A Novel High-Precision Imaging Radar for Quality Inspection of Building Insulation Layers

Abstract

Featured Application

Abstract

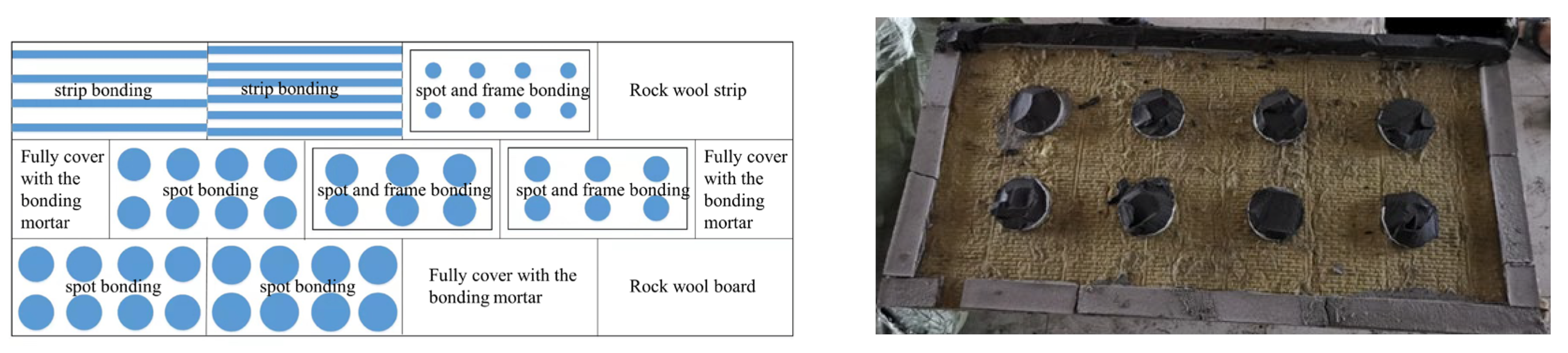

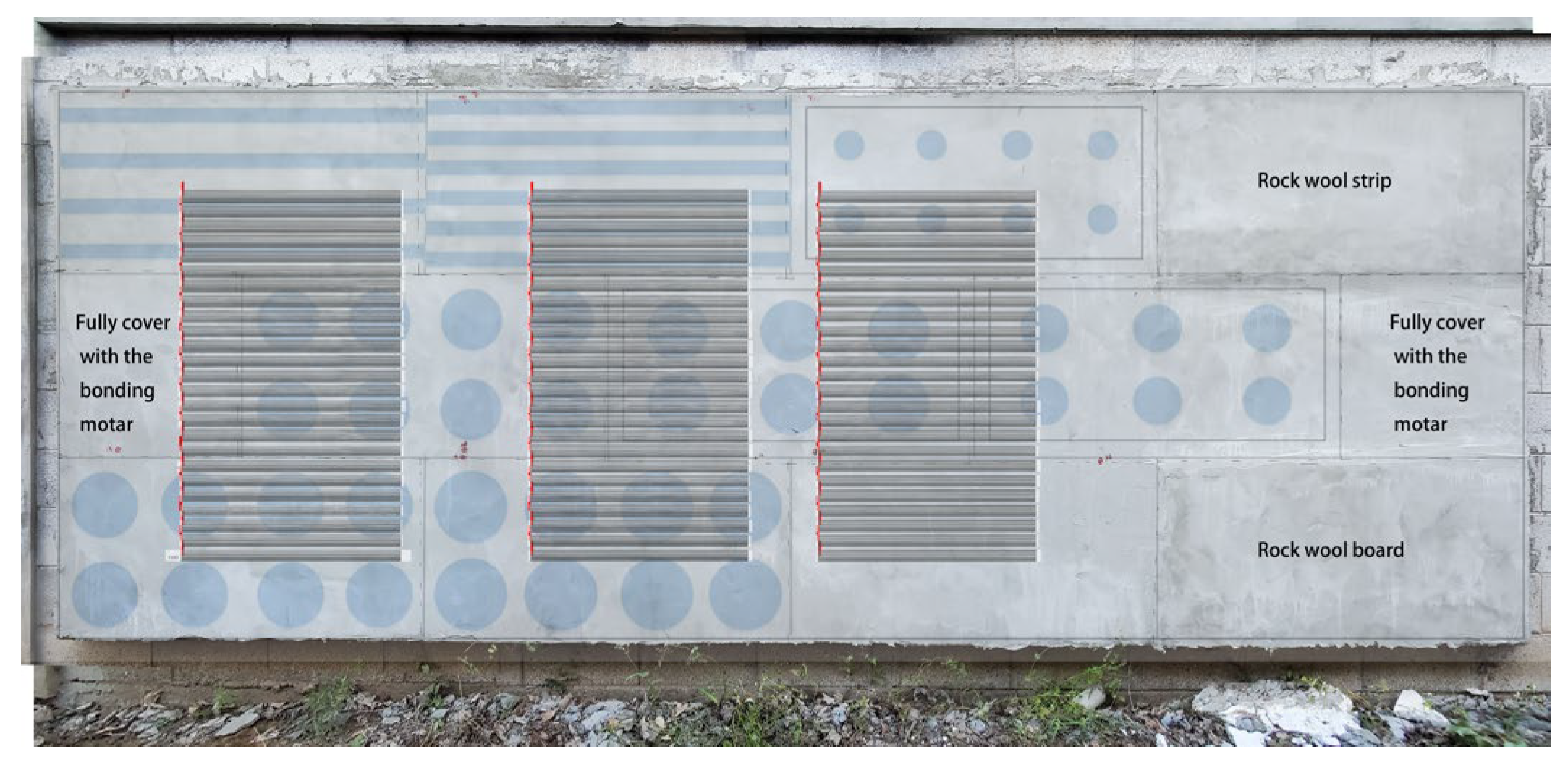

1. Introduction

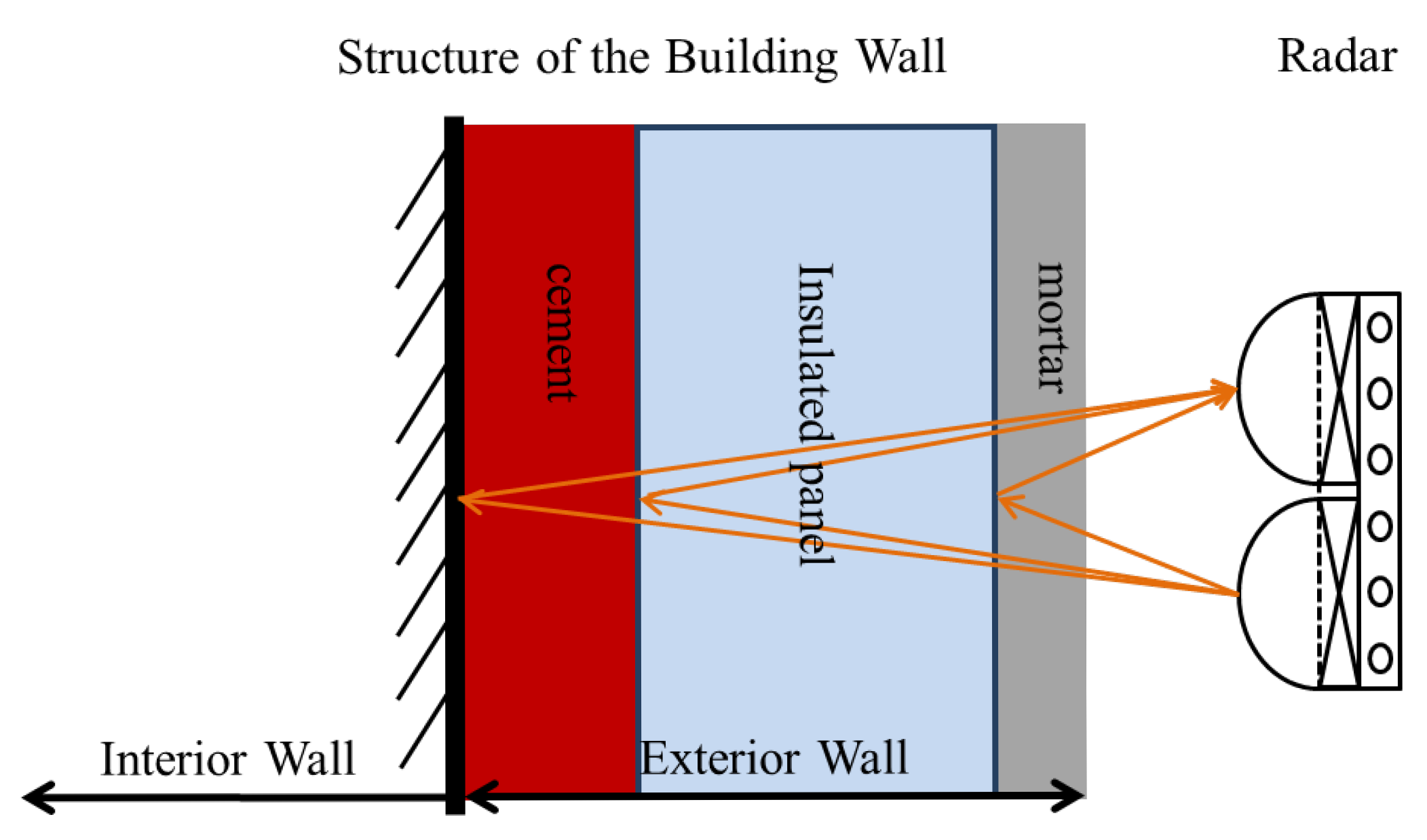

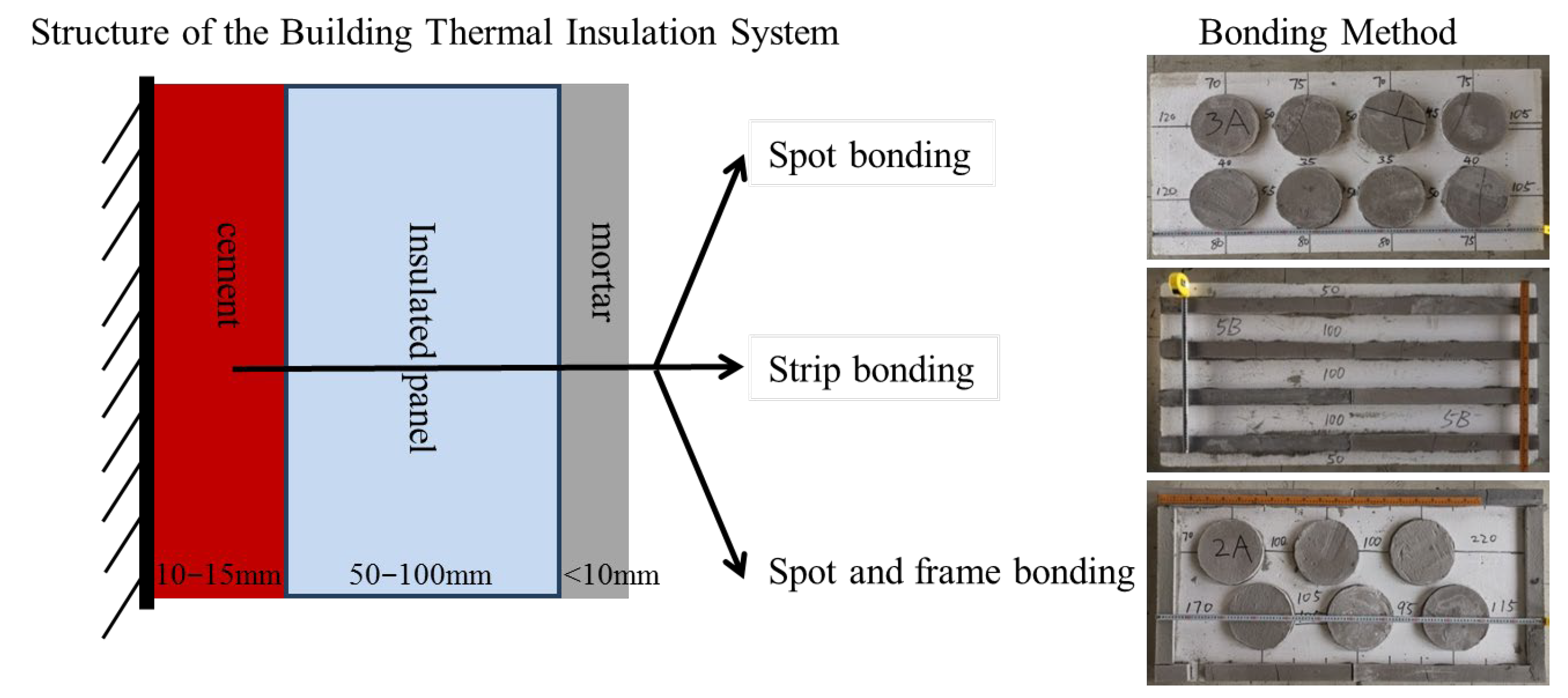

2. Radar Inspection Principle and Main Technical Parameters

2.1. Radar Inspection Principle

2.2. Main Technical Parameters

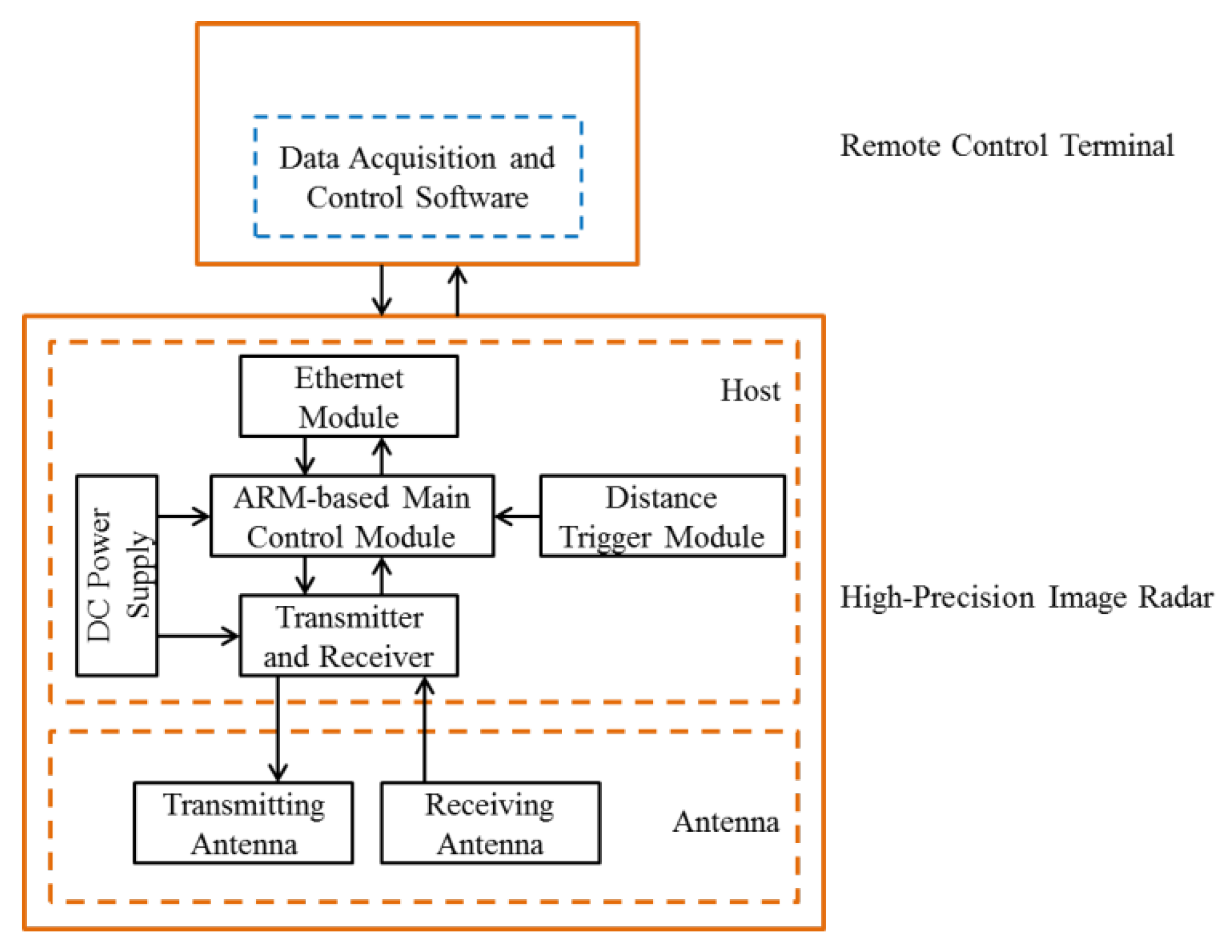

3. Radar System Design

3.1. System Composition

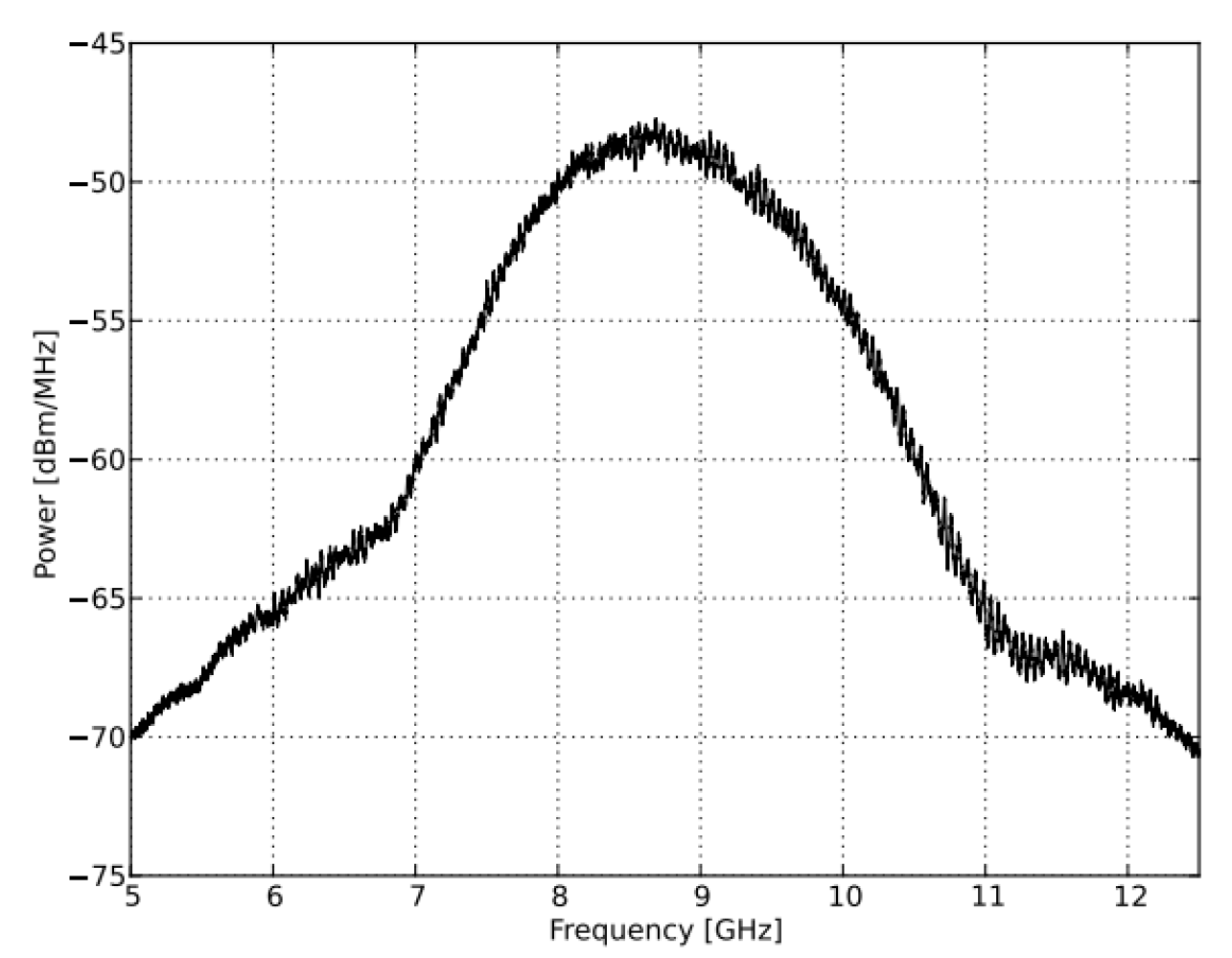

3.2. Radar Signal Selection

3.3. Ultra-Wideband High-Bunching Antenna Design

3.3.1. Antenna Selection

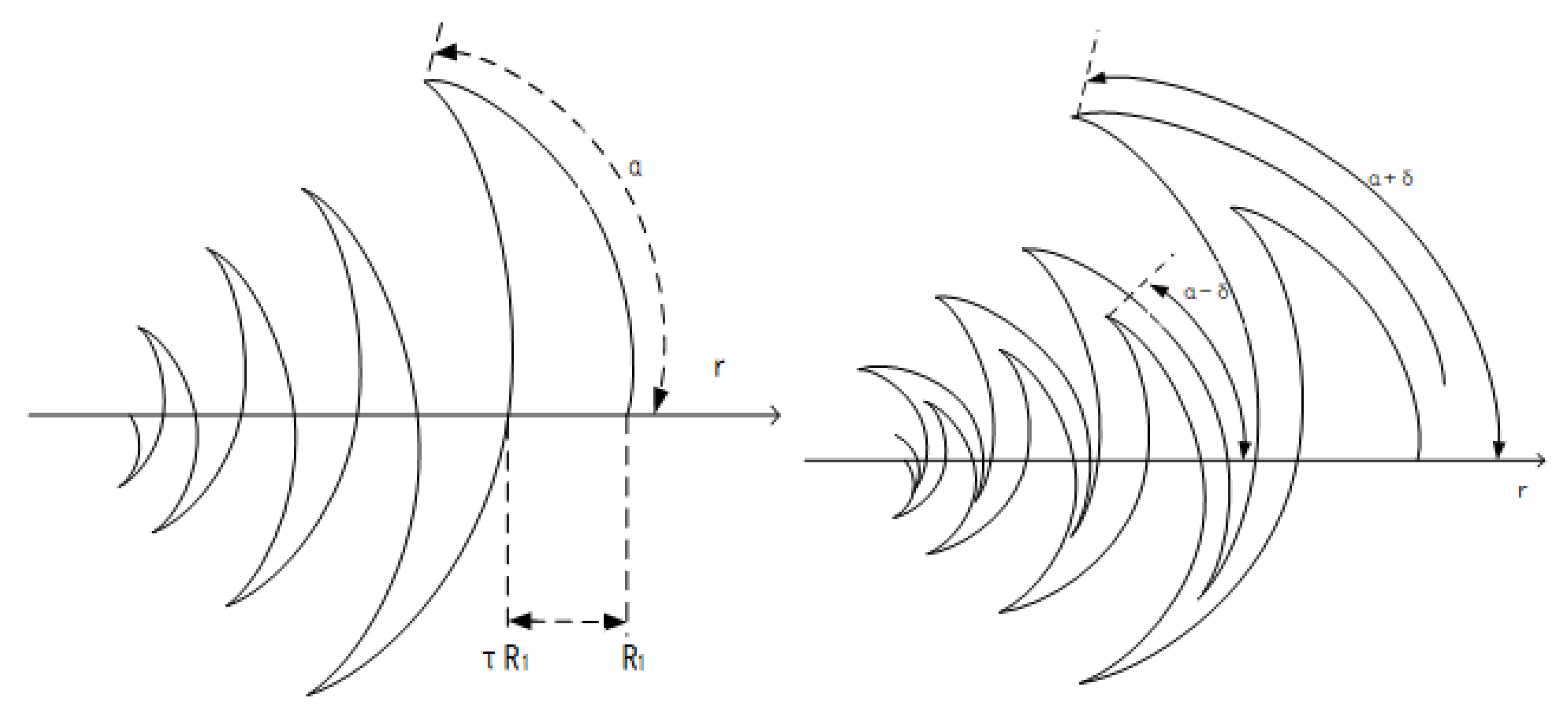

3.3.2. Ultra-Wideband High-Bunching Antenna

Radiation Oscillator

Lens Design

Reflective Backplane

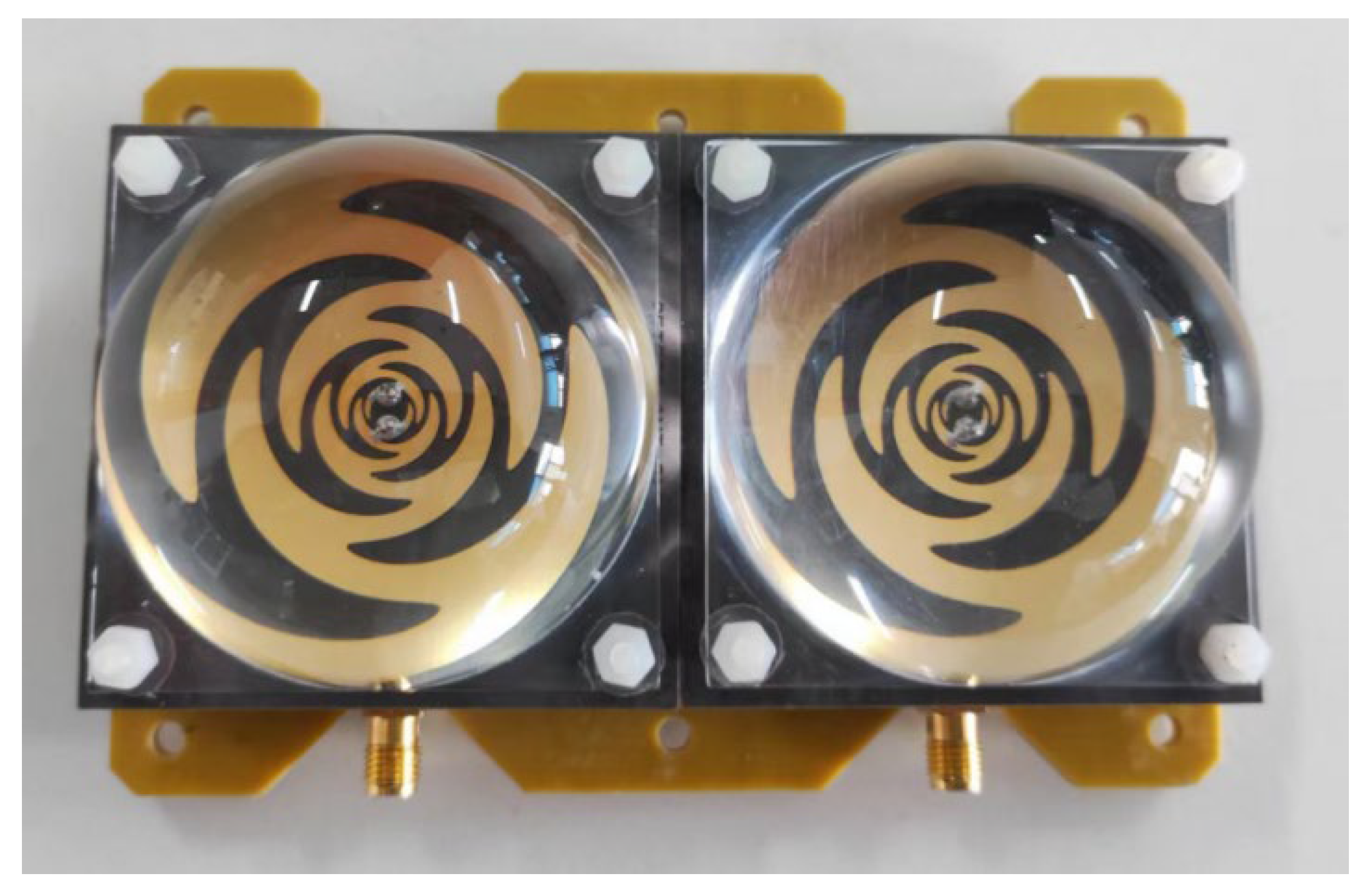

Structure Design

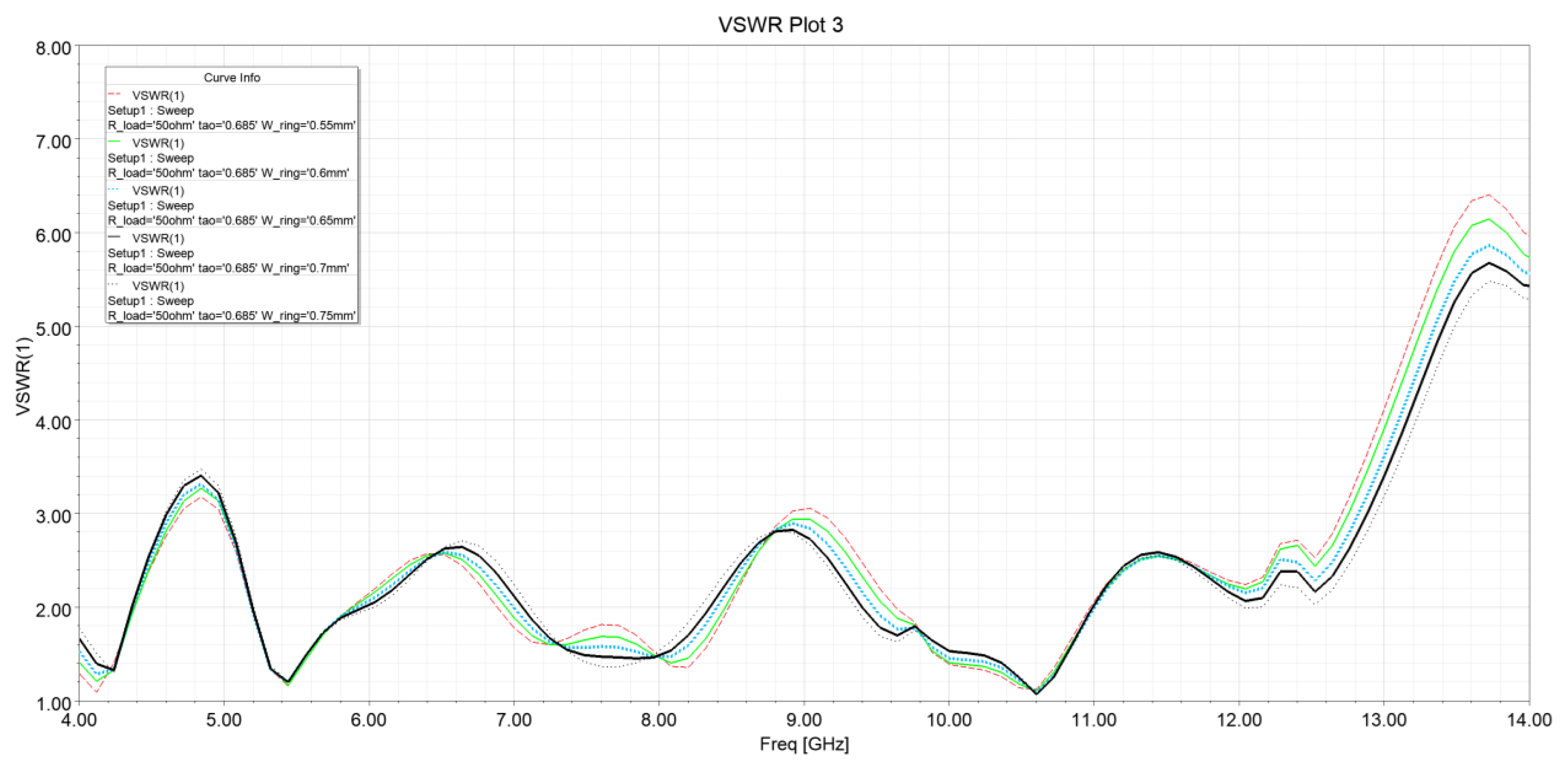

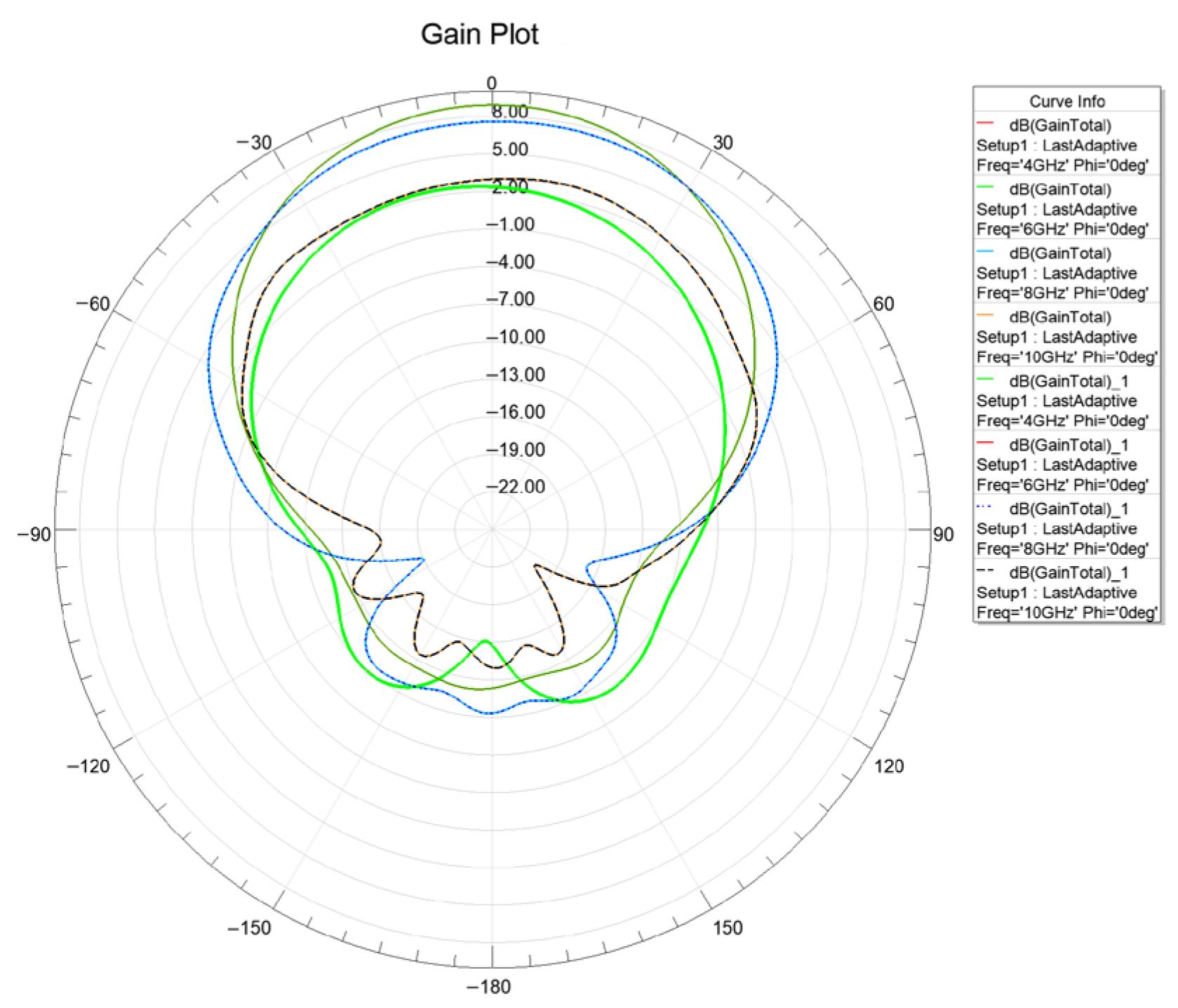

3.3.3. Antenna Sample Test Results

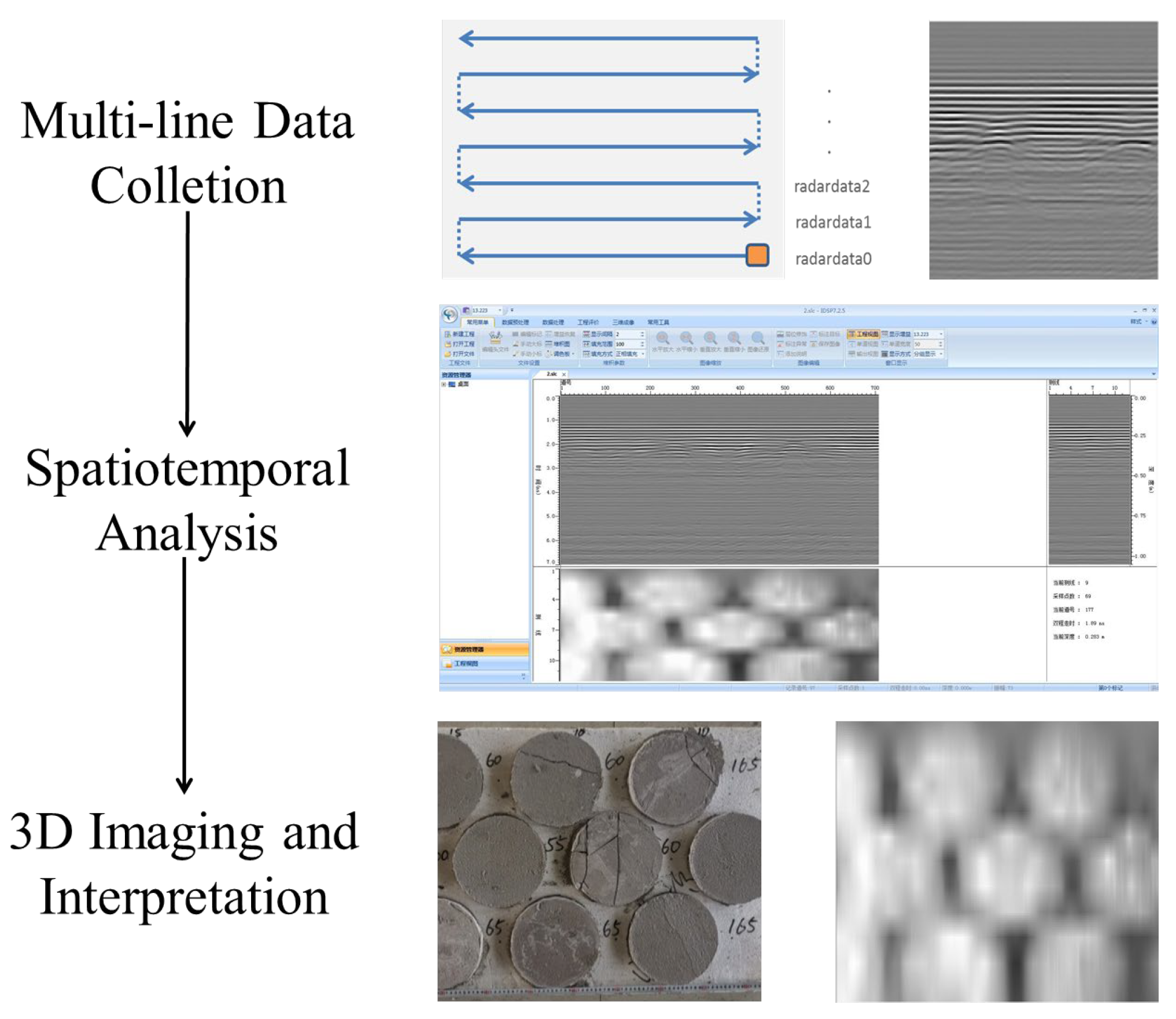

4. Test and Imaging Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ARM | Advanced RISC Machine |

| SMA | SubMiniature version A |

| SWR | Standing wave ratio |

| VSWR | Voltage standing wave ratio |

| PCB | Printed Circuit Board |

References

- Kośny, J.; Yarbrough, D.W. Thermal Efficiency of Insulation in Building Structures—The Impact of Thermal Bridging. Thermal Insulation and Radiation Control Technologies for Buildings; Springer International Publishing: Cham, Germany, 2022; pp. 443–486. [Google Scholar]

- Chai, J.; Fan, J. Advanced thermal regulating materials and systems for energy saving and thermal comfort in buildings. Mater. Today Energy 2022, 24, 100925. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Essien, V.; Ikumapayi, O.M.; Nnochiri, E.S.; Okokpujie, K.; Akinlabi, E.T. An overview of thermal insulation material for sustainable engineering building application. Int. J. Des. Nat. Ecodynamics 2022, 17, 831–841. [Google Scholar] [CrossRef]

- Schiavoni, S.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Zach, J.; Novák, V.; Peterková, J.; Bubeník, J.; Košir, M.; Božiček, D.; Krejza, Z. The Use of Advanced Environmentally Friendly Systems in the Insulation and Reconstruction of Buildings. Buildings 2023, 13, 404. [Google Scholar] [CrossRef]

- Fan, C. Research on Material Selection and Construction Technology Application of Exterior Insulation System. Ph.D. Thesis, Shenyang Jianzhu University, Shenyang, China, 2015. [Google Scholar]

- Wang, D.T. Analysis on Quality Issues for External Thermal Insulation System on Outer Walls. Adv. Mater. Res. 2012, 430–432, 1628–1631. [Google Scholar] [CrossRef]

- JGJ 144-2019; Technical Standard for External Wall Insulation Engineering. The Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Sadowski, Ł. Non-Destructive Testing for Building Evaluation. Buildings 2022, 12, 1030. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, H.; Wang, X. Research on the detection and control of external insulation materials for building exterior walls. Build. Technol. 2015, 42, 36–40. [Google Scholar]

- Li, Z.; Wang, M.; Xu, Y. Research on Detection Technology and Application of Building Exterior Wall Insulation Layer. Archit. Eng. Technol. Des. 2017, 6, 87–91. [Google Scholar]

- Song, F.; Luo, Y.; Wang, T. Research Progress of Nondestructive Testing Technology for Insulation Layer. Mater. Test. 2018, 34, 11–15. [Google Scholar]

- Zhang, D.; Wang, Z.; Jiang, L. Application of 3D laser scanning technology in defect detection of external wall thermal insulation system. Constr. Technol. 2020, 49, 4. [Google Scholar]

- Chen, X.; Wang, Z.; Xu, Q.; Zhang, D.; Chen, L. Application Research of Infrared Thermal Imaging Technology in Safety Detection of External Wall and External Insulation System. Build. Struct. 2023, 53, 105–112. [Google Scholar]

- Jiao, C. Research on the detection and identification of defects in the external insulation layer of building exterior walls based on infrared images. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2022. [Google Scholar]

- Gao, C.; Zhang, T. Application of Infrared Thermography for Detecting Delamination in Thermal Insulation Layers. In Proceedings of the International Conference on Civil Engineering and Construction, Lyon, France, 21–23 September 2017; pp. 98–103. [Google Scholar]

- Li, X.; Li, Y. Application of Infrared Thermography in Evaluating the Quality of Thermal Insulation Layers in Buildings. Energy Build. 2020, 208, 109671. [Google Scholar]

- Yang, S.; Li, Z. Detection and Evaluation of Thermal Insulation Layer Defects in Buildings Using Ultrasonic and Infrared Imaging. Constr. Build. Mater. 2019, 224, 937–947. [Google Scholar]

- Wang, L.; Chen, Z. Non-Destructive Evaluation of Insulation Layer in Buildings Using Acoustic Emission and Thermograph. In Proceedings of the International Symposium on Non-Destructive Testing in Civil Engineering, Zurich, Switzerland, 16–18 August 2022; pp. 244–251. [Google Scholar]

- Wang, Z.; Zhang, D.; Chen, X.; Jiang, L.; Zheng, S. Experimental Research on Defect Detection of EPS Board Thin Plastering External Wall External Insulation System Based on Acoustics. Constr. Technol. 2020, 49, 20–23. [Google Scholar]

- Wang, Z.; Zhang, D.; Jiang, L.; Chen, X.; Li, Y.; Zhang, Y. Experimental Research on Defect Detection of Inorganic Insulation Mortar External Wall and External Insulation System Based on Acoustics. Constr. Technol. 2020, 49, 5–8. [Google Scholar]

- Zhang, D. Application of Ground Penetrating Radar Technology in Nondestructive Testing of Inorganic Thermal Insulation Mortar Exterior Wall and Exterior Thermal Insulation System. Constr. Technol. 2020, 49, 16–19. [Google Scholar]

- Neal, A. Ground-penetrating radar and its use in sedimentology: Principles, applications and recent advances. Earth-Sci. Rev. 2004, 66, 261–330. [Google Scholar] [CrossRef]

- Loizos, A.; Vasilenko, G. Application of ground-penetrating radar for the investigation of building materials and structures. J. Appl. Geophys. 2014, 107, 50–56. [Google Scholar]

- Tosti, F.; Luciani, M. Assessment of the quality of thermal insulation materials in existing buildings through ground-penetrating radar. J. Build. Phys. 2016, 39, 242–259. [Google Scholar]

- Cesare, S.; Pepe, M. Application of ground-penetrating radar for the evaluation of building insulation materials and structures. Constr. Build. Mater. 2013, 38, 556–562. [Google Scholar]

- He, Z.; Zhang, L. Application of Ground Penetrating Radar for Non-destructive Testing of Insulating Materials in Civil Engineering. Int. J. Nondestruct. Test. Ultrason. Test. 2018, 3, 22–30. [Google Scholar]

- Muqaibel, A.; Safaai-Jazi, A.; Bayram, A.; Attiya, A.; Riad, S. Ultrawideband through-the-wall propagation. IEEE Proc. Microw. Antennas Propag. 2005, 152, 581–588. [Google Scholar] [CrossRef]

- Zhekov, S.S.; Franek, O.; Pedersen, G.F. Dielectric Properties of Common Building Materials for Ultrawideband Propagation Studies. IEEE Antennas Propag. Mag. 2020, 62, 72–81. [Google Scholar] [CrossRef]

- Yasmeen, K.; Ram, S.S. Estimation of Electrical Characteristics of Inhomogeneous Walls Using Generative Adversarial Networks. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2023, 16, 15. [Google Scholar] [CrossRef]

- Zeng, Z.; Liu, S.; Wang, Z.; Xue, J. Principle and Application of Ground Penetrating Radar; Science Press: Beijing, China, 2006; pp. 91–92. [Google Scholar]

- Novelda. X2 Impulse Radar Transceiver; Novelda: Trondheim, Norway, 2015. [Google Scholar]

- Sammeta, R.; Filipović, D.S. A low-profile sinuous antenna. 2014 IEEE Antennas and Propagation Society International Symposium (APSURSI), Memphis, TN, USA, 6–12 July 2014; pp. 1333–1334. [Google Scholar]

- Crocker, D.A.; Scott, W.R. Sinuous Antenna Design for UWB Radar. 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA,, 7–12 July 2019. [Google Scholar] [CrossRef]

- Seo, B.; Yoon, I.; Oh, J. Practical Design Considerations for Compact Array-Fed Huygens’ Dielectric Lens Antennas. Sensors 2019, 19, 538. [Google Scholar] [CrossRef]

- Yan, Y. Research and Design of Planar Microstrip Antenna with Back Cavity. Ph.D. Thesis, Nanjing University, Nanjing, China, 2011. [Google Scholar]

| Existing Nondestructive Testing (NDT) Methods | Advantages | Limitations |

|---|---|---|

| Optical Testing -Laser Scanning -Infrared Thermographic Testing | Capable of airborne operation and enables quantitative detection of surface defects (e.g., cracks, deformations) in insulation layers with high efficiency and accuracy | Surface-level detection only, limited to severe surface defects (e.g., cracks), cannot penetrate insulation to assess internal voids, water infiltration, bonding mortar distribution, and area coverage |

| Acoustic Testing -Ultrasonic Testing -Tap Testing | Low-cost solution and requires minimal technical expertise for operators, reducing training barriers | Subjective analysis, defect localization relies heavily on empirical interpretation, introducing operator bias |

| Conventional High-Frequency Ground Penetrating Radar (GPR) Testing | Deep detection capability, identifies subsurface features such as reinforcing bars (rebar) and protective layer thickness beneath the insulation. | Higher operational expenses, resolution insufficient to distinguish 1–2 cm thick bonded mortar layers |

| Parameter | Test Level | Min. | Typ. | Max. | Unit |

|---|---|---|---|---|---|

| Output port match, S22 | |||||

| 6.0–10.2 GHz | III (vn-tr) | −3.8 | dB | ||

| Output pulse center frequency | |||||

| PGSelect = 9 | III (vn-ti) | 8.2 | GHz | ||

| PGSelect = 10 | III (vn-ti) | 8.8 | GHz | ||

| Bandwidth, −10 dB | |||||

| PGSelect = 9 | III (vn-ti) | 2.35 | 2.65 | 3.20 | GHz |

| PGSelect = 10 | III (vn-ti) | 2.65 | 3.10 | 4.40 | GHz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, D.; Zeng, Z.; Ge, W.; Yin, Y.; Wang, C.; Li, S. A Novel High-Precision Imaging Radar for Quality Inspection of Building Insulation Layers. Appl. Sci. 2025, 15, 5991. https://doi.org/10.3390/app15115991

Cheng D, Zeng Z, Ge W, Yin Y, Wang C, Li S. A Novel High-Precision Imaging Radar for Quality Inspection of Building Insulation Layers. Applied Sciences. 2025; 15(11):5991. https://doi.org/10.3390/app15115991

Chicago/Turabian StyleCheng, Dandan, Zhaofa Zeng, Wei Ge, Yuemeng Yin, Chenghao Wang, and Shaolong Li. 2025. "A Novel High-Precision Imaging Radar for Quality Inspection of Building Insulation Layers" Applied Sciences 15, no. 11: 5991. https://doi.org/10.3390/app15115991

APA StyleCheng, D., Zeng, Z., Ge, W., Yin, Y., Wang, C., & Li, S. (2025). A Novel High-Precision Imaging Radar for Quality Inspection of Building Insulation Layers. Applied Sciences, 15(11), 5991. https://doi.org/10.3390/app15115991