Effect of High-Pressure Processing on Proteolysis, Texture and Sensorial Attributes of Raw Ewe’s Cheeses Throughout Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Cheese Manufacturing and High-Pressure Processing

2.2. Proteolytic Indexes

2.3. Aminopeptidase Activity

2.4. Instrumental Texture Profile Analysis (TPA)

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

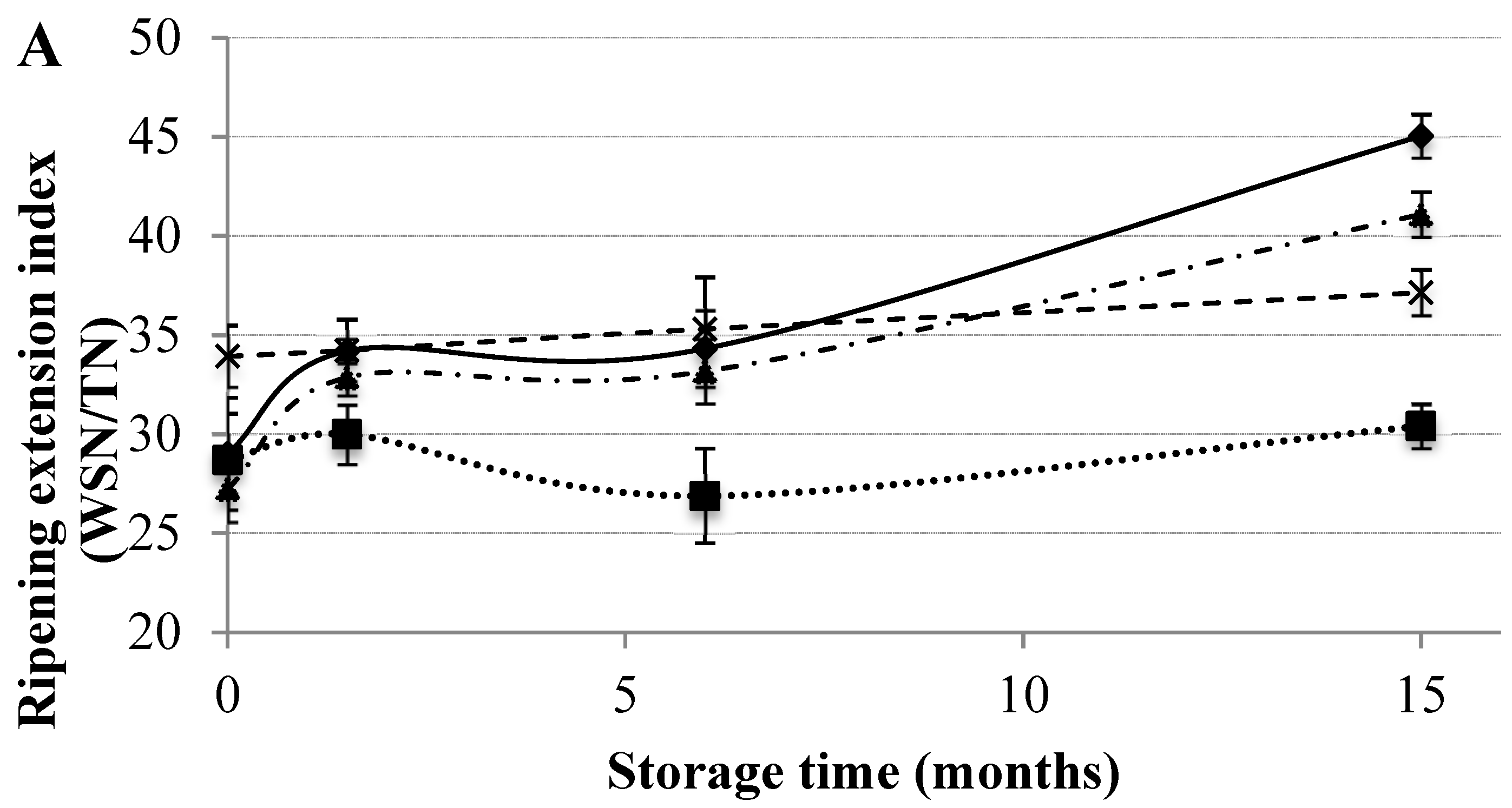

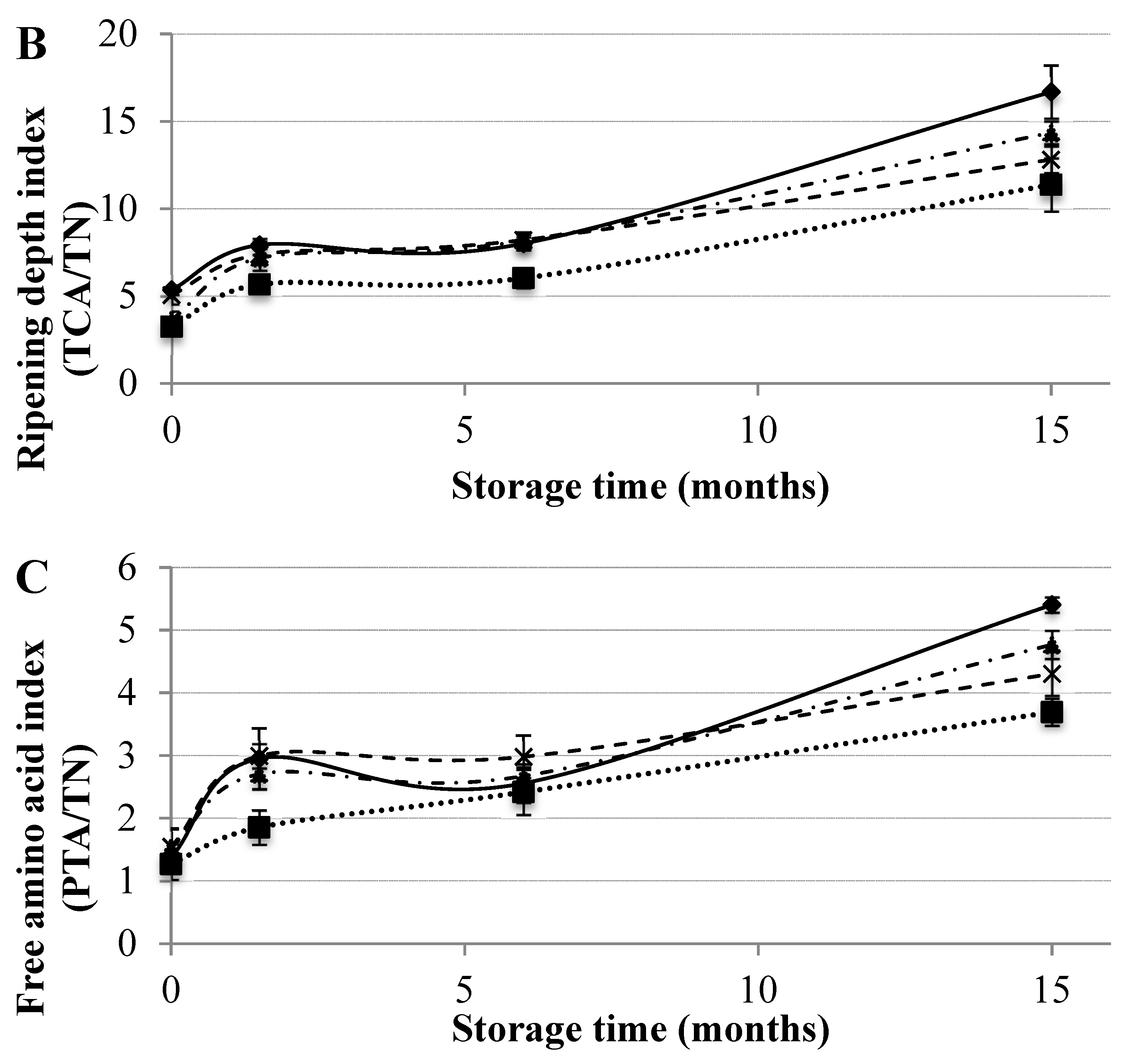

3.1. Effect of HPP on Proteolytic Indexes

3.2. Effect of HPP on Aminopeptidase Activity

3.3. Effect of HPP on Textural Properties

3.4. Effect of HPP on Sensorial Attributes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HPP | High-pressure processing |

| PDO | Protected denomination of origin |

| WSN | Water-soluble nitrogen |

| TCA | Trichloroacetic-acid-soluble nitrogen |

| PTA | Phosphotungstic-acid-soluble nitrogen |

| TN | Total nitrogen content |

| WSN/TN | Water-soluble nitrogen to total nitrogen |

| TCA/TN | Ripening depth index |

| PTA/TN | Free amino acid index |

References

- Macedo, A.C.; Malcata, F.X.; Oliveira, J.C. The Technology, Chemistry, and Microbiology of Serra Cheese: A Review. J. Dairy Sci. 1993, 76, 1725–1739. [Google Scholar] [CrossRef]

- Inácio, R.S.; Gomes, A.M.P.; Saraiva, J.A. Serra Da Estrela Cheese: A Review. J. Food Process. Preserv. 2020, 44, e14412. [Google Scholar] [CrossRef]

- European Commission. Product Specification—Serra da Estrela (PDO). eAmbrosia—The EU Geographical Indications Register. Available online: https://ec.europa.eu/agriculture/eambrosia/geographical-indications-register/details/EUGI00000013223 (accessed on 4 June 2025).

- Macedo, A.C.; Malcata, F.X. Secondary Proteolysis in Serra Cheese during Ripening and throughout the Cheese-Making Season. Eur. Food Res. Technol. 1997, 204, 173–179. [Google Scholar] [CrossRef]

- Macedo, A.C.; Tavares, T.G.; Malcata, F.X. Influence of Native Lactic Acid Bacteria on the Microbiological, Biochemical and Sensory Profiles of Serra Da Estrela Cheese. Food Microbiol. 2004, 21, 233–240. [Google Scholar] [CrossRef]

- Tavaria, F.K.; Franco, I.; Carballo, J.F.; Malcata, F.X. Amino Acid and Soluble Nitrogen Evolution throughout Ripening of Serra Da Estrela Cheese. Int. Dairy J. 2003, 13, 537–545. [Google Scholar] [CrossRef]

- Reis, P.J.M.; Malcata, F.X. Ripening-Related Changes in Serra Da Estrela Cheese: A Stereological Study. J. Dairy Sci. 2011, 94, 1223–1238. [Google Scholar] [CrossRef]

- Sousa, M.J.; Malcata, F.X. Advances in the Role of a Plant Coagulant (Cynara cardunculus) in Vitro and during Ripening of Cheeses from Several Milk Species. Lait 2002, 82, 151–170. [Google Scholar] [CrossRef]

- Delgado, F.J.; Rodríguez-Pinilla, J.; Márquez, G.; Roa, I.; Ramírez, R. Physicochemical, Proteolysis and Texture Changes during the Storage of a Mature Soft Cheese Treated by High-Pressure Hydrostatic. Eur. Food Res. Technol. 2015, 240, 1167–1176. [Google Scholar] [CrossRef]

- Barracosa, P.; Simões, I.; Martins, A.P.; Barros, M.; Pires, E. Biochemical Diversity of Cardoon Flowers (Cynara cardunculus L.): Predicting PDO Mediterranean Cheese Textures. Food Biosci. 2021, 39, 100805. [Google Scholar] [CrossRef]

- Inácio, R.S.; Fidalgo, L.G.; Santos, M.D.; Queirós, R.P.; Saraiva, J.A. Effect of High-Pressure Treatments on Microbial Loads and Physicochemical Characteristics during Refrigerated Storage of Raw Milk Serra Da Estrela Cheese Samples. Int. J. Food Sci. Technol. 2014, 49, 1272–1278. [Google Scholar] [CrossRef]

- Garde, S.; Arqués, J.L.; Gaya, P.; Medina, M.; Nuñez, M. Effect of High-Pressure Treatments on Proteolysis and Texture of Ewes’ Raw Milk La Serena Cheese. Int. Dairy J. 2007, 17, 1424–1433. [Google Scholar] [CrossRef]

- Calzada, J.; Del Olmo, A.; Picon, A. Using High-Pressure Processing for Reduction of Proteolysis and Prevention of over-Ripening of Raw Milk Cheese. Food Bioproc. Technol. 2014, 7, 1404–1413. [Google Scholar] [CrossRef]

- Inácio, R.S.; Rodríguez-Alcalá, L.M.; Pimentel, L.L.; Saraiva, J.A.; Gomes, A.M.P. Evolution of Qualitative and Quantitative Lipid Profiles of High-Pressure-Processed Serra Da Estrela Cheese throughout Storage. Appl. Sci. 2023, 13, 5927. [Google Scholar] [CrossRef]

- AOAC International. Official Method 2001.14: Nitrogen (Total) in Cheese—Kjeldahl Method. In Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2002. [Google Scholar]

- Standard 20B; Milk—Determination of Nitrogen Content (Kjeldahl Method). IDF (International Dairy Federation): Brussels, Belgium, 1993.

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- Pereira, C.I.; Gomes, E.O.; Gomes, A.M.P.; Malcata, F.X. Proteolysis in Model Portuguese Cheeses: Effects of Rennet and Starter Culture. Food Chem. 2008, 108, 862–868. [Google Scholar] [CrossRef]

- Macedo, A.C.; Malcata, F.X. Role of Adventitious Microflora in Proteolysis and Lipolysis of Serra Cheese: Preliminary Screening. Eur. Food Res. Technol. 1997, 205, 25–30. [Google Scholar] [CrossRef]

- Juan, B.; Ferragut, V.; Guamis, B.; Trujillo, A.J. The Effect of High-Pressure Treatment at 300 MPa on Ripening of Ewes’ Milk Cheese. Int. Dairy J. 2008, 18, 129–138. [Google Scholar] [CrossRef]

- Martínez-Rodríguez, Y.; Acosta-Muñiz, C.; Olivas, G.I.; Guerrero-Beltrán, J.; Rodrigo-Aliaga, D.; Sepúlveda, D.R. High Hydrostatic Pressure Processing of Cheese. Compr. Rev. Food Sci. Food Saf. 2012, 11, 399–416. [Google Scholar] [CrossRef]

- Delgado, F.J.; Delgado, J.; González-Crespo, J.; Cava, R.; Ramírez, R. High-Pressure Processing of a Raw Milk Cheese Improved Its Food Safety Maintaining the Sensory Quality. Food Sci. Technol. Int. 2013, 19, 493–501. [Google Scholar] [CrossRef]

- Sousa, M.J.; Malcata, F.X. Influence of Pasteurization of Milk and Addition of Starter Cultures on Protein Breakdown in Ovine Cheeses Manufactured with Extracts from Flowers of Cynara cardunculus. Food Chem. 1996, 57, 549–556. [Google Scholar] [CrossRef]

- Inácio, R.S. Effect of High-Pressure as a Non-Thermal Pasteurisation Technology for Raw Ewes’ Milk and Cheese Safety and Quality: Case Study on Serra Da Estrela Cheese. Ph.D. Thesis, Universidade Católica Portuguesa, Lisboa, Portugal, 2020. [Google Scholar]

- Delgado, F.J.; González-Crespo, J.; Cava, R.; Ramírez, R. Changes in Microbiology, Proteolysis, Texture and Sensory Characteristics of Raw Goat Milk Cheeses Treated by High-Pressure at Different Stages of Maturation. Food Sci. Technol. 2012, 48, 268–275. [Google Scholar] [CrossRef]

- Ávila, M.; Gómez-Torres, N.; Delgado, D.; Gaya, P.; Garde, S. Effect of High-Pressure Treatments on Proteolysis, Volatile Compounds, Texture, Colour, and Sensory Characteristics of Semi-Hard Raw Ewe Milk Cheese. Food Res. Int. 2017, 100, 595–602. [Google Scholar] [CrossRef] [PubMed]

- Macedo, A.C.; Tavares, T.G.; Malcata, F.X. Purification and Characterization of an Intracellular Aminopeptidase from a Wild Strain of Lactobacillus Plantarum Isolated from Traditional Serra Da Estrela Cheese. Enzym. Microb. Technol. 2003, 32, 41–48. [Google Scholar] [CrossRef]

- Sousa, M.J.; Malcata, F.X. Comparison of Plant and Animal Rennets in Terms of Microbiological, Chemical, and Proteolysis Characteristics of Ovine Cheese. J. Agric. Food Chem. 1997, 45, 74–81. [Google Scholar] [CrossRef]

- Trujillo, A.J.; Capellas, M.; Buffa, M.; Royo, C.; Gervilla, R.; Felipe, X.; Sendra, E.; Saldo, J.; Ferragut, V.; Guamis, B. Application of High Pressure Treatment for Cheese Production. Food Res. Int. 2000, 33, 311–316. [Google Scholar] [CrossRef]

- Juan, B.; Ferragut, V.; Buffa, M.; Guamis, B.; Trujillo, A.J. Effects of High Pressure on Proteolytic Enzymes in Cheese: Relationship with the Proteolysis of Ewe Milk Cheese. J. Dairy Sci. 2007, 90, 2113–2125. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Fontes, L.; Lima, M.J. Evaluation of Texture in Serra Da Estrela Cheese Manufactured in Different Dairies. Open Agric. 2019, 4, 475–486. [Google Scholar] [CrossRef]

- Batty, D.; Meunier-Goddik, L.; Waite-Cusic, J.G. Camembert-Type Cheese Quality and Safety Implications in Relation to the Timing of High-Pressure Processing during Aging. J. Dairy Sci. 2019, 102, 8721–8733. [Google Scholar] [CrossRef]

- Bourne, M. Food Texture & Viscosity: Concept and Measuremente; Academic Press: Cambridge, MA, USA, 2002; ISBN 0121190625. [Google Scholar]

- Arqués, J.L.; Garde, S.; Fernández-García, E.; Gaya, P.; Nuñez, M. Volatile Compounds, Odor, and Aroma of La Serena Cheese High-Pressure Treated at Two Different Stages of Ripening. J. Dairy Res. 2007, 90, 3627–3639. [Google Scholar] [CrossRef]

- Calzada, J.; Del Olmo, A.; Picon, A.; Gaya, P.; Nuñez, M. High-Pressure Processing for the Control of Lipolysis, Volatile Compounds and Off-Odours in Raw Milk Cheese. Food Bioproc. Tech. 2014, 7, 2207–2217. [Google Scholar] [CrossRef]

- Calzada, J.; Del Olmo, A.; Picon, A.; Nuñez, M. Effect of High Pressure Processing on the Lipolysis, Volatile Compounds, Odour and Colour of Cheese Made from Unpasteurized Milk. Food Bioproc. Tech. 2015, 8, 1076–1088. [Google Scholar] [CrossRef]

| Property | Storage Time (Months) | ChC | P1 600 MPa/6′ | P2 450 MPa/6′ | P3 450 MPa/9′ |

|---|---|---|---|---|---|

| Activity for Leu-p-Na * | 0 | 11.0 ± 0.8 a,A | 11.2 ± 0.5 a,B | 10.4 ± 0.8 a,A | 10.4 ± 0.8 a,A |

| 3 | 9.8 ± 0.6 b,B | 14.2 ± 0.6 a,A | 10.1 ± 0.8 b,A | 10.6 ± 0.2 b,A | |

| 6 | 7.9 ± 0.5 c,C | 13.3 ± 0.6 a,A | 8.2 ± 0.3 c,B | 9.8 ± 0.4 b,A | |

| 15 | 5.3 ± 0.8 c,D | 10.2 ± 0.9 a,B | 6.7 ± 0.4 b,C | 6.6 ± 0.6 b,B | |

| Activity for Lys-p-Na # | 0 | 21.9 ± 2.5 c,A | 28.0 ± 4.1 b,A | 34.9 ± 3.7 a,A | 20.8 ± 2.6 c,A |

| 3 | 7.2 ± 1.4 c,B | 20.6 ± 1.3 a,B | 13.7 ± 2.2 b,B | 17.6 ± 4.0 a,A,B | |

| 6 | 7.7 ± 0.3 d,B | 19.7 ± 2.1 a,B,C | 13.5 ± 0.7 c,B | 15.7 ± 1.2 b,B,C | |

| 15 | 9.0 ± 1.6 b,B | 16.2 ± 1.5 a,C | 15.8 ± 3.8 a,B | 13.0 ± 0.6 a,C |

| Property |

Storage Time (Months) | ChC |

P1 600 MPa/6 min |

P2 450 MPa/6 min |

P3 450 MPa/9 min |

|---|---|---|---|---|---|

| Hardness (N) | 0 | 0.16 ± 0.03 a,B,C | 0.12 ± 0.03 a,C | 0.12 ± 0.05 a,A | 0.14 ± 0.04 a,C |

| 1.5 | 0.19 ± 0.04 a,b,B | 0.22 ± 0.09 a,A,B | 0.14 ± 0.07 b,A | 0.20 ± 0.04 a,b,B | |

| 3 | 0.12 ± 0.01 b,C,D | 0.20 ± 0.02 a,B | 0.10 ± 0.04 b,A | 0.12 ± 0.04 a,C | |

| 6 | 0.25 ± 0.08 a,A | 0.28 ± 0.06 a,A | 0.14 ± 0.02 b,A | 0.26 ± 0.03 a,A | |

| 15 | 0.11 ± 0.01 c,D | 0.22 ± 0.04 a,A,B | 0.12 ± 0.01 c,A | 0.18 ± 0.03 b,B | |

| Consistency (N/s) | 0 | 0.96 ± 0.25 a,B,C | 0.92 ± 0.33 a,C | 1.1 ± 0.57 a,A | 1.2 ± 0.47 a,C,D |

| 1.5 | 1.4 ± 0.37 b,c,B | 1.8 ± 0.88 b,A,B | 1.0 ± 0.65 c,A | 2.7 ± 0.64 a,B | |

| 3 | 0.72 ± 0.26 b,C,D | 1.5 ± 0.19 a,B | 0.68 ± 0.31 b,A | 0.89 ± 0.34 b,D | |

| 6 | 1.9 ± 0.76 a,A | 2.1 ± 0.54 a,A | 1.1 ± 0.14 b,A | 1.9 ± 0.32 a,A | |

| 15 | 0.67 ± 0.10 c,D | 1.6 ± 0.28 a,A,B | 0.78 ± 0.17 c,A | 1.3 ± 0.25 b,B,C | |

| Adhesiveness (N/s) | 0 | 0.16 ± 0.08 a,D | 0.16 ± 0.09 a,D | 0.25 ± 0.18 a,B,C | 0.15 ± 0.05 a,C |

| 1.5 | 0.36 ± 0.13 a,b,B | 0.53 ± 0.27 b,B,C | 0.26 ± 0.17 a,B,C | 0.38 ± 0.12 a,b,C | |

| 3 | 0.18 ± 0.05 a,C,D | 0.48 ± 0.09 c,C | 0.18 ± 0.10 a,C | 0.30 ± 0.05 b,C | |

| 6 | 0.82 ± 0.26 b,A | 0.97 ± 0.26 a,A | 0.47 ± 0.09 b,A | 0.89 ± 0.19 b,A | |

| 15 | 0.33 ± 0.06 a,B,C | 0.72 ± 0.16 b,B | 0.39 ± 0.06 a,A,B | 0.68 ± 0.16 b,B | |

| Cohesiveness | 0 | 0.56 ± 0.12 a,B | 0.47 ± 0.06 a,B | 0.56 ± 0.11 a,B | 0.54 ± 0.19 a,B |

| (dimensionless) | 1.5 | 0.72 ± 0.14 a,A | 0.73 ± 0.15 a,A | 0.61 ± 0.24 a,B | 0.61 ± 0.11 a,B |

| 3 | 0.68 ± 0.11 a,A,B | 0.71 ± 0.12 a,A | 0.73 ± 0.08 a,A,B | 0.57 ± 0.08 a,B | |

| 6 | 0.76 ± 0.09 a,b,A,B | 0.73 ± 0.06 b,A | 0.73 ± 0.09 b,A,B | 0.82 ± 0.08 a,A | |

| 15 | 0.012 ± 0.003 b,C | 0.78 ± 0.07 a,A | 0.87 ± 0.14 a,A | 0.80 ± 0.09 a,A | |

| Gumminess (N) | 0 | 0.09 ± 0.03 a,B,C | 0.06 ± 0.02 a,C | 0.07 ± 0.04 a,A | 0.07 ± 0.04 a,C |

| 1.5 | 0.14 ± 0.04 a,A,B | 0.17 ± 0.09 b,A,B | 0.10 ± 0.07 b,A | 0.11 ± 0.04 a,b,B | |

| 3 | 0.08 ± 0.01 b,C | 0.14 ± 0.03 a,B | 0.07 ± 0.04 b,A | 0.07 ± 0.03 b,C | |

| 6 | 0.16 ± 0.09 a,A | 0.20 ± 0.04 a,A | 0.10 ± 0.01 b,A | 0.22 ± 0.03 a,A | |

| 15 | 0.001 ± 0.000 d,D | 0.17 ± 0.03 a,A,B | 0.10 ± 0.03 c,A | 0.14 ± 0.03 b,B |

| Months | P1 vs. ChC | P2 vs. ChC | P3 vs. ChC | |

|---|---|---|---|---|

| Appearance | ||||

| Colour | 0 | −0.38 ± 1.19 | −0.88 ± 1.36 | −0.25 ± 0.89 |

| 1.5 | −1.22 ± 2.28 | −0.56 ± 1.74 | −1.11 ± 2.15 | |

| 6 | −0.90 ± 1.29 | −0.60 ± 1.58 | −1.00 ± 2.00 | |

| 15 | −1.00 ± 0.82 * | −1.00 ± 1.05 * | −1.00 ± 0.94 * | |

| Consistency | 0 | −1.43 ± 2.70 | −1.29 ± 3.50 | −0.43 ± 2.23 |

| 1.5 | 0.89 ± 2.21 | 1.00 ± 2.18 | 0.67 ± 2.06 | |

| 6 | 1.50 ± 2.72 | 0.20 ± 2.74 | −0.20 ± 1.87 | |

| 15 | 0.30 ± 1.06 | −1.40 ± 1.27 * | −0.70 ± 1.06 | |

| Odour | ||||

| Lactic | 0 | −0.57 ± 1.13 | 0.00 ± 1.29 | −0.29 ± 1.98 |

| 1.5 | −0.10 ± 1.52 | −0.10 ± 2.42 | 0.50 ± 2.22 | |

| 6 | −0.90 ± 2.89 | −0.40 ± 1.35 | −0.50 ± 1.43 | |

| 15 | −0.30 ± 1.25 | −0.20 ± 2.15 | −0.60 ± 1.84 | |

| Acid | 0 | −0.75 ± 1.91 | −0.13 ± 1.96 | 0.13 ± 1.73 |

| 1.5 | −0.30 ± 1.16 | −2.10 ± 1.52 * | −1.80 ± 1.93 * | |

| 6 | 0.50 ± 2.46 | −0.20 ± 1.55 | 0.50 ± 1.43 | |

| 15 | 0.00 ± 1.00 | 1.00 ± 2.18 | 0.33 ± 1.23 | |

| Animal | 0 | 0.43 ± 1.72 | −0.71 ± 0.95 | −0.29 ± 1.11 |

| 1.5 | −0.20 ± 1.62 | −1.10 ± 2.08 | −0.70 ± 2.00 | |

| 6 | −0.60 ± 1.78 | −0.10 ± 1.73 | −0.20 ± 1.48 | |

| 15 | −0.44 ± 0.73 | −0.78 ± 1.09 | −0.44 ± 1.01 | |

| SCFA | 0 | 0.13 ± 1.73 | 0.13 ± 2.53 | −0.38 ± 1.77 |

| 1.5 | −0.80 ± 1.40 | −1.90 ± 1.52 * | −0.80 ± 1.87 | |

| 6 | −0.78 ± 2.17 | −0.44 ± 0.88 | −0.22 ± 1.72 | |

| 15 | 0.60 ± 2.12 | 0.30 ± 3.65 | −0.10 ± 2.23 | |

| Texture | ||||

| Consistency | 0 | −0.71 ± 1.25 | −0.86 ± 0.90 | 0.00 ± 1.29 |

| 1.5 | 0.11 ± 1.36 | 0.33 ± 1.80 | 0.67 ± 1.23 | |

| 6 | 1.30 ± 1.57 | −1.10 ± 1.52 | −0.40 ± 1.51 | |

| 15 | 1.00 ± 0.94 * | −2.00 ± 0.67 * | −0.20 ± 0.79 | |

| Friability | 0 | 0.38 ± 1.06 | 0.13 ± 0.84 | 0.50 ± 1.07 |

| 1.5 | 0.40 ± 1.17 | 0.40 ± 0.97 | 0.30 ± 0.68 | |

| 6 | 0.50 ± 0.85 | −0.30 ± 0.68 | −0.30 ± 0.68 | |

| 15 | 0.50 ± 1.08 | −1.00 ± 1.70 | −0.40 ± 0.70 | |

| Taste | ||||

| Salty | 0 | −0.71 ± 1.80 | −1.00 ± 2.24 | −1.14 ± 1.77 |

| 1.5 | 0.00 ± 1.58 | −0.22 ± 1.72 | −0.89 ± 1.69 | |

| 6 | −1.00 ± 1.66 | −0.11 ± 0.93 | −0.56 ± 1.74 | |

| 15 | −1.89 ± 2.03 * | −0.56 ± 1.94 | −0.11 ± 2.09 | |

| Acid | 0 | 2.33 ± 0.56 | 1.19 ± 0.18 | 1.25 ± 0.79 |

| 1.5 | 1.16 ± 0.09 | 0.92 ± 0.51 | 1.25 ± 0.47 | |

| 6 | 1.67 ± 0.45 | 1.87 ± 0.61 | 1.05 ± 0.76 | |

| 15 | 1.64 ± 0.58 * | 1.99 ± 0.76 * | 1.16 ± 1.00 | |

| Bitter | 0 | 0.50 ± 1.60 | −0.63 ± 1.41 | −0.13 ± 1.36 |

| 1.5 | 0.70 ± 0.71 | 0.20 ± 1.55 | 0.30 ± 1.77 | |

| 6 | −0.44 ± 2.50 | −0.33 ± 1.39 | −0.11 ± 1.00 | |

| 15 | −0.30 ± 2.44 | 0.20 ± 2.00 | 0.00 ± 1.49 | |

| After-taste | 0 | −0.50 ± 1.60 | −0.38 ± 1.41 | 1.13 ± 1.36 |

| 1.5 | 0.25 ± 0.71 | 0.13 ± 1.55 | 0.63 ± 1.77 | |

| 6 | −0.67 ± 2.50 | −0.22 ± 1.39 | 0.00 ± 1.00 | |

| 15 | 1.75 ± 2.44 | 0.00 ± 2.00 | 0.75 ± 1.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inácio, R.S.; Monteiro, M.J.P.; Lopes-da-Silva, J.A.; Saraiva, J.A.; Gomes, A.M.P. Effect of High-Pressure Processing on Proteolysis, Texture and Sensorial Attributes of Raw Ewe’s Cheeses Throughout Storage. Appl. Sci. 2025, 15, 6562. https://doi.org/10.3390/app15126562

Inácio RS, Monteiro MJP, Lopes-da-Silva JA, Saraiva JA, Gomes AMP. Effect of High-Pressure Processing on Proteolysis, Texture and Sensorial Attributes of Raw Ewe’s Cheeses Throughout Storage. Applied Sciences. 2025; 15(12):6562. https://doi.org/10.3390/app15126562

Chicago/Turabian StyleInácio, Rita S., Maria J. P. Monteiro, José A. Lopes-da-Silva, Jorge A. Saraiva, and Ana M. P. Gomes. 2025. "Effect of High-Pressure Processing on Proteolysis, Texture and Sensorial Attributes of Raw Ewe’s Cheeses Throughout Storage" Applied Sciences 15, no. 12: 6562. https://doi.org/10.3390/app15126562

APA StyleInácio, R. S., Monteiro, M. J. P., Lopes-da-Silva, J. A., Saraiva, J. A., & Gomes, A. M. P. (2025). Effect of High-Pressure Processing on Proteolysis, Texture and Sensorial Attributes of Raw Ewe’s Cheeses Throughout Storage. Applied Sciences, 15(12), 6562. https://doi.org/10.3390/app15126562