3.2.1. Processes and Materials

Although some of the reviewed articles [

1,

2,

3,

4,

5] justify the emergence and usefulness of hybrid additive and subtractive manufacturing, literally, with the need to reduce the limitations of additive manufacturing, such as the lack of surface quality, and subtractive, including the waste of high-cost material, and the desire to take advantage of its strengths, the ability to generate complex geometries in the case of additive manufacturing and the great geometric, dimensional, and surface quality in the case of subtractive manufacturing, this idea underlies practically all of the selected works, assuming it in a natural and unquestionable way.

Perez et al. [

1] developed an experimental investigation to relate LPBF (Laser Powder Bed Fusion) parameters with cutting forces and milling anisotropy of Incolel 718 parts, in the context of a hybrid additive–subtractive manufacturing flow. After highlighting the capacity of hybrid manufacturing to achieve complex geometries, they emphasize the need for the participation of subtractive manufacturing to provide the parts with the required surface, dimensional, and geometric quality. The rapid heating and cooling cycles of the parts manufactured by LPBF give rise to columnar grain structures, which consequently produce crystalline textures and anisotropy. This makes both the mechanical properties and the cutting forces depend on the spatial directions. Through a study based on a Taylor oblique cutting model, the microstructures of the parts manufactured by LPBF, the layer thickness and the cutting parameters are related. The authors make a relevant contribution by limiting machining parameters to a finishing context, given that the objective of additive manufacturing is to obtain near-net-shape parts.

Research shows that although the influence of the crystalline structure on cutting forces is reduced when working with low VED (Volumetric Energy Density), this increases the impact of grain shape. Under these conditions, the increase in the density of the boundary grain requires lower cutting forces for a tool axis parallel to the main grain axis. On the contrary, they are higher for planes of the shear bands transverse to the columnar grains [

1].

Feng et al. [

2] conducted a review of the scientific literature published on the manufacturing of molds with conformal cooling (CC), integrating L-PBF and CNC milling in a hybrid flow. The objective of CC is to achieve faster and more homogeneous cooling than that obtained with conventional channels.

Throughout their systematic review, they focus on the additive manufacturing of multimaterial molds, such as 316L stainless steel/H13 hot work steel or steel/Cu combinations, after which they conclude that monomaterial additive manufacturing presents higher quality. They also conclude that the great capacity of hybrid additive and subtractive manufacturing to achieve higher standards in the production of parts with complex geometry, with high surface, geometric, and dimensional quality, becomes especially relevant and applicable in the mold manufacturing industry with conformal cooling (CC), since with traditional processes it would be impossible to provide the channels with the characteristics and qualities obtained through the integration and alternation of additive and subtractive subprocesses within the same manufacturing flow [

2].

Veiga et al. [

40] conduct a practical investigation to study the quality of hybrid additive and subtractive manufacturing (PAW-WAAM and milling) of Ti6Al-4V titanium parts. The study is focused on PAW (Plasma Arc Welding), a type of WAAM (wire arc additive manufacturing) technology, and its feasibility is validated in combination with CNC milling. In fact, it is concluded from the study that the wall manufactured in their experiments meets aeronautical standards and does not present significant variations due to the position and orientation of the samples analyzed. Neither does the torque change significantly when performing up-milling or down-milling, although up-milling does improve surface quality. Torque is not affected by cutting depth, but it is affected by speed. Surface quality also improves when the tool approaches the clamping system.

The work of Ingarao et al. [

41] presents comparative models of costs and accumulated energy demand of subtractive and hybrid additive–subtractive processes. These models consider the complete life cycle, including the operations that follow the hybrid manufacturing phase, such as final surface machining or the removal of support structures. The research proposes models based on hybrid additive and subtractive manufacturing of Ti-6Al-4V parts through Electron Beam Melting and turning. The use phase is also considered. In the model, variables include the shape, the possibilities for part lightening, and the usage time. To compare the subtractive and hybrid processes, the premise is that both can meet the geometric requirements, which indicates the eminently economic focus of the study. Different approaches are alternated in the study: identical part; weight reduction thanks to additive manufacturing; focus on improving usage conditions. Although the study concludes that the hybrid process is the most advantageous from the point of view of energy demand, it does not go so far as to affirm the same from an environmental or economic perspective, as these are highly conditioned by the geometry or recyclability of the materials.

Korkmaz et al. [

3] conduct a technical review of hybrid manufacturing processes of metallic parts present in the scientific literature. Within this study, hybrid additive and subtractive manufacturing is addressed, identifying pairs of materials and processes such as 6511 Steel through SLM–milling (selective laser melting–milling), 316L Steel through DED–milling, ER2319 aluminum alloy through Laser Cold Metal Transfer, or 316 Stainless Steels through directed energy deposition—Process Laser Remelting Process.

Feldhausen et al. [

42] conduct an experimental study to analyze the mechanical properties and microstructure of 316L stainless steel parts manufactured through hybrid additive and subtractive manufacturing (DED and milling). For the fabrication of the designed hexagonal parts, a five-axis hybrid machine, Mazak VC500A/5x AM, was used. Both porosity and part distortion during the process were studied. The study led to the conclusion that hybrid manufacturing, in which the machine process is not interrupted, reduces total cycle time by 68%. It also reduced the average relative porosity by 83% and the relative elongation at failure by 71%, compared to the additively manufactured part. Hybridization does not affect the crystalline structure. With these results, the future of hybrid additive and subtractive manufacturing, although it must still mature, is promising.

The study by Mirzendehdel et al. [

43] proposes a topology optimization (TO) framework with the objective of automating the design of complex parts manufacturable on five-axis machine tools. For this purpose, multi-axis machining constraints are established, with the consequent reduction of time and material in trial-and-error processes, which are inevitable due to the mismatch between design and manufacturing models. Although the study focuses on the machining process, the author directs it toward hybrid manufacturing, first by including the concept “hybrid manufacturing” among its keywords, and then, in the conclusions, by pointing out as future work the extension of the proposed method to hybrid additive and subtractive manufacturing. Although briefly, it clearly defines what the hybrid process should be, alternating additive and subtractive subprocesses. To extend the method, the defined concept of inaccessibility measure field (IMF) must be applied to the additive subprocess, both in terms of accessibility and in cases of over-deposition or under-cut. Clearly, the study is focused on a context of five-axis CNC manufacturing, in which hybrid flows are included.

Sunny et al. [

44] address in an experimental study the influence of the residual stress (RS) produced by additive manufacturing on the stresses and distortion induced by the subsequent machining of these parts. To carry out the study, the DED manufacturing of thin walls is simulated by finite element software, followed by a high-speed milling phase. The material considered in the simulations is Inconel 625. In the simulations, one hypothesis is used in which the residual stresses generated by additive manufacturing are disregarded, and another hypothesis in which the stresses produced by the DED process are incorporated. The work confirms the importance of the residual stresses generated by the rapid heating and cooling cycles of DED on the stresses and distortion produced by subsequent milling. It also concludes that the design of the machining strategy is crucial in the effect caused by high-speed machining of DED parts.

Careri et al. [

45] carry out an investigation on the wear processes of turning tools for parts made of Ni alloys, specifically IN718, manufactured by DED. In the experiments, additive and subtractive subprocesses are also combined with heat treatments to evaluate their effect. Adhesive and abrasive wear are identified as the main types of tool wear. In the case of the as-deposited material, the wear is due to the low surface quality, although no tool failures occur. When heat treatment is applied to the DED part, although the machinability is similar to that of the forged material, high-speed turning causes rapid tool failure, and surface quality depends to a greater extent on the cutting parameters.

Working with a hybrid machine (Matsuura LUMEX Avance-25, Fukui, Japan), Wüst et al. [

4] manufacture maraging steel 1.2709 parts in a hybrid way, using SLM and five-axis milling. Subsequently, they carry out a statistical optimization study of surface roughness. For this purpose, they rely on the Taguchi method. The study was carried out distinguishing between contour surfaces and hatch, or filling surfaces, and varying the laser power, the scanning speed, and hatch distance. Energy input and energy density were also considered. In milling, variations of feed per tooth, cutting speed, and radial depth were considered. It is concluded that the application of the analysis method and the selection of the most favorable combination of parameters allow for the reduction of surface roughness to 9.0 μm (40% compared to the values obtained with the manufacturer’s recommendations) and the roughness of contour surfaces to 7.5 μm (37.5%), which confirms the usefulness of the Taguchi method [

4].

In the study by Stavropoulos et al. [

47], hybrid additive and subtractive manufacturing is addressed from the perspective of a hybrid process chain. This is done by considering the repair of a gas turbine blade, manufactured in 316L stainless steel. The research develops a hybrid process planning methodology aimed at improving the life-to-value ratio. The method is based on simulation and experimentation. Although it is concluded that the results in terms of surface roughness are similar, it is emphasized that the selected process chain does affect different KPIs (Key Performance Indicators), such as tool wear or total manufacturing time.

Moritz et al. [

48] address in their study hybrid additive and subtractive manufacturing, LMD and cryogenic milling. They justify it on the basis that the latter leaves surfaces clean of coolants that could affect the subsequent additive process within the hybrid process. The experimental part was carried out with cryogenic CO

2 milling of Ti-6Al-4V parts. The influence on surface integrity and tool wear was evaluated. The study alternated hybrid and subtractive sequences, AM–SM–AM (additive manufacturing–subtractive manufacturing–additive manufacturing). The additive subprocess was carried out with an ABB IRB 4400 multi-axis robot and the subtractive one with an ABB IRB 6660 robot, integrated into the same station.

Guo et al. [

49] seek with their study the reduction of the staircase effect and the improvement of surface quality in parts manufactured through hybrid additive and subtractive manufacturing, FDM (Fused Deposition Modeling) and dry milling. They use polymeric materials, PEEK (Polyetheretherketone) and CF/PEEK (Carbon Fiber Reinforced Polyetheretherketone), for their work, in which they evaluate the relationship between raster angle and layer thickness and spindle speed, depth of cut, and feed rate per tooth. Dry milling is used, considering the surface requirements of molds and medical implants. The study demonstrates that the dry milling subprocess can substantially improve the surface quality of the parts.

Reisch et al. [

50] configured a robotic WAAM system, with the possibility of adaptation to hybrid additive and subtractive manufacturing of large-sized parts in AlSi12. They emphasize the monitoring system to ensure compliance with quality requirements and aim for the industrialization of the system. The research covers the entire process, from design and process planning to WAAM deposition and precision milling. Everything is configured and modeled beforehand with Siemens NX. It is confirmed that the best results are obtained with a tilt angle of 0° and a lead angle of 0°, −5°, and −15°. A digital twin of the manufactured part will be the basis for future adaptations of the process.

The review by Feldhausen et al. [

5] on hybrid additive and subtractive manufacturing concludes that the complexity of the parts, as well as of the manufacturing strategies and toolpaths, is an inherent part of the process. For this reason, the crucial importance of CAM software and the CAM strategies developed to date by different industries is analyzed and highlighted for a successful application. However, the quality of the result is linked not only to CAM but also to the associated processes, mentioning DED and milling, the materials, applied heat treatments, intricate geometries, or the level of the machine tools used.

As Braun et al. [

51] recognize the great potential of metal additive manufacturing, in this case PBF-LB/M (Laser-Based Powder Bed Fusion of Metals), they investigated its combination with subtractive manufacturing, integrated in a hybrid manufacturing flow, to overcome the porosity of the additively produced material and improve its surface roughness, factors that reduce its corrosion and fatigue resistance. The study is specifically applied to the effect on the fatigue resistance of AISI 316L produced through hybrid additive and subtractive manufacturing. It also compares it with the same parameters of wrought 316L. The study confirms that the as-built material has low fatigue strength, while the machining of the additively manufactured part significantly increases its fatigue strength (up to 87%). Since most of the major defects are found in the 250 μm closest to the surface, this allows for improvement in surface quality and integrity.

Among the routes analyzed by Braun et al. [

51] are the following hybrid routes: PBF-LB/M + CNC Milling; PBF-LB/M + HIP (Hot Isostatic Pressing) + CNC Milling; PBF-LB/M + Annealing + CNC Milling. These are compared with conventional routes such as: Wrought (316L) + Heat Treatment + CNC Milling; PBF-LB/M (as-built); PBF-LB/M + Annealing; PBF-LB/M + HIP.

Soffel et al. [

52] conducted an experimental study in which they analyze various manufacturing sequences, combining and alternating casting, milling, and additive manufacturing DMD, to evaluate the interface strength and the resulting mechanical properties. Among the studied flows, the following fit hybrid additive and subtractive manufacturing: Casting + CNC milling + DMD; Casting + heat treatment + CNC milling + DMD. The authors conclude that the hybrid sequences are suitable for the manufacturing and repair of Inconel 718 parts. When comparing them, it is observed that the first, without heat treatment, presents a smoother transition, a better interface strength, and less thermal affectation. In contrast, the route with heat treatment before machining presents worse mechanical and interface behavior due to the precipitation of undesired phases (such as δ) and heterogeneous microstructures.

The work of Mirzendehdel et al. [

53] is oriented toward hybrid additive and subtractive manufacturing with materials that require the use of sacrificial support structures. For this reason, they propose a systematic methodology of topology optimization (TO) that allows removal while overcoming accessibility problems. Their approach is validated through the simulation of the manufacturing of several parts, in Ti-6Al-4V, from the aerospace, robotics, and automotive sectors: GE bracket, +Z (Powder Bed Fusion + 3-axis CNC machining); quad-copter (Powder Bed Fusion + 14-orientation CNC milling); upright example (Powder Bed Fusion + Multi-tool CNC milling with vise fixture). The authors conclude that the approach ensures the successful removal of the support structures from the design phase. To achieve this, they apply the idea of the ‘inaccessibility measure field’ (IMF) to the near net shape parts produced in the additive phase of hybrid additive and subtractive manufacturing.

González Barrio et al. [

21] developed a hybrid additive and subtractive manufacturing methodology for high added-value parts, within a single CAM environment. In the work, an API (Application Programming Interface) is developed for the additive manufacturing module, with options for Planar LMD and three-axis and five-axis LMD. A methodology for predicting the shape manufactured by LMD is also developed, for the subsequent milling process. To validate the methodology, a blisk made of Hastelloy

®X over Inconel

®718 is selected for manufacturing. Work is carried out in the NX™ environment from Siemens. Milling is then applied to provide the geometric, dimensional, and surface quality required in the aerospace industry context. Finally, deviations from the designed part are studied. After a hybrid additive and subtractive manufacturing process, which requires continuous five-axis work due to the complexity of the selected geometry, it is concluded that the deviation does not exceed 10% compared to the predicted geometry.

Zhang et al. [

54] developed a state of the art on the machining of Ti-6Al-4V parts manufactured additively, which led them to directly address various hybrid additive and subtractive manufacturing processes (DED/PBF-LB / EBM + Turning/Milling). Porosity, residual stresses, surface defects, or anisotropy resulting from the additive subprocesses, and cutting forces, heating during the process, and hardness, resulting from the machining process, are some of the aspects studied.

Sebbe et al. [

11] conducted an extensive review of the scientific literature on hybrid additive and subtractive manufacturing oriented toward the production of complex parts. They present a comprehensive summary of the different hybrid flows addressed in the reviewed articles. This allows the authors to approach the process solidly from a technological point of view, considering challenges and opportunities. Beyond overcoming the weaknesses of the independent additive and subtractive subprocesses through their combination, they highlight the versatility of hybrid manufacturing, its ability to reduce the waste of high added-value materials, such as aluminum and titanium alloys used in the aerospace industry, and the possibility of performing the entire process in a single machine. In their work, they identify the issue addressed by many authors concerning the residual stresses caused by the additive subprocess, with the resulting problems of distortion or requirements for heat treatments.

The work of Liu et al. [

55] develops a novel approach compared to most studies on hybrid additive and subtractive manufacturing. In the hybrid process, the additive manufacturing of ceramic precursors is combined—that is, polymeric materials loaded with ceramic materials—by Blade Coating (2D printing) or DIW (Direct Ink Writing) (3D additive manufacturing), followed by the application of the subtractive subprocess, laser cutting, and ending with the application of the thermal process, pyrolysis, which converts it into ceramic material. This last step is what leads the authors to call it 4D-additive–subtractive manufacturing. In their experimental development, they work with PDMS (Polydimethylsiloxane) materials with ceramic particles of ZrO

2, AlON, or Al

2O

3.

In the study by Ghafoori et al. [

56], ER70S-6 wire is used to repair S355J2+N steel parts by additive manufacturing WAAM, given the metallurgical compatibility of both materials. The repaired specimens present central cracks caused for the experimental approach. After the material addition process, a subtractive subprocess, CNC milling (pyramid shaping), is applied. Finally, they were subjected to HCF (High-Cycle Fatigue) loading to evaluate the results and draw conclusions. It is demonstrated that the hybrid process reduces the stresses in the crack area and reduces premature detachment. Pyramid shaping milling helps to reduce stresses. The process as a whole limits the tendency of the crack to propagate.

Wu et al. [

57] analyzed the effect of the machining subprocess, within hybrid additive and subtractive manufacturing, on the stresses generated by the additive manufacturing of 316L stainless steel and, therefore, on the resulting deformation of the part. The experimental approach was carried out using a three-axis LMD machine (Beijing Beiyi Machine Tool Co., Ltd., Beijing, China). The hybrid process was also simulated, considering temperature and stresses, using Finite Element Method through ANSYS Mechanical APDL19.2. Thanks to the simulation, it is confirmed that the direction has a significant influence on the stress distribution in the additively manufactured thin walls. Their milling significantly alters both the values and the distribution of the residual stresses. The milling force changes tensile stress into compressive stress, and its extended gradient distribution transforms into regional distribution. Finally, the result of the experimental work confirms the conclusions of the simulation.

Oyesola et al. [

58] developed a theoretical cost model of hybrid additive and subtractive manufacturing, as a tool for the MRO (Maintenance, Repair, and Overhaul) sector, especially focused on the aerospace sector. The study is centered on the manufacturing of parts. Their intention is to integrate in the model the benefit of cost reduction. In the work, analytical techniques are applied to help the aerospace sector increase its competitiveness. Although the process is not addressed from a technical point of view, it is described clearly and precisely: additive and subtractive subprocesses are alternated in the same machine, where the part can remain fixed, to achieve free and complex geometries with the high quality required by the sector. The difficulty lies in identifying the costs of the different phases of the hybrid process, understanding its complexity. This will allow the cost–benefit balance to be adjusted, optimizing the different variables. The authors apply their model to the case of an aerospace bracket manufactured in Titanium 6Al-4V.

The work of Sommer et al. [

59] is novel, as it designs a series of rules for a hybrid additive and subtractive manufacturing process, SLM and high-speed micromilling. The intention of the set of rules developed is to serve as guidance during the design phase. To define them, different elements recognizable in any manufacturable geometry are analyzed: cylinders, overhangs, chamfers, radii, holes, etc., both from the additive point of view and from the hybrid additive and subtractive perspective. The designed rules are applied in the manufacturing of different parts in Maraging steel 1.2709 on the hybrid machine Lumex Avance-25 (Matsuura Machinery GmbH, Wiesbaden, Germany), using SLM and high-speed micromilling. The injection mold with conformal cooling stands out, as it perfectly synthesizes the concept of hybrid additive and subtractive manufacturing. The authors consider the advantages of applying the established rules in hybrid manufacturing to be demonstrated.

Figure 9 shows an example of the application of hybrid additive and subtractive manufacturing in the production of molds with conformal cooling (CC) channels.

Table 7 provides a summary of the five most cited articles that address a specific hybrid manufacturing flow, breaking down the main additive and subtractive subprocesses and indicating the work material. As it can be seen, although the additive subprocesses are varied, it is clear that the subtractive subprocess generally integrated into the different hybrid flows is milling. In turn, the materials column clearly synthesizes the materials on which hybrid additive and subtractive manufacturing is focused.

A synthesis of the reviewed studies allows us to conclude that, in order to achieve parts manufactured by hybrid additive and subtractive manufacturing with adequate physical and mechanical properties, it is essential to overcome some challenges, among which the following are worth highlighting: [

1,

5,

11,

40,

42,

44,

46,

48,

49,

51,

52,

54,

55,

56,

57]

Controlling grain orientation and phase formation so as to improve the microstructure of the material, as this directly influences the mechanical properties.

Optimizing the process parameters to minimize porosity, as this can reduce the mechanical strength and durability of the parts.

Controlling process conditions such as cooling rate and material composition to ensure adequate mechanical properties such as tensile strength and hardness.

Addressing these challenges comprehensively is key to achieving high quality parts.

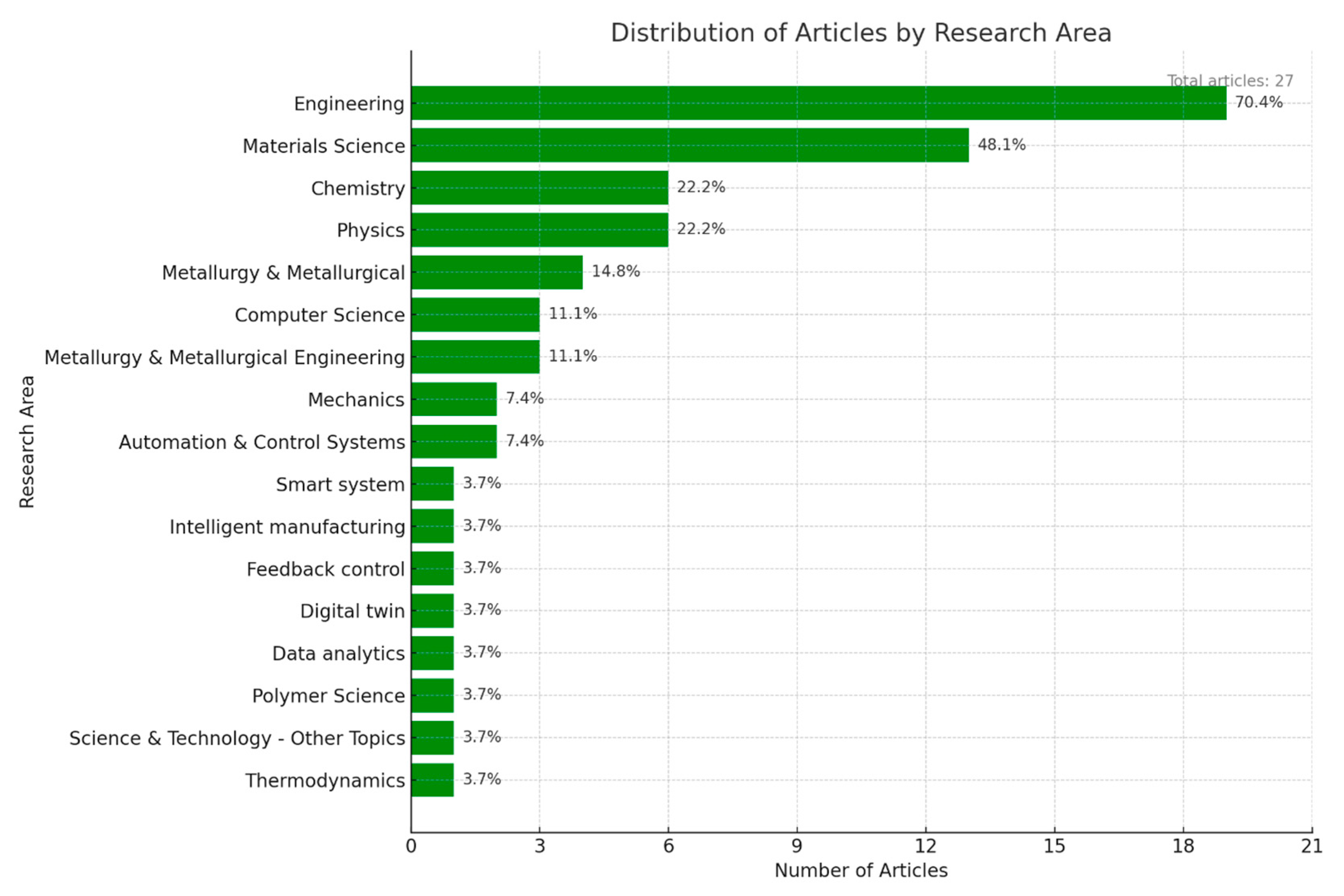

3.2.2. Areas and Sectors

Hybrid manufacturing combines the advantages of additive and subtractive manufacturing. Therefore, it allows, on the one hand, to produce parts with high precision and good surface finishes, taking advantage of the great capacity of machining processes to finish parts with a high level of detail and, on the other hand, to optimize the material by combining both techniques, as waste is reduced by allowing additive manufacturing to generate parts of complex shapes with dimensions very close to those included in the design plans which, subsequently, by means of subtractive manufacturing, will be brought to the final dimensions of the part. Therefore, it finds a direct field of application in sectors such as aeronautics and aerospace, automotive, and medical, where complex parts with high precision are required [

1,

2,

5,

11,

21,

40,

41,

46,

48,

52,

54,

58,

59].

In their work on the influence of the anisotropy of near net shape parts manufactured by LPBF on milling parameters, Perez-Ruiz et al. [

1] point out the manufacturing of aircraft engine parts and power system components as the natural application of hybrid additive and subtractive manufacturing (LPBF–milling). In this regard, they reinforce their statement by highlighting the capability of the process to ensure the assembly of the manufactured parts in complex systems. The work of Feng et al. [

2] clearly identifies a sector of application and development, with great importance in the manufacturing industry in general, by pointing out the use of hybrid additive and subtractive manufacturing (L-PBF and milling) in the manufacturing of conformal cooling channels in molds, as an alternative to manufacturing with straight-drilled cooling channels.

Once again, the aerospace sector is pointed out in the work of Veiga et al. [

40] as a current field of application and future development of hybrid additive and subtractive manufacturing. Moreover, it is specified in the production of titanium alloy parts, for which it is confirmed that machines are already available. Ingarao et al. [

41] present a different perspective when locating the field of application of hybrid additive and subtractive manufacturing, since they do not link it directly to any industrial or research sector, although they model the manufacturing of Ti-6Al-4V parts, which are of great importance in the aerospace sector. On the contrary, they contextualize it in what could be considered a transversal sector, such as sustainable economy, with a clear environmental vision: cost reduction, energy savings, recyclability, and reduction of material waste. In turn, Korkmaz et al. [

3] state that, at the time of their study, it is the company Airbus that uses most of the aircraft parts designed and manufactured through hybrid manufacturing. Once again, the aerospace sector is presented as the field with the greatest potential for the development and application of hybrid additive and subtractive manufacturing. Sunny et al. [

44] also point to the aerospace sector, specifically to the manufacturing of monolithic structures, as a field of application for hybrid additive and subtractive manufacturing, and they do so by highlighting the challenge that distortion and residual stresses caused by machining in additively manufactured parts represent for its applications.

The study by Careri et al. [

45] is contextualized by the need of the aerospace sector to manufacture and repair high added-value parts with a superior finish to that obtained through their manufacturing by DED, something that is achieved with hybrid additive and subtractive manufacturing. Likewise, Stavropoulos et al. [

47] propose the manufacturing of a gas turbine blade, which shifts the focus of the application sector of hybrid additive and subtractive manufacturing from the aerospace field to the energy industry, considered from the point of view of manufacturing and not of generation, although with similar parts. Moritz et al. [

48] identify the aerospace and biomedical sectors as potential fields of application for hybrid additive and subtractive manufacturing, both for repair and for the manufacturing of parts with high requirements. Guo et al. [

49] point out, while acknowledging the problem of the staircase effect in FDM processes as the basis of hybrid additive and subtractive processes, the mold manufacturing, aerospace, and medical sectors, with high surface quality requirements, for the application of hybrid additive and subtractive manufacturing.

The aerospace industry, with a focus on reducing the waste of high-value materials, is the sector in which Reisch et al. [

50] place the application of hybrid additive and subtractive manufacturing, in this case integrating WAAM and milling. Similarly, throughout the entire work by Feldhausen et al., the aerospace sector appears transversally in the analysis of the reviewed articles [

5] as the main target of hybrid additive and subtractive manufacturing. Likewise, the manufacturing of conformal channels is mentioned, to allow for faster, more homogeneous, and more efficient cooling of molds, which are fundamental in the general manufacturing industry. On the other hand, since their study focuses on fatigue resistance, Braun et al. [

51] mention throughout it different applications in which this factor is relevant, as in the case of the manufacturing of turbine blades. Corrosion resistance, improved by hybrid processes, points toward the offshore industry.

Throughout the work of Soffel et al. [

52], sectors such as aerospace and the energy industry are mentioned again, but the automotive industry is also mentioned. In all of them, with the presence of complex high added-value parts, hybrid additive and subtractive manufacturing is indicated. The fact that the experimental part of the research is carried out with Inconel 718 reinforces its orientation toward the aerospace sector. The parts whose hybrid manufacturing is simulated by Mirzendehdel et al. [

53] are once again framed within the aerospace and automotive sectors, which reinforces the trend followed by researchers in recent years.

González-Barrio et al. [

21] clearly contextualize the application and future development of hybrid additive and subtractive manufacturing in the aerospace field, which they highlight with the part (blisk) and the material (Inconel 718) studied. In their review, Zhang et al. [

54] clearly identify the interest shown by the automotive, biomedical, and aerospace sectors in the hybrid additive and subtractive manufacturing of titanium parts, driven by the complexity and high mechanical, geometric, and surface finish requirements of many of their components. Throughout the research of Liu et al. [

55], the uses of 4D hybrid additive and subtractive manufacturing are not only projected onto the aerospace sector, with numerous examples and scenarios, or the biomedical sector, but a new field is also proposed: the restoration of cultural heritage. The work of Oyesola et al. [

58] on a cost model for hybrid additive and subtractive manufacturing is clearly focused, throughout the entire article, on the aerospace sector, which is highlighted by the case study of the aerospace bracket. However, it should be noted that it is oriented toward the MRO business for aerospace companies, which in itself constitutes a sector of great economic, industrial, and technological importance. Sommer et al. [

59] clearly define, and justify their definition based on the capabilities of hybrid additive and subtractive manufacturing to achieve intricate geometries with appropriate surface finishes and surface integrity, the injection mold sector—as fundamental in so many industries—as the main field of application.

Table 8 presents the five most cited articles among those that clearly identify a sector or area of application and development for hybrid additive and subtractive manufacturing. Some specific applications are also included. A clear predominance of the aerospace sector is observed, with a focus on high added-value parts.

3.2.3. Challenges and Outlook

Parts made by additive manufacturing generally require further processing to achieve the characteristics specified in the design plans. Hybrid manufacturing is very useful as it reduces production time and costs as, in many cases, it avoids the need for post-treatment. Case studies can be found in industries such as aerospace, automotive and medical. With these new hybrid additive–subtractive manufacturing techniques, there is a broad consensus that parts with complex geometries are first produced by additive manufacturing and then the surface finish is improved to meet the specifications of each sector. Moreover, the process can be carried out through several repeated additive–subtractive sequences, so that the improvement in surface quality can reach areas that would be inaccessible once the part is finished [

1,

2,

5,

11,

21,

46,

50,

51,

52,

58].

Sommer et al. and Liu et al. provide detailed evidence of how hybrid processes improve surface quality and precision in metallic and ceramic contexts [

49,

59]; however, other studies support this advantage across different applications. Furthermore, Wu et al. highlight the role of intermediate machining in reducing distortion and enhancing surface uniformity [

57], while Ghafoori et al. show that machining WAAM repairs reduces stress concentrators by refining deposited profiles [

56]. González-Barrio et al. emphasize the value of adaptive toolpaths in correcting geometric deviations in LMD processes [

21], and Ding et al. confirm that finishing improves surface integrity and removes thermal defects [

54]. Moreover, Perez-Ruiz et al. [

1] point out as the main challenge the development of predictive models for the cutting forces in the milling of parts manufactured by LPBF, given the nonlinearity of this process. The complexity of the interactions between the additive and subtractive subprocesses must be addressed, focusing on grain characteristics and crystallographic structure.

Hybrid manufacturing systems entail substantial initial investment costs, primarily due to the need for specialized equipment and highly skilled operators [

21,

47]. Nevertheless, opinions are divided regarding their overall economic viability. Oyesola et al. posit that the utilization of hybrid additive and subtractive manufacturing methodologies can yield cost-effectiveness in high-value applications, such as aerospace Maintenance, Repair, and Overhaul (MRO), particularly when evaluated through activity-based costing models that account for lifecycle benefits [

58]. Conversely, alternative studies posit that, in the absence of such niche contexts, the elevated per-unit cost and diminished scalability render hybrid manufacturing less viable for small to medium production volumes [

21,

47]. Furthermore, Feng et al. [

2] outline a path of work and evolution by highlighting that one of the main current challenges is the complexity and high cost of hybrid manufacturing machines. The future of the mold industry with conformal cooling channels is promising, but it requires the development of more economically affordable solutions. They also anticipate that the manufacturing of CC channels by hybrid additive and subtractive manufacturing will expand to gas turbine engines, gears, and other systems and parts with special self-cooling requirements.

Practical examples are evident across multiple sectors, in the aerospace sector for the production and repair of engine parts and aircraft structures, in the automotive industry, hybrid processes are applied to the manufacturing of engine components and suspension systems, and, in the medical field, for customized implants and prostheses [

1,

2,

11,

21,

46]. However, current results are difficult to compare due to the lack of standardized testing and validation protocols. Some authors offer partial solutions, such as FEM-based predictive models validated experimentally [

57], or design rules tailored to specific machines [

59]. Others call for coordinated international efforts to define hybrid manufacturing-specific standards and benchmark systems [

47].

Regarding the challenges of hybrid additive and subtractive manufacturing in the demanding context of the aerospace industry, there is a broad consensus in the literature that hybrid additive and subtractive manufacturing poses significant challenges in terms of process planning and automation. One of the most critical issues is the absence of commercially mature CAM/CAx tools capable of synergistically managing additive and subtractive stages in an integrated and automated workflow. Veiga et al. [

40] make clear the importance of further analysis of milling strategies to optimize the process and emphasize that the digitalization of hybrid workflows is still at a critical stage, constrained by the large number of process variables and poor communication between machines and design software. Ingarao et al. [

41] argue that beyond current automation limitations, future research should focus on leveraging hybrid manufacturing for geometric complexity and weight reduction through part re-design. They also point out the need to increase studies that combine environmental and economic sustainability and the development of decision-making tools to choose between processes. In turn, with the aim of being able to predict results, both in the production and design phases, to reduce material waste, Korkmaz et al. [

3] point out the need to use simulation software. The possibility is also opened for the participation of artificial intelligence in hybrid manufacturing. The study concludes that, in the hybrid context, the difficulty of combining different additive technologies makes it necessary to develop hybrid processes that are independent of the additive manufacturing method. For their part, subtractive processes must evolve to avoid requiring special tools, aiming for greater simplicity and autonomy. Feldhausen et al. [

42], based on their study on the properties of 316L stainless steel manufactured by hybrid additive and subtractive manufacturing, state that this will be applicable to the manufacturing of large and complex parts, among which nosecones and marine propulsors are mentioned. Thus, the marine sector appears as a field of application for hybrid additive and subtractive manufacturing. Likewise, Sunny et al. [

44] present as future work the application of the simulation methodology used in their study on the effect of residual stress from DED manufacturing on the stresses and distortion generated by subsequent high-speed milling to new hybrid flows involving other additive technologies.

Based on the results of their study, Careri et al. [

45] identify as both a challenge and a line of future work the necessity to develop processes that adapt to the needs of manufacturers. In this respect, Stavropoulos et al. [

47] agree with the need to develop a complete software solution for the generation of hybrid additive and subtractive processes that would address economic and technical challenges. This solution would establish a solid foundation for the evaluation of hybrid manufacturing in relation to structural integrity and repair standards. On the other hand, Moritz et al. [

48] develop a study in which they propose that in the future, further understanding of the parameters of cryogenic cooling and their influence on the hybrid additive and subtractive process will be necessary, in order to optimize it.

Looking ahead, Feldhausen et al. [

5] indicate that closed-loop control systems, the increased capacity for surface characterization, and the continuous improvement of the machines involved will be key to the development of hybrid additive and subtractive manufacturing. This will require great research effort in what they call digital manufacturing. In this regard, Braun et al. [

51], in their comparison of traditional, additive, and hybrid additive and subtractive manufacturing routes, with a focus on fatigue resistance, propose to further investigate in the future the evaluation methods for local fatigue. For this, they point out several options, such as crack growth studies or stress-based models, which can be combined with models that consider production-related defects. For their topology optimization (TO) model for the manufacturing of parts with sacrificial structures, Mirzendehdel et al. [

53] propose as future developments the definition of a general fixturing constraint.

In this respect, González-Barrio et al. [

21] highlight the need to deepen the understanding of the hybrid process in all its stages, as well as of each of the technologies and materials involved. They also indicate the need to develop CAD/CAE/CAM environments that cover the entire hybrid additive and subtractive manufacturing process, in this case for parts as complex as an 18-blade blisk, within a single software tool. Zhang et al. [

54] point out that the most widely used technologies in hybrid additive and subtractive manufacturing for the production of near net shape parts have been PBF and DED. Regarding research, they conclude that these have also been the most present. They end by noting the lack of studies, and therefore the need to increase them, on WAAM manufacturing in the studied hybrid context. Sebbe et al. [

11] point out that the risks of metal powder, with serious safety implications, the training of operators, waste management, and cutting fluids will be factors to study and improve in the future to make hybrid additive and subtractive manufacturing successful.

Table 9 lists the five most cited articles that clearly identify future work in the context of hybrid additive and subtractive manufacturing. It is worth noting that all the proposed research directions fall within the CAD/CAE/CAM framework, highlighting its great importance for the development of hybrid manufacturing.

Current research on hybrid manufacturing is heavily focused on metallic alloys, particularly titanium, Inconel, and stainless steels, while applications involving high-performance polymers, ceramics, or composite materials remain scarce [

55,

59]. However, opinions diverge on the feasibility of extending hybrid additive and substrative manufacturing to non-metallic materials, in their study to relate the parameters of polymer additive manufacturing and dry milling within a hybrid additive and subtractive manufacturing flow Guo et al. [

49] propose the possibility of applying the method to new amorphous polymers and high-performance polymers. Liu et al. present encouraging results using hybrid approaches with shape-memory ceramics, demonstrating the potential of additive–subtractive integration in complex ceramic architectures [

55]. For Liu et al., in the future the range of materials used in 4D hybrid additive and subtractive manufacturing should be expanded, such as UV/ozone. They also propose increasing research in the production of parts that combine hard and soft materials in the biomedical field. Conversely, other studies, such as that of Wu et al., argue that adapting hybrid additive and subtractive manufacturing to non-metal systems would require significant advances in deposition parameters, thermal processing, and fixturing technologies, which are still in early stages of development [

57].

Finally, they highlight the need to improve the mechanical properties of the materials used. In the work of Ghafoori et al. [

56], a very interesting and somewhat novel approach is proposed, as they state that single-sided deposition should be investigated—that is, the application of the process from only one side of the part—in order to avoid the accessibility problems that a real case of in situ repair may present.