Research Progress and Technology Outlook of Deep Learning in Seepage Field Prediction During Oil and Gas Field Development

Abstract

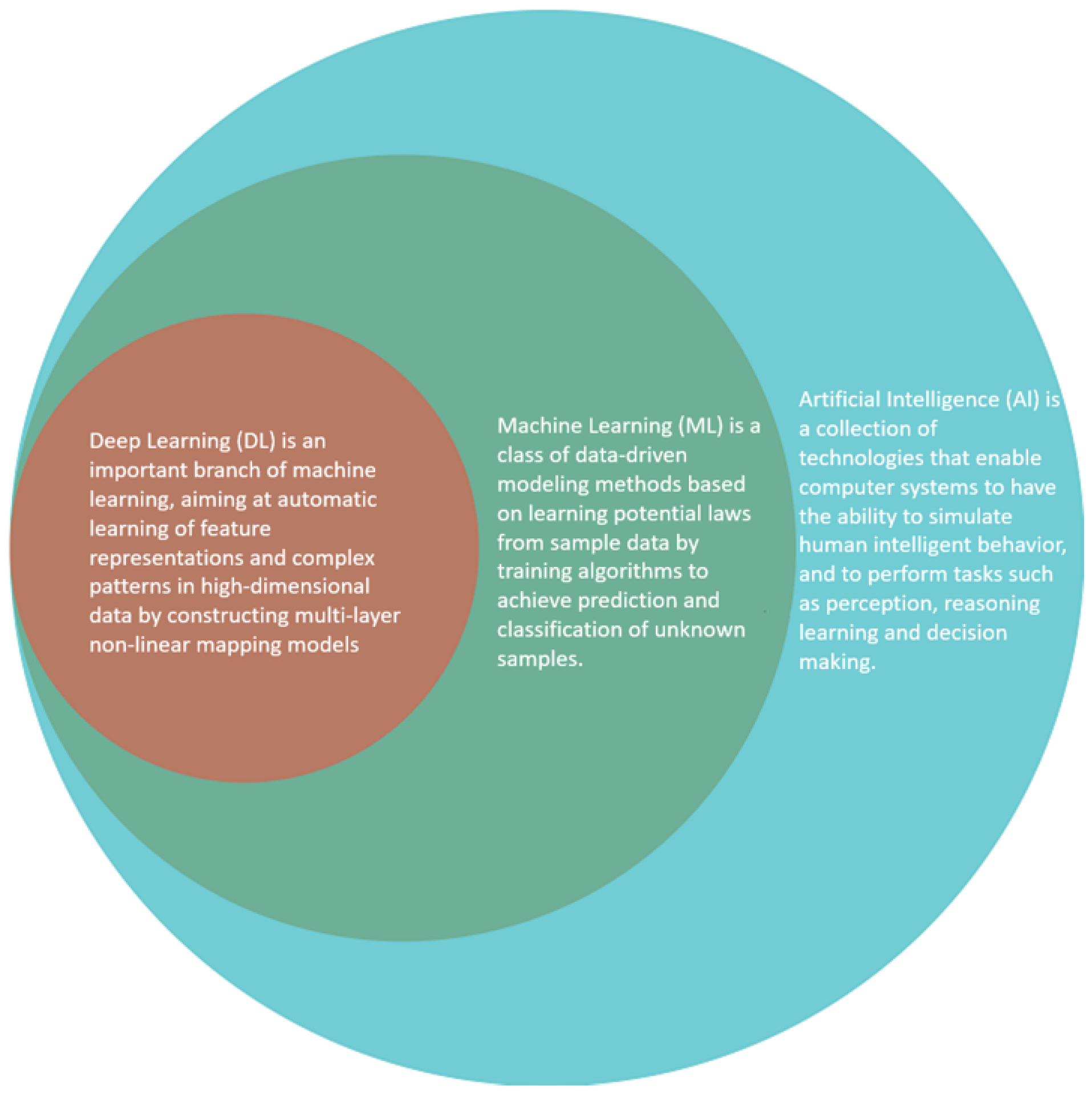

1. Introduction

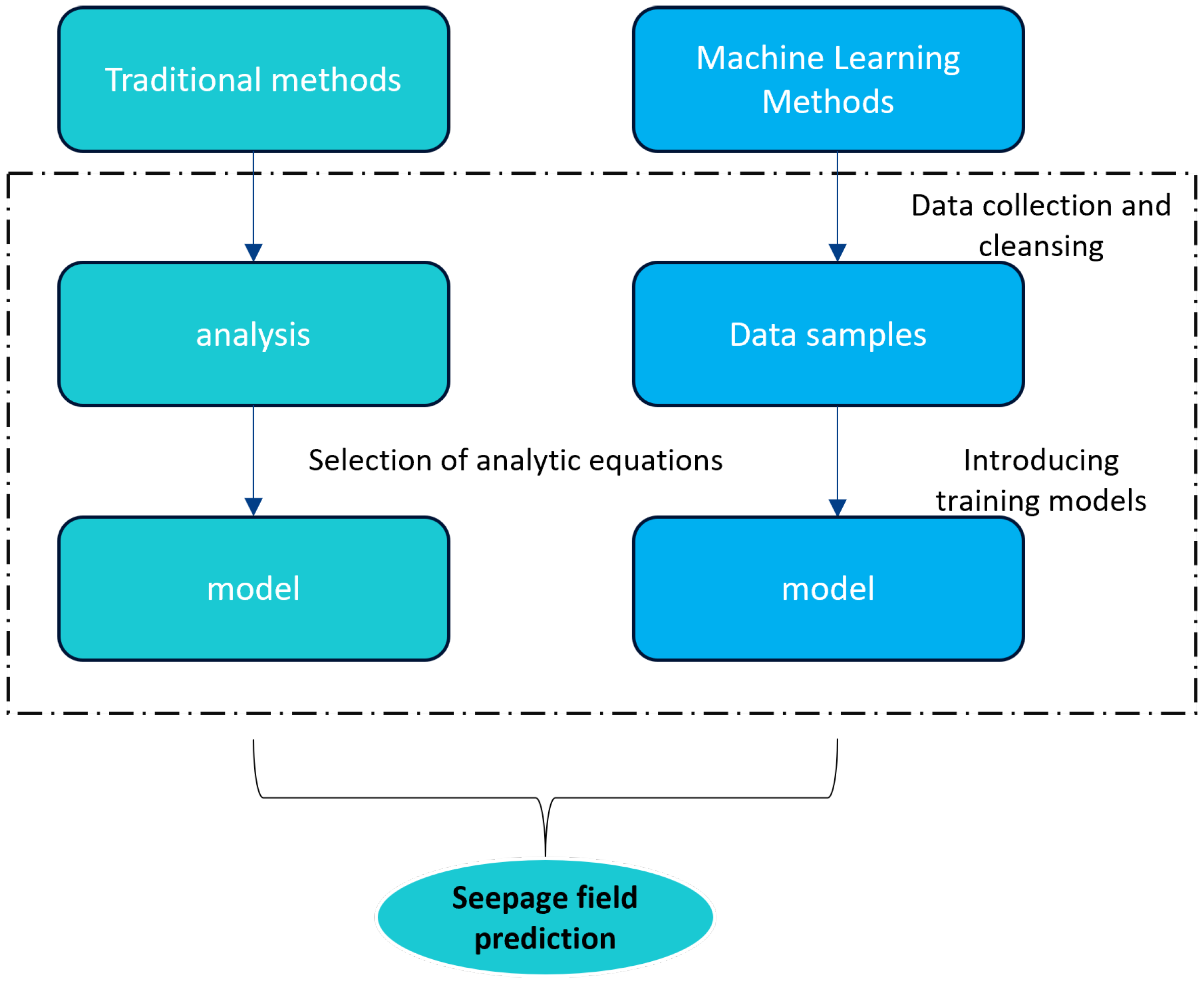

2. Development of Seepage Field Prediction Methods

2.1. Conventional Seepage Field Prediction Methods

2.2. A Machine Learning-Based Method for Seepage Field Prediction

2.3. Deep Learning-Based Method for Seepage Field Prediction

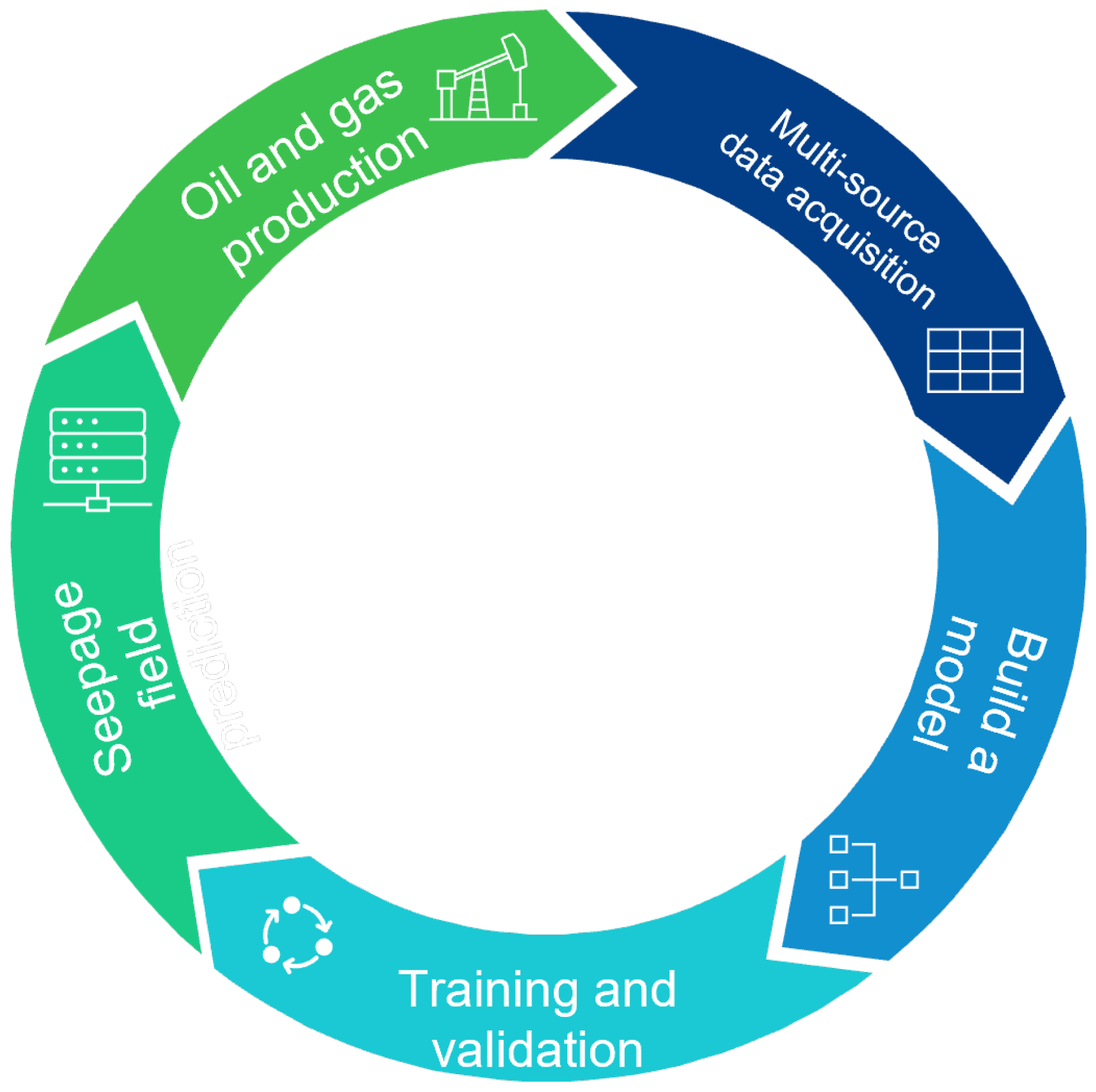

3. Key Processes for Deep Learning-Based Seepage Field Prediction

3.1. Feature Engineering

3.2. Neural Network Construction Methods

- FeedForward Neural network model: A FeedForward Neural network is a kind of Deep Neural Network (DNN) with a simple structure but a powerful function, which is suitable for small- and medium-scale data modeling tasks. It can be used for single-point response prediction, such as pressure and saturation, by capturing the higher-order relationships between input and output variables through multi-layer linear and nonlinear transformations. For example, Xue et al. [2] used physics-regularized DNN for seepage field prediction, they embedded the single-phase seepage control equation in the form of residuals into the loss function, they realized automatic constraints on physical laws during the model training process, and they effectively improved the physical consistency and generalization ability of the pressure prediction [2]. Wang et al. [15] developed a hybrid modeling framework that integrates nonlinear coupled seepage control equations with deep FeedForward Neural networks to predict the evolution of pressure and saturation in complex reservoirs. The model obtains initial samples through numerical simulation and inputs the coupled pressure and saturation time series into the DNN for regression modeling, which realizes the joint data–physical-structural drive. Compared with traditional numerical methods, the model has better performance in simulation speed and predicting response trends, and it is suitable for the rapid assessment and response prediction of seepage behavior under complex injection and mining regimes [35,36,37,38]. Hong et al. [20] applied DNNs to the task of predicting pore throat features in micro-scale core images, and they constructed a seepage structure feature learning model based on parameters from well logging and core images. The model predicts the pore throat radius distribution with multidimensional static inputs (porosity, image features, gray moments, etc.), which is used to reflect the influence of the core microstructure on the biphasic seepage capacity. The input variables were strictly screened and normalized in the study, and the nonlinear mapping between pore structure and seepage capacity was successfully established by a FeedForward Neural network, which provided a novel alternative path for seepage parameter inversion [39,40,41,42].Overall, DNN-like models are suitable for small- and medium-scale parameter prediction tasks, with their advantages of simple structure and efficient computation, and they can still play an important role in seepage modeling if combined with physical constraints or multivariate fusion mechanisms [43,44,45,46].

- Spatio–temporal prediction network model: In order to more fully explore the influence of time series features on the evolution process of seepage response variables (e.g., pressure, WC, saturation, etc.) in the production data of reservoirs during the high WCP, some researchers have adapted and improved the structure of temporal neural networks, such as traditional RNNs, LSTMs, GRUs, etc., in order to enhance the ability of the model to portray complex nonlinear dynamic processes. In addition, some studies have also introduced heuristic optimization methods, such as genetic algorithms and particle swarms, to adaptively adjust the model hyper-parameters, thus further improving the training efficiency and time-series prediction accuracy, and providing a more stable and reliable technical path for modeling dynamic seepage behavior [47]. For example, Garsole et al. [13] proposed an integrated network model based on RNN in hydraulic seepage modeling, combining time-series clustering and automatic feature extraction to achieve dynamic identification and modeling of seepage risk from multivariate monitoring data; Qian et al. [22] introduced the LSTM structure to investigate the gas–water two-phase microscopic seepage process in coal rock fissures, realizing the high-precision time-sequence portrayal of the fracture–matrix periodic response process and showing good results in the modeling of a microscale dynamic evolution process.From the current study, within the Deep Learning framework, LSTM, RNN, and GRU as the basic models have been widely used to solve time-series dynamic prediction problems, and experts and scholars have developed different variant models according to the actual needs of different scenarios, which provide a flexible and efficient technical path for modeling seepage behaviors in high WCPs [48,49,50].

- Convolutional Neural Network model: Convolutional Neural Networks (CNNs) have been widely used in reservoir seepage modeling by virtue of their advantages in spatial feature extraction and local pattern recognition, which are especially suitable for processing gridded distribution maps such as pressure and saturation fields, or three-dimensional structural data such as digital core images [22]. In complex seepage systems, CNNs can extract features such as inter-well interference, hyper-permeable channels, and non-homogeneous structures through a local sensing mechanism, and they capture the spatial variation patterns in the seepage field [51]. For example, Xue et al. [2] used the Physical Difference Convolutional Neural Network (PD-CNN), which integrates the finite difference idea with the convolutional structure, and they embedded the residuals of the control equations as a convolution kernel into the CNN network to realize high-precision prediction of the distribution of the joint pressure–saturation field. Guo et al. [3] constructed a deep convolutional network model based on U-Net for dynamic prediction of three-dimensional saturation fields in complex fault block reservoirs. By designing jump connections and a multi-scale structure, the model can reconstruct high-resolution oil saturation distribution maps in the low well control region, which improves the accuracy and spatial consistency of residual oil identification. Telvari et al. [23] applied 3D CNN to digital core image modeling; they extracted pore structure information through 3D convolution, and they predicted the pressure gradient and saturation evolution process of a two-phase flow in the core. This method can automatically learn microscopic seepage paths in complex pore channels, expanding the application space of CNN in microscale seepage modeling.Overall, the Convolutional Neural Network-like model has become one of the mainstream modeling tools in reservoir seepage field prediction by virtue of its powerful spatial structure perception capability and good scalability. Especially in complex flow patterns during high WCPs, CNN shows good ability to portray the response mechanism of non-homogeneous seepage by introducing multi-scale structures, physical constraints, and spatio–temporal fusion [24,52].

- Graph Neural Network model: The Graph Neural Network (GNN) is a class of Deep Learning. GNN models are capable of handling non-Euclidean spatial structure data, which are especially suitable for describing data forms with irregular topology, such as pore networks, fracture systems, well network arrangements, and other complex spatial relationships. In reservoir seepage modeling, GNNs can regard pores or well points as “nodes” in the graph, and their connection relationships (such as flow paths, neighboring wells interference, etc.) as “edges”, and they can extract spatial topological features through graph convolution, message passing, and other mechanisms, so as to model the propagation pattern of the fluid in the complex structure. The topological features are extracted through graph convolution and message passing to model the propagation of fluids in complex structures [53,54,55]. For example, Fu et al. [16] constructed a multi-scale nonlinear seepage simulation model based on Graph Neural Networks for predicting microscopic seepage paths in DCSs. They reconstructed the core CT image into a pore node graph, with node features including pore size, width of connecting channels, etc., and with edge weights representing the infiltration fluxes between neighboring pores. The transfer of physical information between nodes was realized by graph convolution layers and combined with a multilayer message aggregation strategy to predict the local velocity field and saturation evolution process. Experiments showed that the model has strong accuracy and spatial sensitivity in reconstructing microchannel flow paths and identifying residual oil-rich zones.Although the GNN model is still in the preliminary exploration stage in the field of oil and gas engineering, its potential in digital core analysis, fracture network simulation, and spatial coupling prediction has been initially shown [8], and it is expected to be fused with physical modeling, image recognition, and other technologies in the future, to construct a seepage intelligent simulation system with more generalized capability [23].

- Physical information neural network model: Physics-Informed Neural Networks (PINNs) are a class of Deep Learning methods that have emerged in recent years, which embed physical control equations into the neural network training process [56]. Unlike the traditional “physical modeling followed by numerical solution” approach, PINNs transform the control equations (e.g., Darcy’s law, mass conservation equation) into the loss terms of neural networks, so that the model automatically satisfies the basic physical laws while fitting the data [57]. In the field of reservoir seepage, PINNs provide a novel modeling paradigm for prediction, inversion, and continuous field reconstruction of seepage response variables (e.g., pressure, saturation, velocity, etc.), which is especially suitable for problem scenarios with incomplete data, restricted observations, and high nonlinearity. For example, Raissi et al. first systematically proposed the Hidden Fluid Mechanics (HFM) framework, which inverts complete fluid dynamics variables (e.g., pressure, velocity, vorticity, etc.) from partially observable velocity fields based on PINNs. Although this study did not focus on oil reservoirs, the modeling idea of image-variable mapping and physical constraints laid a methodological foundation for the subsequent application of PINNs in seepage [5,58]. Xue et al. [2] introduced the idea of PINNs into the pressure field modeling of inhomogeneous reservoirs and proposed the physics-regularized DNN, which is a methodology to model the pressure field of non-homogeneous reservoirs that enables the model to learn both physical laws and numerical data in the training stage by embedding the residuals of the Darcy flow control equation. Their experiments showed that the PINN model has stronger stability and physical consistency than the traditional DNN in the case of sparse boundary data and complex well control. Yan et al. [21] constructed a complete three-dimensional multiphase seepage PINN model to predict the pressure–saturation evolution process in a non-homogeneous pore medium. They embedded the coupled governing equations of two-phase flow in the loss function and introduced a regular term to constrain the WC evolution trajectory, which significantly improved the smoothness and physical interpretability of the prediction results.PINNs, with their embedded representation of the control equations, provide a new way of thinking for modeling reservoir seepage fields by integrating physical-driven and data-driven approaches. Combined with the research progress of Xue [2], Yan [21], and Raissi et al. [5]., it has been shown that PINNs are not only suitable for pressure and saturation prediction under complex boundary conditions but also show significant advantages in small-sample inverse modeling and continuous field reconstruction [26]. With the development of adaptive weight balancing, multiscale decoupling, and efficient derivation algorithms, PINNs are expected to play a greater role in the intelligent simulation of seepage response in reservoirs with high WCPs [59].

- Multi-modal integration model: In order to improve the generalization ability and physical consistency of the model, researchers have explored Deep Learning integration strategies—such as multi-network structure fusion, physical information embedding, and sample enhancement—in recent years to construct a more adaptive seepage prediction framework [27]. For example, Xue et al. [2] introduced the control equation residuals into the convolutional kernel structure and proposed the Physical Difference CNN (PD-CNN), which balances data-driven accuracy and physical consistency; Guo et al. [3] combined the Unet network with a multi-sample pooling strategy to improve the saturation reconstruction accuracy in low-well-control regions in fractured-block reservoirs; Zhang et al. [28] enhanced the model’s ability to capture the changes of the key time series by fusing the GRU with an attentional mechanism; Jiang et al. [47] proposed a convolutional time-series network (CSN) fusing CNN and LSTM to achieve joint spatio–temporal modeling of the WC rate and pressure field under injection and extraction dynamics [4]. The above work shows that the integrated modeling approach of Deep Learning is gradually evolving from the fusion of structural layers to the multidimensional synergy of physics, data, and mechanism, which has become an important direction for constructing the next-generation intelligent seepage simulation model Table 4.

3.3. Comprehensive Example

- Feature extraction and sample construction. Aiming at the data non-uniformity and production dynamic differences between injection and extraction well sites, Chen et al. designed a temporal–spatial fusion sample organization strategy to standardize the injection and extraction data (e.g., injection intensity, WC, daily oil production, etc.) between wells and construct the sample sequence based on the temporal sliding window in order to maintain the temporal continuity of the data and the spatial consistency of the well group. The Dynamic Sample Pool design enhances the adaptability of the model to data from different production stages and alleviates the problem of “data drift” in high WC areas.

- Construct neural network. In order to better extract the temporal and spatial coupling features in the seepage response variables, Chen et al. proposed a Convolutional Spatio–temporal Network (CSN) structure that integrates a Convolutional Neural Network (CNN) and a Long Short-Term Memory (LSTM) network. The CNN part is used to extract the spatial feature pattern of injection and extraction, the LSTM is used to model the dynamic response of the production parameters over time, and the output of the network contains the predicted values of the key response variables such as pressure and WC. In an actual case of a reservoir, the model jointly predicted the WC and daily fluid production of a typical well group in the next 50 days, and compared with the traditional numerical simulation and shallow neural network methods the CSN performed better, in terms of prediction accuracy and trend fitting, which verified the validity of Deep Learning in predicting the dynamics of reservoirs during high WCPs [34].

3.4. Comparative Framework for Deep Learning Architectures in Seepage Modeling

3.4.1. Analysis of Differences in Mathematical Structures

- FeedForward Neural (FFN) networksMathematical expression:Explanation: purely data-driven layer-by-layer nonlinear transformations with no spatial/temporal structure awareness.Structural Features:FFN networks pass information through multiple fully connected layers (Dense Layer) step by step, and each layer applies a nonlinear activation function (e.g., ReLU, Siqmoid) to the inputs after a linear transformation (weight matrix W with bias b), which are essentially higher-order nonlinear function fitters capable of capturing complex mapping relationships between input features and target variables.Limitations in seepage field applications:(i) Blind-box modeling: FFN networks rely on end-to-end data-driven modeling and lack explicit encoding of spatial topology or physical laws, leading to unphysical results (e.g., negative pressure regions) when predicting continuous fields (e.g., pressure distributions); (ii) Scenario adaptation: suitable for single-point parameter prediction (e.g., WC in a single well), but low reconstruction resolution due to neglect of local spatial correlations when dealing with gridded field data [10].

- Convolutional Neural Networks, CNNsMathematical expression:Explanation: extraction of local spatial features by convolution kernel for gridded data (e.g., permeability field images).Structural features:CNNs extract local spatial features by sliding convolutional kernels (e.g., 3 × 3 filters) and realize feature dimensionality reduction and translation invariance by using a Pooling operation (Pooling). A CNN’s local sensing mechanism is naturally adapted to gridded data (e.g., permeability field images) and is capable of capturing spatial patterns such as inter-well disturbances and hyper-permeable channels.Advantages in seepage field applications:(i) “Pictorial” modeling: Treating the seepage field as a 2D/3D image, spatial heterogeneity can be automatically identified by convolution kernels (e.g., saturation field reconstruction in Guo et al. [3]); (ii) Potential for physical customization: By designing specific convolutional kernels (e.g., difference kernels), physical laws (e.g., Darcy’s law gradient computation) can be partially embedded to improve the consistency of predictions (e.g., PD-CNN in Xue et al. [2]).

- Graph Neural Networks, GNNsMathematical expression:Explanation: processing of non-Euclidean spatial data (e.g., fractured networks) by node aggregation (Aggregation) and message passing (Message Passing).Structural features:GNNs abstract the seepage system as a graph structure (nodes = wells/pores, edges = flow paths) and dynamically update the node states through Message Passing and node aggregation (Aggregation). Their non-Euclidean data-processing capability is particularly suitable for describing complex topologies such as fracture networks and unstructured grids.Uniqueness in seepage field applications:(i) “Social network” modeling: Similar to the propagation of user relationships in social networks, GNNs simulate fluid flow paths along a fracture or pore network (e.g., the microscopic seepage simulation of Fu et al. [16]); (ii) Multi-scale fusion: The macroscopic well network layout and microscopic pore structure can be encoded simultaneously to realize cross-scale seepage coupling (Zhang et al. [18] for fracture–matrix interaction modeling).

- Physics-Informed Neural Networks, PINNsMathematical expression:Explanation: embedding control equation residuals (e.g., Darcy’s law) in the loss function enforces physical consistency.Structural Features:PINNs explicitly introduce the residuals of control equations, e.g., the mass conservation equation () = Q) in the loss function, and they harmonize data-driven and physical constraints through a dual-loss equilibrium mechanism ().Revolutionary in seepage field applications Table 5:(i) “Equations as constraints”: Reconstructing full-field variables from partial boundary conditions without complete observations (e.g., Raissi et al. [5], inverting pressure distributions from flow velocity fields); (ii) Small sample size: In data-scarce scenarios (e.g., exploration of new blocks), physical approximation significantly improves generalization (e.g., Xue et al. [2], 40% error reduction at 10% sample size).

3.4.2. Capacity Boundary Matrix

- Capacity to deal with spatial and temporal dependencies:The ability of Deep Learning models to process spatio–temporal data directly determines their applicability in seepage field prediction. FeedForward Neural (FFN) networks, as an infrastructure, only process independent sample points through a fully connected layer and lack explicit modeling of spatial correlations or temporal evolution (Hussen et al. [10]). For example, in single-well pressure prediction, although FFN networks can capture wellbore dynamics, they cannot reconstruct the pressure gradient between wells, resulting in distorted global field predictions. In contrast, Convolutional Neural Networks (CNNs) extract local spatial features by sliding convolutional kernels, which are naturally adapted to gridded data. Guo et al. [3] successfully reconstructed a 3D saturation field of a complex fracture-block reservoir using 3D CNNs, which was critically dependent on the spatial perception mechanism of the convolutional kernel to identify hyper-permeable channels and hypo-permeable barriers. Graph Neural Networks (GNNs) further break through the Euclidean spatial limitation by abstracting the fracture network as a topology of nodes and edges, which simulates the flow path of fluid in an unstructured medium through message passing (Fu et al. [16]). Physical Information Neural Networks (PINNs), on the other hand, directly characterize the spatio–temporal continuous evolution of field variables by embedding the governing equations, e.g., Raissi et al. [5] inverted the full-field pressure distribution based on partial flow rate observations only.

- Physical constraint embedding capability:The incorporation of physical laws is the key to improving the reasonableness of model predictions. FeedForward Neural (FFN) networks, as purely data-driven models, rely solely on the statistical laws of the training data and are prone to produce results that violate mass conservation or Darcy’s law (e.g., negative pressure prediction). Convolutional Neural Networks (CNNs) can be partially embedded with physical laws beforehand by customized convolution kernels, such as the Physical Difference Convolution Neural Network (PD-CNN) kernel designed by Xue et al. [2], which incorporates the residuals of Darcy’s equation in finite difference form into the convolution operation, so as to make the prediction results satisfy the conservation of mass. Graph Neural Networks (GNNs), on the other hand, encode physical connectivity relations through the natural properties of graph structures: in Fu et al.’s [16] microscopic seepage model, pore nodes are characterized by containing geometric parameters (e.g., aperture diameter, curvature), and edge weights characterize the flow impedance to implicitly satisfy Darcy–Weisbach equations. Physical Information Neural Networks (PINNs) are “hard” physically driven by directly constraining the residuals of the control equations through loss functions. For example, Xue et al. [2] forced the partial differential equations for single-phase seepage during training, allowing the model to remain physically consistent (violation rate < 5%) with only 10% of the observed data.

- Small sample generalization capability:Data scarcity is a common challenge in oilfield development, and the small-sample fitness of different models varies significantly. FeedForward Neural (FFN) networks require more than 10,000 sets of samples to avoid overfitting due to the large number of parameters and lack of inductive bias (Hussen et al. [10]). Convolutional Neural Networks (CNNs) reduce the number of parameters through local weight sharing, but they still require at least 5000 labeled images to capture spatial patterns (Guo et al. [3]). Graph Neural Networks (GNNs) benefit from the ability to generalize topology and require only 1000 sets of graph structure samples to model fracture network flows (Fu et al. [16]). Physical Information Neural Networks (PINNs) can achieve field predictions with an error of <10% with 500 samples (Xue et al. [2]) through the regularization of the physics equations, and they are particularly suitable for scenarios where new blocks are being explored or where experimental data are limited Table 6.

- Computational efficiency:The efficiency of model computation has a direct impact on engineering utility. FeedForward Neural (FFN) networks are suitable for real-time monitoring tasks due to their simple and highly parallelized structure, which can be trained on NVIDIA V100 GPUs in 2.1 h (Hussen et al. [10]). The 3D convolutional operation of Convolutional Neural Networks (CNNs) increases the computational effort but can still be trained in 5.3 h with CUDA optimization (Guo et al. [3]). Graph Neural Networks (GNNs) take up to 8.7 h to train due to the irregular data access pattern of the graph structure (Fu et al. [16]), and they need to be accelerated by specialized graph computing libraries (e.g., DGL). Physical Information Neural Networks (PINNs) take up to 12.5 h (Xue et al. [2]) to train due to the need to compute higher-order derivatives (e.g., the second-order gradient of the pressure field) at high frequencies, and they usually require distributed training or mixed-accuracy optimization.

- Typical application scenarios Table 7:FFN networks: Scenarios: single well water content prediction (Hussen et al. [10]); core porosity regression (Hong et al. [20]).Advantage: simple and efficient, suitable for low-dimensional mapping tasks.CNNs: Scenarios: 2D permeability field reconstruction Table 8 (Guo et al. [3]); digital core two-phase flow simulation (Telvari et al. [23]).Strengths: spatial pattern extraction; adaptation to pictorial data.GNNs: Scenarios: fracture network flow simulation (Fu et al. [16]); well network connectivity optimization (Raissi et al. [29]).Strengths: unstructured topology modeling; multi-scale coupling.PINNs: Scenarios: control equation inversion (Raissi et al. [5]); small sample pressure field prediction (Xue et al. [2]).Strengths: physical consistency guarantees; few-sample generalization.

3.4.3. Model Selection Decision Tree

- Initial judgment: are there enough data?Sufficient data (yes): Enter real-time requirements analysis for scenarios with well-developed historical databases or rich experimental data (e.g., long-term monitoring data from mature oil fields).Insufficient data (No): Enter data structure analysis, applicable to the early stage of exploration or scenarios with high experimental costs (e.g., small amount of logging data in new areas of unconventional reservoirs).

- Data-sufficient branching: is high real time required?Need high real-time performance (yes): Choose FFN (FeedForward Neural) network or CNN (Convolutional Neural Network)Applicable Scenario:Real-time monitoring of production parameters in a single well (FFN: Hussen et al. [5])Dynamic visualization of injection response (CNN: Wang et al. [15])Technical Advantage: An FFN/CNN has a simple structure and high computational efficiency, can complete the prediction in seconds, and is adapted to the deployment of edge devices.No need for high real time (No): Access to field continuity judgment; suitable for medium-to-long-term development scenario optimization or research-level simulation tasks.

- Field continuity judgment: is the predicted target a spatio–temporally continuous field? Field continuity (Yes): Select PINNs (Physically Informed Neural Networks)Applicable Scenario:Dynamic evolution of pressure field (Xue et al. [2])Coupled multi-phase flow simulation (Yan et al. [21])Technical Advantage: PINNs guarantee physical consistency by embedding control equations (e.g., Darcy’s law) and are suitable for mathematical modeling of continuous fields.Field discontinuity (no): Selection of GNN (Graph Neural Network)Applicable scenarios:Fracture network flow path identification (Fu et al. [16])Unstructured grid seepage analysis (Chen et al. [59])Technical Advantage: GNNs are naturally adapted to discrete and non-homogeneous scenarios through topological relationship modeling.

- Insufficient data branching: is the structure non-Euclidean? Structure is non-Euclidean (yes): Select GNN (Graph Neural Network)Applicable Scenario:Digital core pore-level flow simulation (Chen et al. [4])Modeling of inter-well interference relations (Zhang et al. [18])Technical advantage: GNNs utilize graph structure to encode complex connectivity relationships and maintain high generalization ability with few samples.Structure Euclidean (No): Selection of PINNs (Physically Informed Neural Networks)Applicable Scenarios:Small sample pressure field inversion (Raissi et al. [5])Permeability estimation based on sparse observations (Xue et al. [2])Technical advantage: PINNs significantly reduce the dependence on data volume by regularizing the physics equations.

4. Future Directions for Technology

4.1. Real-Time Prediction and Closed-Loop Optimization Control

- Data level: Based on the Dynamic Sample Pool (DSP) architecture proposed by Telvari et al. [23], feature extraction and prioritization of high-frequency monitoring data streams are realized through the sliding time window mechanism. The migration learning framework developed by Wang et al. [15] is further integrated to construct an incremental sample pool updating strategy to solve the cold-start and small-sample learning problems [25].

- Algorithmic level: The sample space expansion method proposed by Mouketou et al. [54] in Generative Adversarial Networks (GANs) is introduced to compensate for the missing data segments in the process of injection and mining adjustment through the generative adversarial mechanism, and, at the same time, coupling the production optimization algorithms (e.g., gradient descent method, reinforcement learning) with the feedback control theory, to establish a quantitative response function for the adjustment of injection and mining parameters [50].

- System level: Drawing on the closed-loop optimization paradigm of Chen et al. [4], the above method is embedded into the control chain of “monitoring-prediction-decision-execution”, and the parameters of the seepage prediction model are dynamically corrected through the real-time WC feedback (error tolerance < 5%), forming an adaptive optimization mechanism [4].

- Inheriting the real-time data capture capability of DSP architecture, and solving the generalization problem of cross-reservoir samples through migration learning.

- Integrating the adversarial generation mechanism to effectively mitigate model oscillations caused by sudden changes in injection and recovery parameters.

- Constructing a feedback control module with physical constraints to ensure that the optimization results comply with the seepage mechanics.

4.2. Multi-Source Data Fusion and Enhanced Expressive Power

4.3. Physical Consistency Modeling and Interpretability Enhancement

4.4. Model Migration Capabilities and Online Adaptive Updates

5. Conclusions

- (1)

- Paradigm shift in seepage-prediction technology: The evolution of reservoir seepage prediction has undergone three distinct phases: from physics-based analytical models to data-driven Machine Learning approaches, culminating in the current paradigm of physics-informed Deep Learning systems. This progression reflects the oil industry’s growing demand for intelligent solutions to address the complex nonlinear dynamics of high-water cut reservoirs. Deep Learning architectures (CNNs, GNNs, PINNs) demonstrate superior capability in modeling multiphase flow heterogeneities compared to traditional numerical simulations (FDM/FVM), achieving >85% accuracy in saturation field reconstruction under low well-control conditions [3,15]. The integration of Deep Learning mechanisms with governing equations (e.g., Darcy’s law, mass conservation) enables these models to maintain physical consistency while capturing complex spatial–temporal patterns.

- (2)

- Current implementation landscape: Practical implementations reveal distinct architectural advantages: • CNN-based models achieve 92.4% accuracy in inter-well pressure gradient prediction through 3D convolutional feature extraction [2]; • PINN frameworks reduce pressure field inversion errors to <8% under sparse data conditions (n = 500 samples) [5]; • GNN solutions enable fracture network flow simulations with 15% faster convergence than conventional discrete fracture models [16]. Case studies in Daqing and Shengli oilfields demonstrated 20–35% improvement in remaining oil recovery rates through Deep Learning-driven injection optimization [4,25].

- (3)

- Strategic development pathways: Four critical frontiers emerge for next-generation intelligent systems:

- Real-time closed-loop control: Integrating edge-computing optimized CNNs (inference time < 50 ms) with IoT sensor networks enables dynamic waterflood adjustment. The DSP-XGBoost framework achieved 92.7% real-time decision accuracy in pilot tests [25].

- Multimodal data fusion: Transformer-based architectures incorporating seismic attributes, production logs, and core CT images improve heterogeneity characterization accuracy by 40% compared to single-modality models [30].

- Cross-domain adaptability: Meta-learning enhanced models maintain >80% prediction accuracy when transferred between carbonate and sandstone reservoirs, significantly reducing recalibration costs [35].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dou, L.; Wen, Z.; Wang, J.; Wang, Z.; He, Z.; Liu, X. Analysis of the World Oil and Gas Exploration Situation in 2021. Pet. Explor. Dev. 2022, 49, 1195–1209. [Google Scholar] [CrossRef]

- Xue, L.; Zhao, Z.; Liu, H.; Xu, Z. A physics-regularized deep neural network for pressure field prediction in heterogeneous reservoirs. SPE J. 2022, 27, 2741–2753. [Google Scholar]

- Guo, Q. Establishment of sample pool and prediction of saturation field in complex fault block reservoir based on deep learning algorithm. Geoenergy Sci. Eng. 2023, 225, 211654. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, Y.; Meng, F.; Zhao, H.; Zhan, W. A deep learning-based convolutional spatiotemporal network proxy model for reservoir production prediction. Phys. Fluids 2024, 36, 087124. [Google Scholar] [CrossRef]

- Raissi, M.; Yazdani, A.; Karniadakis, G.E. Hidden fluid mechanics: Learning velocity and pressure fields from flow visualizations. Science 2020, 367, 1026–1030. [Google Scholar] [CrossRef]

- Beiranvand, B.; Rajaee, T. Application of artificial intelligence-based single and hybrid models in predicting seepage and pore water pressure of dams: A state-of-the-art review. Adv. Eng. Softw. 2022, 173, 103268. [Google Scholar] [CrossRef]

- Nourani, V.; Behfar, N.; Dabrowska, D.; Zhang, Y. The applications of soft computing methods for seepage modeling: A review. Water 2021, 13, 3384. [Google Scholar] [CrossRef]

- Qi, G.; Lixin, M. Evaluation and Reconstruction of Reservoir Seepage Field in High Water Cut Stage Based on Seepage Characteristics Analysis. J. Pet. Explor. Prod. Technol. 2019, 9, 417–426. [Google Scholar] [CrossRef]

- Hou, W.; Wen, Y.; Deng, G.; Zhang, Y.; Wang, X. A multi-target prediction model for dam seepage field. Front. Earth Sci. 2023, 11, 1156114. [Google Scholar] [CrossRef]

- Hussen, A.; Munshi, T.A.; Jahan, L.N.; Hashan, M. Advanced machine learning approaches for predicting permeability in reservoir pay zones based on core analyses. Heliyon 2024, 10, e32666. [Google Scholar] [CrossRef]

- Anifowose, F.; Labadin, J.; Abdulraheem, A. Ensemble machine learning: An untapped modeling paradigm for petroleum reservoir characterization. J. Pet. Sci. Eng. 2017, 151, 480–487. [Google Scholar] [CrossRef]

- Otchere, D.A.; Ganat, T.O.A.; Gholami, R.; Ridha, S. Application of supervised machine learning paradigms in the prediction of petroleum reservoir properties: Comparative analysis of ANN and SVM models. J. Pet. Sci. Eng. 2021, 200, 108182. [Google Scholar] [CrossRef]

- Garsole, P.A.; Bokil, S.; Kumar, V.; Pandey, A.; Topare, N.S. A review of artificial intelligence methods for predicting gravity dam seepage, challenges and way-out. AQUA—Water Infrastruct. Ecosyst. Soc. 2023, 72, 1228–1244. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, Z.; Yang, J. Inversion model for permeability coefficient based on Random Forest–Secretary Bird Optimization algorithm: Case study of lower reservoir of C-pumped storage power station. Water 2024, 16, 3096. [Google Scholar] [CrossRef]

- Wang, X.; Jia, Z. Porous Media Model of Reservoir Considering Seepage Stress Coupling and Seepage Field Analysis. Geofluids 2023, 2023, 3759667. [Google Scholar] [CrossRef]

- Fu, Y.; Zhai, Q.; Yuan, G.; Wang, Z.; Cheng, Y.; Wang, M.; Wu, W.; Ni, G. Multi-scale nonlinear reservoir flow simulation based on digital core reconstruction. Geoenergy Sci. Eng. 2024, 242, 213218. [Google Scholar] [CrossRef]

- Brunton, S.L.; Noack, B.R.; Koumoutsakos, P. Physics-Informed Neural Networks for Fluid Mechanics: A Review. Annu. Rev. Fluid Mech. 2020, 52, 477–508. [Google Scholar] [CrossRef]

- Zhang, W.W.; Wang, X.; Kou, J.Q. Prospects of Multi-Paradigm Fusion Research for Fluid Mechanics. Adv. Mech. 2023, 53, 433–467. (In Chinese) [Google Scholar] [CrossRef]

- Wong, J.C.; Ooi, C.C.; Gupta, A.; Ong, Y.-S. Learning in Sinusoidal Spaces With Physics-Informed Neural Networks. IEEE Trans. Artif. Intell. 2024, 5, 985–1000. [Google Scholar] [CrossRef]

- Hong, Y.; Li, S.; Wang, H.; Liu, P.; Cao, Y. Quantitative prediction of rock pore-throat radius based on deep neural network. Energies 2023, 16, 7277. [Google Scholar] [CrossRef]

- Yan, B.; Harp, D.R.; Chen, B.; Pawar, R. A physics-constrained deep learning model for simulating multiphase flow in 3D heterogeneous porous media. Fuel 2022, 313, 122693. [Google Scholar] [CrossRef]

- Qian, C.; Xie, Y.; Zhang, X.; Zhou, R.; Mou, B. Study on numerical simulation of gas–water two-phase micro-seepage considering fluid–solid coupling in the cleats of coal rocks. Energies 2024, 17, 928. [Google Scholar] [CrossRef]

- Telvari, S.; Sayyafzadeh, M.; Siavashi, J.; Sharifi, M. Prediction of two-phase flow properties for digital sandstones using 3D convolutional neural networks. Adv. Water Resour. 2023, 176, 104442. [Google Scholar] [CrossRef]

- Liu, C.; Feng, Q.; Zhou, W.; Li, S.; Zhang, X. Infill well location optimization method based on recoverable potential evaluation of remaining oil. Energies 2024, 17, 3492. [Google Scholar] [CrossRef]

- Zhang, W.W.; Noack, B.R. Artificial Intelligence in Fluid Mechanics. Acta Mech. Sin. 2021, 37, 1715–1717. [Google Scholar] [CrossRef]

- Haghighat, E.; Raissi, M.; Moure, A.; Gomez, H.; Juanes, R. A deep learning framework for solution and discovery in solid mechanics. Nat. Commun. 2020, 11, 4601. [Google Scholar]

- Sharma, R.; Raissi, M.; Guo, Y.B. Physics-informed machine learning for smart additive manufacturing. arXiv 2024, arXiv:2407.10761. [Google Scholar]

- Zhang, X.L.; Liu, Y.; He, G.W. Ensemble Kalman Method and Its Applications in Turbulence Modelling. Aerodyn. Res. Exp. 2023, 1, 34–44. (In Chinese) [Google Scholar]

- Raissi, M. Deep Hidden Physics Models: Deep Learning of Nonlinear Partial Differential Equations. J. Mach. Learn. Res. 2018, 19, 1–24. [Google Scholar]

- Song, H.Q.; Du, S.Y.; Wang, J.L.; Lao, J.M.; Xie, C.Y. Development of Digital Intelligence Fluid Dynamics and Applications in the Oil & Gas Seepage Fields. Chin. J. Theor. Appl. Mech. 2023, 55, 765–791. (In Chinese) [Google Scholar] [CrossRef]

- Cuomo, S.; Di Cola, V.S.; Giampaolo, F.; Rozza, G.; Raissi, M.; Piccialli, F. Scientific Machine Learning Through Physics–Informed Neural Networks: Where We Are and What’s Next. J. Sci. Comput. 2022, 92, 88. [Google Scholar] [CrossRef]

- Raissi, M.; Babaee, H.; Givi, P. Deep Learning of Turbulent Scalar Mixing. Phys. Rev. Fluids 2019, 4, 124501. [Google Scholar] [CrossRef]

- Almajid, M.M.; Abu-Al-Saud, M.O. Prediction of Porous Media Fluid Flow Using Physics Informed Neural Networks. J. Pet. Sci. Eng. 2022, 208 Pt A, 109205. [Google Scholar] [CrossRef]

- Rudy, S.H.; Brunton, S.L.; Proctor, J.L.; Kutz, J.N. Data-Driven Discovery of Partial Differential Equations. Sci. Adv. 2017, 3, e1602614. [Google Scholar] [CrossRef] [PubMed]

- Raissi, M.; Perdikaris, P.; Ahmadi, N.; Karniadakis, G.E. Physics-Informed Neural Networks and Extensions. arXiv 2024, arXiv:2408.16806. [Google Scholar]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Multistep Neural Networks for Data-Driven Discovery of Nonlinear Dynamical Systems. arXiv 2018, arXiv:1801.01236. [Google Scholar] [CrossRef]

- Al-Amri, M.A.; Mahmoud, M.N.; Al-Yousef, H.Y.; Al-Ghamdi, T.M. Integrated Petrophysical and Reservoir Characterization Workflow to Enhance Permeability and Water Saturation Prediction. J. Afr. Earth Sci. 2017, 131, 105–116. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.; Wei, H. Modified UNet with Attention Gate and Dense Skip Connection for Flow Field Information Prediction with Porous Media. Flow Meas. Instrum. 2023, 89, 102300. [Google Scholar] [CrossRef]

- Kuang, L.; He, L.I.U.; Yili, R.E.N.; Kai, L.U.O.; Mingyu, S.H.I.; Jian, S.U.; Xin, L.I. Application and Development Trend of Artificial Intelligence in Petroleum Exploration and Development. Pet. Explor. Dev. 2021, 48, 1–14. [Google Scholar] [CrossRef]

- Wang, Q.; Ji, M.; Liu, G.; Fan, S. Multi-Field Coupled Mathematical Modeling and Numerical Simulation Technique of Gas Transport in Deep Coal Seams. Adv.-Geo-Energy Res. 2025, 15, 87–90. [Google Scholar] [CrossRef]

- Lv, S.; Li, D.; Zha, W.; Xing, Y. Physics-Informed Radial Basis Function Neural Network for Efficiently Modeling Oil–Water Two-Phase Darcy Flow. Phys. Fluids 2025, 37, 013605. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, C.; Liu, Y.; Zhang, Z.; Chen, P.; Jiang, L. Machine learning in reservoir engineering: A review. Processes 2024, 12, 1219. [Google Scholar] [CrossRef]

- Ao, Y.; Lu, W.; Hou, Q.; Jiang, B. Sequence-to-Sequence Borehole Formation Property Prediction via Multi-Task Deep Networks with Sparse Core Calibration. J. Pet. Sci. Eng. 2022, 208, 109637. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Zhou, F.; Li, X.; Liu, Y.; Zhou, J.; Liu, T. The Practice and Understanding of Reconstructing the Flow Field by the Homogenization-Flowline Method. IOP Conf. Ser. Earth Environ. Sci. 2019, 358, 032003. [Google Scholar] [CrossRef]

- Paterson, L. Radial Fingering in a Hele Shaw Cell. J. Fluid Mech. 1981, 113, 513–529. [Google Scholar] [CrossRef]

- Aifa, T. Neural network applications to reservoirs: Physics-based models and data models. J. Pet. Sci. Eng. 2014, 123, 1–6. [Google Scholar] [CrossRef]

- Jiang, C.; Liu, Q.; Leng, K.; Zhang, Z.; Chen, X.; Wu, T. The Temporal and Spatial Evolution of Flow Heterogeneity During Water Flooding for an Artificial Core Plate Model. Energies 2025, 18, 309. [Google Scholar] [CrossRef]

- Abdelazim, R.; Rahman, S.S. Estimation of permeability of naturally fractured reservoirs by pressure transient analysis: An innovative reservoir characterization and flow simulation. J. Pet. Sci. Eng. 2016, 145, 404–422. [Google Scholar] [CrossRef]

- Liu, W.; Lv, X.C.; Shen, B. Forward Modeling of Tight Sandstone Permeability Based on Mud Intrusion Depth and Its Application in the South of the Ordos Basin. Appl. Geophys. 2021, 18, 277–287. [Google Scholar] [CrossRef]

- Luna, P.; Hidalgo, A. Numerical Approach of a Coupled Pressure–Saturation Model Describing Oil–Water Flow in Porous Media. Commun. Appl. Math. Comput. 2023, 5, 946–964. [Google Scholar] [CrossRef]

- Xue, L.; Liu, P.; Zhang, Y. Status and prospect of improved oil recovery technology of high water cut reservoirs. Water 2023, 15, 1342. [Google Scholar] [CrossRef]

- Yu, C.; Deng, S.C.; Li, H.B.; Li, J.C.; Xia, X. The anisotropic seepage analysis of water-sealed underground oil storage caverns. Tunn. Undergr. Space Technol. 2013, 38, 26–37. [Google Scholar] [CrossRef]

- Li, Y.; Liu, D.; Zhao, L.; Wang, R.; Xu, H.; Liu, L.; Si, Y. Research on flow field reconstruction of complex fault-block reservoir during ultra-high water cut period. Discov. Appl. Sci. 2024, 7, 39. [Google Scholar] [CrossRef]

- Mouketou, F.N.; Kolesnikov, A. Modelling and simulation of multiphase flow applicable to processes in oil and gas industry. Chem. Prod. Process Model. 2019, 14, 20170066. [Google Scholar] [CrossRef]

- Yu, G.; Xu, F.; Cui, Y.; Li, X.; Kang, C.; Lu, C.; Du, S. A new method of predicting the saturation pressure of oil reservoir and its application. Int. J. Hydrogen Energy 2020, 45, 30244–30253. [Google Scholar] [CrossRef]

- Deng, R.; Dong, J.; Dang, L. Numerical simulation and evaluation of residual oil saturation in waterflooded reservoirs. Fuel 2025, 384, 134018. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Y.; Zhang, L.; Zhang, Q.; Guo, Z.; Wang, B.; Sun, T. Remaining oil distribution characteristics in an oil reservoir with ultra-high water-cut. Energy Geosci. 2024, 5, 100116. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, Z.; Qu, G.; Zhi, J.; Zhang, R. Distribution characteristics of micro remaining oil of class III reservoirs after fracture flooding in Daqing oilfield. Energies 2022, 15, 3385. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Deng, L.; Yan, J.; Gong, C.; Yang, B.; Liu, J. Towards a new paradigm in intelligence-driven computational fluid dynamics simulations. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2407005. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, J.; Li, Y.; Wu, L.; Qiao, M. Recent development of smart field deployment for mature waterflood reservoirs. Sustainability 2023, 15, 784. [Google Scholar] [CrossRef]

- Abbassi, F.; Karrech, A.; Islam, M.S.; Seibi, A.C. Poromechanics of fractured/faulted reservoirs during fluid injection based on continuum damage modeling and machine learning. Nat. Resour. Res. 2023, 32, 413–430. [Google Scholar] [CrossRef]

- Tang, D.; Yin, T.; Xiao, Z.; Jiang, Z.; Li, Y. Development of a Modeling Tool to Assess Seepage Management Options for Large-Scale Water-Sealed Oil Storage Caverns. Environ. Earth Sci. 2021, 80, 652. [Google Scholar] [CrossRef]

- Amini, D.; Haghighat, E.; Juanes, R. Inverse modeling of nonisothermal multiphase poromechanics using physics-informed neural networks. J. Comput. Phys. 2023, 490, 112323. [Google Scholar] [CrossRef]

- Li, D.; Sun, L.; Zhang, W.; Liu, X.; Tang, J. Physics-constrained deep learning for solving seepage equation. J. Pet. Sci. Eng. 2021, 206, 109046. [Google Scholar]

- Zhang, X.L.; Xiao, H.; He, G. Assessment of regularized ensemble Kalman method for inversion of turbulence quantity fields. AIAA J. 2022, 60, 3–13. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-Informed Deep Learning II: Data-Driven Discovery of Nonlinear Partial Differential Equations. arXiv 2017, arXiv:1711.10566. [Google Scholar] [CrossRef]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Distributed Systems. arXiv 2015, arXiv:1603.04467. [Google Scholar]

- Wu, Z.; Fan, D.W.; Zhou, Y. Advances in control of turbulence by artificial intelligence: Systems, algorithms, achievements and data analysis methods. Adv. Mech 2023, 53, 273. [Google Scholar]

- Banerjee, C.; Nguyen, K.; Fookes, C.; Raissi, M. A Survey on Physics-Informed Reinforcement Learning: Review and Open Problems. IEEE Trans. Pattern Anal. Mach. Intell. 2023; 1–28, early access. [Google Scholar]

| Model Type | Applicable Scenarios | Numerical Method Examples |

|---|---|---|

| Black oil model | Conventional three-phase drive systems | FDM, FVM |

| Component model | Multi-component scenarios such as gas drive/volatile reservoirs | FVM, FEM |

| Fiducia model | Unconventional reservoirs such as shale and tight oil reservoirs | Forchheimer–FEM |

| Method | Advantages | Disadvantages |

|---|---|---|

| Traditional method | Good physical consistency, strict adherence to conservation laws, and strong interpretability; suitable for theoretical deduction and program design in the early development stage. | Its performance is limited in dealing with nonlinear seepage response and complex working conditions (such as non-homogeneous, fracture, fracture block, and complex well network perturbation) in high-water-bearing periods, and it often needs to simplify the assumptions, which results in the prediction accuracy being limited by the completeness and accuracy of the physical parameter acquisition. |

| Deep Learning | With its data-driven core, it can effectively learn complex input–output relationships through automatic feature extraction and nonlinear mapping capability, which is especially suitable for modeling seepage response during high WCPs and the later dynamic adjustment stage. | The underlying model is a “black box” structure that does not allow for a clear understanding of the causal reasoning processes involved. |

| Year | Author | Network Type | Scenario | Model |

|---|---|---|---|---|

| 2017 | Anifowose et al. [11] | FeedForward NN | Petrophysical modeling | Ensemble ANN |

| 2021 | Hussen et al. [10] | FeedForward NN | Core-based permeability | MLP |

| 2023 | Hong et al. [20] | FeedForward NN | Pore-throat prediction | DNN |

| 2022 | Yan et al. [21] | Convolutional NN | Multiphase field prediction | CNN + PDE |

| 2023 | Telvari et al. [23] | Convolutional NN | Digital rock two-phase flow | 3D CNN |

| 2024 | Liu et al. [24] | Convolutional NN | Mud invasion depth prediction | CNN + Regression |

| 2021 | Otchere et al. [12] | Time-series NN | Lithology parameter modeling | RNN + SVM |

| 2023 | Garsole et al. [13] | Time-series NN | Dam seepage sequence modeling | AutoML–LSTM |

| 2024 | Qian et al. [22] | Time-series NN | Gas–water microseepage simulation | LSTM |

| 2023 | Wang et al. [15] | Graph NN | Well pattern optimization | Production-GNN |

| 2023 | Zhang et al. [18] | Graph NN | Connectivity-based flow simulation | Graph Topology Net |

| 2024 | Fu et al. [16] | Graph NN | Multi-scale heterogeneity modeling | GraphSAGE |

| 2020 | Raissi et al. [5] | Physics-Informed NN | Hidden fluid mechanics | PINN |

| 2022 | Xue et al. [2] | Physics-Informed NN | Pressure prediction in porous media | PR-DNN |

| 2023 | Wong et al. [19] | Physics-Informed NN | Sinusoidal-space learning | Sin-PINN |

| 2023 | Guo et al. [3] | Multimodal NN | Saturation prediction from seismic + logs | Sample Pool + Fusion |

| 2024 | Ma et al. [14] | Multimodal NN | Permeability coefficient inversion | RF–SBO Hybrid |

| 2024 | Chen et al. [4] | Multimodal NN | Spatio–temporal production prediction | CSTN (CNN + LSTM) |

| Year | Author(s) | Application Target | Problem Addressed | Model Used |

|---|---|---|---|---|

| 2021 | Otchere et al. [12] | Production forecast | Oil production sequence modeling | RNN–SVM |

| 2023 | Garsole et al. [13] | Production forecast | Dam seepage sequence prediction | AutoML–LSTM |

| 2024 | Chen et al. [4] | Production forecast | Coupled spatio–temporal modeling | CSTN (CNN–LSTM) |

| 2020 | Raissi et al. [5] | Pressure field | Reconstruction from velocity data | PINNs |

| 2022 | Xue et al. [2] | Pressure field | Prediction in heterogeneous media | Physics-Reg. DNN |

| 2023 | Wong et al. [19] | Pressure field | Learning in sinusoidal domain | Sinusoidal PINN |

| 2022 | Yan et al. [21] | Saturation field | 3D multiphase saturation modeling | CNN + PDE loss |

| 2023 | Telvari et al. [23] | Saturation field | Two-phase prediction in digital core | 3D CNN |

| 2023 | Guo et al. [3] | Saturation field | Fault block saturation mapping | CNN–Attention Fusion |

| 2017 | Anifowose et al. [11] | Porosity/permeability | Log-based property modeling | Ensemble ANN |

| 2021 | Hussen et al. [10] | Permeability | Core-based prediction | MLP |

| 2023 | Hong et al. [20] | Pore-throat radius | Prediction from image data | DNN |

| 2021 | Liu et al. [24] | Microscale seepage | Mud invasion in tight sandstone | CNN + Regression |

| 2023 | Qian et al. [22] | Microscale seepage | Micro gas–water flow in cleats | LSTM |

| 2024 | Fu et al. [16] | Microscale seepage | Multiscale nonlinear flow | Graph-based CNN |

| 2022 | Wang et al. [15] | Well network modeling | Optimization of injection–production layout | Graph NN |

| 2023 | Zhang et al. [18] | Well network modeling | Flow reconstruction via mesh graph | GNN with topology |

| 2024 | Ma et al. [11] | Connectivity classification | Classification by optimization | RF–SBO Hybrid |

| 2023 | Hussen et al. [10] | Multimodal permeability | Core–log data fusion prediction | ANN–RF |

| 2023 | Guo et al. [3] | Multimodal saturation | Seismic–log fusion for saturation | Sample Pool + CNN |

| 2024 | Chen et al. [4] | Multimodal proxy modeling | Dynamic modeling from mixed input | CSTN + Fusion Block |

| Model | Structural Implication | Data Dependency | Physics Integration |

|---|---|---|---|

| FFN | Black-box function approximator | High | None |

| CNN | Spatial feature extractor | Medium | Convolution-based scheme |

| GNN | Relationship expansion analyzer | Low | Graph structure encoding physics linkage |

| PINNs | Physics equation solver | Very low | Loss function physics constraint |

| Model Type | Study Example | MSE (Pressure Field) | Physics Violation Rate | Training Time (h) | Data Requirement |

|---|---|---|---|---|---|

| FFN | Hussen et al. [10] | 0.32 | 28% | 2.1 | High |

| CNN | Guo et al. [3] | 0.18 | 15% | 5.3 | Medium |

| GNN | Fu et al. [16] | 0.12 | 8% | 8.7 | Low |

| PINNs | Xue et al. [2] | 0.09 | <5% | 12.5 | Very Low |

| Model Type | Typical Application |

|---|---|

| FFN | Single-point parameter prediction (Wellhead Pressure/WC) |

| CNN | 2D permeability field reconstruction |

| GNN | Simulation of multiphase flow in fractured reservoirs |

| PINNs | Inversion of PDE with continuous field reconstruction |

| Model Type | Spatio–Temporal Processing | Physics Constraint | Small Sample Generalization | Computational Efficiency |

|---|---|---|---|---|

| FFN | × | × | × | ★★★★ |

| CNN | Spatial locality | Δ (custom kernel) | × | ★★★ |

| GNN | Unstructured relationships | ✓ | ✓ | ★★ |

| PINNs | Spatio–temporal continuity | ✓✓✓ | ✓ | ★ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Liu, Q.; Wang, Y.; Xu, Y.; Shi, J.; Yao, Y.; Chen, Q.; Liang, J.; Tang, S. Research Progress and Technology Outlook of Deep Learning in Seepage Field Prediction During Oil and Gas Field Development. Appl. Sci. 2025, 15, 6059. https://doi.org/10.3390/app15116059

Wu T, Liu Q, Wang Y, Xu Y, Shi J, Yao Y, Chen Q, Liang J, Tang S. Research Progress and Technology Outlook of Deep Learning in Seepage Field Prediction During Oil and Gas Field Development. Applied Sciences. 2025; 15(11):6059. https://doi.org/10.3390/app15116059

Chicago/Turabian StyleWu, Tong, Qingjie Liu, Yueyue Wang, Ying Xu, Jiale Shi, Yu Yao, Qiang Chen, Jianxun Liang, and Shu Tang. 2025. "Research Progress and Technology Outlook of Deep Learning in Seepage Field Prediction During Oil and Gas Field Development" Applied Sciences 15, no. 11: 6059. https://doi.org/10.3390/app15116059

APA StyleWu, T., Liu, Q., Wang, Y., Xu, Y., Shi, J., Yao, Y., Chen, Q., Liang, J., & Tang, S. (2025). Research Progress and Technology Outlook of Deep Learning in Seepage Field Prediction During Oil and Gas Field Development. Applied Sciences, 15(11), 6059. https://doi.org/10.3390/app15116059