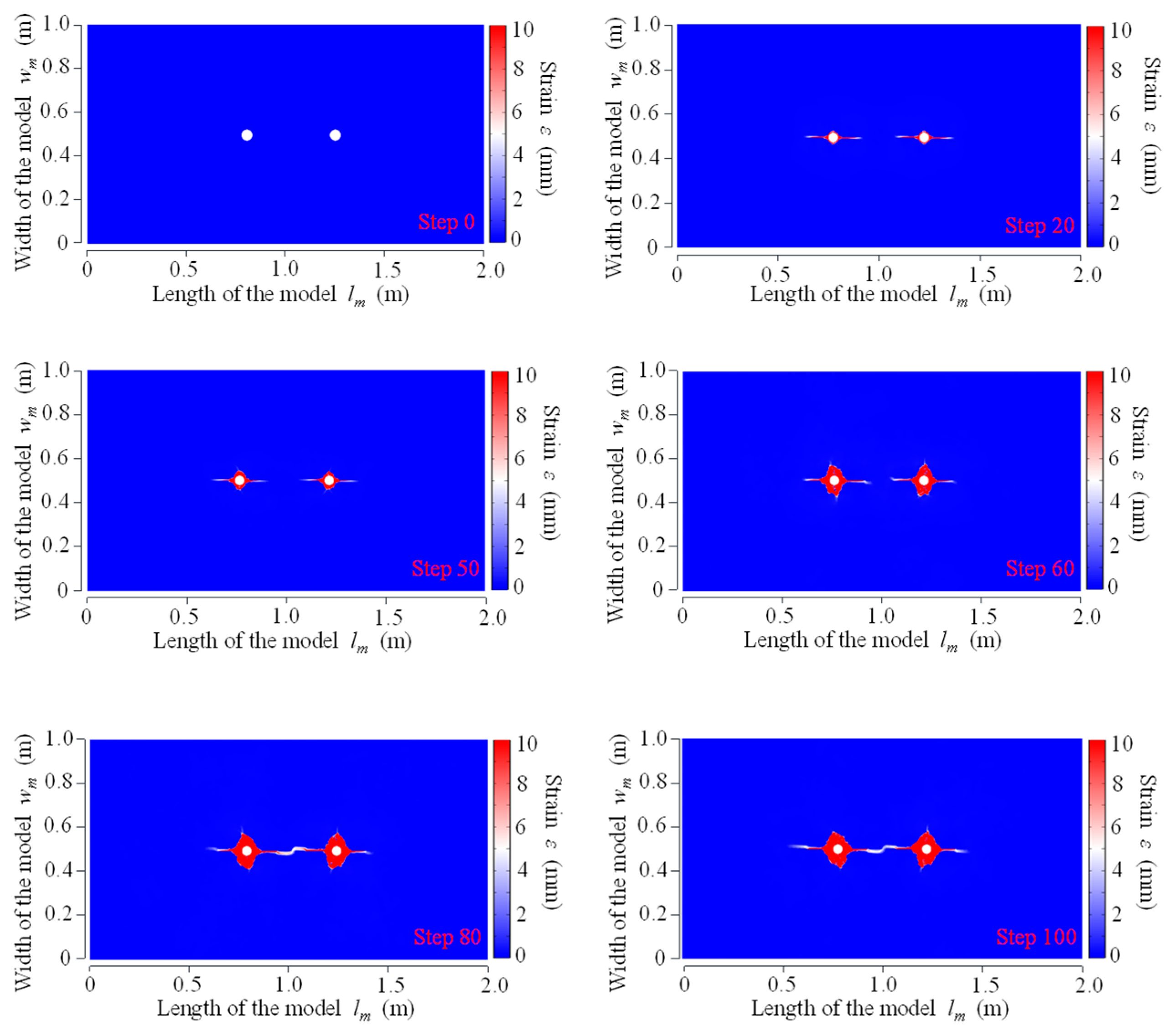

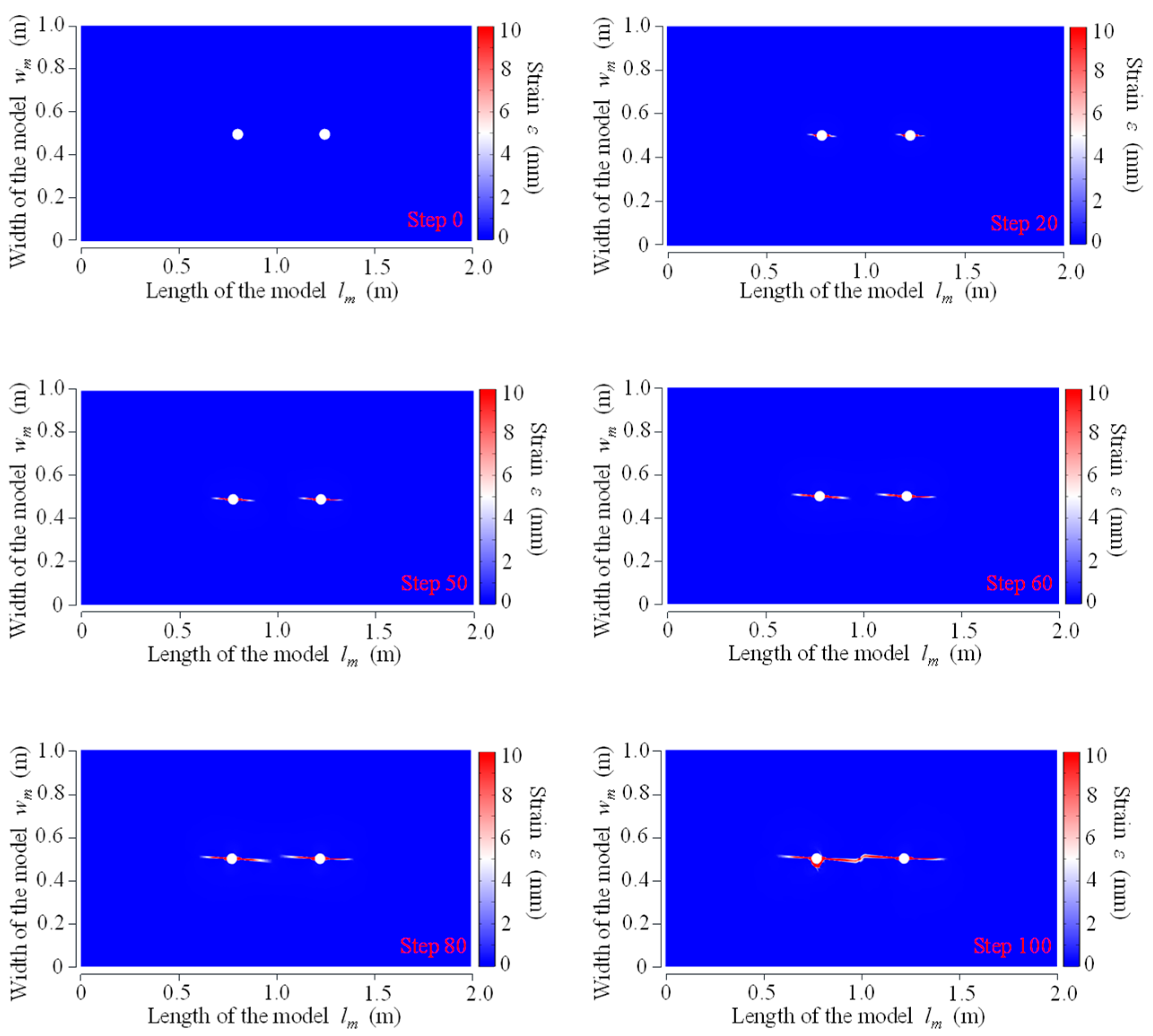

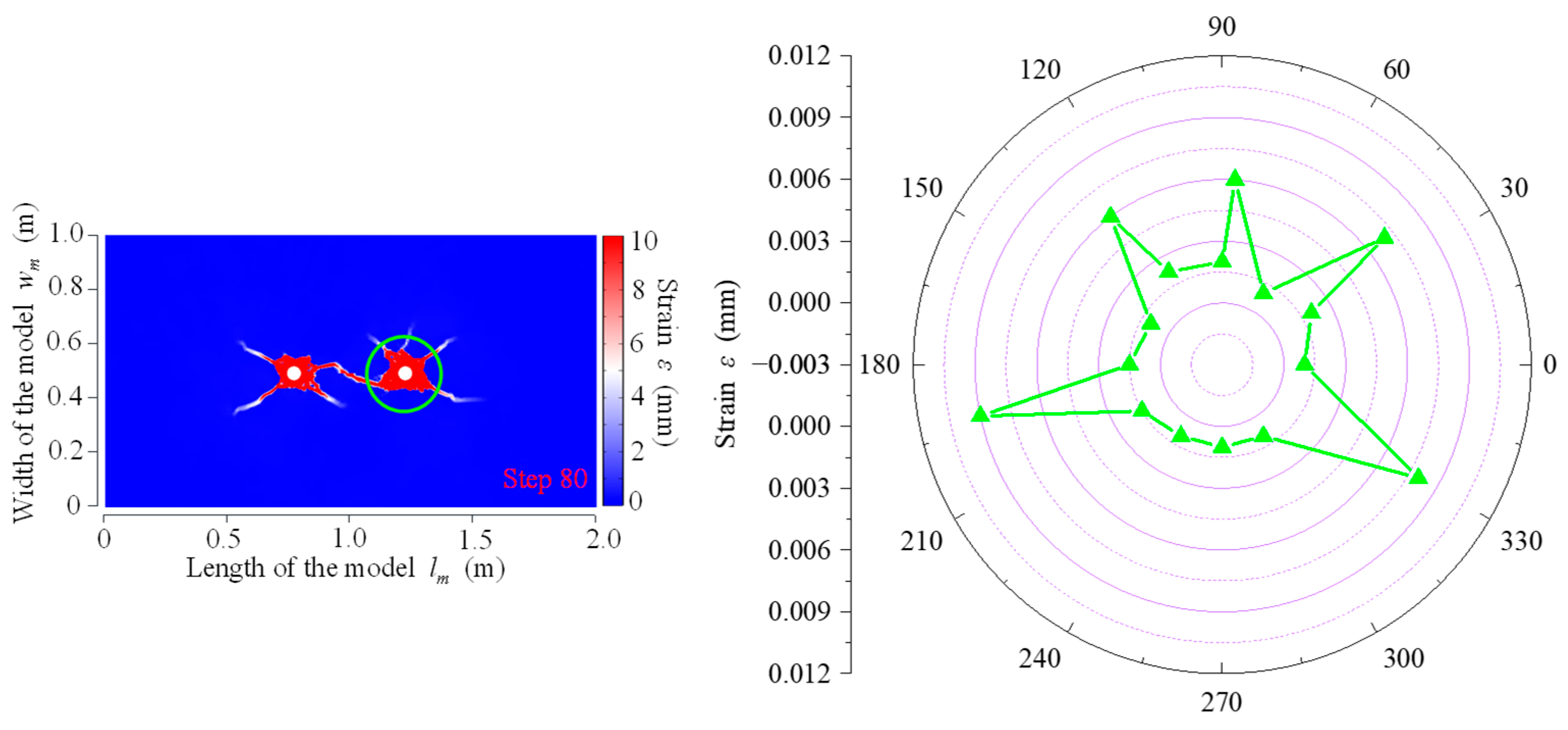

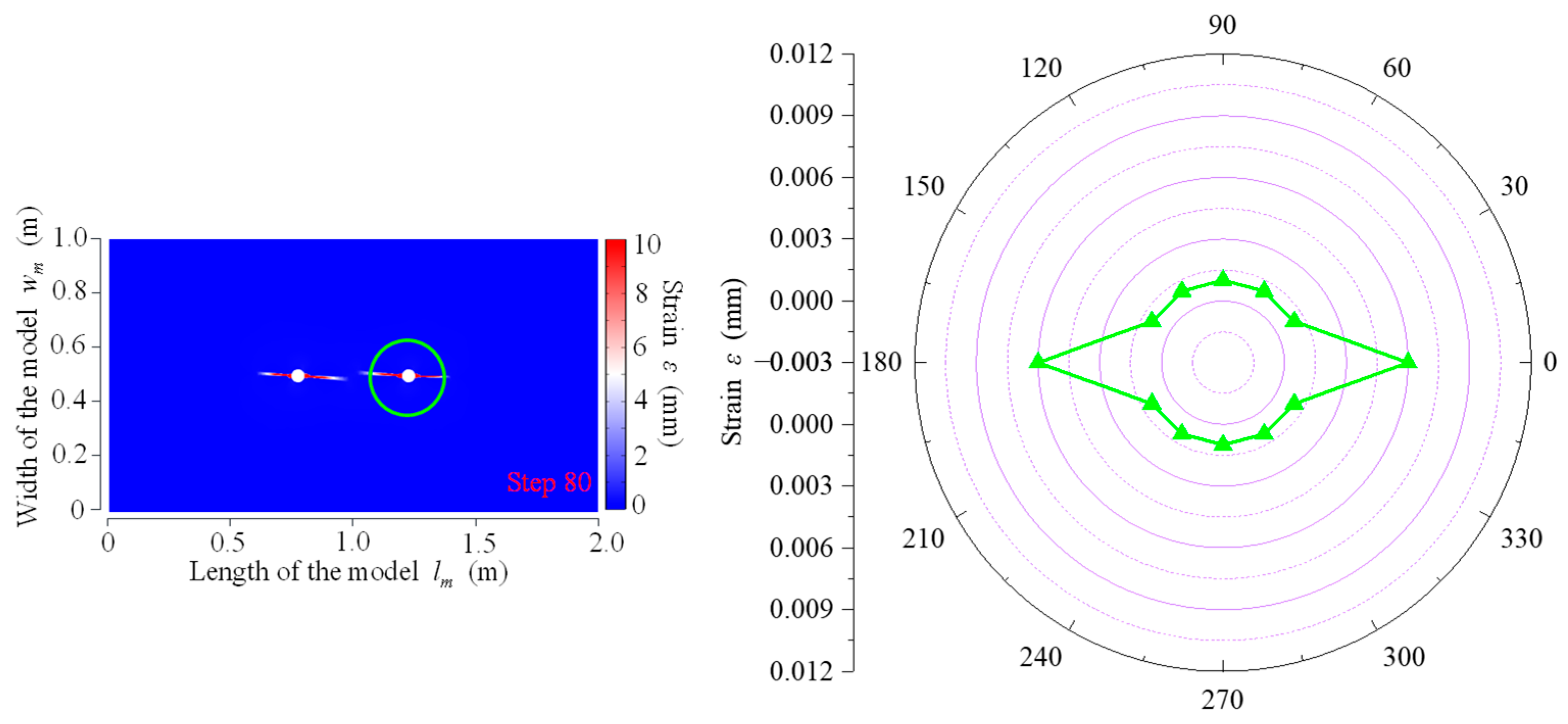

3.1.2. Strain Field Evolution Law for Double-Hole Fracture

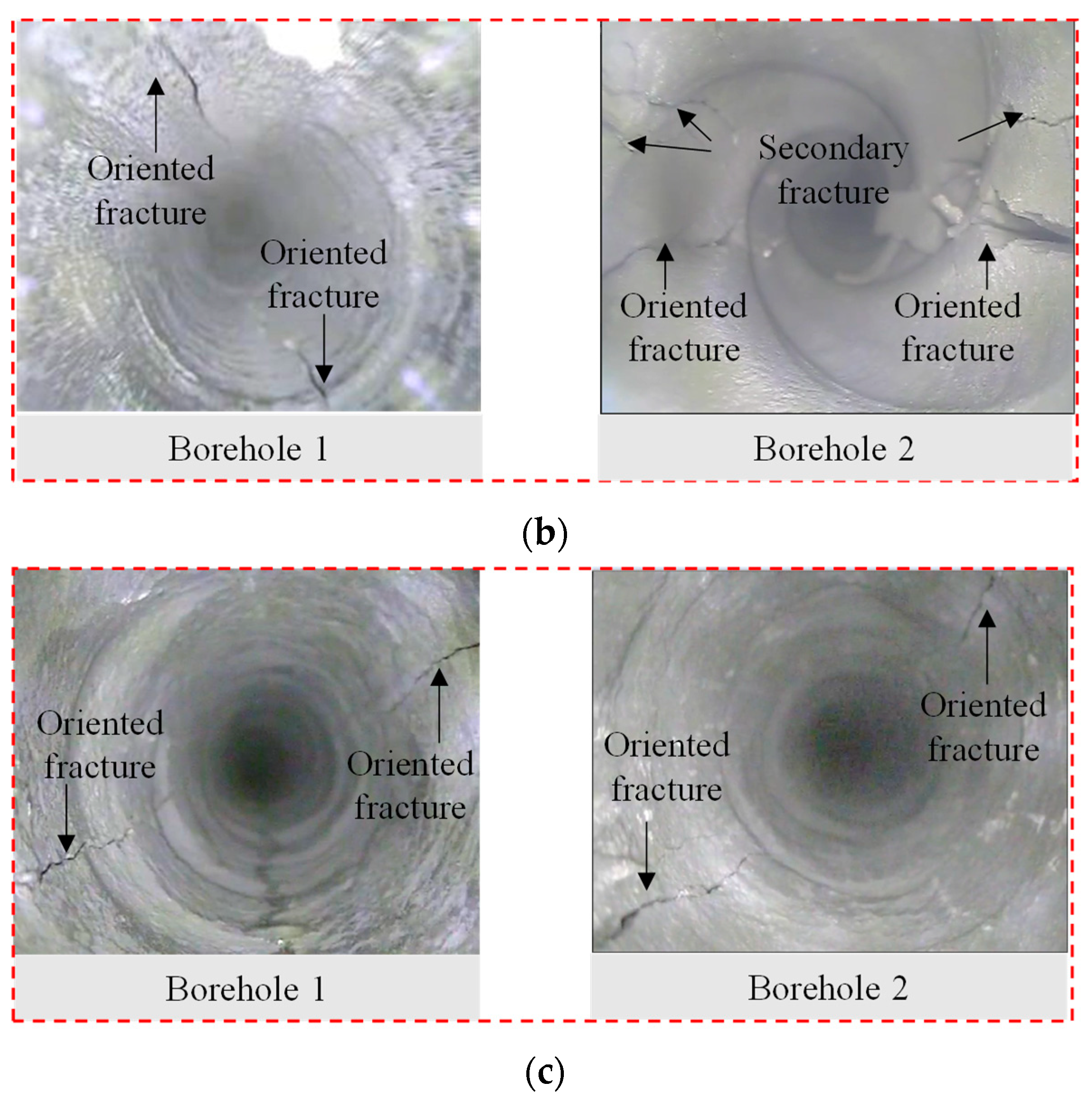

3.2. In Situ Test Results of IESF

4. Discussion

4.1. Comparison of IESF with Other Rock-Breaking Methods

4.2. Interrelationship of Double-Borehole Superimposed Effects Between Different Slotted Methods

5. Conclusions

- (1)

- The instantaneous expansion with a single fracture (IESF) generates approximately 300 mL of high-temperature and high-pressure gases from 1 g of solid material within 0.05–0.5 s. Through the directional action of slit-oriented tubes, these high-pressure gases transform traditional three-dimensional volumetric fracturing into two-dimensional planar fractures. The gas pressure distribution law of IESF in directional cracks was analyzed and the directional fracture expansion criterion was established.

- (2)

- The stress fields of CB, SCB, and IESF were analyzed by numerical simulations. The stress distribution in CB was relatively random, and a wide range of compressive stress field was formed around the borehole. In SCB, the concentration of tensile stress in the energy-gathering direction, tensile stress was −10.89 MPa in the inter-borehole region and −8.33 MPa on the outer-borehole region. The tensile stress in the inter-borehole region was 2.56 MPa greater than the tensile stress in the outer-borehole region. During fracturing by IESF, the concentration of tensile stress in the energy-gathering direction, the tensile stress in the inter-borehole region was −14.47 MPa, greater than the tensile stress of −12.62 MPa in the outer-borehole region. Similar to SCB, there was a stress-superimposed effect between the double holes of IESF, while IESF achieved a better directional effect with less energy.

- (3)

- The strain fields of CB, SCB and IESF were analyzed by numerical simulations. In CB, the strain was concentrated at the main fractures. SCB exhibited higher strain along the energy-gathering direction, with strain values of 7 mm and 8 mm on each side, while the strain perpendicular to the shaped charge direction measured 1.5 mm. IESF exhibited a strain of 6 mm along the slotted orientation, while strains in non-slotted directions measured less than 1 mm. The strains generated by IESF mainly increased rapidly in the energy-focused directions, and there were almost no high-strain zones around the borehole. It indicated that IESF had a greater control ability over the energy distribution than CB as well as SCB.

- (4)

- In situ tests showed that there was a superimposed effect under double-hole loading, and the pattern was consistent with the numerical simulation results. The fracture distribution in CB was relatively random. In SCB, the main fracture was generated along the slotted orientation, while there were small secondary fractures occasionally generated in the other direction, and the damage in the inter-borehole region was greater than that in the outer-borehole region. The average crack rate of SCB was found to be 85.0%, while that of IESF was 95.5%. IESF achieved superior directional fracture control compared to both CB and SCB, generating only two directional fractures along the slotted orientation, and produced longer axial cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IESF | Instantaneous Expansion with a Single Fracture |

| CB | Conventional Blasting |

| SCB | Shaped Charge Blasting |

References

- Zhang, X.F.; Mu, Z.L.; Jiang, C.L.; Wang, H.; Chen, Y.; Zhuang, J.X.; Man, C.; Cao, J.L.; Liu, C.; Yang, J.; et al. Numerical and experimental study on pressure relief mechanism of roof blasting along gob-side roadway. Appl. Sci. 2025, 15, 3168. [Google Scholar] [CrossRef]

- Lu, Y.; He, B.G.; Li, H.P.; Li, Q.; Ren, C. Theoretical and numerical investigation of damage zones in deep tunnels within a layered rock mass under full-face blasting. Int. J. Rock Mech. Min. Sci. 2025, 188, 106053. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.C.; Guo, S.; Yang, R.Z.; Chen, K.; Wang, C. Study on the mechanism and preliminary application of efficient directional rock breaking using a coal-based solid waste non-explosive expansive agent. Chin. J. Rock Mech. Eng. 2025, 44, 898–911. [Google Scholar] [CrossRef]

- He, M.C.; Wang, Q.; Wu, Q.Y. Innovation and future of mining rock mechanics. J. Rock Mech. Geotech. Eng. 2021, 13, 1–21. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.C.; Wang, J.; Guo, S.; Wang, C.; Hong, C.J.; Chen, K.; Yang, R.Z.; Zhang, X.P.; Yang, J.W. Non-explosive directional fracturing blasting using coal-based solid waste expanding agent. J. Rock Mech. Geotech. Eng. 2025, 17, 3691–3710. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Hu, J.Z.; Xue, H.J.; Mao, W.B.; Gao, Y.B.; Yang, J.; He, M.C. Innovative approach based on roof cutting by energy-gathering blasting for protecting roadways in coal mines. Tunn. Undergr. Space Technol. 2020, 99, 103387. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.C.; Wang, J.; Guo, S.; Zhu, C.; Tao, Z.G.; Wang, C. Investigation of a non-explosive directional roof cutting technology for self-formed roadway. Int. J. Min. Sci. Technol. 2022, 32, 997–1008. [Google Scholar] [CrossRef]

- He, C.L.; Yang, J. Experimental and numerical investigations of dynamic failure process in rock under blast loading. Tunn. Undergr. Space Technol. 2019, 83, 552–564. [Google Scholar] [CrossRef]

- Li, Q.; Li, H.B.; Fu, S.Y.; Ju, M.H.; Li, X.F. Study on the most optimistic hole spacing for double-hole blasting under high in-situ stresses. Chin. J. Rock Mech. Eng. 2025, 44, 678–690. [Google Scholar] [CrossRef]

- Yang, J.H.; Sun, W.B.; Yao, C.; Zhang, X.B. Mechanism of rock fragmentation by multi-hole blasting in highly-stressed rock masses. Explos. Shock Waves 2020, 40, 075202. [Google Scholar] [CrossRef]

- Zhao, J.J.; Zhang, Y.; Ranjith, P.G. Numerical simulation of blasting-induced fracture expansion in coal masses. Int. J. Rock Mech. Min. Sci. 2017, 100, 28–39. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, S.G.; Wang, W.; Su, X.B.; Li, Z.H.; Li, J.X.; Wen, L.; Chang, J.F.; Sun, X.Y. Numerical study on the fracturing mechanism of shock wave interactions between two adjacent blast holes in deep rock blasting. Earthq. Eng. Eng. Vib. 2019, 18, 735–746. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, J.; Wang, J.; Guan, S.; Zhang, X.; Yang, Y. Evolution Characteristics of Strain and Displacement Fields in Double-Hole Short-Delay Blasting Based on DIC. Processes 2024, 12, 1291. [Google Scholar] [CrossRef]

- Wei, C.H.; Zhu, W.C.; Bai, Y.; Li, S. Numerical simulation on two-hole blasting of rock under different joint angles and in-situ stress conditions. Chin. J. Theor. Appl. Mech. 2016, 48, 926–935. [Google Scholar] [CrossRef]

- Cao, R.Y.; Li, Y.P.; Feng, C.; Zhang, Y.M. Study on the guiding mechanism of multiple and empty holes under explosion load. Min. Metal. Explor. 2024, 41, 277–286. [Google Scholar] [CrossRef]

- Guo, D.Y.; Zhao, J.C.; Zhang, C.; Zhu, T.G. Mechanism of control hole on coal crack initiation and propagation under deep-hole cumulative blasting in coal seam. Chin. J. Rock Mech. Eng. 2018, 37, 919–930. [Google Scholar] [CrossRef]

- Song, Y.Q.; Li, X.S.; Guo, D.Y. Numerical simulation of multi-hole and same delay time of cumulative blasting in coal seam and its application. J. Chin. Coal Soc. 2018, 43, 469–474. [Google Scholar] [CrossRef]

- Li, X.S. Splitting Mechanism and Influencing Factors of the Cumulative Blasting. Doctor’s Thesis, China University of Mining & Technology-Beijing, Beijing, China, 2021. [Google Scholar]

- Wu, B.; Xu, S.X.; Meng, G.W.; Cui, Y.Z.; Cai, J.H.; Zhang, Y. Study on the dynamic evolution of through-crack in the double hole of elliptical bipolar linear-shaped charge blasting. Shoc. Vib. 2021, 2021, 3792765. [Google Scholar] [CrossRef]

- Yue, Z.W.; Tian, S.Y.; Chen, Z.Y. Influence of the interval between holes on crack propagation in slit charge blasting. Chin. J. Rock Mech. Eng. 2018, 37, 2460–2467. [Google Scholar] [CrossRef]

- He, M.C.; Gao, Y.B.; Yang, J.; Guo, Z.B.; Wang, E.Y.; Wang, Y.J. An energy-gathered roof cutting technique in no-pillar mining and its impact on stress variation in surrounding rocks. Chin. J. Rock Mech. Eng. 2017, 36, 1314–1325. [Google Scholar] [CrossRef]

- Yang, L.Y.; Wang, Q.C.; Xu, L.N.; Yang, R.S.; Cao, Y.J. Fracture path of cracks emigrating from two circular holes under blasting load. Theor. Appl. Fract. Mech. 2020, 108, 102559. [Google Scholar] [CrossRef]

- Shnorhokian, S.; Mitri, H. Evaluating the application of rock breakage without explosives in underground construction—A critical review of chemical demolition agents. Minerals 2022, 12, 220. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.C.; Guo, S.; Qi, J.C.; Yang, J.; Wang, C.; Xia, M.; Li, L.N. Investigation on the key techniques and application of the new-generation automatically formed roadway without coal pillars by roof cutting. Int. J. Rock Mech. Min. Sci. 2022, 152, 105058. [Google Scholar] [CrossRef]

- Li, J.T. Propagation Rules of Hydraulic Fracturing Under Multi-Boreholes Synchronous Linkage Control for Coal Seam and Its Application. Doctor’s Thesis, Northeastern University, Shenyang, China, 2021. [Google Scholar]

- Huang, L.K.; Tan, J.; Fu, H.F.; Liu, J.J.; Chen, X.Y.; Liao, X.C.; Wang, X.H.; Wang, C. The non-plane initiation and propagation mechanism of multiple hydraulic fractures in tight reservoirs considering stress shadow effects. Eng. Fract. Mech. 2023, 292, 109570. [Google Scholar] [CrossRef]

- Yang, W.D.; Lv, X.X.; Wang, L.G.; Peng, D.; Chen, X.Z. A DEM–CFD coupling method for modelling two-hole synchronous hydraulic fracturing. Geomech. Geophys. Geo-Energ. Geo-Resour. 2023, 9, 6. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Liang, W.G.; Lian, H.J.; He, W. Experimental study of hydraulic fracture propagation in multi-hole synchronous fracturing in horizontal wells in sandstone. Int. J. Rock Mech. Min. Sci. 2025, 186, 106013. [Google Scholar] [CrossRef]

- Wang, L.C.; Duan, K.; Zhang, Q.Y.; Zhang, X.F.; Liu, C.C. Visualization of the dynamic propagation of two simultaneously-stimulated hydraulic fractures: Competition and interaction. Int. J. Rock Mech. Min. Sci. 2025, 186, 106036. [Google Scholar] [CrossRef]

- Zhao, X.L.; Huang, B.X.; Wang, Z. Experimental investigation on the basic law of directional hydraulic fracturing controlled by dense linear multi-hole drilling. Rock Mech. Rock Eng. 2018, 51, 1739–1754. [Google Scholar] [CrossRef]

- Li, L.W.; Wu, W.B. Directional hydraulic fracturing technology for prefabricated longitudinal guide seams in a coal mine tight sandstone roof. Energy Explor. Exploit. 2022, 40, 400–420. [Google Scholar] [CrossRef]

- Hu, S.C.; Han, J.M.; Cheng, Y.F.; Qi, J.L.; Huang, J.H.; Gao, Z.H.; Guo, S.H.; Yang, L. Analysis of mechanical mechanism and influencing factors of directional fracturing of multi-hole sleeve. J. Chin. Coal Soc. 2024, 49, 3366–3380. [Google Scholar] [CrossRef]

- Jaber, T.S.; Amir, G.; Seyedahmad, H.; Abdolnabi, H. Debonding and coalescence in the interaction between hydraulic and natural fracture: Accounting for the effect of leak-off. J. Nat. Gas Sci. Eng. 2016, 36, 454–462. [Google Scholar] [CrossRef]

- Sampath, K.H.S.M.; Perera, M.S.A.; Elsworth, D.; Ranjith, P.G.; Matthai, S.K.; Rathnaweera, T.; Zhang, G. Effect of coal maturity on CO2-based hydraulic fracturing process in coal seam gas reservoirs. Fuel 2019, 236, 179–189. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, B.B.; He, Q.Y. Visualized hydraulic fracture re-orientation in directional hydraulic fracturing by laboratory experiments in gelatin samples. Appl. Sci. 2024, 14, 2047. [Google Scholar] [CrossRef]

- Huang, B.X.; Liu, J.W.; Zhang, Q. The reasonable breaking location of overhanging hard roof for directional hydraulic fracturing to control strong strata behaviors of gob-side entry. Int. J. Rock Mech. Min. Sci. 2018, 103, 1–11. [Google Scholar] [CrossRef]

- Valderrama, J.O. The state of the cubic equations of state. Ind. Eng. Chem. Res. 2003, 42, 1603–1618. [Google Scholar] [CrossRef]

- Nilson, R.H.; Proffer, W.J.; Duff, R.E. Modelling of gas-driven fractures induced by propellant combustion within a borehole. Int. J. Rock Mech. Min. Sci. Geomech. Abs. 1985, 22, 3–19. [Google Scholar] [CrossRef]

- Man, K.; Liu, X.L.; Song, Z.F.; Song, X.R.; Cheng, H.L.; Guo, Z.F.; Liu, Z.X.; Yu, Y.P. Research on fracture surface morphology of rock with static and dynamic fracture toughness. J Cent. South Univ. (Sci. Technol.) 2021, 52, 2876–2886. [Google Scholar] [CrossRef]

- Xie, Q.; Li, S.X.; Liu, X.L.; Gong, F.Q.; Li, X.B. Effect of loading rate on fracture behaviors of shale under mode I loading. J. Cent. South Univ. 2020, 27, 3118−3132. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Zhu, W.C.; Yan, B.X.; Liu, X.G.; Yang, Z.; Guan, K. Rock creep deformation triggered by dynamic disturbance: Numerical simulation. Int. J. Geomech. 2022, 22, 04022101. [Google Scholar] [CrossRef]

- Chen, S.K.; Wei, C.H.; Yang, T.H.; Zhu, W.C.; Liu, H.L.; Ranjith, P.G. Three-dimensional numerical investigation of coupled flow-stress-damage failure process in heterogeneous poroelastic rocks. Energy 2018, 11, 1923. [Google Scholar] [CrossRef]

- Zhu, W.C.; Wei, C.H.; Li, S.; Wei, J.; Zhang, M.S. Numerical modeling on destress blasting in coal seam for enhancing gas drainage. Int. J. Rock Mech. Min. Sci. 2013, 59, 179–190. [Google Scholar] [CrossRef]

- Gao, Y.B. Study on Key Issues of 110 Mining Method Used in a Thick Coal Seam—A Case Study in Ningtiaota Coal Mine. Doctor’s Thesis, China University of Mining & Technology-Beijing, Beijing, China, 2018. [Google Scholar]

- Zhang, Q.; Tao, Z.G.; Yang, C.; Guo, S.; He, M.C.; Zhang, C.Y.; Niu, H.Y.; Wang, C.; Wang, S. Experimental and numerical investigation into the non-explosive excavation of tunnels. J. Rock Mech. Geotech. Eng. 2022, 14, 1885–1900. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.C.; Wang, J.; Guo, S.; Guo, Z.B.; Liu, X.Y.; Hu, J.Z.; Ma, Z.M.; Fan, L.X.; Guo, P.F. Instantaneous expansion with a single fracture: A new directional rock-breaking technology for roof cutting. Int. J. Rock Mech. Min. Sci. 2020, 132, 104399. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.G.; Chang, X.; Xue, Y.L.; Zhang, J.Y. Study on damage characteristics and fracture mechanisms of coal under high stress environment during blasting. Eng. Fract. Mech. 2025, 314, 110772. [Google Scholar] [CrossRef]

- Yi, C.P.; Johansson, D.; Nyberg, U.; Beyglou, A. Stress wave interaction between two adjacent blast holes. Rock Mech. Rock Eng. 2016, 49, 1803–1812. [Google Scholar] [CrossRef]

- Gao, Y.B.; Yang, J.; Zhang, X.Y.; Xue, H.J.; He, M.C. Study on surrounding rock control of roadways in deep coal mines based on roof cutting and pressure release technology by directional tensile blasting. Chin. J. Rock Mech. Eng. 2019, 38, 2045–2056. [Google Scholar] [CrossRef]

- Wang, K.F.; Zhang, C.S.; Hao, B.Y.; Zhang, S.L. Study on initiation and propagation mechanism of internal cracks caused by dynamic and static action of shaped charge blasting under in-situ stress. Coal Sci. Technol. 2023, 51, 50–64. [Google Scholar] [CrossRef]

- Cao, A.Y.; Hao, Q.; Cui, Y.J.; Huang, S.X.; Peng, Y.J.; Gao, Z.; Gao, H.B.; Li, D.; Gao, F. Crack extension mechanism of deep-hole blasting in the roof of high-tectonic-stress region and its application. J. Min. Saf. Eng. 2025, 42, 97–107. [Google Scholar] [CrossRef]

- Ji, L.; Yao, Y.K.; Zhou, C.B.; Zhang, Z.; Cao, H.Q.; Wu, T.Y. Research on cumulative damage effects and safety criterion of surrounding rock in bench blasting of a large cross-section tunnel. Alex. Eng. J. 2024, 108, 626–639. [Google Scholar] [CrossRef]

- Guo, Y.C.; Yang, R.S.; Peng, S.P.; Xiao, C.L. Experimental study on decoupled charge blasting-induced crack propagation with parabolic shaped charge. Eng. Frac. Mech. 2024, 304, 110178. [Google Scholar] [CrossRef]

- Xu, S.X.; Wu, B.; Zhang, H.L.; Qi, S.X.; Bian, H.B.; Wang, J.J. Directional crack propagation and optimization strategies for multi-hole shaped charge blasting in tunnel construction. Structures 2025, 72, 108268. [Google Scholar] [CrossRef]

- Huang, W.; Jing, G.; Ma, L.Q.; Zhao, L.L.; Wang, S. Research on blasting technology for thick and hard roof fracturing in isolated island coal mine working face. Sci. Rep. 2025, 15, 14534. [Google Scholar] [CrossRef] [PubMed]

- Qiao, G.D.; Liu, Z.G.; Gao, K.; Zhang, S.C.; Zhang, J.Y.; Fu, S.G. Experimental study on optimum blasting method of crossing hard rock normal fault in fully mechanized mining face. J. Min. Saf. Eng. 2023, 40, 507–516. [Google Scholar] [CrossRef]

- Pu, C.J.; Yang, X.; Xiao, D.J.; Cheng, J.L.; Zhou, L.; Chen, X. Numerical simulation of double-hole crack propagation under explosion load. J. Vib. Shock 2022, 41, 300–311. [Google Scholar] [CrossRef]

- Yin, Y.; Sun, Q.; Zou, B.P.; Ma, Q.Y. Numerical study on an innovative shaped charge approach of rock blasting and the timing sequence effect in microsecond magnitude. Rock Mech. Rock Eng. 2021, 54, 4523–4542. [Google Scholar] [CrossRef]

- Guo, P.F. Study and Application on Gob-Side Entry Retaining by Roof Cut and Pressure Relief in Hecaogou Coal Mine in Yanan. Doctor’s Thesis, China University of Mining & Technology-Beijing, Beijing, China, 2017. [Google Scholar]

| Borehole Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Crack length/m | 11.3 | 11.1 | 10.7 | 11.5 | 10.5 | 10.9 | 11.1 | 11.2 | 10.8 | 11.4 |

| Length of slit-oriented tubes/m | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 |

| Crack rate/% | 86.9 | 85.4 | 82.3 | 88.5 | 80.8 | 83.8 | 85.4 | 86.2 | 83.1 | 87.7 |

| Borehole Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Crack length/m | 12.4 | 12.6 | 12.3 | 12.5 | 12.2 | 12.5 | 12.7 | 12.9 | 12.3 | 11.8 |

| Length of slit-oriented tubes/m | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 |

| Crack rate | 95.4 | 96.9 | 94.6 | 96.2 | 93.8 | 96.2 | 97.7 | 99.2 | 94.6 | 90.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; He, M.; Chen, K.; Guo, S.; Yang, C.; Yang, R.; Wu, Y.; Wang, J.; Wang, C. Double-Borehole Superimposed Effect of a New Non-Explosive Directional Rock-Breaking Method. Appl. Sci. 2025, 15, 6805. https://doi.org/10.3390/app15126805

Zhang Q, He M, Chen K, Guo S, Yang C, Yang R, Wu Y, Wang J, Wang C. Double-Borehole Superimposed Effect of a New Non-Explosive Directional Rock-Breaking Method. Applied Sciences. 2025; 15(12):6805. https://doi.org/10.3390/app15126805

Chicago/Turabian StyleZhang, Quan, Manchao He, Kai Chen, Shan Guo, Chun Yang, Rongzhou Yang, Yun Wu, Jiong Wang, and Chao Wang. 2025. "Double-Borehole Superimposed Effect of a New Non-Explosive Directional Rock-Breaking Method" Applied Sciences 15, no. 12: 6805. https://doi.org/10.3390/app15126805

APA StyleZhang, Q., He, M., Chen, K., Guo, S., Yang, C., Yang, R., Wu, Y., Wang, J., & Wang, C. (2025). Double-Borehole Superimposed Effect of a New Non-Explosive Directional Rock-Breaking Method. Applied Sciences, 15(12), 6805. https://doi.org/10.3390/app15126805