Abstract

The increasing demand for induction hobs necessitates efficient cooling systems to ensure the safe operation of electronic cut-outs. This study investigates the thermal representation of three different ignition designs integrated into an induction hob cooling system. A simplified model consisting of a radial fan, a daughterboard, and the electronics installed in the systems is used for the maintenance of the system. Remote measurements of air velocities at the cooler outlets are compared with the results obtained through programmable system dynamics (CFD) operations using FloEFD v2021.1 software. The findings of the study using the k-ε turbulence model show that Type 1 temperature is resistant to the lowest surface temperature for both the closest (IGBT 1) and the farthest (IGBT 2) temperature to the fan. Conversely, Type 3 temperatures exhibited high temperatures. Air velocity comparisons showed a maximum error rate of 30%, which is acceptable considering the variability in Type 1. Measurement system evaluation and DOE study were continued to increase the experimental range. This study demonstrates the utility offered by heatsink design in optimizing the cooling system of induction hobs and provides valuable insights for integrating thermal management systems.

1. Introduction

The demand for induction hobs continues to grow due to their advantages over gas and vitro-ceramic alternatives. Unlike conventional methods, induction hobs directly heat cookware using electromagnetic fields. They feature a flat, non-magnetic glass–ceramic surface with copper coils underneath. When a current passes through these coils, a changing magnetic field forms. If a ferromagnetic pan is placed on top, this field generates eddy currents inside it, creating heat through resistance. The generated heat then transfers to the food or liquid efficiently and precisely. Since heat is generated directly inside the cookware rather than on the hob surface, induction hobs offer rapid heating and precise temperature control. However, they require cookware with a magnetic base, such as cast iron or stainless steel. Recently, various numerical and experimental methods have been used to model thermal and fluid behavior. Techniques like the Lattice Boltzmann Method (LBM), Discrete Element Method (DEM), and Particle Image Velocimetry (PIV) provide detailed insights into microscale flows and particle dynamics. Yet, these methods often demand specialized setups, limiting their practical use in household appliances.

In contrast, computational fluid dynamics (CFD), based on Navier–Stokes equations, is a reliable and widely used approach for simulating turbulent, forced-convection flows in electronic cooling. This study uses CFD analyses performed with FloEFD, which applies the finite volume method (FVM) and the k-ε turbulence model. This method was selected for its ability to simulate steady-state thermal and fluid behavior in compact systems, its alignment with fan P-Q curves, and its easy integration with CAD during product development. Additionally, CFD enables parametric studies and allows validation through air velocity and temperature comparisons, as shown in this work [1,2,3]. Numerous studies have investigated induction hobs in the literature. For instance, Kawakami et al. [4] visualized the temperature and flow distributions on induction and gas hobs using CFD, comparing the heat distribution characteristics of both hob types. Kranjc et al. [5] examined the induction heating process through numerical and experimental methods, simulating the induction heating of steel workpieces with temperature-dependent and -independent analyses. Within the electronic systems of induction hobs, heat accumulates in the electronic components during operation. Therefore, a well-designed ventilation system is essential for the safe and sustainable use of induction hobs, comprising primarily a fan and a heatsink. Studies on heatsink design have shown various approaches. In recent years, emerging heatsink geometries such as topology-optimized or porous media-based structures have gained considerable attention, particularly for high-performance thermal management. While such approaches offer significant potential, this study focuses on geometries compatible with current domestic appliance production methods. Future work may explore these innovative designs in more detail, especially as additive manufacturing capabilities advance [6,7]. Teertstra et al. [8] developed an analytical model to calculate the average heat transfer rate in forced convection for slotted fin heatsinks. Gupta et al. [9] experimentally investigated the heat transfer and flow performance in plate-fin heatsinks by adding dimples and protrusions to enhance heat transfer. In the literature, statistical and experimental approaches have also been studied. Chiang K. [10] focused on optimizing the cooling performance of a Parallel-Plain Finned (PPF) heatsink module. Due to the compact structure and high performance requirements of electronic devices, effective management of the heat generated is critical for the reliability and lifetime of the devices. In this study, the effects of the design parameters of the PPF heatsink module on the cooling performance were investigated using the Taguchi method and Analysis of Variance (ANOVA). The seven factors were evaluated at three levels and the number of experiments was reduced by using an L18 orthogonal array. The most effective factors in this study were determined as fan air capacity (36.24%) and blade pitch (30.73%). As a result, the highest temperature value on the heatsink was reduced by about 8 °C and an improvement of 15% was achieved. In engineering and scientific research, optimizing system performance often requires a structured approach to experimentation and data analysis. Design of Experiments (DOE) is a powerful statistical methodology used to systematically investigate the effects of multiple factors on a response variable, reducing the number of trials while maximizing the information gained. By utilizing techniques such as full factorial and fractional factorial designs, DOE enables researchers to identify key variables that influence system performance, leading to efficient decision-making in experimental studies. Analysis of Variance (ANOVA), on the other hand, is a statistical tool employed to evaluate the significance of differences between multiple sets of experimental data. ANOVA determines whether observed variations in a response variable are due to the influence of independent factors or merely the result of random fluctuations. In the study conducted by Yin T. and others [11], the arrangement of racks, the location of cooling devices (CRAC units), and the spacing between racks in a raised-floor data center were examined. The DOE method was applied to determine the most effective factors, and a full factorial design was chosen, testing a total of 27 different combinations through CFD analyses. The results of these analyses revealed that corridor width had the least effect, while the positioning of the cooling devices had the greatest impact. Based on DOE and CFD results, the optimal combination was achieved by strategically positioning CRAC units and utilizing corridor containment. In the study conducted by Li and others [12], the cooling performance and temperature distribution uniformity of a battery pack were analyzed using DOE and Response Surface Methodology (RSM). A full factorial design was applied, and the obtained data were analyzed using the RSM method. The cartridge width, spacing between batteries, and the distance of the batteries to the wall were evaluated at three different levels (−1, 0, and 1). The results of the study indicated that the temperature difference between batteries was reduced by approximately 22%, achieving a more homogeneous temperature distribution. Due to the compact structure and high-performance requirements of electronic devices, effective management of the generated heat is critical for device reliability and lifespan. In the study, the effects of design parameters of the PPF heatsink module on cooling performance were investigated using the Taguchi method and Analysis of Variance (ANOVA). Seven factors were evaluated at three levels, and the number of experiments was reduced using an L18 orthogonal array. The most influential factors identified in the study were fan air capacity (36.24%) and fin spacing (30.73%). As a result, the maximum temperature on the heatsink was reduced by approximately 8 °C, achieving a 15% improvement in performance. In the study conducted by Fu J. and Cai J. [13], the heat transfer performance of a vertical sinter cooling bed was optimized using the Taguchi method and ANOVA. The study analyzed the effects of structural and operational parameters influencing gas–solid heat transfer in the sinter cooling bed. The investigated parameters included gas flow rate, air inlet temperature, sinter inlet temperature, and the diameter and height of the cooling bed, each evaluated at three levels. The Taguchi method was applied using an L27 orthogonal array, and the most significant factor was determined to be sinter inlet temperature, contributing 61.65% to the overall effect. As a result, exergy recovery increased by 1.29 times, and heat transfer efficiency (gc) improved by 4%. In a study conducted by Sun H. and Dixon R. [14], the thermal performance of lithium-ion battery packs in hybrid electric vehicles was optimized using the DOE method to develop an air-cooled strategy. The Optimal Latin Hypercube DOE method was applied to analyze the effects of cooling channel geometry, cooling plates, and fluid guidance on the temperature distribution and pressure drop of the battery pack. By implementing a tapered design at the inlet and outlet of the flow channels, the temperature difference between battery cells was reduced from 10.8 °C to 3.6 °C, and the maximum cell temperature was decreased by 6.3 °C. Additionally, this design reduced the total pressure drop by approximately 24%. Stewart T. and Stiver D. [15] used a Design of Experiments (DoE)- and computational fluid dynamics (CFD)-based methodology to achieve thermal optimization of next-generation network servers. In the study, the effects of different design parameters on the temperature distribution were analyzed using the partial factorial design method of DoE. In the DoE analysis, the main components affecting the cooling performance such as disc drives, CPU modules, DIMM memory modules, fans, and air diverters are considered. Thanks to the optimum parameters obtained by DoE, the number of physical prototypes was reduced from four to two, the efficiency of the cooling design was increased, and the cost was reduced. This study demonstrates that the use of DoE in combination with CFD-based analyses is an effective method to improve cooling performance in large-scale electronic systems. In the study by Icoz et al. [16], experimental and numerical simulation data were combined with the Design of Experiments (DOE) method to optimize the cooling systems of electronic devices. In the study, the main design parameters such as placement of electronic components, duct dimensions, flow rate, and heat input were tested by the partial factorial DOE method. With DOE analysis, the optimum layout configuration of the components is determined to minimize the surface temperature of the system. According to the results, with the optimum configuration, the electronic device surface temperature is reduced by 15% and the fan power requirement is reduced by 20%. The study accelerated the design process and reduced costs by halving the number of prototypes by using experimental and numerical simulation data together. This method demonstrates the effectiveness and cost advantage of DOE in the optimization process of electronic cooling systems.

This study investigates how heatsink design parameters affect IGBT surface temperatures during induction hob operation, using FloEFD 2021 for numerical analysis. First, airflow measurements were taken using the Type 1 heatsink to evaluate measurement reliability. Based on these results, a Design of Experiments (DOE) study was conducted in Minitab v22.2 to optimize the measurement method and reduce operational variability. The DOE considered heatsink positions (aligned, angled, and offset from the fan) and probe stability (fixed vs. free). After identifying the optimal method, experiments were repeated for all three heatsink types (Type 1, Type 2, and Type 3). Air velocities were measured at multiple outlet points, with each test repeated three times by two operators. These repetitions supported both uncertainty analysis and measurement system evaluation. Uncertainty was calculated using both Type A (statistical) and Type B (systematic) components based on standard deviation and mean values. CFD simulations were then run for each heatsink to validate airflow behavior. Once validated, thermal loads from electronic components were applied, and IGBT surface temperatures were predicted. By analyzing measurement data and factor effects, the key parameters influencing cooling performance were identified. The combination of statistical analysis, DOE results, and CFD validation offers a complete evaluation of heatsink performance under real conditions.

2. Materials and Methods

2.1. Numerical Study

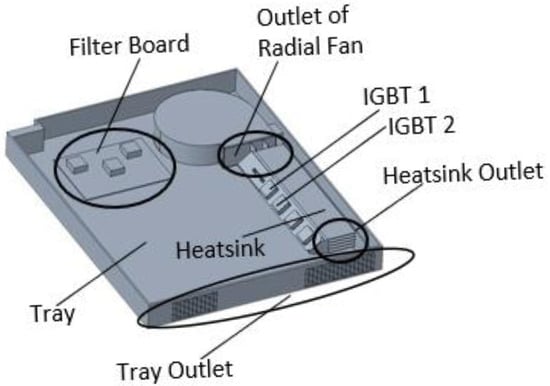

This study examines the compatibility between the radial fan and the heatsink used in an induction hob cooling system, focusing on their impact on electronic component temperatures. To improve analysis time and mesh quality, a simplified model was created. This model includes the radial fan, auxiliary board, customized heatsink, and the tray holding the electronic components, as shown in Figure 1. All components are customized for the Haier Europe Company (Eskisehir, Turkey). The heatsink was placed directly in front of the fan to maximize airflow over its surface. Airflow measurements were taken at the outlet behind the heatsink using probes placed at predefined points. The fan’s inlet is located below the bottom casing of the hob, while its outlet directs air toward the metal heatsink inside the tray. The heatsink outlet is positioned near the hob’s ventilation channels, allowing hot air to exit through these openings.

Figure 1.

Simplified induction hob.

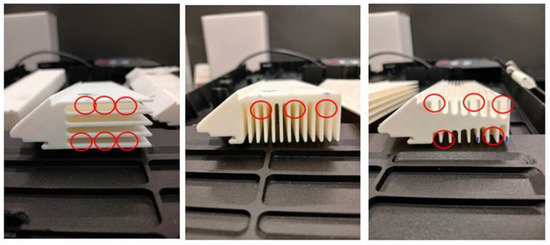

Three different heatsink types were used in the Design of Experiments and velocity comparison studies. Each had different fin structures and surface areas. In the first phase, these heatsinks were produced using 3D printing with ABS material and mounted on the simplified test setup. ABS was chosen due to its ease of manufacturing, mechanical stability, and cost-effectiveness for airflow studies, despite its low thermal conductivity. Metal printing was not preferred due to project limitations. Air velocity measurements were taken at predefined outlet regions using a TESTO device (TESTO SE, Titisee-Neustadt, Germany) while the fan was running. The prototype heatsinks—Type 1, Type 2, and Type 3—are shown in Figure 2. Design constraints from the supplier and product geometry were considered when shaping the heatsinks. Fin height was fixed at 20 mm to fit within the hob design, and fin thickness was set at 1.3 mm based on manufacturability. Accordingly, Type 1 had 5 fins, Type 2 had 12, and Type 3 had 8 fins. Their effective surface areas were calculated as 0.0835 m2, 0.1040 m2, and 0.0683 m2, respectively.

Figure 2.

Types of heatsinks.

As the second step of the study, a CFD model utilizing the simplified experimental setup was developed [17,18,19]. The three types of heatsink models were incorporated into the simulation, where the electronic components attached to them served as heat sources, and the radial fan operated according to its P-Q curve. Through this CFD model, the temperatures occurring on the surfaces of the components were obtained under steady-state conditions. The “FloEFD” software package was used to perform the CFD analyses. For turbulence modeling, it uses the k-ε model with damping functions, as described by Lam (1981) [20] and Trebunskikh et al. [21]. The software generates a Cartesian mesh and utilizes Van Driest’s universal profiles alongside the “Two-Scale wall functions” approach to model the turbulent boundary layer, as noted in the works of Amirabedin et al. [22] and Kalitzin and Iaccarino [23]. To achieve spatial discretization, an axis-aligned rectangular grid is applied in regions distant from the geometry boundary, while a Cartesian cut-cell approach is implemented near the geometry boundary. In computational fluid dynamics, the computational domain is divided into control volumes, with conservation equations discretized into algebraic forms to enable numerical solutions. In this study, the continuity equation, one of the fundamental equations used for calculating airflow and heat transfer within the system, was applied to ensure mass conservation. With the operation of the fan, airflow was generated within the system, and the continuity equation ensured that there was neither mass loss nor accumulation. The airflow produced by the fan and its interaction with heatsink surfaces and electronic components were analyzed using the momentum equation.

Through this equation, variations in air velocity and direction, forces acting on surfaces, and pressure changes within the system were modeled. The heat loads generated by the electronic components within the system were transferred to the environment through convection, facilitated by the airflow and the heatsinks. This heat transfer process was modeled based on the energy equation, allowing for the calculation of both the component surface temperatures and the overall cooling performance of the system. Within this context, the fundamental conservation equations employed in this study are presented below.

In Equation (1), ρ is fluid density, t is fluid time, and is velocity component. In Equation (2), u, v, and w are the velocity components of Cartesian coordinates.

In Equations (3) and (4) shown above, p is the pressure, τ is the stress tensor, μ is the dynamic viscosity, f is the external force, and ∇. (ρνν) is the convective momentum transfer. In Equation (5) below, et is the total energy, q is the total heat flux, and φ is the dissipation due to viscosity.

For modeling the turbulence, the RANS model was used with the model. Turbulence kinetic energy and turbulence dissipation are given in Equations (6) and (7) below.

In the equations above, is the density, is the turbulence kinetic energy, is the turbulent viscosity, is the Prandtl number, is turbulent energy creation, is the turbulent dissipation, and C1ε and are the empirical constants. The coefficient of empirical constants for the model is given in Equation (8) below:

Considering the properties of air as an ideal gas, state Equation (9) was used in conjunction with the energy conservation equation. The internal energy was modeled based on the constant-volume specific heat assuming incompressible flow conditions at low Mach numbers.

In Equations (9) and (10) shown above, is the pressure [Pa], is the density, R is the ideal gas constant, T is the absolute temperature, e is the density of internal energy, q is the heat flux, and is the viscos dissipation.

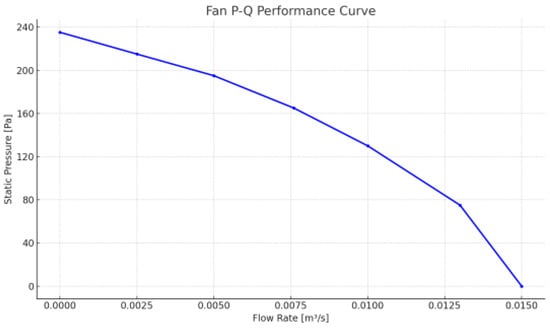

- Airflow Phase:

In the airflow study phase of the CFD analysis, the airflow generated by the radial fan was modeled based on its actual P-Q (pressure–flow rate) performance curve, provided by the manufacturer. Rather than explicitly modeling the internal rotating blades of the fan using computationally intensive rotating region methods such as the Multiple Reference Frame (MRF) technique, the fan’s performance was directly represented through a pressure jump boundary condition corresponding to its operational curve. Utilizing the P-Q curve approach offered several advantages over conventional MRF methods. First, it significantly reduced the computational cost by eliminating the need to resolve complex rotating blade geometries. Second, it allowed for the representation of real fan behavior under varying system resistance conditions, thereby improving the practical accuracy of airflow predictions. In the simulation setup, the pressure increase generated by the fan at different volumetric flow rates was matched to the corresponding values defined by the P-Q curve. This approach enabled a realistic estimation of airflow distribution across the heatsink outlet region under steady-state conditions. The P-Q curve provided by manufacturer of the fan is shown in Figure 3 below.

Figure 3.

Fan P-Q curve.

- Thermal Phase:

After validating the airflow results, the second phase of the CFD study focused on thermal analysis using the energy conservation equation. Heat transfer simulations were performed for each heatsink type (Type 1, Type 2, and Type 3). IGBT modules, located beneath the induction coil where heat accumulation is critical, were modeled as volumetric heat sources. Their placement in the model reflected their actual positions in the assembly. The airflow behavior from the previous phase was preserved to maintain consistency between flow and thermal analyses. Thermal boundary conditions were defined based on real hob operation. IGBTs are key components in induction hobs, switching high-frequency current (20–50 kHz) to generate the alternating magnetic field. During operation, they produce switching and conduction losses, which were used as heat inputs in the simulations. Thermal dissipation for each IGBT was calculated assuming 1.8 kW coil power, using efficiency values from manufacturer datasheets. Material properties (thermal conductivity, density, and specific heat) listed in Table 1 were matched to those used in the experimental setup. Solving the energy equation under steady-state conditions allowed calculation of temperature distributions across heatsinks and electronic components. This enabled comparison of IGBT surface temperatures and assessment of each heatsink’s cooling performance.

Table 1.

CFD model—material properties.

In Equation (11) above, is the thermal dissipation [W], is the coil power [W], and is the efficiency [%] provided by manufacturer of the IGBT. In this analysis, IGBT heat dissipation was taken as 10.37 W and the heat dissipation of other small components on the fillet board shown in Figure 1 above was taken as 1.3 W.

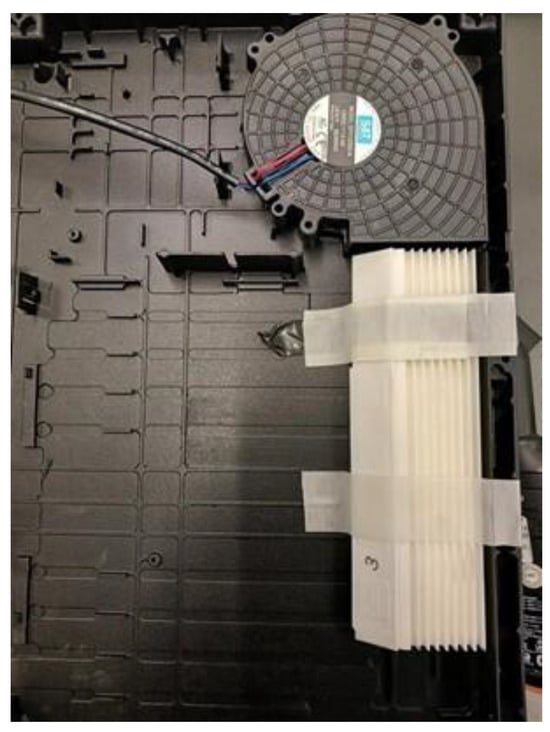

2.2. Experimental Study

In this section, an experimental approach was used to evaluate the performance of different heatsink designs used in the cooling systems of induction hobs. The cooling system consists of a radial fan and a customized heatsink to dissipate the heat generated by electronic components. The experimental setup, as shown in Figure 4, includes a bottom plastic casing, a radial fan, and a metal heatsink. A radial-type fan was positioned in front of the metal heatsink to ensure temperature control between the heatsink and electronic components.

Figure 4.

Experimental setup.

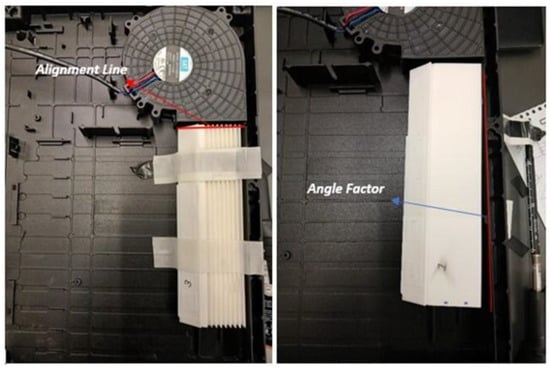

A Design of Experiments (DOE) study was first conducted to optimize the measurement method for the Type 1 heatsink. Three factors were considered: heatsink position, measurement location, and probe freedom. Table 2 shows the full factorial design, which included three factors at various levels and a total of 12 measurements. During assembly, it is essential that the heatsink fins are aligned with the fan airflow to ensure efficient heat transfer. Misalignment during production or testing can distort airflow and lead to incorrect conclusions about cooling performance. To investigate this effect, heatsink position was defined as the first factor, with three levels. While angular misalignment was randomized, the same angle was kept constant across all tests to avoid additional variation. In the “in fan” configuration, the heatsink was placed directly inside the fan outlet channel. In addition, two more factors were introduced to assess their influence on airflow measurement accuracy. One is measurement type (two levels: fixed hand position vs. free hand position while holding the probe), and other is probe freedom (two levels: probe tip fixed vs. probe tip free).

Table 2.

Full factorial experimental design.

After completing the DOE study, air velocity measurements were taken at specific points located (middle of the red circles) at the outlets of Type 1, Type 2, and Type 3 heatsinks, each positioned in front of the radial fan. These points highlighted as red circles are illustrated in Figure 5. For consistency, the Testo anemometer probe was carefully placed in the center of the fin spacing, and positioned between the fins rather than on their surfaces to avoid influencing the airflow or surface temperature. To further reduce variability in the measurements, an additional DOE study was conducted focusing on two experimental factors: the steadiness of the operator’s hand and the freedom of the probe tip. These factors were systematically analyzed to understand their effect on measurement accuracy. As a result, an optimized methodology with reduced error margins was established, ensuring greater reliability and repeatability in airflow measurements for all heatsink types.

Figure 5.

Measurement points for each type of heatsink.

The determined heatsink position, measurement type, and factors are shown in Figure 6. The probe freedom factor is defined based on whether the probe is fixed with a fixture or left unfixed.

Figure 6.

Factors.

Air velocity measurements were taken at several predefined points in the outlet region of each heatsink, as shown in Figure 5. To ensure measurement reliability, each point was tested three times. Two different operators (ASM and MHR) performed the measurements to evaluate operator-related effects. The collected data were analyzed using One-Way Analysis of Variance (ANOVA) to examine the influence of the operator, measurement point, and timing on airflow results. ANOVA helps determine whether differences in group means are statistically significant.

In this study, the null hypothesis (H0) stated that all group means are equal, while the alternative hypothesis (H1) suggested that at least one group differs. Levene’s test was used to assess whether the variances across groups were equal. If the p-value from this test was less than the significance level (α = 0.05), the variances were considered significantly different. If the p-value exceeded this threshold, the group variances were assumed to be equal.

Bonferroni Confidence Intervals

Bonferroni confidence intervals were used to evaluate the differences between measurement variances. The Bonferroni method is employed to control the error rate in multiple comparisons. Bonferroni confidence intervals were calculated at a 95% confidence level for each measurement group, and the variations between measurements were examined. These confidence intervals were computed for each measurement using the standard deviation (SD) value as follows:

In the formula, is the Bonferroni correction, is the comparison number, and is the degree of freedom.

In this study, statistical analyses were performed using Minitab, combining graphical and numerical methods. Time Series Plots were used to visualize how air velocity measurements changed over time, helping to detect trends, inconsistencies, or sudden shifts related to operator, time, or measurement location. These plots were especially useful for comparing the consistency of measurements taken by different operators. Additionally, Individual Value Plots were employed to show the distribution of each air velocity measurement point-by-point. These plots highlighted variations between points, operator-related differences, and overall measurement consistency. Both graphical tools were instrumental in identifying potential errors, evaluating data quality, and ensuring the robustness of the measurement procedure.

2.3. Uncertainty Analysis

For experimental studies, uncertainty analysis is critical to provide reliability of the measured results. While the mean values of the measurements provide an estimation of system performance, the uncertainty quantifies the potential error margins associated with these measurements. Considering uncertainties enables researchers to distinguish between actual effects caused by experimental factors and random measurement variations. Furthermore, uncertainty analysis supports better decision-making by identifying the confidence intervals of the results and ensuring the robustness of the conclusions drawn from the experiments. First, the arithmetic mean of the measured values is calculated according to Equation (13). Then, the standard deviation, which reflects the spread of the measurements around the mean, is obtained using Equation (14). Type A uncertainty, originating from statistical variations in repeated measurements, is determined by Equation (15). Type B uncertainty, arising from equipment inaccuracies and systematic effects, is calculated by combining independent sources, as shown in Equation (16). Finally, the combined uncertainty is evaluated according to Equation (17), and the Z-score Equation (18) is used to assess the agreement between experimental and simulation results within the uncertainty bounds.

In the equations above, is the mean of the measurements, n is the number of experiments, s is the standard deviation of the measurements, is uncertainty Type A, is uncertainty Type B, is the combination of uncertainty Type A and Type B, is the CFD results, and Z is the control score of the harmony between experimental results and CFD results.

3. Results

3.1. Design of Experiment (DoE)

To evaluate measurement adequacy, measurements were performed on the Type 2 heatsink based on the factors and levels determined through the Design of Experiments. The factors and measurement results are presented in Table 3.

Table 3.

Type 2 Design of Experiments and measurements.

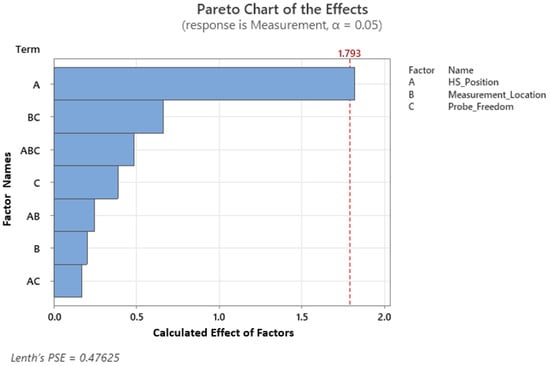

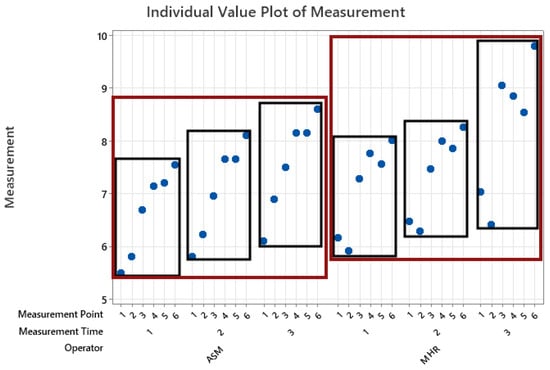

The results obtained from the experiments conducted based on the full factorial design were evaluated according to the effects of factors and their interactions. In the Pareto Effect Chart shown in Figure 7, the Pareto efficiency curve illustrates the calculated effect magnitudes of each factor on the measured airflow velocity. The higher the bar, the stronger the factor’s impact. On the Y axis, the main factors and their interactions are shown. On the X axis, the effects of each main factor and their interactions are calculated based on their low values and high values. The confidence level was taken as 95% to minimize the error percentage in the DOE model. Lenth’s Pooled Standard Error (PSE) is shown below the Pareto chart. It was used to predict the noise level of experimental data and calculate the significance limit, which is shown as 1.793 in the graphic. Additionally, the main effects plot is presented in Figure 8. The main effects plot shows how changes in factor levels affect the mean measured airflow velocity. Each point represents the average response at each level. HS (heatsink) position, measurement location and probe freedom are factors of the DOE design, as shown in Table 3 above. HS position is the most critical effect for the measured velocity, and it is correlated with the Calculated Effect of Factors shown in Figure 6 above.

Figure 7.

Pareto efficiency curve.

Figure 8.

Main effects plot.

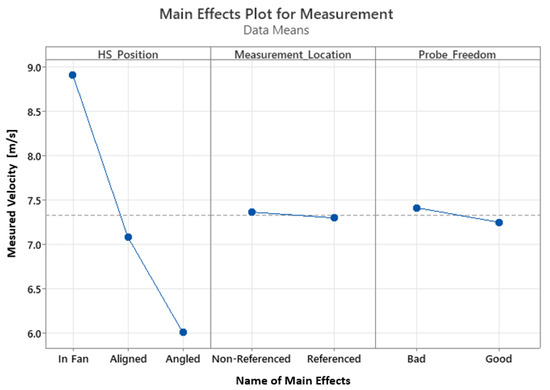

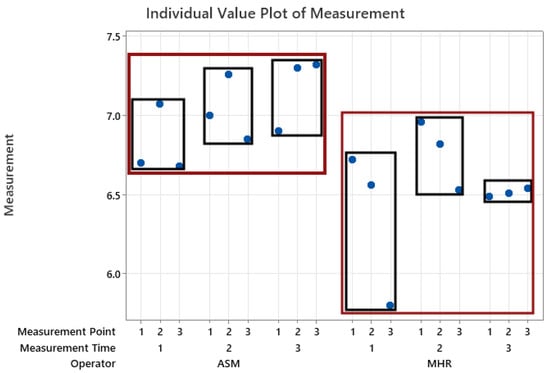

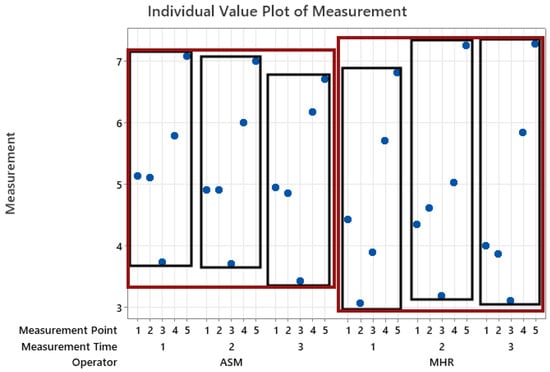

3.2. Analysis of Variance (ANOVA)

This analysis evaluated the effects of different heatsink types and positions on cooling performance. Using a full factorial DOE setup, three heatsink types were tested in various positions—angled, aligned, and in fan—based on the most influential factors identified earlier. The results showed that heatsink positioning had the greatest impact on airflow and cooling performance. Air velocity data from different measurement points and operators were analyzed, revealing that both positioning and probe freedom significantly affected the results. To assess measurement reliability and identify potential errors, Bonferroni confidence intervals and ANOVA were applied. Figure 9, Figure 10 and Figure 11 present airflow measurements across different times, points, and operators for each heatsink type, supporting the overall evaluation of the measurement system. Blue balls represent the velocity, black boxes represent one measurement for all points of related heatsink type and red boxes represent the full measurement of one operator.

Figure 9.

Type 2 measurement plot.

Figure 10.

Type 1 measurement plot.

Figure 11.

Type 3 measurement plot.

Variations in measurements may arise due to operator differences. This variation highlights the need to optimize the measurement process by addressing factors such as calibration and stability. Based on the most influential factors identified in the Design of Experiments, as well as the effects of other factors, air velocity measurements for other heatsink types were conducted at the specified points.

3.3. Uncertainty Results

In order to assess the reliability of the experimental measurements, an uncertainty analysis was performed considering both Type A (statistical) and Type B (systematic) components. Based on the repeated airflow velocity measurements, the Type A uncertainty was calculated as 0.2193 m/s, while the Type B uncertainty, which accounts for instrumentation errors, fan performance variations, and geometrical positioning effects, was determined as 0.4807 m/s. The combined uncertainty was obtained by the root sum square (RSS) method, yielding a total uncertainty of 0.5284 m/s. Based on a total uncertainty of 0.5284 m/s and a mean measured airflow velocity of 6.1817 m/s, the calculated relative uncertainty was approximately 8.55%. According to the standards commonly accepted in thermal and fluid mechanics experimental studies, a relative uncertainty within the range of 5–10% is considered normal and acceptable. This result indicates that the overall experimental setup maintained an acceptable level of precision, providing a solid basis for the validation of CFD simulations and the comparative evaluation of different heatsink configurations.

3.4. CFD Study

In the first phase of the CFD study, initially, the airflow distribution was validated by comparing the experimentally measured air velocities with the CFD-predicted values. Comparisons presented in Table 4, Table 5 and Table 6 demonstrate a strong agreement between the experimental and numerical results, indicating that the airflow behavior was accurately captured by the simulation model. Upon successful validation of the airflow characteristics, it was concluded that the CFD setup could reliably predict the flow field within the system.

Table 4.

Velocity [m/s] comparison for Type 1.

Table 5.

Velocity [m/s] comparison for Type 2.

Table 6.

Velocity [m/s] comparison for Type 3.

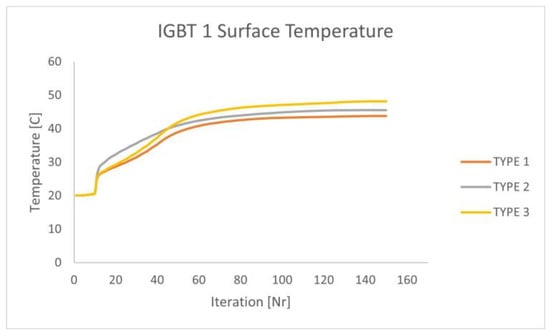

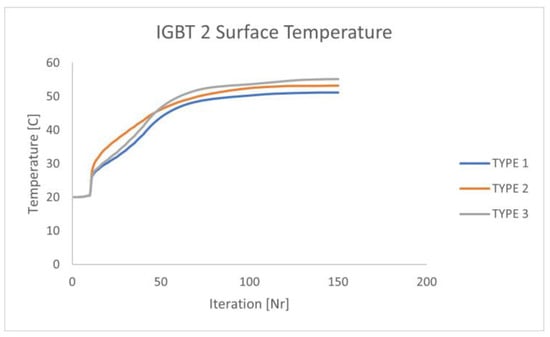

In the second phase of the study, an induction hob was analyzed numerically to make an evaluation for electronic component temperatures. The model contains four electronic components attached to the heatsinks. When creating the result monitoring graphs, the component closest to the fan (IGBT 1) and the component furthest from the fan (IGBT 2) were taken as reference points. To evaluate the numerical analyses, different points were identified at the heatsink outlet, and air velocity measurements were conducted experimentally. These measurements were then compared with the air velocities obtained from the numerical results. Figure 12 and Figure 13 below show a comparison of the surface temperatures of the IGBT 1 and IGBT 2 components for three different types of heatsinks. IGBT 1 is positioned as the closest component to the cooling fan, while IGBT 2 is located as the second closest inverter module relative to the fan, as shown in Figure 1 above.

Figure 12.

IGBT 1 surface temperatures.

Figure 13.

IGBT 2 surface temperatures.

A computational fluid dynamics (CFD) approach was employed using the FloEFD 2021 software package. Within FloEFD, the solution process for steady-state simulations involves iterative solving of the governing equations (continuity, momentum, and energy) until the predefined convergence criteria are satisfied. The term “iteration” used in Figure 11 and Figure 12 specifically refers to the solver iterations performed during the steady-state solution process. Each iteration represents an incremental numerical step where the residuals of the governing equations are progressively minimized, leading the solution towards convergence. Therefore, “iteration number” corresponds to the number of solver steps needed to achieve convergence, and it does not represent time steps or transient progression.

As seen in the results above, the comparison between the experimental and CFD-predicted air velocities for all heatsink types (Table 4, Table 5 and Table 6) demonstrated a generally good agreement. The calculated Z-scores, based on the total uncertainty of 0.5284 m/s, were predominantly below 2 across all measurement points, indicating that the deviations between experimental and CFD results are within acceptable limits. Therefore, the CFD model was deemed validated in terms of airflow prediction. As illustrated in Figure 12 and Figure 13, the surface temperatures of IGBT 1 and IGBT 2 modules show observable differences depending on the heatsink configurations. It is important to note that, during actual induction hob assembly (as depicted in Figure 1), IGBT modules are thermally bonded to the heatsink using thermal interface materials (TIMs) such as thermal paste to minimize contact resistance and enhance heat transfer efficiency. However, in the simplified CFD model developed for this study, the effect of thermal paste was not explicitly modeled. According to the heatsink supplier, the thermal paste introduces an additional thermal resistance of approximately 0.5 °C/W. Therefore, when interpreting the CFD results, this additional resistance should be considered as a correction factor, slightly increasing the predicted IGBT surface temperatures in real-world conditions.

Despite this modeling simplification, the relative comparison between different heatsink types remains valid, as the absence of the thermal interface material uniformly affects all configurations. Furthermore, the observed differences in IGBT surface temperatures between heatsink types are within acceptable ranges when compared to typical thermal management thresholds for power electronics. Specifically, the critical temperature threshold for IGBT modules typically ranges between 125 °C and 150 °C for safe and reliable operation. Although the maximum surface temperatures observed in the CFD analysis remain significantly below the critical failure thresholds (125–150 °C) for IGBT modules, it is important to consider the impact of operating temperature on component longevity. According to the Arrhenius model of accelerated aging, it is generally accepted that every 10 °C increase in operating temperature results in approximately a 50% reduction in the lifespan of electronic components. Therefore, while all heatsink configurations evaluated in this study provide thermally safe conditions for operation, minimizing the surface temperature as much as possible remains crucial for enhancing the long-term reliability and operational life of the system.

4. Conclusions

This study comprehensively evaluated the cooling system of induction hobs through experimental measurements, Design of Experiments (DOE), uncertainty analysis, and computational fluid dynamics (CFD) simulations. Initially, airflow measurements with the Type 1 heatsink were used in a DOE study to optimize the measurement method and reduce operational variation. CFD and experimental results were compared for all heatsink types, and Z-scores remained mostly below 2, confirming CFD model accuracy. Following airflow validation, thermal analysis was performed using realistic heat dissipation values based on IGBT operation under a 1.8 kW coil load. Surface temperatures of IGBT 1 and IGBT 2 were compared across heatsink types. Type 1 consistently resulted in lower temperatures, while Type 3 showed higher values. Although all heatsinks maintained temperatures below the critical 125–150 °C range, minimizing surface temperature remains important due to thermal aging effects described by the Arrhenius model. Cooler components can significantly extend system lifetime and reliability. These findings highlight the importance of heatsink placement, geometry, and accurate measurement methods in enhancing cooling performance. The combined use of CFD, experimental data, and statistical validation offers a strong framework for optimizing electronic cooling systems. Future work may explore more advanced heatsink geometries, transient simulations, and detailed modeling of thermal interface materials to further improve system-level thermal management.

Author Contributions

Conceptualization, A.S.M. and C.T.; methodology, A.S.M. and C.T.; software, A.S.M.; validation, A.S.M.; formal analysis, A.S.M. and C.T.; investigation, A.S.M. and C.T.; resources, A.S.M. and C.T.; data curation, A.S.M.; writing—original draft preparation, A.S.M. and C.T.; writing—review and editing, C.T.; visualization, A.S.M.; supervision, C.T.; project administration, A.S.M. and C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Özcan, Z.; Ekici, Ö. Akış Problemleri İçin Lattice Boltzmann Yöntemi ve Uygulamaları. Gazi Univ. J. Sci. Part C Des. Technol. 2016, 4, 115–126. [Google Scholar]

- Théodon, L.; Debayle, J.; Coufort-Saudejaud, C. Morphological characterization of aggregates and agglomerates by image analysis: A systematic literature review. Powder Technol. 2023, 430, 119033. [Google Scholar] [CrossRef]

- Tunçer, O.; Kahraman, S.; Kaynaroğlu, B. Girdap vanesinden geçen akişin piv yöntemi ile incelenmesi. Gazi Üniversitesi Mühendislik Mimar. Fakültesi Derg. 2016, 31, 4. [Google Scholar]

- Kawakami, H.; Llave, Y.; Fukuoka, M.; Sakai, N. CFD analysis of the convection flow in the pan during induction heating and gas range heating. J. Food Eng. 2013, 116, 726–736. [Google Scholar] [CrossRef]

- Kranjc, M.; Zupanic, A.; Miklavcic, D.; Jarm, T. Numerical analysis and thermographic investigation of induction heating. Int. J. Heat Mass Transf. 2010, 53, 3585–3591. [Google Scholar] [CrossRef]

- Hetsroni, G.; Gurevich, M.; Rozenblit, R. Sintered porous medium heat sink for cooling of high-power mini-devices. Int. J. Heat Fluid Flow 2006, 27, 259–266. [Google Scholar] [CrossRef]

- Ozguc, S.; Teague, T.F.; Pan, L.; Weibel, J.A. Experimental study of topology optimized, additively manufactured microchannel heat sinks designed using a homogenization approach. Int. J. Heat Mass Transf. 2023, 209, 124108. [Google Scholar] [CrossRef]

- Teertstra, P.; Culham, J.R.; Yovanovich, M.M. Analytical modeling of forced convection in slotted plate fin heat sinks. In Proceedings of the ASME 1999 International Mechanical Engineering Congress and Exposition, Nashville, TN, USA, 14–19 November 1999. [Google Scholar]

- Gupta, A.; Kumar, M.; Patil, A.K. Enhanced heat transfer in plate fin heat sink with dimples and protrusions. Heat Mass Transf. 2019, 55, 2247–2260. [Google Scholar] [CrossRef]

- Chiang, K.-T. Optimization of the design parameters of parallel-plain fin heat sink module cooling phenomenon based on the Taguchi method. Int. Commun. Heat Mass Transf. 2005, 32, 1193–1201. [Google Scholar] [CrossRef]

- Yin, T.; Xu, Q.; Fang, L.; Zhang, J. Numerical investigation for effects of layout factors on temperature distribution in a raised-floor data center using a three-level full-factorial design. In Proceedings of the 4th International Conference on Energy, Electrical and Power Engineering (CEEPE), Chongqing, China, 23–25 April 2021; pp. 351–355. [Google Scholar]

- Li, Z.-Z.; Cheng, T.-H.; Xuan, D.-J.; Ren, M.; Shen, G.-Y.; Shen, Y.-D. Optimal design for cooling system of batteries using DOE and RSM. Int. J. Precis. Eng. Manuf. 2012, 13, 1641–1645. [Google Scholar] [CrossRef]

- Fu, J.-P.; Cai, J.-J. Numerical investigation and optimisation of heat transfer performance in a vertical sinter cooling packed bed using Taguchi and ANOVA methods. J. Iron Steel Res. Int. 2020, 27, 898–912. [Google Scholar] [CrossRef]

- Sun, H.; Dixon, R. Development of cooling strategy for an air-cooled lithium-ion battery pack. J. Power Sources 2014, 272, 404–414. [Google Scholar] [CrossRef]

- Stewart, T.; Stiver, D.W. Thermal optimization of electronic systems using Design of Experiments based on numerical inputs. In Proceedings of the Twentieth Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 11 March 2004. [Google Scholar]

- Icoz, T.; Jaluria, Y. Design of cooling systems for electronic equipment using both experimental and numerical inputs. J. Electron. Packag. 2004, 126, 471–478. [Google Scholar] [CrossRef]

- Ploteau, J.P.; Nicolas, V.; Glouannec, P. Numerical and experimental characterization of a batch bread baking oven. Appl. Therm. Eng. 2012, 48, 289–295. [Google Scholar] [CrossRef]

- Bilen, F.; Yıldıran, V.C.; Mayıl, A.S.; Erbaş, O. Cooking Performance Optimization with New Types of Fan Baffles in Domestic Built-in Ovens. In Proceedings of the 8th World Congress on Momentum, Heat and Mass Transfer (MHMT 23), Lisbon, Portugal, 26–28 March 2023. [Google Scholar]

- Chhanwal, N.; Anishaparvin, A.; Indrani, D.; Raghavarao, K.S.M.S.; Anandharamakrishnan, C. Computational fluid dynamics (CFD) modeling of an electrical heating oven for bread-baking process. J. Food Eng. 2010, 100, 452–460. [Google Scholar] [CrossRef]

- Lam, C.K.G.; Bremhorst, K. A modified form of the k-ε model for predicting wall turbulence. J. Fluids Eng. 1981, 103, 456–460. [Google Scholar] [CrossRef]

- Trebunskikh, T.V.; Ivanov, A.V.; Dumnov, G.E. FloEFD simulation of micro-turbine engines. In Proceedings of the Applied Aerodynamics Conference on Modelling & Simulation in the Aerodynamic Design Process, New York, NY, USA, 17–19 July 2012. [Google Scholar]

- Amirabedin, E.; Anık, T.; Karaduman, A. Feasibility of Using CFD Analysis for Improving the Gas Hobs Performance In Terms of Efficiency and Emissions. In Proceedings of the 4th World Congress on Momentum Heat and Mass Transfer, Rome, Italy, 10–12 April 2019. [Google Scholar]

- Kalitzin, G.; Iaccarino, G. Turbulence modeling in an immersed-boundary RANS method. CTR Annu. Briefs 2002, 415–426. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).