Machine Learning-Driven Optimization of Machining Parameters Optimization for Cutting Forces and Surface Roughness in Micro-Milling of AlSi10Mg Produced by Powder Bed Fusion Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

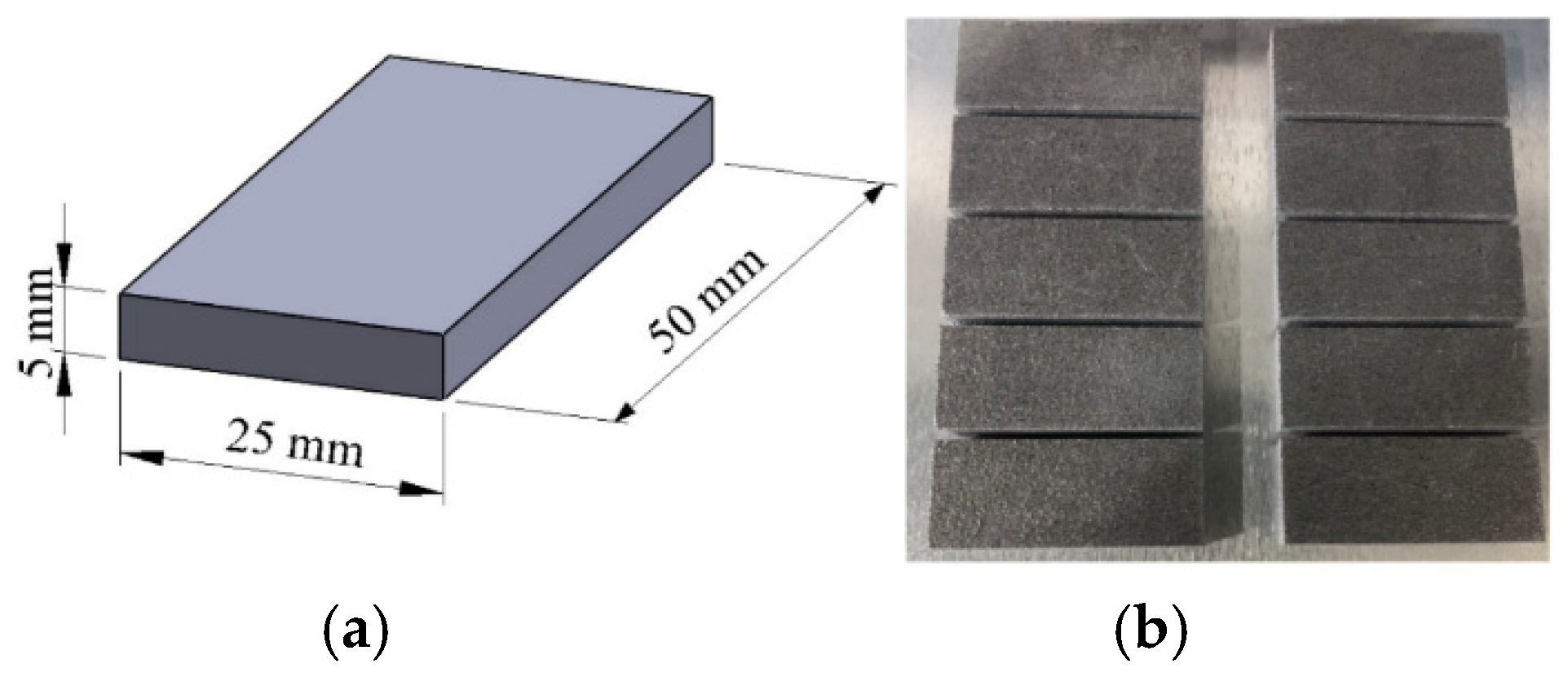

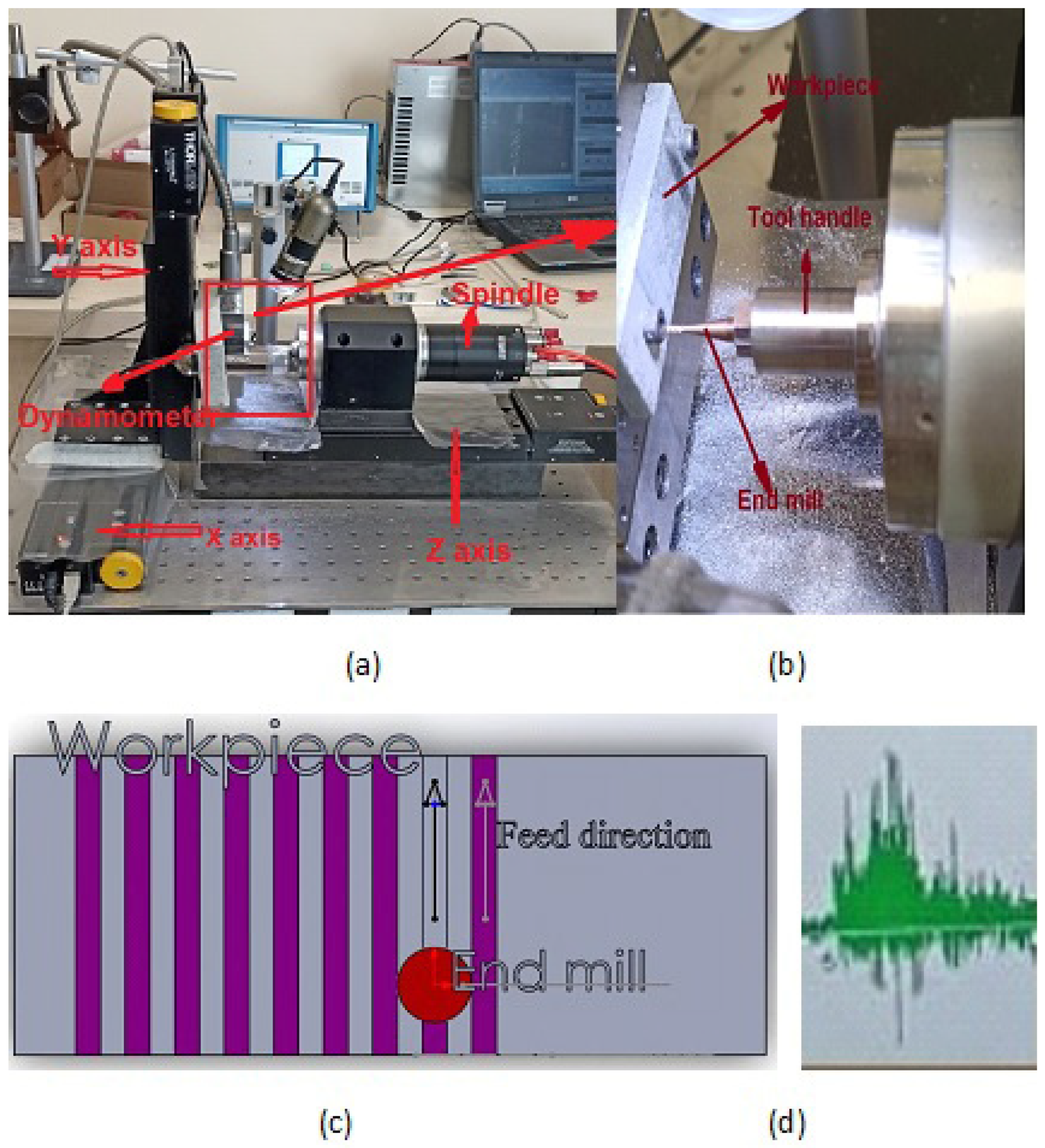

2.1. Material Specifications and Sample Preparation

2.2. Machine Learning Models

3. Results and Discussion

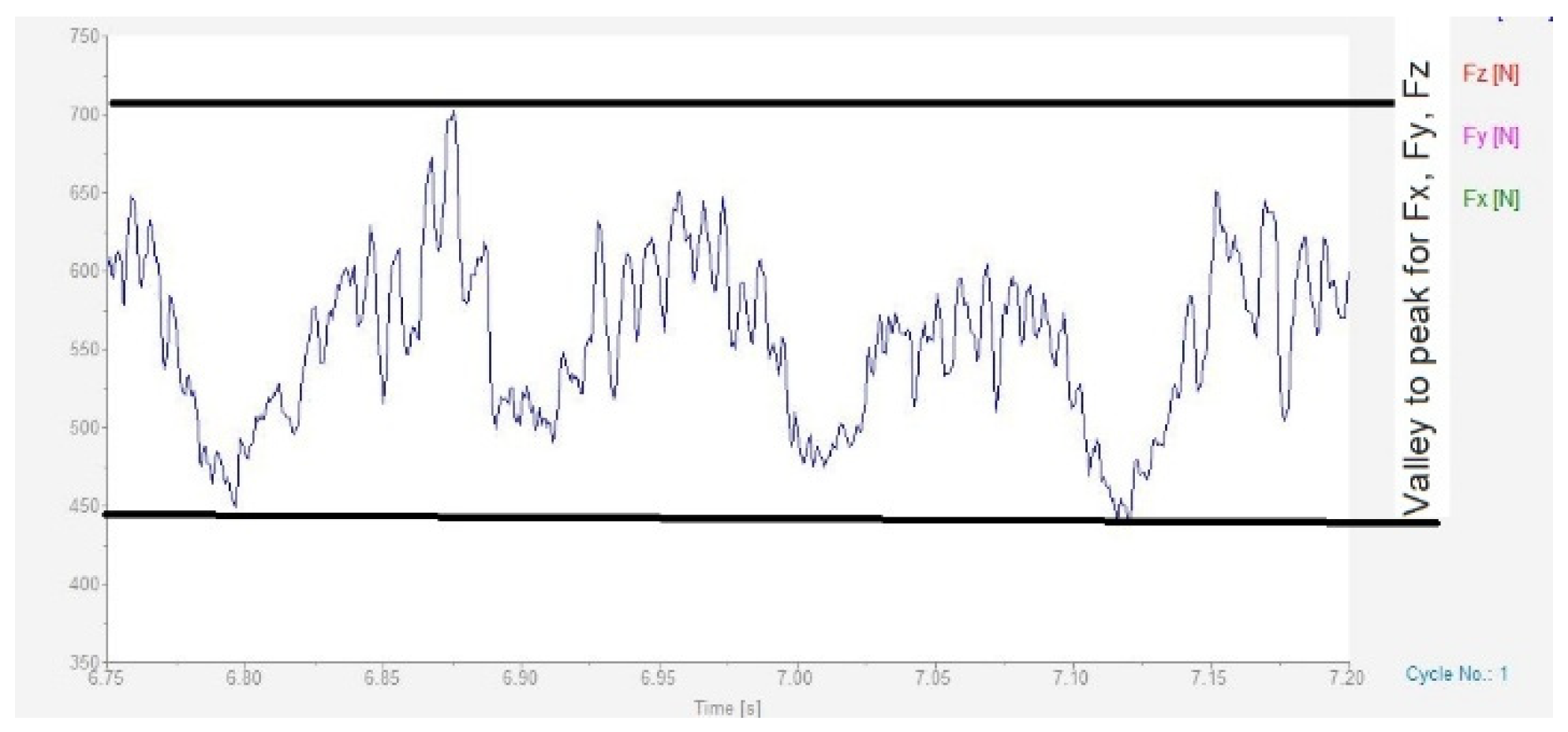

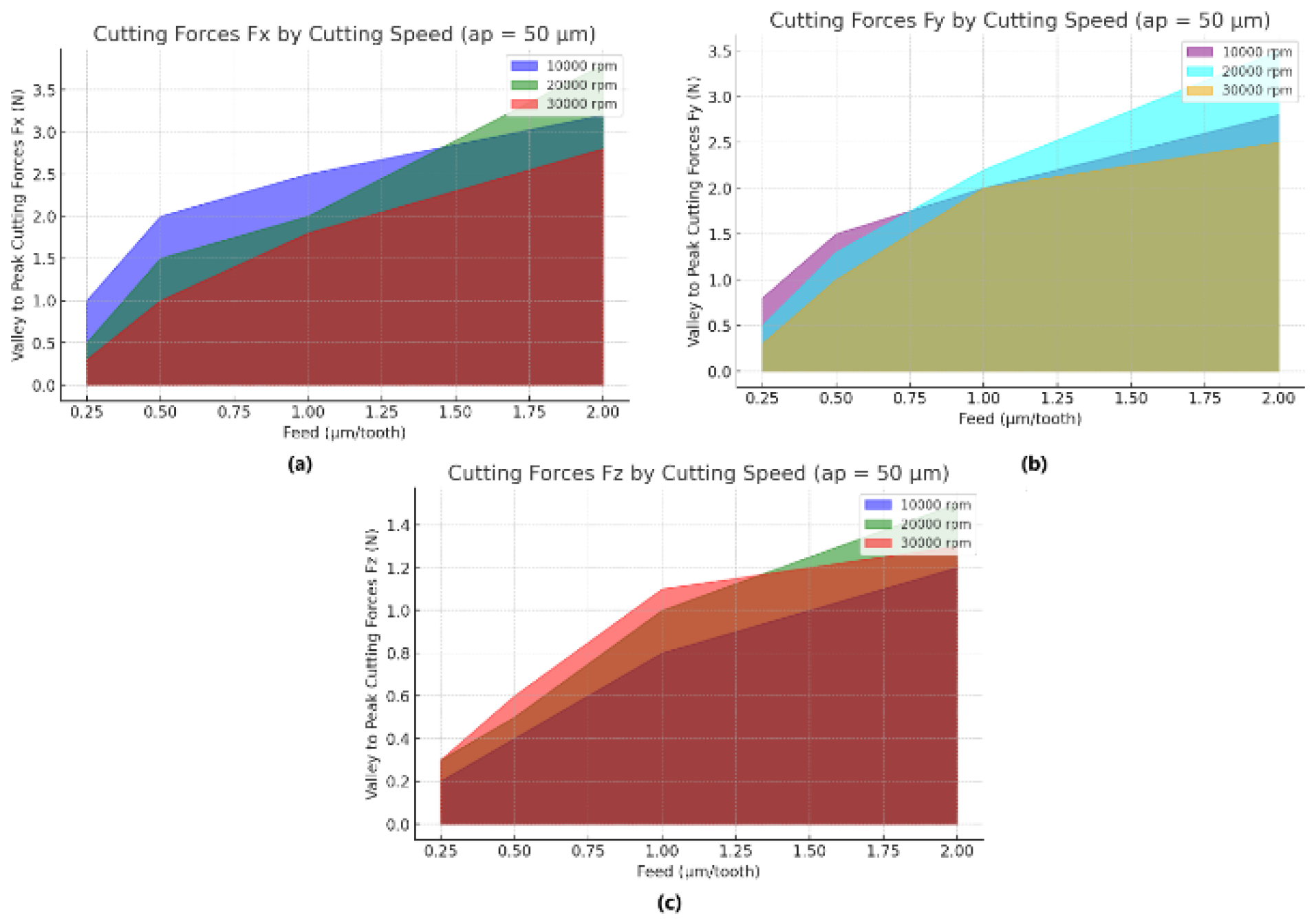

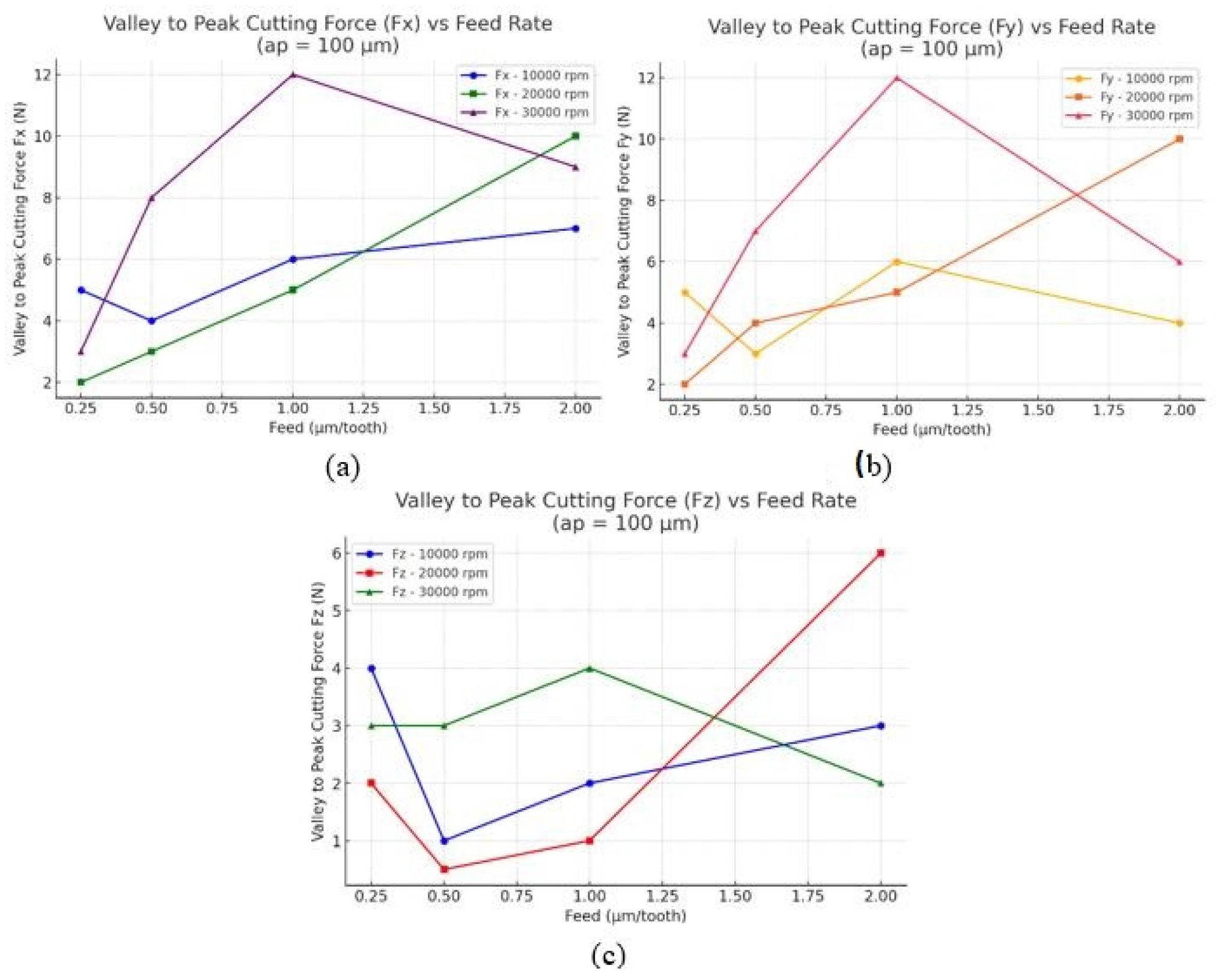

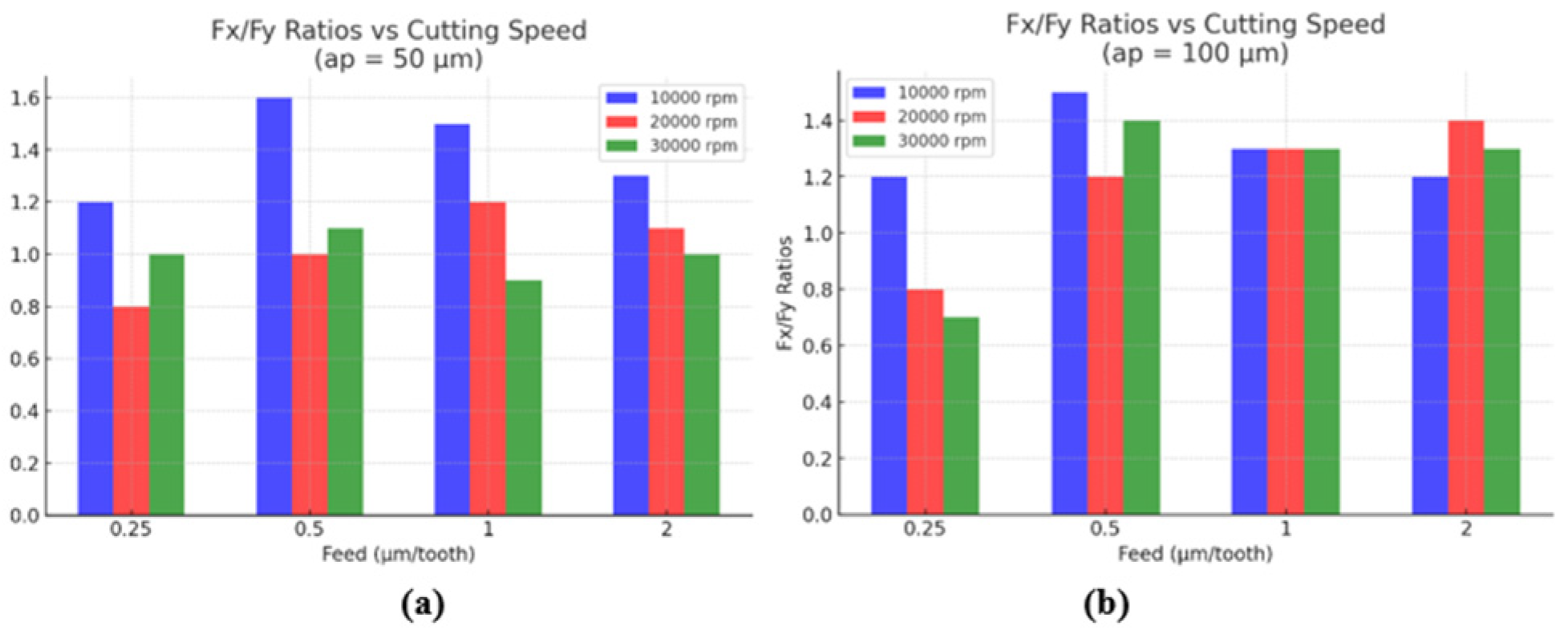

3.1. Effects of Cutting Parameters on Cutting Forces in Micro-Milling

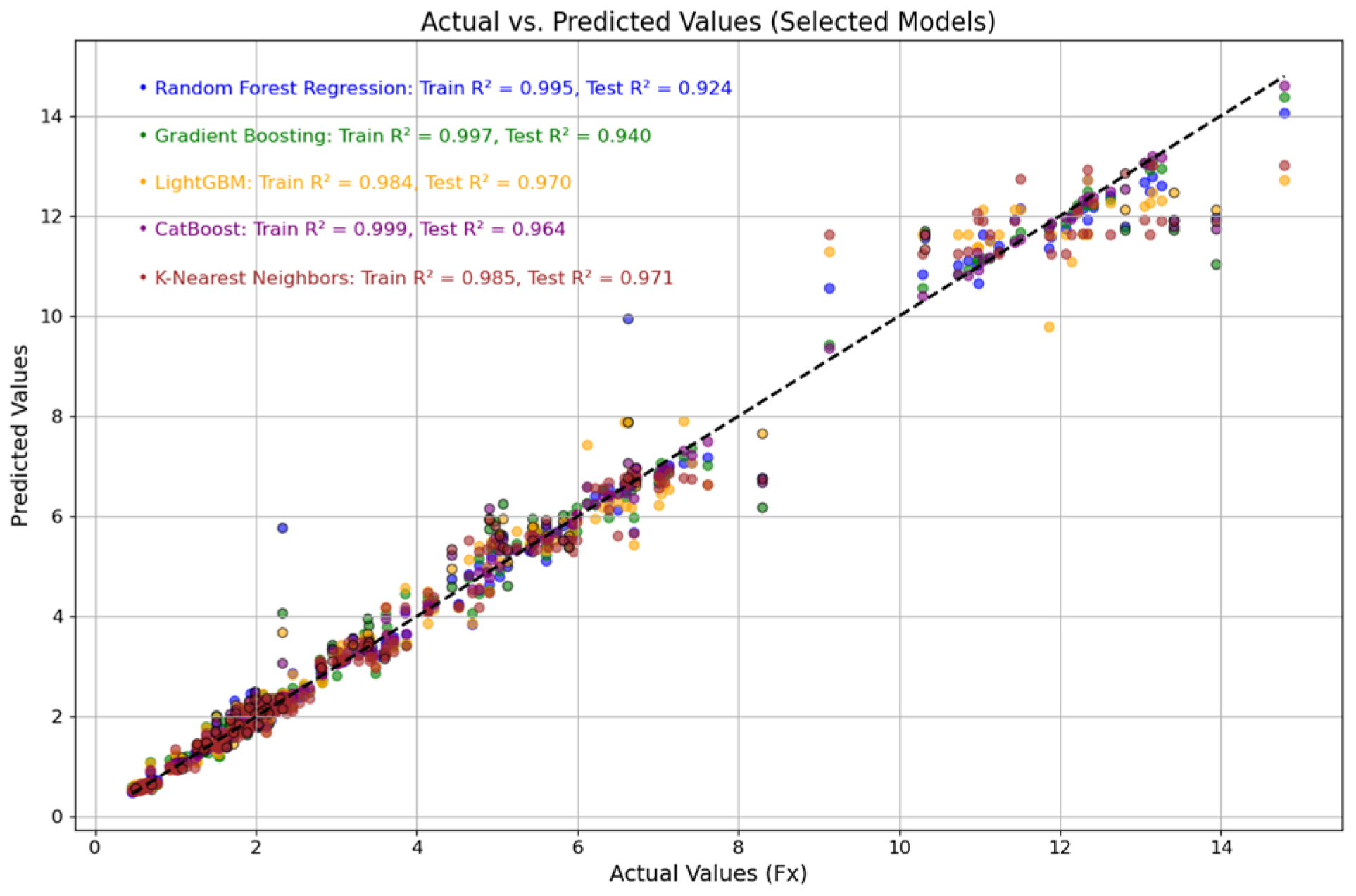

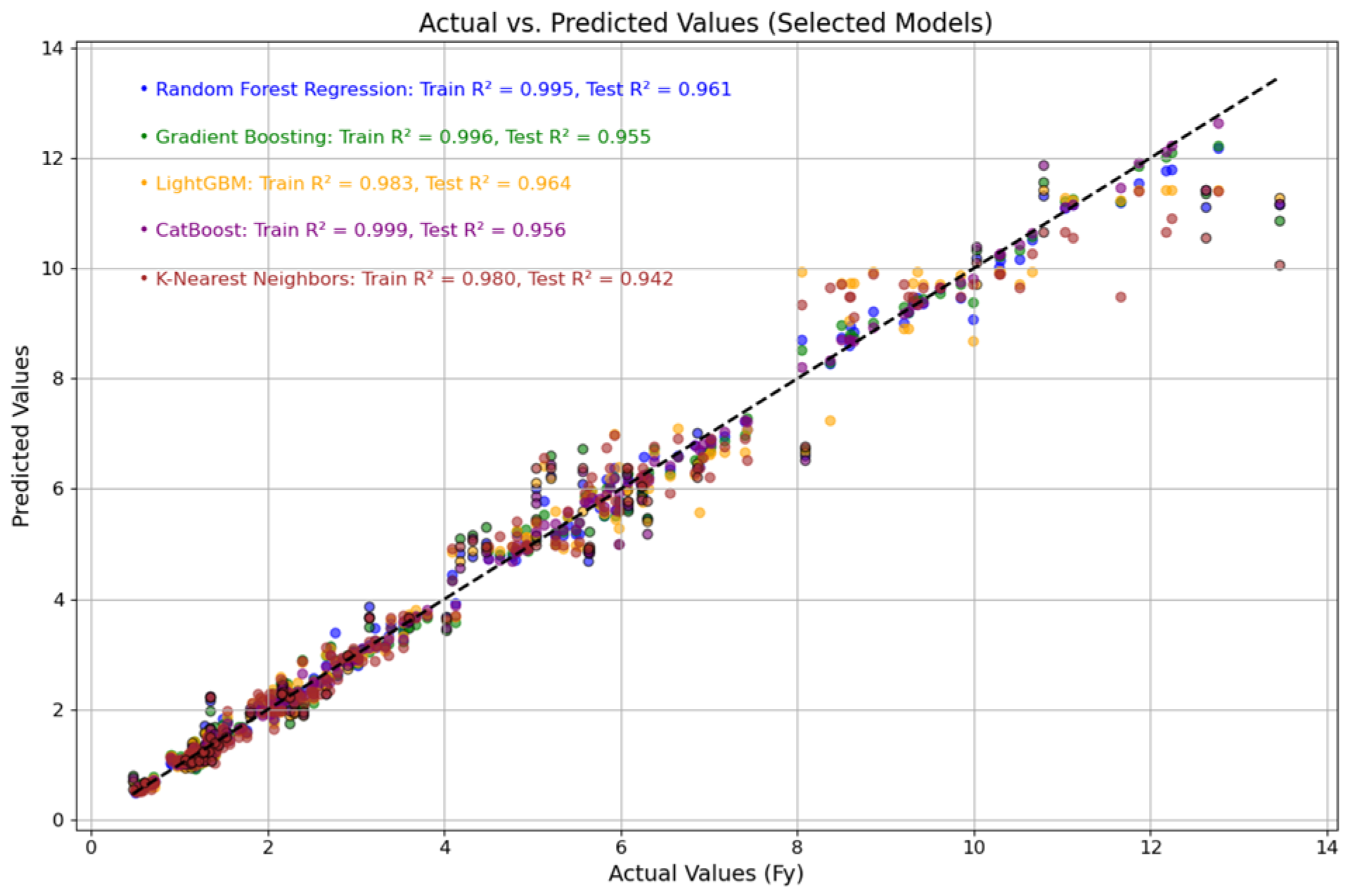

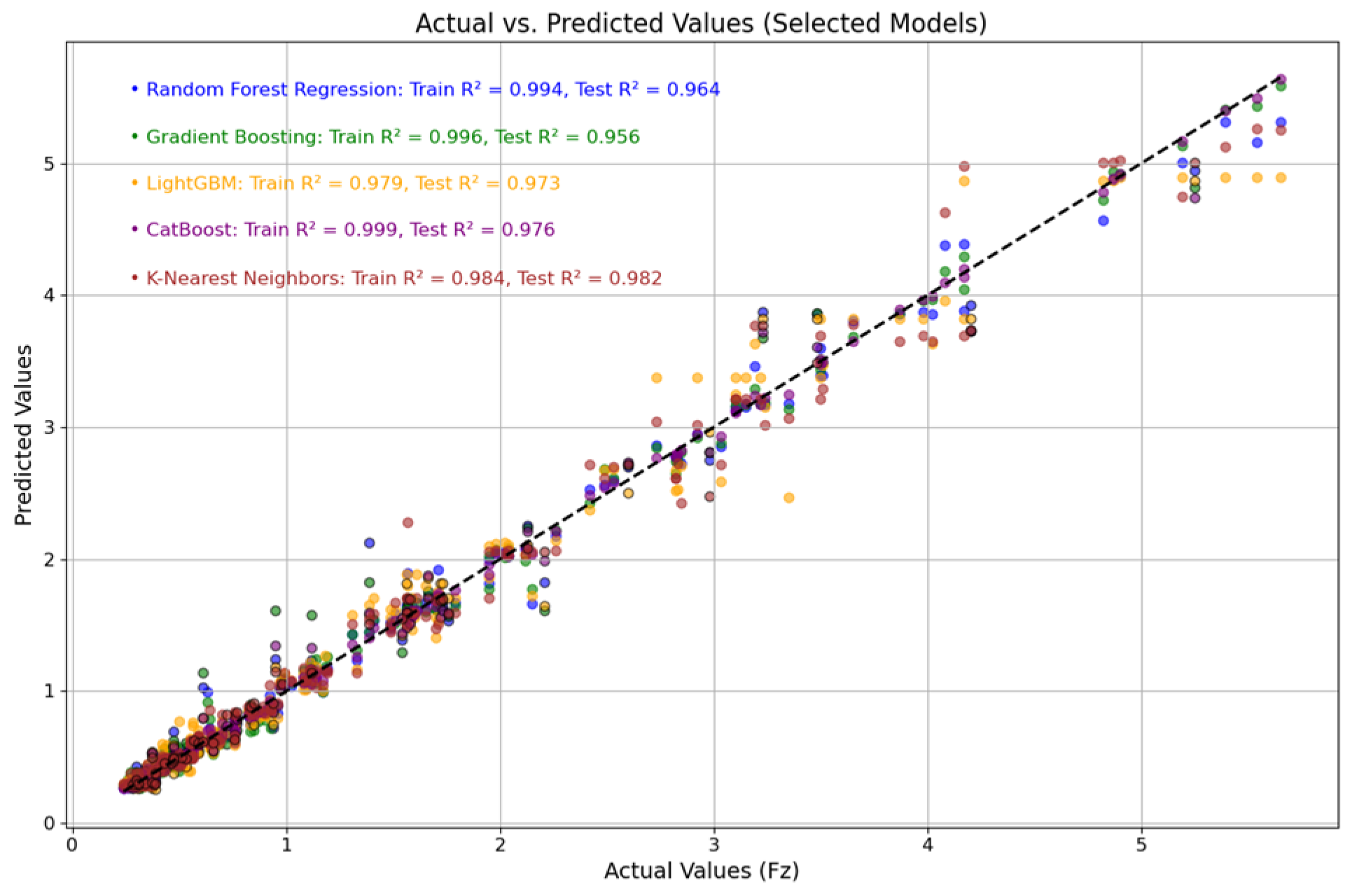

3.2. Predictive Modeling of Cutting Forces

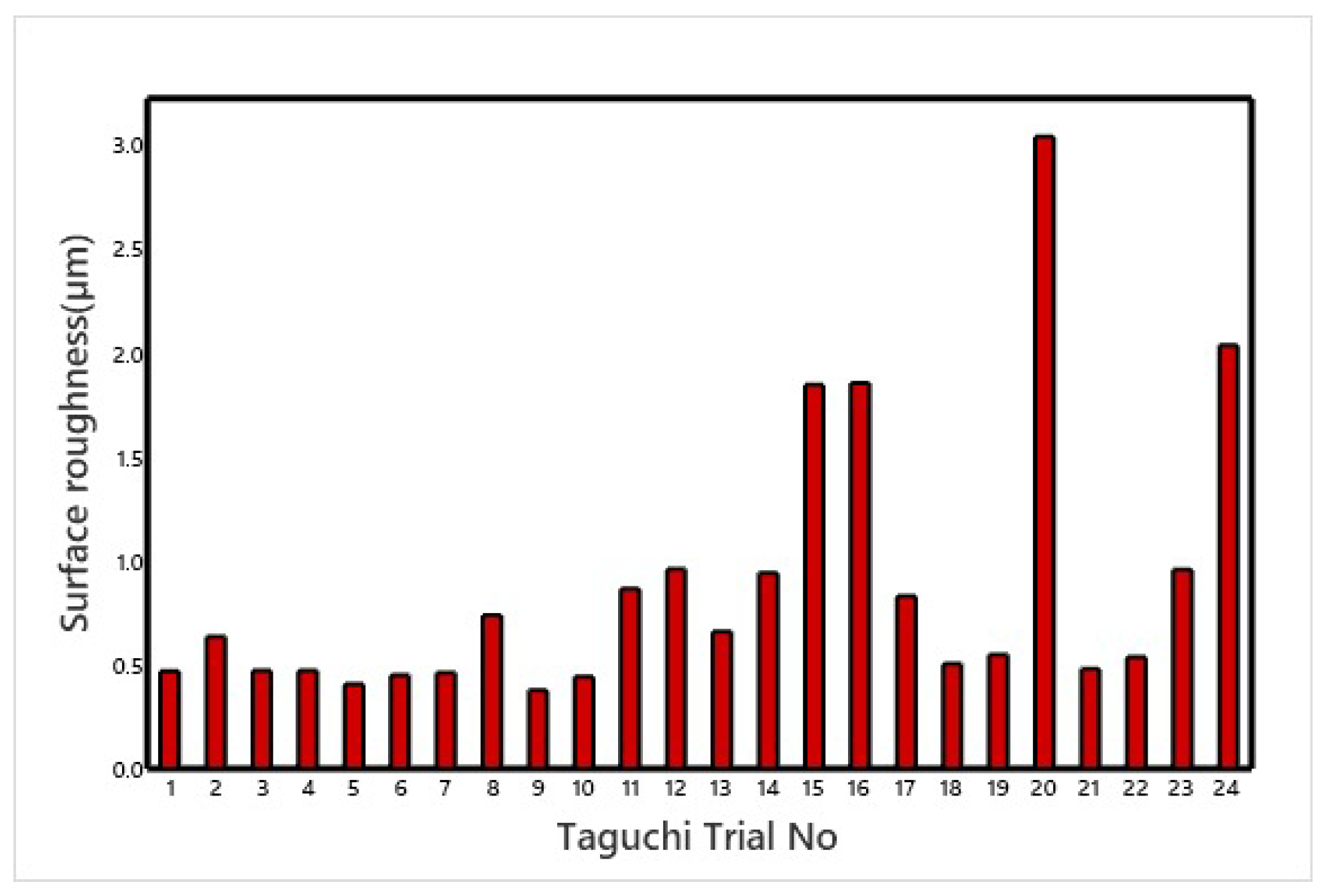

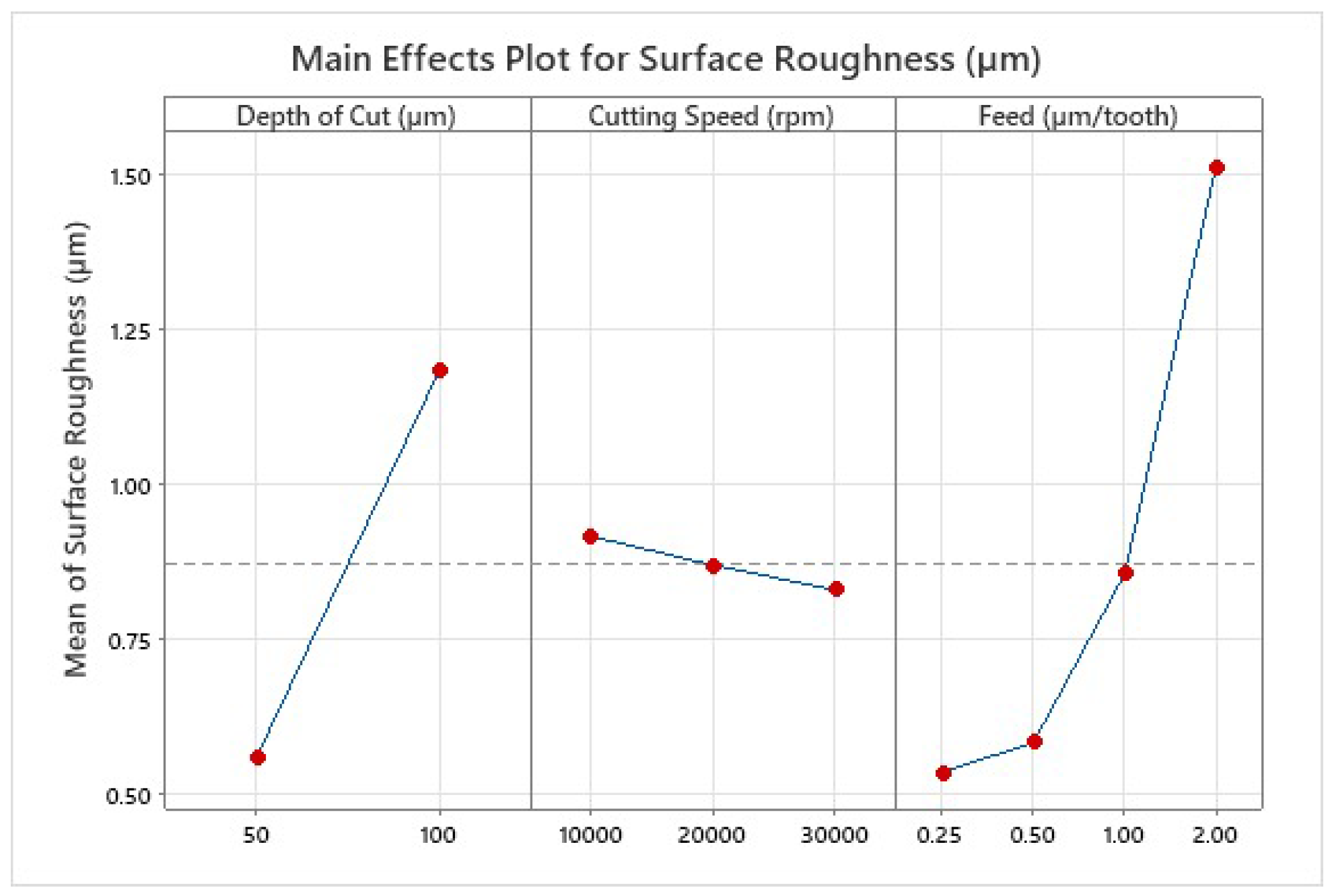

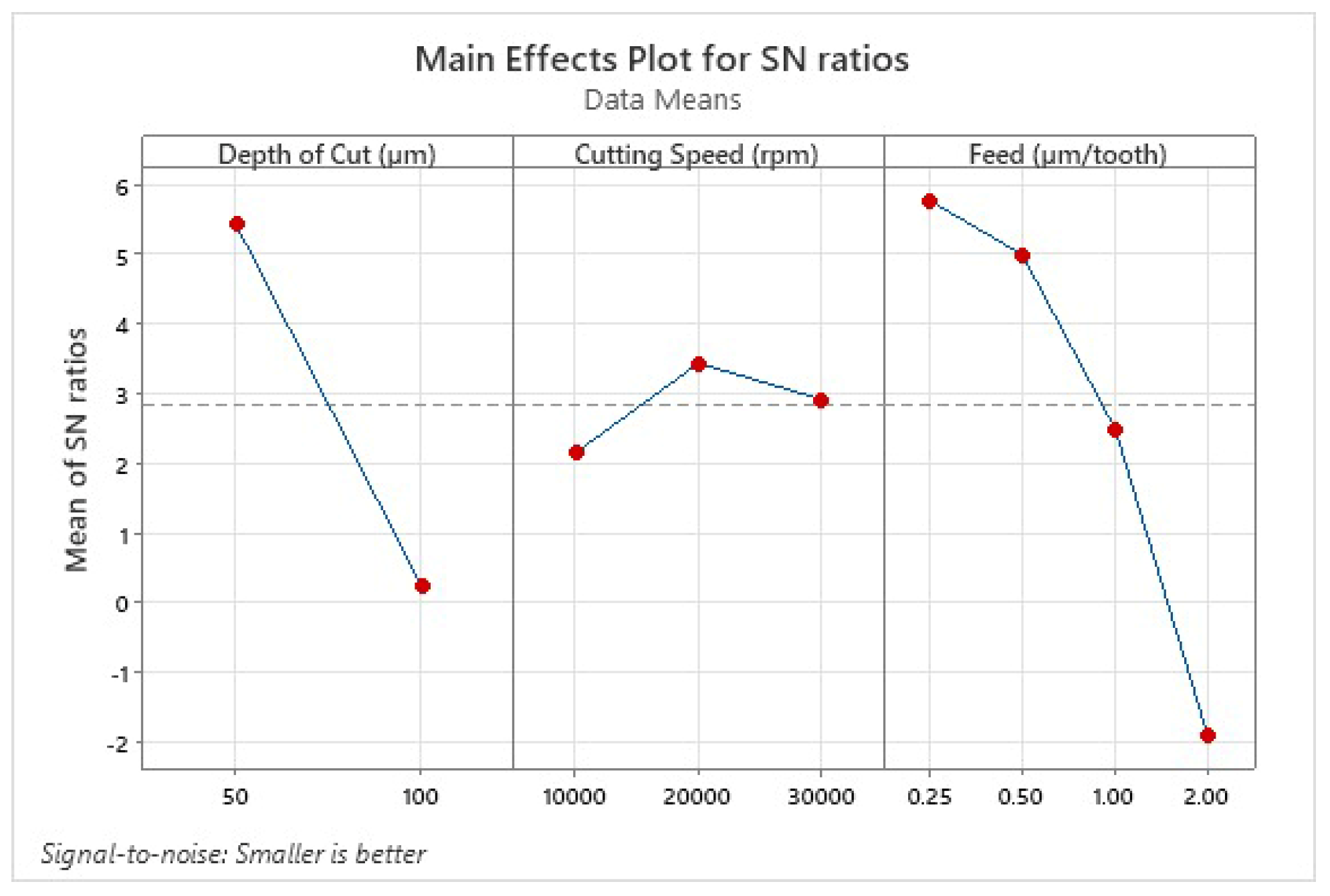

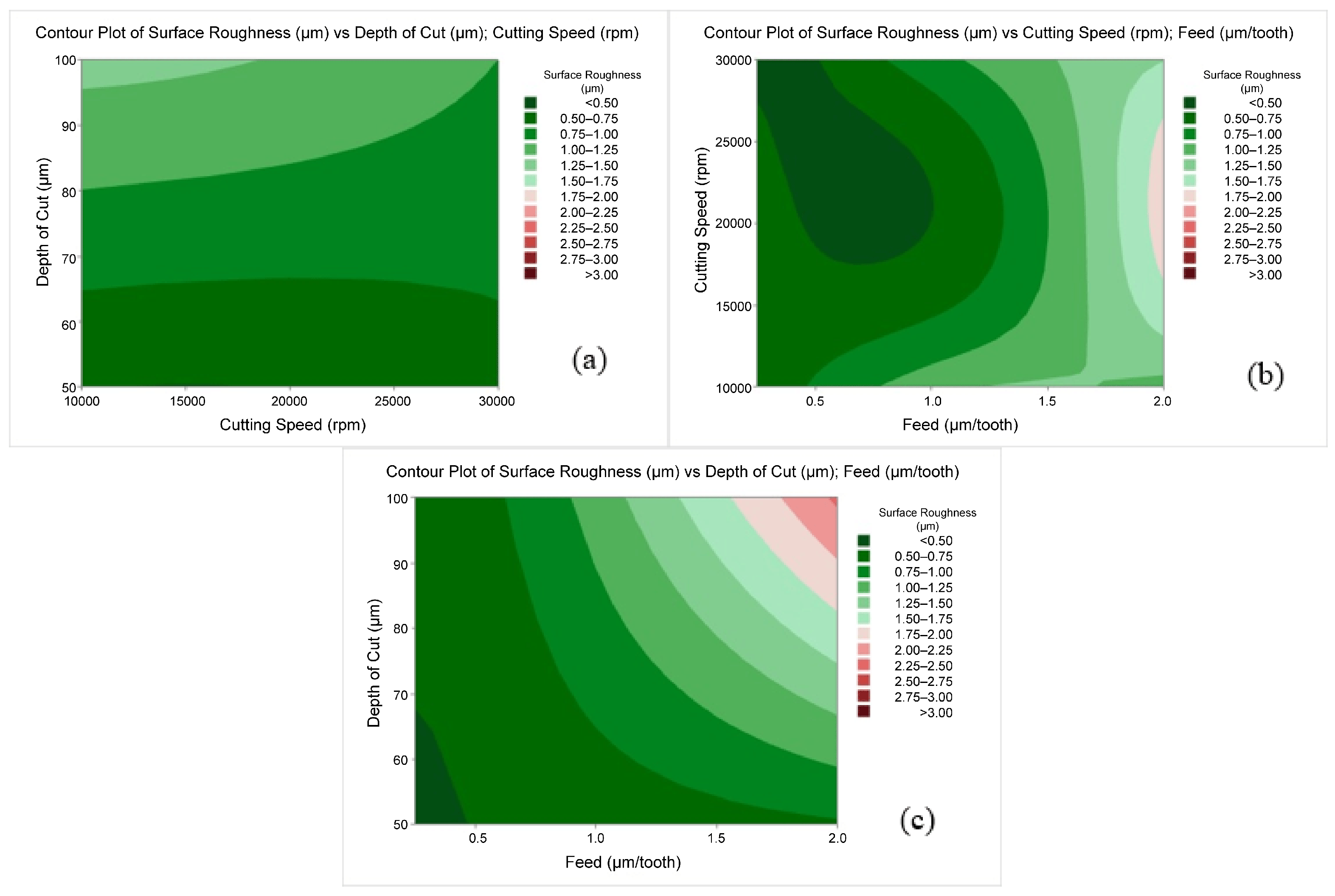

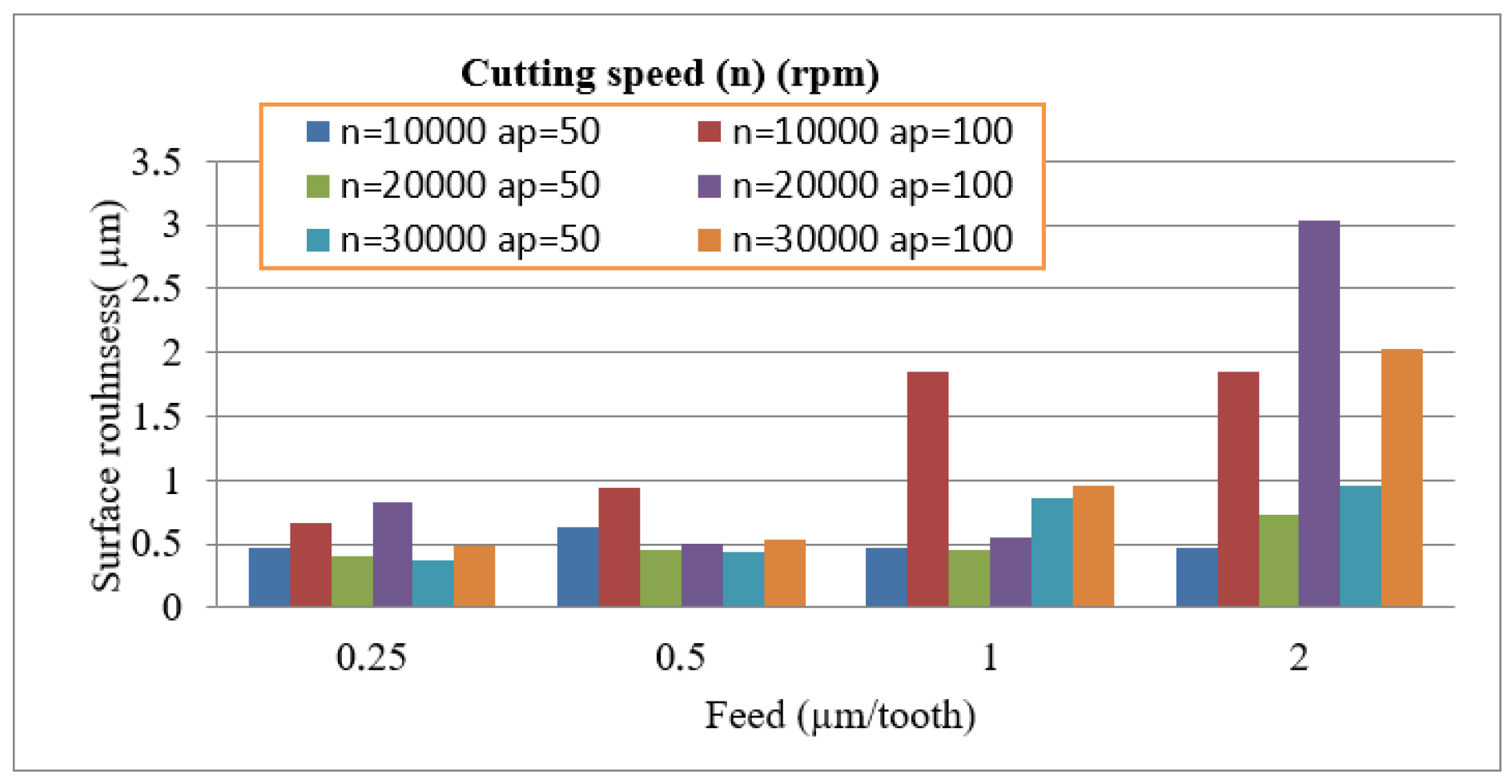

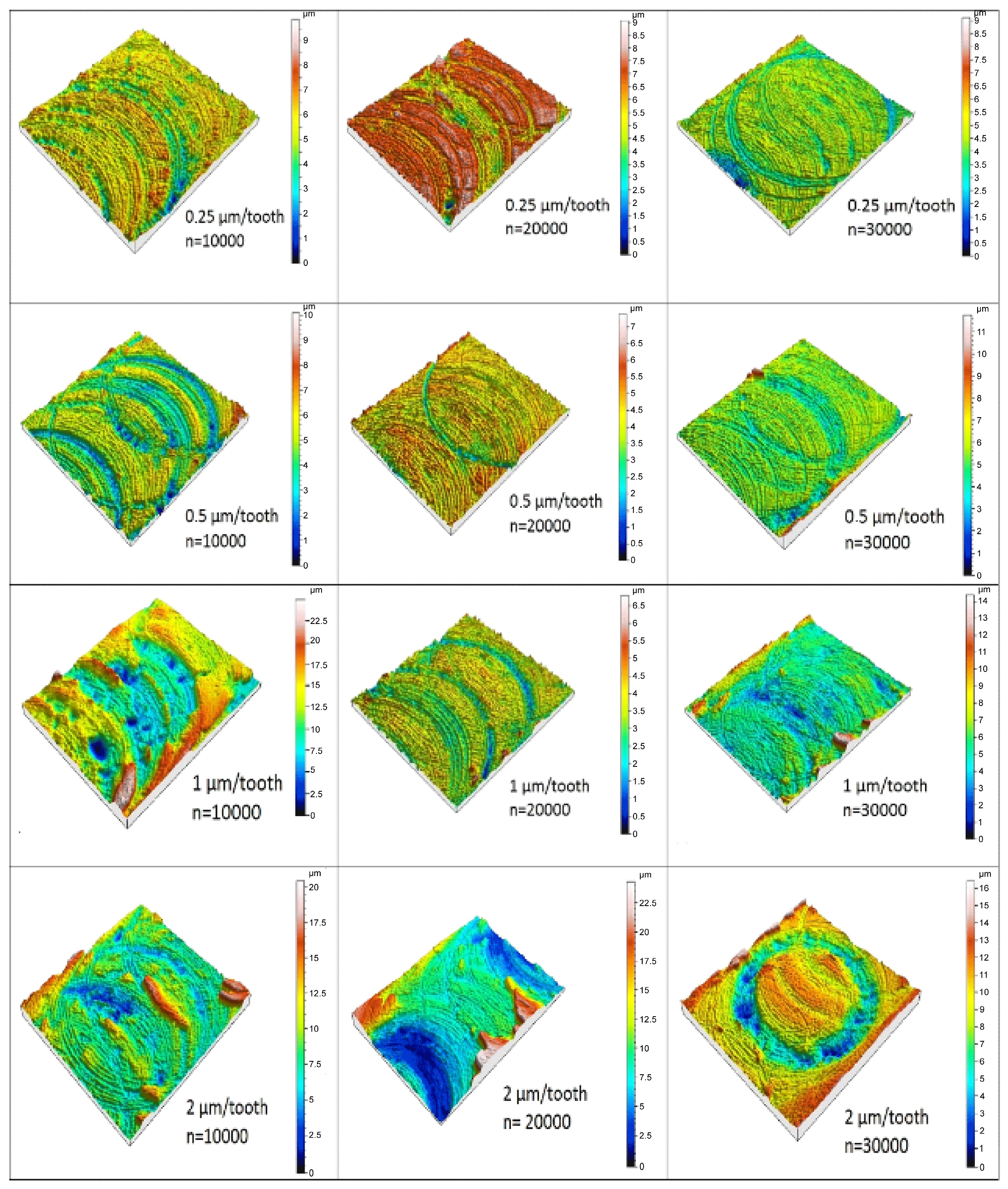

3.3. Effects of Cutting Parameters on Surface Roughness in Micro-Milling

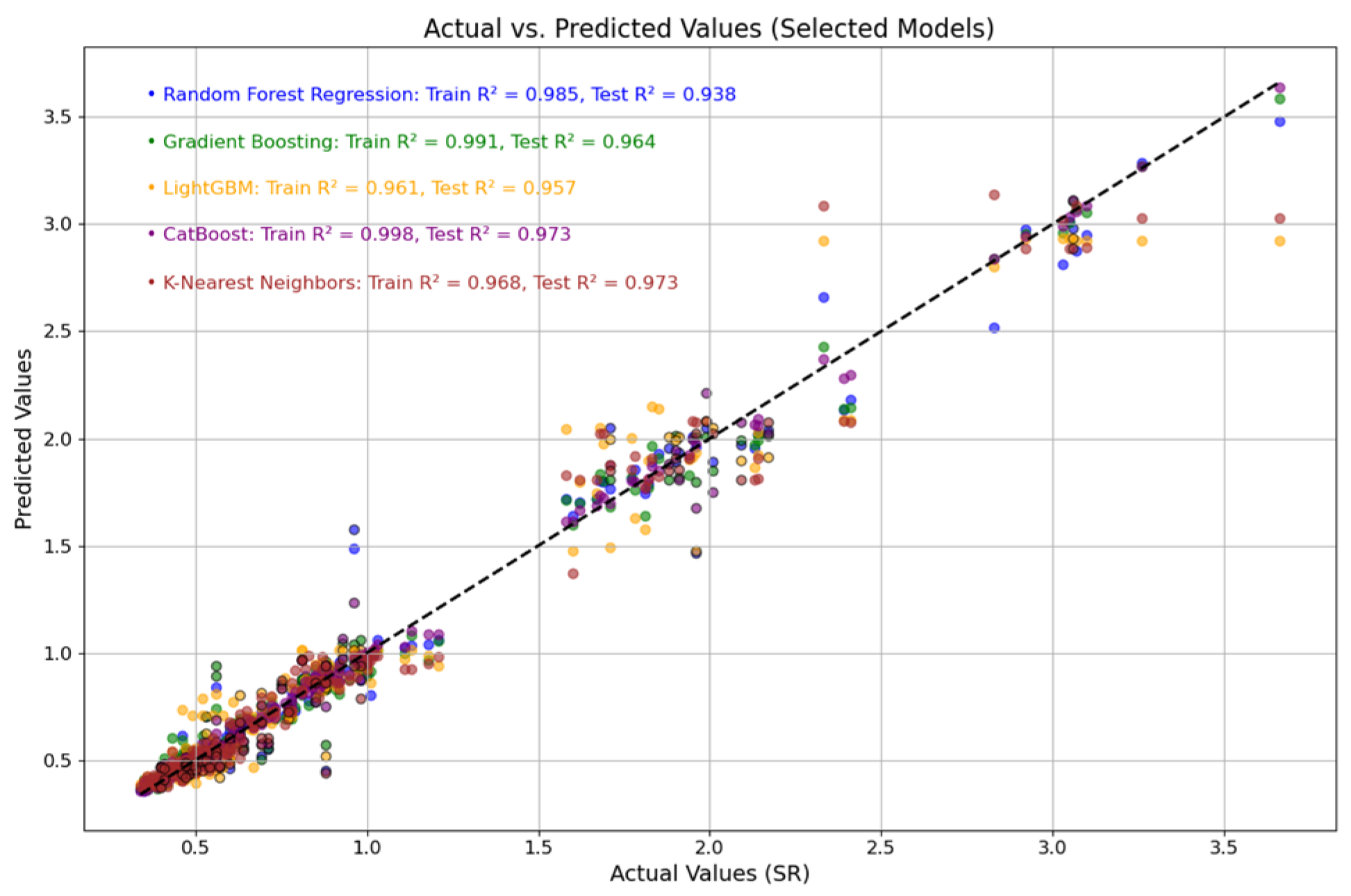

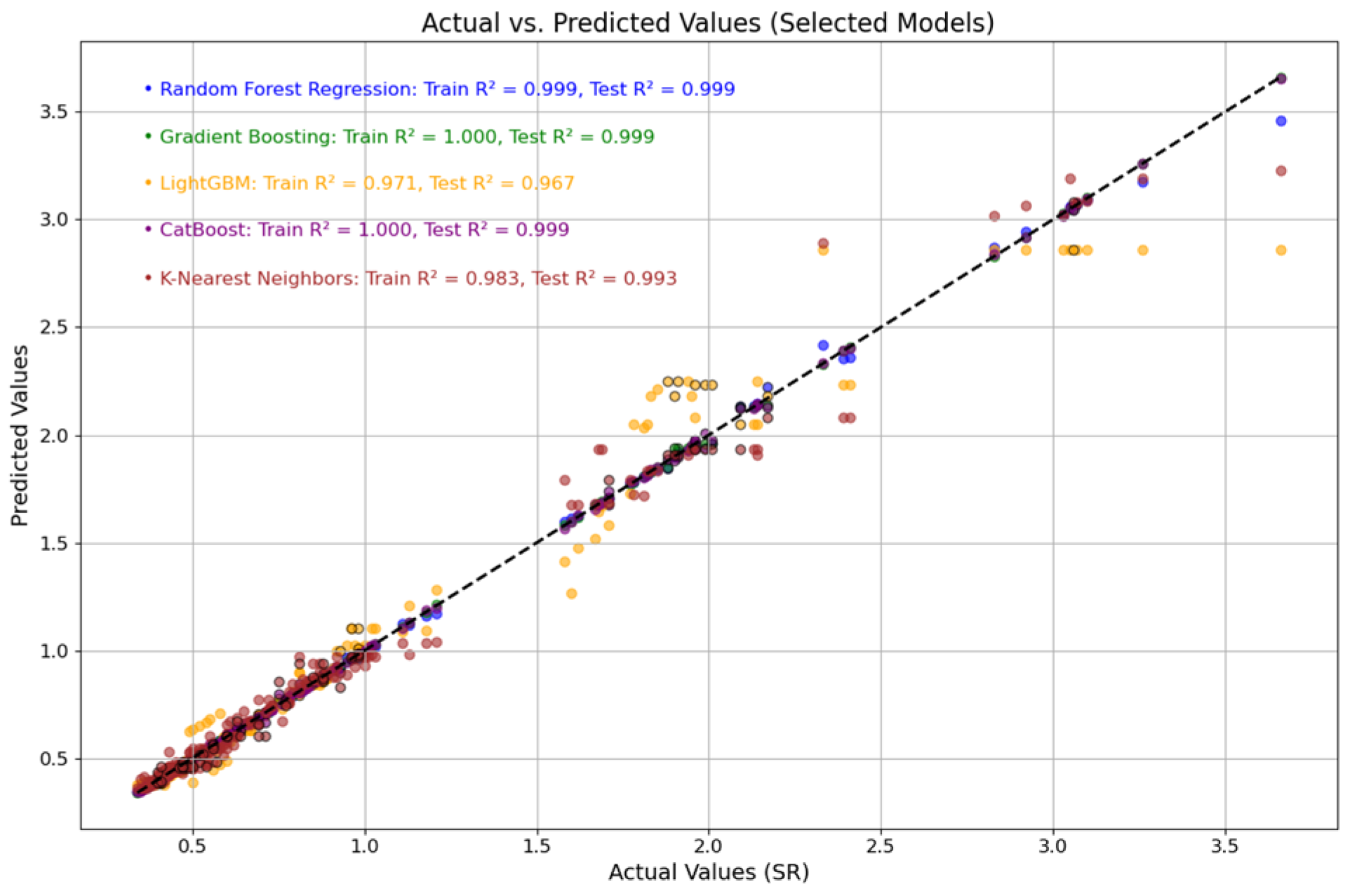

3.4. Predictive Modeling of Surface Roughness

3.5. Modeling Surface Roughness Based on Cutting Force Components

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Kushwaha, S.; Park, J.; Koric, S.; He, J.; Jasiuk, I.; Abueidda, D. Advanced deep operator networks to predict multiphysics solution fields in materials processing and additive manufacturing. Addit. Manuf. 2024, 88, 104266. [Google Scholar] [CrossRef]

- Brandão, A.D.; Gumpinger, J.; Gschweitl, M.; Seyfert, C.; Hofbauer, P.; Ghidini, T. Fatigue properties of additively manufactured AlSi10Mg-surface treatment effect. Procedia Struct. Integr. 2017, 7, 58–66. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Güler, S.; Serindağ, H.T.; Çam, G. Tel ark eklemeli imalat: Son gelişmeler ve değerlendirmeler. Mühendis Ve Makina 2022, 63, 82–116. [Google Scholar] [CrossRef]

- Singh, D.D.; Mahender, T.; Reddy, A.R. Powder bed fusion process: A brief review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- Khaing, M.W.; Fuh, J.Y.H.; Lu, L. Direct metal laser sintering for rapid tooling: Processing and characterization of EOS parts. J. Mater. Process. Technol. 2001, 113, 269–272. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Stutzman, P.E.; Ferraris, C.F.; Watson, S.S.; Peltz, M.A. Characterization of metal powders used for additive manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 460. [Google Scholar] [CrossRef]

- Shu, C.; Chen, S.; Lei, P.; Shu, X.; Abdel-Wahab, A.; Essa, K. Effect and mechanism of powder morphology on mechanical properties of nickel-based metal matrix composites TiC-IN738LC in laser powder bed fusion. Prog. Addit. 2025, 1–19. [Google Scholar] [CrossRef]

- Li, H.; Brodie, E.G.; Hutchinson, C. Predicting the chemical homogeneity in laser powder bed fusion (LPBF) of mixed powders after remelting. Addit. Manuf. 2023, 65, 103447. [Google Scholar] [CrossRef]

- Akhai, S.; Rana, M. Taguchi-based grey relational analysis of abrasive water jet machining of Al-6061. Mater. Today Proc. 2022, 65, 3165–3169. [Google Scholar] [CrossRef]

- Thareja, P.; Akhai, S. Processing parameters of powder aluminium-fly ash P/M composites. J. Adv. Res. Manuf. Mater. Sci. Met. Eng. 2017, 4, 24–35. [Google Scholar]

- Akhai, S.; Srivastava, P.; Sharma, S. Developments in horizontal axis wind turbines-A brief review. J. Crit. Rev. 2020, 7, 255–260. [Google Scholar]

- Isaac, J.P.; Lee, S.; Thompson, S.; Saharan, A.; Shamsaei, N.; Tippur, H.V. Role of build orientation on quasi-static and dynamic fracture responses of additively manufactured AlF357 and AlSi10Mg alloys. Addit. Manuf. 2022, 59, 103080. [Google Scholar] [CrossRef]

- Narayanan, Y.S.; Nguyen, N.; Hosseini, A. Milling of additively manufactured AlSi10Mg with microstructural porosity defects, finite element modeling and experimental analysis. J. Manuf. Process. 2024, 118, 242–260. [Google Scholar] [CrossRef]

- Bolat, Ç.; Karakılınç, U.; Yalçın, B.; Öz, Y.; Yavaş, Ç.; Ergene, B.; Ercetin, A.; Akkoyun, F. Effect of drilling parameters and tool geometry on the thrust force and surface roughness of aerospace grade laminate composites. Micromachines 2023, 14, 1427. [Google Scholar] [CrossRef]

- Mallick, P.S.; Pratap, A.; Patra, K. Review on cryogenic assisted micro-machining of soft polymer: An emphasis on molecular physics, chamber design, performance analysis and sustainability. J. Manuf. Process. 2022, 80, 930–957. [Google Scholar] [CrossRef]

- Tan, R.; Zhao, X.; Liu, Q.; Guo, X.; Lin, F.; Yang, L.; Sun, T. Investigation of surface integrity of selective laser melting additively manufactured AlSi10Mg alloy under ultrasonic elliptical vibration-assisted ultra-precision cutting. Materials 2022, 15, 8910. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Nguyen, V.H.; Le, T.T.; Nguyen, N.T. A hybridization of machine learning and NSGA-II for multi-objective optimization of surface roughness and cutting force in AISI 4340 alloy steel turning. J. Mach. Eng. 2023, 23, 133–153. [Google Scholar]

- Nguyen, A.T.; Nguyen, V.H.; Le, T.T.; Nguyen, N.T. Multiobjective Optimization of Surface Roughness and Tool Wear in High-Speed Milling of AA6061 by Machine Learning and NSGA-II. Adv. Mater. Sci. Eng. 2022, 2022, 5406570. [Google Scholar] [CrossRef]

- Yeganefar, A.; Niknam, S.A.; Asadi, R. The use of support vector machine, neural network, and regression analysis to predict and optimize surface roughness and cutting forces in milling. Int. J. Adv. Manuf. Technol. 2019, 105, 951–965. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Machine learning cutting force, surface roughness, and tool life in high speed turning processes. Manuf. Lett. 2021, 29, 84–89. [Google Scholar] [CrossRef]

- Agarwal, R.; Gupta, V.; Singh, J.; Jain, V. Prediction of surface roughness and cutting force induced during rotary ultrasonic bone drilling via statistical and machine learning algorithms. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 11123–11135. [Google Scholar] [CrossRef]

- Das, A.; Das, S.R.; Panda, J.P.; Dey, A.; Gajrani, K.K.; Somani, N.; Gupta, N.K. Machine learning-based modeling and optimization in hard turning of AISI D6 Steel with advanced altisin-coated carbide inserts to predict surface roughness and other machining characteristics. Surf. Rev. Lett. 2022, 29, 2250137. [Google Scholar] [CrossRef]

- Kumar, R.; Rafighi, M.; Özdemir, M.; Şahinoğlu, A.; Kulshreshta, A.; Singh, J.; Singh, S.; Prakash, C.; Bhowmik, A. Modeling and optimization of hard turning: Predictive analysis of surface roughness and cutting forces in AISI 52100 steel using machine learning. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 1–30. [Google Scholar] [CrossRef]

- Charalampous, P. Prediction of cutting forces in milling using machine learning algorithms and finite element analysis. J. Mater. Eng. Perform. 2021, 30, 2002–2013. [Google Scholar] [CrossRef]

- Lu, J.; Mu, H.; Ouyang, H.; Zhang, Z.; Ding, W. Modeling and effect analysis of machining parameters for surface roughness and specific energy consumption during TC18 machining using deep reinforcement learning and neural networks. Artif. Intell. Rev. 2025, 58, 193. [Google Scholar] [CrossRef]

- Dubey, V.; Sharma, A.K.; Pimenov, D.Y. Prediction of surface roughness using machine learning approach in MQL turning of AISI 304 steel by varying nanoparticle size in the cutting fluid. Lubricants 2022, 10, 81. [Google Scholar] [CrossRef]

- Metal Powder EOS. Aluminium AlSi10Mg Material Data Sheet, E.O.S. GmbH—Electro Optical Systems, Krailling/Munich, Germany. Available online: https://www.eos.info/var/assets/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/aluminium/material_datasheet_eos_aluminium-alsi10mg_en_web.pdf (accessed on 2 June 2025).

- Ercetin, A.; Aslantaş, K.; Özgün, Ö.; Perçin, M.; Chandrashekarappa, M.P.G. Optimization of machining parameters to minimize cutting forces and surface roughness in micro-milling of Mg13Sn alloy. Micromachines 2023, 14, 1590. [Google Scholar] [CrossRef]

- Xu, P.; Ji, X.; Li, M.; Lu, W. Small data machine learning in materials science. npj Comput. Mater. 2023, 9, 42. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Breiman, L. Classification and Regression Trees; Routledge: London, UK, 2017. [Google Scholar]

- Sharma, S.; Gupta, V.; Mudgal, D. Response surface methodology and machine learning based tensile strength prediction in ultrasonic assisted coating of poly lactic acid bone plates manufactured using fused deposition modeling. Ultrasonics 2024, 137, 107204. [Google Scholar] [CrossRef]

- Ke, G.; Meng, Q.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Liu, T.Y. Lightgbm: A highly efficient gradient boosting decision tree. In Proceedings of the Advances in Neural Information Processing Systems 30 (NIPS 2017), Long Beach, CA, USA, 4–9 December 2017; Volume 30. [Google Scholar]

- Zhou, Y.; Wang, W.; Wang, K.; Song, J. Application of LightGBM Algorithm in the Initial Design of a Library in the Cold Area of China Based on Comprehensive Performance. Buildings 2022, 12, 1309. [Google Scholar] [CrossRef]

- Hussain, S.; Mustafa, M.W.; Jumani, T.A.; Baloch, S.K.; Alotaibi, H.; Khan, I.; Khan, A. A Novel Feature Engineered-CatBoost-Based Supervised Machine Learning Framework for Electricity Theft Detection. Energy Rep. 2021, 7, 4425–4436. [Google Scholar] [CrossRef]

- Ibrahim, A.A.; Ridwan, R.L.; Muhammed, M.M.; Abdulaziz, R.O.; Saheed, G.A. Comparison of the CatBoost Classifier With Other Machine Learning Methods. Int. J. Adv. Comput. Sci. Appl. 2020, 11, 738–748. [Google Scholar] [CrossRef]

- Kramer, O.; Kramer, O. K-nearest neighbors. In Dimensionality Reduction with Unsupervised Nearest Neighbors; Springer Nature: Dordrecht, The Netherlands, 2013; pp. 13–23. [Google Scholar]

- Pan, Z.; Wang, Y.; Pan, Y. A new locally adaptive k-nearest neighbor algorithm based on discrimination class. Knowl.-Based Syst. 2020, 204, 106185. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Kadirgama, K.; Abou-El-Hossein, K.A.; Noor, M.M.; Sharma, K.V.; Mohammad, B. Tool life and wear mechanism when machining Hastelloy C-22HS. Wear 2011, 270, 258–268. [Google Scholar] [CrossRef]

- Saglam, H.; Yaldiz, S.; Unsacar, F. The effect of tool geometry and cutting speed on main cutting force and tool tip temperature. Mater. Des. 2007, 28, 101–111. [Google Scholar] [CrossRef]

- Bhagat, K.C.; Kumar, A.; Thakur, A.; Gangopadhyay, S. Analysis of cutting forces and surface quality during micro milling of AZ31B magnesium alloy. Int. J. Adv. Manuf. Technol. 2024, 134, 3465–3480. [Google Scholar] [CrossRef]

- Bao, W.Y.; Tansel, I.N. Modeling micro-end-milling operations. Part I: Analytical cutting force model. Int. J. Mach. Tools Manuf. 2000, 40, 2155–2173. [Google Scholar] [CrossRef]

- Malekian, M.; Park, S.S.; Jun, M.B. Tool wear monitoring of micro-milling operations. J. Mater. Process. Technol. 2009, 209, 4903–4914. [Google Scholar] [CrossRef]

- Köpf, A.; Feistritzer, S.; Udier, K. Diamond coated cutting tools for machining of non-ferrous metals and fibre reinforced polymers. Int. J. Refract. Met. Hard Mater. 2006, 24, 354–359. [Google Scholar] [CrossRef]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–332. [Google Scholar] [CrossRef]

- Gupta, M.; Kumar, S. Investigation of surface roughness and MRR for turning of UD-GFRP using PCA and Taguchi method. Eng. Sci. Technol. Int. J. 2015, 18, 70–81. [Google Scholar] [CrossRef]

- Uhlmann, E.; Lypovka, P.; Hochschild, L.; Schröer, N. Influence of rail grinding process parameters on rail surface roughness and surface layer hardness. Wear 2016, 366, 287–293. [Google Scholar] [CrossRef]

- Erçetin, A.; Aslantas, K.; Özgün, Ö. Micro-end milling of biomedical TZ54 magnesium alloy produced through powder metallurgy. Mach. Sci. Technol. 2020, 24, 924–947. [Google Scholar] [CrossRef]

- Karakılınç, U.; Ergene, B.; Yalçın, B.; Aslantaş, K.; Erçetin, A. Comparative analysis of minimum chip thickness, surface quality and burr formation in micro-milling of wrought and selective laser melted Ti64. Micromachines 2023, 14, 1160. [Google Scholar] [CrossRef]

- Tsai, M.H.; Lee, J.N.; Tsai, H.D.; Shie, M.J.; Hsu, T.L.; Chen, H.S. Applying a neural network to predict surface roughness and machining accuracy in the milling of SUS304. Electronics 2023, 12, 981. [Google Scholar] [CrossRef]

- Gross, D.; Spieker, H.; Gotlieb, A.; Knoblauch, R.; Elmansori, M. Efficient Milling Quality Prediction with Explainable Machine Learning. IFAC-Pap. 2024, 58, 43–48. [Google Scholar] [CrossRef]

- Charde, M.M.; Najan, T.P.; Cepova, L.; Jadhav, A.D.; Rash-inkard, N.S.; Samal, S.P. Predictive Modelling of Surface Roughness in Grinding Operations Using Machine Learning Techniques. Manuf. Technol. 2025, 25, 14–23. [Google Scholar] [CrossRef]

| Material | Element | Fe | Si | Ti | Mn |

|---|---|---|---|---|---|

| lSi10Mg | Percent | 0.55% | 9.0–11.0% | 0.15% | 0.45% |

| Cu | Ni | Mg | Al | ||

| 0.05% | 0.05% | 0.25–0.45% | Balance |

| Material | Tensile Strength (MPa) | Elong. at Break (%) | Surface Roughness (Ra–Rz µm) | Den. (g/cm3) |

|---|---|---|---|---|

| AlSi10Mg | 460 | 6.3 | 9–20 µm 70–120 µm | 2.67 |

| Shaft Diameter (mm) | Tool Diameter (mm) | Length (mm) | Flute Number | Helix Angle (°) | Hardness HRC | Coating Type |

|---|---|---|---|---|---|---|

| 4 | 1 | 50 | 4 | 35° | 55 | TİSİN Coated |

| Test Number | Feed Amount, fz (µm/Tooth) | Milling Speed, (rpm) | Depth of Cut, Doc (µm) |

|---|---|---|---|

| 1–2–3–4–5–6–7–8–9–10–11–12 | 0.25 0.5 1 2 | 10,000 20,000 30,000 | 50 |

| 1–2–3–4–5–6–7–8–9–10–11–12 | 0.25 0.5 1 2 | 10,000 20,000 30,000 | 100 |

| Model Name | Description | Theory | Mathematical Formulation | Sources |

|---|---|---|---|---|

| RFR | An ensemble model consisting of multiple decision trees, where predictions are determined through majority voting. | Each tree is trained on a bootstrap sample, and the final prediction is obtained by averaging or majority voting. | [31,32,33] | |

| GBR | A boosting technique that converts weak learners into strong learners by iteratively correcting errors. | The model sequentially adds weak learners and optimizes by minimizing the loss function. | [31,32,33,34,35] | |

| LightGBM | A histogram-based machine learning algorithm optimized for speed and memory usage, particularly fast on large datasets. | Optimizes speed and memory usage using gradient-based one-side sampling (GOSS) and exclusive feature bundling (EFB). | [36,37] | |

| CatBoost | A machine learning algorithm designed for processing categorical data, producing low-variance and nonlinear model outputs. | Effectively handles categorical data and produces low-variance model outcomes. | [38,39] | |

| KNN | A simple yet effective algorithm used for classification and regression tasks by considering the k-nearest neighbors in the feature space. | The model predicts a data point’s label by considering the majority class of its k-nearest neighbors. | [40,41] |

| Dependent Variable | Model | R2 Train | R2 Test | MAE Train | MAE Test | RMSE Train | RMSE Test |

|---|---|---|---|---|---|---|---|

| Fx | RFR | 0.9959 | 0.9243 | 0.1627 | 0.4910 | 0.2562 | 0.8887 |

| GBR | 0.9967 | 0.9409 | 0.1571 | 0.4832 | 0.2062 | 0.7800 | |

| LightGBM | 0.9837 | 0.9698 | 0.2824 | 0.3825 | 0.4576 | 0.5572 | |

| CatBoost | 0.9990 | 0.9642 | 0.0849 | 0.3889 | 0.1113 | 0.6073 | |

| KNN | 0.9849 | 0.9707 | 0.2781 | 0.3370 | 0.4397 | 0.5493 | |

| Fy | RFR | 0.9957 | 0.9613 | 0.1338 | 0.4072 | 0.2037 | 0.6102 |

| GBR | 0.9958 | 0.9549 | 0.1517 | 0.4530 | 0.2000 | 0.6663 | |

| LightGBM | 0.9831 | 0.9645 | 0.2570 | 0.4079 | 0.4022 | 0.5848 | |

| CatBoost | 0.9987 | 0.9563 | 0.0891 | 0.4607 | 0.1135 | 0.6481 | |

| KNN | 0.9800 | 0.9420 | 0.2790 | 0.4370 | 0.4374 | 0.7467 | |

| Fz | RFR | 0.9942 | 0.9642 | 0.0543 | 0.1372 | 0.0953 | 0.2282 |

| GBR | 0.9962 | 0.9562 | 0.0564 | 0.1538 | 0.0776 | 0.2371 | |

| LightGBM | 0.9794 | 0.9730 | 0.1105 | 0.1221 | 0.1798 | 0.1800 | |

| CatBoost | 0.9992 | 0.9763 | 0.0292 | 0.1126 | 0.0357 | 0.1688 | |

| KNN | 0.9843 | 0.9818 | 0.0963 | 0.0866 | 0.1567 | 0.1477 |

| Dependent Variable | Model | R2 Train | R2 Test | MAE Train | MAE Test | RMSE Train | RMSE Test |

|---|---|---|---|---|---|---|---|

| SR | RFR | 0.9854 | 0.9382 | 0.0418 | 0.0969 | 0.0778 | 0.1600 |

| GBR | 0.9906 | 0.9639 | 0.0449 | 0.0848 | 0.0640 | 0.1190 | |

| LightGBM | 0.9611 | 0.9569 | 0.0791 | 0.0895 | 0.1303 | 0.1301 | |

| CatBoost | 0.9977 | 0.9729 | 0.0238 | 0.0731 | 0.0315 | 0.1032 | |

| KNN | 0.9676 | 0.9725 | 0.0674 | 0.0687 | 0.1188 | 0.1038 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cevik, Z.A.; Ozsoy, K.; Ercetin, A.; Sariisik, G. Machine Learning-Driven Optimization of Machining Parameters Optimization for Cutting Forces and Surface Roughness in Micro-Milling of AlSi10Mg Produced by Powder Bed Fusion Additive Manufacturing. Appl. Sci. 2025, 15, 6553. https://doi.org/10.3390/app15126553

Cevik ZA, Ozsoy K, Ercetin A, Sariisik G. Machine Learning-Driven Optimization of Machining Parameters Optimization for Cutting Forces and Surface Roughness in Micro-Milling of AlSi10Mg Produced by Powder Bed Fusion Additive Manufacturing. Applied Sciences. 2025; 15(12):6553. https://doi.org/10.3390/app15126553

Chicago/Turabian StyleCevik, Zihni Alp, Koray Ozsoy, Ali Ercetin, and Gencay Sariisik. 2025. "Machine Learning-Driven Optimization of Machining Parameters Optimization for Cutting Forces and Surface Roughness in Micro-Milling of AlSi10Mg Produced by Powder Bed Fusion Additive Manufacturing" Applied Sciences 15, no. 12: 6553. https://doi.org/10.3390/app15126553

APA StyleCevik, Z. A., Ozsoy, K., Ercetin, A., & Sariisik, G. (2025). Machine Learning-Driven Optimization of Machining Parameters Optimization for Cutting Forces and Surface Roughness in Micro-Milling of AlSi10Mg Produced by Powder Bed Fusion Additive Manufacturing. Applied Sciences, 15(12), 6553. https://doi.org/10.3390/app15126553