An Optimal Sizing Methodology for a Wind/PV Hybrid Energy Production System for Agricultural Irrigation in Skikda, Algeria

Abstract

1. Introduction

- Hydraulic Energy Storage Strategy: A novel energy storage concept, replacing conventional electrochemical batteries with a high-capacity water reservoir, is proposed. In this approach, excess solar or wind energy is utilized to pump water into an elevated tank, thereby converting electrical energy into hydraulic potential. This storage method offers a cost-effective and environmentally friendly solution, making it particularly well suited to agricultural applications where the stored water simultaneously serves as a vital resource for irrigation.

- Gravity-Driven Irrigation: During periods of low solar irradiance or wind availability, the system uses the stored hydraulic energy to deliver water purely through gravitational flow, entirely avoiding the need for electrical input. This contributes to improved energy autonomy and operational reliability, especially in off-grid rural settings.

- The integrated system modeling framework explicitly incorporates the reservoir’s storage capacity and hydraulic dynamics, enabling simulation and quantification of the impacts of the storage strategy. The results demonstrate that this framework effectively reduces dependence on electrical storage, improves irrigation reliability, and significantly lowers total system costs over the project’s lifetime.

- Multi-Objective Optimization Framework: A multi-objective optimization model was implemented to design and size the hybrid renewable energy system. This model concurrently minimizes system component costs and maximizes renewable electricity production while adhering to defined technical and operational constraints. The approach enables the generation of design configurations that are both economically efficient and technically robust.

2. Materials and Methods

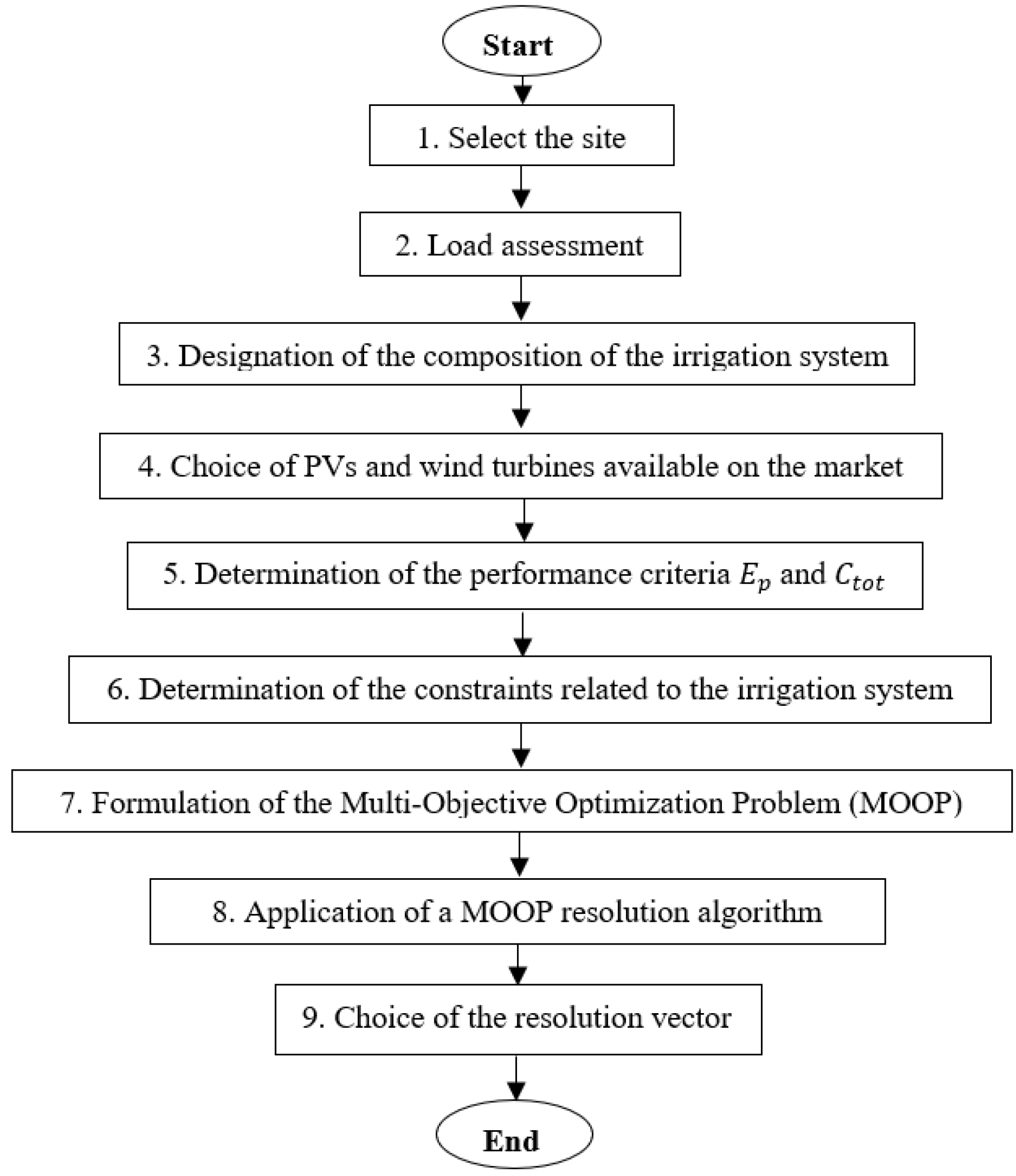

2.1. Proposed Sizing Methodology for a Hybrid Energy System

2.2. Case Study of the Selected Area: The Skikda Region

2.2.1. Load Modeling (Energy Required)

2.2.2. System Components

- : The number of devices.

- : The rated power of each device.

- t: Number of hours of use.

- : Energy consumed by these devices (energy requested by the system).

- The total energy consumed was 24 kWh.

- The pump is assigned a constant overall efficiency of 70%. This single efficiency value (power out versus power in) is used for every operating point rather than modeling the pump’s performance curve or efficiency variation with flow or age.

- Open-water evaporation from the reservoir is accounted for by subtracting a fixed depth (in mm/day) for each time-step. This rate is taken from local climatic averages (for example, a hot, arid reservoir may typically lose an order of 3–5 mm of water per day).

- Equipment aging (such as PV module degradation over years of service) is not applied to the simulated time-series output. Instead of gradually reducing solar conversion or pump efficiency over time, the model treats all components as ‘new’ throughout. (In practice, one would budget for end-of-life replacement; for example, PV modules lose on the order of 0.5% of output per year, but this degradation is implicitly captured only in the financial life-cycle cost analysis, not in the operational model itself.)

- All meteorological forcing (solar irradiance, temperature, wind, etc.) is drawn from a multi-year historical dataset (e.g., a long-term weather station record or reanalysis data). By design, the model, therefore, assumes that future weather will be statistically similar to the past and does not explicitly include any rare or unprecedented weather extremes beyond those contained in the historical record.

2.2.3. Problem Formulation Based on a Multi-Objective Optimization Approach

- Find a vector that:

- Minimize

- subject to (m inequality constraints).

- and (l equality constraints).

- : Vector of the decision variables.

- : Vector of the objectives function.

- : Number of PV panels.

- : Number of wind turbines.

- The aim to maximize the electrical energy produced by the hybrid system, which is represented by and is defined as follows:

- The purpose to minimize the total cost represented by , which is defined as follows:

- Number of PV: .

- Number of wind turbines: .

- Unit cost of PV: $.

- Unit cost of wind turbine: $.

- Maximum energy produced by a PV: kWh.

- Maximum energy produced by a wind turbine: kWh.

- Minimum load to be satisfied kWh.

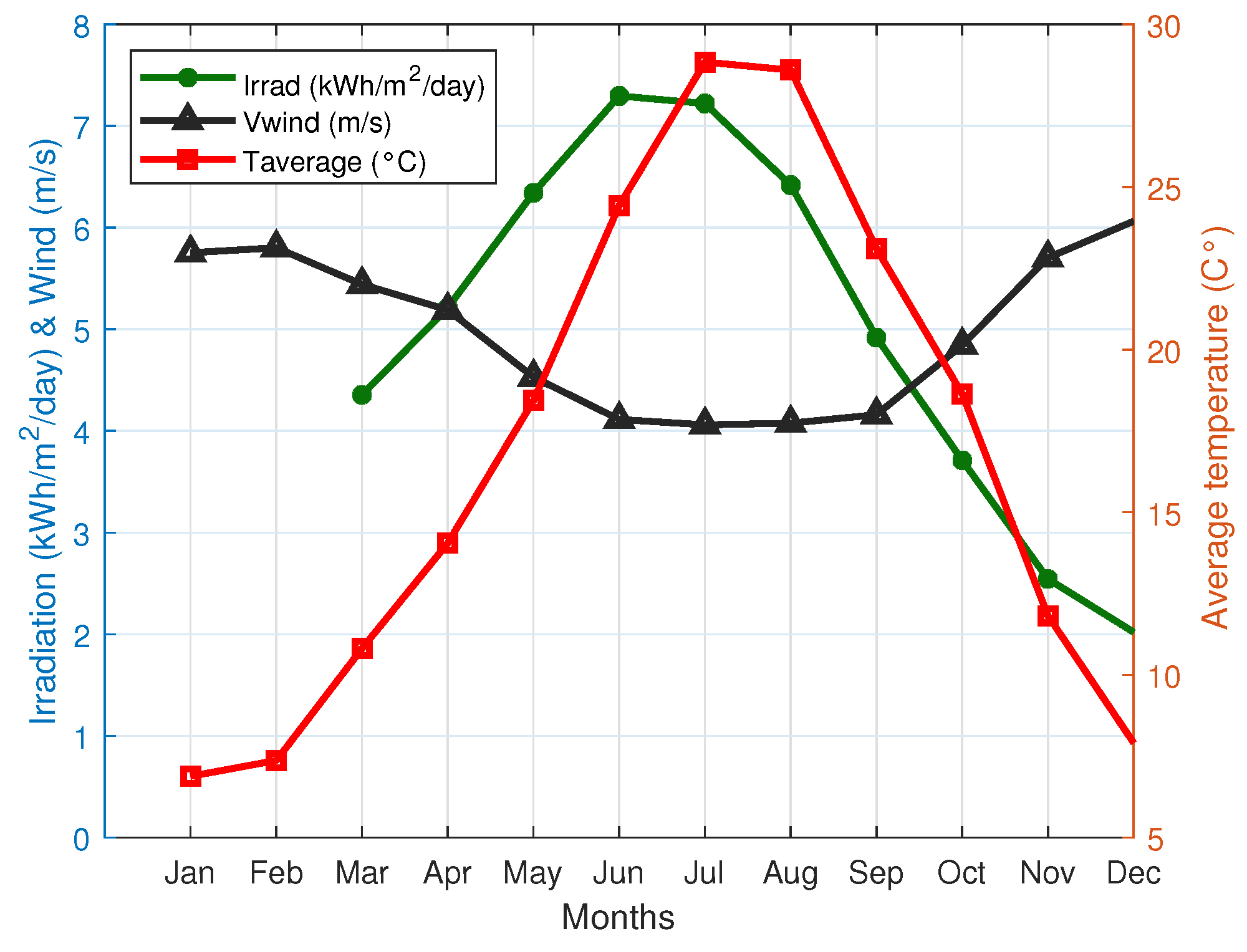

- The temperature is important during the period from March to September. Hence, the electrical energy produced by the PVs is at the maximum (maximum efficiency), whereas the electrical energy produced by the wind turbines is negligible. In the interest of satisfying the load of the system in this period, the energy produced will be based solely on the PVs, which allows us to determine the maximum number of PVs:

- The wind speed is very important between the months of January to April; therefore, the electrical energy produced by the wind turbines is at the maximum (maximum efficiency). On the other hand, the electrical energy produced by the PVs is negligible. In order to satisfy the load of the system in this period, the energy produced will be based solely on the wind turbines. This allows us to determine the maximum number of wind turbines:

3. Results

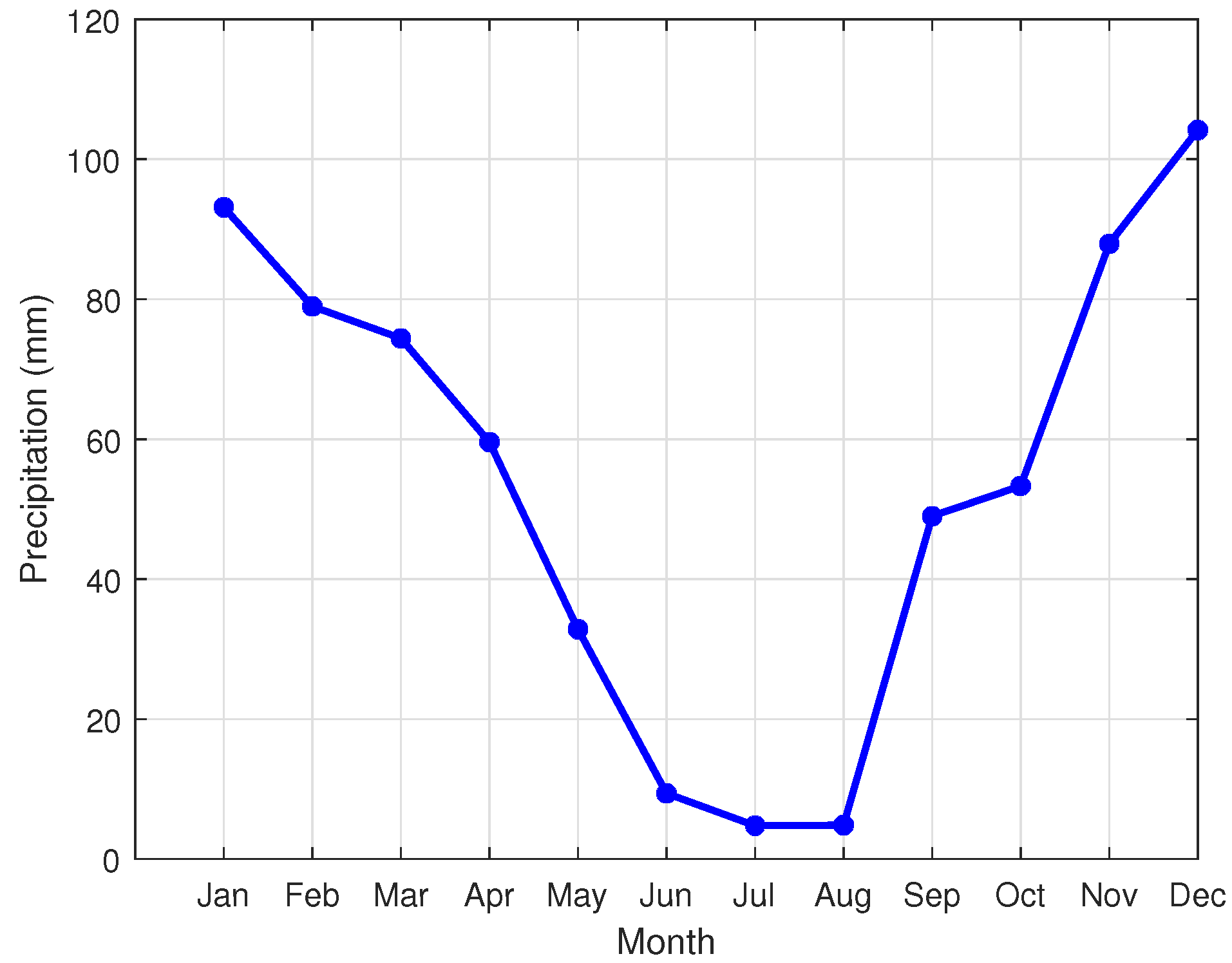

3.1. Meteorological Conditions and Irrigation Demand in the Selected Region

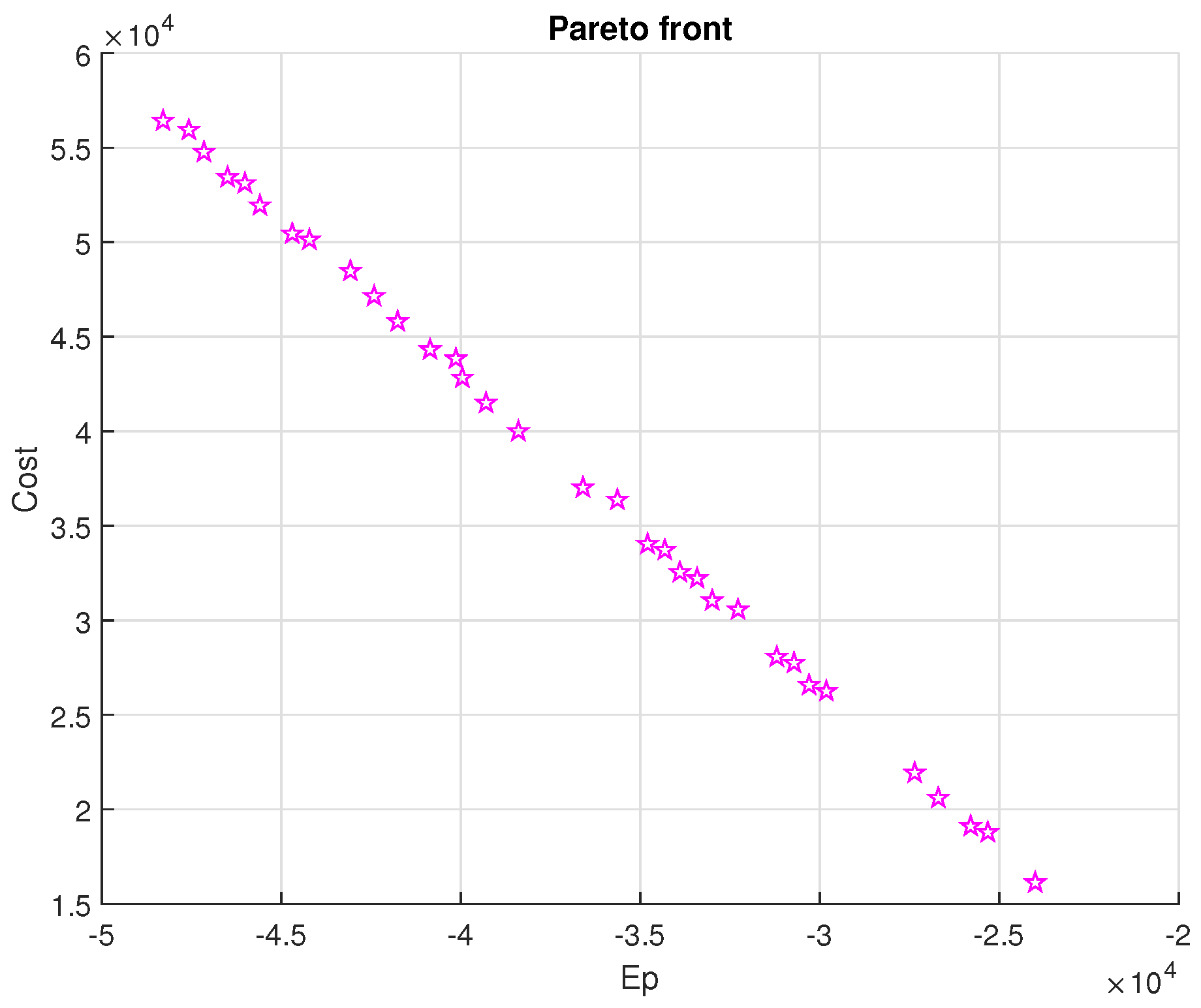

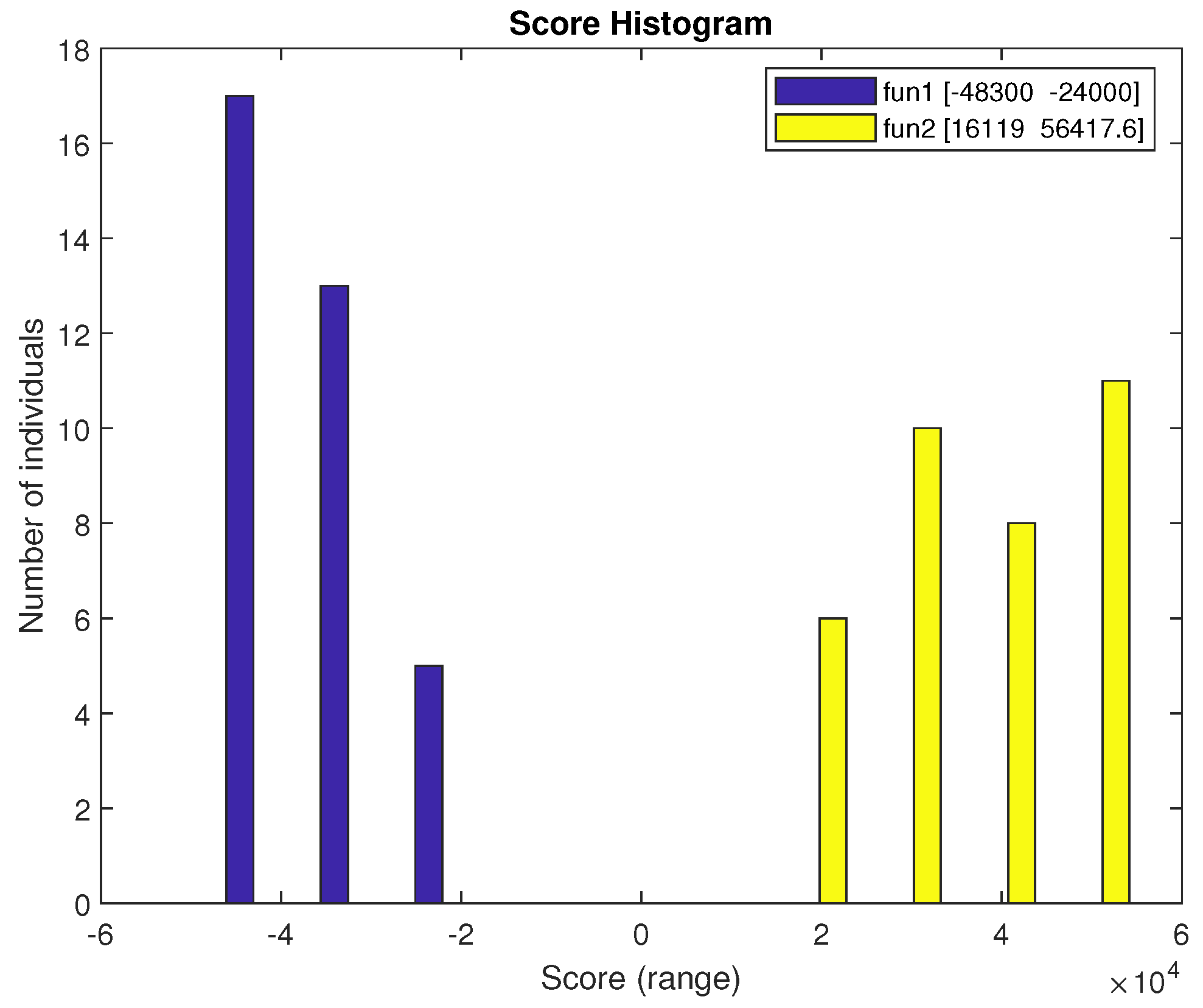

3.2. Resolution Method for the Multi-Objective Optimization Problem

3.3. Choice of the Final Optimized Solution

- The user’s intervention in selecting the optimized vector.

- The introduction of a new classification criterion, reflecting the user’s preference for one of the objectives.

- The incorporation of decision aid methods, which establish an ordered relationship among the various objectives.

3.4. Cost vs. Area vs. Energy Trade-Off Analysis

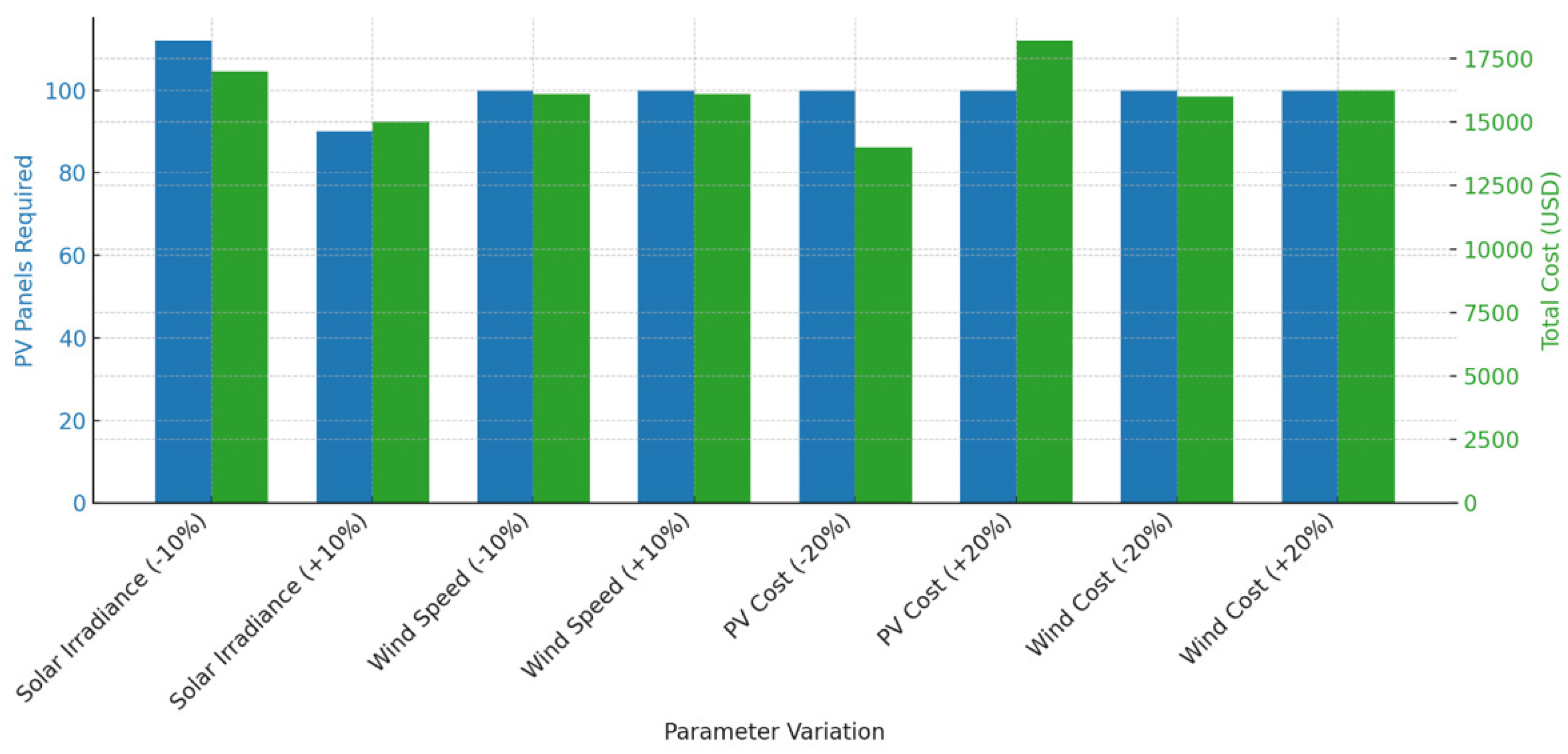

3.5. Sensitivity Analysis of Model Parameters

- Solar irradiance .

- Wind speed .

- PV panel cost .

- Wind turbine cost .

4. Discussion

- Cost vs. Performance Trade-off: The decision to exclude wind turbines highlights a critical trade-off.

- Cost Savings: Avoiding wind turbines reduces upfront capital expenditure by 1492.54 $ per turbine and simplifies system maintenance.

Technical Viability Criteria for the Proposed Configuration

- Energy Match Criterion: The total energy production (24 kWh/day) exactly met the irrigation demand. This was verified using component-specific generation data (24 kWh per PV panel), ensuring that no excess or deficit could compromise system operation or inflate costs.

- Component Utilization Efficiency: The design uses 100 PV panels, achieving close to maximum daily generation under average solar irradiance. The elimination of wind turbines was technically justified by the site’s low wind potential, minimizing underutilized components.

- Cost-to-Performance Ratio: The selected configuration provided the lowest total cost (16,119.40 $) that satisfies energy demand without reliance on costly battery storage. The system achieves a levelized cost of energy (LCOE) that is competitive with the grid-subsidized electricity in the region, further supporting economic viability.

- Storage Substitution Feasibility: Instead of batteries, a water reservoir stores potential energy. This design decision is technically sound as gravitational flow can reliably power the irrigation system without introducing the conversion losses that are typically found in battery-based systems.

- Environmental Suitability: Based on meteorological data and local resource assessment, solar energy was identified as the dominant viable source. The configuration aligns with seasonal solar availability and matches crop water needs during peak sun months.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Modeling of the Wind/PV Hybrid System

Appendix A.1. Modeling of a PV

- : Performance ratio (mean value 0.72 or 0.75, with 0.75 for optimal panel orientation);

- : Factor that takes losses into account;

- : Effective annual irradiance of the incident (W/m2);

- : Irradiance under standard conditions (1000 W/m2);

- : Rated power under standard conditions provided by the manufacturer .

Appendix A.2. Modeling of a Wind Turbine

- : The density of the air (kg/m3);

- A: The area swept by the blades of the turbine (m2);

- : Wind speed (m/s);

- : The power coefficient of the rotor, which is defined as the ratio between the extractable power and the available power.

- h is the mast height (m);

- is the reference height (10 m);

- V is the wind speed (m/s) at the height h of the mast;

- is the wind speed (m/s) at the reference height ;

- is the power law exponent (taken as ).

Appendix B. The Various Devices Used in HRESs

Appendix B.1. Components

| Device | Power in Watt |

|---|---|

| Photovoltaic module | 240 |

| Regulator | 270 |

| Converter | 650 |

| Inverter + Wiring | 12.50 |

| Wind turbine + Wiring | 900 |

| Motor-pump CASELLA agricultural machinery SRL Algeria | 175,049 |

| Irrigation accessories | / |

Appendix B.2. Accessories

| Number | Designation | Unit Price in $ | Quantity | Total Price in $ |

|---|---|---|---|---|

| 1 | Pipes ∅ 75 | 95.52 | 45 | 4298.40 |

| 2 | Pipes ∅ 400 | 37.13 | 16 | 594.08 |

| 3 | Gutters | 0.075 | 1600 | 120.00 |

| 4 | Flanges ∅ 75 | 1.34 | 65 | 87.10 |

| 5 | Valves ∅ 20 threaded | 0.36 | 65 | 23.40 |

| 6 | Plugs ∅ 20 | 0.11 | 65 | 7.28 |

| 7 | Valves ∅ 63 | 5.97 | 1 | 5.97 |

| 8 | Valves ∅ 75 | 11.94 | 1 | 11.94 |

| 9 | Reed Plugs ∅ 75 | 6.72 | 1 | 6.72 |

| 10 | Teflon | 1.49 | 1 | 1.49 |

| Total | 4298.51 |

Appendix B.3. Characteristics of the Hybrid System Used

- (a)

- The parameters of a photovoltaic module.

- A Condor brand panel CEM240P-60 (Figure A1).

- The open-circuit voltage = 37.2 V.

- The short-circuit current = 8.65 A.

- The maximum voltage = 30 V.

- The maximum current = 8 A.

- The price of the panel: 161.19 $.

- (b)

- The parameters of the wind turbine.

References

- Sebbagh, T.; Kelaiaia, R.; Abdelouahed, A.; Zaatri, A. Optimizing the use of green energies, an application to crop irrigation. Carpathian J. Electr. Eng. 2018, 12, 87–98. [Google Scholar]

- Gaabour, A.; Metatla, A.; Kelaiaia, R.; Bourennani, F.; Kerboua, A. Recent Bibliography on the Optimization of Multi-source Energy Systems. Arch. Comput. Methods Eng. 2019, 26, 809–830. [Google Scholar] [CrossRef]

- Sebbagh, T.; Kelaiaia, R.; Zaatri, A. Investigation of the use of a central unique renewable energy system versus distributed units for crop irrigation. Clean Technol. Environ. Policy 2018, 20, 2365–2373. [Google Scholar] [CrossRef]

- Pérez Uc, D.A.; de León Aldaco, S.E.; Aguayo Alquicira, J. Trends in Hybrid Renewable Energy System (HRES) Applications: A Review. Energies 2024, 17, 2578. [Google Scholar] [CrossRef]

- Coelho, J.S.T.; Alves, A.B.; Morillo, J.G.; Coronado-Hernández, O.E.; Perez-Sanchez, M.; Ramos, H.M. Hybrid Energy Solution to Improve Irrigation Systems: HY4RES vs. HOMER Optimization Models. Energies 2024, 17, 4037. [Google Scholar] [CrossRef]

- Giedraityte, A.; Rimkevicius, S.; Marciukaitis, M.; Radziukynas, V.; Bakas, R. Hybrid Renewable Energy Systems—A Review of Optimization Approaches and Future Challenges. Appl. Sci. 2025, 15, 1744. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Bawayan, H.M.; Enany, M.A.; Elymany, M.M.; Shaier, A.A. Modern advancements of energy storage systems integrated with hybrid renewable energy sources for water pumping application. Eng. Sci. Technol. Int. J. 2025, 62, 101967. [Google Scholar] [CrossRef]

- Elkadeem, M.; Wang, S.; Sharshir, S.W.; Atia, E.G. Feasibility analysis and techno-economic design of grid-isolated hybrid renewable energy system for electrification of agriculture and irrigation area: A case study in Dongola, Sudan. Energy Convers. Manag. 2019, 196, 1453–1478. [Google Scholar] [CrossRef]

- Al-Rawashdeh, H.; Al-Khashman, O.A.; Arrfou, L.M.; Gomaa, M.R.; Rezk, H.; Shalby, M.; Al Bdour, J.T.; Louzazni, M. Different Scenarios for Reducing Carbon Emissions, Optimal Sizing, and Design of a Stand-Alone Hybrid Renewable Energy System for Irrigation Purposes. Int. J. Energy Res. 2023, 2023, 6338448. [Google Scholar] [CrossRef]

- Ghosh, D.; Saha, A.; Rashid, H.A.; Shafin, M.S.; Sadhu, P.; Ahmed, K.F. Design and Development of Hybrid Renewable Energy Based Smart Irrigation System. In Proceedings of the 2023 IEEE 11th International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 13–15 August 2023; pp. 224–229. [Google Scholar] [CrossRef]

- Kose, F.; Aksoy, M.H.; Ozgoren, M. Experimental Investigation of Solar/wind Hybrid System for irrigation in Konya, Turkey. Therm. Sci. 2019, 23, 4129–4139. [Google Scholar] [CrossRef]

- Tarife, R.; Nakanishi, Y.; Chen, Y.; Zhou, Y.; Estoperez, N.; Tahud, A. Optimization of Hybrid Renewable Energy Microgrid for Rural Agricultural Area in Southern Philippines. Energies 2022, 15, 2251. [Google Scholar] [CrossRef]

- Cao, Y.; Yao, H.; Wang, Z.; Jermsittiparsert, K.; Yousefi, N. Optimal Designing and Synthesis of a Hybrid PV/Fuel cell/Wind System using Meta-heuristics. Energy Rep. 2020, 6, 1353–1362. [Google Scholar] [CrossRef]

- Carroquino, J.; Dufo-López, R.; Bernal-Agustín, J.L. Sizing of off-grid renewable energy systems for drip irrigation in Mediterranean crops. Renew. Energy 2015, 76, 566–574. [Google Scholar] [CrossRef]

- Muhammad Zeeshan, A.; Muhammad, Y.; Saleem, U.; Muhammad, H. Design, sizing and economic feasibility of a hybrid PV/diesel/battery based water pumping system for farmland. Int. J. Green Energy 2022, 19, 614–637. [Google Scholar] [CrossRef]

- Khadidja Mostefa, S.; Yahia, B.; Abdelhamid, K.; Soumia, K. Sizing of A Hybrid (Photovoltaic/Wind) Pumping Systembased on Metaheuristic Optimization Methods. In Proceedings of the 2018 International Conference on Wind Energy and Applications in Algeria (ICWEAA), Algiers, Algeria, 6–7 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Guven, A.F.; Yorukeren, N.; Tag-Eldin, E.; Samy, M.M. Multi-Objective Optimization of an Islanded Green Energy System Utilizing Sophisticated Hybrid Metaheuristic Approach. IEEE Access 2023, 11, 103044–103068. [Google Scholar] [CrossRef]

- Geleta, D.K.; Manshahia, M.S. Gravitational search algorithm-based optimization of hybrid wind and solar renewable energy system. Comput. Intell. 2022, 38, 1106–1132. [Google Scholar] [CrossRef]

- Samia, S.; Gherbi, A.; Bayindir, R.; Kaabeche, A. Multi-objective Optimization of a Hybrid Renewable Energy System with a Gas Micro-turbine and a Storage Battery. Arab. J. Sci. Eng. 2020, 45, 1553–1566. [Google Scholar] [CrossRef]

- Bashir, M.; Sadeh, J. Optimal sizing of hybrid wind/photovoltaic/battery considering the uncertainty of wind and photovoltaic power using Monte Carlo. In Proceedings of the 2012 11th International Conference on Environment and Electrical Engineering, Venice, Italy, 18–25 May 2012; pp. 1081–1086. [Google Scholar] [CrossRef]

- Kaabeche, A.; Diaf, S.; Ibtiouen, R. Firefly-inspired algorithm for optimal sizing of renewable hybrid system considering reliability criteria. Sol. Energy 2017, 155, 727–738. [Google Scholar] [CrossRef]

- Samy, M.; Barakat, S.; Ramadan, H. A flower pollination optimization algorithm for an off-grid PV-Fuel cell hybrid renewable system. Int. J. Hydrogen Energy 2019, 44, 2141–2152. [Google Scholar] [CrossRef]

- Farh, H.M.H.; Al-Shamma’a, A.A.; Al-Shaalan, A.M.; Alkuhayli, A.; Noman, A.M.; Kandil, T. Technical and Economic Evaluation for Off-Grid Hybrid Renewable Energy System Using Novel Bonobo Optimizer. Sustainability 2022, 14, 1533. [Google Scholar] [CrossRef]

- Al-Shamma, A.A.; Hussein Farh, H.M.; Noman, A.M.; Al-Shaalan, A.M.; Alkuhayli, A. Optimal Sizing of a Hybrid Renewable Photovoltaic-Wind System-Based Microgrid Using Harris Hawk Optimizer. Int. J. Photoenergy 2022, 2022, 4825411. [Google Scholar] [CrossRef]

- Abdullah, H.M.; Park, S.; Seong, K.; Lee, S. Hybrid Renewable Energy System Design: A Machine Learning Approach for Optimal Sizing with Net-Metering Costs. Sustainability 2023, 15, 8538. [Google Scholar] [CrossRef]

- Osyczka, A. Multicriteria optimization for engineering design. Des. Optim. 1985, 1, 193–227. [Google Scholar]

- Kasbadji, M. Carte des Vents de l’Algerie—Resultats Preliminaires. Rev. Energ. Ren. Valoris. 1999, 20, 209–214. [Google Scholar]

- NASA Surface Meteorology and Solar Energy-Location. 2025. Available online: https://power.larc.nasa.gov/data-access-viewer/ (accessed on 10 June 2025).

- Deb, K. Multiobjective Optimization Using Evolutionary Algorithms; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Sengül, Ü.; Eren, M.; Seyedhadi, S.E.; Gezder, V.; Sengül, A.B. Fuzzy TOPSIS method for ranking renewable energy supply systems in Turkey. Renew. Energy 2015, 75, 617–625. [Google Scholar] [CrossRef]

- Chakraborty, S. TOPSIS and Modified TOPSIS: A comparative analysis. Decis. Anal. J. 2022, 2, 100021. [Google Scholar] [CrossRef]

- Panda, M.; Jagadev, A.K. TOPSIS in Multi-Criteria Decision Making: A Survey. In Proceedings of the 2018 2nd International Conference on Data Science and Business Analytics (ICDSBA), Changsha, China, 21–23 September 2018; pp. 51–54. [Google Scholar] [CrossRef]

- Sebbagh, T.; Kelaiaia, R.; Zaatri, A. An experimental validation of the effect of partial shade on the I-V characteristic of PV panel. Int. J. Adv. Manuf. Technol. 2018, 96, 4165–4172. [Google Scholar] [CrossRef]

- Durisch, W.; Bitnar, B.; Mayor, J.C.; Kiess, H.; hang Lam, K.; Close, J. Efficiency model for photovoltaic modules and demonstration of its application to energy yield estimation. Sol. Energy Mater. Sol. Cells 2007, 91, 79–84. [Google Scholar] [CrossRef]

- Betz, A. Theoretical limit for best utilization of wind by wind-motors. Mag. Entire Turbine Syst. 1920, 20, 307–309. [Google Scholar]

- Southwest Windpower, Inc. 2024. Available online: http://www.windenergy.com (accessed on 10 June 2025).

| Tree Type | Water Need (1st Year) | Water Need (2nd Year) | Water Need (>2nd Year) | Number of Trees | Area Occupied (%) |

|---|---|---|---|---|---|

| Olive | 100 L (2–3 times/ week) | 80 L (1–2 times/week) | 50 L (1 time/week) | 225 | ≈27% |

| Fig | 100 L (2–3 times/week) | 80 L (1–2 times/week) | 50 L (1 time/week) | 150 | ≈18% |

| Almond | 100 L (2–3 times/week) | 80 L (1–2 times/week) | 50 L (1 time/week) | 120 | ≈14.45% |

| Prune | 100 L (2–3 times/week) | 80 L (1–2 times/week) | 50 L (1 time/week) | 335 | ≈40.3% |

| (kWh) | ($) | ||

|---|---|---|---|

| 100 | 0 | 24 | 16,119.40 |

| Number of PV Panels | Area (m2) | Energy Produced (kWh) | Cost ($) |

|---|---|---|---|

| 60 | 96 | 14.4 | 9671.40 |

| 80 | 128 | 19.2 | 12,895.20 |

| 100 | 160 | 24.0 | 16,119.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abderrahmane, N.; Brahmia, A.; Kerboua, A.; Kelaiaia, R. An Optimal Sizing Methodology for a Wind/PV Hybrid Energy Production System for Agricultural Irrigation in Skikda, Algeria. Appl. Sci. 2025, 15, 6704. https://doi.org/10.3390/app15126704

Abderrahmane N, Brahmia A, Kerboua A, Kelaiaia R. An Optimal Sizing Methodology for a Wind/PV Hybrid Energy Production System for Agricultural Irrigation in Skikda, Algeria. Applied Sciences. 2025; 15(12):6704. https://doi.org/10.3390/app15126704

Chicago/Turabian StyleAbderrahmane, Nadhir, Allaoua Brahmia, Adlen Kerboua, and Ridha Kelaiaia. 2025. "An Optimal Sizing Methodology for a Wind/PV Hybrid Energy Production System for Agricultural Irrigation in Skikda, Algeria" Applied Sciences 15, no. 12: 6704. https://doi.org/10.3390/app15126704

APA StyleAbderrahmane, N., Brahmia, A., Kerboua, A., & Kelaiaia, R. (2025). An Optimal Sizing Methodology for a Wind/PV Hybrid Energy Production System for Agricultural Irrigation in Skikda, Algeria. Applied Sciences, 15(12), 6704. https://doi.org/10.3390/app15126704