Numerical Simulation on Dynamic Response of Drilling Parameters in Loaded Rock Mass

Abstract

1. Introduction

2. In Situ Drilling Test in Underground Coal Mine

2.1. Downhole Test Equipment and Methods

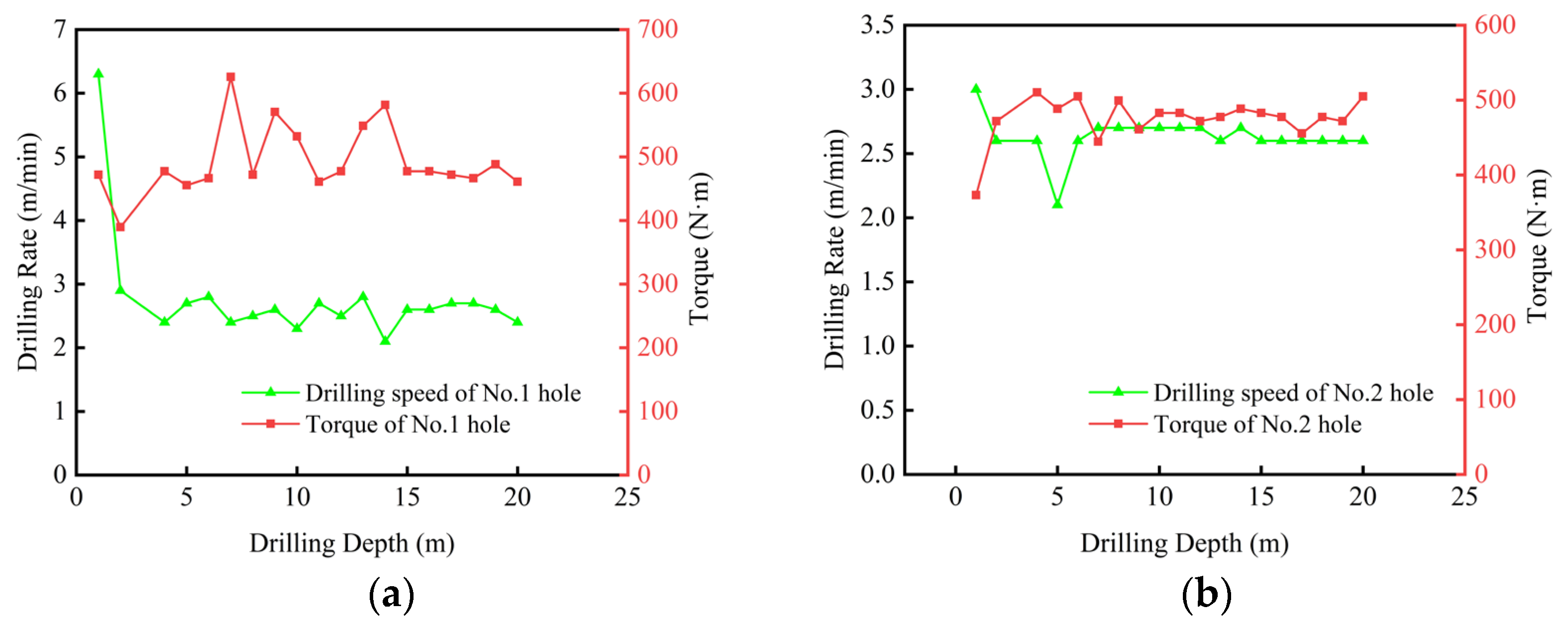

2.2. Test Result Analysis

3. Establishment of Numerical Model

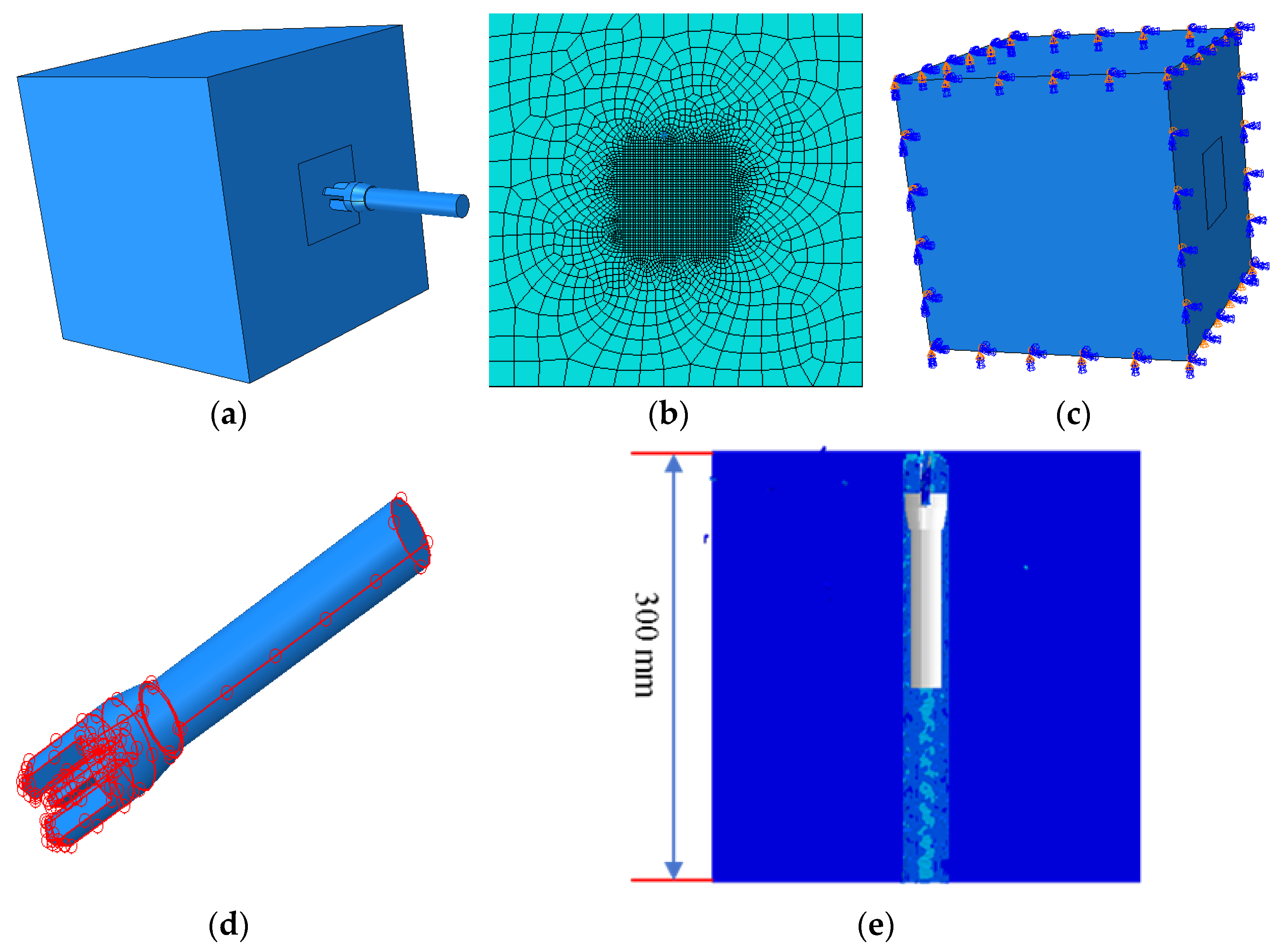

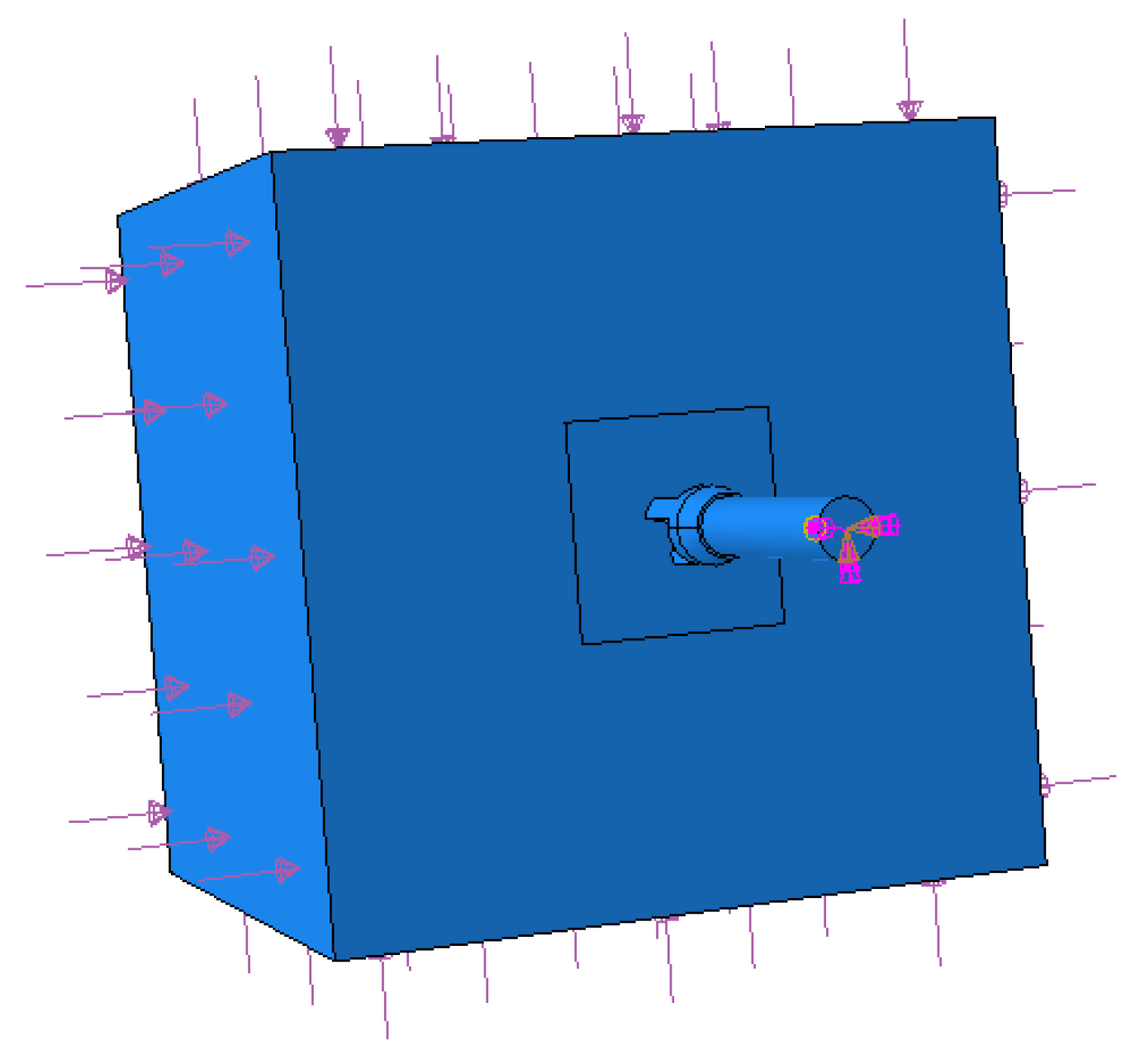

3.1. Drilling Model Establishment

3.2. Reliability Analysis of Drilling Simulation

- (1)

- During the drilling process, the drill bit is drilled in a manner perpendicular to the rock specimen, and the borehole does not deflect;

- (2)

- The stiffness and strength of the drill bit are much higher than that of the rock, so the drill bit is assumed to be a rigid body;

- (3)

- When the rock unit fails to drill, it is directly removed. Without considering the problem of repeated crushing, the broken rock unit will no longer affect the subsequent rock drilling work;

- (4)

3.3. Numerical Simulation Experiment Scheme

4. Numerical Simulation Results Analysis

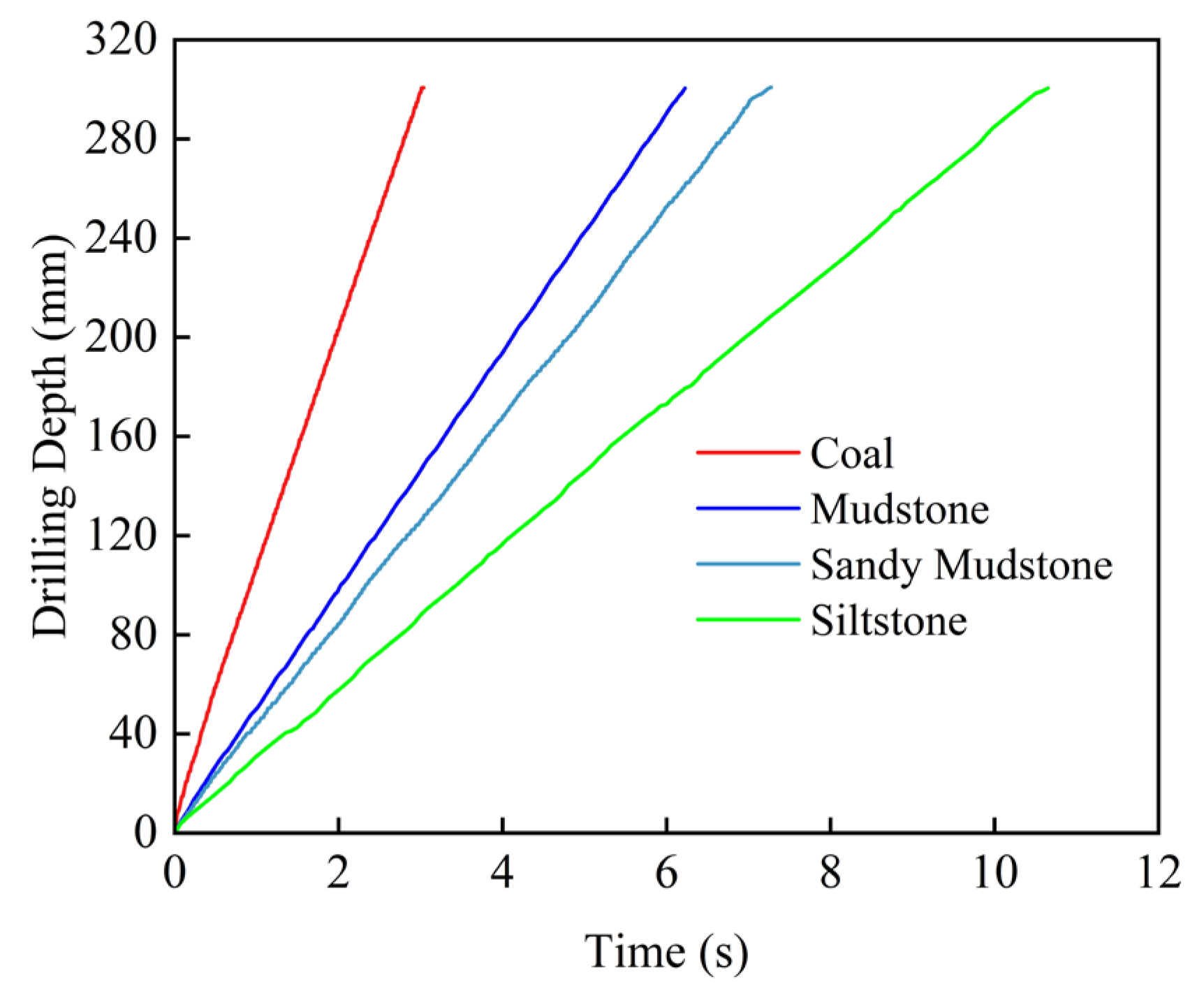

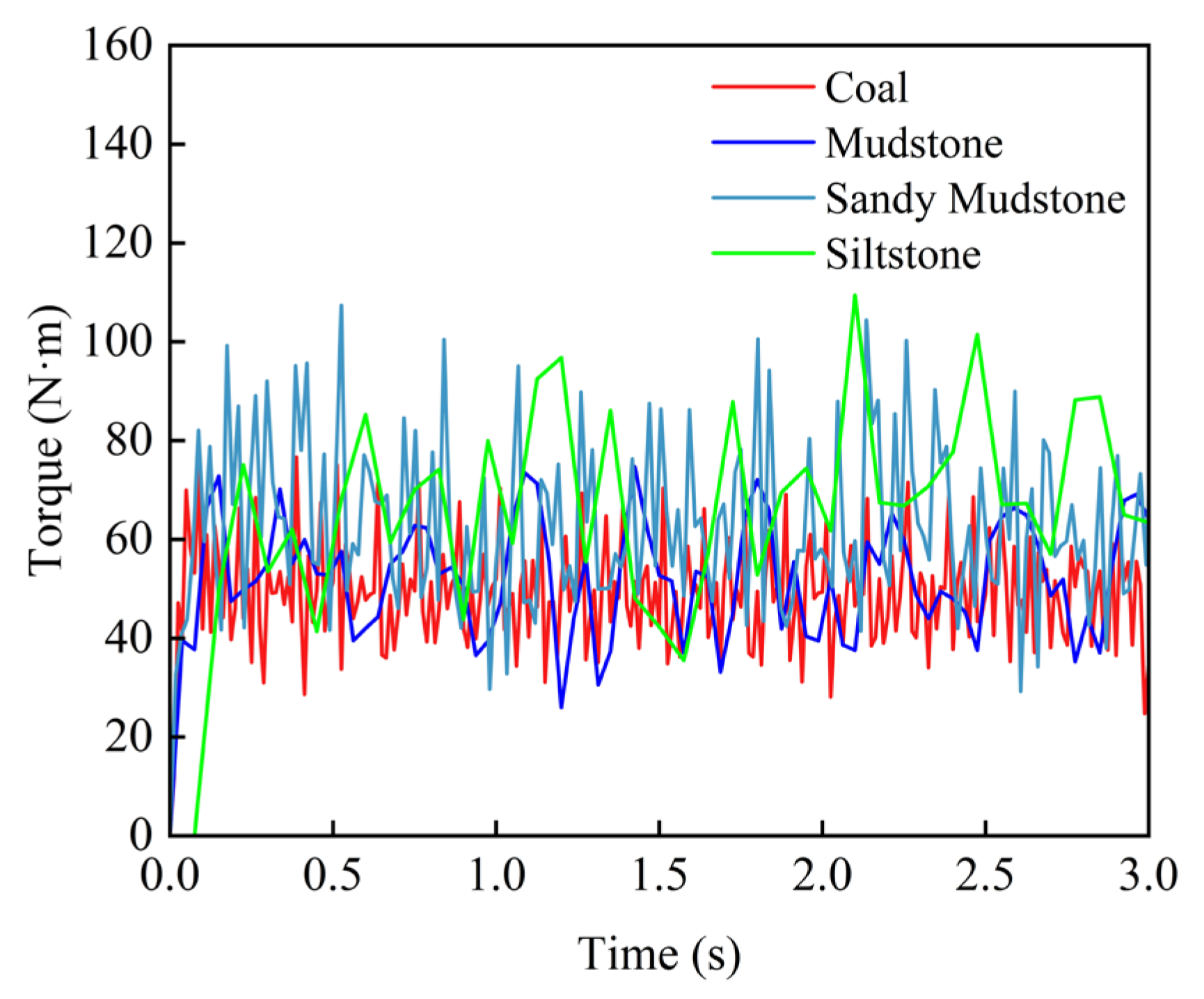

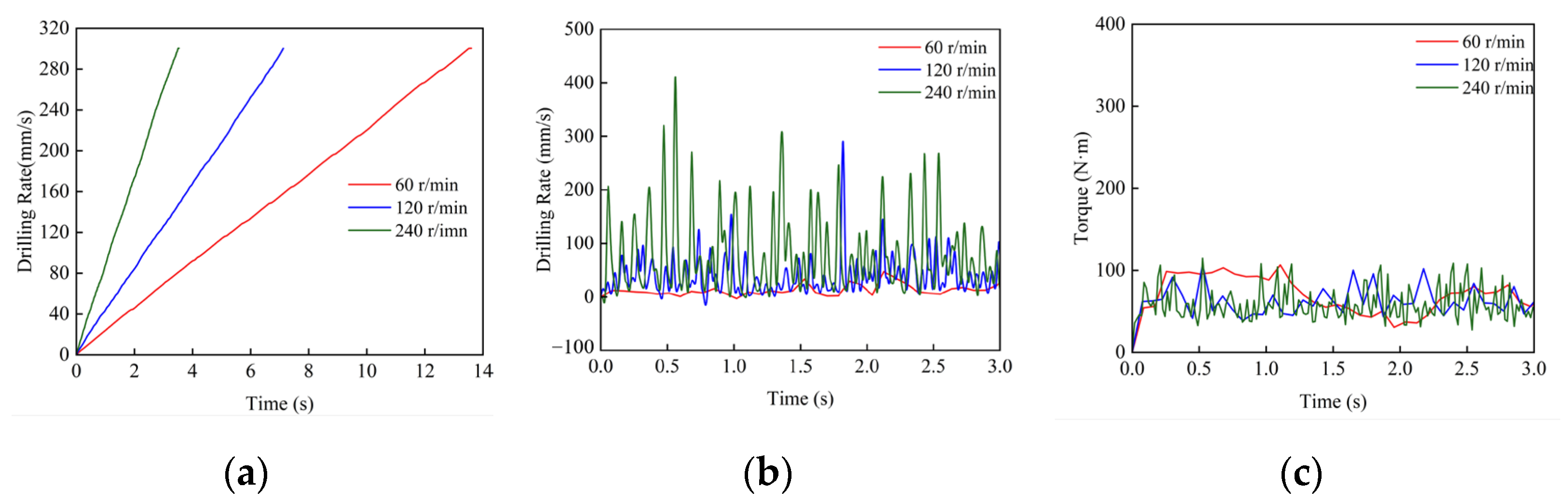

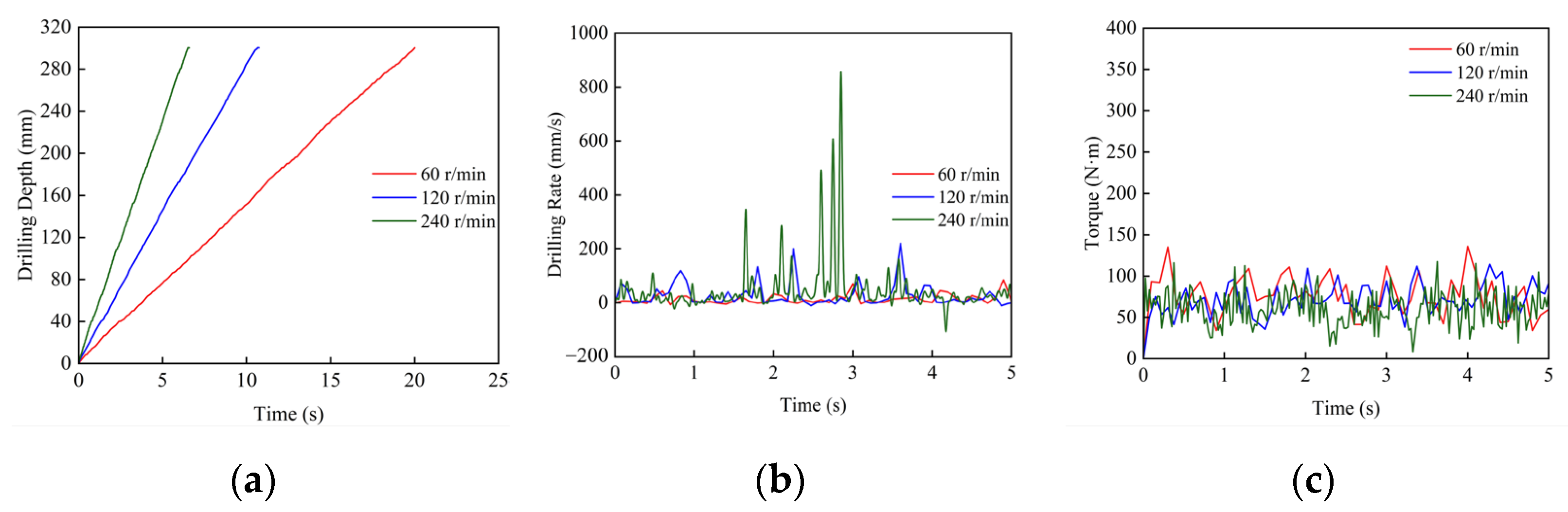

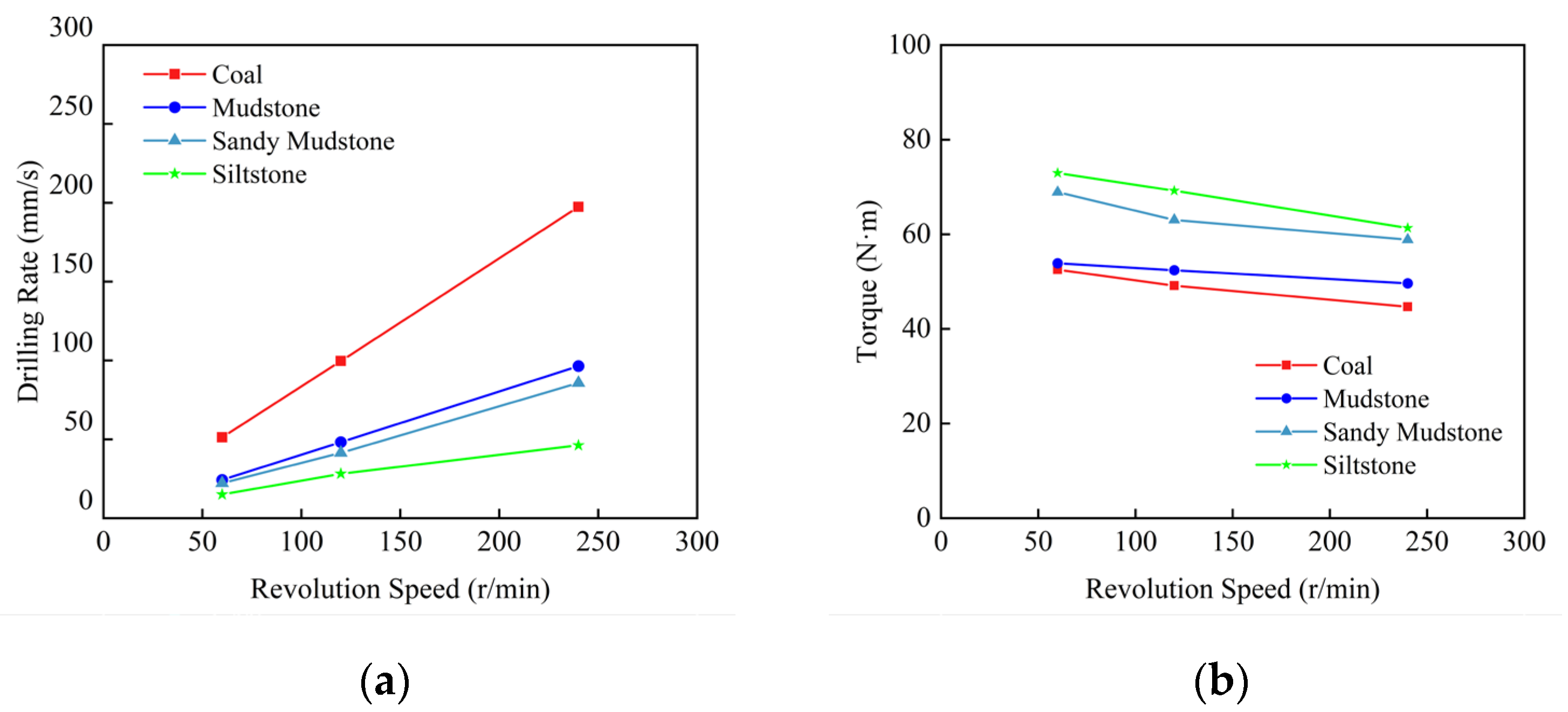

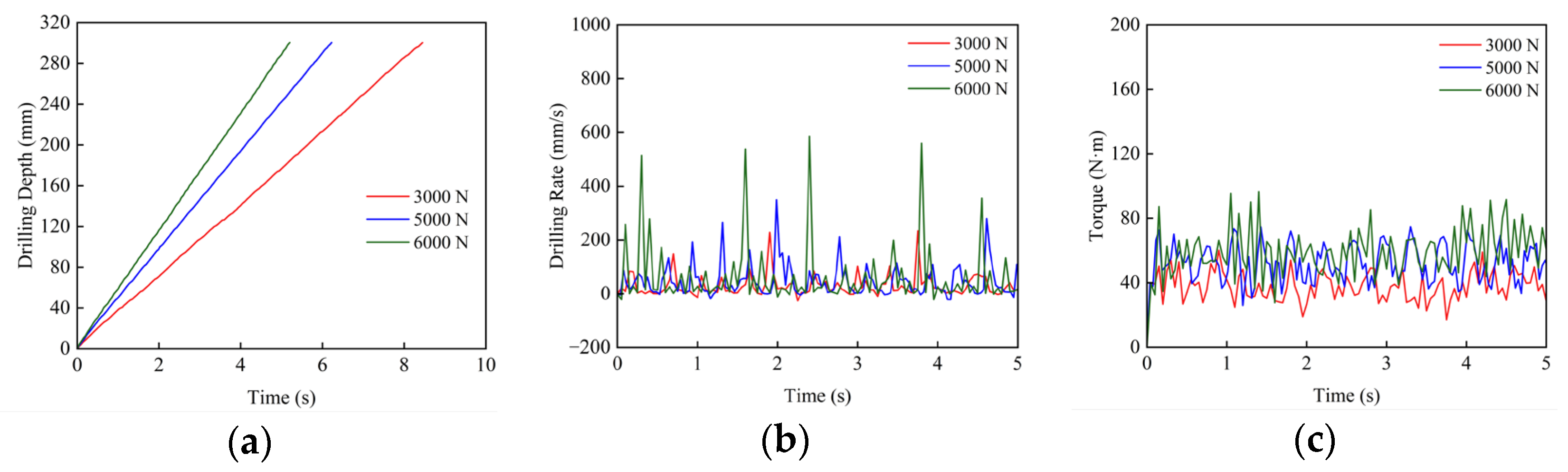

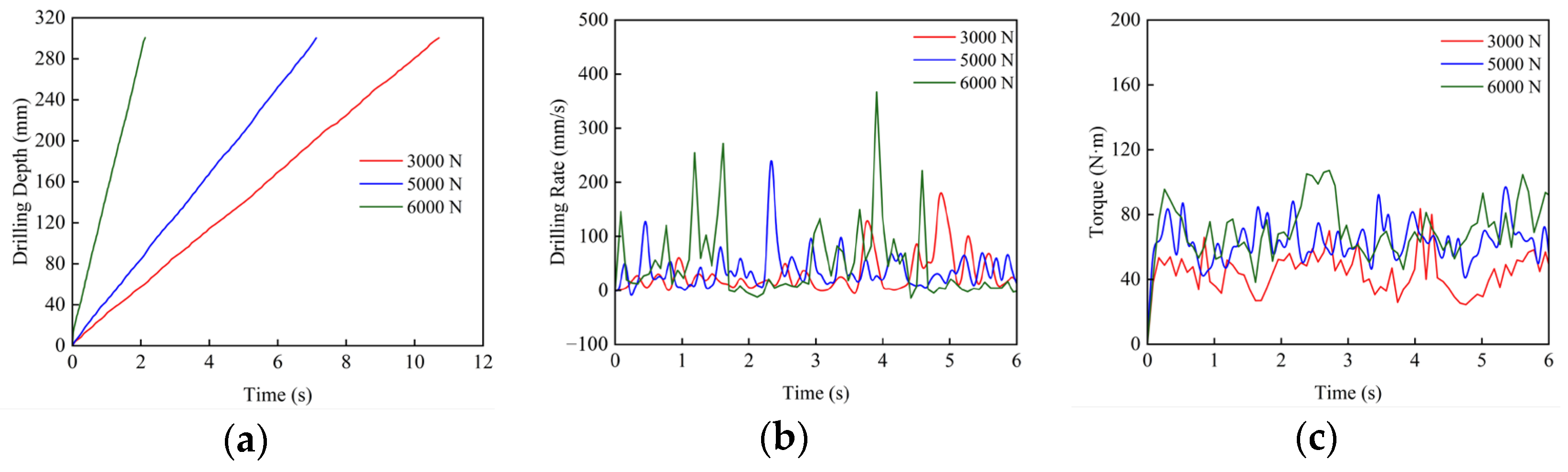

4.1. Analysis of Drilling Parameters Under Different Lithology Conditions

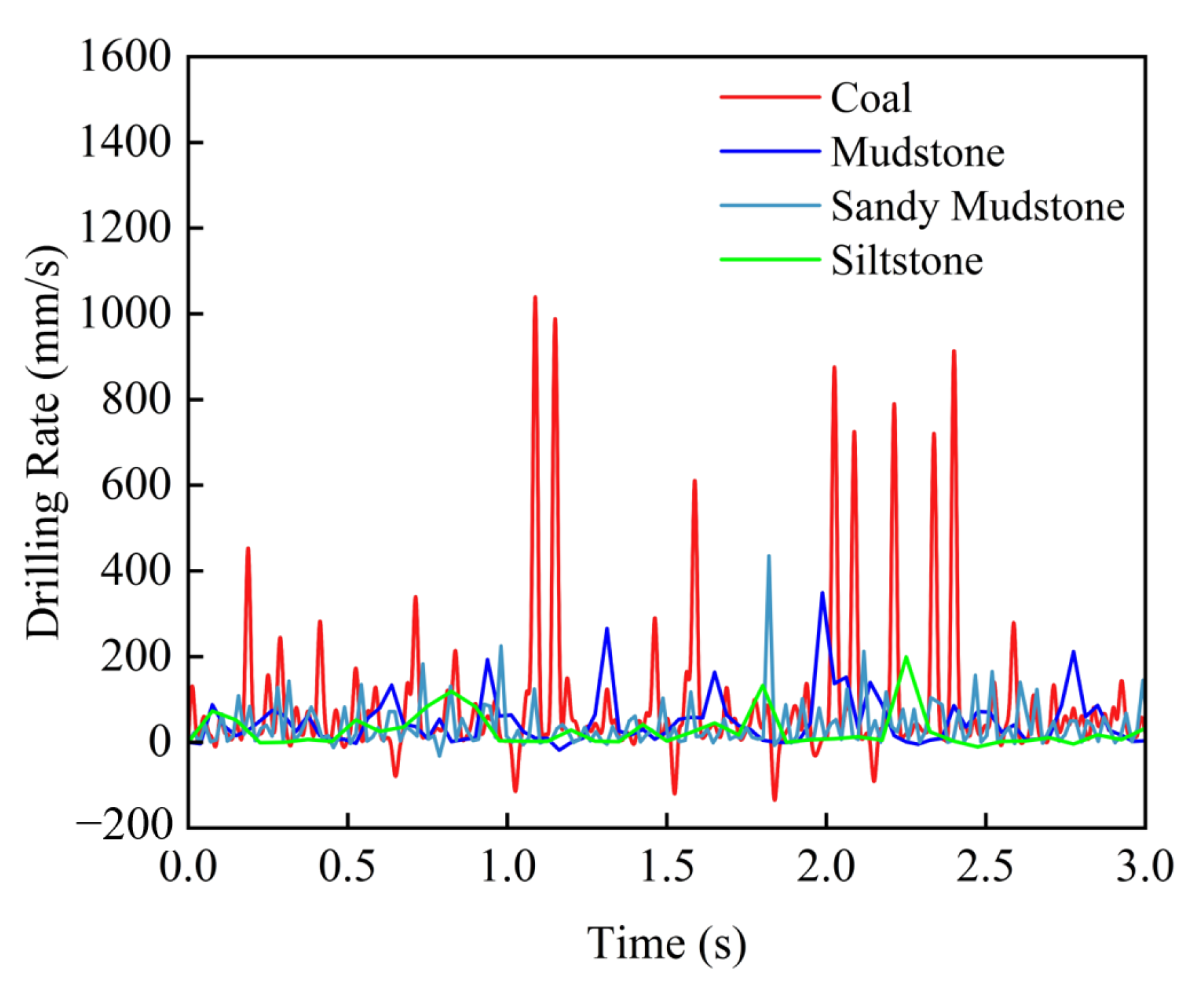

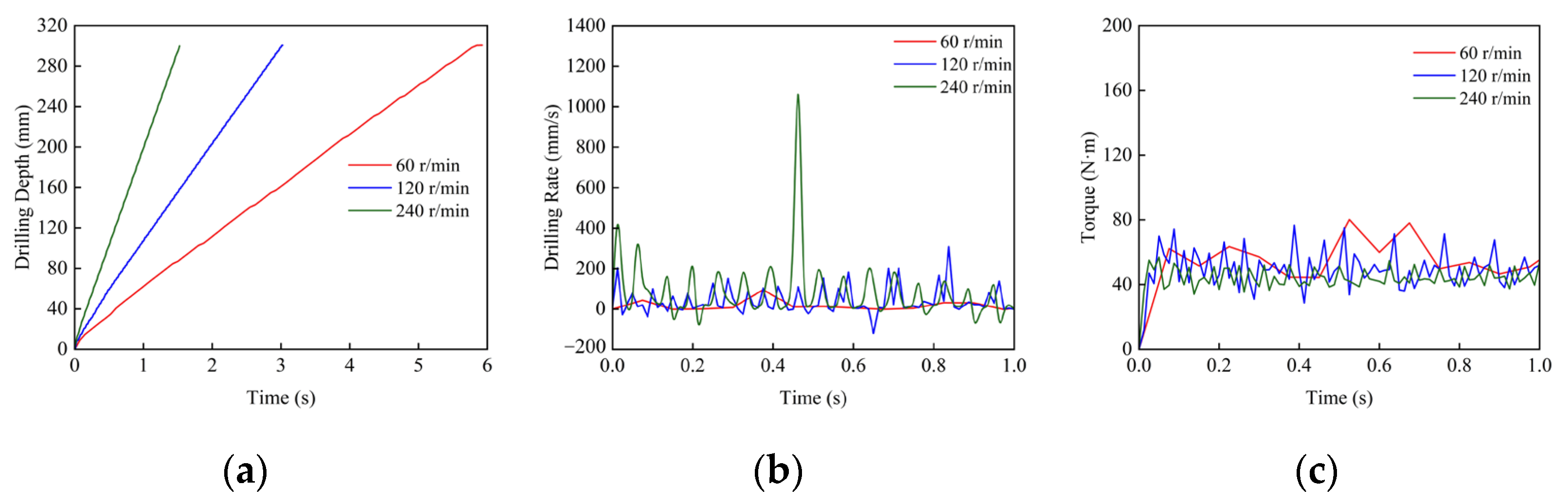

4.2. Analysis of Drilling Parameters Under Different Revolution Speed Conditions

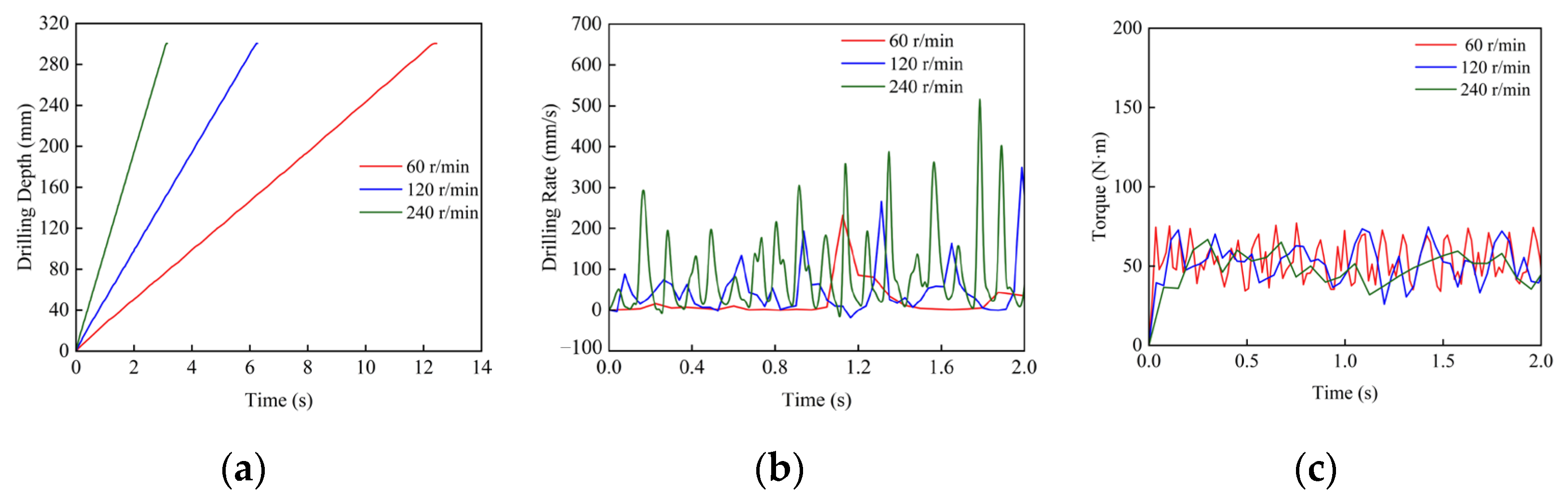

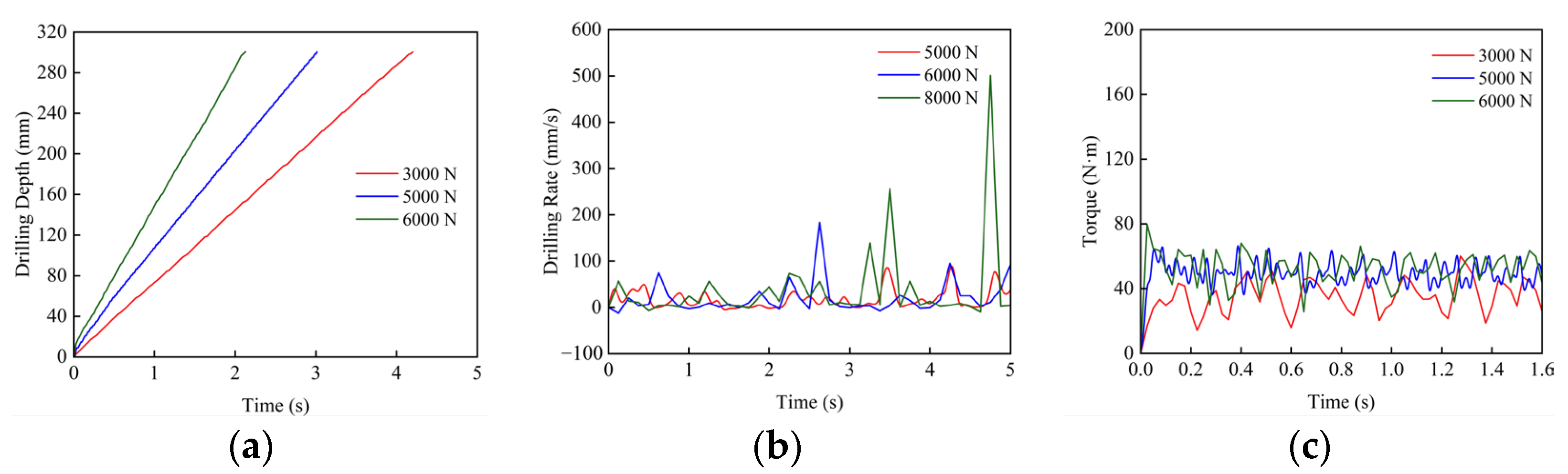

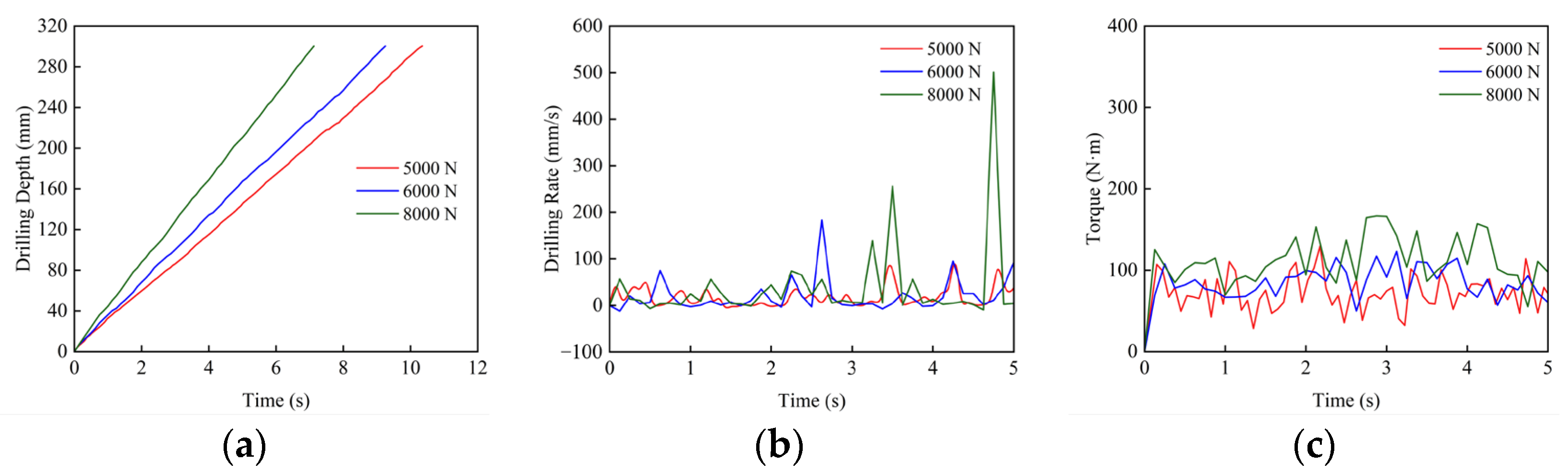

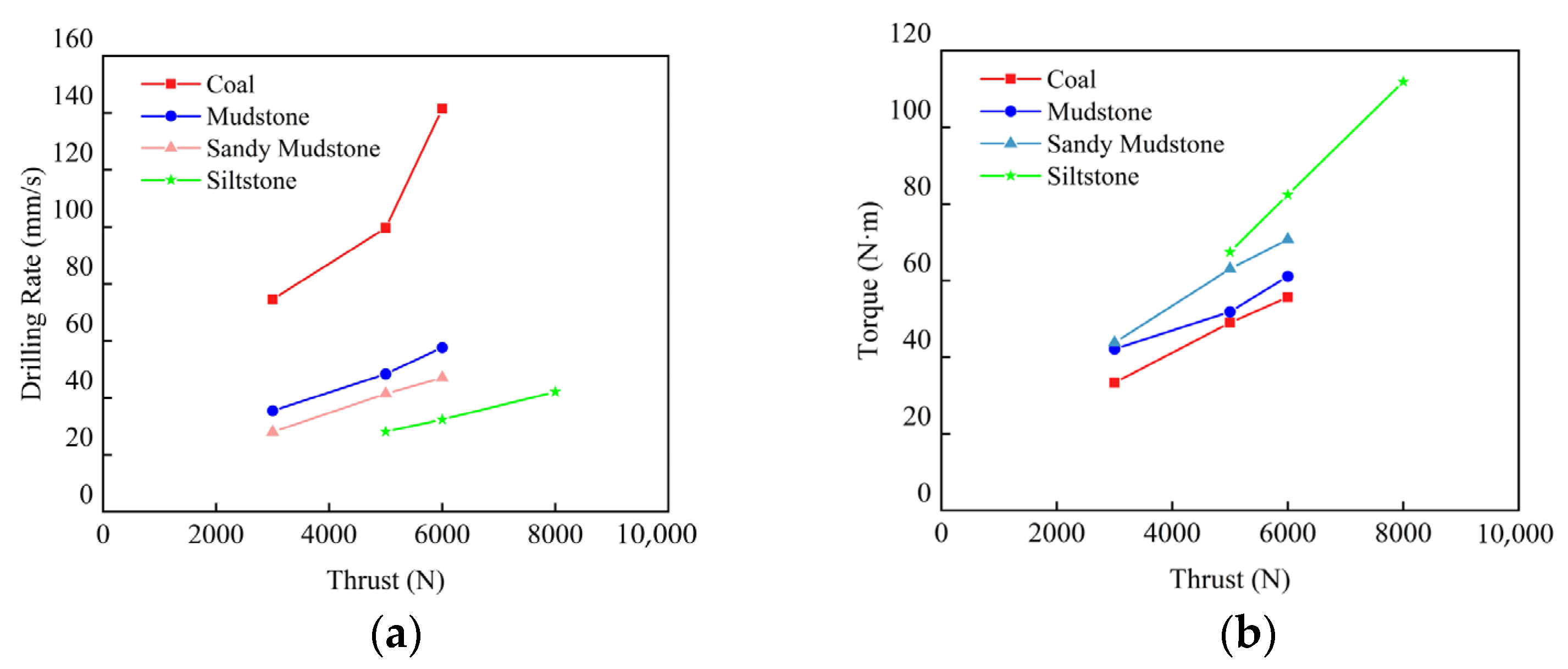

4.3. Analysis of Drilling Parameters Under Different Thrust Conditions

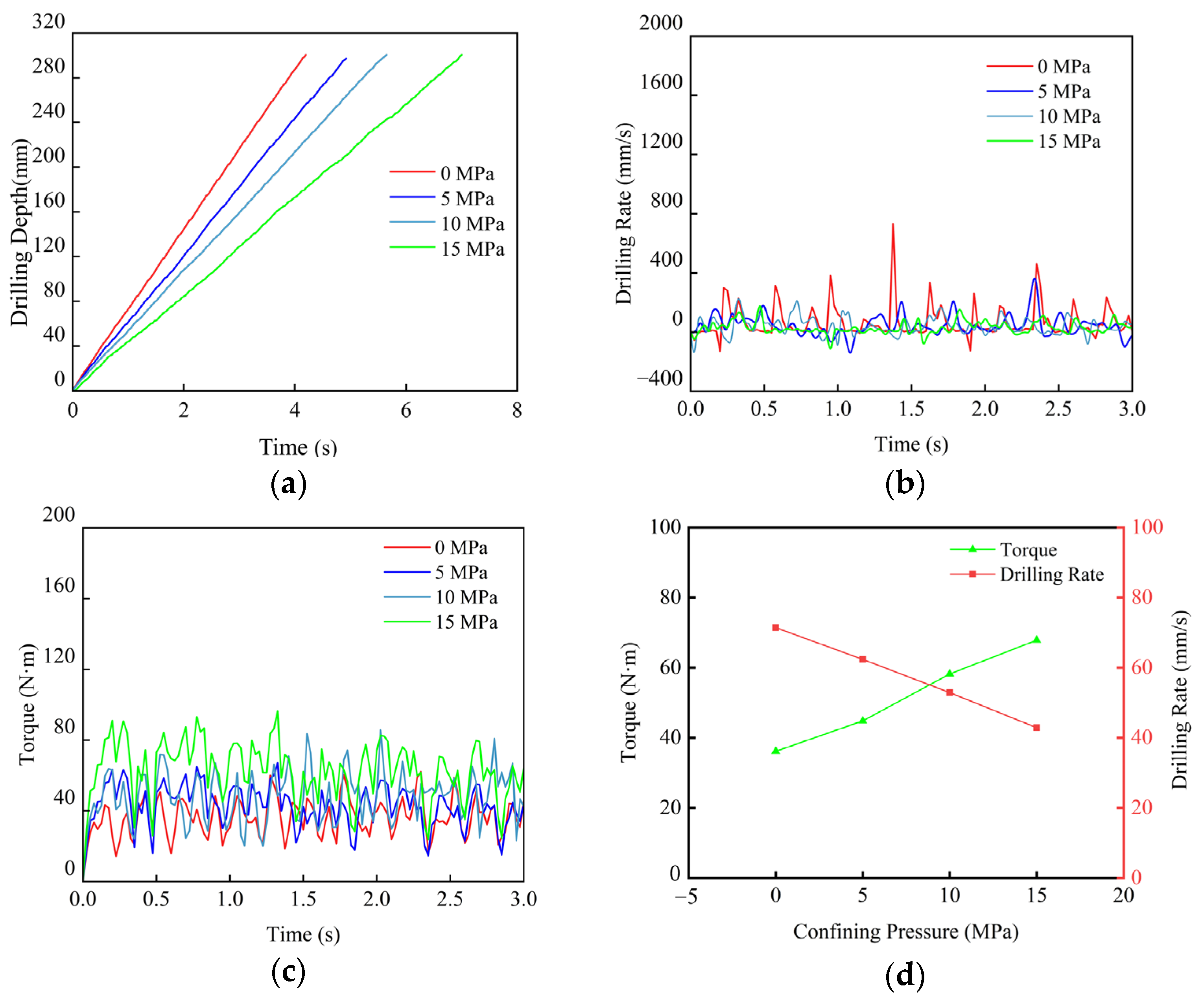

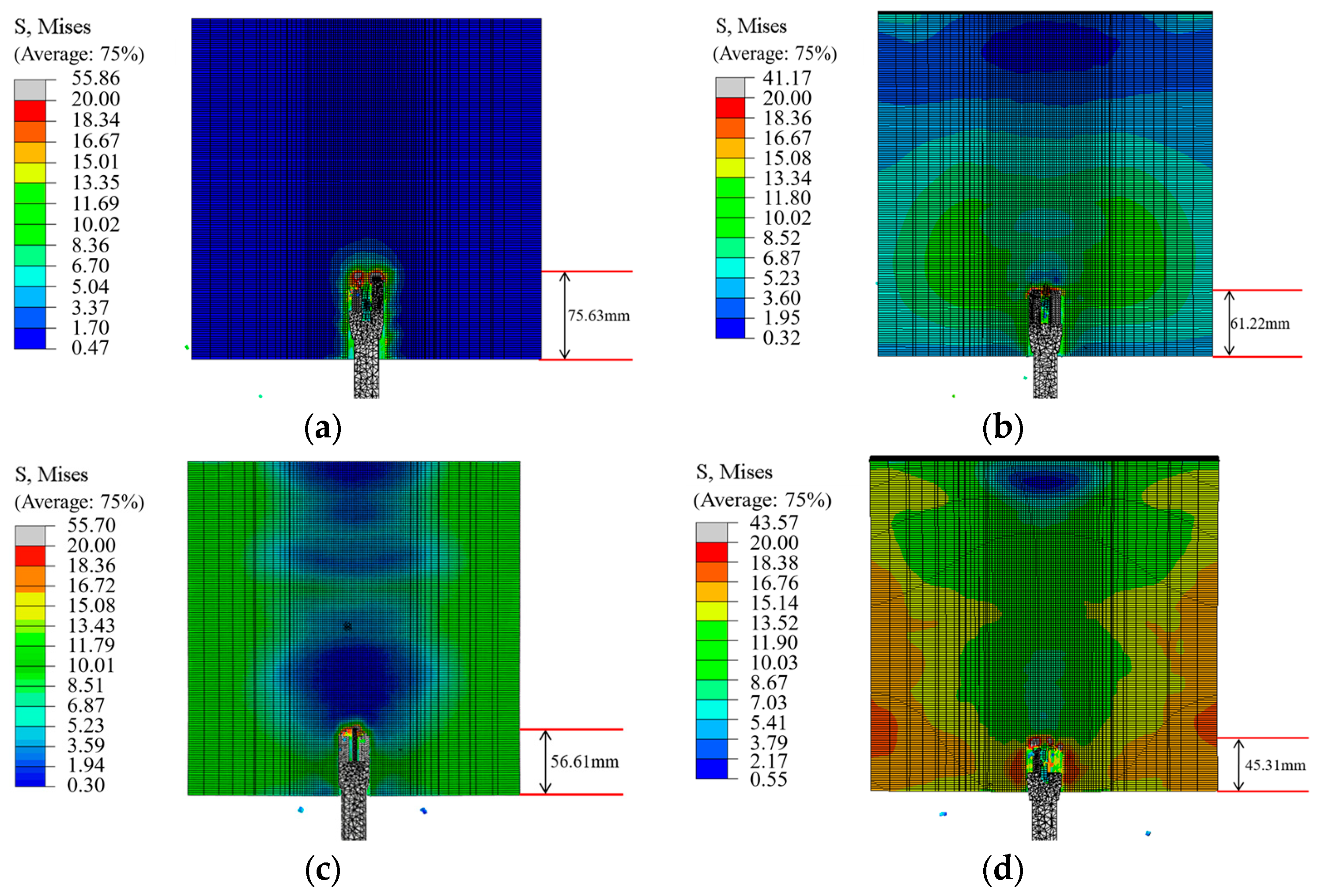

4.4. Analysis of Drilling Parameters Under Different Confining Pressure Conditions

5. Conclusions

- (1)

- At the same thrust–revolution speed level, the higher the strength of the rock, the greater the torque required for the drilling process and the slower the drilling rate. The average drilling rate of the four kinds of rock drilling is coal > mudstone > sandy mudstone > siltstone;

- (2)

- When the thrust is constant, with the increase in revolution speed, the drilling rate of coal, mudstone, sandy mudstone, and siltstone is approximately proportional to the linear increase, and the torque shows a negative correlation trend with the increase in the drilling rate. When the revolution speed is constant, with the increase in thrust, the drilling rate and torque of all kinds of rocks will gradually increase accordingly, showing a significant positive correlation trend;

- (3)

- With the increase in the confining pressure of the specimen, the average value of the torque increases gradually, and the average value of the drilling rate decreases gradually. There is an approximate linear negative correlation between drilling rate and rock confining pressure, and an approximate linear positive correlation between torque and rock confining pressure;

- (4)

- In this paper, the variation in parameters while drilling under different influence conditions is preliminarily studied. At the same time, there are also some shortcomings. For example, only four rock samples of coal, mudstone, sandy mudstone, and siltstone are selected for research, and other common rock types are not involved. The limited selection of rock types limits the universality of the research results. Therefore, future research can consider further increasing the types of rock samples (such as limestone, shale, etc.) and discuss the response characteristics of drilling parameters under complex geological conditions to further improve and expand the experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, Z.L.; Wang, L. Comparative experimental study on point load strength and tension-compression strength of coal seam roof and floor rock. J. Rock Mech. Eng. 2013, 32, 88–96. [Google Scholar]

- Li, N.; Li, Q.; Song, L. A new idea for obtaining rock mechanics parameters based on rotary cutting. J. Rock Mech. Eng. 2015, 34, 323–329. [Google Scholar] [CrossRef]

- Yang, W.W.; Yue, Z.Q.; Tham, L.G. Automatic monitoring of inserting or retrieving SPT sampler in drillhole. Geotech. Test. J. 2012, 35, 420–436. [Google Scholar] [CrossRef]

- Gui, M.W.; Soga, K.; Bolton, M.D.; Hamelin, J.P. Instrumented borehole drilling for subsurface investigation. J. Geotech. Geoenviron. Eng. 2002, 128, 283–291. [Google Scholar] [CrossRef]

- Kahraman, S.A.I.R.; Bilgin, N.; Feridunoglu, C. Dominant rock properties affecting the penetration rate of percussive drills. Int. J. Rock Mech. Min. Sci. 2003, 40, 711–723. [Google Scholar] [CrossRef]

- Yu, Q.L.; Wang, Y.H.; Li, Y.; Cao, Y.S.; Pu, J.Y. Research progress on characterization of rock mass structure and mechanical parameters based on measurement while drilling. Met. Mine 2023, 45–58. [Google Scholar] [CrossRef]

- Tan, Z.Y.; Cai, M.F.; Yue, Z.Q.; Tan, G.H.; Li, Z.F. Drilling parameters are used to identify the interface of complex weathered granite strata in Hong Kong. J. Rock Mech. Eng. 2006, S1, 2939–2945. [Google Scholar]

- Teale, R. The Concept of Specific Energy in Rock Drilling. In International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts; Pergamon: Oxford, UK, 1965; Volume 2, pp. 57–73. [Google Scholar]

- Song, L.; Li, N.; Liu, F.Y. Feasibility study on the application of rotary penetration technology in harder strata. Geomechanics. Rock Soil Mech. 2011, 32, 635–640. [Google Scholar] [CrossRef]

- Yue, Z.Q. Drilling process monitoring (DPM) improves the evaluation method of engineering rock mass quality. J. Rock Mech. Eng. 2014, 10, 1977–1996. [Google Scholar] [CrossRef]

- Tan, Z.Y.; Yue, Z.Q.; Tan, G.H.; Li, Z.F. Diamond drilling specific work and real-time classification of weathered granite. J. Rock Mech. Eng. 2007, S1, 2907–2912. [Google Scholar]

- Wang, Q.; Qin, Q.; Gao, S.; Li, S.C.; Gao, H.K.; He, M.C.; Zhang, C. The relationship between digital drilling parameters and rock uniaxial compressive strength. Coal J. 2018, 43, 1289–1295. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, H.K.; Jiang, Z.H.; Li, J.B. Development and application of digital drilling test system for surrounding rock of underground engineering. J. Rock Mech. Eng. 2020, 39, 301–310. [Google Scholar] [CrossRef]

- Shi, J.; Wang, J.; Liu, X. The Nonlinear Dynamics Simulation of Drill String-drill Bit-rock Based on ABAQUS. In Proceedings of the 2nd International Conference on Civil, Materials and Environmental Sciences, London, UK, 13–14 March 2015; Atlantis Press: Dordrecht, The Netherlands, 2015; pp. 454–457. [Google Scholar]

- Li, X.T. Experimental Study on Drilling Characteristics of Anchor Hole in Coal Roadway Roof. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2015. [Google Scholar]

- Liu, S.W.; Liu, D.L.; Feng, Y.L.; Li, X.T.; Shang, P.X. Influence of stress state on drilling speed of roof anchoring hole in coal roadway. Coal J. 2014, 39, 608–613. [Google Scholar] [CrossRef]

- Liu, S.W.; Feng, Y.L.; Liu, D.L. Numerical test of dynamic response characteristics of layered roof rock drilling in coal roadway. J. Rock Mech. Eng. 2014, S1, 3170–3176. [Google Scholar] [CrossRef]

- Lin, T.J.; Lian, Z.H.; Meng, Y.F.; Yang, B.; Wu, X.Z.; Xiao, Z. Finite element simulation of dynamic rock breaking in air drilling. J. Rock Mech. Eng. 2008, S2, 3592–3597. [Google Scholar]

- Che, D.; Smith, J.; Ehmann, K.F. Finite element study of the cutting mechanics of the three dimensional rock turning process. In Proceedings of the International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–12 June 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 56826, p. V001T02A021. [Google Scholar]

- Wang, S.Y.; Sloan, S.W.; Liu, H.Y.; Tang, C.A. Numerical simulation of the rock fragmentation process induced by two drill bits subjected to static and dynamic (impact) loading. Rock Mech. Rock Eng. 2011, 44, 317–332. [Google Scholar] [CrossRef]

- Zhang, G.H. Research on Rock Breaking Mechanism and Surrounding Rock State Identification Technology of PDC Bit. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Fu, M.X.; Liu, S.W.; Fan, K.; Bloomberg; Kang, Y.L.; Jia, H.S. Numerical simulation study on vibration characteristics of drill pipe drilling in roof anchoring hole of coal roadway. J. Min. Saf. Eng. 2019, 36, 473–481. [Google Scholar] [CrossRef]

- Liu, S.W.; Zhu, Q.K.; Jia, H.S.; Li, X.T. Dynamic response characteristics and identification of rock interface in coal roadway roof anchoring hole drilling. J. Min. Saf. Eng. 2017, 34, 748–753+759. [Google Scholar] [CrossRef]

- Liu, J.L.; Luan, M.T.; Xu, C.S.; Wang, J.L.; Yuan, F.F. Drucker-Prager criterion parameter characteristics analysis. J. Rock Mech. Eng. 2006, S2, 4009–4015. [Google Scholar]

- Shiyun, X.; Gao, L.; Zhe, W. Wang Drucker-Prager material consistent rate constitutive model. Eng. Mech. 2003, 4, 147–151. [Google Scholar]

- Liu, D.L. Study on the Dynamic Response Characteristics of Roof Anchoring Hole Drilling in Coal Roadway. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2014. [Google Scholar]

- Kong, S.T. Simulation Study on Rock Breaking of Rotary Drilling Rig. Master’s Thesis, China University of Geosciences (Beijing), Beijing, China, 2021. [Google Scholar] [CrossRef]

| Drilling Depth/m | Torque of No.1 hole/(N·m) | Drilling Rate of No.1 Hole/(m/min) | Torque of No.2 Hole/(N·m) | Drilling Rate of No.2 Hole/(m/min) |

|---|---|---|---|---|

| 1 | 471.8 | 6.3 | 373.1 | 3 |

| 2 | 389.5 | 2.9 | 471.8 | 2.6 |

| 3 | 384.1 | 3 | 548.7 | 2 |

| 4 | 477.3 | 2.4 | 510.2 | 2.6 |

| 5 | 455.4 | 2.7 | 488.3 | 2.1 |

| 6 | 466.4 | 2.8 | 504.8 | 2.6 |

| 7 | 625.5 | 2.4 | 444.4 | 2.7 |

| 8 | 471.9 | 2.5 | 499.3 | 2.7 |

| 9 | 570.6 | 2.6 | 460.9 | 2.7 |

| 10 | 532.2 | 2.3 | 482.8 | 2.7 |

| 11 | 460.9 | 2.7 | 482.8 | 2.7 |

| 12 | 477.3 | 2.5 | 471.8 | 2.7 |

| 13 | 548.7 | 2.8 | 477.3 | 2.6 |

| 14 | 581.6 | 2.1 | 488.3 | 2.7 |

| 15 | 477.3 | 2.6 | 482.8 | 2.6 |

| 16 | 477.3 | 2.6 | 477.3 | 2.6 |

| 17 | 471.8 | 2.7 | 455.4 | 2.6 |

| 18 | 466.4 | 2.7 | 477.3 | 2.6 |

| 19 | 488.3 | 2.6 | 471.8 | 2.6 |

| 20 | 460.9 | 2.4 | 504.8 | 2.6 |

| Rock Type | Coal | Mudstone | Sandy Mudstone | Siltstone |

|---|---|---|---|---|

| Density /(g/cm3) | 1.35 | 2.66 | 2.61 | 2.88 |

| Elastic Modulus/GPa | 2.80 | 9.50 | 10.00 | 31.60 |

| Poisson Ratio | 0.23 | 0.26 | 0.27 | 0.30 |

| Uniaxial Compressive Strength/MPa | 21.30 | 38.20 | 48.00 | 83.00 |

| Angle of Friction | 28.00 | 38.00 | 48.00 | 29.90 |

| Rock Type | Thrust/(N) | Revolution Speed /(r/min) |

|---|---|---|

| Coal | 5000 | 60, 120, 240 |

| Mudstone | ||

| Sandy Mudstone | ||

| Siltstone | ||

| Coal | 3000, 6000 | 120 |

| Mudstone | ||

| Sandy Mudstone | 6000, 8000 | |

| Siltstone |

| Rock Type | Confining Pressure /MPa | Thrust /N | Revolution Speed /(r/min) |

|---|---|---|---|

| Coal | 0 | 3000 | 120 |

| 5 | |||

| 10 | |||

| 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Bai, Z.; Ge, D.; Liu, J.; Luan, H.; Zheng, Y. Numerical Simulation on Dynamic Response of Drilling Parameters in Loaded Rock Mass. Appl. Sci. 2025, 15, 5977. https://doi.org/10.3390/app15115977

Jiang Y, Bai Z, Ge D, Liu J, Luan H, Zheng Y. Numerical Simulation on Dynamic Response of Drilling Parameters in Loaded Rock Mass. Applied Sciences. 2025; 15(11):5977. https://doi.org/10.3390/app15115977

Chicago/Turabian StyleJiang, Yujing, Zongmeng Bai, Decheng Ge, Jiankang Liu, Hengjie Luan, and Yining Zheng. 2025. "Numerical Simulation on Dynamic Response of Drilling Parameters in Loaded Rock Mass" Applied Sciences 15, no. 11: 5977. https://doi.org/10.3390/app15115977

APA StyleJiang, Y., Bai, Z., Ge, D., Liu, J., Luan, H., & Zheng, Y. (2025). Numerical Simulation on Dynamic Response of Drilling Parameters in Loaded Rock Mass. Applied Sciences, 15(11), 5977. https://doi.org/10.3390/app15115977