BIM-GIS-Based Approach for Quality Management Aligned with ISO 9001

Abstract

1. Introduction

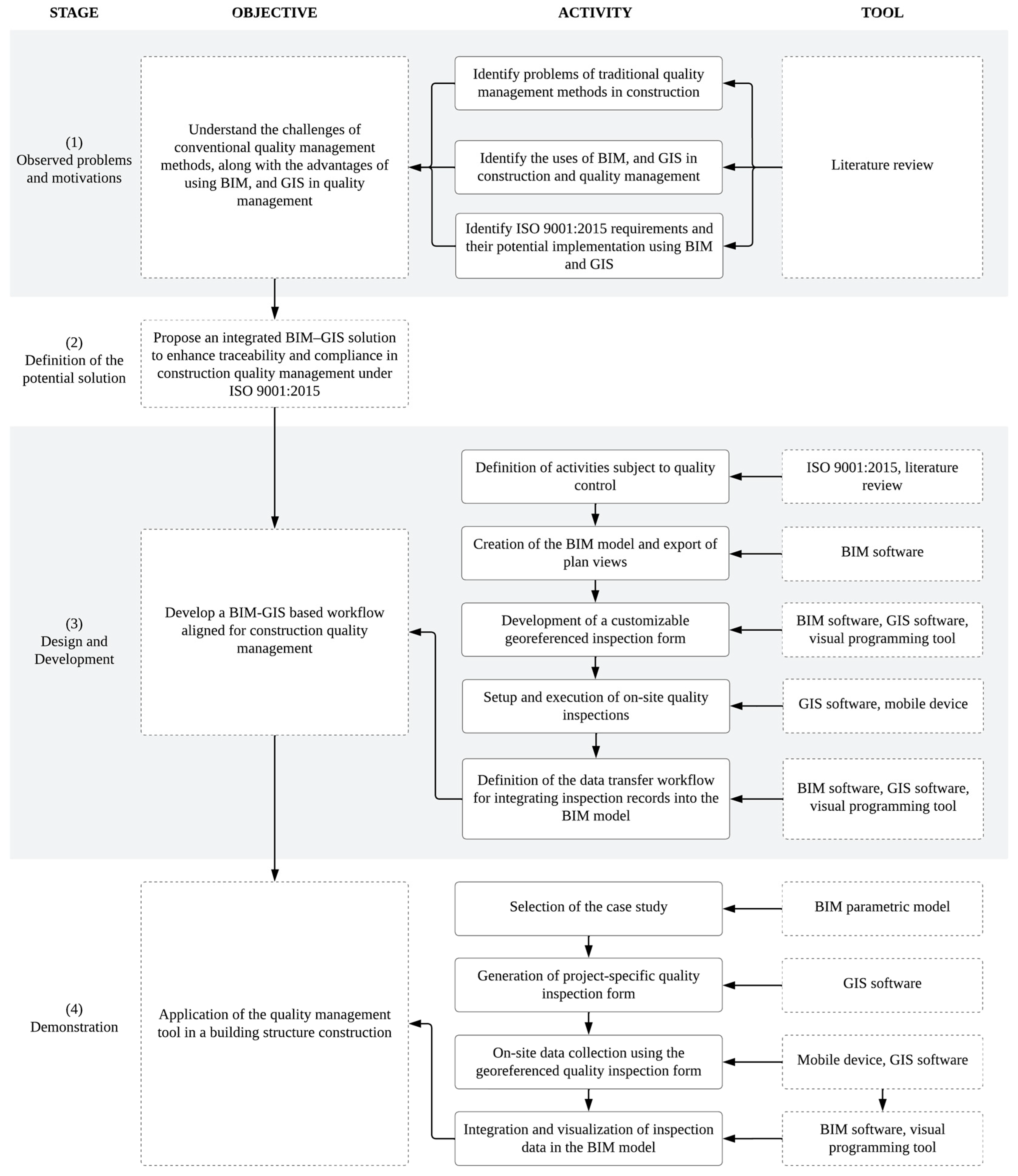

2. Research Methodology

3. Literature Review

3.1. Quality Management in Construction Projects

3.2. Current Quality Control Methods

3.3. BIM for Quality Management

- Reference of the article;

- Aim of the article;

- Tools employed for quality data collection from construction sites;

- Type of structure used for the case study;

- BIM software used within the workflow of the proposed method;

- Hardware employed in the quality management tasks;

- Maturity level of the proposed method in the research concerning its application item.

3.4. GIS for Quality Management

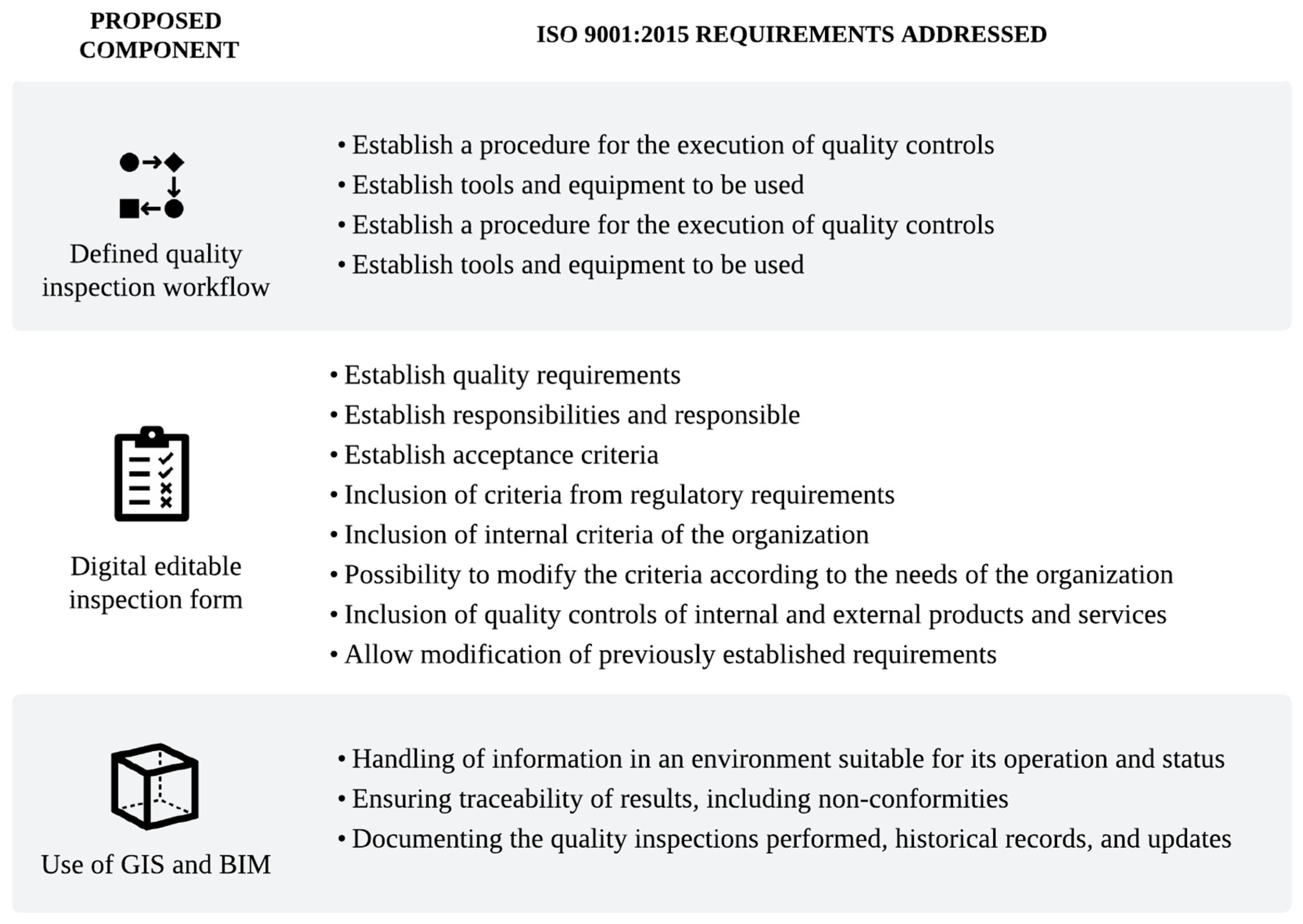

4. Method

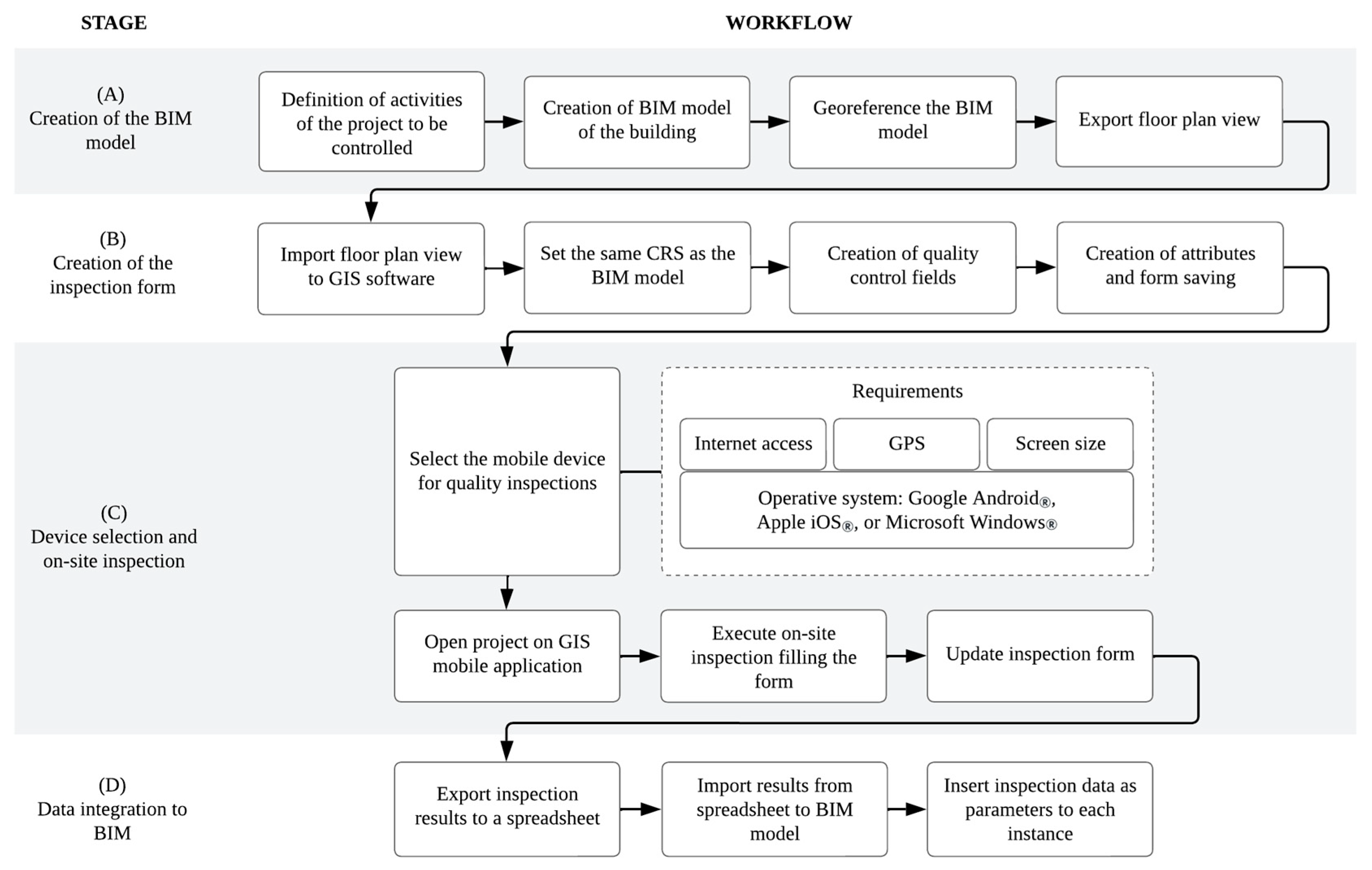

4.1. Stage A: Creation of the BIM Model

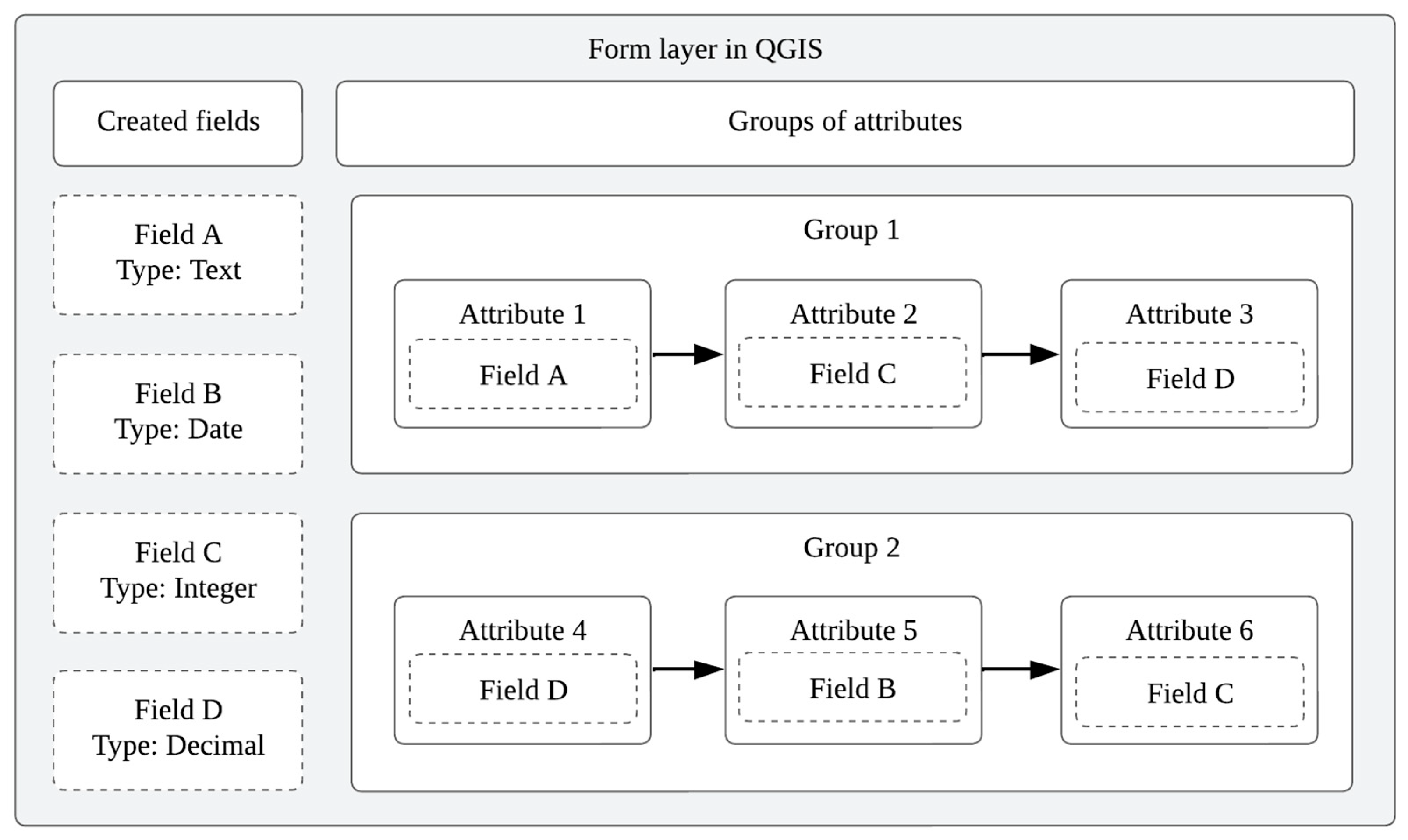

4.2. Stage B: Creation of the Inspection Form

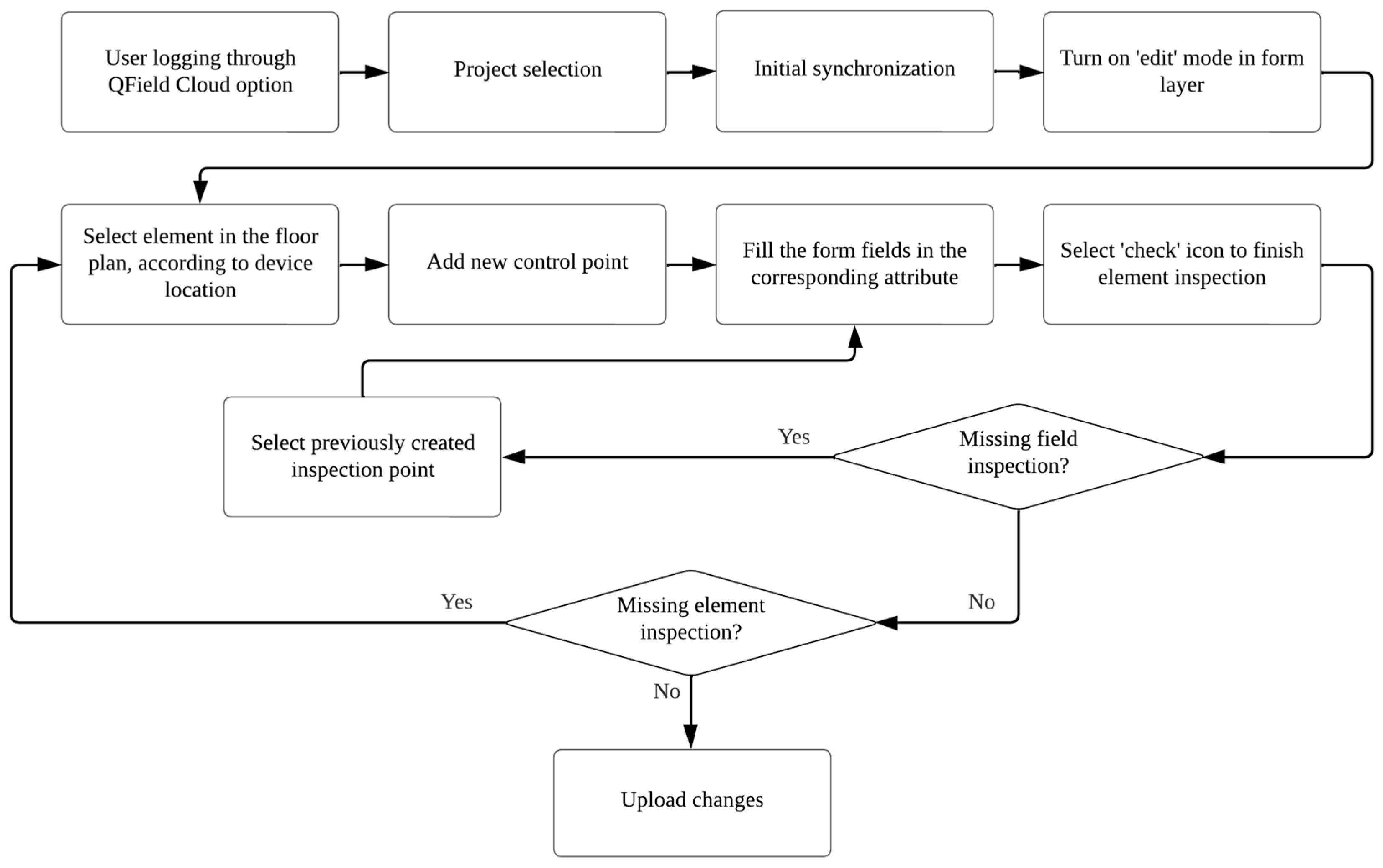

4.3. Stage C: Device Selection and On-Site Inspection

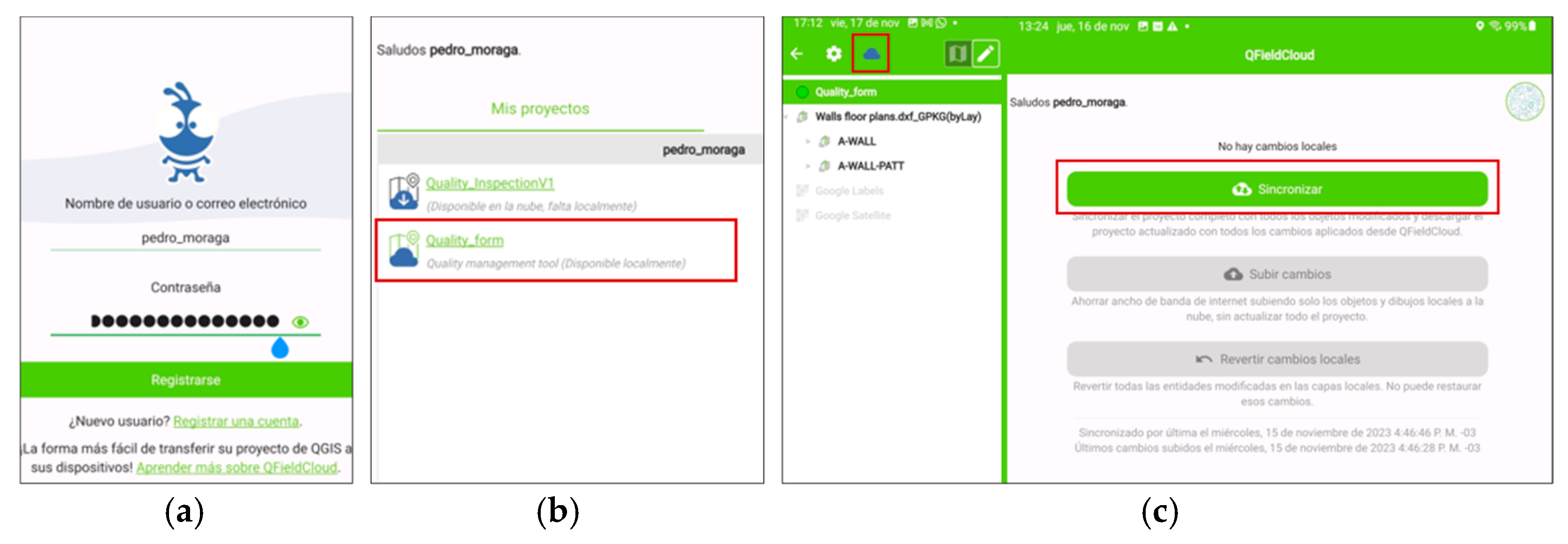

- Stable internet connection for uploading data and maintaining synchronization with QFieldCloud;

- Operating system compatible with the QField application (Android®, iOS®, or Windows®)

- Built-in GPS for real-time geolocation during inspection;

- A screen large enough to display both the project floor plan and the inspection form (a tablet is recommended).

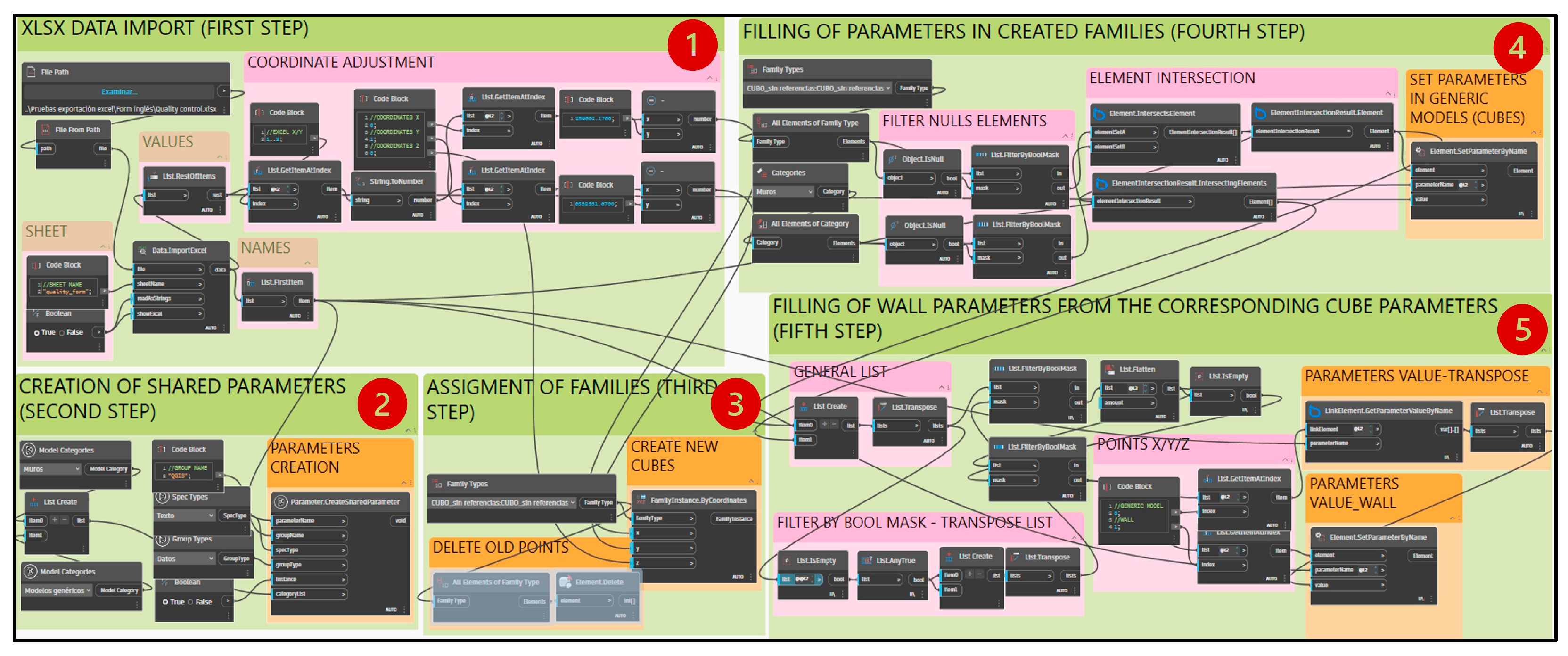

4.4. Stage D: Data Integration to BIM

- Import the XLSX file containing the inspection form data into Revit;

- Create shared parameters within the categories of model elements subject to quality controls;

- Identify the corresponding model instances, based on spatial references or element identifiers;

- Filling in the parameters created with the inspection data on the corresponding model instances;

- Enabling visualization and tabulation of the inspection results within the BIM environment.

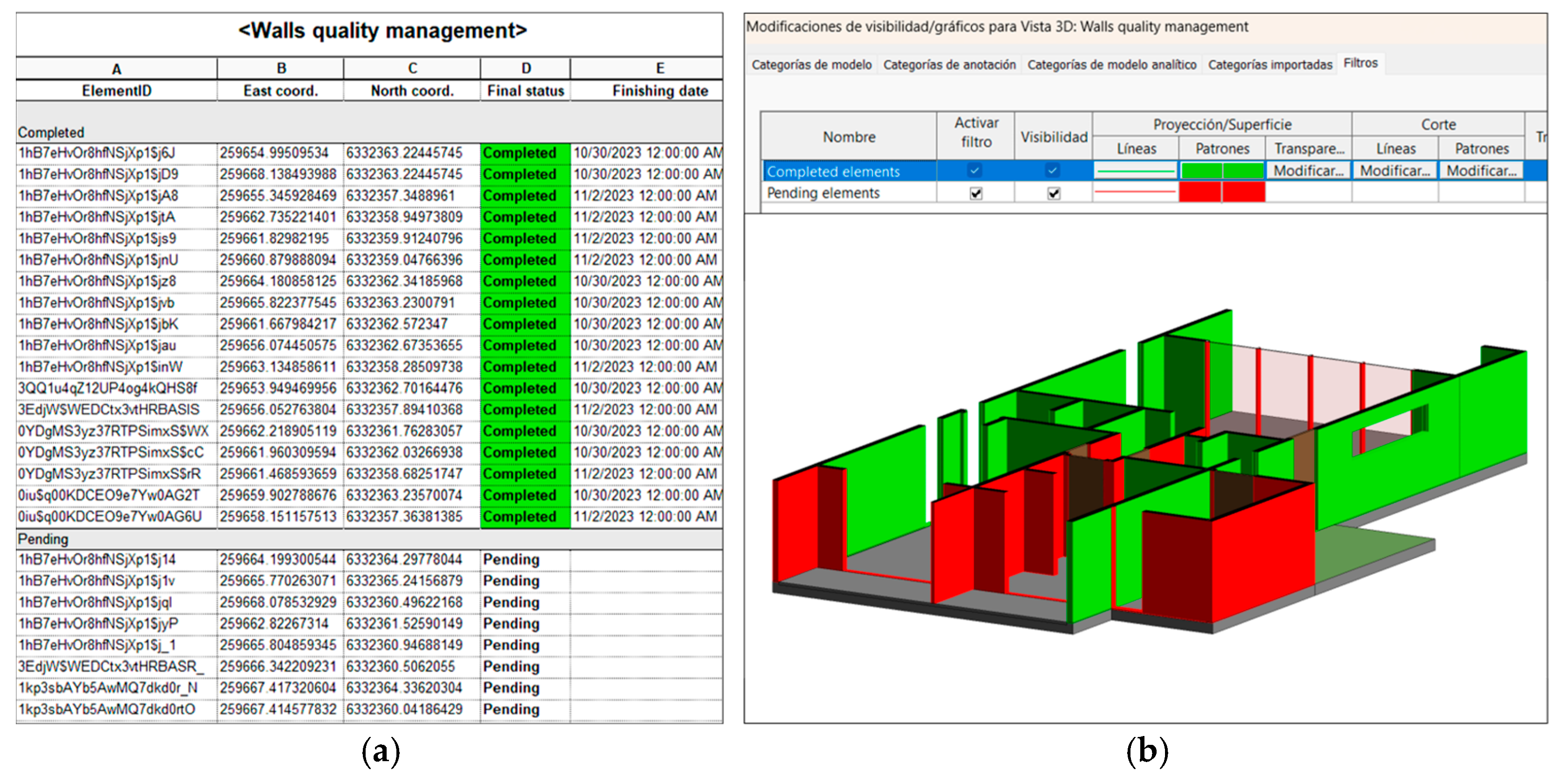

5. Results

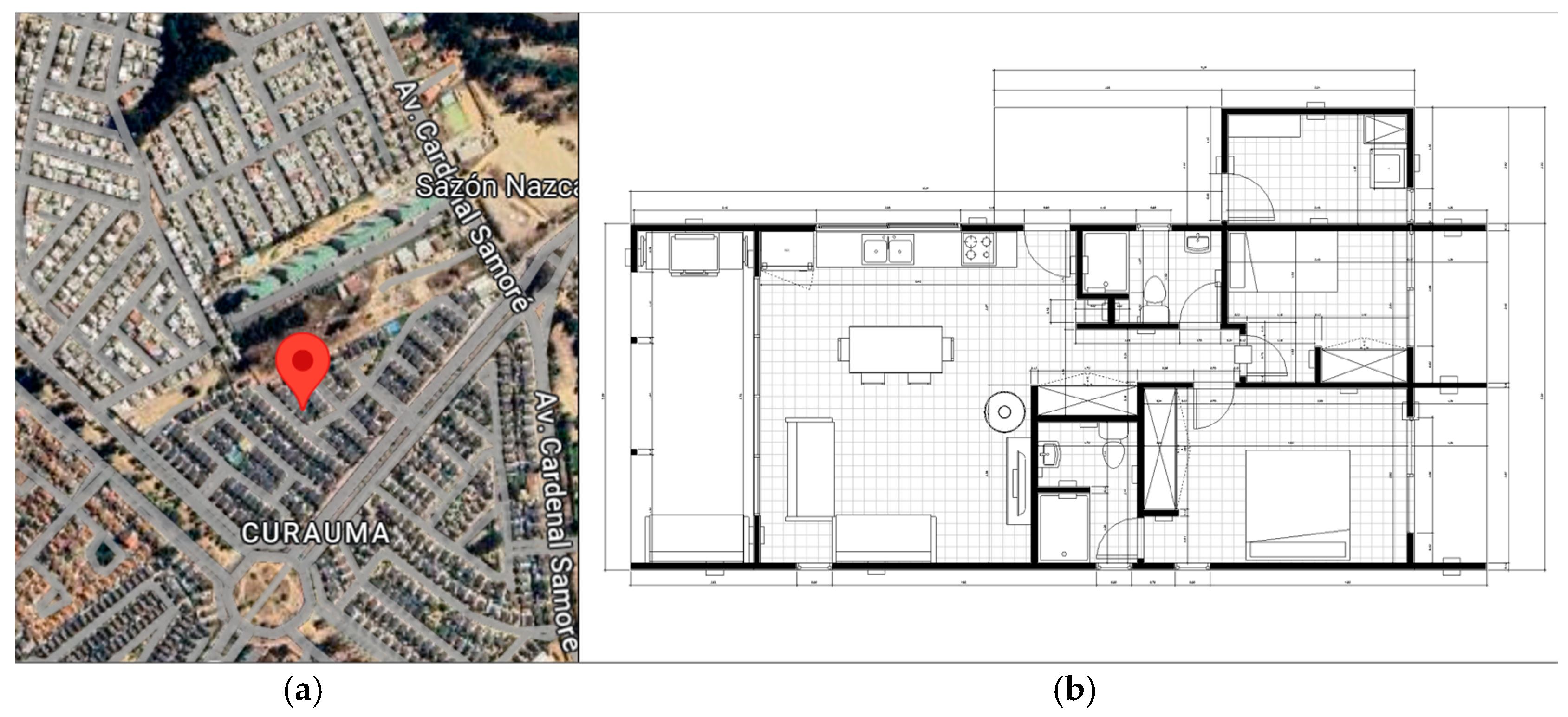

5.1. Case Study

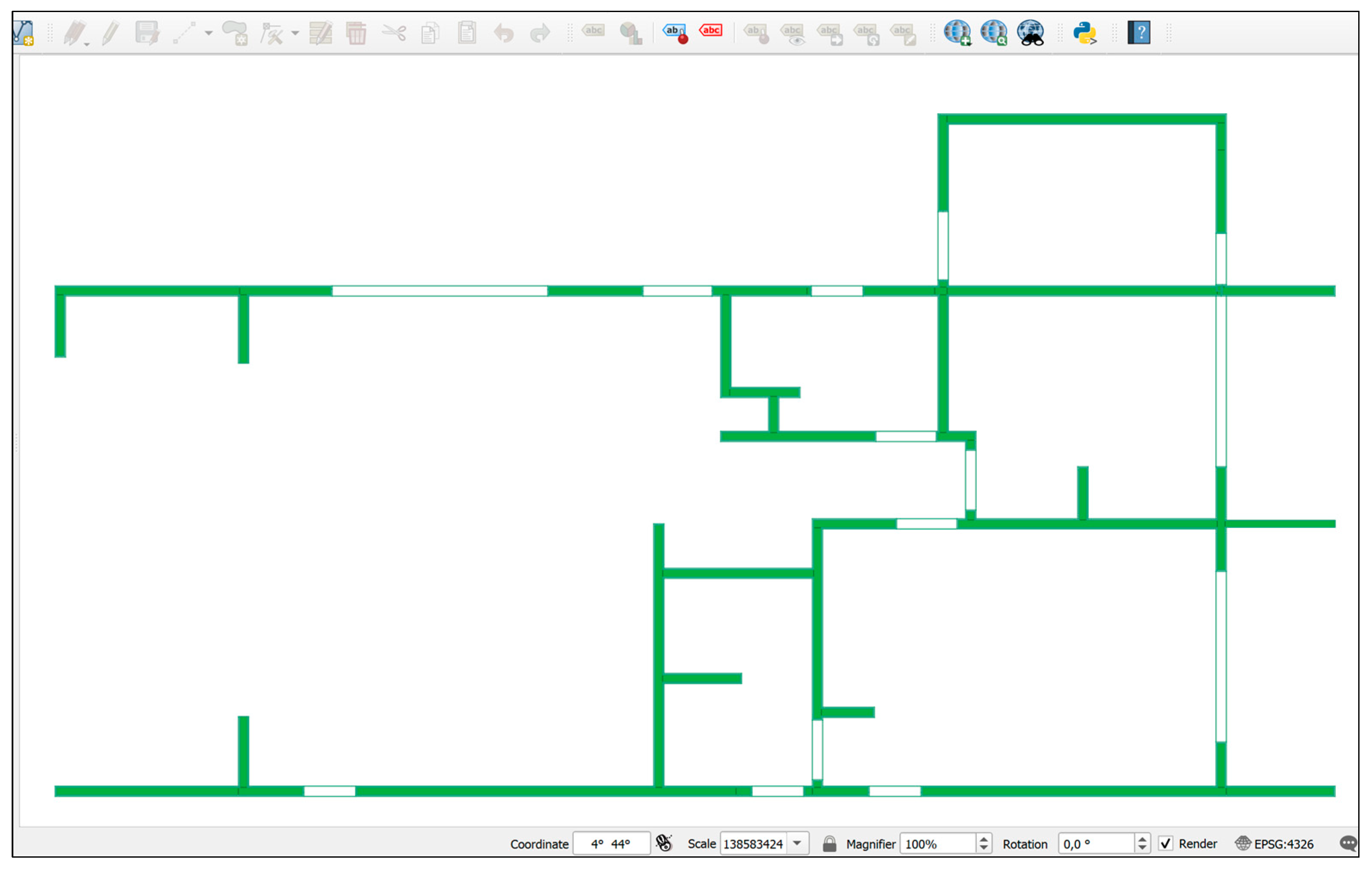

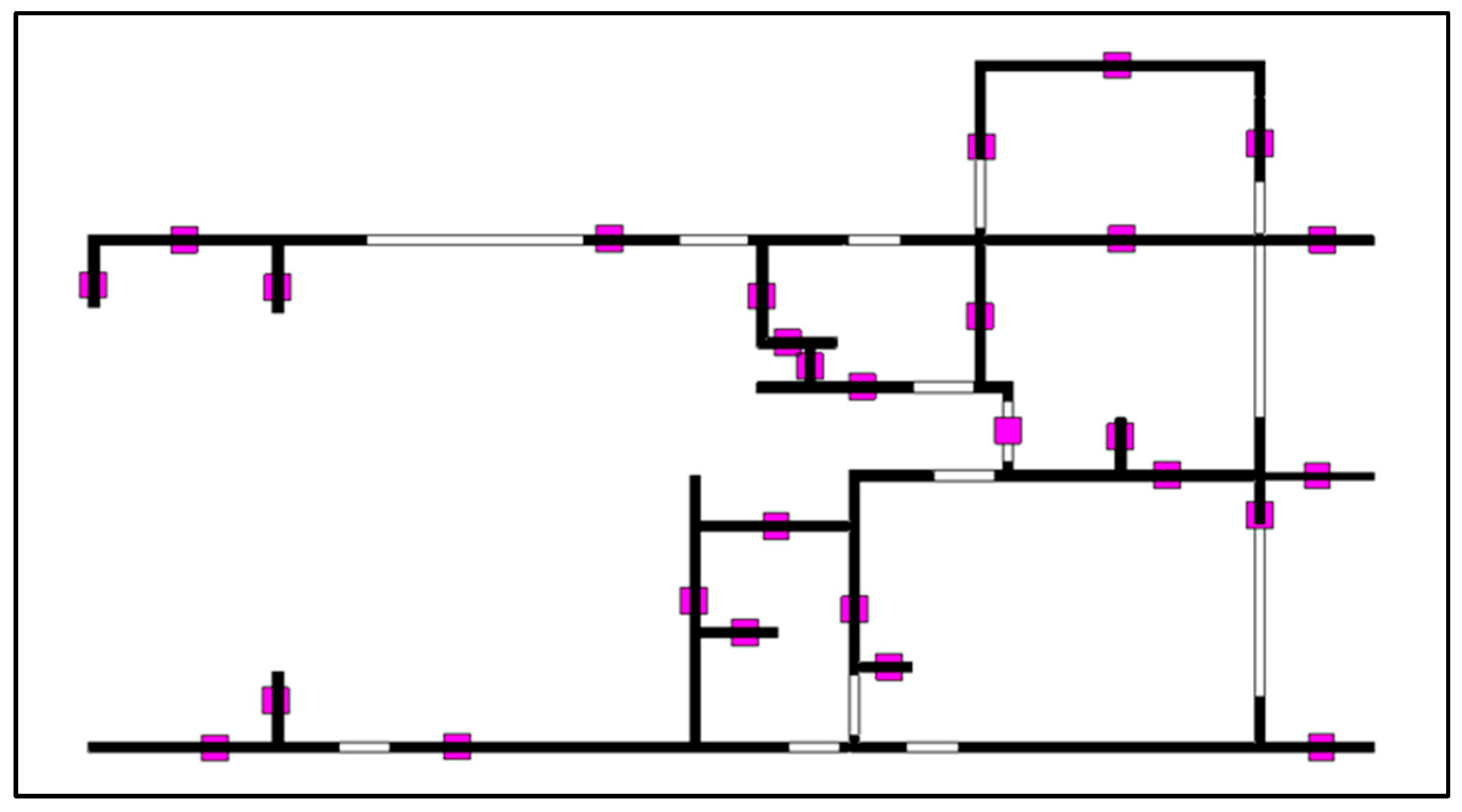

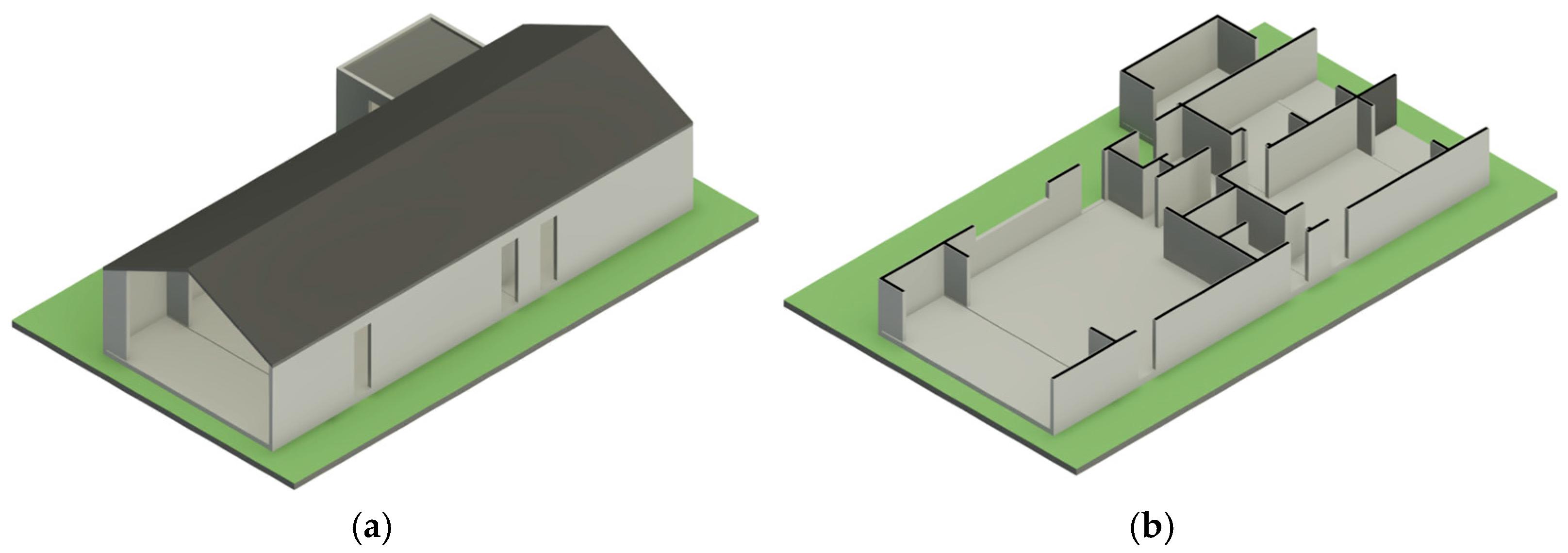

5.2. Creation of the BIM Model and Drawing Exporting

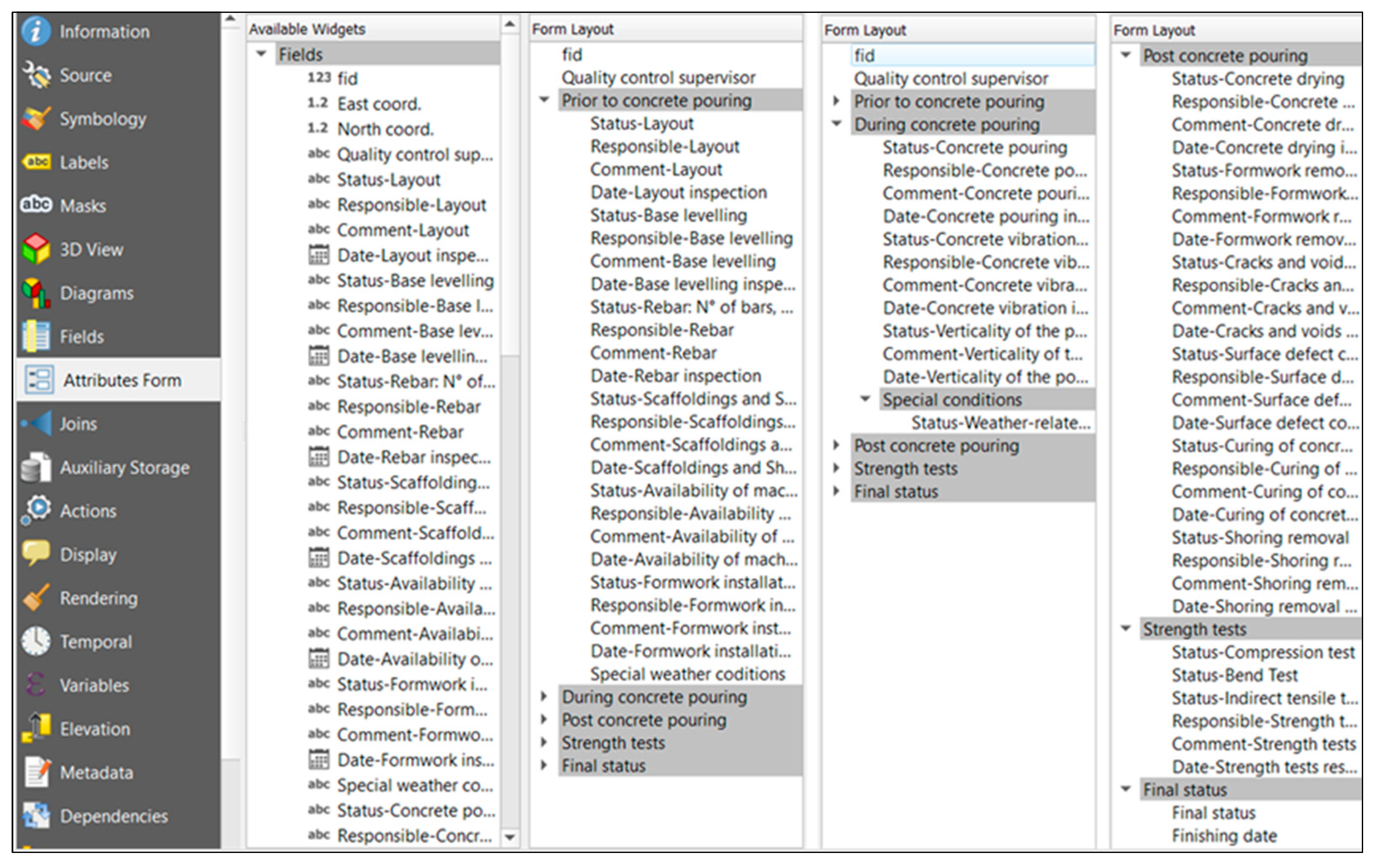

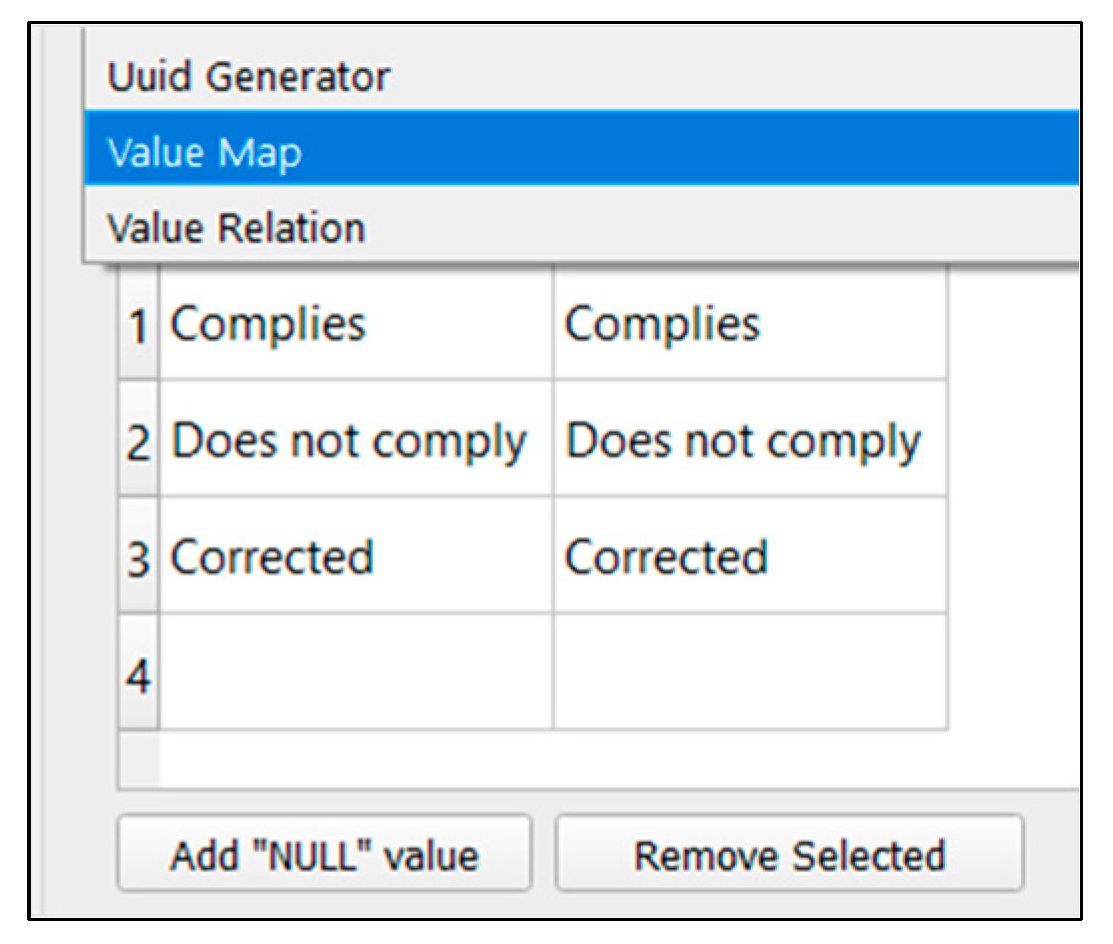

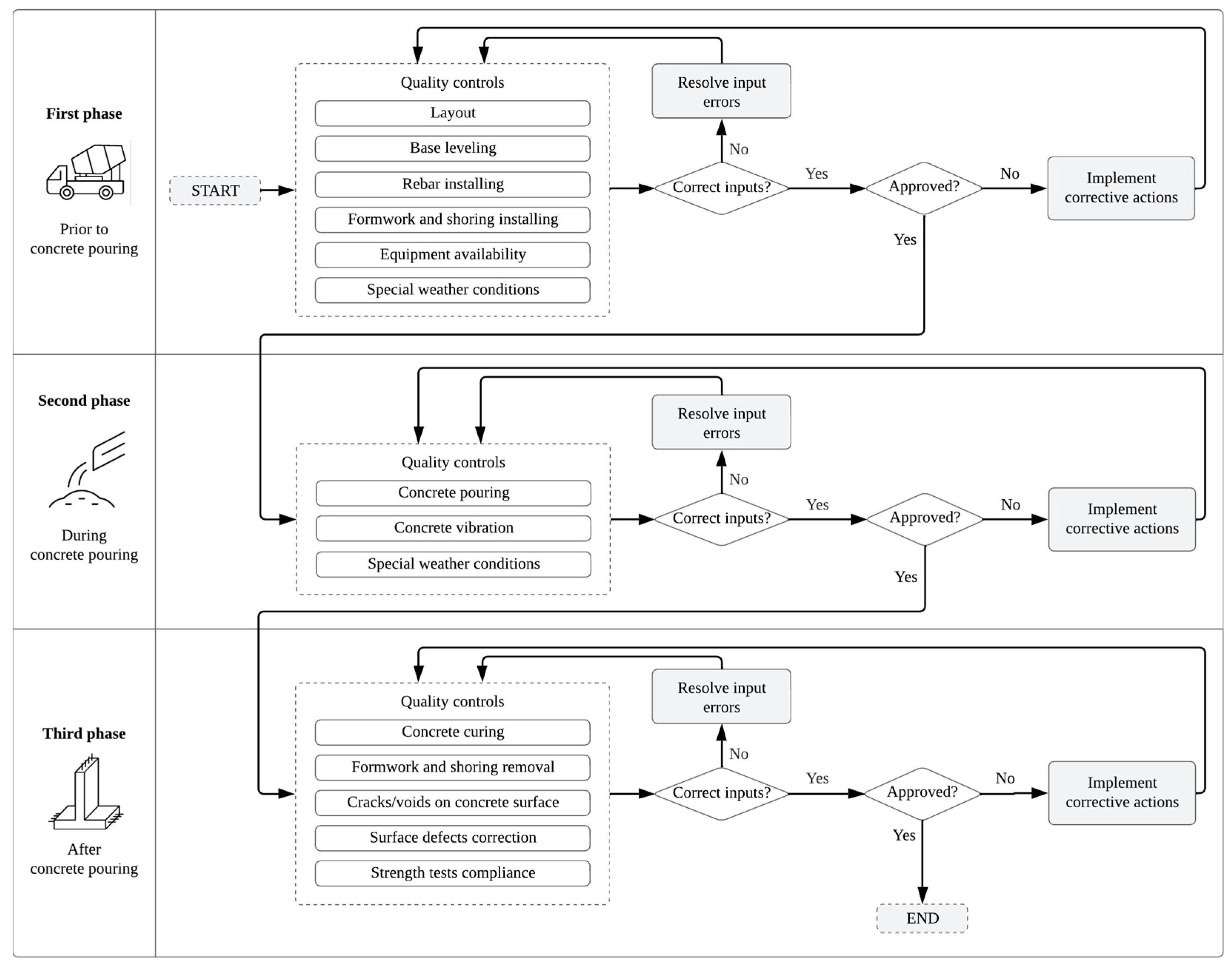

5.3. Creation of the Inspection Form

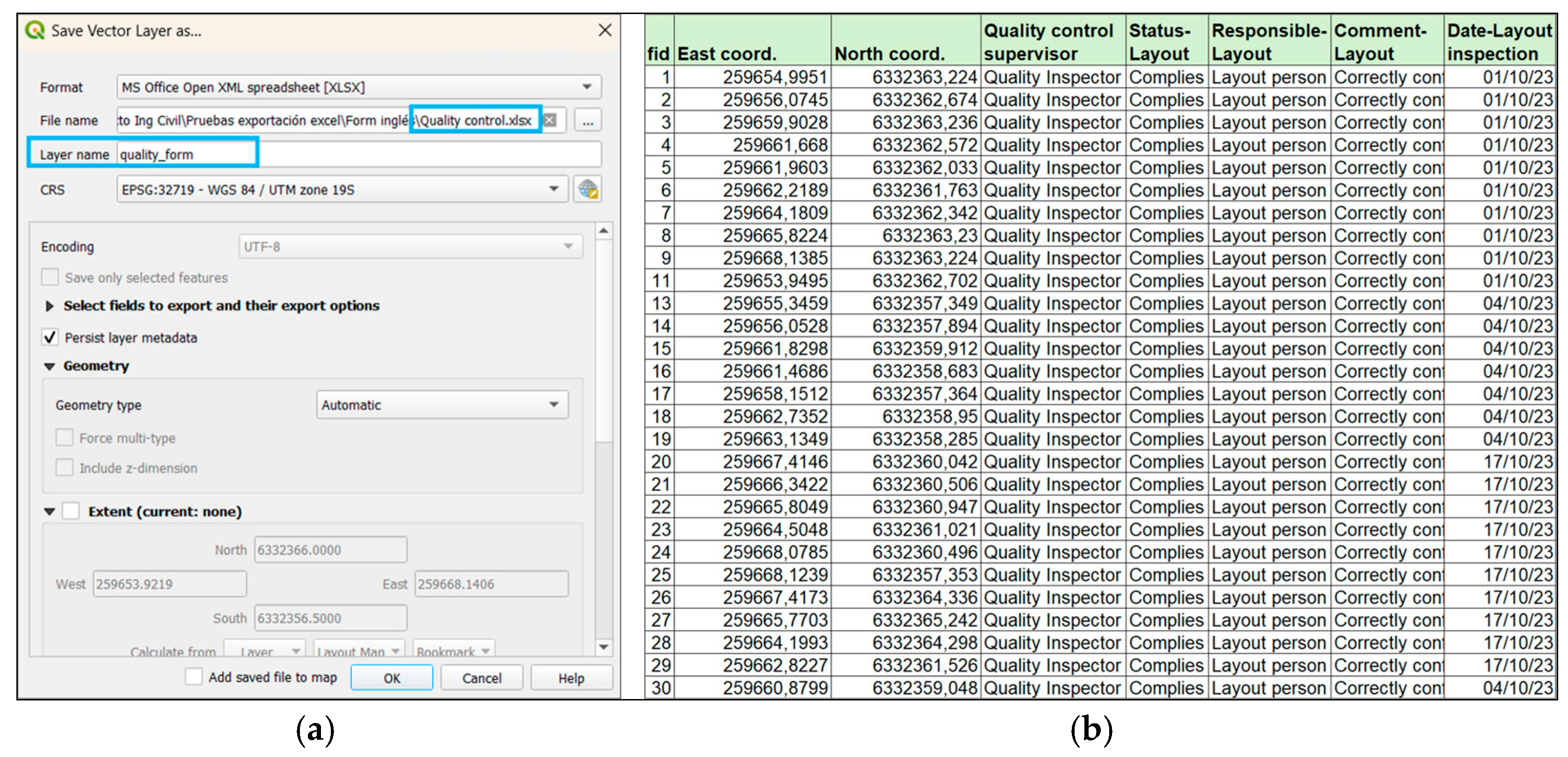

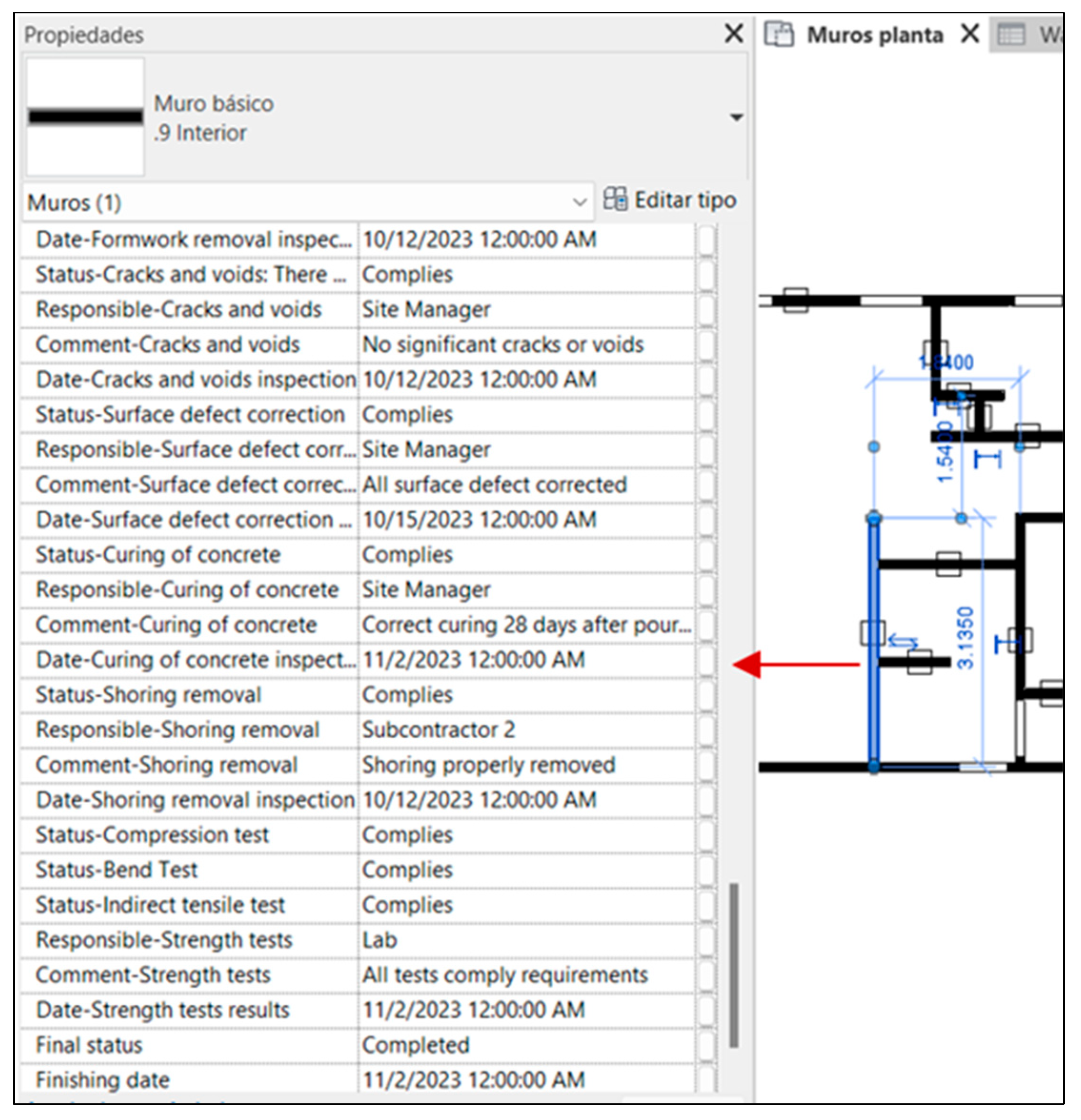

- Quality control supervisor, which records the name of the inspector in charge of each verification;

- Status, which reflects the compliance result of the activity being inspected;

- Responsible, which identifies the person accountable for quality assurance;

- Comment, which allows inspectors to document additional notes or observations;

- Date, which captures the day the inspection was carried out;

- East coordinate and North coordinate, which record the geographic location of each inspection point using the WGS 84 coordinate system.

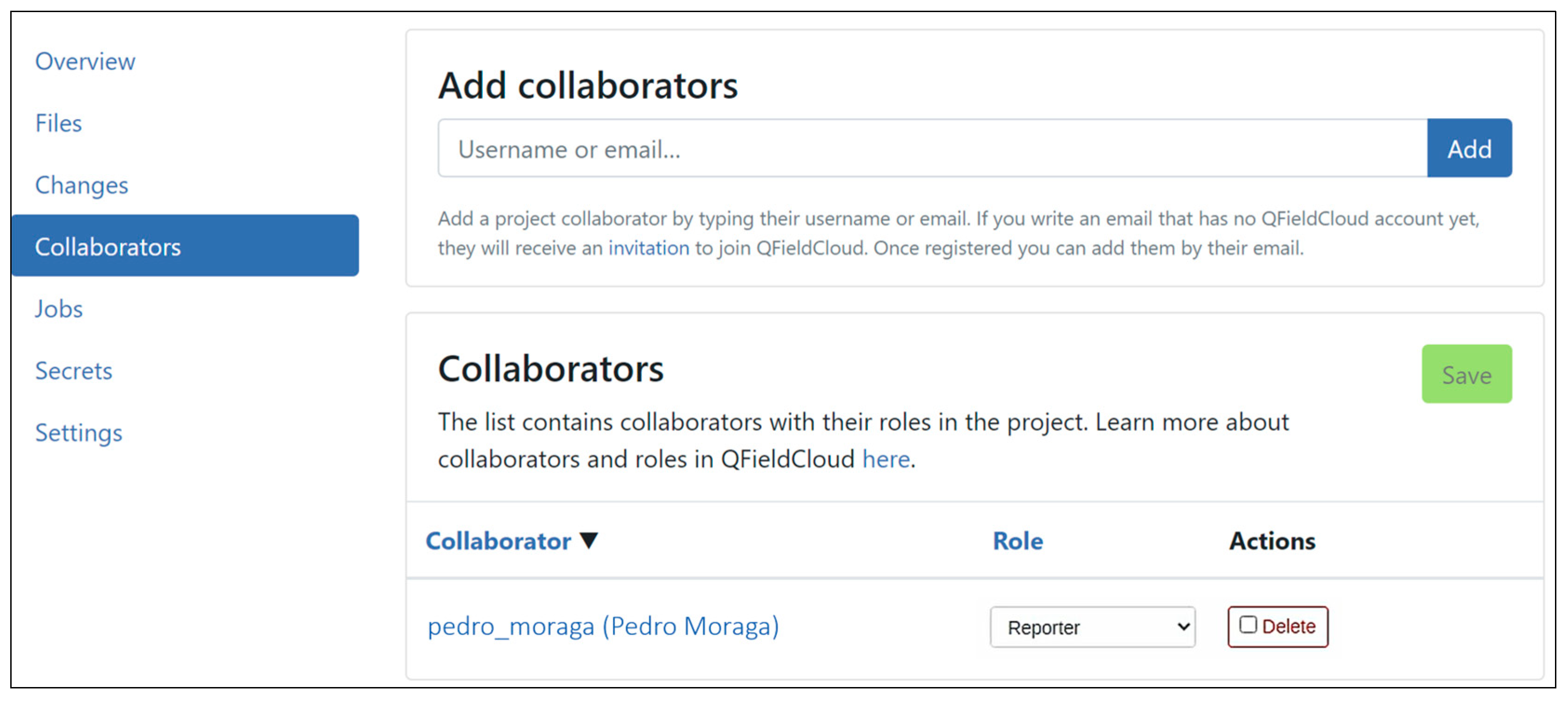

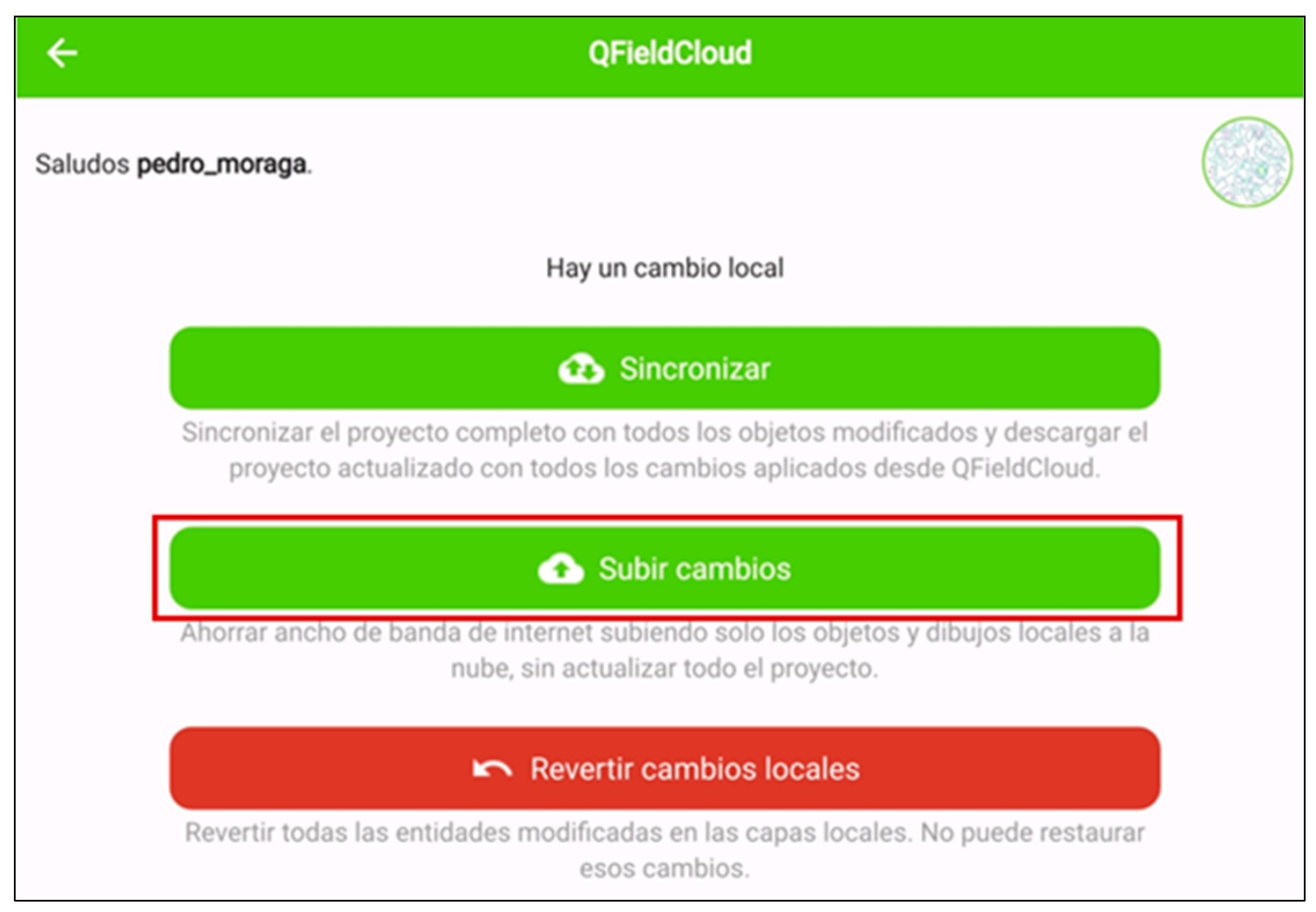

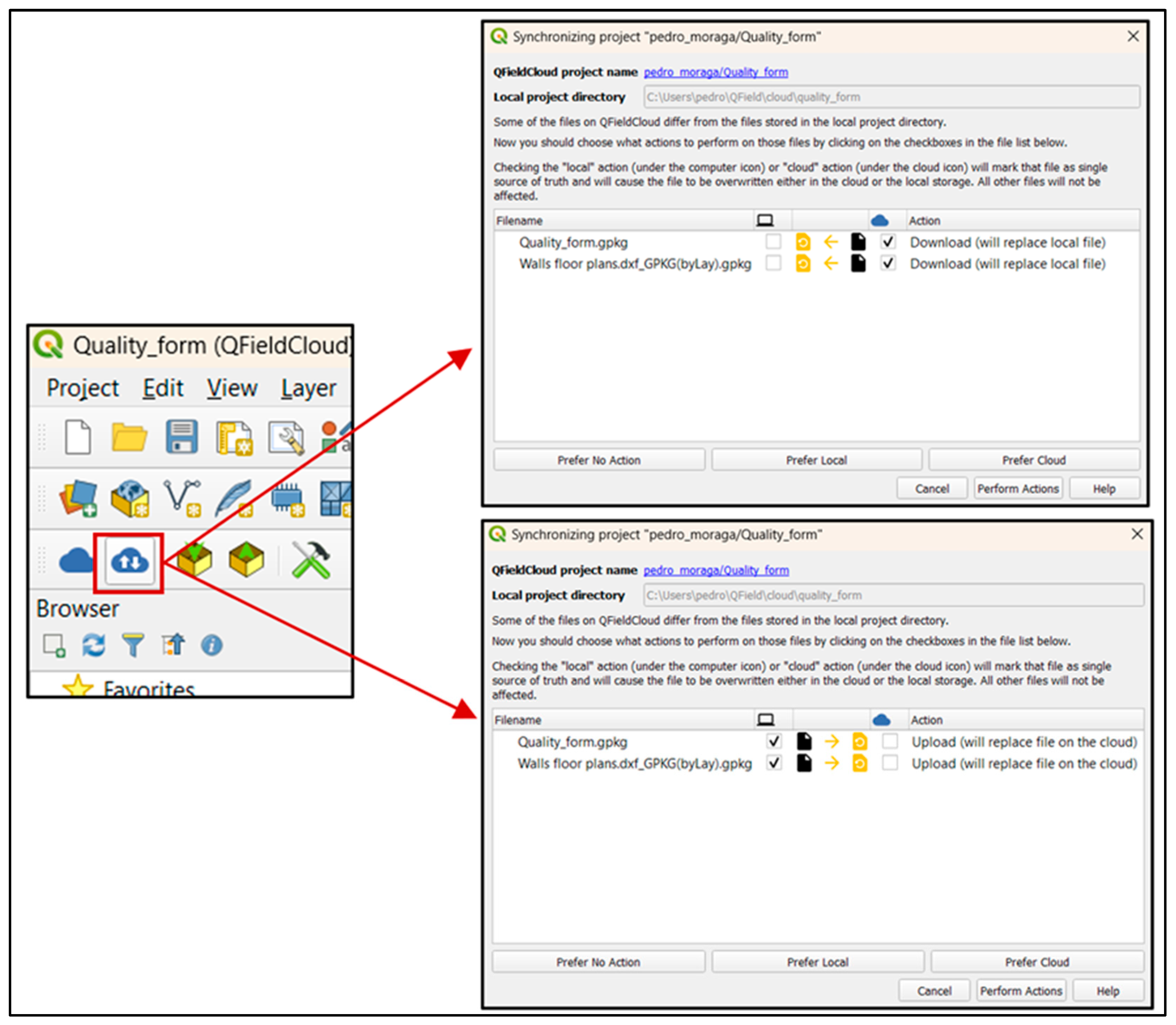

5.4. Creation of Qfield App

5.5. Linking Quality Inspection Results to the BIM Model

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. Quality Control Checklist

| Phase | Quality Controls |

|---|---|

| Prior to concrete pouring | Layout of walls according to blueprint dimensions. |

| Leveling and cleaning of the wall’s support base on the foundation. | |

| Placement of rebar, verifying diameters, lengths, and spacing based on structural design. | |

| Installation of formwork: free of holes, rigid, non-stick; includes scaffoldings for safe concrete pouring. | |

| Verify equipment availability for the execution of the phase. | |

| During concrete pouring | Concrete pouring with appropriate equipment, following technical specifications. |

| Compaction in layers, ensuring vibrator spacing and continuity. | |

| Recording weather conditions during inspection (rain, snow, wind). | |

| After concrete pouring | Curing of concrete using methods to preserve humidity and ensure strength development. |

| Timely removal of formwork and shoring. | |

| Surface inspection for cracks, voids, and other defects. | |

| Correction of surface defects with compatible materials, ensuring homogeneity. | |

| Performance of strength tests: compression, bending, and indirect shear in accordance with standards. |

Appendix A.2. Device Specifications

| Specification | Samsung® Galaxy Tab S6 Lite |

|---|---|

| Operating system | Android® |

| Dimensions | 244.5 × 154.3 × 7.0 mm |

| Screen size | 10.4″ (263.1 mm) |

| Connectivity | Wi-Fi 2.4 G + 5 GHz |

| Location technology | GPS, Glonass, Beidou, Galileo, QZSS |

Appendix A.3. Data Synchronization and Workflow Details

References

- Han, L.; Bian, X.; Gu, S.; Liu, C.; Pan, W.; Zhao, X. Research on Construction Quality Management Based on BIM. Int. J. Front. Eng. Technol. 2022, 4, 56–62. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Nguyen, T.A.; Cao, T.M.; Vo, K.D.; Huynh, D.B.; Nguyen, Q.; Phuong, T.P.; Le, L.P. Construction Project Quality Management Using Building Information Modeling 360 Field. Int. J. Adv. Comput. Sci. Appl. 2018, 9, 228–233. [Google Scholar] [CrossRef]

- Liu, H.; Duan, Y. Production and Construction Quality Management System of Prefabricated Buildings Based on BIM Technology. Int. J. Ind. Syst. Eng. 2023, 43, 103–114. [Google Scholar] [CrossRef]

- Li, X.; Xie, W.; Yang, T.; Lin, C.; Jim, C.Y. Carbon Emission Evaluation of Prefabricated Concrete Composite Plates during the Building Materialization Stage. Build. Env. 2023, 232, 110045. [Google Scholar] [CrossRef]

- Khadim, N.; Thaheem, M.J.; Ullah, F.; Mahmood, M.N. Quantifying the Cost of Quality in Construction Projects: An Insight into the Base of the Iceberg. Qual. Quant. 2023, 57, 5403–5429. [Google Scholar] [CrossRef]

- Holkar, M.R.N.; Pataskar, M.S. Quality Management In Construction Industry By Using Building Information Modelling (BIM). J. Univ. Shanghai Sci. Technol. 2021, 23, 265–276. [Google Scholar] [CrossRef]

- Muhammad, K.M.A.; El Shimy, H.G.; Abd Elsalam, A.A.E.H. Evaluating the Quality of Construction Projects in Egypt and Identifying the Factors That Influence Deviation. HBRC J. 2024, 20, 43–54. [Google Scholar] [CrossRef]

- Silalahi, A.P.; Widjajakusuma, J.; Tanuhendrata, M.S.; Suraji, A. A Conceptual Framework for Integrating QSHE in Construction. In Proceedings of the IOP Conference Series: Earth and Environmental Science; Institute of Physics: London, UK, 2023; Volume 1195. [Google Scholar]

- Santelices, C.; Herrera, R.; Muñoz, F. Problems in Quality Management and Technical Inspection of Work: A Study Applied to the Chilean Context. Rev. Ing. Constr. 2019, 34, 242–251. [Google Scholar] [CrossRef]

- Muruganandham, R.; Venkatesh, K.; Devadasan, S.; Harish, V. TQM through the Integration of Blockchain with ISO 9001:2015 Standard Based Quality Management System. Total Qual. Manag. Bus. Excell. 2022, 34, 1–21. [Google Scholar] [CrossRef]

- Idrissi Gartoumi, K.; Aboussaleh, M.; Zaki, S. Implementing Lean Construction to Improve Quality and Megaproject Construction: A Case Study. J. Financ. Manag. Prop. Constr. 2024, 29, 1–22. [Google Scholar] [CrossRef]

- Sindhwani, R.; Vaidya, O.S.; Antony, J.; Shokri, A. Evaluating Performance of Projects Using Six Sigma Approach. IEEE Trans. Eng. Manag. 2023, 70, 3539–3552. [Google Scholar] [CrossRef]

- Bottani, E.; Montanari, R.; Volpi, A.; Tebaldi, L.; Maria, G. Di Statistical Process Control of Assembly Lines in a Manufacturing Plant: Process Capability Assessment. Procedia Comput. Sci. 2021, 180, 1024–1033. [Google Scholar] [CrossRef]

- Panyukov, D.; Kozlovskii, V.; Aidarov, D.; Shakurskii, M. Effectiveness of FMEA Risk Analysis. Russ. Eng. Res. 2022, 42, 1070–1072. [Google Scholar] [CrossRef]

- ISO 9001:2015; ISO Quality Management Systems-Requirements. International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- Zhuman, Y.; Juman, J.; Makulova, A.; Kalaganov, B.; Tagay, A.; Bastarova, U. Mechanism of introduction of quality management system at the enterprises of the construction industry: Case of the republic of kazakhstan. Bus. Manag. Econ. Eng. 2024, 22, 240–254. [Google Scholar] [CrossRef]

- Castillo-Peces, C.; Mercado-Idoeta, C.; Prado-Roman, M.; Castillo-Feito, C. The Influence of Motivations and Other Factors on the Results of Implementing ISO 9001 Standards. Eur. Res. Manag. Bus. Econ. 2018, 24, 33–41. [Google Scholar] [CrossRef]

- Sweis, R.J.; Jaradat, M. Project Management Performance of Construction Projects in Jordan: A Comparative Study of ISO 9001-Certified and Non-Certified Companies. TQM J. 2022, 34, 1341–1364. [Google Scholar] [CrossRef]

- Meng, Q. A Review of Integrated Applications of BIM and Related Technologies in Whole Building Life Cycle. Eng. Constr. Archit. Manag. 2020, 27, 1647–1677. [Google Scholar] [CrossRef]

- Jofré-Briceño, C.; Rivera, F.M.; Atencio, E.; Herrera, R.F. Implementation of Facility Management for Port Infrastructure through the Use of Uavs, Photogrammetry and Bim. Sensors 2021, 21, 6686. [Google Scholar] [CrossRef]

- Konstantinos Gkoumas Marcin Stepniak, I.C.; dos Santos, F.M. New Technologies for Bridge Inspection and Monitoring: A Perspective from European Union Research and Innovation Projects. Struct. Infrastruct. Eng. 2024, 20, 1120–1132. [Google Scholar] [CrossRef]

- Gang, J.; Feng, C.; Shu, W. A Framework for BIM-Based Quality Supervision Model in Project Management. In Proceedings of the Thirteenth International Conference on Management Science and Engineering Management; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; Volume 1002. [Google Scholar]

- Fidel Lozano-Galant Angela Montalvo, E.A.R.P.; Lozano-Galant, J.A. An Open-Source GIS App for Digitalising Bridge Inspections and Automating BIM Model Integration. Struct. Infrastruct. Eng. 2025, 1–12. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Pelosi, A.; Jia, Y.; Shen, X.; Siddiqui, M.K.; Yang, N. Implementation of Technologies in the Construction Industry: A Systematic Review. Eng. Constr. Archit. Manag. 2022, 29, 3181–3209. [Google Scholar] [CrossRef]

- Altıntaş, Y.D.; Ilal, M.E. Loose Coupling of GIS and BIM Data Models for Automated Compliance Checking against Zoning Codes. Autom. Constr. 2021, 128, 103743. [Google Scholar] [CrossRef]

- Zavari, M.; Shahhosseini, V.; Ardeshir, A.; Sebt, M.H. Multi-Objective Optimization of Dynamic Construction Site Layout Using BIM and GIS. J. Build. Eng. 2022, 52, 104518. [Google Scholar] [CrossRef]

- Cepa, J.J.; Pavón, R.M.; Alberti, M.G.; Caramés, P. TOWARDS BIM-GIS INTEGRATION FOR ROAD INTELLIGENT MANAGEMENT SYSTEM. J. Civ. Eng. Manag. 2023, 29, 621–638. [Google Scholar] [CrossRef]

- Han, C.; Tang, F.; Ma, T.; Gu, L.; Tong, Z. Construction Quality Evaluation of Asphalt Pavement Based on BIM and GIS. Autom. Constr. 2022, 141, 104398. [Google Scholar] [CrossRef]

- Kaya, U.; Özener, O.Ö. A Strategic Evaluation of BIM-Driven Information Management in the Context of ISO 19650-2 Standard. Eng. Constr. Archit. Manag. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Ruzarovsky, R.; Horak, T.; Zelník, R.; Skypala, R.; Csekei, M.; Šido, J.; Nemlaha, E.; Kopcek, M. Development and Validation of Digital Twin Behavioural Model for Virtual Commissioning of Cyber-Physical System. Appl. Sci. 2025, 15, 2859. [Google Scholar] [CrossRef]

- Ismaeil, E.M.H. Asset Information Model Management-Based GIS/BIM Integration in Facility Management Contract. Sustainability 2024, 16, 2495. [Google Scholar] [CrossRef]

- Peffers, K.; Tuunanen, T.; Gengler, C.E.; Rossi, M.; Hui, W.; Virtanen, V.; Bragge, J. Design Science Research Process: A Model for Producing and Presenting Information Systems Research. arXiv 2020, arXiv:2006.02763. [Google Scholar]

- Cheng, Y. Application of BIM on Documenting Construction Defects. Int. J. Eng. Technol. 2018, 9, 392–397. [Google Scholar] [CrossRef]

- Moradabadi, B.; Noorzai, E.; Abbasi, S. BIM-Based Optimization Approach to Reduce Life Cycle Costs by Focusing on the Integration of Construction and Operation Phases in Office-Commercial Buildings. J. Build. Eng. 2024, 98, 111126. [Google Scholar] [CrossRef]

- Cherkina, V.; Shushunova, N.; Zubkova, J. Application of BIM-Technologies in Tasks of Quality Management and Labour Safety. MATEC Web Conf. 2018, 251, 06004. [Google Scholar] [CrossRef]

- Pelden, S.; Banihashemi, S.; Mohandes, S.R.; Arashpour, M.; Kalantari, M. Enhancing Infrastructure Planning and Design through BIM-GIS Integration. Struct. Infrastruct. Eng. 2025, 1–20. [Google Scholar] [CrossRef]

- Apriani, S.; Mursitama, T.N.; Fawzi, A.; Bali, A.; Syamil, A.; Saroso, H. An Empirical Study on the Factors Affecting the Implementation of Quality Management Systems Among Indonesian Multinational Companies. J. Syst. Manag. Sci. 2023, 13, 430–442. [Google Scholar] [CrossRef]

- PMI. PMBOK® Guide, 7th ed.; Project Management Institute, Inc.: Newtown Square, PA, USA, 2021. [Google Scholar]

- Darsono, F.B.; Nurdin, A.; Koin, S.T.; Thomas, A.K.; Mulyono, T.; Setiyawan, A.; Huda, K.; Fitriyana, D.F.; Widodo, R.D. Rusiyanto Visual Inspection and Non-Destructive Test (NDT) on ASTM A36 Welded Joints Produced by GMAW. Int. J. Integr. Eng. 2024, 16, 114–125. [Google Scholar] [CrossRef]

- Sabelli, R.; Adams, A.; Landis, D. Application of AISC Specification Requirements for Second-Order Analysis and Stability Design. Eng. J. 2023, 60, 155–174. [Google Scholar] [CrossRef]

- Hadidi, L.; Assaf, S.; Aluwfi, K.; Akrawi, H. The Effect of ISO 9001 Implementation on the Customer Satisfaction of the Engineering Design Services. Int. J. Build. Pathol. Adapt. 2017, 35, 176–190. [Google Scholar] [CrossRef]

- Arfan Bakhtiar Aditya Nugraha, H.S.; Pujotomo, D. The Effect of Quality Management System (ISO 9001) on Operational Performance of Various Organizations in Indonesia. Cogent Bus. Manag. 2023, 10, 2203304. [Google Scholar] [CrossRef]

- Martins, A.C.P.; de Carvalho, J.M.F.; Alvarenga, M.C.S.; de Oliveira, D.S.; Júnior, K.M.L.C.; Ribeiro, J.C.L.; Santos, G.S.; Verly, R.C. Detecting, Monitoring and Modeling Damage within the Decision-Making Process in the Context of Managing Bridges: A Review. Struct. Infrastruct. Eng. 2024, 1–23. [Google Scholar] [CrossRef]

- Lozano, F.; Emadi, S.; Komarizadehasl, S.; González-Arteaga, J.; Xia, Y. Enhancing Performance Evaluation of Low-Cost Inclinometers for the Long-Term Monitoring of Buildings. J. Build. Eng. 2024, 87, 109148. [Google Scholar] [CrossRef]

- Mitsuyoshi Akiyama, D.M.F.; Xu, Z. Probabilistic Service Life Assessment of Corroded Concrete Structures: A State-of-the-Art Review. Struct. Infrastruct. Eng. 2025, 1–20. [Google Scholar] [CrossRef]

- Cheng, Y.M. Building Information Modeling for Quality Management. In Proceedings of the ICEIS 2018—Proceedings of the 20th International Conference on Enterprise Information Systems, Funchal, Portugal, 21–24 March 2018; Volume 2, pp. 351–358. [Google Scholar] [CrossRef]

- Allen, E.; Costello, S.B.; Henning, T.F.P.; Chamorro, A.; Echaveguren, T. Integration of Resilience and Risk to Natural Hazards into Transportation Asset Management of Road Networks: A Systematic Review. Struct. Infrastruct. Eng. 2023, 1–19. [Google Scholar] [CrossRef]

- Marinho, A.; Couto, J.; Teixeira, J. Relational Contracting and Its Combination with the BIM Methodology in Mitigating Asymmetric Information Problems in Construction Projects. J. Civ. Eng. Manag. 2021, 27, 217–229. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chang, J.X.; Su, Y.C. Developing Construction Defect Management System Using BIM Technology in Quality Inspection. J. Civ. Eng. Manag. 2016, 22, 903–914. [Google Scholar] [CrossRef]

- Riaz, H.; Iqbal Ahmad Khan, K.; Ullah, F.; Bilal Tahir, M.; Alqurashi, M.; Alsulami, B.T. Key Factors for Implementation of Total Quality Management in Construction Sector: A System Dynamics Approach. Ain Shams Eng. J. 2023, 14, 101903. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Machado, R.L.; Vilela, C. Conceptual Framework for Integrating BIM and Augmented Reality in Construction Management. J. Civ. Eng. Manag. 2020, 26, 83–94. [Google Scholar] [CrossRef]

- Choi, J.; Lee, S.; Kim, I. Development of Quality Control Requirements for Improving the Quality of Architectural Design Based on Bim. Appl. Sci. 2020, 10, 7074. [Google Scholar] [CrossRef]

- Namhun, L.; Talat, S.; Wang, G. Building Information Modeling for Quality Management in Infrastructure Construction Projects. In Proceedings of the 15th International Conference on Computing in Civil and Building Engineering; Springer: Berlin/Heidelberg, Germany, 2014; pp. 955–1865. [Google Scholar]

- Ma, G.; Wu, M.; Wu, Z.; Yang, W. Single-Shot Multibox Detector- and Building Information Modeling-Based Quality Inspection Model for Construction Projects. J. Build. Eng. 2021, 38, 102216. [Google Scholar] [CrossRef]

- Zhang, T.; Doan, D.T.; Kang, J. Application of Building Information Modeling-Blockchain Integration in the Architecture, Engineering, and Construction / Facilities Management Industry: A Review. J. Build. Eng. 2023, 77, 107551. [Google Scholar] [CrossRef]

- Fang, Z.; Liu, Y.; Lu, Q.; Pitt, M.; Hanna, S.; Tian, Z. BIM-Integrated Portfolio-Based Strategic Asset Data Quality Management. Autom. Constr. 2022, 134, 104070. [Google Scholar] [CrossRef]

- Park, S.; Kim, I. BIM-Based Quality Control for Safety Issues in the Design and Construction Phases. Archnet-IJAR 2015, 9, 111–129. [Google Scholar] [CrossRef]

- Chen, L.; Luo, H. A BIM-Based Construction Quality Management Model and Its Applications. Autom. Constr. 2014, 46, 64–73. [Google Scholar] [CrossRef]

- Shin, H.J.; Cha, H.S. Proposing a Quality Inspection Process Model Using Advanced Technologies for the Transition to Smart Building Construction. Sustainability 2023, 15, 815. [Google Scholar] [CrossRef]

- Biel, S. Concept of Using the BIM Technology to Support the Defect Management Process. Arch. Civ. Eng. 2021, 67, 209–229. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, T.; Li, B.; Li, H.; Li, Q. Developing an IFC-Based Database for Construction Quality Evaluation. Adv. Civ. Eng. 2018, 2018, 3946051. [Google Scholar] [CrossRef]

- Ding, L.; Li, K.; Zhou, Y.; Love, P.E.D. An IFC-Inspection Process Model for Infrastructure Projects: Enabling Real-Time Quality Monitoring and Control. Autom. Constr. 2017, 84, 96–110. [Google Scholar] [CrossRef]

- Kalyan, T.S.; Zadeh, P.A.; Staub-French, S.; Froese, T.M. Construction Quality Assessment Using 3D As-Built Models Generated with Project Tango. Procedia Eng. 2016, 145, 1416–1423. [Google Scholar] [CrossRef]

- Bellido-Montesinos, P.; Lozano-Galant, F.; Castilla, F.J.; Lozano-Galant, J.A. Experiences Learned from an International BIM Contest: Software Use and Information Workflow Analysis to Be Published in: Journal of Building Engineering. J. Build. Eng. 2019, 21, 149–157. [Google Scholar] [CrossRef]

- Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A.; Aguilera, M. Using RPA for Performance Monitoring of Dynamic SHM Applications. Buildings 2022, 12, 1140. [Google Scholar] [CrossRef]

- Cann, S.; Mahamadu, A.-M.; Prabhakaran, A.; Dziekonski, K.; Joseph, R. An Approach for Semi-Automated Data Quality Assurance within BIM Models. Eng. Manag. Prod. Serv. 2022, 14, 114–125. [Google Scholar] [CrossRef]

- Pinto, R.; Torres, P.M.B.; Lohweg, V. Closing Editorial: Advances and Future Directions in Autonomous Systems for Cyber-Physical Systems and Smart Industry. Appl. Sci. 2024, 14, 10673. [Google Scholar] [CrossRef]

- Bansal, V.K. Potential Application Areas of GIS in Preconstruction Planning. J. Prof. Issues Eng. Educ. Pract. 2016, 142. [Google Scholar] [CrossRef]

- Hazar Dib, N.A.-V.; Issa, R.R.A. A GIS-Based Visual Information Model for Buildng Construction Project Management. Int. J. Constr. Manag. 2013, 13, 1–18. [Google Scholar] [CrossRef]

- Chowdary, M.H.; Karthik, N.; Raju, N. Applications of 4D GIS Model in Construction Management. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 2597–2608. [Google Scholar] [CrossRef]

- Alnaser, A.A.; Maxi, M.; Elmousalami, H. AI-Powered Digital Twins and Internet of Things for Smart Cities and Sustainable Building Environment. Appl. Sci. 2024, 14, 12056. [Google Scholar] [CrossRef]

- ESRI. ArcGIS for Personal Use. Available online: https://www.esri.com/en-us/arcgis/products/arcgis-for-personal-use/overview (accessed on 23 May 2025).

- QGIS. Spatial without Compromise. Available online: https://qgis.org/ (accessed on 23 May 2025).

- GRASS. Development Team. Bringing Advanced Geospatial Technologies to the World. Available online: https://grass.osgeo.org/ (accessed on 23 May 2025).

- HEXAGON. Leverage Your Geospatial Data with GeoMedia for GIS and Mapping. Available online: https://hexagon.com/products/geomedia (accessed on 23 May 2025).

- GEOBIS. International MapInfo Profesional V16.0. Available online: https://www.geobis.com/mapinfo-gis-software/ (accessed on 23 May 2025).

- Blue Marble Geographics Global Mapper. Available online: https://www.bluemarblegeo.com/global-mapper/ (accessed on 23 May 2025).

- Collao, J.; Lozano-Galant, F.; Lozano-Galant, J.A.; Turmo, J. BIM Visual Programming Tools Applications in Infrastructure Projects: A State-of-the-Art Review. Appl. Sci. 2021, 11, 8343. [Google Scholar] [CrossRef]

- Atta, I.; Bakhoum, E.S.; Marzouk, M.M. Digitizing Material Passport for Sustainable Construction Projects Using BIM. J. Build. Eng. 2021, 43, 103233. [Google Scholar] [CrossRef]

- Lozano, F.; Jurado, J.C.; Lozano-Galant, J.A.; de la Fuente, A.; Turmo, J. Integration of BIM and Value Model for Sustainability Assessment for Application in Bridge Projects. Autom. Constr. 2023, 152, 104935. [Google Scholar] [CrossRef]

- Solminihac, H.; Thenoux, G. Procesos y Técnicas de Construcción, 5th ed.; Ediciones Universidad Católica de Chile: Santiago, Chile, 2011. [Google Scholar]

- Patel, C.S.; Pitroda, J.R. Quality Management System in Construction: A Review. Reliab. Theory Appl. 2021, 16, 121–131. [Google Scholar] [CrossRef]

- Lin, Y.-C. Use of BIM Approach to Enhance Construction Interface Management: A Case Study. J. Civ. Eng. Manag. 2015, 21, 201–217. [Google Scholar] [CrossRef]

- Su, X.; Andoh, A.R.; Cai, H.; Pan, J.; Kandil, A.; Said, H.M. GIS-Based Dynamic Construction Site Material Layout Evaluation for Building Renovation Projects. Autom. Constr. 2012, 27, 40–49. [Google Scholar] [CrossRef]

- Song, Y.; Wang, X.; Tan, Y.; Wu, P.; Sutrisna, M.; Cheng, J.C.P.; Hampson, K. Trends and Opportunities of BIM-GIS Integration in the Architecture, Engineering and Construction Industry: A Review from a Spatio-Temporal Statistical Perspective. ISPRS Int. J. Geoinf. 2017, 3976. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K.; Chiou, E.; Patrick, R.; Hamed, K.A. Construction Inspection & Monitoring with Quadruped Robots in Future Human-Robot Teaming: A Preliminary Study. J. Build. Eng. 2023, 65, 105814. [Google Scholar] [CrossRef]

- Chan, D.W.M.; Olawumi, T.O.; Ho, A.M.L. Perceived Benefits of and Barriers to Building Information Modelling (BIM) Implementation in Construction: The Case of Hong Kong. J. Build. Eng. 2019, 25, 100764. [Google Scholar] [CrossRef]

- Lidelöw, S.; Engström, S.; Samuelson, O. The Promise of BIM? Searching for Realized Benefits in the Nordic Architecture, Engineering, Construction, and Operation Industries. J. Build. Eng. 2023, 76, 107067. [Google Scholar] [CrossRef]

- Xiang, Y.; Mahamadu, A.-M.; Florez-Perez, L. Engineering Information Format Utilisation across Building Design Stages: An Exploration of BIM Applicability in China. J. Build. Eng. 2024, 95, 110030. [Google Scholar] [CrossRef]

| (1) Ref. | (2) Article Aim | (3) On-Site Quality Data Acquisition Tool | (4) Type of Structure | (5) BIM Software | (6) Hardware | (7) Maturity Level |

|---|---|---|---|---|---|---|

| [59] | Development of a 4D BIM-based application for quality management data recording. | Checklist | Foundations | Revit, Navisworks | Computer | Prototype, case study |

| [6] | Creation of a 4D BIM-based program for construction quality control. | N.S. | Building | Revit, Navisworks | Computer | Prototype, case study |

| [60] | Development of a quality inspection workflow through the implementation of a BIM-based Application Programming Interface (API) system. | Inspection forms | Building | Revit, BIM server (cloud) | Computer, Laser scanner | Prototype, case study |

| [49] | Real-time BIM-based defect management system to illustrate and analyze defect information at the jobsite during construction. | Inspection forms | Building | Revit, Navisworks | Computer, mobile device, system server | Prototype, case study |

| [61] | Development of a quality control support application that collects data about construction defects, recording on-site defects on a BIM model, using a mobile device. | Inspection forms | Building | BIM Vision | Computer, mobile device | Prototype |

| [33] | Creation of a prototype to display on-site quality defect reports on BIM model instances. | N.S. | Building | Revit, Microsoft Visual Studio | Computer | Prototype |

| [2] | Real-time quality management using checklists, BIM cloud services, and mobile devices. | Checklist | Building | BIM360, BIM360Field app | Computer, mobile device (tablet) | Prototype, case study |

| [62] | Development of an IFC-based database for construction quality evaluation, using neural networks. | N.S. | Structural elements (beam, slab, column, wall) | Revit, STEP Tools, MATLAB | Computer | Prototype, case study |

| [63] | Real-time exchange of quality and schedule information through IFC models during construction. | N.S. | Railway infrastructure | Revit, Navisworks, STEP Tools | Computer | Prototype, case study |

| [64] | Development of construction quality assessment reports using laser scanner, photogrammetry, infrared camera, and 3D models. | Laser scanner, photogrammetry, infrared camera | Building | Navisworks, MeshLab | Computer, mobile device, laser scanner, infrared camera | Prototype, case study |

| GIS Software | Pricing | Operative System Compatibility | Own Virtual Storage | Mobile Application Used for on-Site Quality Management | Reference |

|---|---|---|---|---|---|

| ArcGIS Desktop | USD 100 to USD 3800/year | Windows | ArcGIS Online | ArcGIS Field Maps®, ArcGIS Survey123 | [73] |

| QGIS | Free | Windows, Linux, MacOS | QFieldCloud | QField | [74] |

| Grass GIS | Free | Windows, Linux, MacOS | N.S. | N.S. | [75] |

| GeoMedia | From USD 1500/year | Windows | M.App | GeoMedia WebMap Mobile | [76] |

| MapInfo | USD 2500 to USD 4000/year | Windows | N.S. | N.S. | [77] |

| Global Mapper | From USD 700 | Windows | N.S. | Global Mapper Mobile | [78] |

| Component | Implemented Functionality | Planned Enhancements |

|---|---|---|

| Data collection | Georeferenced inspection forms with structured attributes via QGIS/QField | Automated input validation and error checking in mobile forms |

| Data integration | Manual export of XLSX file and semi-automated import into BIM using Dynamo | Full automation of data synchronization between GIS and BIM environments |

| Visualization and traceability | Parameter visualization and inspection tracking in Revit | Use of 3D GIS tools and Z-coordinate integration for multi-level buildings |

| Interoperability | Revit and Dynamo-based environment | Expansion to IFC-compatible platforms and open standards |

| Performance assessment | Functional validation in a small-scale case study | Quantitative evaluation: time reduction, error rates, and scalability |

| Model update cycle | Cube regeneration and data replacement routine in BIM | Support for differentiated vertical elements and spatial hierarchy |

| Record permanence | Cloud-based inspection data storage with manual oversight | Integration of blockchain for immutable quality records |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araya-Santelices, P.; Moraga, P.; Atencio, E.; Lozano-Galant, F.; Lozano-Galant, J.A. BIM-GIS-Based Approach for Quality Management Aligned with ISO 9001. Appl. Sci. 2025, 15, 6107. https://doi.org/10.3390/app15116107

Araya-Santelices P, Moraga P, Atencio E, Lozano-Galant F, Lozano-Galant JA. BIM-GIS-Based Approach for Quality Management Aligned with ISO 9001. Applied Sciences. 2025; 15(11):6107. https://doi.org/10.3390/app15116107

Chicago/Turabian StyleAraya-Santelices, Pablo, Pedro Moraga, Edison Atencio, Fidel Lozano-Galant, and José Antonio Lozano-Galant. 2025. "BIM-GIS-Based Approach for Quality Management Aligned with ISO 9001" Applied Sciences 15, no. 11: 6107. https://doi.org/10.3390/app15116107

APA StyleAraya-Santelices, P., Moraga, P., Atencio, E., Lozano-Galant, F., & Lozano-Galant, J. A. (2025). BIM-GIS-Based Approach for Quality Management Aligned with ISO 9001. Applied Sciences, 15(11), 6107. https://doi.org/10.3390/app15116107