A Comparative Review of Mechanical and Petrographic Properties and Their Role in Estimating the Brittleness Index of Norite: Implications for Geomechanical Applications

Abstract

1. Introduction

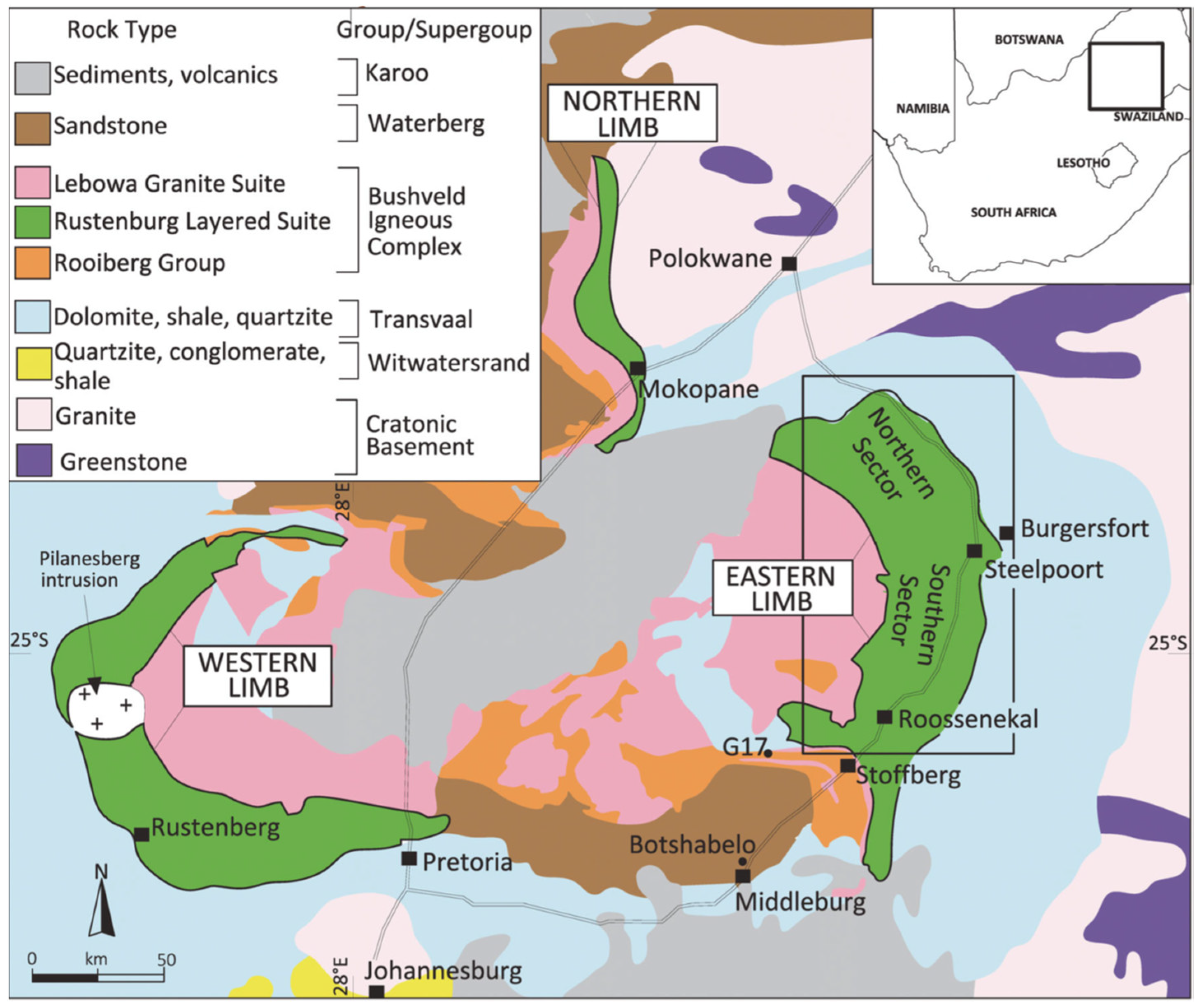

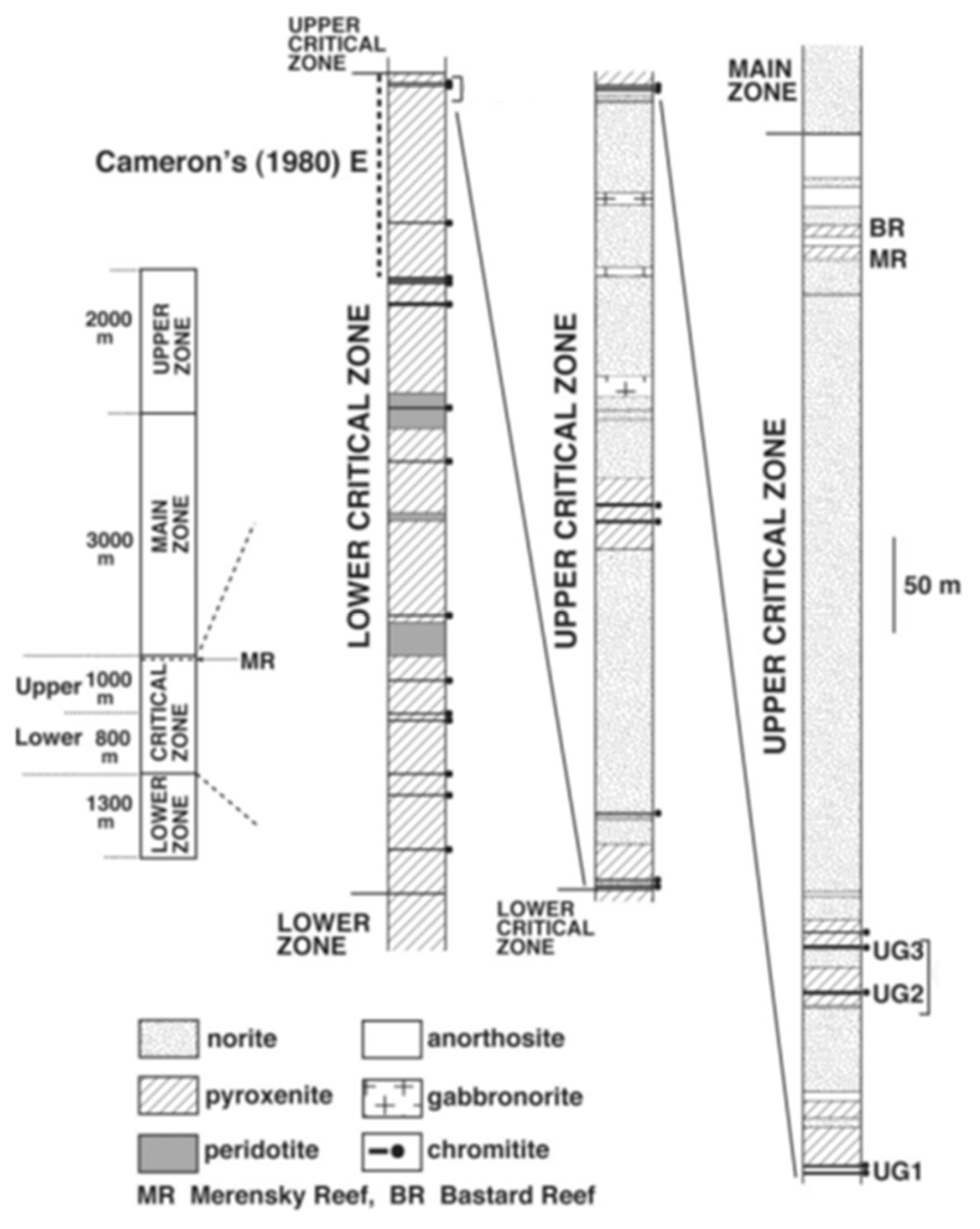

2. Geological and Petrographic Overview of Norite

2.1. Origin and Formation of Norite

2.2. Petrographic Properties of Norite

2.3. Influence of Petrographic Properties on Mechanical Behavior

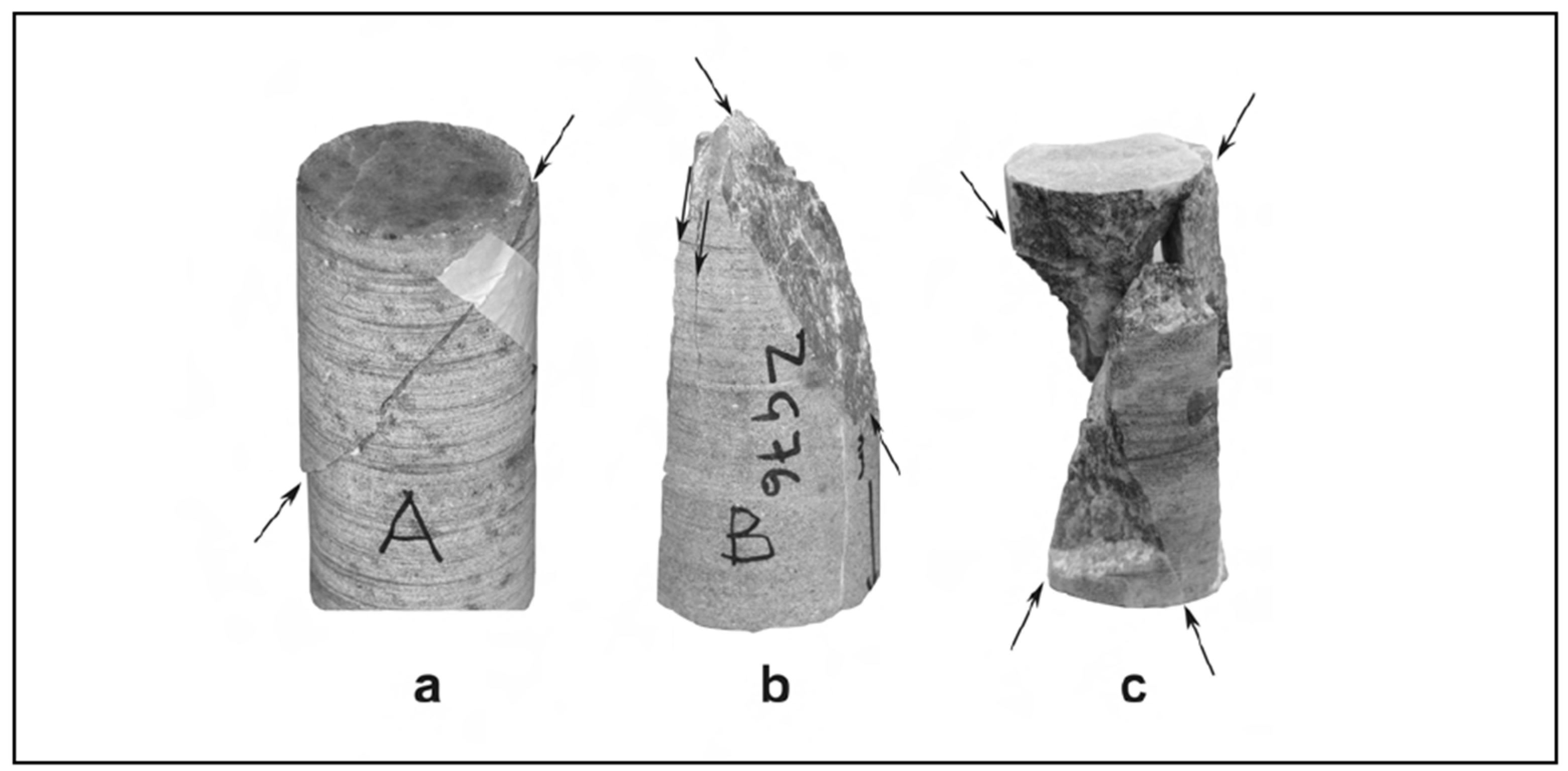

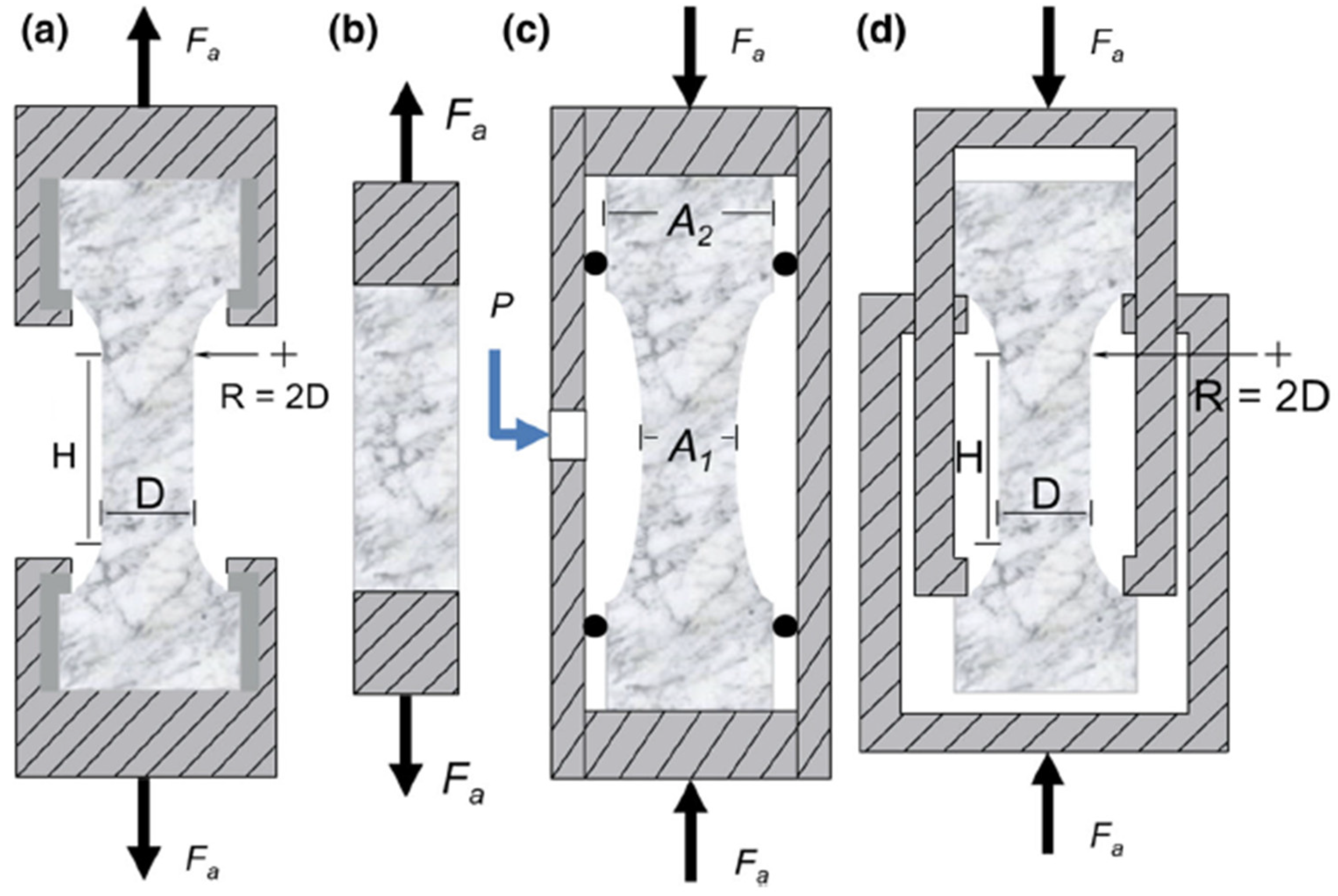

3. Mechanical Properties of Norite

3.1. Strength Parameters

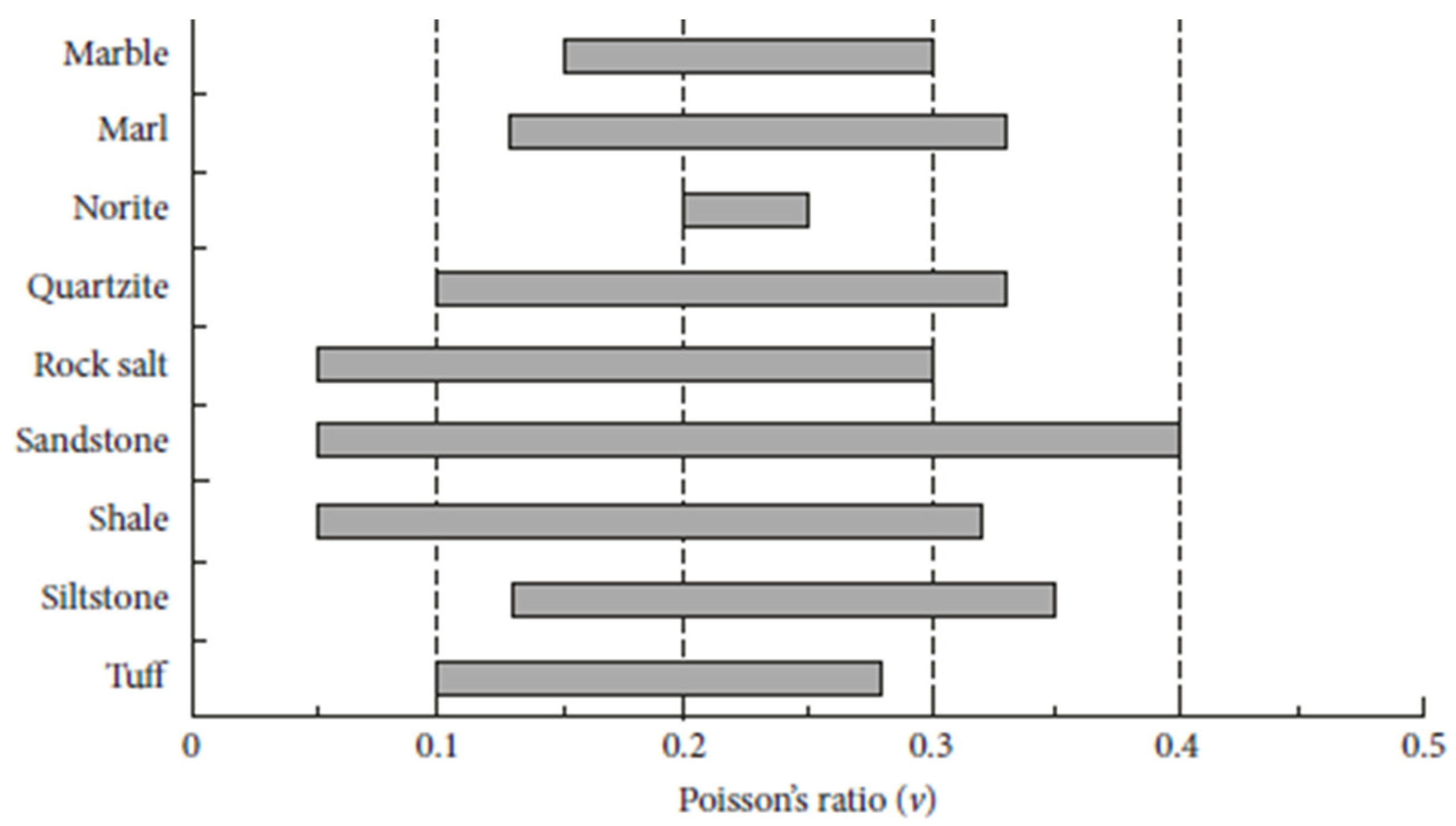

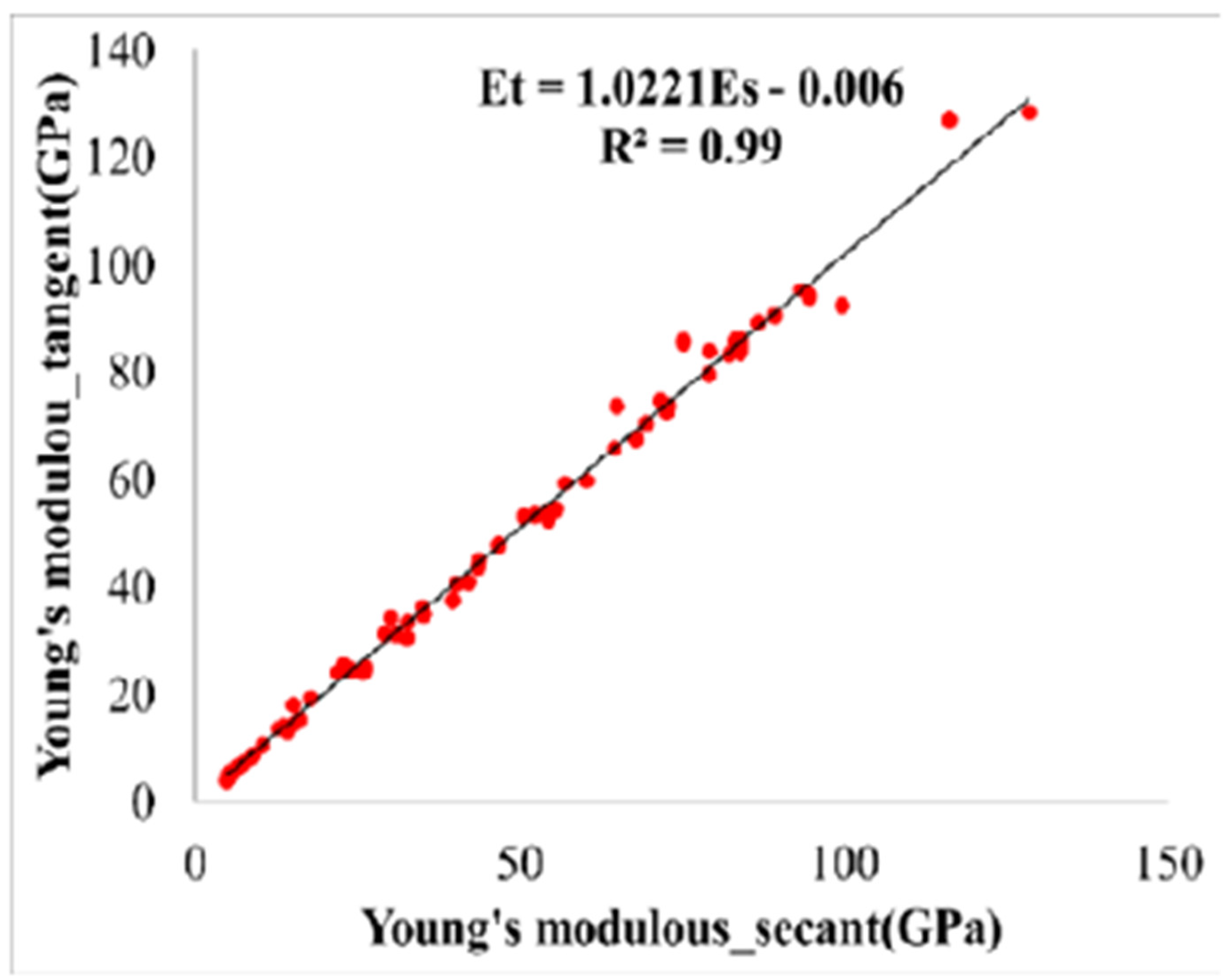

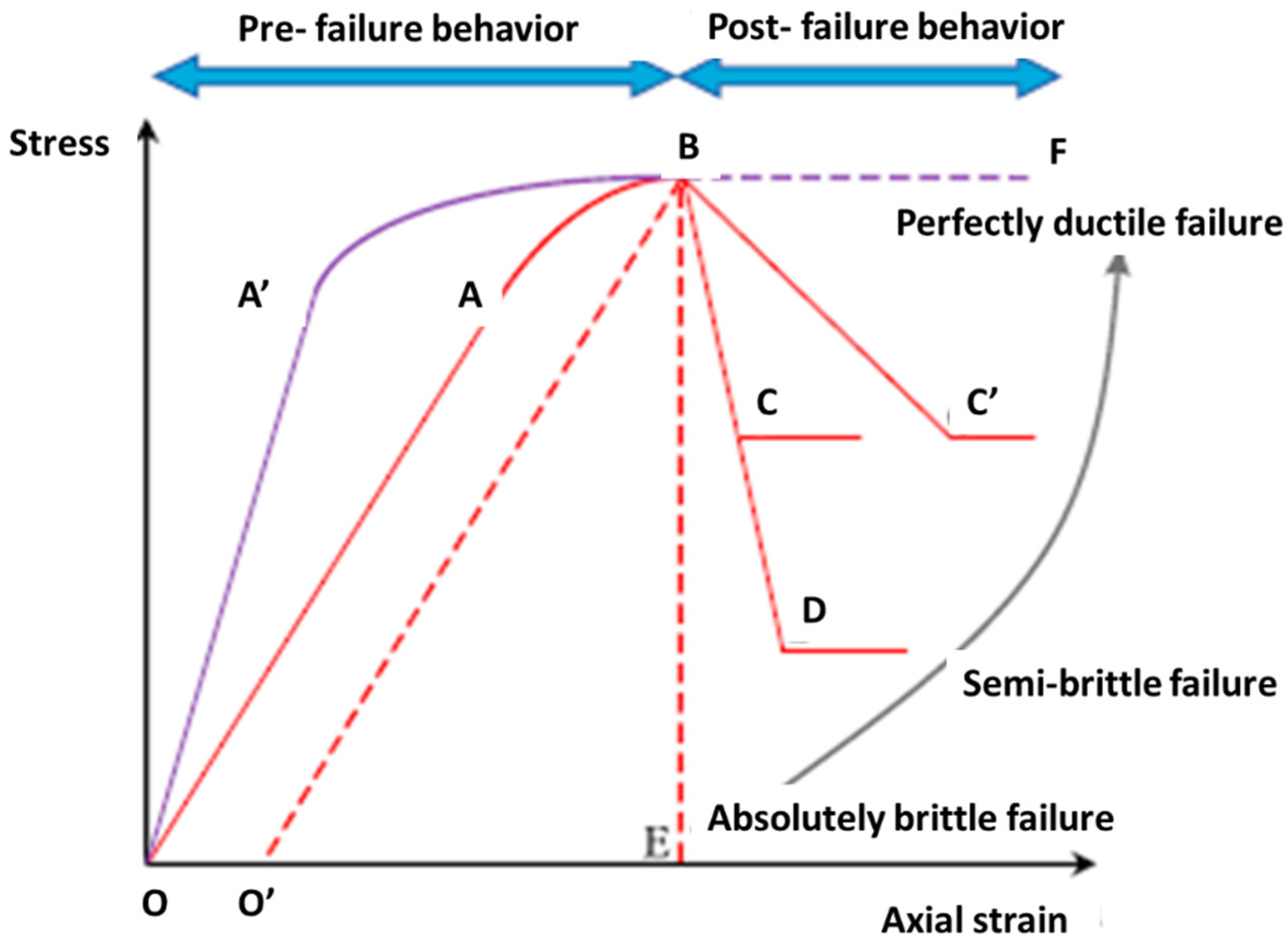

3.2. Deformation Characteristics

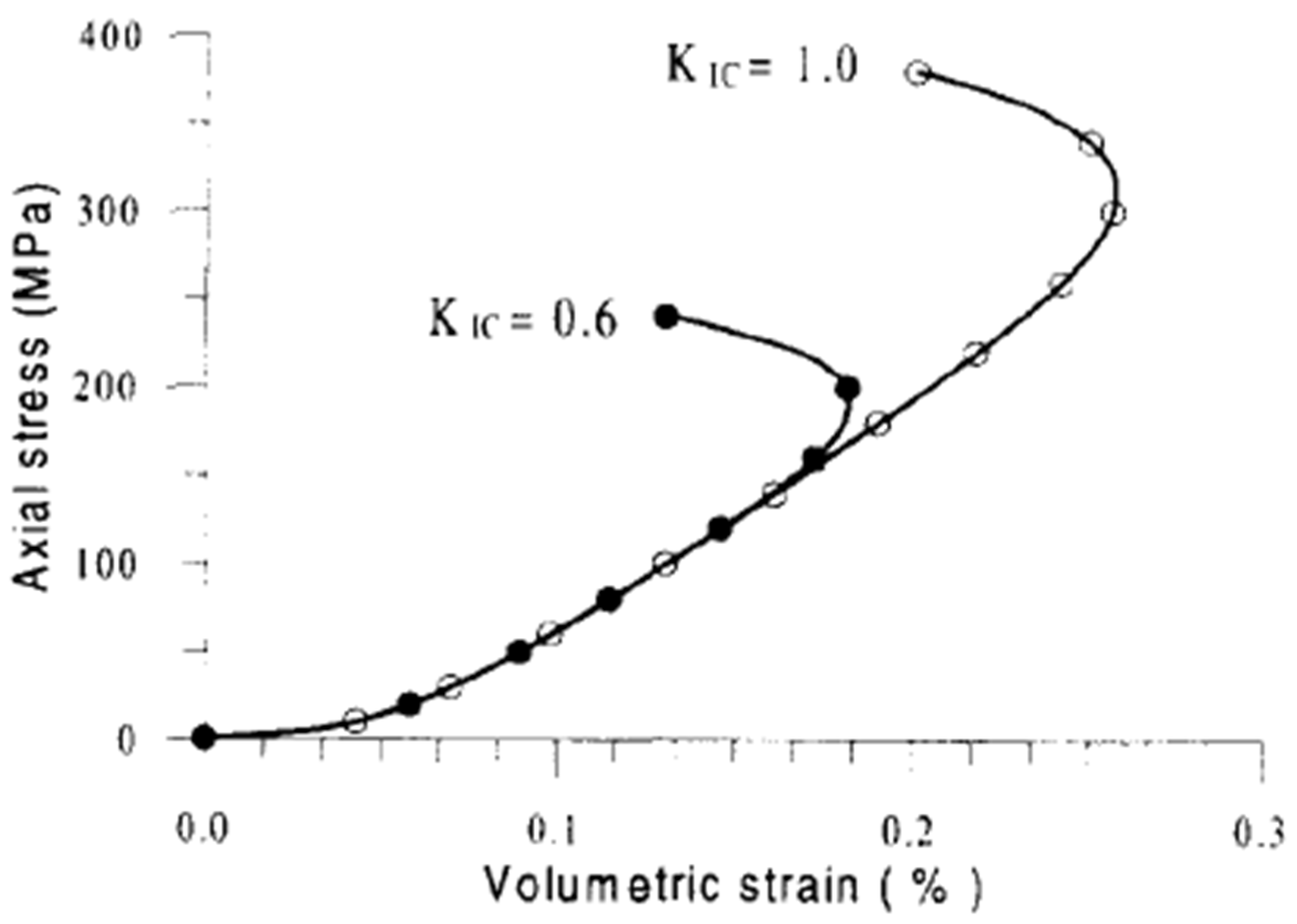

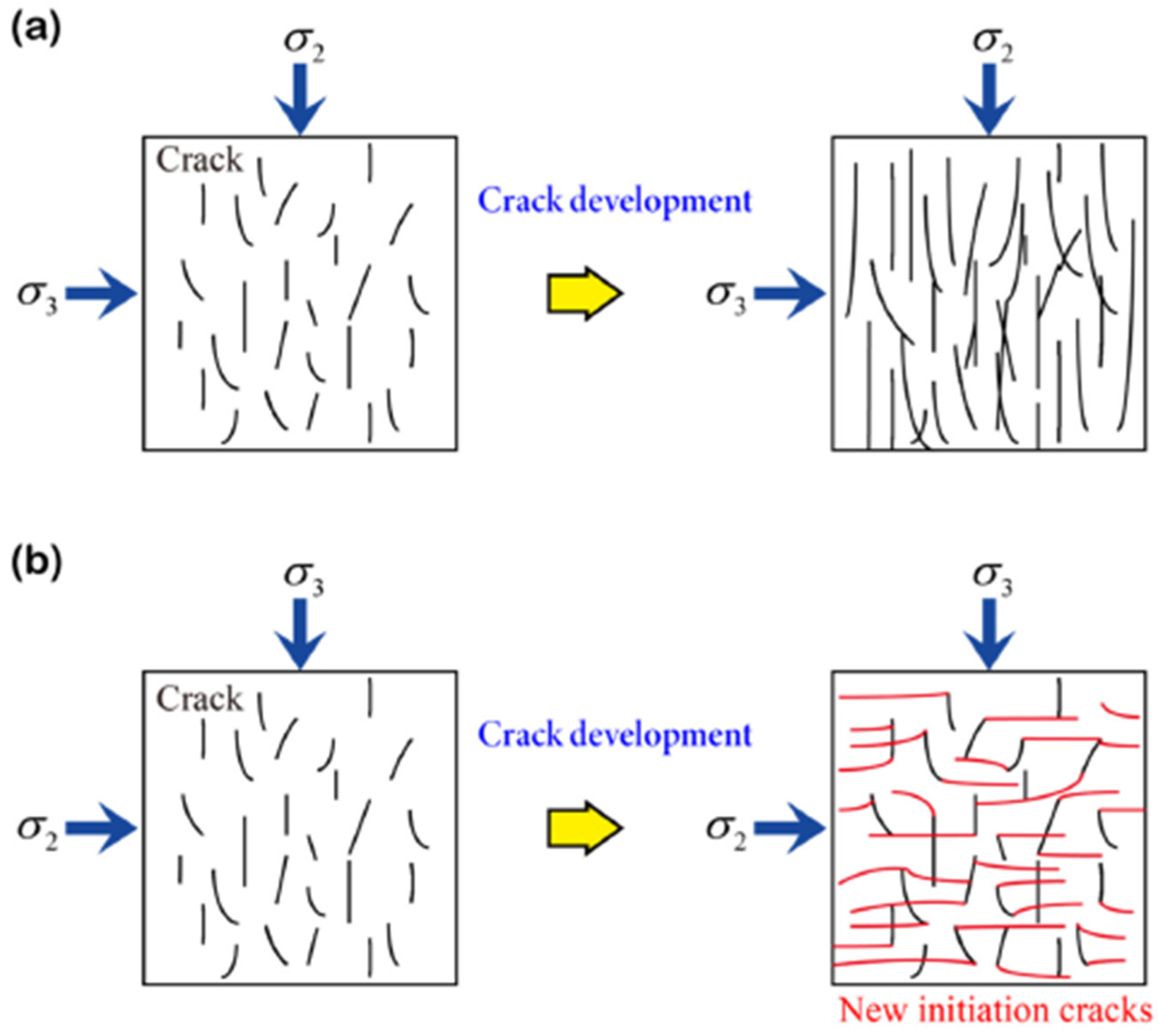

3.3. Fracture Mechanics

4. Definition and Estimation of Brittleness Indexes

5. Comparative Analysis: Mechanical vs. Petrographic Properties

5.1. Correlation Between Mechanical Properties and Petrographic Characteristics

5.2. Case Studies and Experimental Results

6. Engineering and Mining Implications

7. Challenges and Future Research Directions

8. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Wilson, A.H.; Jermy, C.A.; Ridgeway, M. Rock-Strength and Physical Properties of Norites of the Merensky and Bastard Units, Western Bushveld Complex. Geol. Soc. S. Afr. 2005, 108, 525–540. [Google Scholar] [CrossRef]

- Dong, L.; Xu, H.; Fan, P.; Wu, Z. On the Experimental Determination of Poisson’s Ratio for Intact Rocks and Its Variation as Deformation Develops. Adv. Civ. Eng. 2021, 2021, 8843056. [Google Scholar] [CrossRef]

- Waterton, P.; Hyde, W.R.; Tusch, J.; Hollis, J.A.; Kirkland, C.L.; Kinney, C.; Yakymchuk, C.; Gardiner, N.J.; Zakharov, D.; Olierook, H.K.H.; et al. Geodynamic Implications of Synchronous Norite and TTG Formation in the 3 Ga Maniitsoq Norite Belt, West Greenland. Front. Earth Sci. 2020, 8, 562062. [Google Scholar] [CrossRef]

- Hunt, E.J.; Latypov, R.; Horváth, P. The Merensky Cyclic Unit, Bushveld Complex, South Africa: Reality or Myth? Minerals 2018, 8, 144. [Google Scholar] [CrossRef]

- Khalifeh, M.; Todorovic, J.; Vrålstad, T.; Saasen, A.; Hodne, H. Long-Term Durability of Rock-Based Geopolymers Aged at Downhole Conditions for Oil Well Cementing Operations. J. Sustain. Cem. Based Mater. 2017, 6, 217–230. [Google Scholar] [CrossRef]

- Xia, Y.; Zhou, H.; Zhang, C.; He, S.; Gao, Y.; Wang, P. The Evaluation of Rock Brittleness and Its Application: A Review Study. Eur. J. Environ. Civ. Eng. 2019, 26, 239–279. [Google Scholar] [CrossRef]

- Askaripour, M.; Saeidi, A.; Mercier-Langevin, P.; Rouleau, A. A Review of Relationship between Texture Characteristic and Mechanical Properties of Rock. Geotechnics 2022, 2, 262–296. [Google Scholar] [CrossRef]

- Tao, W.; Tang, H.; Wang, Y.; Ma, J. Evaluation of Methods for Determining Rock Brittleness under Compression. J. Nat. Gas. Sci. Eng. 2020, 78, 103321. [Google Scholar] [CrossRef]

- Li, D.; Han, M.; Zhu, Q. Evaluation of Rock Brittleness Index under Dynamic Load. Appl. Sci. 2023, 13, 4698. [Google Scholar] [CrossRef]

- Gardner, L.J.; Bosman, J.D. Determining the Mechanical Properties of Igneous Rocks in the Western Limb of South Africa’s Bushveld Complex. In Proceedings of the Paper Presented at the 13th ISRM International Congress of Rock Mechanics, One Petrography. Montreal, QC, Canada, 10–13 May 2015. [Google Scholar]

- Bourdeau, J.E.; Hayes, B.; Zhang, S.E.; Logue, A.; Bybee, G.M. Origin and Significance of Noritic Blocks in Layered Anorthosites in the Bushveld Complex, South Africa. Contrib. Mineral. Petrol. 2022, 177, 1–26. [Google Scholar] [CrossRef]

- Scoon, R.N.; Viljoen, M.J. Geoheritage of the Eastern Limb of the Bushveld Igneous Complex, South Africa: A Uniquely Exposed Layered Igneous Intrusion. Geoheritage 2019, 11, 1723–1748. [Google Scholar] [CrossRef]

- Mendes, J.C.; De Campos, C.M.P. Norite and Charnockites from the Venda Nova Pluton, SE Brazil: Intensive Parameters and Some Petrogenetic Constraints. Geosci. Front. 2012, 3, 789–800. [Google Scholar] [CrossRef]

- Wilson, A.H. The Earliest Stages of Emplacement of the Eastern Bushveld Complex: Development of the Lower Zone, Marginal Zone and Basal Ultramafic Sequence. J. Petrol. 2015, 56, 347–388. [Google Scholar] [CrossRef]

- Harger, H.G.S. The Geological Society of South Africa; 1934; Volume 37. Available online: https://journals.co.za/doi/pdf/10.10520/AJA10120750_1669 (accessed on 24 April 2025).

- Cawthorn, R.G. The Bushveld Complex, South Africa. In Springer Geology; Springer: Berlin/Heidelberg, Germany, 2015; pp. 517–587. ISBN 9789401796521. [Google Scholar]

- Cawthorn, R.G.; Webb, S.J. Connectivity between the Western and Eastern Limbs of the Bushveld Complex. Tectophysics 2001, 330, 195–209. [Google Scholar] [CrossRef]

- Beard, J.S.; Fedele, L.; Bodnar, R.J. A Quartz-Bearing Norite Formed by the Bowen Reaction at a Dioritepelite Contact. Geology 2017, 45, 883–886. [Google Scholar] [CrossRef]

- Mondal, S.K.; Mathez, E.A. Origin of the UG2 Chromitite Layer, Bushveld Complex. J. Petrol. 2007, 48, 495–510. [Google Scholar] [CrossRef]

- Eales, H.V.; Cawthorn, R.G. The Bushveld Complex. Elsevier Sci. 1996, 15, 181–229. [Google Scholar]

- Prevec, S.A. Igneous Rock Associations 23. The Bushveld Complex, South Africa: New Insights and Paradigms. Geosci. Can. 2018, 45, 117–135. [Google Scholar] [CrossRef]

- Bowen, N.L. The Reaction Principle In Petrogenesis. Am. J. Sci. 1922, 30, 177–198. [Google Scholar] [CrossRef]

- Bowen, N.L. The Evolution of the Igneous Rocks; Dover Publications: New York, NY, USA, 1928. [Google Scholar]

- Arndt, N.; Jenner, G.; Ohnenstetter, M.; Deloule, E.; Wilson, A.H. Trace Elements in the Merensky Reef and Adjacent Norites Bushveld Complex South Africa. Min. Depos. 2005, 40, 550–575. [Google Scholar] [CrossRef]

- Kwékam, M.; Affaton, P.; Bruguier, O.; Liégeois, J.P.; Hartmann, G.; Njonfang, E. The Pan-African Kekem Gabbro-Norite (West-Cameroon), U-Pb Zircon Age, Geochemistry and Sr-Nd Isotopes: Geodynamical Implication for the Evolution of the Central African Fold Belt. J. Afr. Earth Sci. 2013, 84, 70–88. [Google Scholar] [CrossRef]

- Page, N.J.; Moring, B.C. Petrology of the Noritic and Gabbronoritic Rocks below the J-M Reef in the Mountain View Area, Stillwater Complex, Montana. U.S. Geol. Surv. Bull. 1990, 1674, 1–54. [Google Scholar]

- Nouri, M.; Khanlari, G.; Rafiei, B.; Sarfarazi, V.; Zaheri, M. Estimation of Brittleness Indexes from Petrographic Characteristics of Different Sandstone Types (Cenozoic and Mesozoic Sandstones), Markazi Province, Iran. Rock Mech. Rock Eng. 2022, 55, 1955–1995. [Google Scholar] [CrossRef]

- Khorasani, R.; Ajalloeian, R.; Jamshidi, A. Predicting the Brittleness of Granitic Rocks in Tavandasht and Gosheh (Borujerd) by Schmidt Hardness and Petrographic Characteristics. Iran. J. Eng. Geol. 2019, 11, 55–68. [Google Scholar]

- Schulz, B.; Sandmann, D.; Gilbricht, S. Sem-Based Automated Mineralogy and Its Application in Geo-and Material Sciences. Minerals 2020, 10, 1004. [Google Scholar] [CrossRef]

- Kutsukake, T. Ryoke Zone Of The Toyone-Mura Area, Aichi Prefecture, Japan. J. Jpn. Assoc. Mineral. Petrol. Econ. Geol. 1974, 69, 52–74. [Google Scholar] [CrossRef]

- Malki, J.; Vennes, I.; Rowe, C.D.; Mitri, H.S. Evaluation of Rock Burstability with Mechanical Property Testing and Microscopic Image Analysis. Rock Mech. Rock Eng. 2024, 58, 4441–4457. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stimpson, B.; Stead, D. Effects of Grain Size on the Initiation and Propagation Thresholds of Stress-Induced Brittle Fractures. Rock Mech. Rock Eng. 1999, 32, 81–99. [Google Scholar] [CrossRef]

- Zhang, Y.; Meng, Y.; Hao, P.; Shang, Y.; Fu, X. Brittleness Index of High-Rank Coal Reservoir and Its Influencing Factors in Mabidong Block, Qinshui Basin, China. Geofluids 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Keikha, T.; Keykha, H.A. Correlation between Mineralogical Characteristics and Engineering Properties of Granitic Rocks. Electron. J. Geotech. Eng. 2013, 18, 4055–4064. [Google Scholar]

- Göğüş, Ö.D.; Avşar, E.; Develi, K.; Çalık, A. The Role of Mineralogical and Textural Complexity in the Damage Evolution of Brittle Rocks. Sci. Rep. 2024, 14, 28641. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Elsworth, D.; He, Y.; Hu, W.; Wang, T. A Grain Texture Model to Investigate Effects of Grain Shape and Orientation on Macro-Mechanical Behavior of Crystalline Rock. Int. J. Rock Mech. Min. Sci. 2021, 148, 104971. [Google Scholar] [CrossRef]

- Peng, J.; Wong, L.N.Y.; Teh, C.I. Influence of Grain Size Heterogeneity on Strength and Microcracking Behavior of Crystalline Rocks. J. Geophys. Res. Solid. Earth 2017, 122, 1054–1073. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Estimating the Strength of Rock Materials. Prof. Eng. Dr. Sci. Eng. 1967, 74, 312–320. [Google Scholar] [CrossRef]

- Zhang, F.; Pant, D.; Logan, B.E. Long-Term Performance of Activated Carbon Air Cathodes with Different Diffusion Layer Porosities in Microbial Fuel Cells. Biosens. Bioelectron. 2011, 30, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Lewis, M.J.; Bucholz, C.E.; Jagoutz, O.E. Evidence for Polybaric Fractional Crystallization in a Continental Arc: Hidden Lakes Mafic Complex, Sierra Nevada Batholith, California. Contrib. Mineral. Petrol. 2021, 176, 90. [Google Scholar] [CrossRef]

- Trouw, R.A.J.; Passchier, C.W. Microtectonics; Springer: Cham, Switzerland, 2005. [Google Scholar]

- He, Q.; Li, Y.; Xu, J.; Zhang, C. Prediction of Mechanical Properties of Igneous Rocks Under Combined Compression and Shear Loading Through Statistical Analysis. Rock Mech. Rock Eng. 2020, 53, 841–859. [Google Scholar] [CrossRef]

- Kahraman, S. Correlation of TBM and Drilling Machine Performances with Rock Brittleness. Eng. Geol. 2003, 67, 405. [Google Scholar] [CrossRef]

- Šancer, J.; Široký, T.; Krenžel, V. Determination of the Uniaxial Compressive Strength of Rocks from the Strength Index. Geosci. Eng. 2022, 68, 158–166. [Google Scholar] [CrossRef]

- Jaeger, J.C.; Cooke, N.G.W. Fundamentals of Rock Mechanics; Chapman Hall: New York, NY, USA, 1877; p. 585. [Google Scholar]

- Fairhurst, C.; Cooke, N.G.W. The Phenomenon of Rock Splitting Parallel to a Free Surface under Compressive Stress. In Proceedings of the First Congress of the International Society of Rock Mechanics, Lisbon, Portugal, 25 September–1 October 1966; Volume 1, pp. 687–692. [Google Scholar]

- Erarslan, N.; Alehossein, H.; Williams, D.J. Tensile Fracture Strength of Brisbane Tuff by Static and Cyclic Loading Tests. Rock Mech. Rock Eng. 2014, 47, 1135–1151. [Google Scholar] [CrossRef]

- Perras, M.A.; Diederichs, M.S. A Review of the Tensile Strength of Rock: Concepts and Testing. Geotech. Geol. Eng. 2014, 32, 525–546. [Google Scholar] [CrossRef]

- Hoek, B.E. Fracture of Anisotropic Rock. J. S. Afr. Inst. Min. Metall. 1964, 64, 501–518. [Google Scholar]

- Brace, W.F. Dependence of Fracture Strength of Rocks on Grain Size. Bulletin of Mineral Industries Experiment Station, Mining Engineering Series. Rock Mechanics. Rock Mech. 1961, 76, 99–103. [Google Scholar]

- Ulusay, R.; Hudson, J.A. The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006; Commission on Testing Methods, International Society of Rock Mechanics; The ISRM Turkish National Group: Ankara, Turkey, 2007; ISBN 9789759367541. [Google Scholar]

- Davarpanah, S.M.; Bar, N.; Török, Á.; Tarifard, A.; Vásárhelyi, B. Technical Note: Determination Of Young’s Modulus And Poisson’s Ratio For Intact Stratified Rocks and Their Relationship with Uniaxial Compressive Strength. Aust. Geomech. J. 2020, 55, 101–118. [Google Scholar]

- Blake, O.O.; Faulkner, D.R.; Tatham, D.J. The Role of Fractures, Effective Pressure and Loading on the Difference between the Static and Dynamic Poisson’s Ratio and Young’s Modulus of Westerly Granite. Int. J. Rock Mech. Min. Sci. 2019, 116, 87–98. [Google Scholar] [CrossRef]

- Gercek, H. Poisson’s Ratio Values for Rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 1–13. [Google Scholar] [CrossRef]

- Sonmez, H.; Gokceoglu, C.; Nefeslioglu, H.A.; Kayabasi, A. Estimation of Rock Modulus: For Intact Rocks with an Artificial Neural Network and for Rock Masses with a New Empirical Equation. Int. J. Rock Mech. Min. Sci. 2006, 43, 224–235. [Google Scholar] [CrossRef]

- Li, L.Q.; Zhang, C.S.; Wang, W.A. Modified Hoek-Brown Failure Criterion for Anisotropic Rock Mass. Chin. J. Rock Mech. Eng. 2018, 37, 3239–3246. [Google Scholar]

- Li, C.; Prikryl, R.; Nordlund, E. The Stress-Strain Behaviour of Rock Material Related to Fracture under Compression. Eng. Geol. 1998, 49, 293–302. [Google Scholar] [CrossRef]

- Roylance, D. Introduction to Fracture Mechanics; NBS Special Publication: Washington, DC, USA, 2001; pp. 1–17. [Google Scholar]

- Cai, M.; Kaiser, P.K.; Tasaka, Y.; Maejima, T.; Morioka, H.; Minami, M. Generalized Crack Initiation and Crack Damage Stress Thresholds of Brittle Rock Masses near Underground Excavations. Int. J. Rock Mech. Min. Sci. 2004, 41, 833–847. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.; Meng, X.; Huo, B. Effects of Ground Fracturing with Horizontal Fracture Plane on Rock Breakage Characteristics and Mine Pressure Control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.; Li, X.Y.; Di, B.R.; Zeng, L.B. Quantitative Seismic Interpretation of Rock Brittleness Based on Statistical Rock Physics. Geophysics 2019, 84, IM63–IM75. [Google Scholar] [CrossRef]

- Zhang, J.C.; Xu, W.Y.; Wang, H.L.; Wang, R.B.; Meng, Q.X. Testing and Modeling of the Mechanical Behavior of Dolomite in the Wudongde Hydropower Plant. Geomech. Geoengin. 2016, 11, 270–280. [Google Scholar] [CrossRef]

- Kahraman, S.; Altindag, R. A Brittleness Index to Estimate Fracture Toughness. Int. J. Rock Mech. Min. Sci. 2004, 41, 343–348. [Google Scholar] [CrossRef]

- Altindag, R. The Evaluation of Rock Brittleness Concept on Rotary Blast Hole Drills. J. S. Afr. Inst. Min. Metall. 2002, 102, 61–66. [Google Scholar]

- Yagiz, S. Assessment of Brittleness Using Rock Strength and Density with Punch Penetration Test. Tunn. Undergr. Space Technol. 2009, 24, 66–74. [Google Scholar] [CrossRef]

- Meng, F.; Wong, L.N.Y.; Zhou, H. Rock Brittleness Indices and Their Applications to Different Fields of Rock Engineering: A Review. J. Rock Mech. Geotech. Eng. 2021, 13, 221–247. [Google Scholar] [CrossRef]

- Xia, Y.J.; Li, L.C.; Tang, C.A.; Li, X.Y.; Ma, S.; Li, M. A New Method to Evaluate Rock Mass Brittleness Based on Stress–Strain Curves of Class I. Rock Mech. Rock Eng. 2017, 50, 1123–1139. [Google Scholar] [CrossRef]

- Rahimzadeh Kivi, I.; Ameri, M.; Molladavoodi, H. Shale Brittleness Evaluation Based on Energy Balance Analysis of Stress-Strain Curves. J. Pet. Sci. Eng. 2018, 167, 1–19. [Google Scholar] [CrossRef]

- Chen, G.; Jiang, W.; Sun, X.; Zhao, C.; Qin, C.A. Quantitative Evaluation of Rock Brittleness Based on Crack Initiation Stress and Complete Stress–Strain Curves. Bull. Eng. Geol. Environ. 2019, 78, 5919–5936. [Google Scholar] [CrossRef]

- Wu, D.; Li, B.; Wu, J.; Hu, G.; Gao, X.; Lu, J. Influence of Mineral Composition on Rock Mechanics Properties and Brittleness Evaluation of Surrounding Rocks in Soft Coal Seams. ACS Omega 2024, 9, 1375–1388. [Google Scholar] [CrossRef] [PubMed]

- Corkum, A.G.; Lorig, L.J.; DeGagne, D.O. Continuum Representation of Brittle Rock Failure Bulking-Induced Displacements around Tunnels. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; American Rock Mechanics Association (ARMA): Alexandria, VA, USA, 2012. [Google Scholar]

- Singh, S.P. Brittleness and the Mechanical Winning of Coal. Min. Sci. Technol. 1986, 3, 173–180. [Google Scholar] [CrossRef]

- Goktan, R.M. Brittleness and Micro-Scale Rock Cutting Efficiency. Min. Sci. Technol. 1991, 13, 237–241. [Google Scholar] [CrossRef]

- Gong, Q.M.; Zhao, J. Influence of Rock Brittleness on TBM Penetration Rate in Singapore Granite. Tunn. Undergr. Space Technol. 2007, 22, 317–324. [Google Scholar] [CrossRef]

- Mohammadi, S.D.; Torabi-Kaveh, M.; Bayati, M. Prediction of TBM Penetration Rate Using Intact and Mass Rock Properties (Case Study: Zagros Long Tunnel, Iran). Arab. J. Geosci. 2015, 8, 3893–3904. [Google Scholar] [CrossRef]

- Hucka, V.; Das, B. Brittleness Determination of Rocks by Different Methods. Pergamon Press: Oxford, UK, 1974; Volume 11. [Google Scholar]

- Jin, X.C.; Shah, S.N.; Truax, J.A.; Roegiers, J. A Practical Petrophysical Approach for Brittleness Prediction from Porosity and Sonic Logging in Shale Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014; Society of Petroleum Engineers (SPE): Richardson, TX, USA, 2014. [Google Scholar]

- Wang, J.-A.; Park, H.D. Comprehensive Prediction of Rockburst Based on Analysis of Strain Energy in Rocks. Tunn. Undergr. Space Technol. 2001, 16, 49–57. [Google Scholar] [CrossRef]

- Zhang, J.J.; Fu, B.J. Rockburst and Its Criteria and Control. Chin. J. Rock Mech. Eng. 2008, 27, 2034–2042. [Google Scholar]

- Adoko, A.C.; Gokceoglu, C.; Wu, L.; Zuo, Q.J. Knowledge-Based and Data-Driven Fuzzy Modeling for Rockburst Prediction. Int. J. Rock Mech. Min. Sci. 2013, 61, 86–95. [Google Scholar] [CrossRef]

- Cai, M. Prediction and Prevention of Rockburst in Metal Mines—A Case Study of Sanshandao Gold Mine. J. Rock Mech. Geotech. Eng. 2016, 8, 204–211. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wu, Y.F.; Ben, Y.X.; Li, D.S.; Hao, J.M.; Zhang, B. Research on Relationship between Crack Initiation Stress Level and Brittleness Indices for Brittle Rocks. Chin. J. Rock Mech. Eng. 2014, 22, 264–275. [Google Scholar]

- Bishop, A.W. Progressive Failure with Special Reference to the Mechanism Causing It. In Proceedings of the Geotechnical Conference, Oslo, Norway, 19–22 September 1967; pp. 142–150. [Google Scholar]

- Coates, D.F.; Parsons, R.C. Experimental Criteria for Classification of Rock Substances; Pergamon Press Ltd.: Oxford, UK, 1966; Volume 3. [Google Scholar]

- Hajiabdolmajid, V.; Kaiser, P. Brittleness of Rock and Stability Assessment in Hard Rock Tunneling. Tunn. Undergr. Space Technol. 2002, 18, 35–48. [Google Scholar] [CrossRef]

- Baron, L.I.; Loguntsov, B.M.; Loguntsov, B.M. Determination of Properties of Rocks. Gozgotekhizdat Mosc. 1962, 231–233. [Google Scholar]

- Tarasov, B.G.; Potvin, Y. Absolute, Relative and Intrinsic Rock Brittleness at Compression. Trans. Inst. Min. Metall. Sect. A Min. Technol. 2012, 121, 218–225. [Google Scholar] [CrossRef]

- Tarasov, B.G.; Potvin, Y. Universal criteria for rock brittleness estimation under triaxial compression. Int. J. Rock Mech. Min. Sci. 2013, 59, 57e69. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, H.; Zhang, C.; Xu, R.; Lu, J. Evaluation Methodology of Brittleness of Rock Based on Post-Peak Stress–Strain Curves. Rock Mech. Rock Eng. 2015, 48, 1787–1805. [Google Scholar] [CrossRef]

- Li, Q.H.; Chen, M.; Jin, Y. Indoor Evaluation Method for Shale Brittleness and Improvement. Chin. J. Rock Mech. Eng. 2012, 8, 1680–1685. [Google Scholar]

- Altindag, R. Assessment of Some Brittleness Indexes in Rock-Drilling Efficiency. Rock Mech. Rock Eng. 2010, 43, 361–370. [Google Scholar] [CrossRef]

- Tarokh, A.; Peng, J.; Fakhimi, A.; Labuz, J.F. Evaluation of Brittleness from Spalling and Bending Test. In Proceedings of the 50th US Rock Mechanics/Geomechanics Symposium, Houston, TX, USA, 26–29 June 2016; American Rock Mechanics Association (ARMA): Alexandria, VA, USA, 2016. [Google Scholar]

- Rybacki, E.; Meier, T.; Dresen, G. What Controls the Mechanical Properties of Shale Rocks?—Part II: Brittleness. J. Pet. Sci. Eng. 2016, 144, 39–58. [Google Scholar] [CrossRef]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional Shale-Gas Systems: The Mississippian Barnett Shale of North-Central Texas as One Model for Thermogenic Shale-Gas Assessment. Am. Assoc. Pet. Geol. Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Hernandez-Uribe, L.A.; Aman, M.; Espinoza, D.N. Assessment of Mudrock Brittleness with Micro-Scratch Testing. Rock Mech. Rock Eng. 2017, 50, 2849–2860. [Google Scholar] [CrossRef]

- Sun, W.; Wang, L.; Wang, Y. Mechanical Properties of Rock Materials with Related to Mineralogical Characteristics and Grain Size through Experimental Investigation: A Comprehensive Review. Front. Struct. Civ. Eng. 2017, 11, 322–328. [Google Scholar] [CrossRef]

- Liu, B.; Wang, S.; Ke, X.; Fu, X.; Liu, X.; Bai, Y.; Pan, Z. Mechanical Characteristics and Factors Controlling Brittleness of Organic-Rich Continental Shales. J. Pet. Sci. Eng. 2020, 194, 107464. [Google Scholar] [CrossRef]

- Ersoy, A. Textural Characterisation of Rocks. Eng. Geol. 1995, 39, 123–136. [Google Scholar] [CrossRef]

- Yusof, N.Q.A.M.; Zabidi, H. Correlation of Mineralogical and Textural Characteristics with Engineering Properties of Granitic Rock from Hulu Langat, Selangor. Procedia Chem. 2016, 19, 975–980. [Google Scholar] [CrossRef]

- Tug, A.; Zarif, I.H. Correlation of Mineralogical and Textural Characteristics with Engineering Properties of Selected Granitic Rocks from Turkey. Eng. Geol. 1999, 51, 303–317. [Google Scholar]

- Sousa, L.M.O. The Influence of the Characteristics of Quartz and Mineral Deterioration on the Strength of Granitic Dimensional Stones. Env. Earth Sci. 2013, 69, 1333–1346. [Google Scholar] [CrossRef]

- Willard, R.J.; Mcwilliams, J.R. Microstructural Techniques in the Study of Physical Properties of Rock. Int. J. Rock Mech. Min. 1969, 6, 1–12. [Google Scholar] [CrossRef]

- Brattli, B. The Influence of Geological Factors on the Mechanical Properties of Basic Igneous Rocks Used as Road Surface Aggregates. Eng. Geol. 1992, 33, 31–44. [Google Scholar] [CrossRef]

- Åkesson, U.; Lindqvist, J.; Göransson, M.; Stigh, J. Relationship between Texture and Mechanical Properties of Granites, Central Sweden, by Use of Image-Analysing Techniques. Bull. Eng. Geol. Environ. 2001, 60, 277–284. [Google Scholar] [CrossRef]

- Brander, L.; Svahnberg, H.; Piazolo, S. Brittle-Plastic Deformation in Initially Dry Rocks at Fluid-Present Conditions: Transient Behaviour of Feldspar at Mid-Crustal Levels. Contrib. Mineral. Petrol. 2012, 163, 403–425. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, T.; Feng, C.; Wang, W.; Han, C. An Improved Method for Predicting Brittleness of Rocks via Well Logs in Tight Oil Reservoirs. J. Geophys. Eng. 2018, 15, 1042–1049. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Sideridis, A.; Koutsovitis, P.; Lampropoulou, P.; Koukouzas, N.; Pomonis, P.; Hatzipanagiotou, K. Influence of Petrogenesis on the Engineering Properties of Ultramafic Aggregates and on Their Suitability in Concrete. Appl. Sci. 2022, 12, 3990. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Papalla, A.; Giamas, V.; Lampropoulou, P.; Koutsovitis, P.; Koukouzas, N.; Hatzipanagiotou, K. The Effect of the Microstructure of Diabases from Greece and Cyprus on Their Engineering Characteristics and the Mechanical Behaviour of Concrete. Buildings 2023, 13, 396. [Google Scholar] [CrossRef]

- Dong, H.; Guo, B.; Ma, Q.; Si, K.; Wang, H. Influencing Factors of Shear Instability Characteristics of Rock Joints: Experimental and Theoretical Study. Appl. Sci. 2025, 15, 561. [Google Scholar] [CrossRef]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground Fracturing of Multi-Strata for Strong Ground Pressure Control in Extra-Thick Coal Seams with Hard Roofs: Numerical Simulation and Case Study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- Meng, Q.B.; Liu, J.F.; Xie, L.X.; Pu, H.; Yang, Y.G.; Huang, B.X.; Qian, W. Experimental Mechanical Strength and Deformation Characteristics of Deep Damaged–Fractured Rock. Bull. Eng. Geol. Environ. 2022, 81, 1–27. [Google Scholar] [CrossRef]

- Yarali, O.; Soyer, E. The Effect of Mechanical Rock Properties and Brittleness on Drillability. Sci. Res. Essays 2011, 6, 1077–1088. [Google Scholar]

- Thuro, K.; Rundsch, G. Drillability Prediction: Geological Influences in Hard Rock Drill and Blast Tunnelling. Geol. Rundsch. 1997, 86, 426–438. [Google Scholar] [CrossRef]

- Wang, Y.; Aladejare, A.E. Bayesian Characterization of Correlation between Uniaxial Compressive Strength and Young’s Modulus of Rock. Int. J. Rock Mech. Min. Sci. 2016, 85, 10–19. [Google Scholar] [CrossRef]

- Aladejare, A.E. Characterization of the Petrographic and Physicomechanical Properties of Rocks from Otanmäki, Finland. Geotech. Geol. Eng. 2021, 39, 2609–2621. [Google Scholar] [CrossRef]

- Aladejare, A.E.; Wang, Y. Influence of Rock Property Correlation on Reliability Analysis of Rock Slope Stability: From Property Characterization to Reliability Analysis. Geosci. Front. 2018, 9, 1639–1648. [Google Scholar] [CrossRef]

- Aladejare, A.E.; Wang, Y. Estimation of Rock Mass Deformation Modulus Using Indirect Information from Multiple Sources. Tunn. Undergr. Space Technol. 2019, 85, 76–83. [Google Scholar] [CrossRef]

- Aligholi, S.; Lashkaripour, G.R.; Ghafoori, M. Estimating Engineering Properties of Igneous Rocks Using Semi-Automatic Petrographic Analysis. Bull. Eng. Geol. Environ. 2019, 78, 2299–2314. [Google Scholar] [CrossRef]

- Sabri, M.S.; Jaiswal, A.; Verma, A.K.; Singh, T.N. Advanced Machine Learning Approaches for Uniaxial Compressive Strength Prediction of Indian Rocks Using Petrographic Properties. Multiscale Multidiscip. Model. Exp. Des. 2024, 7, 5265–5286. [Google Scholar] [CrossRef]

- Fathipour-Azar, H.; Wang, J.; Jalali, S.M.E.; Torabi, S.R. Numerical Modeling of Geomaterial Fracture Using a Cohesive Crack Model in Grain-Based DEM. Comput. Part. Mech. 2020, 7, 645–654. [Google Scholar] [CrossRef]

- Madhubabu, N.; Singh, P.K.; Kainthola, A.; Mahanta, B.; Tripathy, A.; Singh, T.N. Prediction of Compressive Strength and Elastic Modulus of Carbonate Rocks. Measurement 2016, 88, 202–213. [Google Scholar] [CrossRef]

- Liu, G.; Shang, D.; Zhao, Y.; Du, X. Characterization of brittleness index of gas shale and its influence on favorable block exploitation in southwest China. Front. Earth Sci. 2004, 12, 1389378. [Google Scholar] [CrossRef]

- He, M.; Sousa, L.R.; Miranda, T.; Zhu, G. Rockburst Laboratory Tests Database—Application of Data Mining Techniques. Eng. Geol. 2015, 185, 116–130. [Google Scholar] [CrossRef]

| Brittleness Indices | Measurement Parameter |

|---|---|

| B1 to B13 | Strength parameters |

| B14 to B40 | Stress–strain curve |

| B41 to B47 | Elastic parameters |

| B48 to B55 | Mineral composition |

| B56 to B62 | Conversional well logging |

| B63 to B65 | Angle of internal friction |

| B66 to B73 | Indentation test |

| B74 to B75 | Fine content |

| B76 to B77 | Consolidation characteristics |

| B78 | Point load test |

| B79 | Pulling test |

| B80 | Micro-scratch test |

| Measurement Methods | Formulation | Authors | Measurement Parameter |

|---|---|---|---|

| Based on strength parameter | [76] | is the uniaxial compressive strength; is the tensile strength. | |

| [76] | |||

| [64] | |||

| [64] | |||

| Based on strength and crack initiation | [82] | is the uniaxial compressive strength; is the splitting tensile strength; and is the crack initiation stress. is the crack initiation stress level. | |

| [82] | |||

| Based on stress–strain curve | [83] | is the peak compressive strength; is the residual compressive strength; is the peak strain; is the residual strain; is the total strain; and are the plastic strains necessary for cohesion loss and frictional strengthening, respectively; is recoverable strain energy; is the total strain energy; is the elasticity modulus of pre-peak; is the elasticity modulus of post-peak; is the stress slope of post-peak; is peak stress; is residual stress; is peak strain; is residual strain is peak strain; is the reference value of the maximum peak strain; is the reference value of the minimum peak strain; , , and are standardized coefficients; is peak stress; is residual stress; is peak strain; and is residual strain. | |

| [83] | |||

| [84] | |||

| [85] | |||

| [86] | |||

| [87] | |||

| [88] | |||

| [89] | |||

| [67] | |||

| [90] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molomo, S.G.; Madanda, V.C.; Sengani, F. A Comparative Review of Mechanical and Petrographic Properties and Their Role in Estimating the Brittleness Index of Norite: Implications for Geomechanical Applications. Appl. Sci. 2025, 15, 6200. https://doi.org/10.3390/app15116200

Molomo SG, Madanda VC, Sengani F. A Comparative Review of Mechanical and Petrographic Properties and Their Role in Estimating the Brittleness Index of Norite: Implications for Geomechanical Applications. Applied Sciences. 2025; 15(11):6200. https://doi.org/10.3390/app15116200

Chicago/Turabian StyleMolomo, Selaki Grace, Vhutali Carol Madanda, and Fhatuwani Sengani. 2025. "A Comparative Review of Mechanical and Petrographic Properties and Their Role in Estimating the Brittleness Index of Norite: Implications for Geomechanical Applications" Applied Sciences 15, no. 11: 6200. https://doi.org/10.3390/app15116200

APA StyleMolomo, S. G., Madanda, V. C., & Sengani, F. (2025). A Comparative Review of Mechanical and Petrographic Properties and Their Role in Estimating the Brittleness Index of Norite: Implications for Geomechanical Applications. Applied Sciences, 15(11), 6200. https://doi.org/10.3390/app15116200