Adaptive Control of the Aerodynamic Flaps of the Savonius Rotor Under Variable Wind Loads

Abstract

1. Introduction

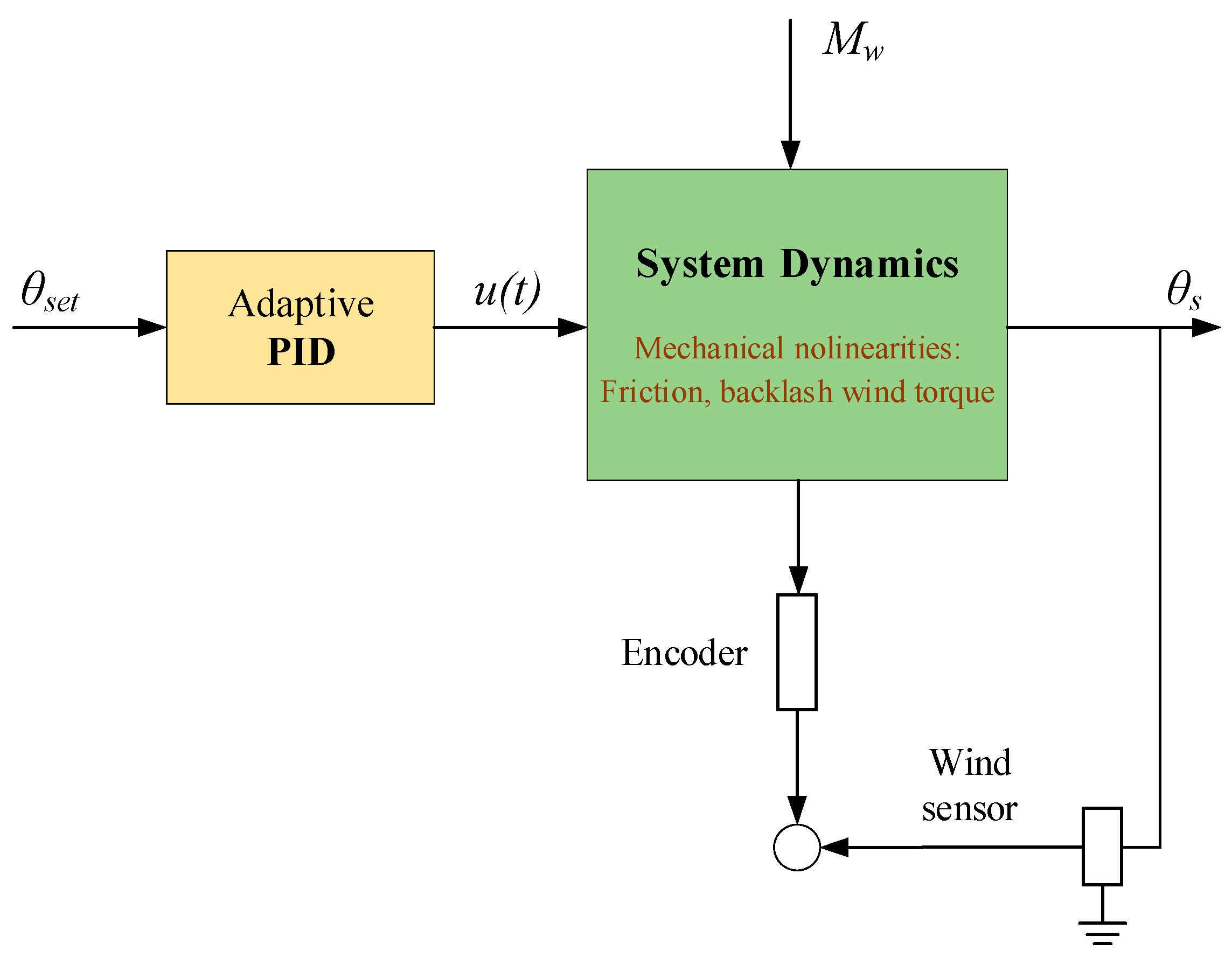

2. Materials and Methods

- The servo motor’s output shaft;

- A steel rod lever (6 mm in diameter);

- A connecting joint (axle) linking the lever to the flap and enabling its rotational movement.

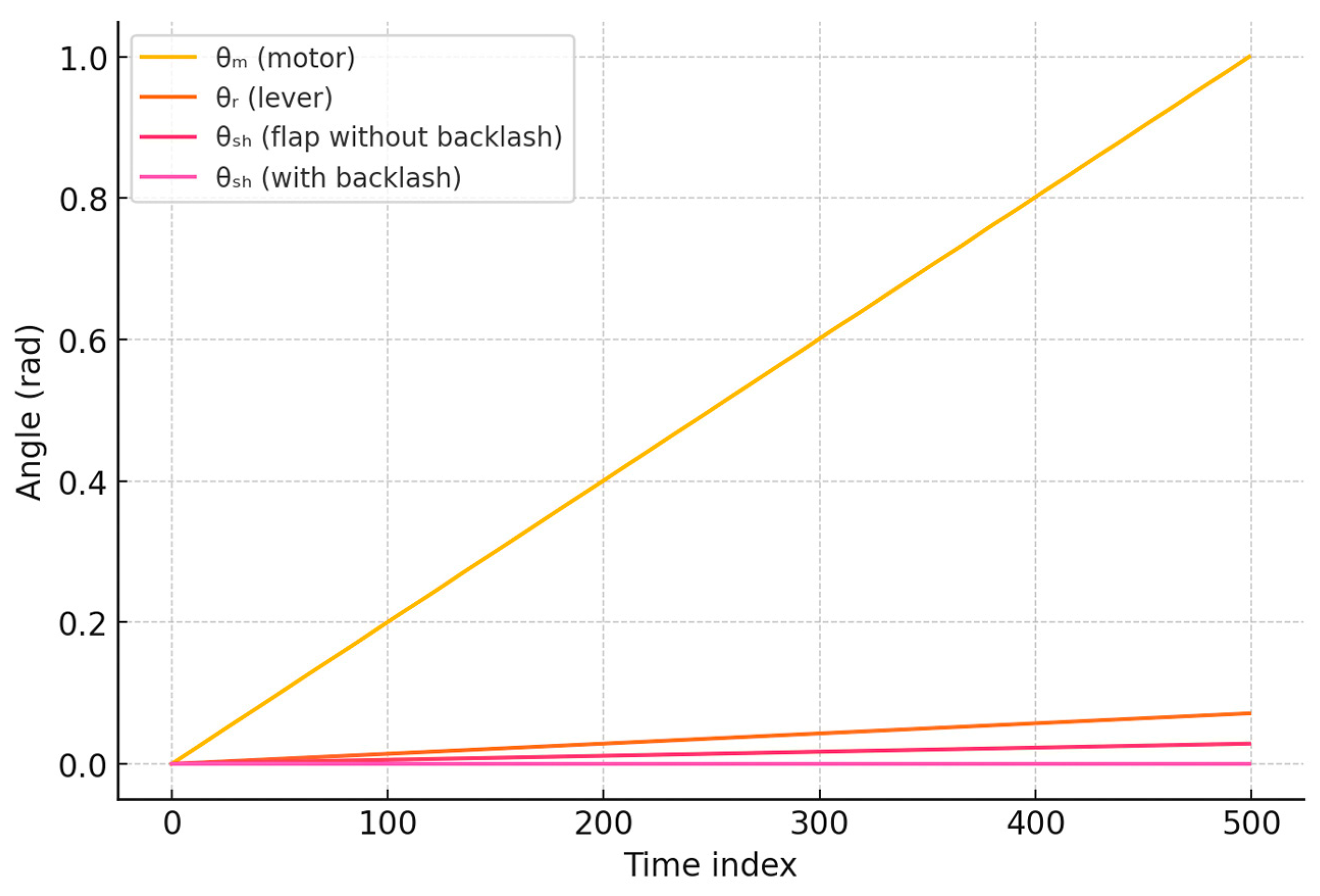

- Servo motor (Link 1)—provides rotational motion. A shaft rigidly connected to the lever is mounted on the motor’s output. The rotation angle is denoted as θm(t).

- Gearbox (Link 2)—built into the servo housing, it reduces speed and increases output torque. Its gear ratio is denoted as ir, and the output angle as θr(t).

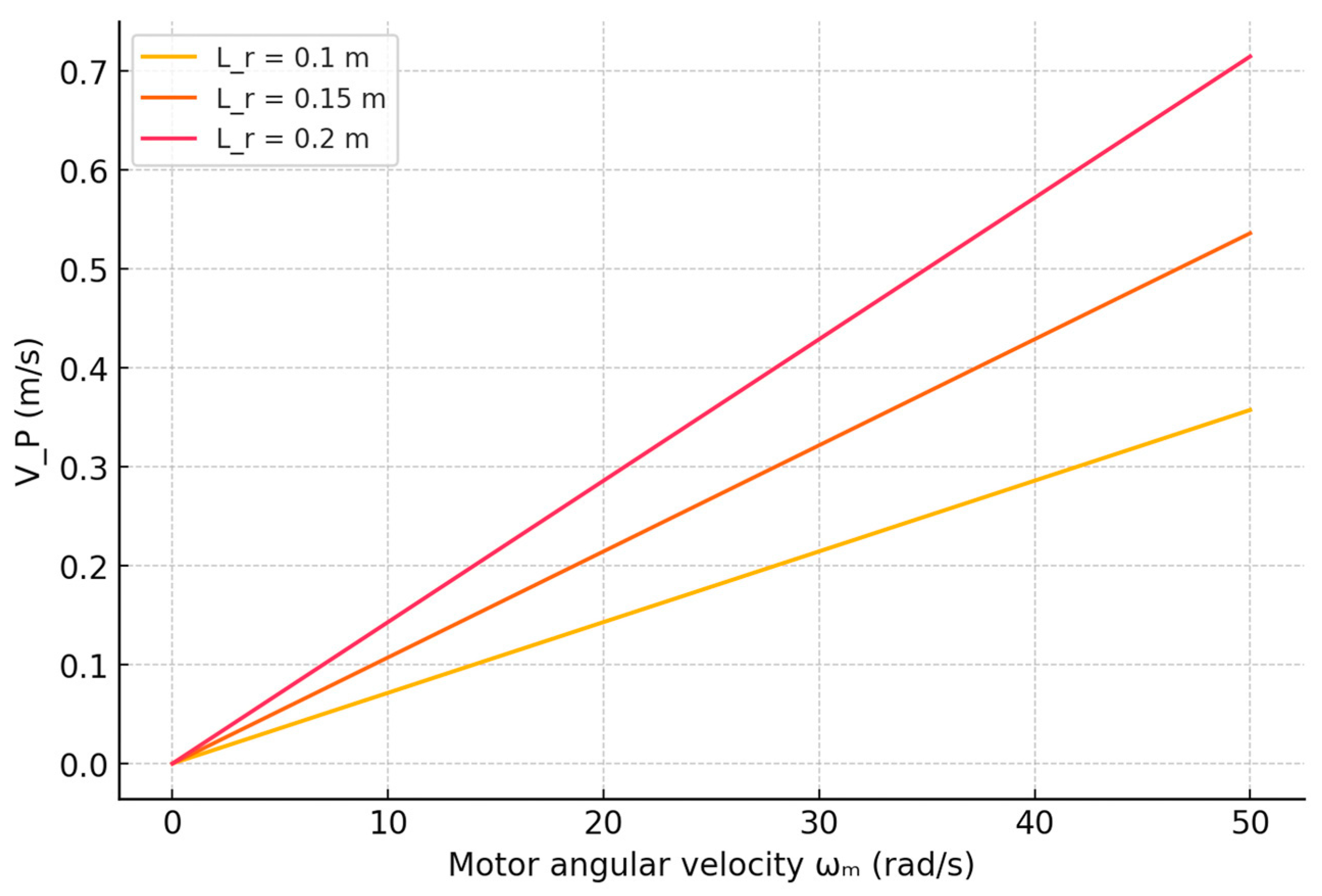

- Lever (Link 3)—a straight link of length Lr, rotating around the gearbox axis. It moves the flap connection point along an arc of a certain radius.

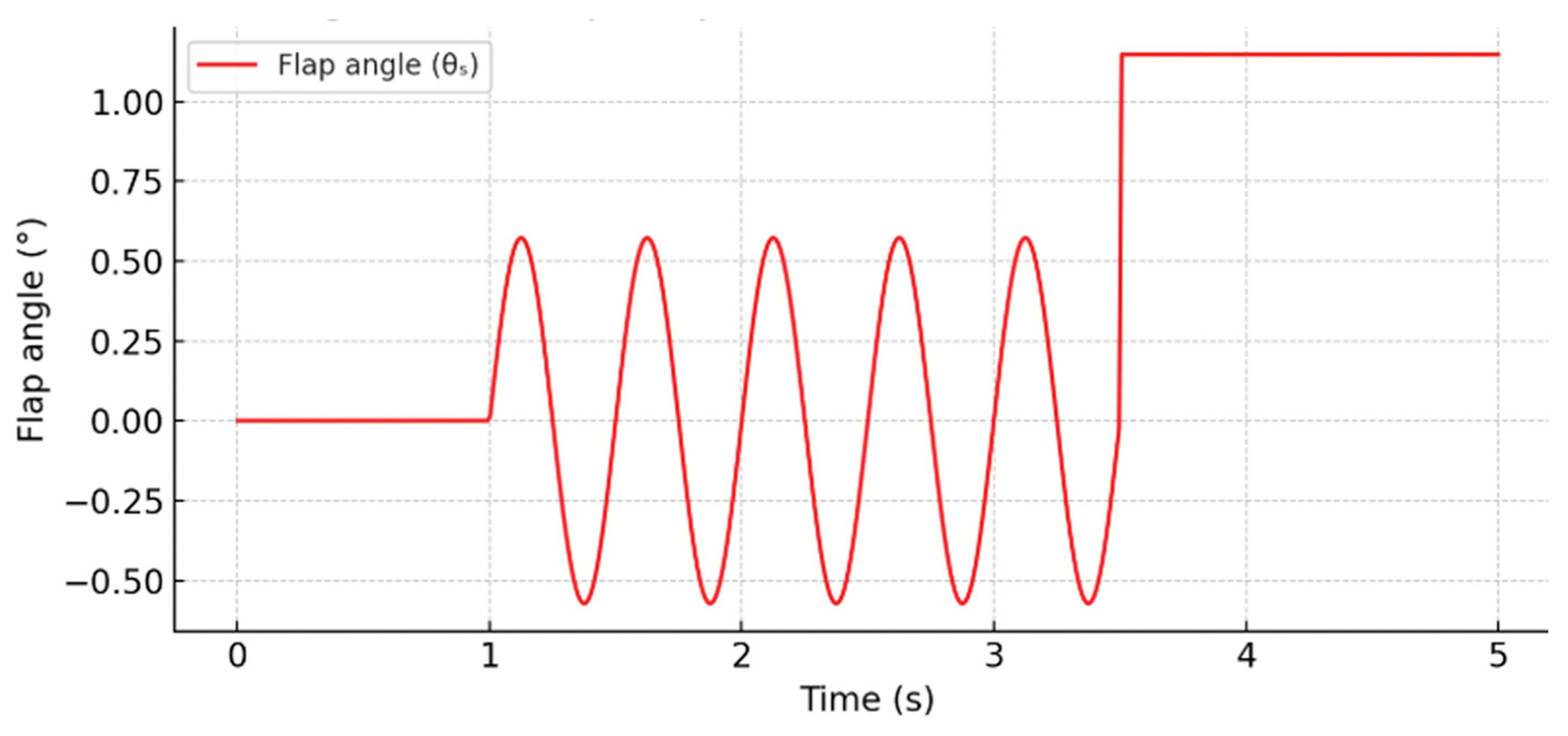

- Connecting joint and flap (Link 4)—the flap receives rotation from the lever. The flap rotation is denoted by the angle θs(t), which is linked to the input angle via the complete kinematic transmission (Figure 1).

- (1)

- (2)

- Angular velocity of the lever:

- (3)

- Angular velocity of the aerodynamic flap:

- (4)

- Angular accelerations:

- Transformation of angular velocity from the motor to the flap. Taking into account two reduction stages—the gearbox and the aerodynamic flap—we get [23]

- 2.

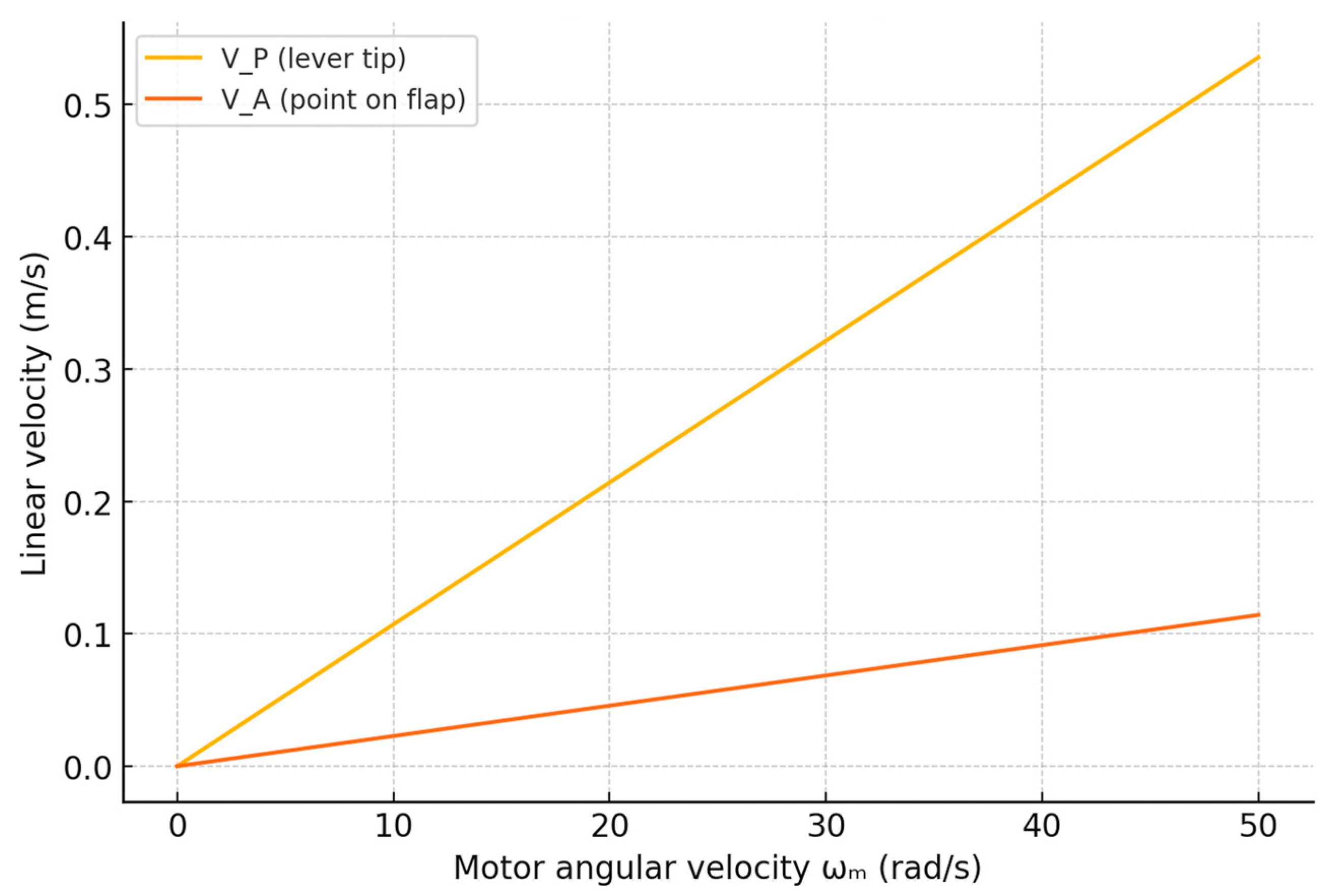

- Linear velocities of characteristic points:

- 3.

- Backlash (dead zone) modeling. To model the phase shift caused by backlash θluft, the following condition was used [25]:

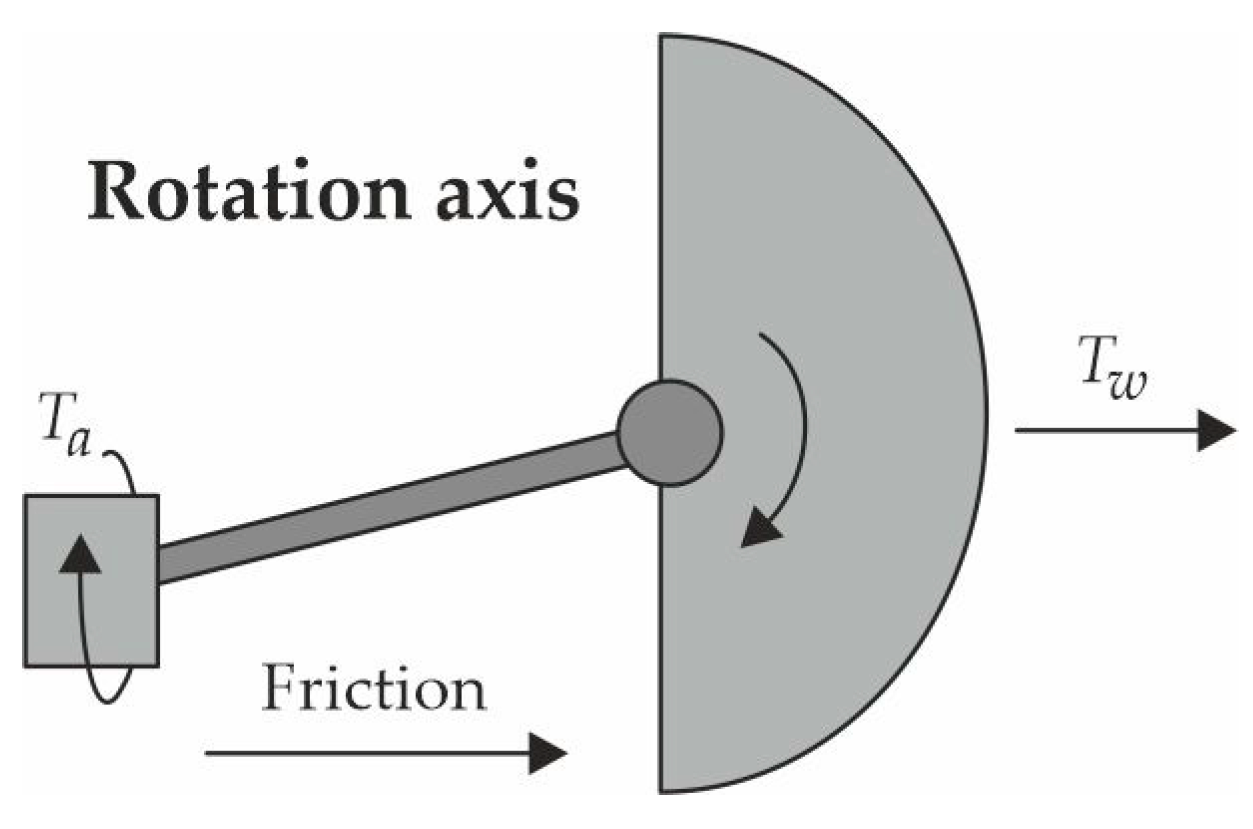

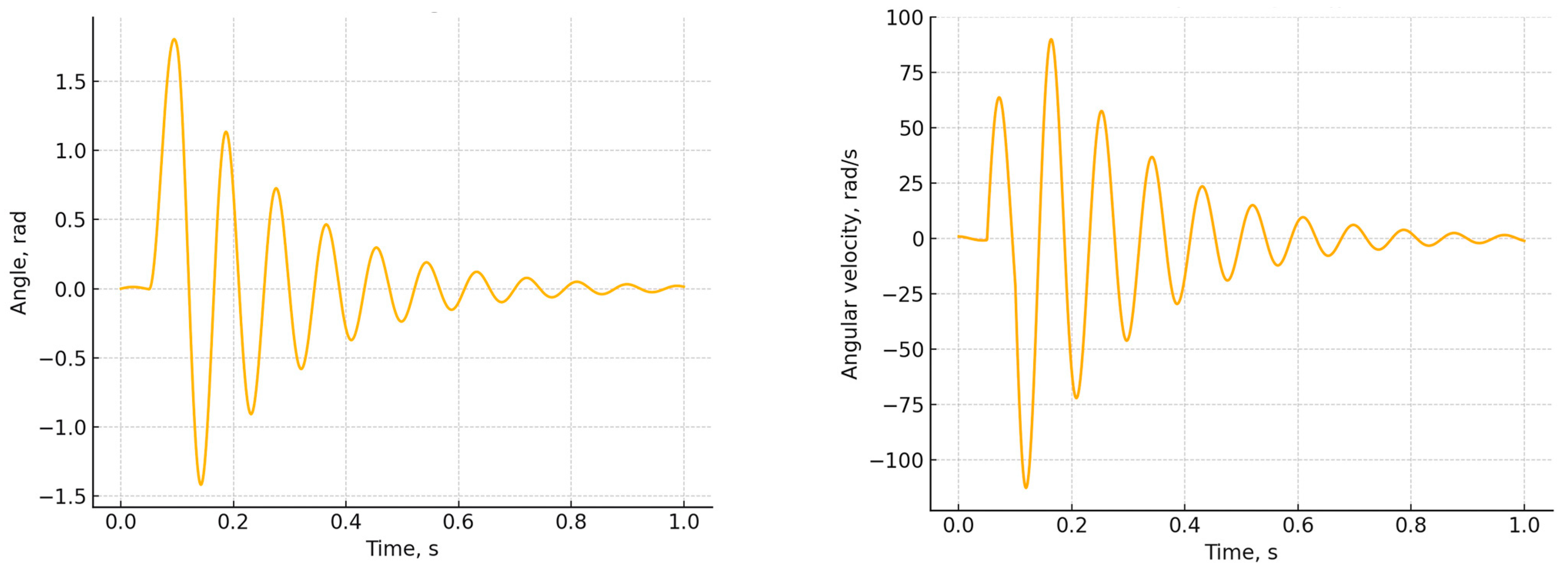

3. Dynamic Analysis of the System

- Analysis of dynamic impact loads caused by sudden wind speed changes and actuator operation;

- Optimization of mass distribution within the mechanism to minimize inertial effects and improve system stability.

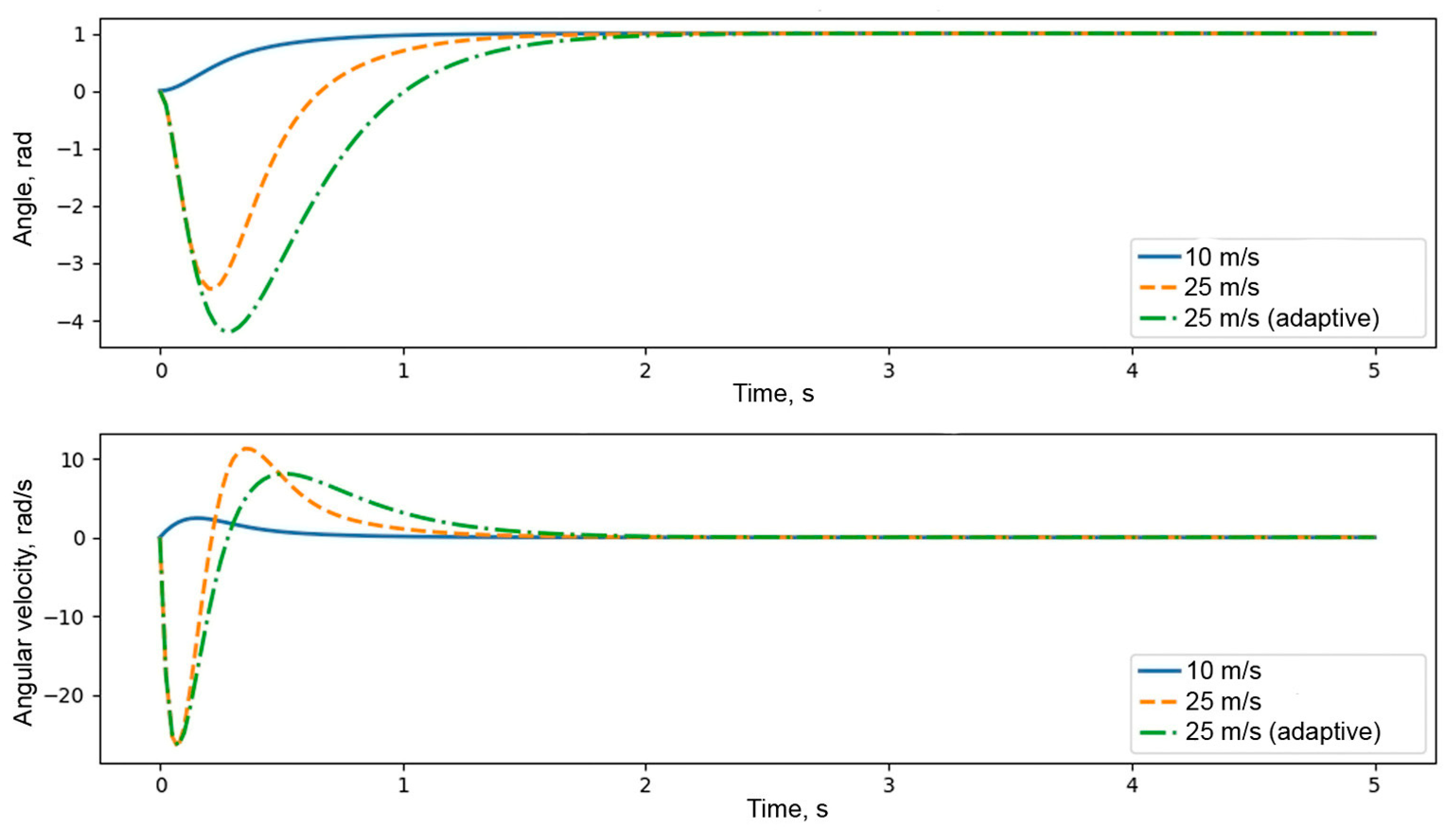

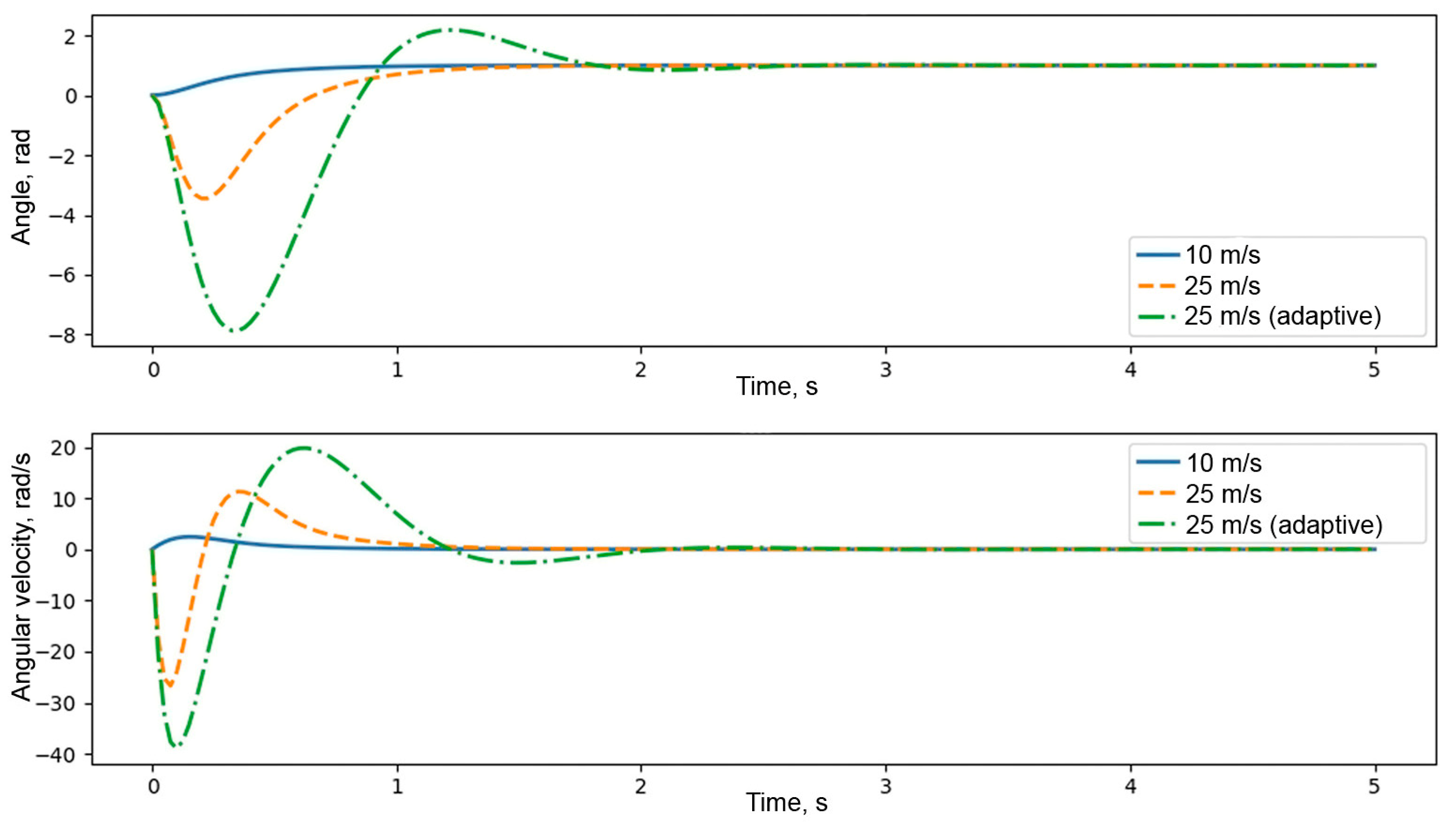

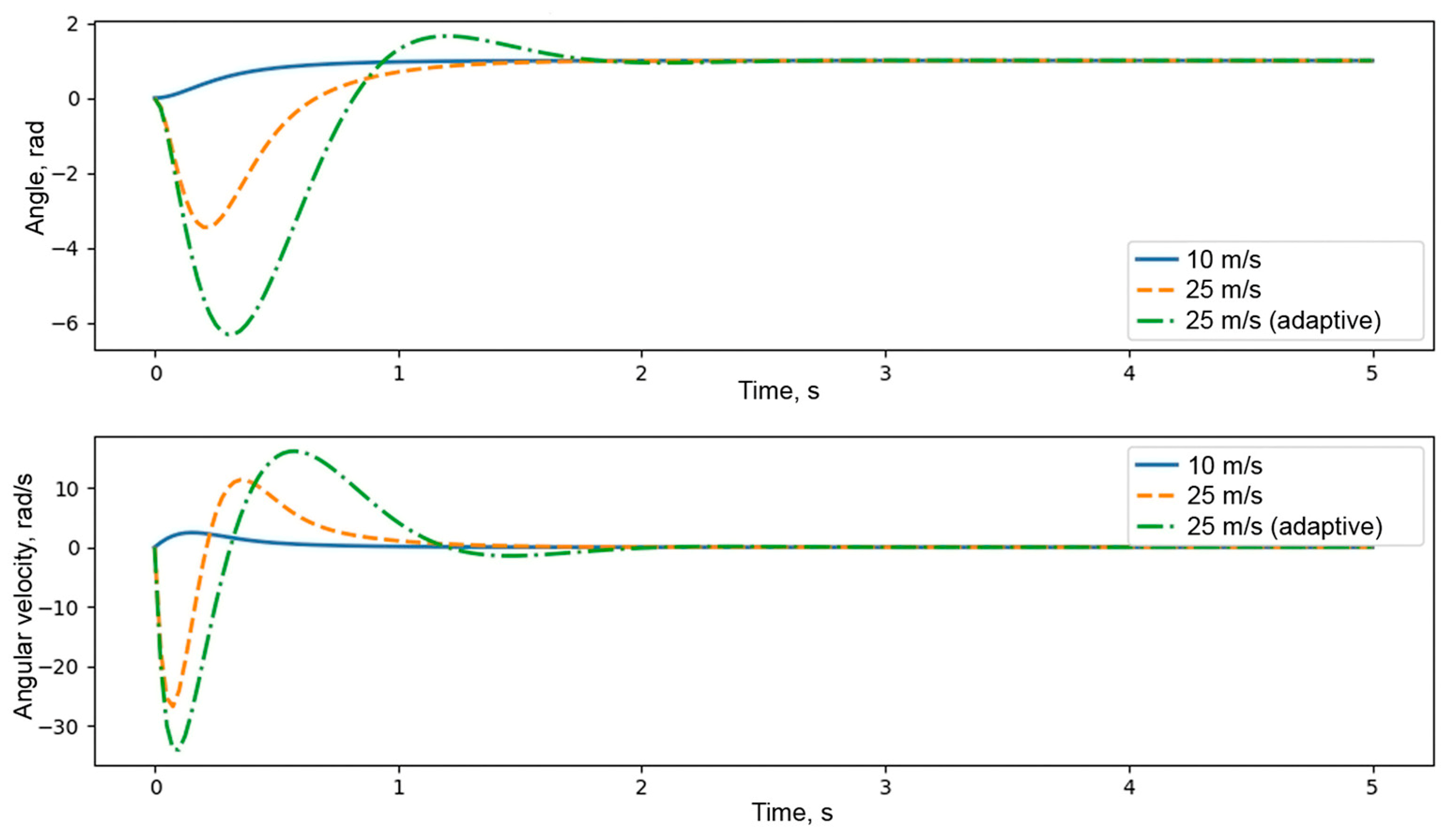

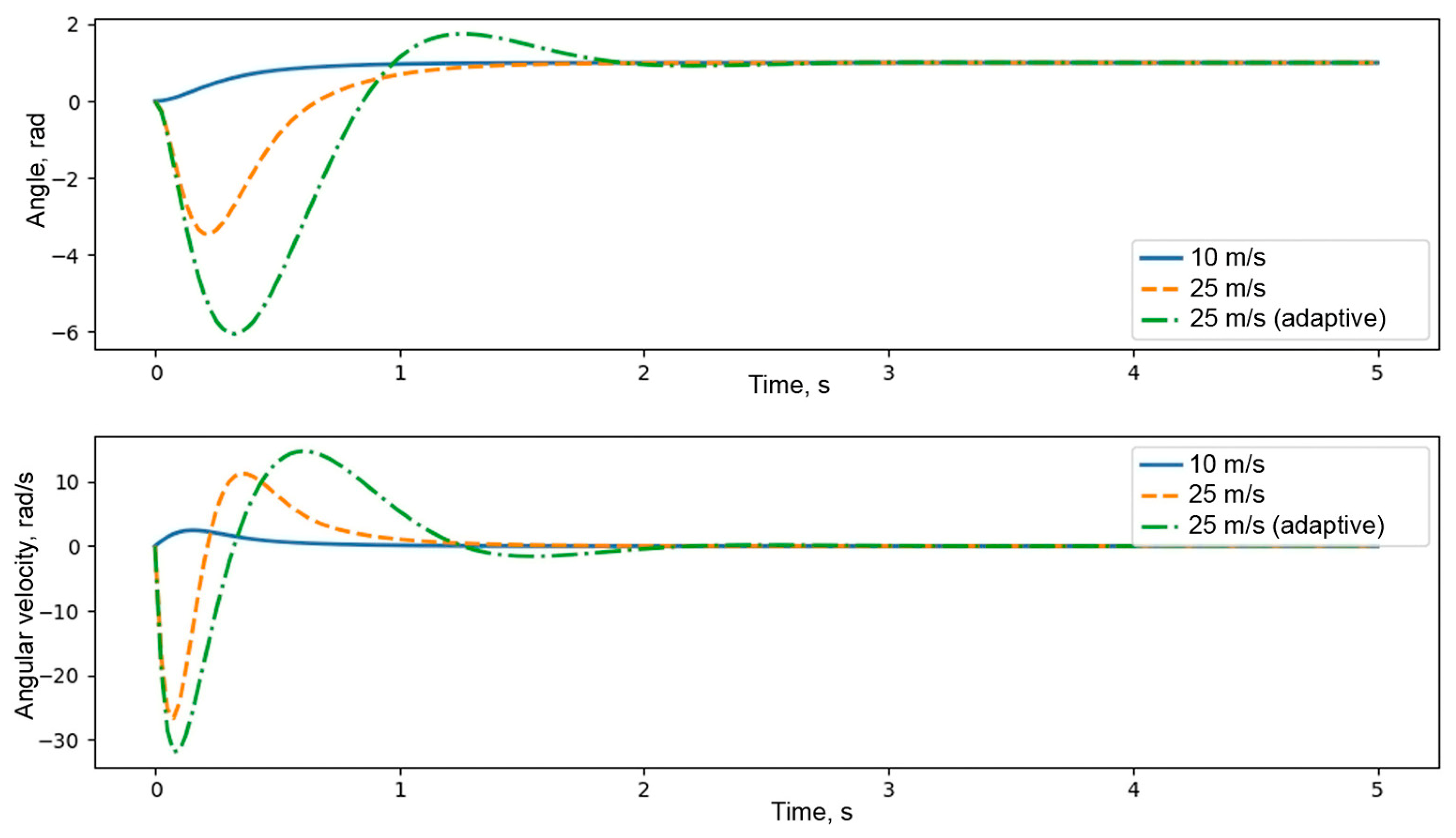

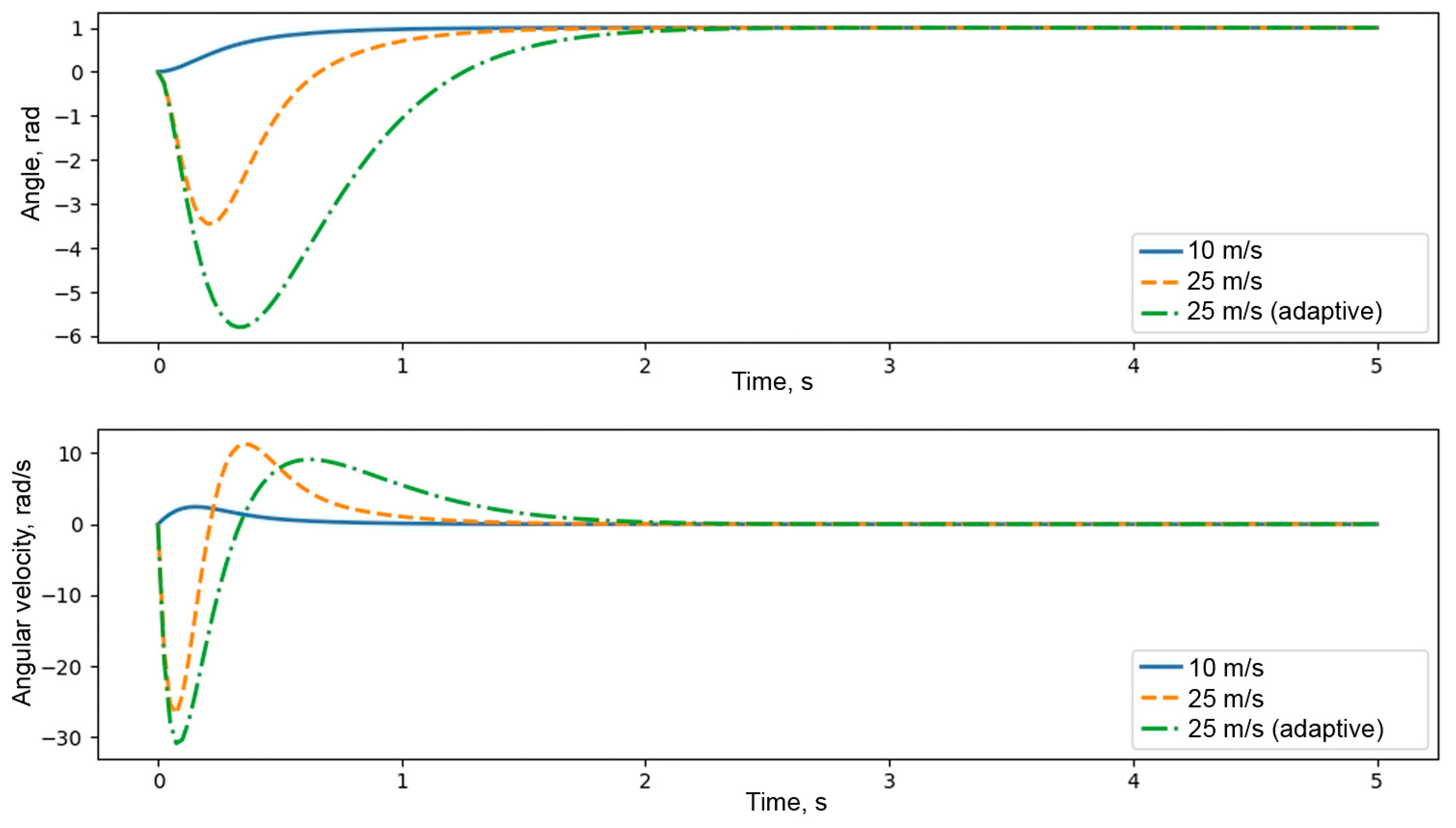

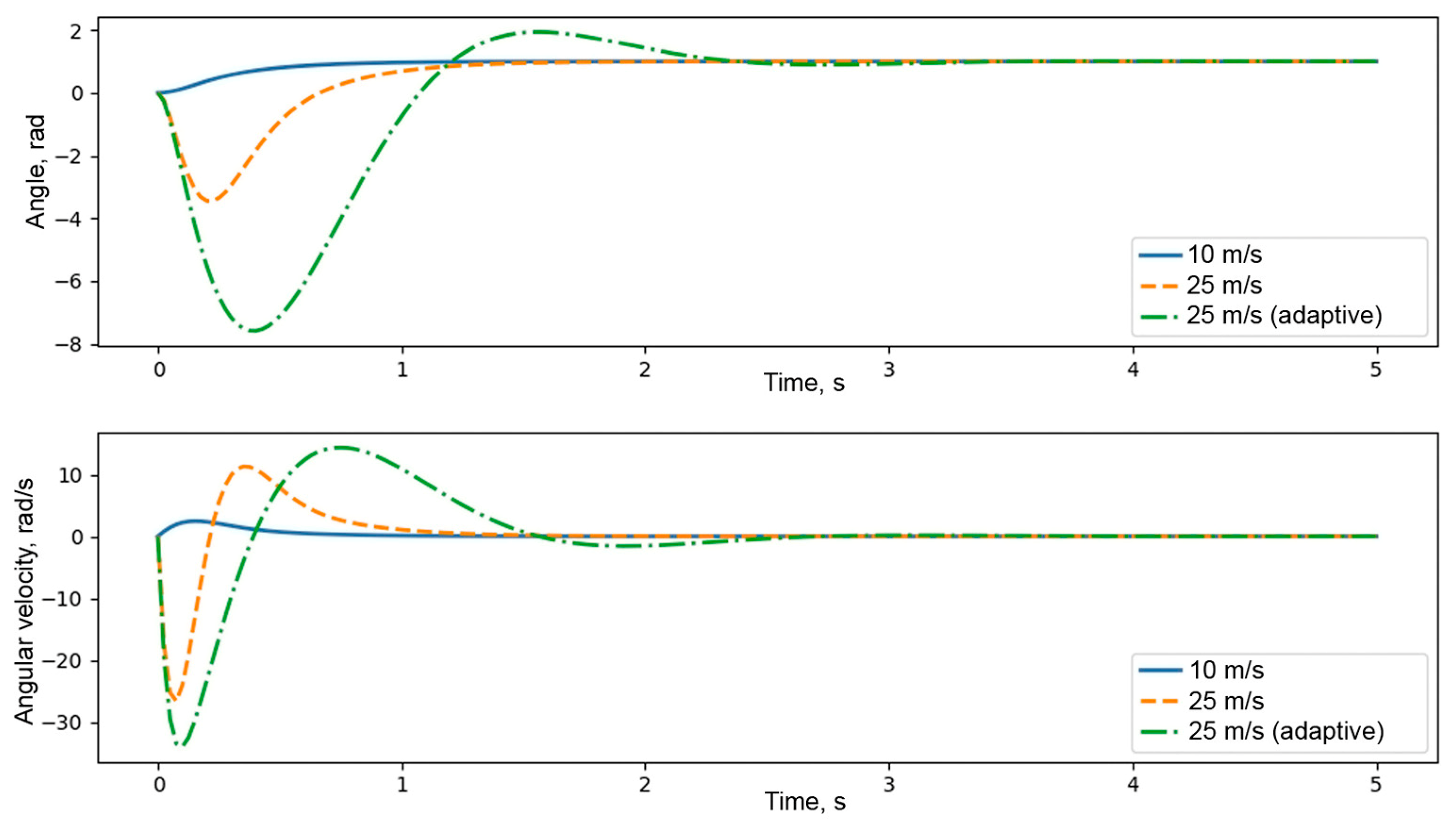

4. Results and Discussion

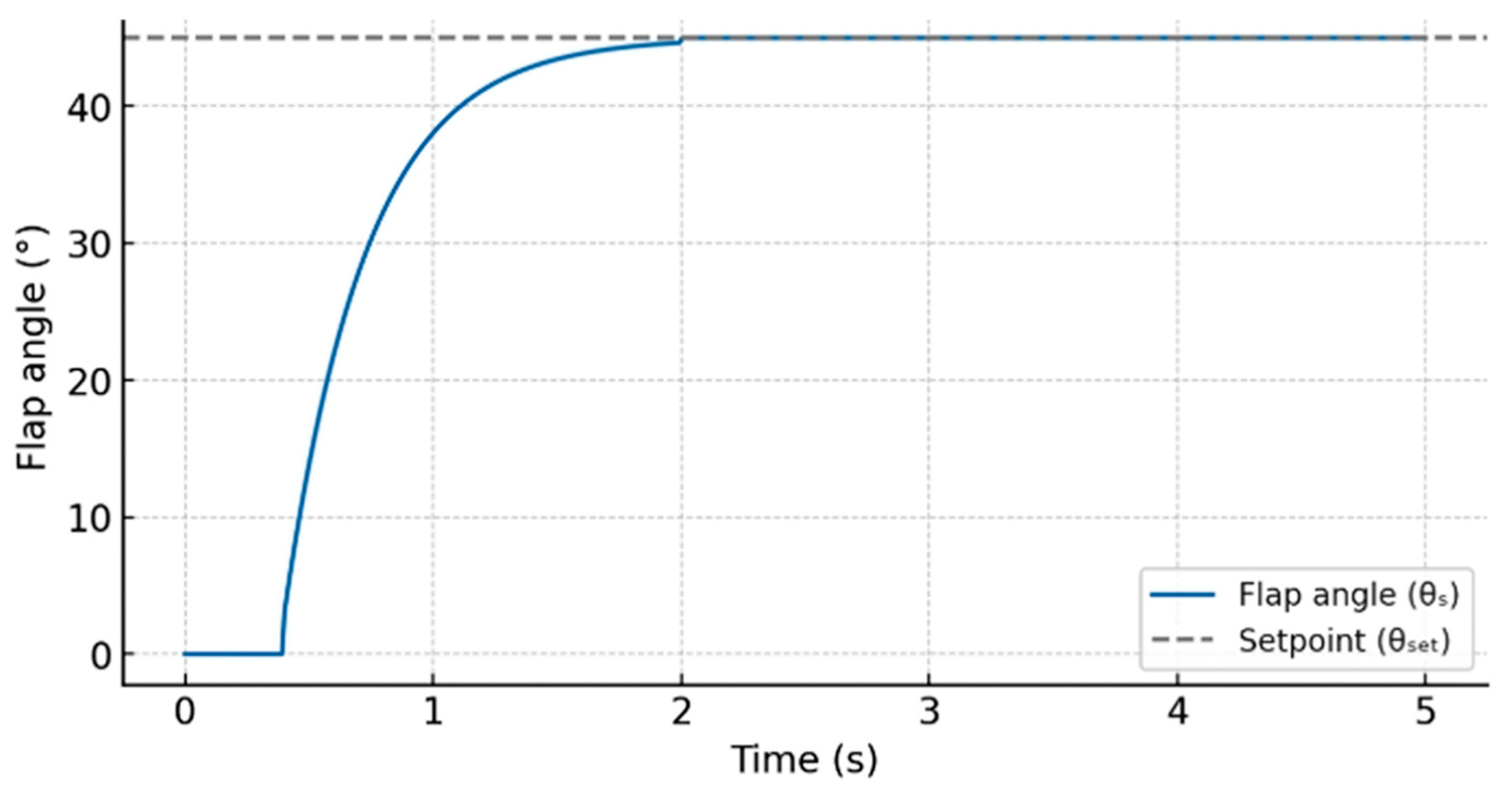

4.1. Kinematic and Dynamic Characteristics

- Overshoot should not exceed 5%;

- Settling time should be no more than 1 s.

- Proportional term —responds immediately to the deviation. The larger the error, the stronger the control action. A large Kp accelerates the response, but if too large, it can cause overshoot.

- Integral term —accumulates the error over time and eliminates systematic deviation (for example, due to a constant wind moment). However, an excessively large Ki makes the system slow and prone to oscillation.

- Differential term —works as a predictor, compensating for sudden changes in error. It effectively dampens oscillations and improves the transient process.

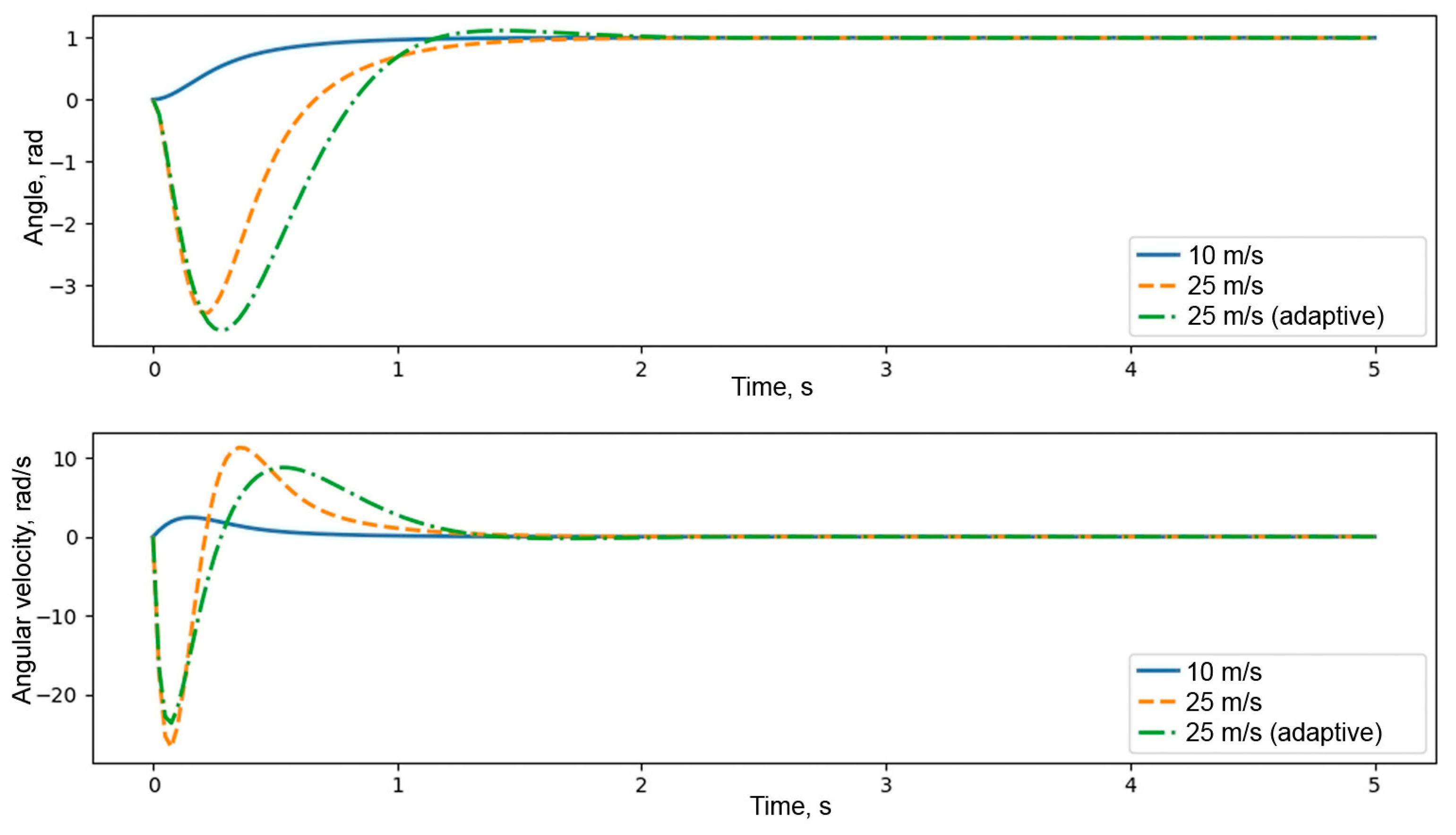

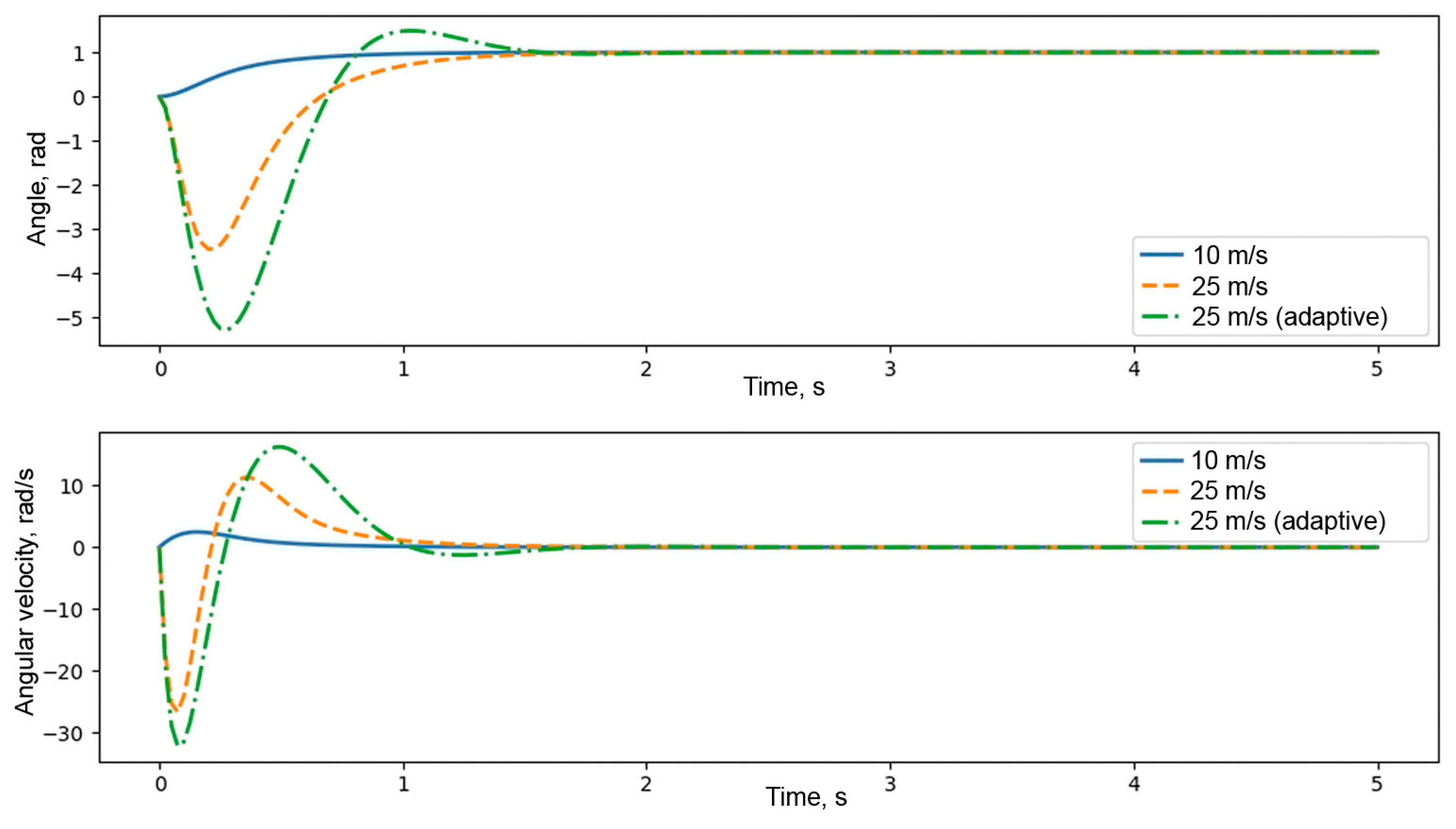

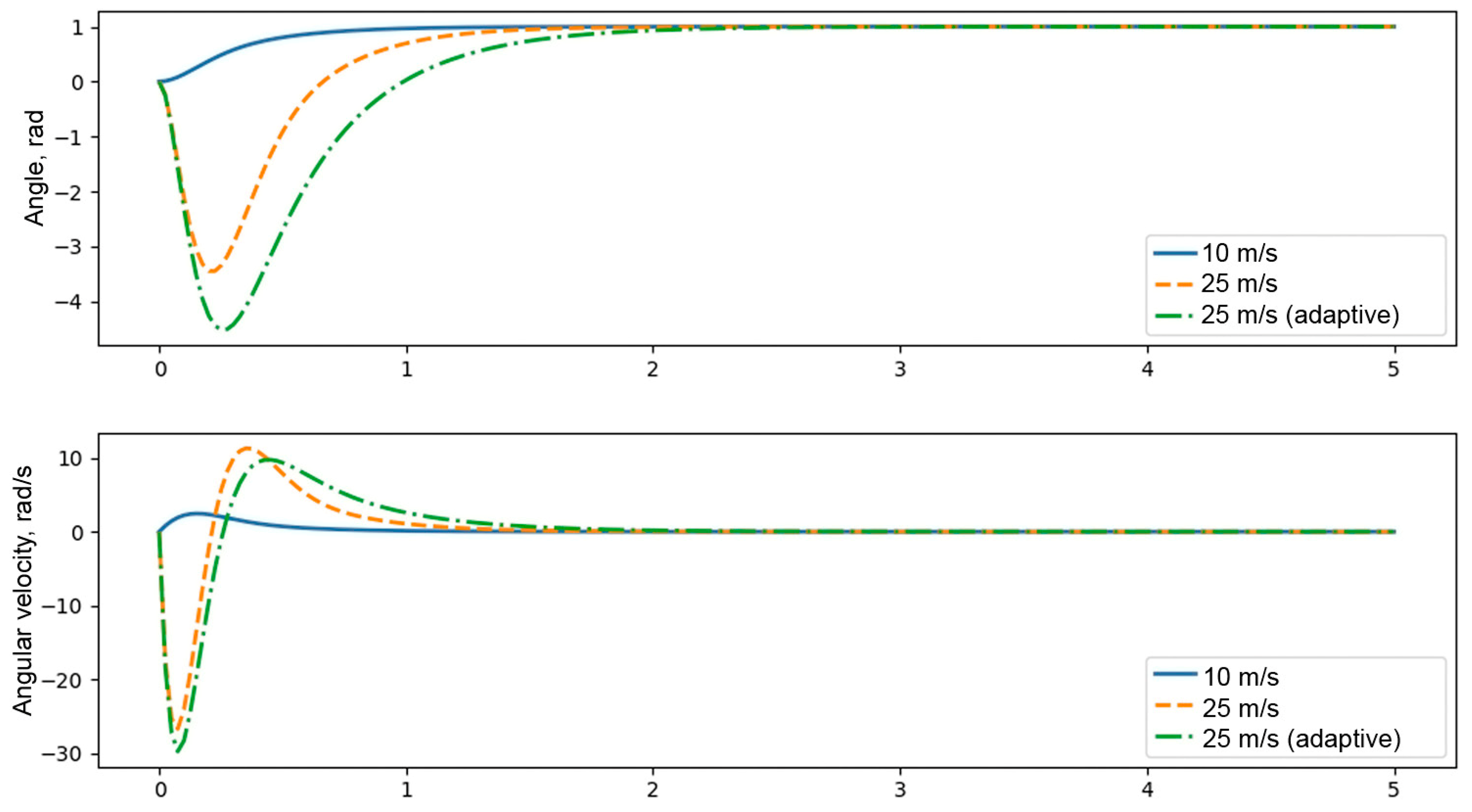

- The control error increases due to insufficient torque compensation;

- The inertial effect manifests—the flap reacts more slowly to control inputs;

- The risk of oscillations and overshoot increases, especially when using fixed controller parameters.

- Decreasing Kp reduces the system’s sensitivity and lowers the likelihood of sharp responses, which is especially important when inertial and mechanical constraints are present;

- Increasing Kd enhances the damping effect, smooths transient processes, and suppresses oscillations caused by impulse wind gusts.

- Minimum settling time;

- Fast damping of oscillations;

- No significant overshoot;

- High stability under external disturbances.

4.2. Practical Implementation Challenges

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saha, H.; Thotla, S.; Maity, D. Numerical Investigation of Flow Characteristics and Performance of a Savonius Wind Turbine with Various Blade Shapes. J. Wind. Eng. Ind. Aerodyn. 2014, 125, 182–194. [Google Scholar] [CrossRef]

- Islam, M.; Ting, D.S.-K.; Fartaj, A. Performance Analysis of a Vertical Axis Wind Turbine with Variable Pitch Mechanism. In Proceedings of the ASME 2008 International Mechanical Engineering Congress and Exposition, Boston, MA, USA, 31 October–6 November 2008; p. 67516. [Google Scholar]

- Fazylova, A.; Iliev, T.; Balbayev, G. Development of a Monitoring System for the State of the Main Components of the Wind Turbine. J. Electr. Electron. Eng. 2022, 15, 27–32. [Google Scholar]

- Tahery, D.; Roshandel, R.; Avami, A. An integrated dynamic model for evaluating the influence of ground to air heat transfer system on heating, cooling and CO2 supply in greenhouses: Considering crop transpiration. Renew. Energy 2019, 173, 42–56. [Google Scholar] [CrossRef]

- Roy, S.; Saha, U.K. Wind tunnel experiments of a newly developed two-bladed Savonius-style wind turbine. Appl. Energy 2015, 137, 117–125. [Google Scholar] [CrossRef]

- Yang, Y.; Li, C.; Zhang, W.; Guo, X.; Yuan, Q. Investigation on aerodynamics and active flow control of a vertical axis wind turbine with flapped airfoil. J. Mech. Sci. Technol. 2017, 31, 1645–1655. [Google Scholar] [CrossRef]

- Mahmoud, M.S.; Oyedeji, M.O. Adaptive and predictive control strategies for wind turbine systems: A survey. IEEE/CAA J. Autom. Sin. 2019, 6, 364–378. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Wang, Z. Responses of vertical axis wind turbines to gusty winds. Proc. Inst. Mech. Eng. Part. A J. Power Energy 2020, 234, 731–744. [Google Scholar] [CrossRef]

- Anthony, M.; Prasad, V.; Raju, K.; Alsharif, M.H.; Geem, Z.W.; Hong, J. Design of Rotor Blades for Vertical Axis Wind Turbine with Wind Flow Modifier for Low Wind Profile Areas. Sustainability 2020, 12, 8050. [Google Scholar] [CrossRef]

- Li, L.; Chopra, I.; Zhu, W.; Yu, M. Performance Analysis and Optimization of a Vertical-Axis Wind Turbine with a High Tip-Speed Ratio. Energies 2021, 14, 996. [Google Scholar] [CrossRef]

- Sayyad, J.; Ramesh, B.T.; Attarde, K. A Systematic PID Tuning for Enhanced Performance in a Wind Turbine Systems. In Proceedings of the 2024 Asia Pacific Conference on Innovation in Technology (APCIT), Mysuru, India, 26–27 July 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Huang, C.; Li, F.; Jin, Z. Maximum power point tracking strategy for large-scale wind generation systems considering wind turbine dynamics. IEEE Trans. Ind. Electron. 2015, 62, 2530–2539. [Google Scholar] [CrossRef]

- Hao, W.; Bashir, M.; Li, C.; Sun, C. Flow control for high-solidity vertical axis wind turbine based on adaptive flap. Energy Convers. Manag. 2021, 249, 114845. [Google Scholar] [CrossRef]

- Hao, W.; Li, C. Performance improvement of adaptive flap on flow separation control and its effect on VAWT. Energy 2020, 213, 118809. [Google Scholar] [CrossRef]

- Syawitri, T.P.; Yao, Y.; Yao, J.; Chandra, B. Geometry optimization of vertical axis wind turbine with Gurney flap for performance enhancement at low, medium and high ranges of tip speed ratios. Sustain. Energy Technol. Assess. 2022, 49, 101779. [Google Scholar] [CrossRef]

- Attie, C.; ElCheikh, A.; Nader, J.; Elkhoury, M. Performance enhancement of a vertical axis wind turbine using a slotted deflective flap at the trailing edge. Energy Convers. Manag. 2022, 273, 116388. [Google Scholar] [CrossRef]

- Guo, G.; Zhu, W.; Sun, Z.; Shen, W.; Chen, J.; Fan, S. Drag reducer design of wind turbine blade under flap-wise fatigue testing. Compos. Struct. 2023, 318, 117094. [Google Scholar] [CrossRef]

- Ni, L.; Miao, W.; Li, C.; Liu, Q. Impacts of Gurney flap and solidity on the aerodynamic performance of vertical axis wind turbines in array configurations. Energy 2021, 215, 118915. [Google Scholar] [CrossRef]

- Diaz, G.P.N.; Saulo, A.C.; Otero, A.D. Wind farm interference and terrain interaction simulation by means of an adaptive actuator disc. J. Wind. Eng. Ind. Aerodyn. 2019, 186, 58–67. [Google Scholar] [CrossRef]

- Kurniati, S.; Syam, S.; Sanusi, A. Numerical investigation and improvement of the aerodynamic performance of a modified elliptical-bladed Savonius-style wind turbine. AIMS Energy 2023, 11, 1211–1230. [Google Scholar] [CrossRef]

- Ang, E.B.; Honra, J.P. Theoretical Aerodynamic Performance and FEA Analysis of a Novel Three-Blade Savonius Wind Turbine Blade with Pointed Deflectors. Dynamics 2025, 5, 8. [Google Scholar] [CrossRef]

- Singh, P.; Jaiswal, V.; Roy, S.; Singh, R.K. Maximizing Savonius Turbine Performance using Kriging Surrogate Model and Grey Wolf-Driven Cylindrical Deflector Optimization. arXiv 2023. [Google Scholar] [CrossRef]

- Singh, P.; Jaiswal, V.; Roy, S.; Tyagi, A.; Kumar, G.; Singh, R.K. Quantum-Based Salp Swarm Algorithm Driven Design Optimization of Savonius Wind Turbine-Cylindrical Deflector System. arXiv 2024. [Google Scholar] [CrossRef]

- Fatahian, E.; Ismail, F.; Ishak, M.H.H.; Chang, W.S. Aerodynamic performance improvement of Savonius wind turbine through a passive flow control method using grooved surfaces on a deflector. Ocean. Eng. 2023, 284, 115282. [Google Scholar] [CrossRef]

- Liu, Q.; Miao, W.; Ye, Q.; Li, C. Performance assessment of an innovative Gurney flap for straight-bladed vertical axis wind turbine. Renew. Energy 2022, 185, 1124–1138. [Google Scholar] [CrossRef]

- Zhu, C.; Yang, H.; Qiu, Y.; Zhou, G.; Wang, L.; Feng, Y.; Shen, Z.; Shen, X.; Feng, X.; Wang, T. Effects of the Reynolds number and reduced frequency on the aerodynamic performance and dynamic stall behaviors of a vertical axis wind turbine. Energy Convers. Manag. 2023, 293, 117513. [Google Scholar] [CrossRef]

- Fazylova, A.; Iliev, T.; Stoyanov, I.; Siemens, E. Height Control System for Wind Turbines Based on Critical Wind Speed Calculation. Appl. Sci. 2024, 14, 9802. [Google Scholar] [CrossRef]

- Sorensen, J.N.; Shen, W.Z. Numerical Modeling of Wind Turbine Wakes. J. Fluids Eng. 2002, 124, 393–399. [Google Scholar] [CrossRef]

- Paraschivoiu, I. Book Review: ‘Wind Turbine Design—With Emphasis on (The) Darrieus Concept’. Wind. Eng. 2003, 27, 73–74. [Google Scholar] [CrossRef]

- Castelli, M.R.; Englaro, A.; Benini, E. The Darrieus wind turbine: Proposal for a new performance prediction model based on CFD. Energy 2011, 36, 4919–4934. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Kalkman, I.; Blocken, B. CFD Simulation of a Vertical Axis Wind Turbine Operating at a Moderate Tip Speed Ratio: Guidelines for Minimum Domain Size and Azimuthal Increment. Renew. Energy 2017, 107, 373–385. [Google Scholar] [CrossRef]

- Balduzzi, F.; Bianchini, A.; Maleci, R.; Ferrara, G.; Ferrari, L. Critical issues in the CFD simulation of Darrieus wind turbines. Renew. Energy 2016, 85, 419–435. [Google Scholar] [CrossRef]

- Howell, R.; Qin, N.; Edwards, J.; Durrani, N. Wind tunnel and numerical study of a small vertical axis wind turbine. Renew. Energy 2010, 35, 412–422. [Google Scholar] [CrossRef]

- Li, Y.; Calisal, S.M. Three-dimensional effects and arm effects on modeling a vertical axis tidal current turbine. Renew. Energy 2010, 35, 2325–2334. [Google Scholar] [CrossRef]

- Bianchini, A.; Ferrara, G.; Ferrari, L. Design guidelines for H-Darrieus wind turbines: Optimization of the annual energy yield. Energy Convers. Manag. 2015, 89, 690–707. [Google Scholar] [CrossRef]

- Fazylova, A.; Alipbayev, K.; Iliev, T.; Aden, A. Advanced Control Strategies for Wind Turbine Blade Pitch Optimization. In Proceedings of the 5th IEEE International Conference on Communications, Information, Electronic and Energy Systems (CIEES), Veliko Tarnovo, Bulgaria, 20–22 November 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Fazylova, A.R.; Balbayev, G.; Tultayev, B. System of short-term forecasting of wind turbine output power consumption. News Acad. Sci. Repub. Kazakhstan 2022, 3, 243–252. [Google Scholar] [CrossRef]

- Shikha, S.; Bhatti, T.S.; Kothari, D.P. Indian scenario of wind energy: Problems and solutions. Energy Sources 2004, 26, 811–819. [Google Scholar] [CrossRef]

- Tjiu, W.; Marnoto, T.; Mat, S.; Ruslan, M.H.; Sopian, K. Darrieus vertical axis wind turbine for power generation II: Challenges in HAWT and the opportunity of multi-megawatt Darrieus VAWT development. Renew. Energy 2015, 75, 560–571. [Google Scholar] [CrossRef]

- Gorle, J.M.R.; Chatellier, L.; Pons, F.; Ba, M. Flow and performance analysis of H-Darrieus hydro turbine in a confined flow: A computational and experimental study. J. Fluids Struct. 2016, 66, 382–402. [Google Scholar] [CrossRef]

- Alipbayev, K.; Ivanov, K.; Sultan, A.; Komekbayev, A. Research and design of an efficient adaptive drive with balancing friction coupling. J. Appl. Eng. Sci. 2024, 22, 81–88. [Google Scholar] [CrossRef]

| Wind Speed, m/s | Wind Torque, Nm | Wind Speed, m/s | Wind Torque, Nm |

|---|---|---|---|

| 0 | 0.0 | 25 | 10.1606 |

| 1 | 0.0176 | 26 | 11.025 |

| 2 | 0.0706 | 27 | 11.9246 |

| 3 | 0.1588 | 28 | 12.8596 |

| 4 | 0.2822 | 29 | 13.8298 |

| 5 | 0.441 | 30 | 14.8352 |

| 6 | 0.635 | 31 | 15.876 |

| 7 | 0.8644 | 32 | 16.952 |

| 8 | 1.129 | 33 | 18.0634 |

| 9 | 1.4288 | 34 | 19.21 |

| 10 | 1.764 | 35 | 20.3918 |

| 11 | 2.1344 | 36 | 21.609 |

| 12 | 2.5402 | 37 | 22.8614 |

| 13 | 2.9812 | 38 | 24.1492 |

| 14 | 3.4674 | 39 | 25.4722 |

| 15 | 3.4574 | 40 | 26.8304 |

| 16 | 3.969 | 41 | 28.224 |

| 17 | 4.5158 | 42 | 29.6528 |

| 18 | 5.098 | 43 | 31.117 |

| 19 | 5.7154 | 44 | 32.6162 |

| 20 | 6.368 | 45 | 34.151 |

| 21 | 7.056 | 46 | 35.721 |

| 22 | 7.7792 | 47 | 37.3262 |

| 23 | 8.5378 | 48 | 38.9668 |

| 24 | 9.3316 | 49 | 40.6426 |

| Link | Mass (kg) | Coordinates |

|---|---|---|

| Flap | 0.3 | (0.15, 0) |

| Lever | 0.1 | (0.075, 0) |

| Gearbox | 0.5 | (0, 0) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazylova, A.; Alipbayev, K.; Iliev, T.; Kaliyeva, N. Adaptive Control of the Aerodynamic Flaps of the Savonius Rotor Under Variable Wind Loads. Appl. Sci. 2025, 15, 6096. https://doi.org/10.3390/app15116096

Fazylova A, Alipbayev K, Iliev T, Kaliyeva N. Adaptive Control of the Aerodynamic Flaps of the Savonius Rotor Under Variable Wind Loads. Applied Sciences. 2025; 15(11):6096. https://doi.org/10.3390/app15116096

Chicago/Turabian StyleFazylova, Alina, Kuanysh Alipbayev, Teodor Iliev, and Nazgul Kaliyeva. 2025. "Adaptive Control of the Aerodynamic Flaps of the Savonius Rotor Under Variable Wind Loads" Applied Sciences 15, no. 11: 6096. https://doi.org/10.3390/app15116096

APA StyleFazylova, A., Alipbayev, K., Iliev, T., & Kaliyeva, N. (2025). Adaptive Control of the Aerodynamic Flaps of the Savonius Rotor Under Variable Wind Loads. Applied Sciences, 15(11), 6096. https://doi.org/10.3390/app15116096