Investigation of Ti65 Powder Spreading Behavior in Multi-Layer Laser Powder Bed Fusion

Abstract

1. Introduction

2. Methodology

2.1. DEM Model

2.2. CFD Model

- (1)

- Mass:

- (3)

- Convection heat loss (qcon):

- Radiation heat loss (qrad):

- Evaporation heat loss (qevap):

- Laser heat input (qlaser) [10]:

3. Simulation Conditions and Model Validation

3.1. Powder Characterization

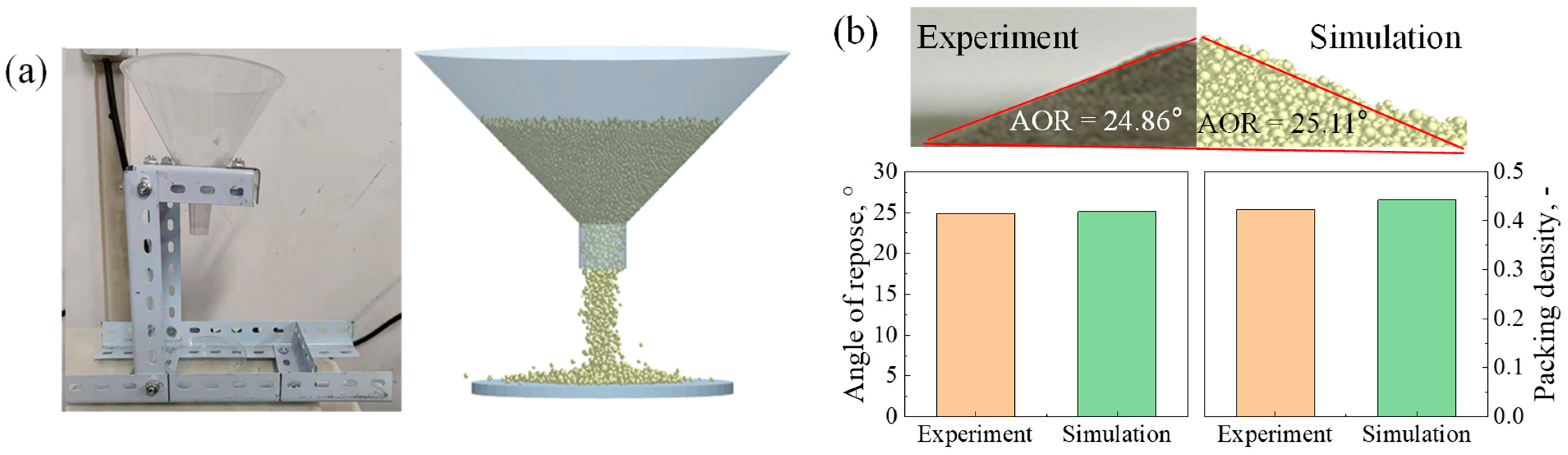

3.2. Parameter Calibration

3.3. Simulation Setup

3.4. Model Validation

4. Results and Discussion

4.1. Variation in Powder Bed Quality over Successive Layers

4.1.1. Macroscopic Properties

4.1.2. Microscopic Properties

4.2. Variation in Powder Bed Quality Across Printed and Non-Printed Regions

4.2.1. Macroscopic Properties

4.2.2. Microscopic Properties

4.3. Mechanism Analysis

5. Conclusions

- The powder bed quality improves with increasing layer number. The first two layers exhibit low packing density and high surface roughness due to limited powder availability and a strong boundary effect. From the third layer onward, the powder bed properties stabilize, indicating a diminishing influence from the initial layer constraints.

- Properly reducing the spreading velocity enhances powder bed quality, as evidenced by increased packing density, improved surface uniformity, a higher coordination number, and a reduced coefficient of variation. This improvement is attributed to the longer time available for particle rearrangement and void filling at lower velocities.

- The printed region influences not only the powder bed formed directly above it (Zone 2) but also indirectly alters the bed quality in front of (Zone 1) and behind (Zone 3) it. As a result, the height profile of the powder bed across the three zones shows a decreasing trend along the spreading direction.

- Mechanism analysis reveals that the printed region induces a high-contact force zone at the interface between Zones 1 and 2 due to the obstruction, leading to the formation of a low-velocity area and enhanced local densification. In Zone 2, particle motion is constrained by printed geometry, promoting a relatively dense packing structure. Driven by the recoating blade, only a limited number of particles fall into the area ahead of Zone 3, leading to the formation of a pit. Additionally, due to insufficient particle supply, a relatively loosely packed powder bed forms in Zone 3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.Y.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy—A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Li, W.Y.; Chen, Z.Y.; Liu, J.R.; Wang, Q.J.; Sui, G.X. Effect of texture on anisotropy at 600 °C in a near-α titanium alloy Ti60 plate. Mater. Sci. Eng. A 2017, 688, 322–329. [Google Scholar] [CrossRef]

- Zhong, W.; Yu, K.; Shi, J.P.; Shen, Y.M.; Li, P.F.; Lu, J.Z. High-temperature oxidation behavior of TA15 aerospace titanium alloy at 500 °C and 800 °C. J. Mater. Res. Technol. 2024, 30, 3355–3366. [Google Scholar] [CrossRef]

- Sun, J.F.; Lu, H.F.; Wang, Z.; Luo, K.Y.; Lu, J.Z. High-temperature oxidation behaviour of Ti65 titanium alloy fabricated by laser direct energy deposition. Corros. Sci. 2024, 229, 111866. [Google Scholar] [CrossRef]

- Yue, K.; Liu, J.R.; Zhang, H.J.; Yu, H.; Song, Y.Y.; Hu, Q.M.; Wang, Q.J.; Yang, R. Precipitates and alloying elements distribution in near α titanium alloy Ti65. J. Mater. Sci. Technol. 2020, 36, 91–96. [Google Scholar] [CrossRef]

- Li, J.M.; Wang, Y.; Jiang, S.W.; Cheng, Y.S.; Zou, Y.S.; Liu, H.B. Correction of the constitutive model and analysis of chip formation in cryogenic machining of TA15 titanium alloy. J. Manuf. Process. 2024, 113, 16–33. [Google Scholar] [CrossRef]

- Balc, A.; Çiçek, A.; Uçak, N.; Aslantas, K. Investigation of the effects of heat treatment and hot isostatic pressing in micro-drilling of Ti6Al4V alloy fabricated by laser powder bed fusion. Precis. Eng. 2024, 91, 617–631. [Google Scholar] [CrossRef]

- Cao, L. Mesoscopic-scale numerical investigation including the influence of scanning strategy on selective laser melting process. Comput. Mater. Sci. 2021, 189, 110263. [Google Scholar] [CrossRef]

- Gao, X.; Faria, G.A.; Zhang, W.; Wheeler, K.R. Numerical analysis of non-spherical particle effect on molten pool dynamics in laser-powder bed fusion additive manufacturing. Comput. Mater. Sci. 2020, 179, 109648. [Google Scholar] [CrossRef]

- Gu, D.D.; Xia, M.J.; Dai, D.H. On the role of powder flow behavior in fluid thermodynamics and laser processability of Ni-based composites by selective laser melting. Int. J. Mach. Tools Manuf. 2019, 137, 67–78. [Google Scholar] [CrossRef]

- Han, Q.Q.; Gu, H.; Setchi, R. Discrete element simulation of powder layer thickness in laser additive manufacturing. Powder Technol. 2019, 352, 91–102. [Google Scholar] [CrossRef]

- Zhou, H.T.; Su, H.J.; Guo, Y.N.; Yang, P.X.; Liu, Y.; Shen, Z.L.; Zhao, D.; Liu, H.F.; Huang, T.W.; Guo, M.; et al. Formation and evolution mechanisms of pores in Inconel 718 during selective laser melting: Meso-scale modeling and experimental investigations. J. Manuf. Process. 2022, 81, 202–213. [Google Scholar] [CrossRef]

- Yan, W.; Ge, W.; Qian, Y.; Lin, S.; Zhou, B.; Liu, W.K.; Lin, F.; Wagner, G.J. Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater. 2017, 134, 324–333. [Google Scholar] [CrossRef]

- Wu, Q.; Qiao, C.; Yao, D.Z.; An, X.Z.; Zhang, H.; Fu, H.T.; Yang, X.H.; Zou, Q.C. Research on improving the spread ability of viscous powder in additive manufacturing. Powder Technol. 2023, 413, 118061. [Google Scholar] [CrossRef]

- Laskowski, R.; Ahluwalia, R.; Hock, G.T.W.; Ying, C.S.; Sun, C.N.; Wang, P.; Cheh, D.T.C.; Sharon, N.M.L.; Vastola, C. Concurrent modeling of porosity and microstructure in multilayer three-dimensional simulations of powder-bed fusion additive manufacturing of INCONEL 718. Addit. Manuf. 2022, 60, 103266. [Google Scholar]

- Wang, J.; Yao, D.Z.; Li, M.; An, X.Z.; Li, S.J.; Hou, W.T.; Zhang, X.; Yang, G.Y.; Wang, J.; Wang, L. Hierarchical effects of multi-layer powder spreading in the electron beam powder bed fusion additive manufacturing of pure tungsten material. Addit. Manuf. 2022, 55, 102835. [Google Scholar] [CrossRef]

- Sun, J.F.; Lu, H.F.; Zhang, H.M.; Luo, K.Y.; Lu, J.Z. Effect of thermal exposure on microstructure and mechanical properties of Ti65 high-temperature titanium alloy deposited by laser direct energy deposition. Mater. Sci. Eng. A 2024, 908, 146757. [Google Scholar] [CrossRef]

- Sun, J.F.; Lu, H.F.; Liang, Y.C.; Zhang, H.M.; Luo, K.Y.; Lu, J.Z. Evolution of microstructure and mechanical properties of Ti65 high-temperature titanium alloy after additive manufacturing and annealing. Mater. Sci. Eng. A 2024, 913, 147002. [Google Scholar] [CrossRef]

- Long, Y.F.; An, X.Z.; Wang, J.; Li, M.; Wu, Q.; Jiang, C.N.; Liu, J.F.; Ren, D.C.; Ji, H.B.; Li, S.J.; et al. Surface roughness and pore evolutions in multi-layer laser powder bed fusion of extra-low interstitial Ti-5Al-2.5Sn powder: A numerical study. Addit. Manuf. 2024, 95, 104530. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar]

- Zhao, H.Y.; An, X.Z.; Wu, Y.L.; Qian, Q. DEM modeling on stress profile and behavior in granular matter. Powder Technol. 2018, 323, 149–154. [Google Scholar] [CrossRef]

- Yang, R.Y.; Zou, R.P.; Yu, A.B. Computer simulation of the packing of fine particles. Phys. Rev. E 2000, 62, 3900. [Google Scholar] [CrossRef]

- Yao, D.Z.; Liu, X.H.; Wang, J.; Fan, W.; Li, M.; Fu, H.T.; Zhang, H.; Yang, X.H.; Zou, Q.C.; An, X.Z. Numerical insights on the spreading of practical 316L stainless steel powder in SLM additive manufacturing. Powder Technol. 2021, 390, 197–208. [Google Scholar] [CrossRef]

- He, Y.; Hassanpour, A.; Behjani, A.M.; Bayly, A.E. A novel stiffness scaling methodology for discrete element modelling of cohesive fine powders. Appl. Math. Model. 2021, 90, 817–844. [Google Scholar] [CrossRef]

- An, X.Z.; Yang, R.Y.; Dong, K.J.; Yu, A.B. DEM study of crystallization of monosized spheres under mechanical vibrations. Comput. Phys. Commun. 2011, 182, 1989–1994. [Google Scholar] [CrossRef]

- Tang, C.; Tan, J.L.; Wong, C.H. A numerical investigation on the physical mechanisms of single track defects in selective laser melting. Int. J. Heat Mass Transf. 2018, 126, 957–968. [Google Scholar] [CrossRef]

- Cao, L. Numerical simulation of the impact of laying powder on selective laser melting single-pass formation. Int. J. Heat Mass Transf. 2019, 141, 1036–1048. [Google Scholar] [CrossRef]

- Xia, M.J.; Gu, D.D.; Yu, G.Q.; Dai, D.H.; Chen, H.Y.; Shi, Q.M. Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2017, 116, 96–106. [Google Scholar] [CrossRef]

- Cao, L. Mesoscopic-scale simulation of pore evolution during laser powder bed fusion process. Comput. Mater. Sci. 2020, 179, 109686. [Google Scholar] [CrossRef]

- Cao, L. Workpiece-scale numerical simulations of SLM molten pool dynamic behavior of 316L stainless steel. Comput. Math. Appl. 2021, 96, 209–228. [Google Scholar] [CrossRef]

- Tian, Y.F.; Yang, L.J.; Zhao, D.J.; Huang, Y.M.; Pan, J.J. Numerical analysis of powder bed generation and single track forming for selective laser melting of SS316L stainless steel. J. Manuf. Process. 2020, 58, 964–974. [Google Scholar] [CrossRef]

- Yuan, W.H.; Chen, H.; Cheng, T.; Wei, Q.S. Effects of laser scanning speeds on different states of the molten pool during selective laser melting: Simulation and experiment. Mater. Des. 2020, 189, 108542. [Google Scholar] [CrossRef]

- Wei, H.L.; Cao, Y.; Liao, W.H.; Liu, T.T. Mechanisms on inter-track void formation and phase transformation during laser Powder Bed Fusion of Ti-6Al-4V. Addit. Manuf. 2020, 34, 101221. [Google Scholar] [CrossRef]

- Wang, Z.; Yan, W.; Liu, W.K.; Liu, M. Powder-scale multi-physics modeling of multi-layer multi-track selective laser melting with sharp interface capturing method. Comput. Mech. 2018, 63, 649–661. [Google Scholar] [CrossRef]

- Al-Hashemi, H.M.B.; Al-Amoudi, O.S.B. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Zhao, H.Y.; An, X.Z.; Gou, D.Z.; Zhao, B.; Yang, R.Y. Attenuation of pressure dips underneath piles of spherocylinders. Soft Matter 2018, 14, 4404–4410. [Google Scholar] [CrossRef]

- Xu, W.; Du, Z.H.; Wang, Z.; Ran, X.; Li, Z.Y.; Chen, R.; Zhu, X.Y.; Zhang, X.H.; Zhang, J.Z.; Lin, X. A comparative study on the corrosion, wear, and tribocorrosion performances of Ti-6.5Al-2Zr-1Mo-1V (TA15) alloy fabricated by selective laser melting and laser metal deposition. J. Mater. Res. Technol. 2024, 30, 6245–6253. [Google Scholar] [CrossRef]

- Wang, L.; Li, E.L.; Shen, H.; Zou, R.P.; Yu, A.B.; Zhou, Z.Y. Adhesion effects on spreading of metal powders in selective laser melting. Powder Technol. 2020, 363, 602–610. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Particle size, D, μm | D50 = 38.7, D90 = 61.5 |

| Poisson’s ratio, υ, - | 0.28 |

| Density, ρ, kg/m3 | 4540 |

| Young’s modulus, E, GPa | 117 |

| Coefficient of restitution, e, - | 0.775 |

| Coefficient of sliding friction, μs, - | 0.564 |

| Coefficient of rolling friction, μr, - | 0.012 |

| Surface energy, γ, J/m2 | 0.0002 |

| Acceleration of gravity, g, m/s2 | 9.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wang, J.; Yu, G.; Li, X.; Li, M.; An, X.; Ni, J.; Zhao, H.; Ma, Q. Investigation of Ti65 Powder Spreading Behavior in Multi-Layer Laser Powder Bed Fusion. Appl. Sci. 2025, 15, 6220. https://doi.org/10.3390/app15116220

Liu Z, Wang J, Yu G, Li X, Li M, An X, Ni J, Zhao H, Ma Q. Investigation of Ti65 Powder Spreading Behavior in Multi-Layer Laser Powder Bed Fusion. Applied Sciences. 2025; 15(11):6220. https://doi.org/10.3390/app15116220

Chicago/Turabian StyleLiu, Zhe, Ju Wang, Ge Yu, Xiaodan Li, Meng Li, Xizhong An, Jiaqiang Ni, Haiyang Zhao, and Qianya Ma. 2025. "Investigation of Ti65 Powder Spreading Behavior in Multi-Layer Laser Powder Bed Fusion" Applied Sciences 15, no. 11: 6220. https://doi.org/10.3390/app15116220

APA StyleLiu, Z., Wang, J., Yu, G., Li, X., Li, M., An, X., Ni, J., Zhao, H., & Ma, Q. (2025). Investigation of Ti65 Powder Spreading Behavior in Multi-Layer Laser Powder Bed Fusion. Applied Sciences, 15(11), 6220. https://doi.org/10.3390/app15116220