Abstract

This study investigates how traditional costing methods hinder the development of modular product architectures. A structured literature review identifies the gap between Management Accounting (MA) and Innovation and Operations Management (IOM), revealing that current costing approaches often fail to provide an accurate cost assessment of the impact of modularity effects across the product life cycle. A hypothesis is proposed, suggesting that defining cost allocation by levels of abstraction—product, subsystem, and component—can address the challenges in current methods. The analysis found that modularity effects are predominantly assessed at the product level in four out of five life-cycle phases, despite product costs being incurred at lower levels, leading to inaccuracies in cost allocation. This study concludes that current costing practices do not offer a sufficient level of detail for informed design decisions based on cost when it comes to developing modular product architectures and proposes the development of more refined cost models. It offers a new perspective on how to assess product variety and its related effects in a product portfolio. This lays the foundation for future research combining the fields of MA and IOM. This paper highlights the absence of a universal method to assess the total life-cycle cost of product portfolios and outlines directions for future work, including the development and testing of refined allocation models through industry case studies.

1. Introduction

Product developers face the challenge of maintaining and developing a high external variety of products to meet increasing demands for customization and personalization while ensuring a low internal variety of parts, modules, and processes [1,2]. The potential economic savings achieved by reducing internal variety can significantly enhance the economic performance of a product [1,3] and influence decision-making in the design process [4,5]. During the development life-cycle phase, the majority of the cost is determined by key product design decisions, such as the functionality and performance of the product, materializing in several product variants offered to the market. These decisions are difficult and costly to reverse later in the product life cycle [6]. Thus, product cost is a governing measure in product development, on which product developers have the greatest impact [7].

Modular product architectures, which refer to a product design approach where a product is divided into distinct, interchangeable modules or components with a specific function [8], offer a viable solution to this challenge by reducing or controlling internal variety. A great part of the benefits of modularization often manifests as reduced indirect costs [9,10,11], which might constitute up to 50% of the total cost in highly specialized products [7,12]. However, quantitative cost decisions regarding product design are typically based on direct costs alone, overlooking indirect costs, as both fields aim to optimize the cost or profit of product portfolios based on an economic rationale [10,13]. This oversight leads to suboptimal design solutions due to a non-transparent cost structure throughout the product life-cycle phases (LCPs) [14]. The product LCPs can be defined as encompassing all operations within the company that are directly influenced by product-related choices [15]. Hence, the lack of comprehensive cost knowledge hinders the development of modular product architectures, limited by the traditional costing methods applied in cost management systems [13,16]. This is illustrated in an empirical example made by Israelsen & Jørgensen [5] and is further underlined in the study by Stadtherr & Wouter [17]. The existing literature presents several methods to address this issue. However, these methods are often too narrowly scoped, resource-intensive, or product-specific, making it challenging to generalize their application [18]. A more generalizable and holistic approach is needed to address this issue comprehensively.

This study conducts a literature review that explores the gap between the research fields of Management Accounting (MA) and Innovation and Operations Management (IOM), with an extended focus on the development of modular product architectures in terms of quantifying the economic benefits of the modularity effects used for decision support in product development. Building on the earlier literature reviews that sought to bridge this gap, Israelsen & Jørgensen highlighted the practical challenges in accurately allocating costs to modular product architectures within accounting systems [5]. Wouters et al. provided an overview of the cost management methods applied during product development [6]. More recently, Magnacca and Gianetti concluded that research in this area remains fragmented and proposed a new research agenda with several suggested directions [19].

This study develops a hypothesis suggesting that defining abstraction levels based on current product structures may improve our understanding of how to address challenges in accurately allocating product costs throughout the life-cycle phases. These insights establish the context for understanding how traditional costing methods hinder the development of modular product architecture and affect product developers’ decision-making. Studies addressing the modularity effects can be categorized by their impact on different abstraction levels, assessing their impact on the product, subsystem, or component level. This categorization provides a platform from which we can begin to interpret the challenge of accurately allocating shared costs across products. It deepens our understanding of the effects of product variance and the costs associated with having product variance and extends our knowledge of why it is difficult to share costs across product variants following existing cost methods. Currently, there is no comprehensive explanation for why existing cost management approaches fall short in accurately assessing modular product design, nor is there a generalizable tool for quantifying its economic benefits [20].

The purpose of this study is thus to highlight the limitations of our current costing methods and discuss the challenges of accurately quantifying the economic benefits of modular product architectures using existing approaches. It contributes to understanding how traditional accounting methods impede the development of modular product architectures by showing that cost allocations tied to specific abstraction levels may lead to the incorrect or inaccurate allocation of indirect costs. Based on this discussion, future research areas are proposed for developing a new cost allocation approach that accounts for different levels of abstraction, as well as addressing the current limitations in the research.

The remainder of this paper is structured as follows: Section 2 provides an account of the research methods used in this study. Section 3 elaborates on the theoretical framework for allocating assessment methods to three different abstraction levels. The result of this study is presented and further described in Section 4. This is followed by a discussion of our findings in Section 5 before concluding the study and elaborating on future research work in Section 6.

2. Research Methods

This study is built on a literature review that investigates the current approaches, methods, and tools for making design decisions based on quantitative measures at the cross-section of the MA and IOM fields. It identifies the gaps in the current research on costing methods and the area concerning the development of modular product architectures within IOM, while outlining in what aspects the two research fields are coherent. The literature spans topics such as the development of modular product architecture, existing challenges in quantifying economic benefits, and proposed solutions to overcome the issues of developing and maintaining a modular product architecture.

2.1. Literature Study Process

The literature search, inspired by the approach of Mortensen et al. [21] and Neri et al. [22], was based on a continuously updated list of relevant keywords identified throughout the process. The first set of keywords relied on previous publications in the field [5,18,23]. However, combining keywords from the research fields of Management Accounting and Design Research would yield dispersed results due to the use of different terminology inherent to each research topic. Therefore, the search strategy was made to include two separate search strings with their own unique set of keywords. The combination of these keywords formed two extensive search strings, specifically targeting each area of research (strings listed below). They were submitted to the scientific databases Scopus and Web of Science, which were deemed appropriate for this review, since Scopus is one of the major scientific databases [24], and both databases are multidisciplinary bibliographic data sources [25]. Additional material was found through the citation and reference-tracing features, which are available within these databases. The papers found in each of the two searches were first manually screened by title to identify relevant work, and then the selection was further narrowed by assessing the abstracts. The remaining papers were thoroughly reviewed before determining their relevance to this study. This procedure allowed for the exclusion of non-relevant articles or duplicates.

- TITLE-ABS-KEY (“complexity management” OR “complexity costs” OR “quantification of complexity costs” OR “complexity reduction” OR “External Product Vari*” OR “Indirect Cost” OR “variant management” OR “variant cost*”) AND TITLE-ABS-KEY (“product architecture” OR “modular*” OR “data management” OR “MBSE” OR “SysML” OR “KPIs” OR “decision support” OR “product concept evaluation” OR “knowledge management” OR “ design knowledge”)

- TITLE-ABS-KEY (“Cost systems” OR “External Product Vari*” OR “variant cost*” OR “Activity-Based cost*” OR “ABC” OR “Cost Accounting” OR “Cost Allocation”) AND TITLE-ABS-KEY (“product architecture” OR “modular*”)

The purpose of the search strings was to collect all the existing and accessible material addressing the cost of product variance and its relation to modular product architectures. And more specifically, how it is affected by current cost allocation practices and methods.

The relevance of the studies included in the final selection was ensured through the application of the following inclusion criteria in the literature review: The retrieved studies should (1) be within the Engineering, Management, and/or Accounting fields. (2) English texts only. (3) Adhering to the purpose of the review as stated above.

The first string found 384 papers with duplicates. The screening for titles reduced the number to 78, and a further reduction to 19 studies was made through the screening of abstracts. Reading the remaining papers revealed that only 10 papers had a relevant scope regarding the assessment of economic benefits when developing modular product architectures, and three of these were highly relevant to this study. The second search string, following the same procedure, reduced the total number of papers from 606 to 19 and 8 after the title and abstract screening, respectively. Upon reviewing the full text, four additional papers were identified as highly relevant to this study by addressing the limitations of current costing methods in allocating costs for a modular product architecture. The final set of included studies spans from 2006 to 2024, with the majority of papers published in the last decade. This study does not claim to cover all papers investigating the gap between MA and IOM research on the topic of the economic benefits of modularization and costing methods across the product LCPs. However, a significant portion of the papers on this specific topic are believed to be covered in this review.

2.2. Categorization of Assessment Methods for Modularity Effects

The structured literature review provided the basis for examining our hypothesis. This was achieved by identifying the abstraction level at which each modularity effect would have an impact according to the reviewed literature. Thus, by categorizing by the three different abstraction levels—product, subsystem, or component—a potential quantifiable assessment could be made, and an overview could be constructed (this is explained in detail in Section 4). The list of effects induced by modularization was composed based on the literature, taking its inspiration from the Impact Model of Modular Product Families (IMF) from Greve et al. and Hackl et al. [15,18]. The effects were adapted from the IMF and expanded upon, with the additional effects found in the literature reviewed for this paper. They were distributed across five different life-cycle phases, considering development, procurement, production, sales, and service. This paper relates its findings to these five LCPs. Each instance was counted after categorizing the sources at the appropriate abstraction level, inspired by the work of Micheli et al. [26]. The results of the categorization can be found in Section 4.

3. Literature Review

This study builds on research in IOM and MA, highlighting a shared gap in the literature. It underscores how traditional costing methods influence the development of modular product structures [20,27], as both fields aim to optimize the cost or profit of product portfolios based on economic rationale [5,28]. The need for methods and tools to structure product programs is growing, driven by the demand for a wide range of external products in today’s market while simultaneously limiting internal product variety within the company to reduce costs and ensure profitability [29]. To better understand the effects of having product variety and the related challenges, we will delve further into this topic in the first paragraph (Section 3.1) of the literature review. One of the primary concerns with product variety is determining the associated cost implications of increased complexity. This is further investigated in the second paragraph (Section 3.2) by looking into current cost allocation practices. Product modularization is often seen as a solution for reducing internal product variety. Hence, in the third paragraph (Section 3.3), current research on the quantitative evaluation of the benefits of modular product architectures is examined.

3.1. The Effects of Product Variety

Globalization, increased pressure from competitors in the market, and increased demand for customized products are all factors that drive the rise in product variety [1,16]. Consequently, new products are developed or existing ones are updated or altered to meet growing market demands, new technological features and function requirements, and certification specifications, leading to an increase in internal product variety [2]. This adds to the rise in product and process complexity, entailing increasing costs [1,7], potentially diminishing any financial benefits from increasing the external product variety [3,13]. The challenge for product developers resides in maintaining a low internal product variety without reducing the external product variety offered to the market or only keeping the variety that customers value [2,30]. As product variety increases, the need for structured tools and an emphasis on flexibility and agility in design and manufacturing becomes more critical [8]. It is estimated that the design decisions made during product development account for over 70% of the product life-cycle costs [31,32]. Ideally, the impact of these design decisions should be visible for every step of the value chain [33]. If the evaluation of a design decision in product development could be made more accurate, it would significantly improve the decision-making of the product developers [34,35]. Particularly, a more accurate estimation of indirect costs, which for highly specialized machinery manufacturers might constitute up to 50% of the total cost [7], would support product developers during the development of product concepts with an effort-reducing cost prognosis [10]. Additionally, it could support the evaluation of existing product variants [3]. Still, to make an informed decision, the actual economic impact of a design or product must be assessed in a quantifiable manner. We need to further examine our existing costing methods and their capabilities to support product developers in this endeavor.

3.2. Methods for Allocation of Costs Related to Product Variety

Several costing methods exist. In practice, they are embedded in costing systems to support companies in tracing cost objects, such as products or services [36]. Cost objects will traditionally incur two distinct types of costs. First, direct costs, such as the cost of direct labor and material costs, which, as a standard practice, are traced and are directly allocatable to specific products or services. These are contrary to the second, indirect costs, where development time, sales, marketing, depreciation, and facility expenditures are not directly allocated to a cost object. Instead, they are divided evenly across products and services through cost-allocation systems [37]. Traditional costing systems, also known as volume-based costing, allocate costs based on units or production volume and primarily operate through direct cost allocation [37,38]. When it comes to indirect costs, this method is only effective in stable environments with limited product variety and small or fixed indirect costs [27,36]. Typically, a fixed indirect cost is divided evenly between the cost objects or as a percentage of the direct costs [39].

Cooper and Kaplan [40] developed activity-based costing (ABC) to provide the more accurate and efficient management of overhead costs. The level of activity consumed by a cost object serves as the basis for cost allocation [41]. It has been proven possible to use ABC to estimate an incurred cost as a result of specific design alternatives regarding part commonality [14,42]. However, ABC has proven challenging to utilize due to its cost- and resource-heavy implementation and the difficulty of maintaining and updating the model [36,43].

Reviewing the problems associated with the traditional estimation of ABC, Kaplan and Anderson [43] evolved the model into a new approach named Time-Driven ABC (TDABC). It is simpler and more accurate, as it requires estimates of only two parameters: the unit cost of supplying capacity and the time required to perform a transaction or an activity. It delivers on all the same parameters as traditional ABC, with the benefit of eased initiation, maintenance, and updating [43]. However, TDABC is difficult to generalize across different types of products, making it challenging to create a generalizable and holistic tool [18].

Target Costing (TC) is another costing method for determining the allowable manufacturing and component costs of a product before development, based on the potential sales price in the market [7]. Traditional TC is limited to determining the direct costs that arise after the start of production and does not provide a solution for allocating indirect costs [6]. However, in a recent study, Stadtherr and Wouters [17] developed an extension to the TC, providing a guide specifically to make technical decisions about modular product architectures based on related costs. Yet, the study is limited to assessing the development cost and production investment and thus advocates for extending or developing a method that can entail various cost elements, including the implication of technical design on costs, and the cost effect associated with interdependencies between products, such as shared components [17]. A review of the above costing methods’ implications and limitations reveals that they fail to adequately allocate indirect costs associated with increased product variety and complexity, costs that are critical to informed design decisions [10]. The cost allocations discussed in this section are listed below in Table 1.

Table 1.

An overview of various costing methods for allocating costs related to product variety with references discussed in this section.

Now, provided we have the costing tools for assessing an increase in process cost, which several studies describe as a direct effect of increasing internal variety [5,41,44], also known as complexity cost in a major part of the literature [39,45], enables the evaluation of individual product variants based on direct and indirect costs. A multitude of methods exist for allocating complexity costs. This is illustrated in the work of Myrodia et al. [46], who built a list of variety-induced complexity cost factors (VCCFs) from the literature, providing the means to identify and quantify the cost of product complexity in a specific process step. The resulting variety-induced complexity cost can be allocated to specific product variants based on the VCCFs and will vary depending on the product [46]. This enables a more precise evaluation of the profitability of each product variant within the portfolio.

Although the availability of the methods mentioned above improves cost transparency, they do not support the separation of various cost elements at a lower level than the product variant level [47]. This can distort a quantitative assessment of products if the design principles are anything other than standardization or unique to one product. For example, modular product structures, component commonality, and product platforms rely heavily on sharing modules and components across the product portfolio [5,9]. Additionally, the most accurate costing methods are too narrowly scoped due to their extensive resource requirements, which limit their ability to provide an accurate cost estimate. This, in turn, means that none of the existing costing methods fully capture the entire value chain or account for the effects between different life-cycle phases [10]. This aligns with the rationale of Wouters and Morales [48] and their classification of cost management methods in product development. Aside from component commonality, modular design, and product platforms, existing cost management approaches are limited in scope. They either concentrate on the entire life-cycle cost of a single product or assess an entire product family or portfolio, but only in terms of direct manufacturing costs. Most critically, they fail to account for indirect costs, leaving a significant gap in the cost evaluation and support of decision-making in product development [20,48].

Currently, no generalizable methods exist for combining a complete product portfolio with the entire life-cycle cost [6,48]. And no existing cost system can accurately allocate the entire cost across a portfolio of products [20]. The known costing methods only give a limited insight into the allocation of costs for products and services. Mertens [27] also describes this, arguing that volume-based costing and ABC either lack accuracy or require ample resources, respectively. However, several researchers have investigated the economic benefits of modularization in an attempt to provide product developers with a financial incentive for developing modular product architectures.

3.3. Economic Benefits and Effects of Modular Product Architectures

Within the subjects of product architectures, modular-based product structures, mass customization, and product commonality are various methods, tools, and frameworks that have been developed to provide a wide array of external product variety while controlling, maintaining, or reducing internal variety [13,34,49]. Reducing or maintaining the complexity stemming from product variance can also be viewed as a decluttering of products and processes [13]. The list of benefits following the implementation of modularization methods found in the literature is long, as illustrated by Hackl et al. [15]. Their IMF is a qualitative knowledge base that systematically identifies the economic impacts of modularity across different life-cycle phases. These effects can potentially create economic savings by reducing component variety [50], increasing component reuse [51,52], reducing lead times [53,54,55], creating less variety in the production process [55,56,57], and reducing tool investment in production [55,58,59]. All of these effects can be traced back to the properties of modularity [15,23]. However, the literature primarily describes the impacts of modular-based product structures through qualitative studies. It is thus difficult to give an accurate quantitative estimate of the cost of variation following these methods [60]. Furthermore, the rising product complexity and numerous design decisions make implementing and maintaining modular architectures challenging [61].

The lack of quantitative economic models is due to the fact that implementing an integrated financial planning model is a comprehensive challenge, as it should account for all the life-cycle effects of modularization to provide accurate measures [16]. More recent studies from the MA field support this point, suggesting that existing costing methods are not suitable for decision support in modular product development from a cost accounting perspective [20,62]. Hence, existing accounting systems and practices are not designed to accurately assess the economic benefits of modularity from a full life-cycle point of view [5,20], and they do not support the separation of the various cost elements [27,47]. Building on this argument, modular structures often face a disadvantage during economic assessment because existing studies typically only consider a portion of the product portfolio, limiting resource scope and utilization. The whole product program must be included when evaluating the effects of modularization, not only individual effects on a specific product but also the combination of all impacts across the entire product portfolio [20]. A recent study investigating the different modeling approaches for supporting architectural decision-making concluded that the majority of approaches do not cover all aspects of the system [63]. This means that previously conducted studies, which examine only individual cost effects, may yield statements with limited validity, asserting results that suggest a monetary disadvantage for modular product structures [9,10,64]. Almost no studies have quantitatively proven the economic benefits of modular product design [20,65,66]. However, as mentioned previously, several methods have been used to document the economic benefits of modularization qualitatively through case studies on both a short- and long-term basis [4,21,29] or through the reviewed literature [10,15].

This may pose a challenge for designers in making informed product decisions on modular product architectures, as they rely on an incomplete picture of the total cost of a product variant. Design choices are typically based on direct costs, often overlooking indirect costs and their impact across the company’s value chain [42]. The indirect cost, as part of the overhead costs, will often be non-transparent, meaning that it cannot be explicitly allocated to a product level or below. This produces a challenge for accurately assessing different product variants based on their costs [14]. It is a well-known fact that customized or specialized products incur a higher cost and will occupy a considerable part of the overhead cost pools [7]. Therefore, quantifying the cost incurred by a specific design at each stage of the life cycle may improve decision-making in product development. Greve et al. [18] developed a design decision support tool to support decision-makers in the early phase of interdisciplinary product development. It is an advancement of the IMF developed by Hackl et al. [15], which encompasses more than 70 known impacts of modularization from the literature. The extension of the IMF focuses on quantifying the cost-saving potential of effects related to modularity by adding KPIs and cost measures. The tool is implemented in a case study, suggesting that considering economic modular effects quantitatively will greatly improve the evaluation of alternative product concepts in early-stage product development [18,23]. However, the tool does not provide a generalizable approach, and it requires the further development of the empirical data underlying it. This means that the tool is tied to the specific results of the case study and cannot be considered generally applicable. Furthermore, it does not provide an opportunity to compare product design quantitatively in monetary terms and in accordance with existing costing methods.

Only a few studies have investigated the actual feasibility of accurately allocating costs to a modular product structure using traditional Management Accounting approaches, primarily within MA research [5,9,20]. As argued in this study, the findings suggest that existing approaches hinder the development of modular product architectures. However, exactly why these approaches fail to provide an accurate and extensive quantitative assessment is not clearly defined. This will be investigated further in the following sections.

4. Categorization of Abstraction Levels

As discussed in the previous section, only a few existing costing methods have successfully attempted to quantify the cost savings associated with a modular product architecture. However, no generalizable or holistic costing tool for quantifying the economic benefits of modular product family design exists [10,18].

4.1. Introducing the Levels of Abstraction

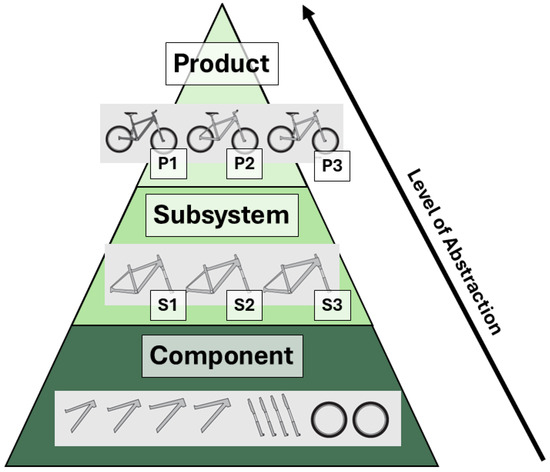

In this study, we seek to investigate the current gap between Management Accounting cost methodologies and the quantification of benefits from modularization effects. The objective is to provide greater insight into why quantifying costs remains a challenge, even when employing comprehensive cost allocation methods such as TDABC. Studies suggest that assessing the economic benefits of modularization, based on the allocation of costs at the product or project level, is not suitable for providing an accurate cost picture [5,10,12]. To accurately assess the cost and profitability of related products that share components and subsystems, the entire product portfolio of related products must be considered [20], enabling an aggregated cost evaluation across the product portfolio based on common modules and components [5]. This may be possible by conducting assessments in smaller increments rather than at the product or project level, which can be considered an aggregation of costs related to subsystems and components [17]. This initial insight informs the study’s hypothesis. The levels of abstraction are defined based on the product data structure found in Enterprise Resource Planning (ERP) systems, 3D models, and Bill-of-Materials (BOMs), in which the decomposition of a product in a manufacturing company can be found [67]. The hypothesis is that defining abstraction levels based on current product structures may provide a means to address the challenges of accurately allocating indirect product costs throughout the life cycle. The three levels of abstraction are defined as product, subsystem, and component, as visualized in Figure 1. A bicycle is depicted in the figure to provide context. The upper-level, product, consists of finished goods or products that can be sold as a single unit (e.g., a fully finished bicycle) [37]. It will have a unique item or product number for the specific variant sold. In this case, we will denote the bicycles as three product variants: P1, P2, and P3. On the next level, we have subsystems (e.g., the frame of the bike), a term similar to subassembly or module, which are used broadly in the literature and industry [56]. Each subassembly will also have a unique item number. The combinations of subsystems make up a product. In this case, we will denote the three frames depicted as three subsystem variants: S1, S2, and S3. On the lowest level of abstraction, we have components (e.g., frame elements, fork legs, tire, etc.). Each component will have a unique part number. A combination of these comprises the subsystems. A component always consists of only one unit. However, the company determines what a single unit or component is in relation to their product. For example, a rubber tube would often be considered a single component for a bicycle manufacturer, even though it consists of a tube and a tube valve, since it is bought from an external supplier. With this definition in place, we can provide a simple example based on Israelsen and Jørgensen’s [5] findings, illustrating why this product structuring proves problematic for allocating costs in a modular product structure following traditional costing methods.

Figure 1.

Illustration of the three abstraction levels with a bicycle example.

A bicycle manufacturer intends to expand its bicycle portfolio to target new customer segments. To this end, it will introduce a new product family entailing three new variants (products): P1, P2, and P3. A new bicycle frame (subsystem) must be designed to meet the market’s requirements. They can either develop an over-specified frame (SX) to meet the requirements of all three variants, following the principles of modular design, or create a unique-to-one solution for each variant (S1–S3). The first option will introduce only one subsystem variant but will be more expensive than its unique-to-one counterpart in terms of upfront development (10,500 in total) and direct costs, which are expected to increase following this design decision but are not expected to amount to a higher cost than for the most expensive unique-to-one subsystem [9,18]. On the other hand, it will attain cost benefits due to modularity effects [15,18], resulting in a lower batch cost. This can be ascribed to the improvement of the learning curve gradient due to larger lot sizes [68,69], reduced inventory holding costs [59,70,71], reduced setup changes [72], and improved purchasing conditions [50,68]. The increase in quantity due to just having one subsystem will lower the batch cost. The second option will introduce three variants of the frame (S1–S3), resulting in lower development (4000 for individual subsystems) and direct costs for each product variant. However, the process and complexity costs of introducing another variant will increase indirect costs, which, as previously described, cannot be accurately allocated to any of the three abstraction levels through existing cost allocation practices. A calculated example of the profitability of the two different solutions can be seen below in Table 2.

Table 2.

An example of a profitability calculation comparing unique-to-one solutions with modular solutions. The development costs for the modular solution are just a total sum, which has been distributed evenly across the products since they share the same subsystem. The result provides a comparison between the calculated gross profit of the unique-to-one product solutions versus the modular solution. First, the gross profit is determined without considering indirect costs (ICs), and afterwards, the profit with ICs.

The total revenue is calculated based on the revenue gained from the number of units sold times the sales price of each product (P1–P3). The direct costs (DCs) are based on the units sold times the material and labor costs. The indirect costs (ICs) are derived from multiplying the batch cost for each product by the number of units sold, adding the development cost as a one-time sum. The gross profit is determined by subtracting the total DCs from the revenue, and the profit with ICs is determined by additionally subtracting the total ICs from the gross profit, taking the indirect costs incurred into account.

The example shows that the overall profitability of the products with a unique-to-one solution is higher when only direct costs following traditional accounting practices are considered. However, correctly allocating the indirect costs and calculating the overall profitability will showcase a better profitability for the modular solution. This has also been documented through empirical case studies. Park and Simpson have developed an estimation framework based on ABC to map activity costs to individual parts in the product family to assess how activity costs are affected by product family design decisions [14]. Israelsen and Jørgensen conducted a case study illustrating the issues of project accounting on a product level, distorting the potential economic benefits of modularization [5], and most recently, Greve et al. provided a knowledge-based decision support model applied to a product family example, enabling the selection of the most suitable modular solution [18].

If P1 and P2 already exist as standard products, introducing a slight variation for P3 requires evaluating whether the existing subsystem meets its requirements or if a new variant must be created. Reusing a subsystem incurs no additional development costs and may only minimally affect direct costs, but the introduction of a new variant, slightly altered from the existing one, will certainly increase indirect costs. However, these indirect costs are often absorbed into overhead cost pools, making them invisible in existing cost systems. Additionally, it is usually the case in development that it is easier to develop new, simple components than to reuse carry-over parts [10].

Returning our focus to our hypothesis and the level of abstraction as defined earlier in this section, the purpose of this study is to identify the abstraction level at which modularity effects have an impact, as per the literature, and whether the effects of modularity have a proposed impact on a product (P), subsystem (S), or component (C) level. This will provide us with a deeper understanding of the level of detailing currently used in existing practices when evaluating product architectures quantitatively and whether the assessment is substantial enough to give an accurate assessment of products for informed decision-making in product development.

4.2. Findings Following the Categorization of Abstraction Levels

Every study addressing a modularity effect was categorized according to one or more of the aforementioned abstraction levels. A total number of references (#Ref) addressing the specific modular effect and a count of instances (#Instances) when the expected impact of the effect was related to one of the three different abstraction levels were recorded. More specifically, the categorization denotes the level of abstraction at which it should be possible to assess the effect (not all sources quantitatively assess the impact). A reference can, in some circumstances, comply with all three levels. For example, when assessing inventory costs, the values of finished goods (products), subassemblies (subsystems), and components kept in stock are taken into account during a quantitative cost allocation. Sources that do not explicitly mention which abstraction level the effect will impact are referred to as the product level. This is generally the level at which traditional product development and project cost targeting are performed [5,20]. The following section will discuss the results for each life-cycle phase before addressing the overall findings in this study. Table 3, listed below, provides an overview of the categorization.

Table 3.

An overview of the modularity effects across the life-cycle phases (LCPs) and the number of instances (#Instances) at which the effect is addressed, at either a product (P), subsystem (S), or component (C) level, with a count of the total number of references addressing the modularity effect (#Ref).

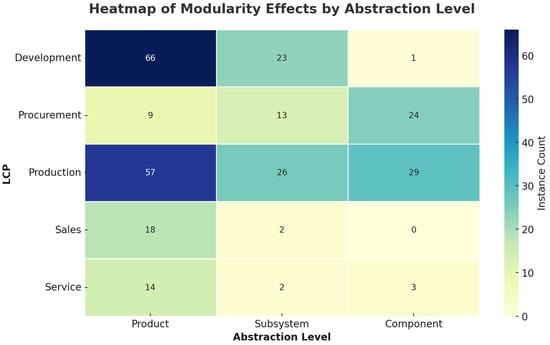

The modularity effects for each life-cycle phase are listed. The total number of references addressing this effect is listed in the second column from the right. The references used for each effect are listed in the far-right column. The number of instances found on each level is detailed in the adjoining columns to the left. A total of thirty-six individual references are used in this categorization. Table 3 summarizes the study’s results, providing an opportunity to enhance our understanding of the level at which the effect of modularity impacts each LCP. A summarization of the results across the LCPs is illustrated with a heatmap in Figure 2.

Figure 2.

Heatmap showing the sum of instances in which modularity effects are addressed at the product, subsystem, and component abstraction levels across each life-cycle phase (LCP).

Thus, the distribution of abstraction levels within each LCP is clearly visualized. For example, in the development phase, modularity effects are predominantly addressed at the product level, with a total of 66 instances, compared to 23 at the subsystem level and just 1 at the component level. The insights that can be drawn from these results will be discussed in the next section.

5. Discussion

This section provides a detailed interpretation of the results presented in Table 3 and discusses whether these findings support the hypothesis outlined in this study. We will begin by examining a selection of effects within each LCP before moving on to discuss the general tendencies across the life-cycle phases.

5.1. Development

A high number of modularity effects can be found in the development life-cycle phase. Product development teams will often have the end product in mind when assessing the overall impact of a modular product architecture. This is evident from this study, where almost every method used to determine an effect in the development LCP predominantly focuses on the product level, as shown in Table 3, whereas a few are assessed at a modular level. Only one of the reviewed methods provides an assessment of the effects at a component level, ‘improve outsourcing of development task’, but it is still primarily addressed at the product and subsystem levels. This tendency to assess the product modularity’s economic effects on a product or project level is one of the many shortfalls for producing accurate cost allocation on which design decisions can be made [5,10]. This becomes more evident when it can be observed that effects such as the ‘improved reliability of a product’, which, among other initiatives, are a result of component reuse, are mainly assessed at the product level and not on the modules or components it comprises. Furthermore, the effects focusing on specific parts and components, ‘reduce time for part search’ and ‘improve part administration’, are only addressed at the product level, even though these effects are directly linked to the component and modular levels [23]. Lastly, it is worth mentioning that one of the key arguments for modularization, the ‘improvement of variant derivations’, is addressed at both the product and modular levels. Addressing the effects on these two abstraction levels enables the quantification of the effects of modular product architectures on a modular level, offering high external product variation while maintaining low internal product complexity [18,57].

5.2. Procurement

We reviewed the literature on the effects of modularity in procurement. It presents a contrasting picture compared to other LCPs. The studies are primarily focused on assessing the impact on a component level, as seen in Figure 2. However, this seems intrinsic to the work conducted in this area, which is closely tied to the procurement of raw materials and components, as well as, to some degree, subsystems. They focus on the basic units that comprise the products across the entire portfolio rather than on the specific product itself.

The impact of the ‘reduce safety stock and inventory levels’ effect will often be related to a component or subsystem level, as the findings suggest in Table 3. This will typically also have a derived impact on the finished goods inventory but is more clearly observed on the other levels of abstraction. The same goes for the effect ‘improve purchasing conditions (economy of scale)’, where increased lot sizes due to less variety will affect the direct costs of components and raw materials. The effect ‘reduce number of purchase orders’ can be observed as only having an impact at the component level. This suggests that costs can be allocated at the component level; however, while direct costs are unlikely to be affected, any impact on indirect costs, such as reduced process complexity, remains difficult to detect [18]. Consequently, the economic effect on the profitability of products, subsystems, or components remains unclear. A key takeaway from the findings in the procurement LCPs is that quantifying effects at the component level offers an opportunity for more accurate cost allocation, for example, by using ABC at the component level, as illustrated in the empirical study by Park and Simpson [14]. This, in turn, enables the allocation of indirect costs associated with specific components across the entire product portfolio.

5.3. Production

Examining the effects of modularity on production reveals a clear tendency to assess the effects at a product level, as can be viewed in Figure 2, except for the effects of ‘reducing manufacturing cost per unit’ and ‘improving learning curve gradient’. The manufacturing costs are tied to multiple levels of abstraction, and the data required is typically well documented, likely due to the fact that they can be traced directly to specific costs. Returning to our cost allocation example in Section 4, if the cost allocation can be conducted at a lower level than the product level, it will be evident that the manufacturing costs of components, subsystems, or finished goods may increase for a specific product when using modular design principles. However, the overall profitability of the product portfolio is expected to improve due to lower manufacturing costs and reduced development costs across the entire product range [5]. Assessing only a limited view of products, subsystems, or parts may result in a distorted picture of the actual profitability. The learning curve gradient should apply to all abstraction levels, as the benefits of reduced variety often materialize in the resources spent on parts and subsystems [5]. Furthermore, it is worth mentioning that added benefits, such as ‘improve parallel manufacturing processes’ and ‘improve postponement in production’, are often assessed at the product level but rarely at the component level, making it difficult to accurately assess the resources spent. It can generally be observed that the effects that can be assessed through direct costs, such as manufacturing costs and the learning curve gradient (in terms of labor hours), are evaluated down to a component level due to their traceability. The effects related to indirect costs are evaluated at a product level in the production life-cycle phase.

5.4. Sales

In the sales LCP, the modularity effects are only evaluated at the product level, except in one case. It may seem obvious that the sales department operates primarily at this level, as it sells finished goods. However, when it comes to configured, customized, or highly specialized products, sales are an integral part of the sales–delivery process to generate the composition of the final product through sales configurators, customer specifications, and one-of-a-kind requests [90]. Thus, it affects and works on a lower level than the product level, indirectly increasing the variety of parts. The only effect evaluated on a subsystem level is ‘reduce/increase cannibalizing sales’. Modularization provides an opportunity to have multiple variants of the same product differentiated only by an interchangeable subsystem or component. This means that sales cannibalization between product variants has less impact, as they largely consist of the same subsystems and components.

5.5. Service

Once again, we observed a tendency to assess the modularity effects at the product level when considering the service life-cycle phase, except for the ‘reduce number of stock items (spare parts)’ effect, which is only assessed at the component level, since a single spare part is often considered an individual part, even though a subsystem might also be considered. The ‘reduce service, maintenance, and repair costs’ effect is only assessed at the product level, even though the actual service and repairs are often bound to specific components or subsystems, making it challenging to accurately quantify the cost of this effect across the product portfolio. In general, as the costs of spare parts, claims, and services are incurred after selling and shipping the product, the actual total cost performance of the product is rarely fully evaluated [18].

5.6. Summary of Tendencies Observed Across Life-Cycle Phases

The findings in this study are characterized by the general direction of research within the field of modularization and accounting management. Based on the number of references addressing either the development or production life-cycle phases, it appears that there is a tendency to focus on the high-cost drivers and the traceability of direct costs related to these areas. As a result, effects in areas such as procurement, sales, and service are investigated to a lesser degree. A reduced traceability of costs makes it difficult to provide accurate cost allocations for specific products, subsystems, and components.

Furthermore, the results of this study suggest a general tendency to evaluate the economic impact of product variance by quantifying and allocating costs and resources at the product level, as indicated across the life-cycle phases in Figure 2. This approach follows the rationale of assigning costs to the specific units that generate revenue through sales, making it highly practical in terms of traditional cost accounting methods. However, the expenses aggregated from subsystems and components reveal the actual costs incurred. From a product-level perspective, the shared costs of these elements are not clearly distinguished, as argued in Section 4. This might obscure the accuracy of the total cost overview. This could potentially benefit and improve practices for distinguishing the actual costs of products in the industry, improving the foundation on which design decisions are made during the development of new products. How an improved cost overview can strengthen the decision support has been illustrated in an empirical example by Greve [18] and Israelsen and Jørgensen [5]. In practice, companies must consider the economic impact across the entire product life cycle when implementing a modular product strategy to support optimal design decisions. As previously discussed, a considerable part of the economic benefit of modular architectures stems from reductions in indirect costs. The financial performance of a portfolio should not be determined by specific projects or products; rather, it should be assessed across the product portfolio, considering the shared costs and benefits of having a modular product strategy on the module and part levels [5,10]. This underscores the need for companies to treat life-cycle cost awareness as a guiding principle in the development and maintenance of modular product architectures. The lack of such consideration may partly explain why modularization principles have not been more widely adopted in industry [91,92].

This also has significant theoretical implications, as prior studies examining isolated cost effects or focusing on only a selection of the product portfolio may offer limited validity, thus, potentially leading to suboptimal product development decisions, as traditional costing methods often present modular product structures at a financial disadvantage in terms of direct costs and initial investments [9,10,64].

The variation created by new, updated, or altered components and subsystems generates additional costs, both direct and indirect, as previously argued in this paper. Future research could investigate how the excess complexity generated by the introduction of new components and subsystems should be allocated to one of the three levels of abstraction, thus creating a more refined cost allocation model, which could potentially provide a more accurate cost picture divided across component, subsystem, and product levels.

The findings in this paper support our hypothesis by defining and categorizing the assessment of modularity effects at abstraction levels based on the structure of products. This paper provides a new perspective on how modularity impacts the product life cycle and on what level it is assessed. It also suggests that the general tendency is to evaluate the economic impact of product variance by quantifying and allocating costs and resources at the product level. We have observed the challenges of accurately allocating indirect product costs through existing costing methods. Hence, it affects the decision-making of product developers when developing modular product architectures.

As the study illustrates, there is a relatively large gap in studying how MA and IOM can improve each other’s methods and tools. This limits the research conducted through the constraints posed by the opposite field. The two research fields are rarely combined in the attempt to challenge the status quo and improve existing methods, tools, and practices through their combined research. The relationship between MA and IOM needs further investigation, as proposed by Magnacca and Gianetti [19]. They suggest involving the MA approaches directly in the product development phase, thereby using the information gathered directly in the decision-making process when developing products.

Lastly, the magnitude of this issue should be seen in the context of the products and the product manufacturer. Manufacturers with mass-produced products with high volumes will typically have a low overhead, which means that the allocation of indirect costs might prove to be negligible or adequately allocated by using an even distribution, whereas manufacturers with highly specialized and customized products with low volumes will experience indirect costs that will add up to a relatively large portion of the total cost [7]. This is why this field of study tends to have a greater impact on companies operating with highly customized, low-volume productions.

6. Conclusions

This study set out to investigate how traditional costing methods hinder the development of modular product architectures. Through a structured literature review, the gap between the research fields of MA and IOM is highlighted. This review revealed that only a few studies exist that address the impact of traditional costing methods on the development of modular product architectures, owing to the challenge of making accurate and comprehensive quantitative cost assessments as a result of product variance. These studies have disclosed that traditional costing methods fail to account for indirect costs when evaluating the cost benefits of modular product structures. However, the literature did not clearly define the underlying reasons as to why the management costing methods failed. Thus, a hypothesis was developed, suggesting that defining abstraction levels based on current product structures could expose challenges in accurately allocating product variance costs throughout their life cycle. The literature addressing the modularity effects was categorized into three different abstraction levels based on their impact. This provided us with a comprehensive overview of the life-cycle phases and the abstraction levels at which specific modularity effects are currently assessed, whether at the product, subsystem, or component level. The findings revealed a tendency to quantify the effects of modularity on a product level in four out of the five life-cycle phases; e.g., there were more than twice as many instances on the product level, compared to the component or subsystem levels, for the development and production LCPs.

These findings suggest that current costing methods are unable to account accurately for the economic benefits of common parts and modules when conducting modularity initiatives. The costs incurred are tied to the lower abstraction levels of subsystems and components; therefore, the current practice of allocating indirect costs at the product variant level may result in significant inaccuracy in indirect cost allocation to product variants. This paper’s contribution lies in its interpretation of the results, which concludes that product-level cost allocations do not provide an adequate level of accuracy for making informed decisions regarding modular design. Thus, it can be suggested that a more refined cost allocation system is needed to provide a more accurate cost basis on which product developers can make informed decisions for modular product designs. Hence, this study contributes to our understanding of how traditional accounting methods hinder the development of modular product architectures by revealing the level of abstraction at which current costing methods allocate costs, which may result in incorrect or inaccurate indirect cost allocations. This suggests that cost management remains a critical factor in modular product development and that a new approach to allocating costs starting on a lower abstraction level might be essential to create accurate costing models for informed decision-making on product design. Additionally, this can serve as a guiding principle for practitioners seeking to implement a modular product strategy. The cost transparency related to products across all life-cycle phases should be improved at both direct and indirect cost levels by partitioning product structures into evaluable units, providing a basis for understanding the effects of design decisions and the derived product variety across the product portfolio.

Furthermore, it is found that no generalizable or holistic costing tool exists for quantifying the economic benefits of modular product family design across all product life-cycle phases [10,18]. This work does not explicitly propose a solution for resolving this challenge, nor does it offer a solution for refining existing costing methods; it simply provides a new perspective, which could be the first step toward future research at the intersection of MA and IOM. The work is moreover limited to investigating the benefits of modularity effects, although it could be argued that further investigation is needed into how current accounting methods affect cost allocation and product design in general.

7. Future Work

It is important to note that this study reveals the absence of a generalizable method that effectively combines a complete product portfolio with total life-cycle cost [6,20,93]. Furthermore, it highlights the inaccuracy of current cost management systems in allocating indirect costs across an entire product portfolio. The absence of a generalizable method limits the ability of product developers to make informed decisions based on quantitative measures when developing modular product architectures. This underscores the need for further research to address this issue.

- (1)

- Current allocation models must be refined to incorporate more accurate indirect cost allocation throughout the various phases of the product life cycle, particularly for modular product structures. This may require restructuring a company’s internal financial system or implementing an external cost model.

- (2)

- To assess the potential impact of a refined cost allocation model on various types of manufacturing companies, a new costing framework should be developed. The framework should encompass the findings regarding the allocation of product variety costs across different abstraction levels addressed in this paper.

- (3)

- As the first step toward a more generalizable and holistic model, a variety of different manufacturing companies should be included in a case study observing the effects of applying a refined cost allocation model.

A central element for future research is to embed and combine methods and knowledge from both IOM and MA to bridge the gap between the two fields, thereby enabling a successful cost allocation framework that can accurately address the challenges in conducting the accurate cost allocations identified in this research paper.

Author Contributions

All authors contributed to the development and validation of this study. Conceptualization, M.N., J.M.G., C.K.F.C. and N.H.M.; review, M.N., J.M.G. and C.K.F.C.; writing—original draft preparation, M.N.; writing—review and editing, M.N., J.M.G., C.K.F.C. and N.H.M.; visualization, M.N.; supervision, C.K.F.C. and N.H.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Thomas B. Thriges Foundation and the Industriens Foundation as part of the AI-Supported Modular Design and Implementation project (AIMO).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

We gratefully acknowledge the support of the aforementioned foundations, as well as the Technical University of Denmark, for providing the funding and facilities necessary to carry out this research project.

Conflicts of Interest

The authors declare no conflicts of interest. The foundations had no role in the design of the study, the collection, analysis, or interpretation of data, the writing of the manuscript, or the decision to publish the results.

References

- Kwapisz, J.; Infante, V.; Cameron, B.G. Commonality opportunity search in industrial product portfolios Virginia Infante. Int. J. Technol. Manag. 2019, 81, 258–273. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Schuh, G.; ElMaraghy, W.; Piller, F.; Schönsleben, P.; Tseng, M.; Bernard, A. Product variety management. CIRP Ann.-Manuf. Technol. 2013, 62, 629–652. [Google Scholar] [CrossRef]

- Hvam, L.; Hansen, C.L.; Forza, C.; Mortensen, N.H.; Haug, A. The reduction of product and process complexity based on the quantification of product complexity costs. Int. J. Prod. Res. 2020, 58, 350–366. [Google Scholar] [CrossRef]

- Windheim, M.; Hackl, J.; Gebhardt, N.; Krause, D. Assessing Impacts of Modular Product Architectures on The Firm: A Case Study. In Proceedings of the 14th International Design Conference, Dubrovnik, Croatia, 16–19 May 2016; pp. 1445–1454. [Google Scholar]

- Israelsen, P.; Jørgensen, B. Decentralizing decision making in modularization strategies: Overcoming barriers from dysfunctional accounting systems. Int. J. Prod. Econ. 2011, 131, 453–462. [Google Scholar] [CrossRef]

- Wouters, M.; Morales, S.; Grollmuss, S.; Scheer, M. Methods for cost management during product development: A review and comparison of different literatures. Adv. Manag. Account. 2016, 26, 139–274. [Google Scholar] [CrossRef]

- Ehrlenspiel, K.; Kiewert, A.; Lindemann, U. Cost-Efficient Design; ASME International: New York, NY, USA, 2007. [Google Scholar]

- Roy, M.A.; Abdul-Nour, G. Integrating Modular Design Concepts for Enhanced Efficiency in Digital and Sustainable Manufacturing: A Literature Review. Appl. Sci. 2024, 14, 4539. [Google Scholar] [CrossRef]

- Thyssen, J.; Israelsen, P.; Jørgensen, B. Activity-based costing as a method for assessing the economics of modularization-A case study and beyond. Int. J. Prod. Econ. 2006, 10, 252–270. [Google Scholar] [CrossRef]

- Ripperda, S.; Krause, D. Cost Effects of Modular Product Family Structures: Methods and Quantification of Impacts to Support Decision Making. J. Mech. Des. Trans. ASME 2017, 139, 021103. [Google Scholar] [CrossRef]

- Gauss, L.; Lacerda, D.P.; Cauchick Miguel, P.A. Module-based product family design: Systematic literature review and meta-synthesis. J. Intell. Manuf. 2021, 32, 265–312. [Google Scholar] [CrossRef]

- Nørgaard, M.; Grønvald, J.M.; Christensen, C.K.F.; Mortensen, N.H. Challenges in product variant costing—A case study. Proc. Des. Soc. 2024, 4, 3003–3012. [Google Scholar]

- Jiao, J.; Simpson, T.W.; Siddique, Z. Product family design and platform-based product development: A state-of-the-art review. J. Intell. Manuf. 2007, 18, 5–29. [Google Scholar] [CrossRef]

- Park, J.; Simpson, T.W. Toward an activity-based costing system for product families and product platforms in the early stages of development. Int. J. Prod. Res. 2008, 46, 99–130. [Google Scholar] [CrossRef]

- Hackl, J.; Krause, D.; Otto, K.; Windheim, M.; Moon, S.K.; Bursac, N.; Lachmayer, R. Impact of Modularity Decisions on a Firm’s Economic Objectives. J. Mech. Des. Trans. ASME 2020, 142, 041403. [Google Scholar] [CrossRef]

- Simpson, T.W.; Marion, T.; De Weck, O.; Hölttä-Otto, K.; Kokkolaras, M.; Shooter, S.B. Platform-based Design and Development: Current Trends and Needs in Industry. In Proceedings of the ASME 2006 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Philadelphia, PA, USA, 10–13 September 2006. [Google Scholar]

- Stadtherr, F.; Wouters, M. Extending target costing to include targets for R&D costs and production investments for a modular product portfolio—A case study. Int. J. Prod. Econ. 2021, 231, 107871. [Google Scholar] [CrossRef]

- Greve, E.; Fuchs, C.; Hamraz, B.; Windheim, M.; Rennpferdt, C.; Schwede, L.-N.; Krause, D. Knowledge-Based Decision Support for Concept Evaluation Using the Extended Impact Model of Modular Product Families. Appl. Sci. 2022, 12, 547. [Google Scholar] [CrossRef]

- Magnacca, F.; Giannetti, R. Management accounting and new product development: A systematic literature review and future research directions. J. Manag. Gov. 2024, 28, 651–685. [Google Scholar] [CrossRef]

- Wouters, M.; Stadtherr, F. Cost management and modular product design strategies. In The Routledge Companion to Performance Management and Control; Routledge: London, UK, 2017; pp. 54–86. [Google Scholar]

- Mortensen, N.H.; Bertram, C.A.; Lundgaard, R. Achieving long-term modularization benefits: A small- and medium-sized enterprise study. Concurr. Eng. Res. Appl. 2019, 27, 14–27. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Susur, E.; Urueña, A.; Nuur, C.; Kumar, V.; Franchi, S.; Sorrentino, C. The relationship between digital technologies and the circular economy: A systematic literature review and a research agenda. R&D Manag. 2024, 55, 617–714. [Google Scholar] [CrossRef]

- Schwede, L.-N.; Greve, E.; Krause, D.; Otto, K.; Moon, S.K.; Albers, A.; Kirchner, E.; Lachmayer, R.; Bursac, N.; Inkermann, D.; et al. How to Use the Levers of Modularity Properly-Linking Modularization to Economic Targets. J. Mech. Des. Trans. ASME 2022, 144, 071401. [Google Scholar] [CrossRef]

- Gusenbauer, M.; Haddaway, N.R. Which academic search systems are suitable for systematic reviews or meta-analyses? Evaluating retrieval qualities of Google Scholar, PubMed, and 26 other resources. Res. Synth. Methods 2020, 11, 181–217. [Google Scholar] [CrossRef]

- Visser, M.; van Eck, N.J.; Waltman, L. Large-scale comparison of bibliographic data sources: Scopus, web of science, dimensions, crossref, and microsoft academic. Quant. Sci. Stud. 2021, 2, 20–41. [Google Scholar] [CrossRef]

- Micheli, G.J.L.; Trucco, P.; Sabri, Y.; Mancini, M. Modularization as a system life cycle management strategy: Drivers, barriers, mechanisms and impacts. Int. J. Eng. Bus. Manag. 2019, 11, 1847979018825041. [Google Scholar] [CrossRef]

- Mertens, K.G. Measure and Manage your Product Costs Right-Development and Use of an Extended Axiomatic Design for Cost Modeling. Ph.D. Thesis, Technische Universität Hamburg, Hamburg, Germany, 2020. [Google Scholar]

- Mertens, K.G.; Schmidt, M.; Yildiz, T.; Meyer, M. Introducing a framework to generate and evaluate the cost effects of product (family) concepts. Proc. Des. Soc. 2021, 1, 1907–1916. [Google Scholar]

- Greve, E.; Krause, D. Long-term effects of modular product architectures: An empirical follow-up study. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 84, pp. 731–736. [Google Scholar]

- Kahn, B. Variety: From the Consumer’s Perspective. In International Series in Operations Research & Management Science; Springer Science + Business Media: New York, NY, USA, 1998; pp. 19–37. [Google Scholar]

- Fadeyi, J.A.; Monplaisir, L. Instilling lifecycle costs into modular product development for improved remanufacturing-product service system enterprise. Int. J. Prod. Econ. 2022, 246, 108404. [Google Scholar] [CrossRef]

- Asiedu, Y.; Gu, P. Product life cycle cost analysis: State of the art review. Int. J. Prod. Res. 1998, 36, 883–908. [Google Scholar] [CrossRef]

- Fixson, S.K. Product architecture assessment: A tool to link product, process, and supply chain design decisions. J. Oper. Manag. 2005, 23, 345–369. [Google Scholar] [CrossRef]

- Windheim, M.; Gebhardt, N.; Krause, D. Towards a Decision-Making Framework for Multi-Criteria Product Modularization in Cooperative Environments. Procedia CIRP 2018, 70, 380–385. [Google Scholar] [CrossRef]

- Martin, M.V.; Ishii, K. Design for Variety: Development of Complexity Indices and Design Charts. In Proceedings of the DETC ‘97 1997 ASME Design Engineering Technical Conferences, Sacramento, CA, USA, 14–17 September 1997; ASME: New York, NY, USA, 1997. [Google Scholar]

- Siguenza-Guzman, L.; Van Den Abbeele, A.; Vandewalle, J.; Verhaaren, H.; Cattrysse, D. Recent evolutions in costing systems: A literature review of Time-Driven Activity-Based Costing. Rev. Bus. Econ. Lit. 2013, 58, 34–64. [Google Scholar]

- Horngren, C.T.; Datar, S.M.; Rajan, M.V. Cost Accounting a Managerial Emphasis, 13th ed.; Pearson Internation Edition: London, UK, 2009. [Google Scholar]

- Drury, C. Cost and Management Accounting—An Introduction; Cengage Learning EMEA: Hampshire, UK, 2015. [Google Scholar]

- Wilson, S.A.; Perumal, A. Reshape your cost structure, free up cash flows, and boost productivity by attacking process, product and organizational complexity. In Waging War on Complexity Costs; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Cooper, R.; Kaplan, R.S. Measure Costs Right: Make the Right Decisions. Harv. Bus. Rev. 1988, 66, 96–103. [Google Scholar]

- Kaplan, R.S.; Cooper, R. Cost & Effect: Using Integrated Cost Systems to Drive Profitability and Performance; Harvard Business Press: Brighton, UK, 1998. [Google Scholar]

- Park, J.; Simpson, T.W. Development of a production cost estimation framework to support product family design. Int. J. Prod. Res. 2005, 43, 731–772. [Google Scholar] [CrossRef]

- Kaplan, R.S.; Anderson, S.R. Time-Driven Activity-Based Costing; Harvard Business Review: Brighton, UK, 2004; Volume 82. [Google Scholar] [CrossRef]

- Trattner, A.; Hvam, L.; Forza, C.; Nadja Lee Herbert-Hansen, Z. Product complexity and operational performance: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2019, 25, 65–83. [Google Scholar] [CrossRef]

- Thonemann, U.W.; Brandeau, M.L. Optimal Commonality in Component Design. Oper. Res. 2000, 48, 1–19. [Google Scholar] [CrossRef]

- Myrodia, A.; Hvam, L.; Sandrin, E.; Forza, C.; Haug, A. Identifying variety-induced complexity cost factors in manufacturing companies and their impact on product profitability. J. Manuf. Syst. 2021, 60, 373–391. [Google Scholar] [CrossRef]

- Yano, C.; Dobson, G. Profit-Optimizing Product Line Design, Selection and Pricing with Manufacturing Cost Consideration. In Product Variety Management; Springer: Berlin/Heidelberg, Germany, 1998; pp. 146–175. [Google Scholar]

- Wouters, M.; Morales, S. The contemporary art of cost management methods during product development. Adv. Manag. Account. 2014, 24, 259–346. [Google Scholar] [CrossRef]

- Bonvoisin, J.; Halstenberg, F.; Buchert, T.; Stark, R. A systematic literature review on modular product design. J. Eng. Des. 2016, 27, 488–514. [Google Scholar] [CrossRef]

- Ericsson, A.; Erixon, G. Controlling Design Variants: Modular Product Platforms; Society of Manufacturing Engineers: Southfield, MI, USA, 1999. [Google Scholar]

- Otto, K.N.; Wood, K.L. Product Design: Techniques in Reverse Engineering and New Product Development; PrenticeHall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development, 5th ed.; McGraw Hill: New York, NY, USA, 2012. [Google Scholar]

- Boer, H.E.E. Product, Organizational and Performance Effects of Product Modularity. In Proceedings of the 7th World Conference on Mass Customization, Personalization and Co-Creation (MCPC 2014), Aalborg, Denmark, 4–7 February 2014; Springer Nature: Berlin/Heidelberg, Germany, 2014; Volume Part F1148, pp. 449–460. [Google Scholar]

- Jacobs, M.; Droge, C.; Vickery, S.K.; Calantone, R. Product and Process Modularity’s Effects on Manufacturing Agility and Firm Growth Performance. J. Prod. Innov. Manag. 2011, 28, 123–137. [Google Scholar] [CrossRef]

- Robertson, D.; Ulrich, K. Planning for Product Platforms. Sloan Manag. Rev. 1998, 39, 19–32. [Google Scholar]

- Salvador, F. Toward a product system modularity construct: Literature review and reconceptualization. IEEE Trans. Eng. Manag. 2007, 54, 219–240. [Google Scholar] [CrossRef]

- Fixson, S.K. A Road Map For Product Architecture Costing. In Product Platform and Product Family Design: Methods and Applications; Simpson, T.W., Siddique, Z., Jiao, J., Eds.; Springer Science + Business Media: New York, NY, USA, 2006; pp. 305–334. [Google Scholar]

- Meyer, M.H.; Lehnerd, A.P. The Power of Product Platforms: Building Value and Cost Leadership; The Free Press: Los Angeles, CA, USA, 1997. [Google Scholar]

- Perera, H.S.C.; Nagarur, N.; Tabucanon, M.T. Component part standardization: A way to reduce the life-cycle costs of products. Int. J. Prod. Econ. 1999, 60–61, 109–116. [Google Scholar] [CrossRef]

- Cameron, B.G.; Rhodes, R.; Boas, R.; Crawley, E.F. Divergence In Platform Commonality: Examination of Potential Cost Implications. In Proceedings of the 11th International Design Conference—Design, Dubrovnik, Croatia, 3–10 March 2010; pp. 157–162. [Google Scholar]

- Sohrt, M.; Blinkenberg, W.; Mortensen, N.H.; Haug, A.; Hvam, L. A Method for Modelling Business-Critical Architecture Decisions in Engineer-to-Order Companies. Appl. Sci. 2025, 15, 1998. [Google Scholar] [CrossRef]

- Taipaleenmäki, J. Absence and Variant Modes of Presence of Management Accounting in New Product Development—Theoretical Refinement and Some Empirical Evidence. Eur. Account. Rev. 2014, 23, 291–334. [Google Scholar] [CrossRef]

- Horber, D.; Pickel, J.; Goetz, S.; Wartzack, S. Utilizing System Models for Multicriteria Decision-Making—A Systematic Literature Review on the Current State of the Art. IEEE Open J. Syst. Eng. 2024, 2, 135–147. [Google Scholar] [CrossRef]

- Boas, R.; Cameron, B.G.; Crawley, E.F. Divergence and lifecycle offsets in product families with commonality. Syst. Eng. 2013, 16, 175–192. [Google Scholar] [CrossRef]

- Gershenson, J.K.; Prasad, G.J.; Zhang, Y. Product modularity: Definitions and benefits. J. Eng. Des. 2003, 14, 295–313. [Google Scholar] [CrossRef]

- Weiser, A.K.; Baasner, B.; Hosch, M.; Schlueter, M.; Ovtcharova, J. Complexity Assessment of Modular Product Families. Procedia CIRP 2016, 50, 595–600. [Google Scholar] [CrossRef]

- Sigsgaard, K.V.; Agergaard, J.K.; Bertram, C.A.; Mortensen, N.H.; Soleymani, I.; Khalid, W.; Hansen, K.B.; Mueller, G.O. Structuring and Contextualizing Historical Data for Decision Making in Early Development. In Design 2020, Proceedings of 16th International Design Conference, Dubrovnik, Croatia, 18–21 May 2020; Cambridge University Press: Cambridge, UK, 2020; Volume 1, pp. 393–402. [Google Scholar]

- Chiu, M.-C.; Okudan, G. An Investigation on the Impact of Product Modularity Level on Supply Chain Performance Metrics: An Industrial Case Study. J. Intell. Manuf. 2014, 25, 129–145. [Google Scholar] [CrossRef]

- Harland, P.E.; Uddin, Z. Effects of Product Platform Development: Fostering Lean Product Development and Production. Int. J. Prod. Dev. 2014, 19, 259. [Google Scholar] [CrossRef]

- Dogramaci, A. Design of Common Components Considering Implications of Inventory Costs and Forecasting. AIIE Trans. 1979, 11, 129–135. [Google Scholar] [CrossRef]

- Eynan, A.; Rosenblatt, M.J. Component commonality effects on inventory costs. IIE Trans. 1996, 28, 93–104. [Google Scholar] [CrossRef]

- Collier, D.A. The Measurement and Operating Benefits of Component Part Commonality. Decis. Sci. 1981, 12, 85–96. [Google Scholar] [CrossRef]

- Danese, P.; Filippini, R. Direct and Mediated Effects of Product Modularity on Development Time and Product Performance. IEEE Trans. Eng. Manag. 2013, 60, 260–271. [Google Scholar] [CrossRef]

- Abdelkafi, N. Variety-Induced Complexity in Mass Customization Concepts and Management; Blecker, T., Huang, G.Q., Salvador, F., Eds.; Erich Schmidt: Berlin, Germany, 2008. [Google Scholar]

- Mikkola, J.H.; Gassmann, O. Managing Modularity of Product Architectures: Toward an Integrated Theory. IEEE Trans. Eng. Manag. 2003, 50, 204–218. [Google Scholar] [CrossRef]

- Baldwin, C.Y.; Clark, K.B. Design Rules; The MIT Press: Cambridge, MA, USA, 2000. [Google Scholar]

- Ulrich, K. The Role of Product Architecture in the Manufacturing Firm. Res. Policy 1995, 24, 419–440. [Google Scholar] [CrossRef]

- Hansen, P.; Andreasen, M.; Ulf, H.; Gubi, E.; Mortensen, N. Understanding the Phenomenon of Modularization. In Design 2002, Proceedings of the 7th International Design Conference, Dubrovnik, Croatia, 14–17 May 2002; Marjanovic, D., Ed.; University of Zagreb, Faculty Mechanical Engineering & Naval Architecture: Zagreb, Croatia, 2002. [Google Scholar]

- Lau Antonio, K.W.; Yam, R.C.M.; Tang, E. The Impacts of Product Modularity on Competitive Capabilities and Performance: An Empirical Study. Int. J. Prod. Econ. 2007, 105, 1–20. [Google Scholar] [CrossRef]

- Vogt, J.; Woeller, L.N.; Krause, D. Effects of Product Personalization: Considering Personalizability in the Product Architecture of Modular Product Families. J. Mech. Des. 2024, 146, 1–47. [Google Scholar] [CrossRef]

- Ulrich, K. Fundamentals of Product Modularity. In Management of Design; Springer: Dordrecht, The Netherlands, 1994; pp. 219–231. [Google Scholar]

- Hölttä-Otto, K. Modular Product Platform Design. Ph.D. Thesis, Helsinki University of Technology, Espoo, Finland, 2005. [Google Scholar]

- Salonen, M.; Otto, K.H.; Otto, K. Effecting Product Reliability and Life Cycle Costs with Early Design Phase Product Architecture Decisions. Int. J. Prod. Dev. 2008, 5, 109. [Google Scholar] [CrossRef]