1. Introduction

Amorphous polymers exhibit a continuous transition in their mechanical behaviors near their glass transition temperatures (

Tg), at which their molecular mobility becomes exponentially altered without phase transition. Below

Tg, the configurational rearrangement of polymer chains occurs substantially slowly, resulting in elastic and brittle characteristics (the glassy state). In contrast, above

Tg, the increased molecular mobility renders extensive plasticity (the rubbery state). Consequently, the temperature-sensitive configurational rearrangement rate causes a second-order transition in their free volume [

1]. Although the typical conditions are where the free volume is thermodynamically determined [

2,

3,

4], polymers can also be subjected to extreme mechanical conditions, where the free volume can be altered on a short time scale to that of the molecular reconfiguration time scale (ns-µs). Consequently, the shot-time-scale modification of the free volume can result in mechanical properties that deviate considerably from conventional expectations. These time-scale-dependent extraordinary behaviors of polymers have gained increasing importance with the recent progress in additive manufacturing (AM), where the AM process inherently requires the rapid volumetric consolidation of small mass elements [

5]. For example, cold spray, a subclass of additive manufacturing, utilizes a supersonic stream of feedstock powder or microparticles (µPs). The CS process uses pressurized gas to accelerate the desired µPs to high velocities through a de Laval converging-diverging nozzle. When the high-velocity gas stream containing these µPs is directed toward a stationary target substrate, the impacting µPs undergo severe plastic deformations and deposit to form a uniform, non-porous coating [

6,

7,

8]. Consequently, as heating-free and solvent-free AM can be realized for polymers using the CS approach, understanding polymers’ extreme behaviors is more critical than ever [

9,

10,

11].

Since its inception as a material coating technique, CS has been used in various industries to spray various feedstock powders, including metals, composites, ceramics, and polymers [

7,

12]. The bond between the deposited µPs and the substrate during this high-velocity collision event can be metallurgical, chemical, and/or mechanical [

6]. CS has been extensively studied for metallic powder particles sprayed onto metallic surfaces, reaching deposition efficiencies near 99%, but studies on the CS of polymer powder have been sparse [

13]. The inherent differences between polymers and metals, such as the size of molecules, transition temperatures, degree of crystallinity, primary bond availability, and thermal conductivity, result in drastically different behavior for polymeric powders from metallic powders during the CS process [

14]. Xu and Hutchings studied the CS deposition of polyolefin powder on polyethylene and aluminum substrates. Through their CS study elevating temperature above the melting temperatures of feedstock polymer microparticles (~110 °C), the formation of a layer of polymer melt formed on the substrate surface aided in the CS deposition of the polyolefin µPs [

15]. Anni et al. studied the CS feasibility of thermoplastic polymers (nylon-6 microparticles) on fiber-reinforced plastics. A deposition efficiency above 30% was demonstrated without damaging the substrates [

16]. In the authors’ extended research studying the effects of CS operating temperature and gas pressure, the CS operating temperature from 150 °C to 175 °C significantly improved nylon-6 deposition due to the concurrent extreme plastic deformation of impacting microparticles and the epoxy polymer matrix substrate [

10]. Bush et al. studied the CS deposition of high-density polyethylene (HDPE) on various polymer substrates to develop a deposition window for the polymer powder–substrate pair [

14]. Khalkhali et al. extended this study to the CS deposition of various polymer µPs on polymeric substrates and developed deposition windows over the impacting particle’s velocity–temperature space [

6]. The velocity of the impacting µPs was calculated using a one-dimensional inviscid gas and particle dynamics model developed by Champagne et al. [

17]. The results showed that deposition temperatures closer to the

Tg of polymers were advantageous for higher deposition efficiencies and wider deposition windows. Bacha et al. studied the effect of pre-heating or pre-cooling the feedstock nylon 6 polymer powders. However, the authors did not observe any meaningful improvement in the deposition efficiency with the pre-heating/-cooling feed powder but reported that in a low-pressure CS system, pre-heating resulted in 28% higher mechanical strength in the CS deposits in comparison to the deposits from room temperature and pre-cooled feedstock powders [

18]. Meanwhile, Kaminskyj et al. reported that the deposition efficiency was inversely proportional to the degree of crystallinity of the feedstock polymer (polyetherketoneketone; PEKK) [

19].

The previous CS studies suggested that several significant factors influence the CS consolidation process of the polymer µPs via their complex interplay. This challenge in understanding the complicated effects of the major factors should be addressed through parametric experimental approaches with the decoupling of the factors. In this aspect, temperature-controlled single µP collision experiments with amorphous polymers can be effective. Due to their noncrystalline nature, amorphous polymers display temperature-dependent characteristics primarily through glass transition. As a model noncrystalline polymer, polystyrene (PS) is investigated in this study. PS is a durable thermoplastic polymer used in a wide range of products owing to its versatile properties [

20]. The temperature-dependent mechanical characteristics of PS are well documented in the low-strain-rate regime. However, very few studies have focused on the ultrahigh-strain-rate (UHSR) behavior of PS, regardless of its cruciality in understanding the CS-relevant characteristics. The current research focuses on the temperature-dependent extreme collision characteristics of PS µPs in normal and tilted impact experiments of PS µPs conducted at different temperatures in a highly controlled single-particle impact method called laser-induced particle impact testing (LIPIT) [

21].

2. Materials and Methods

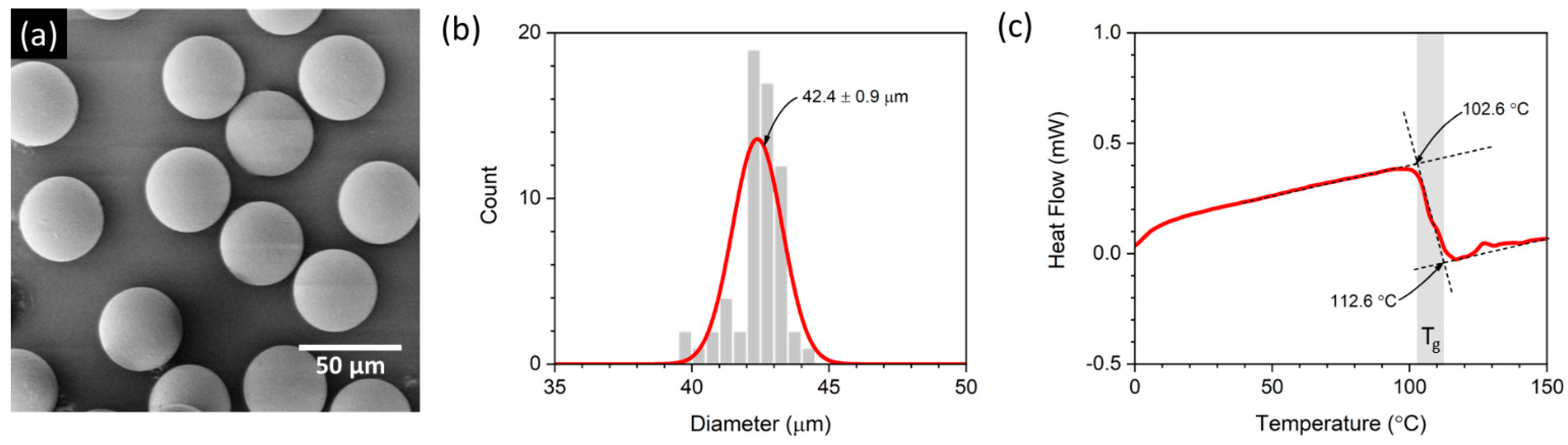

PS µPs, produced by KU Leuven, were used without further modification (

Figure 1a). Most µPs were highly spherical with an average particle diameter (

) of 42.4 ± 0.9 µm (

Figure 1b). Although LIPIT results typically exhibit scaling effects, the 2% variation in particle diameter was negligible and did not produce any noticeable impact. The number-averaged molecular weight (

) of the PS µPs was quantified to be 84.7 kDa with a polydispersity index of 2.19 through gel permeation chromatography (Agilent 1260 infinity system with a G1362A refractive index detector and G1310B isocratic pump, Agilent Technologies, Santa Clara, CA, USA). According to the previous LIPIT studies of PS spherical particles [

22] and PS thin-film [

23], the

of PS significantly affected the UHSR mechanical characteristics. Due to the large

of PS, the fragmentation of µPs upon high-velocity collision with a stationary substrate was negligible, as reported for PS-µPs of similar

having

near 100 kDa [

22]. Differential scanning calorimetry (DSC) was performed (Q200, TA Instruments, New Castle, DE, USA) for ascertaining the

of the PS µPs used in the experimentation. The DSC was performed on 5 mg of PS µPs placed in a hermetically sealed aluminum pan placed in an oxidation-limited (nitrogen) environment. The DSC experiment monitored the heat flow in the material as the temperature was raised from −5 °C to 300 °C and then cooled back to −5 °C at a ramp rate of 5 °C/min. The DSC data for µPs under static conditions is presented to display the glass-to-rubber transition of PS during the first heating cycle. The transition initiated at 102.6 °C and concluded at 112.6 °C (

Figure 1c), highlighted in gray.

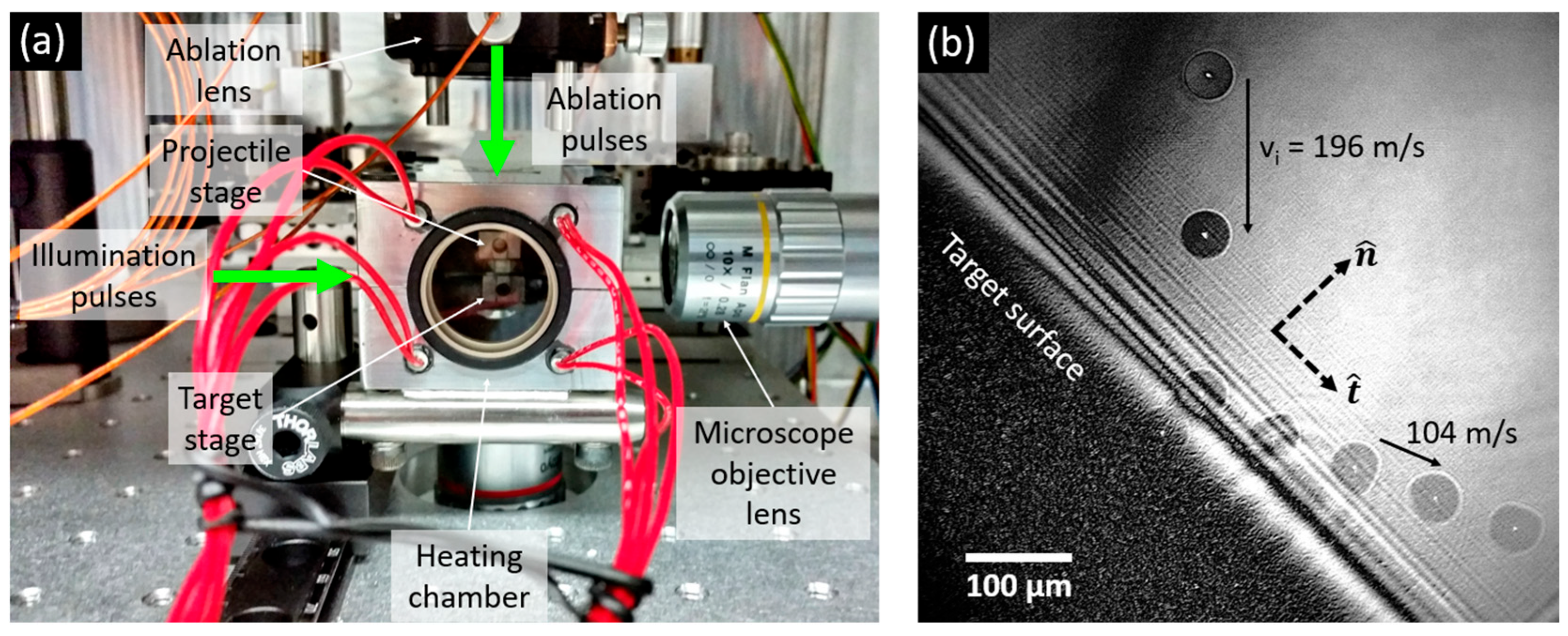

A launch pad to accelerate µPs was prepared by spin coating elastomer resin (Sylgard 184, Dow Chemical, Midland, MI, USA) onto a ~80 nm thick gold-coated glass substrate (Fisherbrand™ Cover glasses No. 2, Fisher Scientific, Waltham, MA, USA), followed by crosslinking at 120 °C for 2 h. The µPs were placed on this launch pad and then mounted to the projectile stage (

Figure 2a). Silicon wafers with native oxide cut to 5 mm × 5 mm were used as the target substrates for conducting normal impact experiments while a fused silica prism (3 mm right angle prism, Thorlabs, Newton, NJ, USA) was the target substrate for all the 45-deg tilted impact experiments. The respective target substrate was mounted on the target stage. The µP-carrying launch pad and a target substrate were enclosed in a heating chamber with four embedded heaters. While the thermocouple reading of the chamber was used for temperature feedback control, the average temperature readings of the projectile and target stages were reported as the experimental temperature (

Texp). After reaching a stable

Texp, it was held for >30 min to ensure uniform temperatures for µPs and target substrate before conducting LIPIT experiments. When a 1064 nm laser pulse ablated the gold layer beneath a targeted µP, the rapidly expanding gold gases inflated the elastomer layer. As a result, the µP atop the inflating elastomer layer was accelerated at desired velocities towards the target substrate. Ultrafast stroboscopic imaging with visible light pulses (<1 ps) captured the impact and rebound motions of the µP (

Figure 2b). Since the duration of the stroboscopic illumination pulses was in the sub-picosecond range, particle motion during this time was virtually negligible (<1 nm) across the entire range of impact velocities. Therefore, the uncertainty in the measured particle velocity (±5 m/s) primarily stems from the spatial resolution of the digitized stroboscopic image. In LIPIT, particle acceleration is achieved by a complex, nonlinear process involving laser ablation and the high-strain-rate transfer of energy from the laser-generated gas to the particle through a PDMS elastomer film [

24,

25]. In our study, the structural parameters of the launch pads were fixed, and the laser pulse energy was adjusted through trial accelerations. By controlling the time between exposure pulses, particles moving at different velocities ranging from 200 m/s to 600 m/s were captured on the stroboscopic imaging screen. The time between each exposure was known, and the distance traveled during this time was calculated by image processing (JMicroVision v1.27 software), which allowed the quantification of the impact and rebound velocities of a µP. For accuracy, the impact

and rebound

velocities were calculated individually for each collision event between the PS µPs and target substrate that have been reported in this study, while

Texp was systematically controlled up to 150 °C using the heating chamber.

For the temperature-controlled LIPIT at 45°, the PS particles were accelerated to controlled velocities of 200 ± 25 m/s, 400 ± 25 m/s, and 600 ± 25 m/se. The impact and rebound velocities were expressed in their respective normal and tangential components along the normal (

) and tangential (

) vectors of the prism surface (as shown in

Figure 2b).

,

, impact angle

, and rebound angle

were measured for each collision while

Texp was systematically varied. The normal component of the impact and rebound velocities represented the compression-dominant interactions experienced by the impacting µP, while the tangential component of velocities conveyed the shear and interfacial interactions. Thus, the three different coefficients of restitution (

CoR) providing complementary information about UHSR elastoplasticity were defined by vector decomposition.

Furthermore, the effective coefficient of friction (

) was introduced in terms of

and

[

26]. The time-averaged effective forces exchanged along

and

was estimated by the momentum changes along these vector directions immediately before and after the PS µP impact. The momentum changes in the µP can be quantified by

and

along

and

, respectively. Considering that these momentum changes represent the normal and frictional forces acting on the µP during the identical contact duration,

can be defined by Equation (4). While

and

represent the bulk inelastic response of µP,

conveys the UHSR tribological response [

26].

3. Results and Discussion

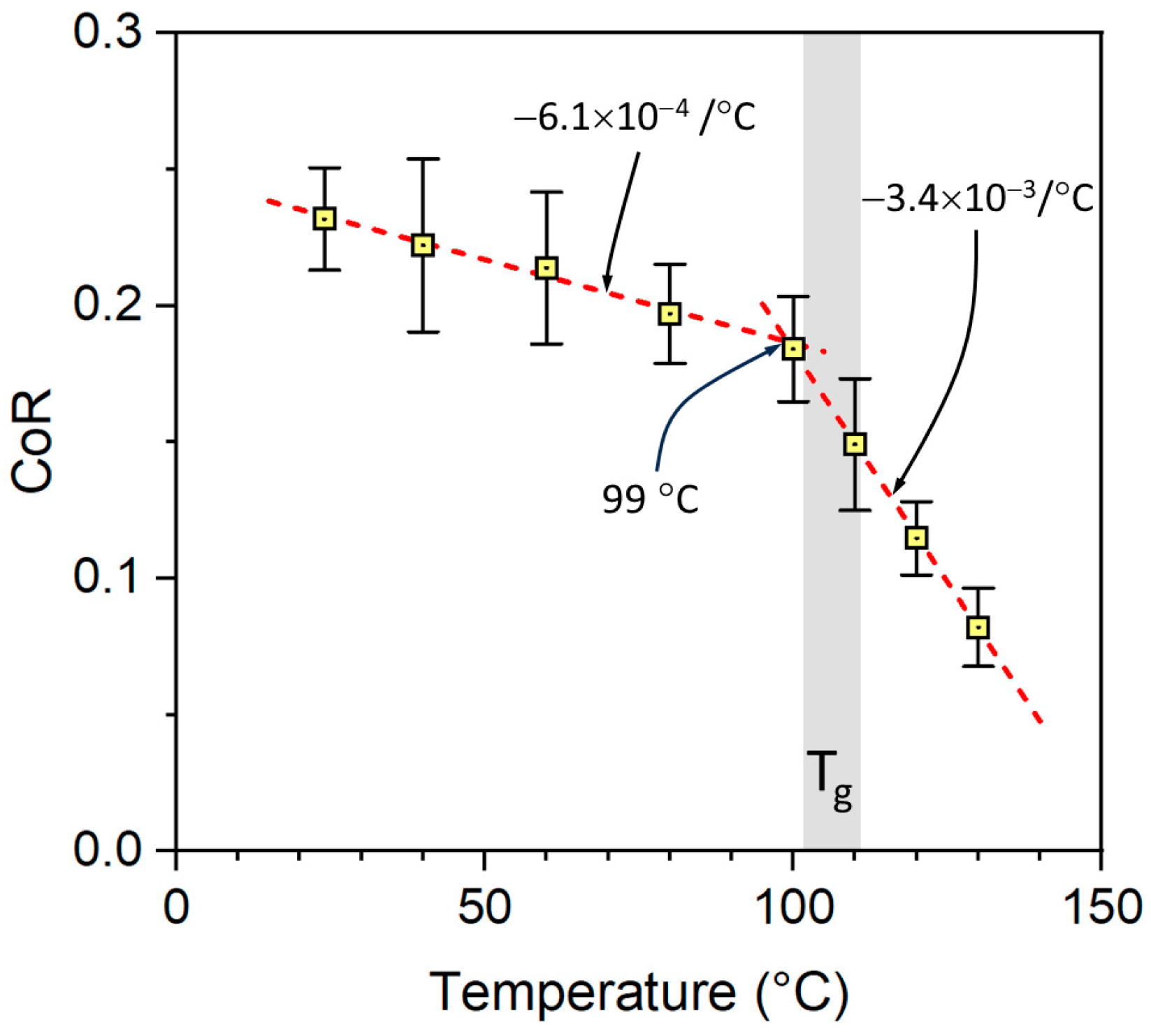

As reference data for angled LIPIT, the PS µPs were perpendicularly impacted on a silicon wafer target substrate having a native oxide layer with controlled velocities of 200 ± 25 m/s while

Texp was systematically varied from room temperature to 130 °C. A minimum of five impact events were performed at each temperature. The

CoR was measured from the perpendicular impact experiments to demonstrate the typical UHSR behavior of the PS µPs (

Figure 3). The error bars represent the standard deviation of

CoR values measured at respective temperatures. A common source of these errors was the error in

(±25 m/s); however, additional fluctuation arose from the unstable interfacial dynamics of PS µPs with the substrate during the rebound stage [

22]. Therefore, the trend in the error bars can provide valuable insight into understanding the UHSR characteristics of PS. Generally, the mean

CoR displayed negative slopes as the temperature increased. This decreasing trend can be understood as the higher energy loss at impact due to the increased plasticity of the PS particles resulting from the softening of the µPs at elevated temperatures. The high rigidity of the silicon substrate resulted in more pronounced plastic deformation, as the plastic deformation was confined within the PS µPs. This led to a lower

CoR trend compared to the more compliant polymeric substrate [

22]. Below

Tg,

CoR was linearly decreased at the rate of −6.1 × 10

−4 according to the linear fitting of the

values from the four lowest temperatures. At the lower edge of

,

started to decrease with a five times higher rate of −3.4 × 10

−3. The larger reduction was attributed to the accelerated molecular motion of PS chains in the rubbery state that shortened the average time of polymer chains escaping from the local configuration traps. Although the representative strain rate estimated by

was extraordinarily high (

s

−1), the bilinear

trend showed that the

defined from the first heating cycle under the static condition still can serve as a valid reference temperature predicting the plasticity of PS. It should be noted that the represented strain rate is an approximate estimate, intended to reflect the order of the actual strain rates, which may vary localized strain variations.

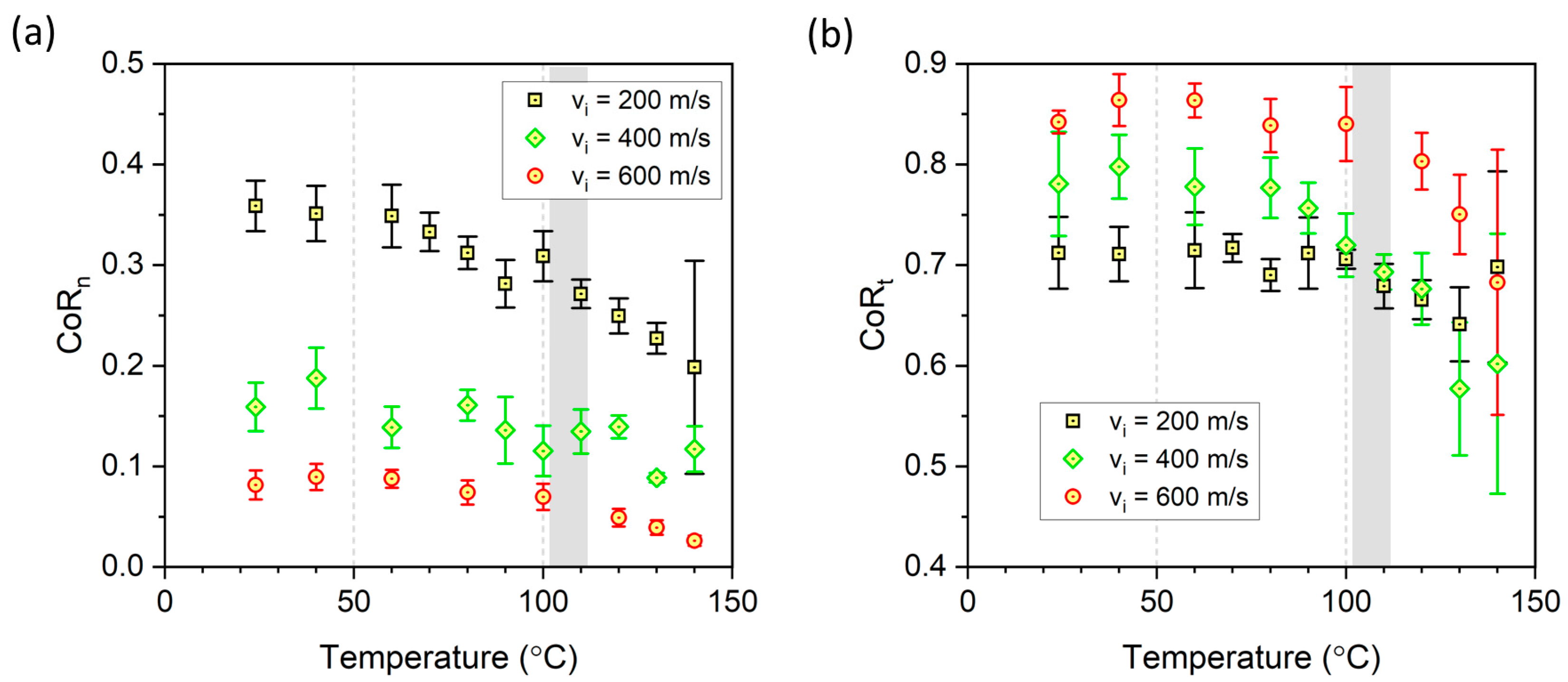

As the perpendicular collision geometry primarily produces the volumetric deformation driven primarily by compressive stresses, the 45-deg tilted LIPIT was performed to elucidate the shear-dominant and interfacial deformation characteristics. Three representative collision regimes were conceived to exhibit the low-, intermediate-, and high-

vi cases based on the previous LIPIT study using 83 kDa PS µPs, which showed the onset of a rheological transition around 400 m/s [

26]. These three velocities were chosen to capture the characteristic responses below and above the activation threshold for interfacial rheological dynamics.

Figure 4 shows the spectra of

and

, defined by Equations (2) and (3). Compared to

CoR in

Figure 3,

(

Figure 4a) was greater than the

under the angled impact of 200 m/s, which could be attributed to the slower normal impact velocity,

. Notably,

CoRn exhibited a transition near 60 °C, significantly lower than that observed in

CoR under the perpendicular impact of 200 m/s. This transition of

CoRn was also observed from the previous 45-degree impact study of PS µPs (

Dp ~ 14.4 µm) at room temperature [

26]. Thus, this inelastic deformation mechanism could be promoted through crazing at a temperature substantially lower than

Tg. While elevated temperature generally increases the plasticity for all three impact velocities,

Tg as a reference temperature was less significant for

CoRn at higher impact velocities. The error bars of

CoRn were significantly reduced at elevated temperatures. This suggests that the plastic behavior of PS becomes more stable, exhibiting greater consistency due to reduced fluctuations caused by unpredictable internal crazing. At 600 m/s, the deformation process exhibited significantly greater consistency, as indicated by the reduced error bars of

CoRn. The reduced fluctuation is attributed to the high-velocity collisions generating local stresses that exceeded PS yield and fracture strength. Meanwhile, in

Figure 4b,

CoRt at 200 m/s showed an apparent transition correlated with

Tg, while

CoRt was significantly higher than

CoRn through the entire range of temperatures. As previously mentioned,

CoRt can more sensitively be affected by the interfacial dynamics between the µP and the substrate. Therefore, the transition of

CoRt near

Tg suggests that intermolecular relaxation at the contact surface of the µP is highly sensitive to the pre-impact temperature of µP. Both

CoRn and

CoRt were exceptional variations at

Texp = 140 °C, indicating an onset of the partial adhesion of µPs. The transition of

CoRt was observed at a significantly lower temperature, approximately 80 °C at 400 m/s, suggesting that the local surface temperature approached the

Tg. As a result, the transition in

CoRt became less distinct at 600 m/s, where the surface temperature was predominantly influenced by the additional temperature rise due to interfacial friction. In contrast to the reduction in error bars observed with increasing

vi in

CoRn, those in

CoRt did not exhibit a significant decrease. Moreover, the error bars were notably larger at temperatures exceeding

Tg, suggesting a rheological transition from a rubber-like to a fluid-like state [

22]. Thus, interfacial wetting and adhesion can lead to additional fluctuation sources in

CoRt.

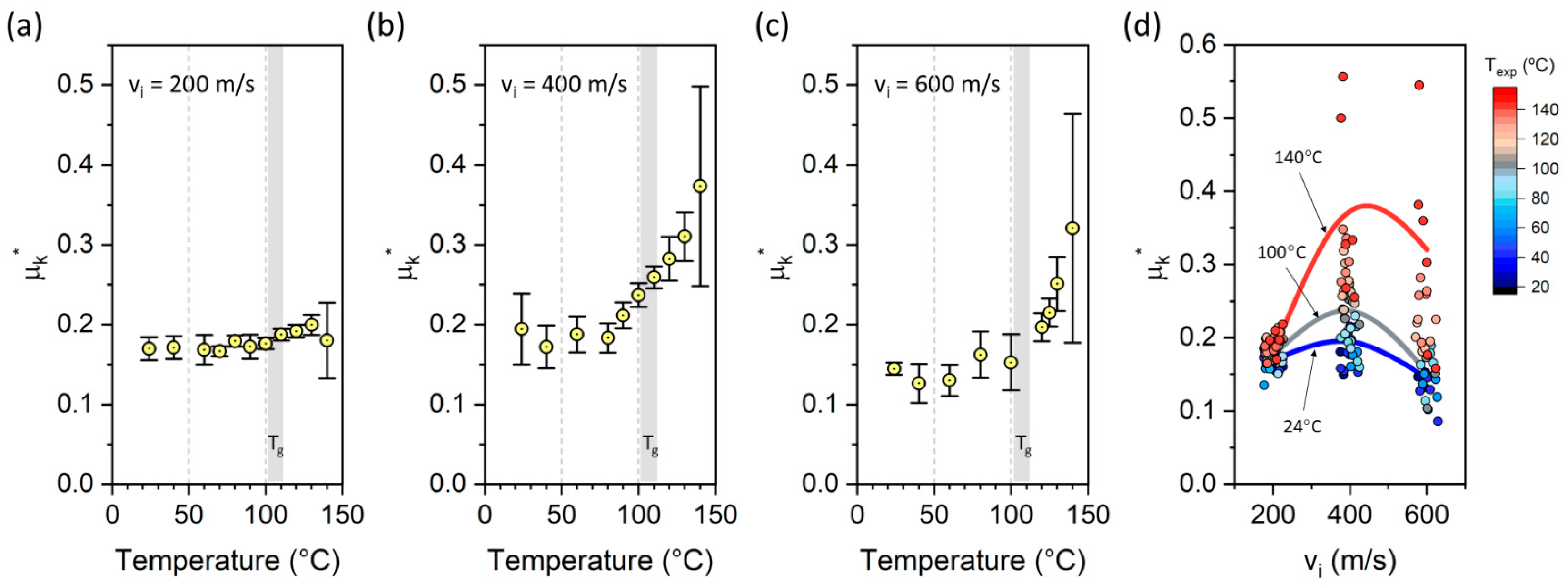

The contribution of interfacial dynamics between µP and the substrate can be understood in terms of

µk* in Equation (4) (

Figure 5). Again, the size of error bars can provide the stability of the interfacial dynamics. At the low-

vi regime (200 m/s),

µk* remained near 0.17 at temperatures below

Tg, slightly lower than 0.21 measured from the room-temperature LIPIT study of PS µPs (

Dp~14.4 µm) [

26]. The minor discrepancy observed in this study may be attributed to the scale effect, as the specific surface area decreased by approximately a factor of three. Additionally,

µk* began to increase at the lower boundary of

Tg, reaching a value of up to 0.2. While the error bar size tends to be reduced at

Texp >

Tg, it suddenly increased at 140 °C, and this trend was commonly observed in the intermediate- and high-

vi regimes. As suggested by

CoRt, the rise in

µk* shifted to 80 °C for

vi = 400 m/s (

Figure 5b), indicating a localized temperature rise at the contact face between the µP and substrate. In the high-

vi regime (

Figure 5c), the deviation point of

µk* was not apparent to specify due to the sizeable fluctuation even at the lower temperature range. The

µk* in the high-

vi range was noticeably lower than the two lower

vi cases at a temperature below

Tg. The reduction in

µk* was understood by the impact-induced formation of the fluid-like phase at the surface of µP, functioning like a lubricating layer without the external temperature elevation [

26]. While the interfacial fluid phase lowers

µk*, the volumetric softening effect governed by

Texp still played a role in enhancing

µk*. Consequently, it shows that

µk* must be explained by the coupled effect of the interfacial (or local) and volumetric (or global) mechanisms. The characteristics of

µk* were empirically explained by Kim et al. using the coupling of the adhesion and softening of PS at the sliding contact face against the stationary surface of a substrate at room temperature [

26]. The measured

µk* values were plotted for the three

vi-ranges with the temperature-dependent color scale (

Figure 5d). The trend curves were produced by the spline of the mean values of

µk* at three respective temperatures. The nonmonotonic trend at room temperature agrees with the reported observation from the room-temperature LIPIT study of PS µPs [

26]. While the nonmonotonic trend was slightly enhanced during the temperature elevation to

Tg, the susceptibility to

vi was greatly amplified at

T >

Tg. The persistence of the nonmonotonic trends, even for

T >

Tg, suggests that the nonmonotonic trend originated not from the global (or volumetric) phase transition to the rubbery state but from the impact-induced rheological transition.

For other amorphous polymers, the temperature-dependent behavior is expected to be qualitatively similar, with variations primarily due to differences in Tg. In contrast, semi-crystalline thermoplastics such as HDPE and nylon-6 contain both rubbery (amorphous) and crystalline phases at room temperature. Their temperature-dependent rheological properties typically exhibit a distinct transition near their melting temperature (Tm), resulting in a sharper change near Tm in UHSR mechanical response compared to the more gradual transitions observed in amorphous polymers.