2.1. General Approach

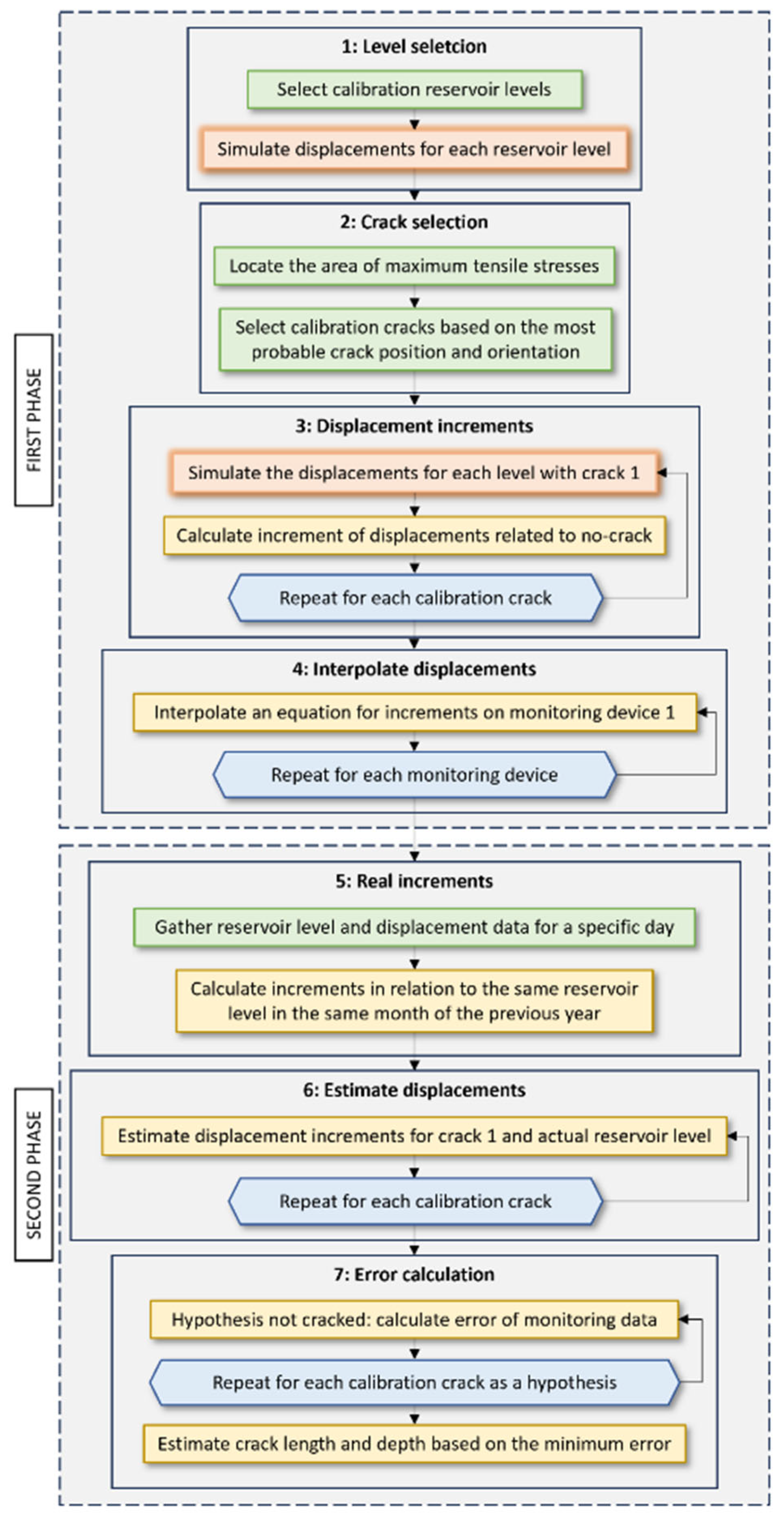

The proposed method for crack detection (

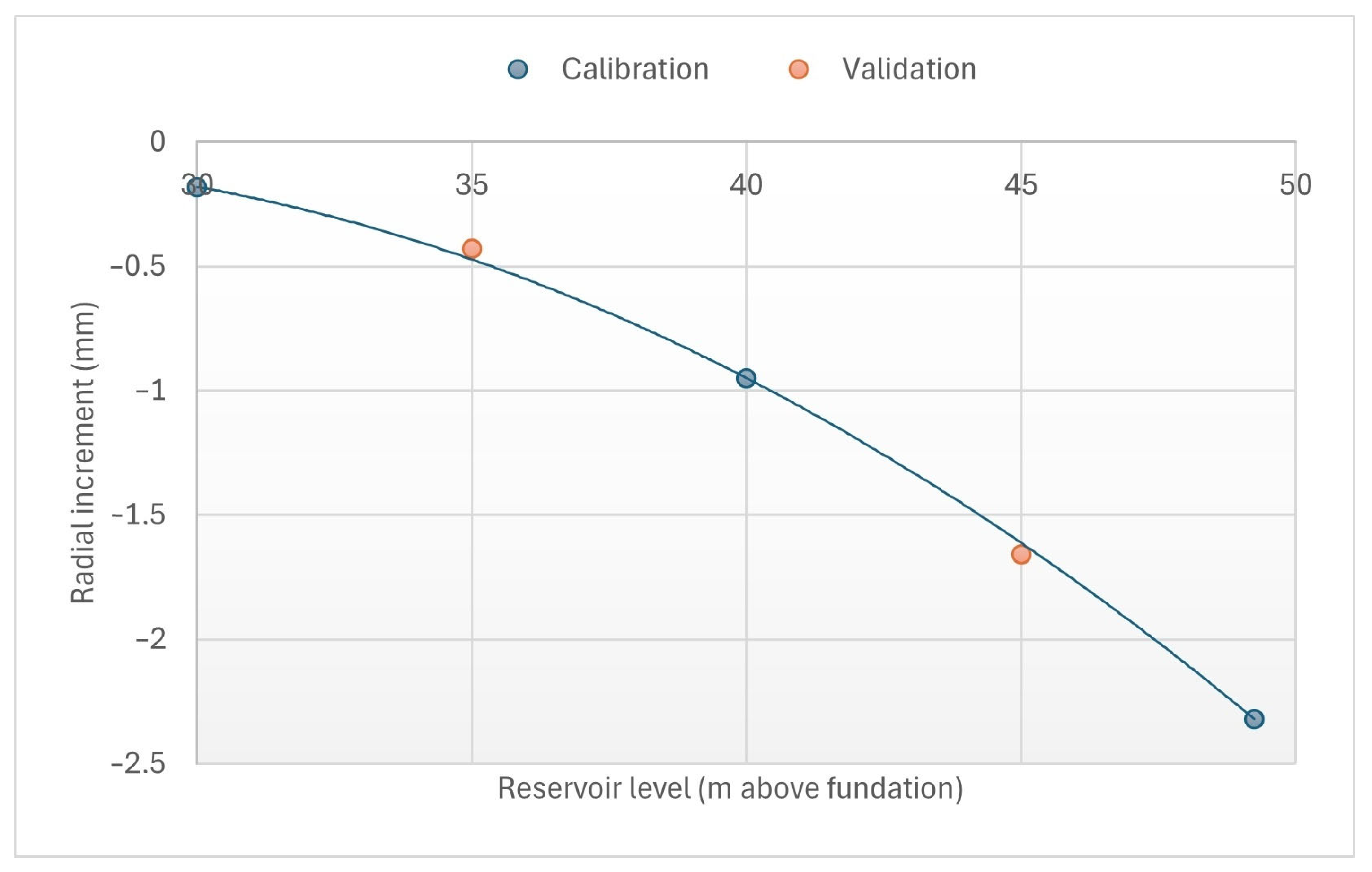

Figure 1) applies to any specific dam with known geometry, material properties, and records of monitoring devices and reservoir level (current and from a previous year). For real cases, the first phase of the methodology is performed before analyzing current dam records and involves four steps. Step 1: Select calibration reservoir levels and simulate, for each one, the displacements at the monitoring points. Step 2: Locate the area where cracks are most likely to appear based on tensile stresses, determine (by expert judgment) the most probable crack shape, and select calibration cracks. Step 3: Simulate, for each crack and reservoir level, the displacements at the monitoring points and calculate their difference against the displacement without any crack. Step 4: For each calibration crack and each monitoring device, determine an equation indicating the incremental value for any given reservoir level, based on the interpolation of the simulated levels. Steps 2 and 3 may be repeated as many times as desired in order to have a good collection of possible cases from which to interpolate. This whole process, which requires computation resources, is only performed once and may be used throughout the life of the dam.

The second phase takes place when data from a specific time of the dam is to be analyzed. This phase consists of three more steps. Step 5: Gather the current reservoir level and displacement data and calculate increments in relation to the dam without cracks, assumed as the same reservoir level in the same month of the previous year. Step 6: Estimate, in accordance with the equations of step 4, for each calibration crack, the displacement increments under the actual reservoir level by interpolating the increments of the representative reservoir levels. Step 7: Under the hypothesis that the dam was not cracked, calculate the error of the real data, then re-calculate, changing the hypothesis to each calibration crack. Finally, the minimum error is interpolated to estimate the real crack dimensions.

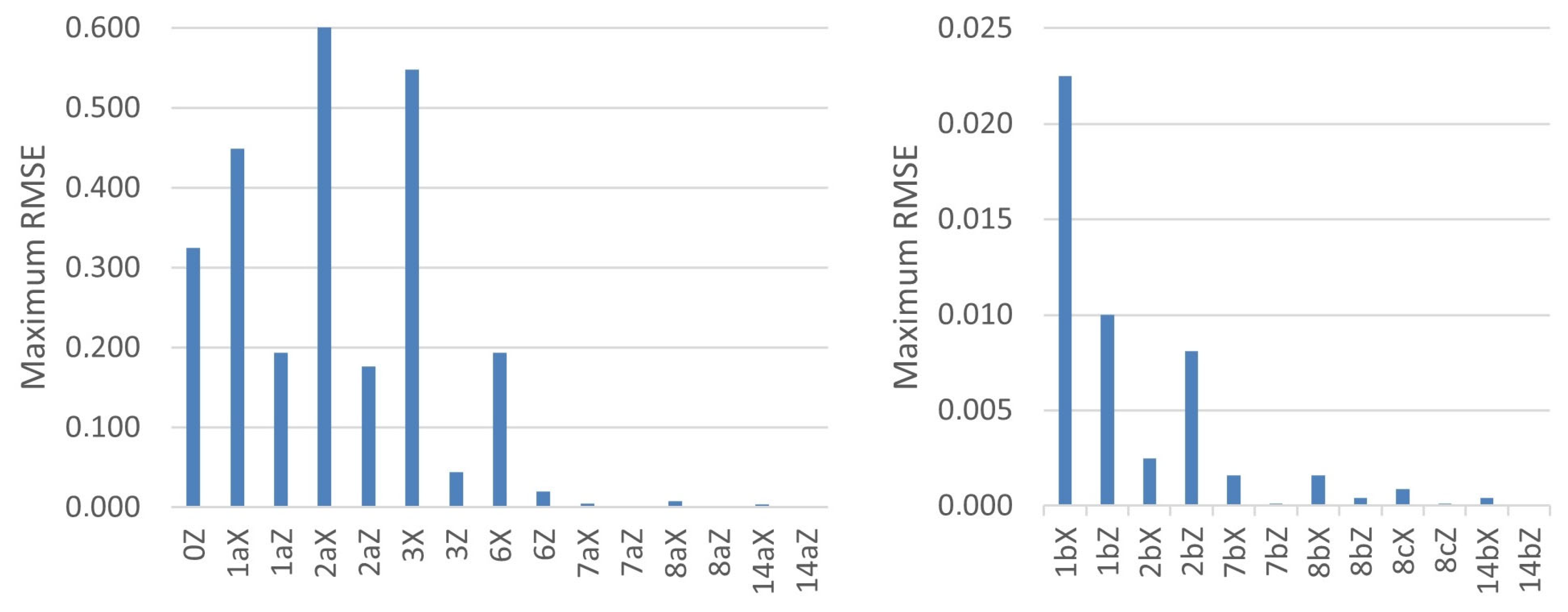

An alternative methodology will be analyzed under the variation that step 4 is omitted and that in step 6, new FEM simulations are performed for each calibration crack with the current reservoir level. This methodology requires more calculation time each time an actual situation is to be monitored; therefore, it is not suitable for continuous monitoring systems. The article focuses on whether these methodologies are valid for detecting cracks or not, compared with the precision of the monitoring devices, rather than on how accurate these are simulated.

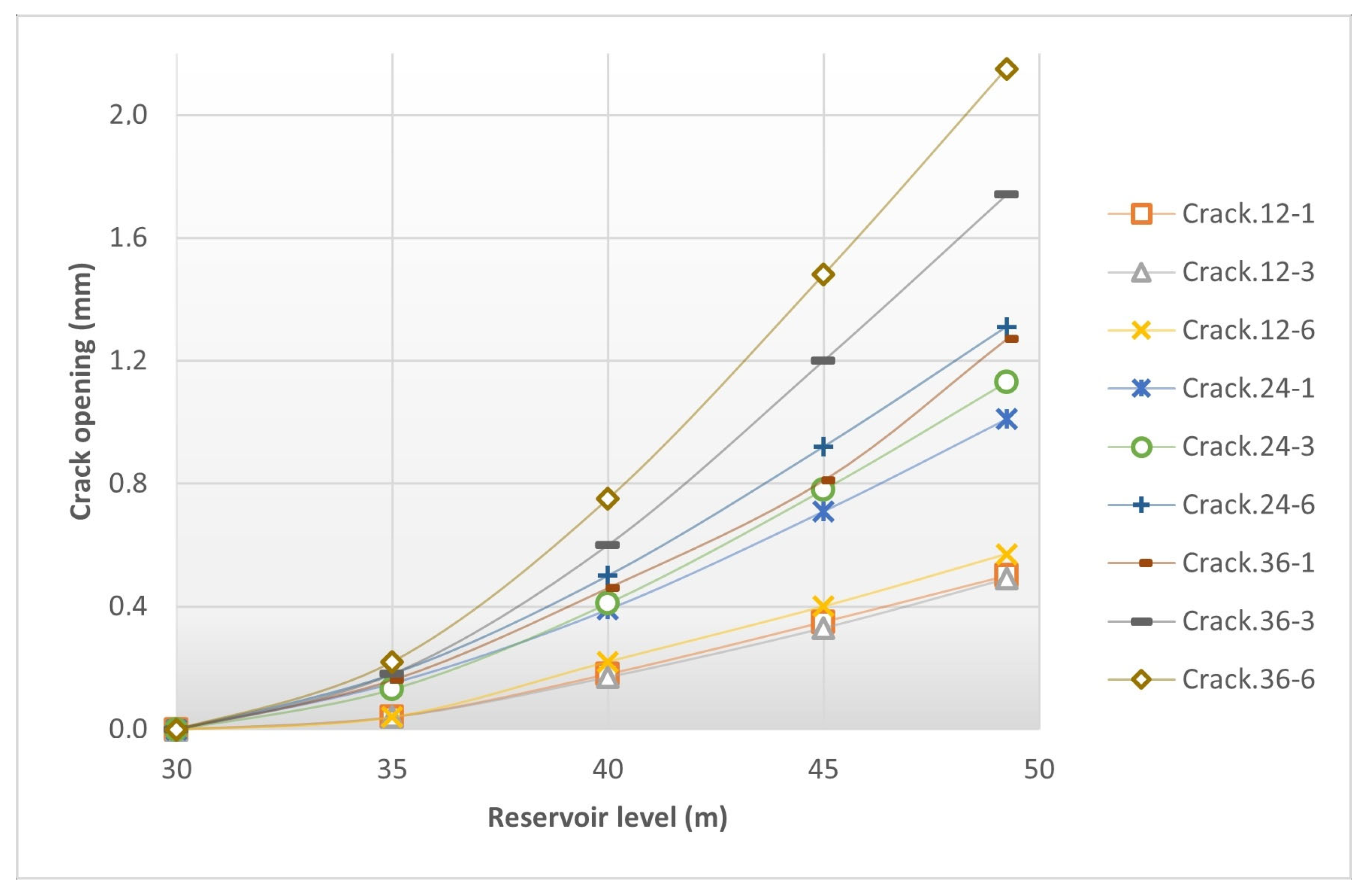

Throughout this paper, a numerical experimentation campaign on a case study was performed to test these methodologies for the detection of cracks in arch dams. It should be clarified that it was decided to use three calibration reservoir levels, although the method would be valid for any number of levels. To verify that the methodologies work properly, nine calibration cracks and four validation cracks were simulated, allowing the number of cases in which the identification works correctly to be tested.

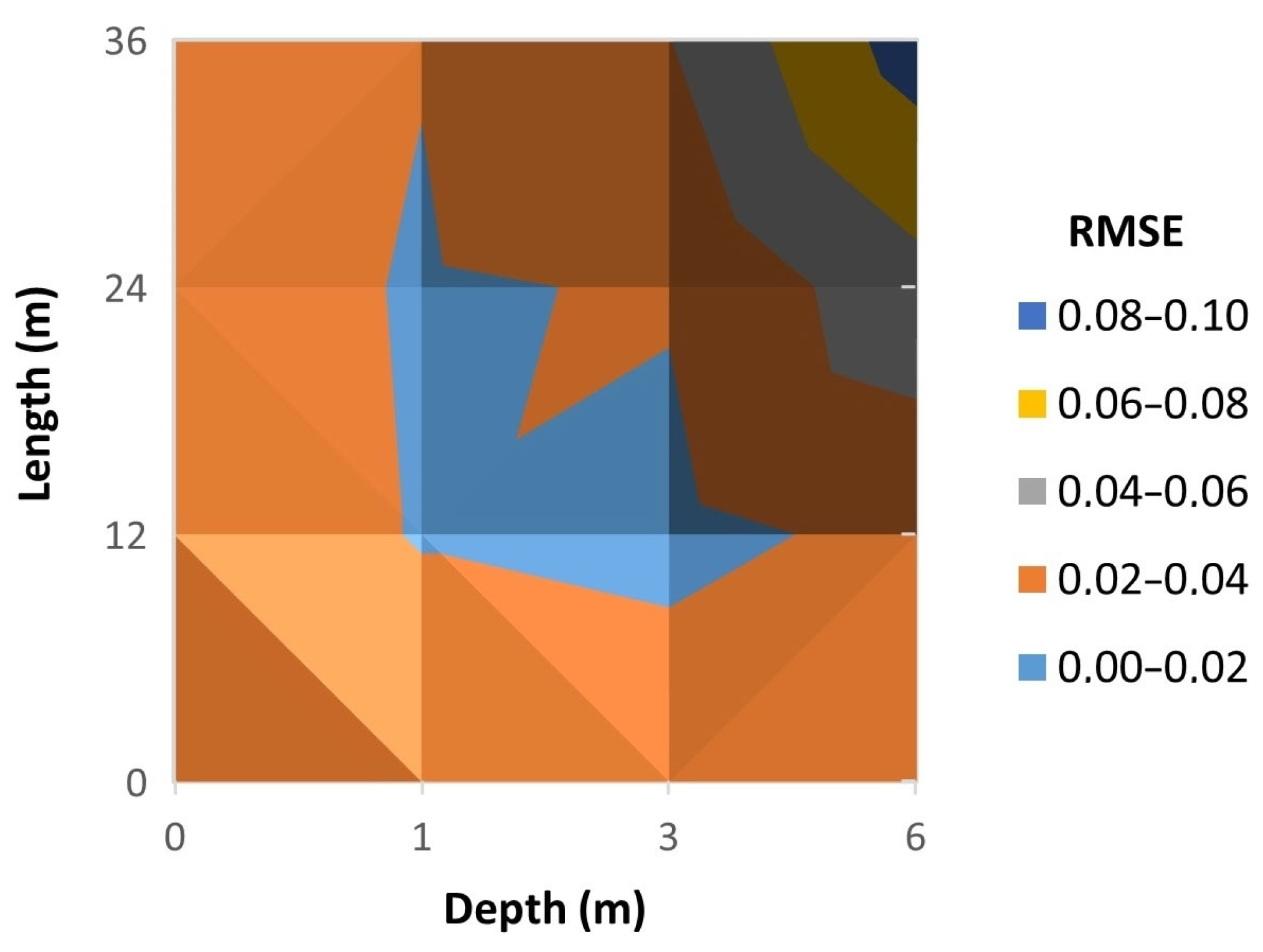

To calculate errors, the results were contrasted using two measures. The first was a plain Mean Absolute Error (

MAE) while the second was the Root Mean Squared Error (

RMSE).

RMSE was included because it increases the importance of large errors and reduces the importance of small errors, which may be due to measurement inaccuracy. Relative error measures were not used in this study because, at points where the displacement is quite low, the measurement uncertainty can lead to exceedingly high relative errors.

(1) Here, x—calculated value; y—expected value; and N—number of monitoring points.

2.2. Numerical Approach

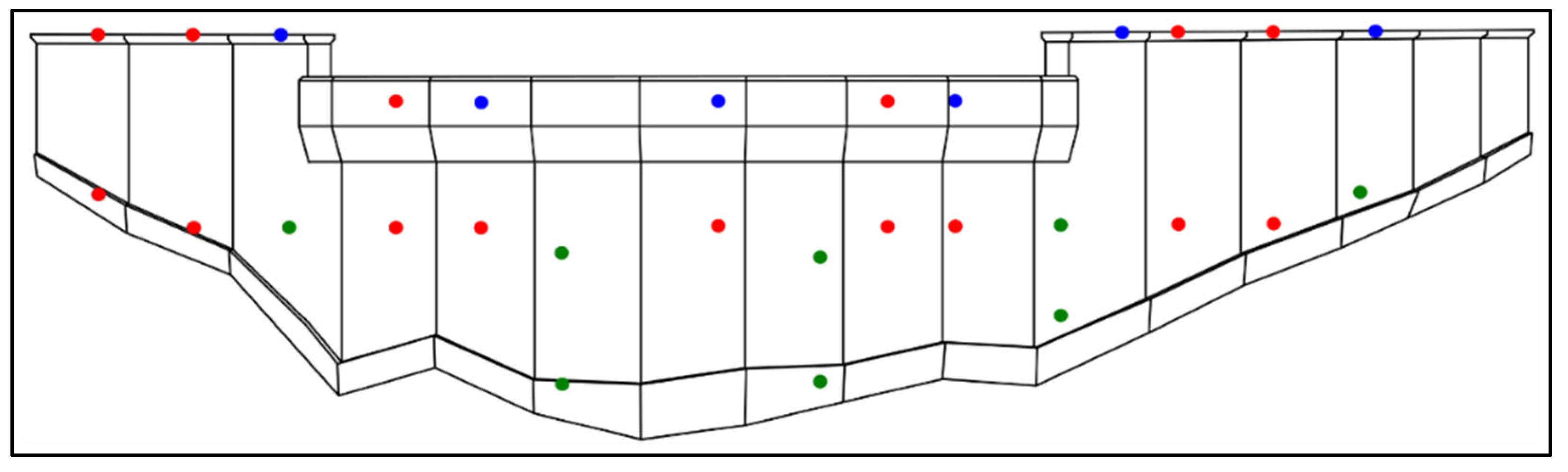

The core work of this study consisted of a campaign of numerical simulations based on the finite element method (FEM) to measure displacements in a real dam when subjected to a crack of variable length and depth. Once the displacements are calculated, the records that would be obtained by monitoring devices at different points of the dam are determined to analyze whether they can detect the size of the cracks.

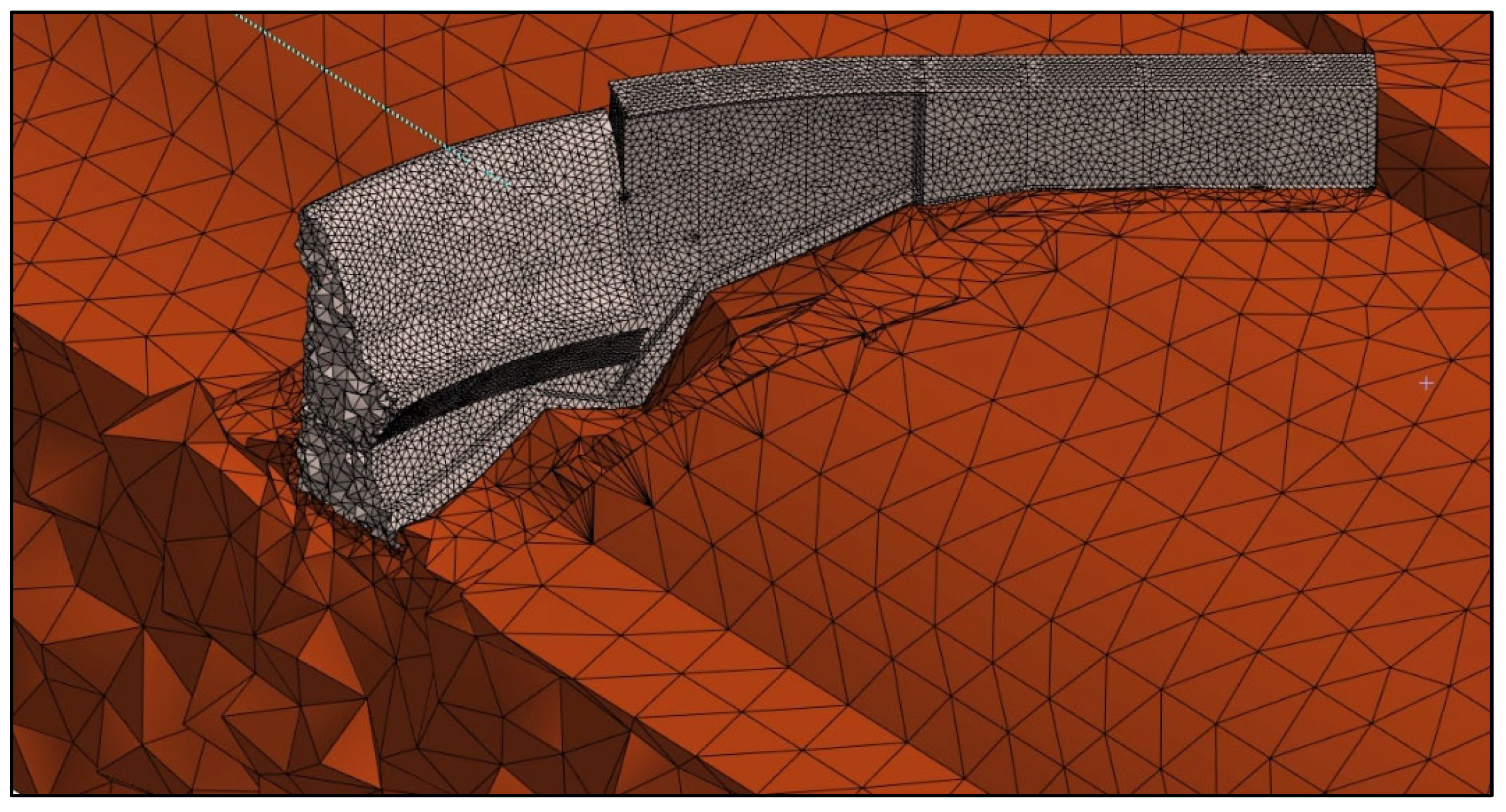

To perform all the numerical simulations of the dam foundation system contemplated in this work, the Ansys Mechanical Finite Element Analysis Software for Structural Engineering 2022 [

14] was employed, along with 3D models. In the calculations involving friction surfaces, the iterative Preconditioned Conjugate Gradient solver was used with a tolerance value of 10

−8, a maximum number of substeps equal to 4, and a maximum number of iterations equal to the number of nodes times the degrees of freedom of each node. The numerical model adopted presented the following features: (a) linear materials (stress–strain curve); (b) static models; (c) no separation between the dam and the ground; (d) nonlinear contacts (cracks).

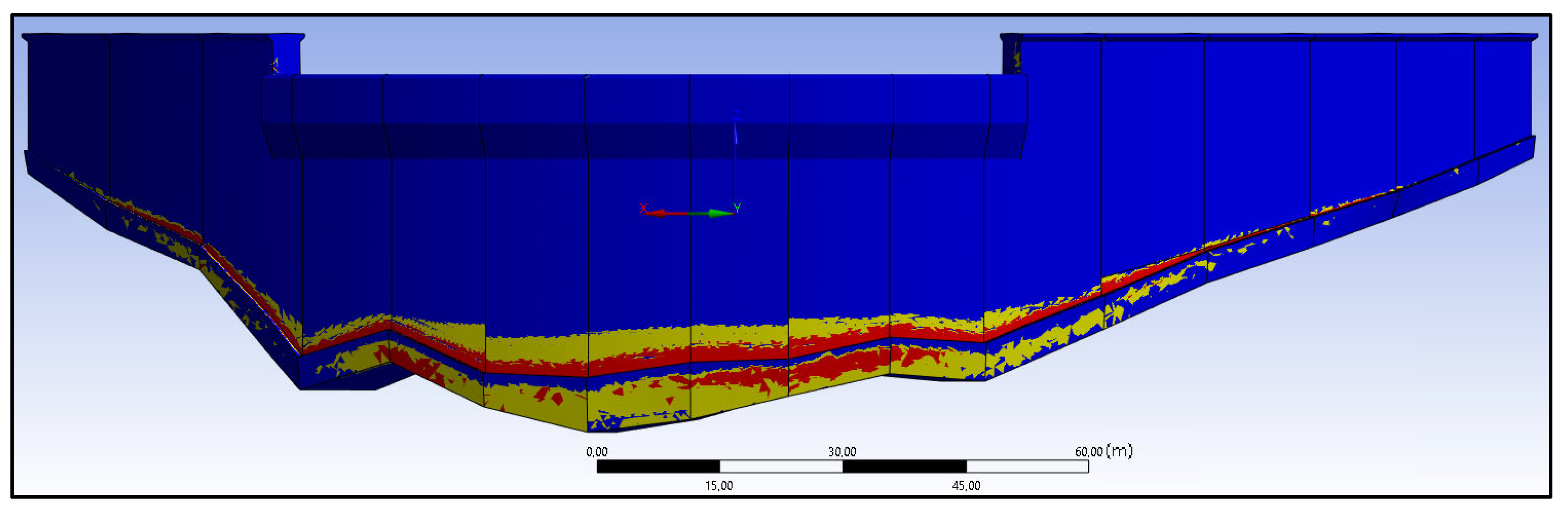

The self-weight of the dam, the thermal stress, and the hydrostatic pressure of the reservoir in the upstream part of the dam and the internal sides of the crack were the only active forces. The nonlinearity of the materials has not been considered since it makes no direct impact on the deformations of the dam after cracking, which is the purpose of this work. Instrumentation devices were used to capture the movement in a small range of years, for which concrete properties are considered constant.

Since the main objective of this work was to analyze cases of dangerous cracking, it was necessary to consider cracks that open up enough to significantly affect the behavioral response of the dam. Therefore, it was of interest to study situations where dam conditions favor the opening of significant cracks; however, dams are specifically engineered to avoid crack opening under the usual loads they would normally bear.

In addition to hydrostatic pressure and temperature variations, other causes can favor or reduce the opening of cracks in the dam: heterogeneity of concrete properties, concrete aging, expansive chemical reactions, shrinkage, alkali–aggregate reactions, microseismicity, foundation deformation, seepage, inadequate design or execution of construction and maintenance, freeze–thaw effects, or hydration heat during concrete curing. Simulating all these conditions in a general approach with the purpose of finding the most unfavorable cases for the creation of cracks would require an unaffordable amount of calculation time. For a specific dam, some of these conditions may need to be simulated. A previous analysis of the dam (history, behavior, etc.) will lead to the conclusion of which aspects to be considered in the analysis.

As this study is interested in the cases that can favor the opening of cracks in the dam, the uncertainty in the results caused by not considering the rest of the forces is assumed to be smaller than the effect of including a large thermal effect. It is important to clarify that the objective of this work was not to achieve an extremely realistic stress distribution but rather to analyze the capacity of a monitoring device to identify a crack in the dam.

For the analysis of the cracking effect, the presence of a significant crack in the dam was assumed; therefore, the mesh was designed to align the faces of the elements with the sides of the crack. These cracks were considered fully formed, so the development process was not considered. Cases in which two relevant cracks open simultaneously or in which cracking develops at the same time as one of the transverse joints opens are very rare, so these cases were not included in the study.

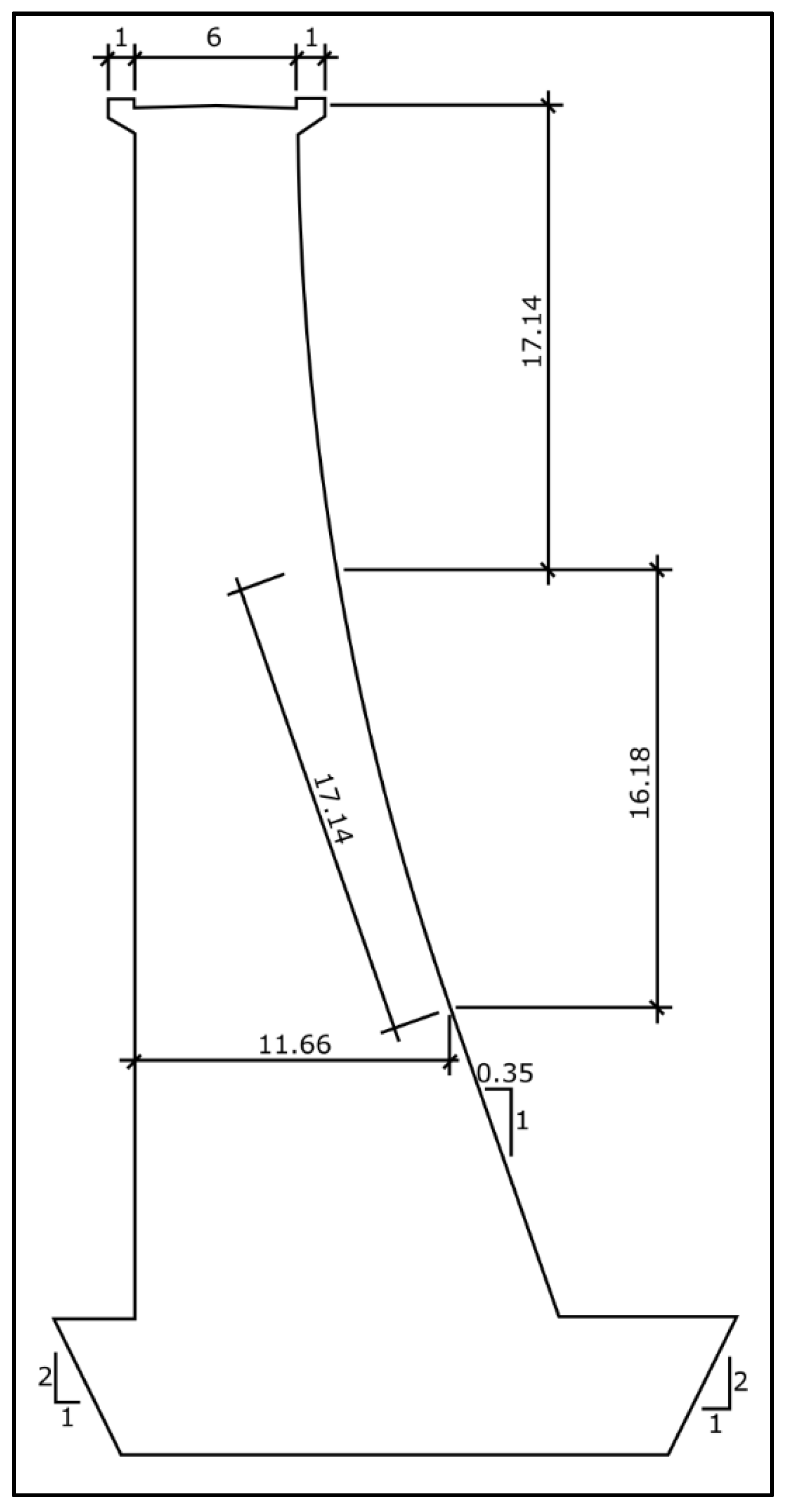

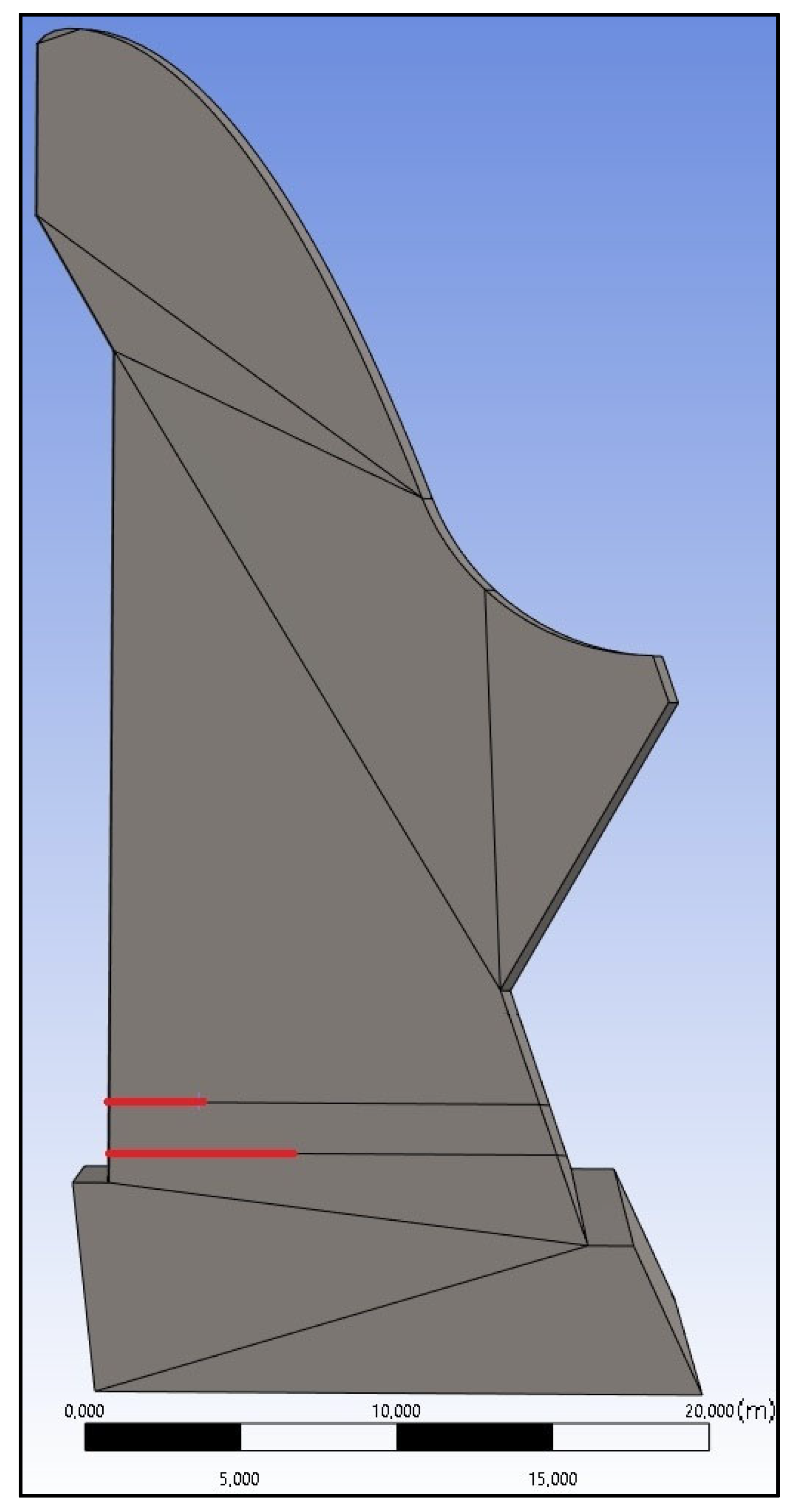

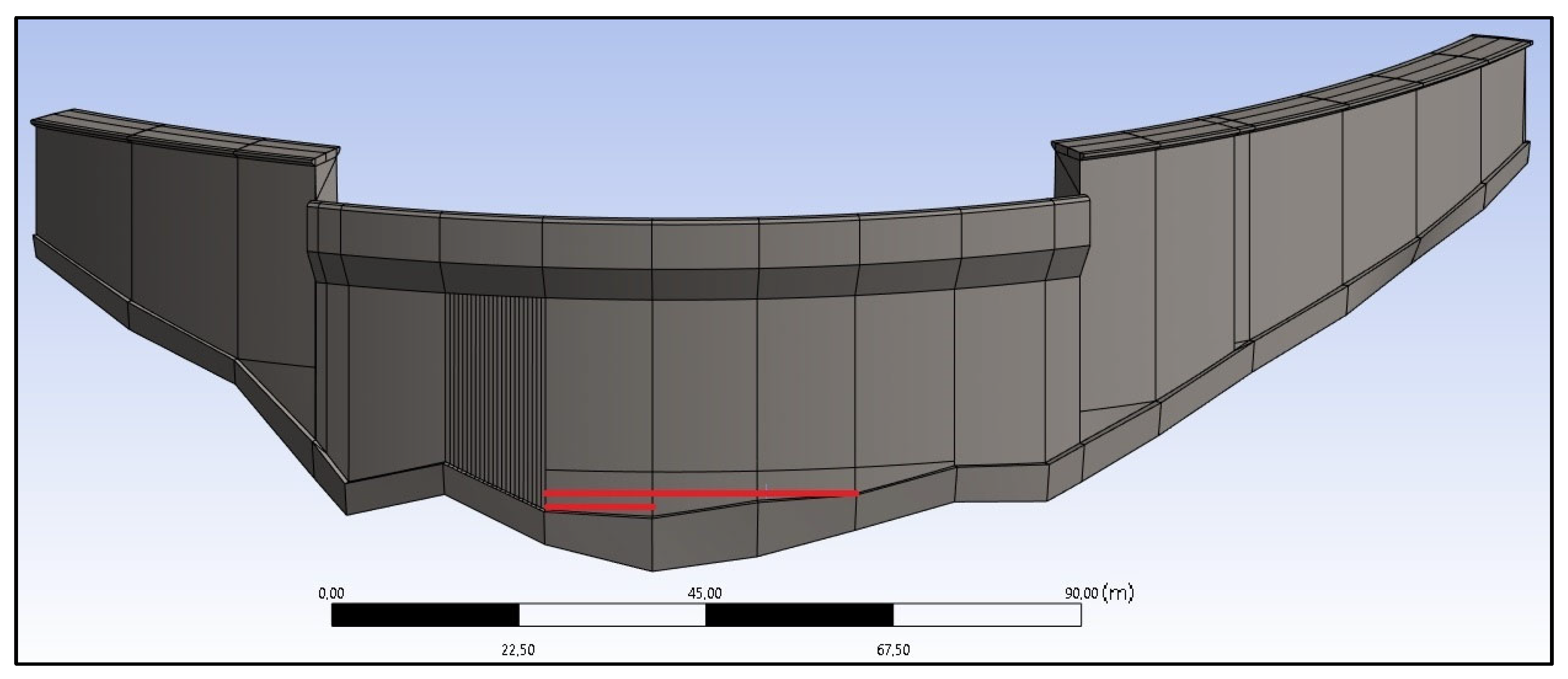

The methodology applied for numerical simulations takes into account that the dam structure is changed before the development of hydrostatic pressures, but after self-weight has already taken effect, by sealing the transverse joints and, therefore, binding the individual blocks together into a monolithic structure. It was also considered that, after joint sealing, the dam changes again to a third configuration at the moment a crack emerges. Consequently, at the first stage, when self-weight is the only load, the sides of the joints can propagate compressive or frictional forces while moving independently, as long as they do not intersect each other, following their actual behavior. On the contrary, in the second and final stages, the dam joints react in a monolithic way. Therefore, the sides of the same joint are deformed as one, while always keeping the same relative position they showed at the end of the self-weighing phase. This study builds on a theoretical model, based on the actual geometry of a dam, to which several simplifications have been made to limit the number of possible variables, thereby making direct evaluation with the real dam measurements no longer applicable; however, the model was previously validated in [

15], where the geometry and properties of the dam belong to the same type.

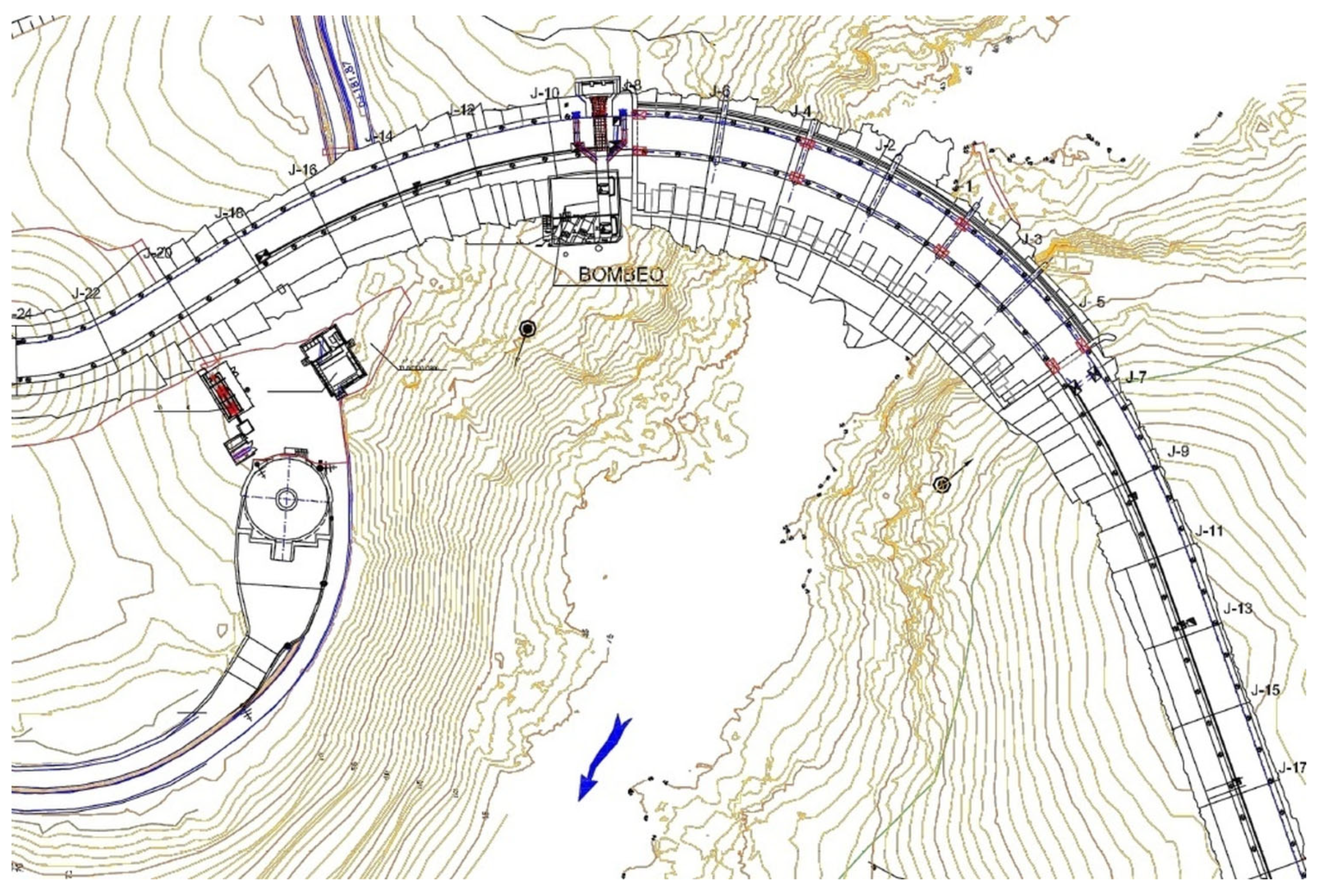

The boundary conditions applied in the numerical models correspond to those common for this type of simulation: constrain the horizontal movements on the sides of the soil body and constrain any movement at the lower base of the soil. The extent of ground included in the 3D model on each side of the structure was the conventional dimensions for structural analyses [

16], so that the applied boundary conditions do not alter the obtained results. Specifically, it was completed with terrain horizontally up to 50% of the length of the dam on the left and right sides, while the depth, upstream, and downstream directions of the terrain extend 150% of the height of the dam.