Quasi-Uniform Density Non-Solid Infill Strategy for Axisymmetric Non-Planar Additive Manufacturing

Abstract

Featured Application

Abstract

1. Introduction

2. Methodology

2.1. Defining a Sufficiently Smooth Build Platform

2.2. Uniformly Meshing a Riemannian Manifold

2.3. Numerically Optimizing the Algorithm

2.4. Generating Infill Paths

2.5. Validating the Uniform Density Hypothesis

2.6. Case Study Definition

3. Results and Discussion

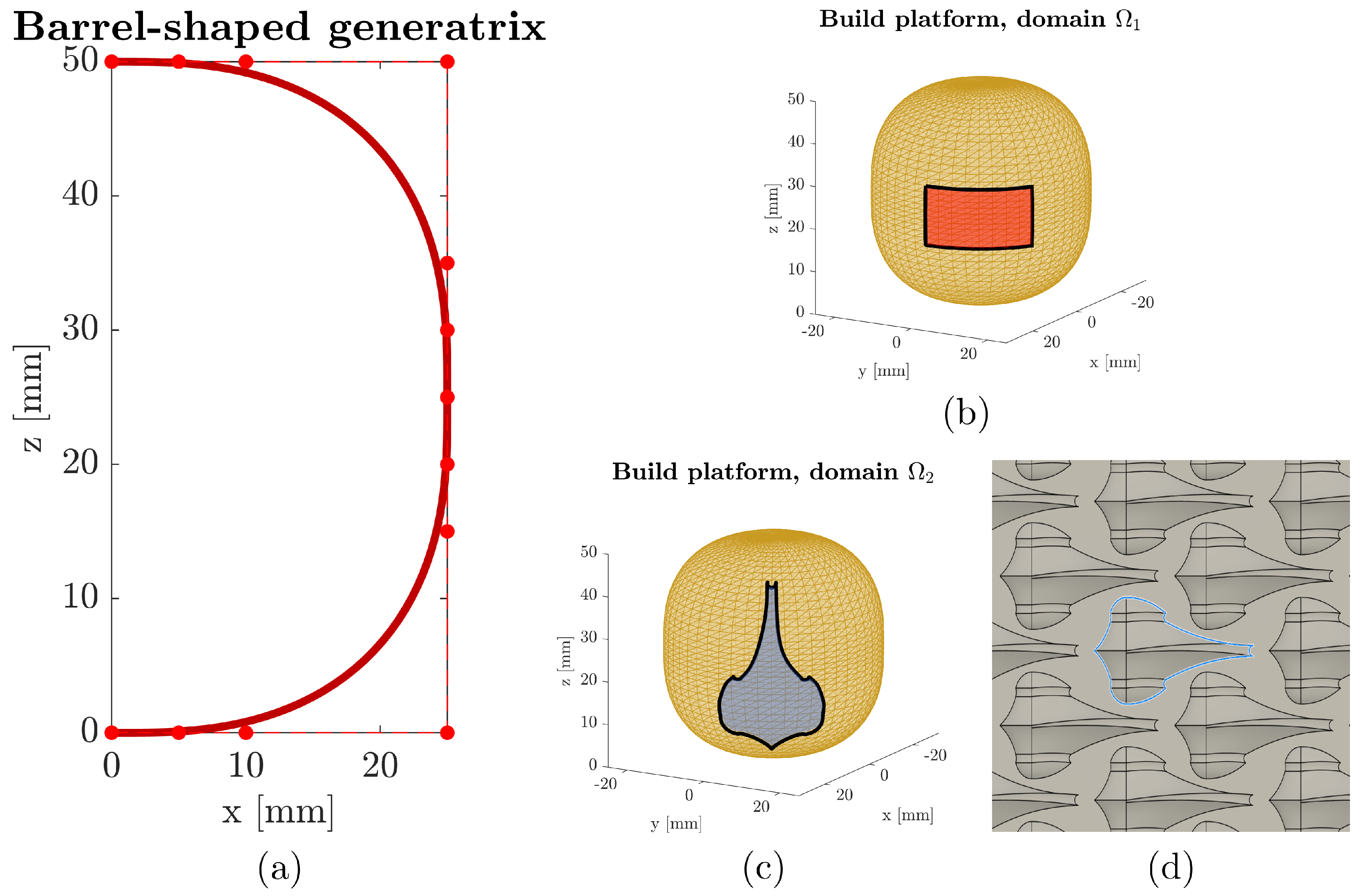

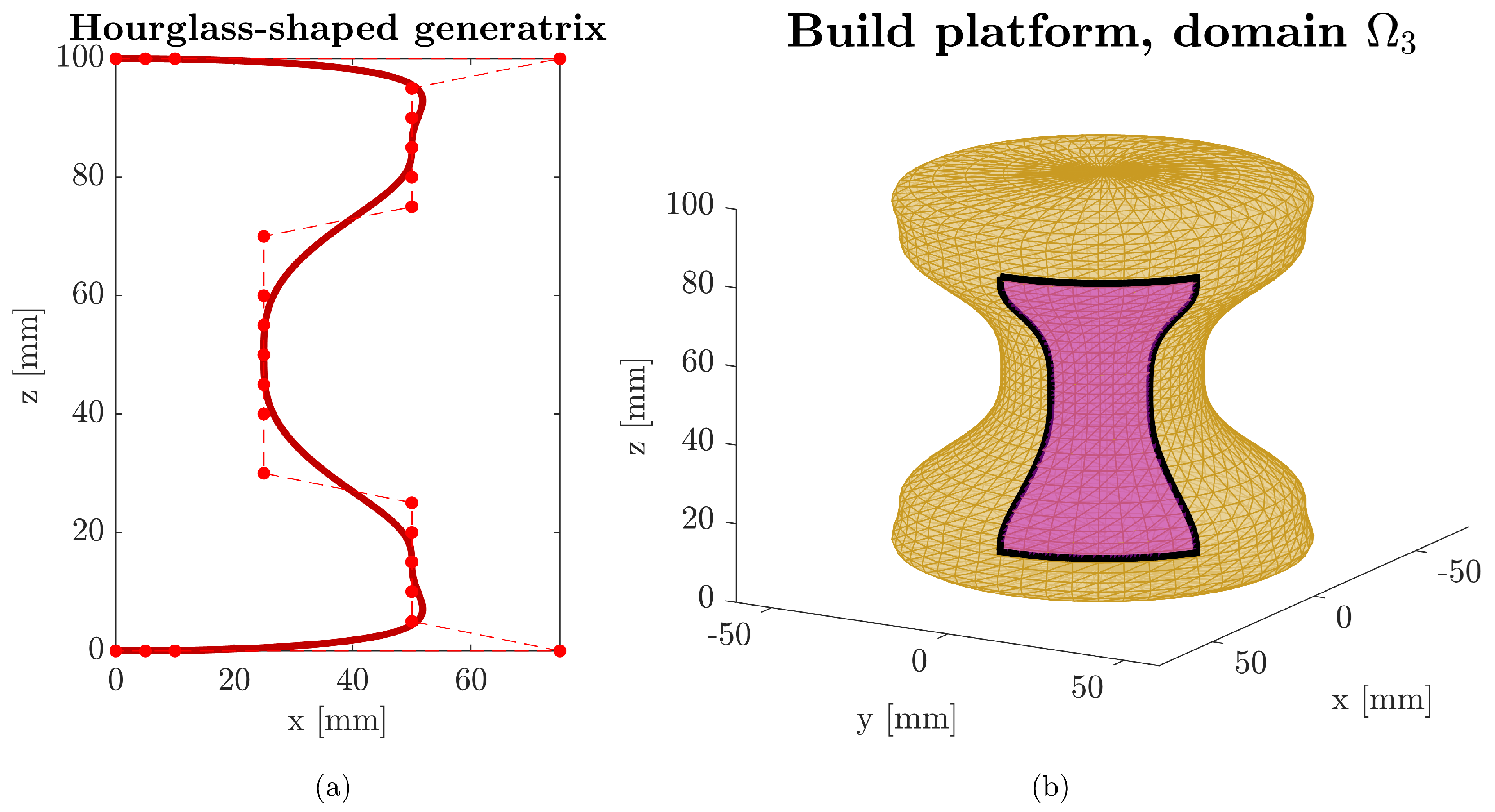

3.1. Generatrix Definition, Continuity, and Geodesics

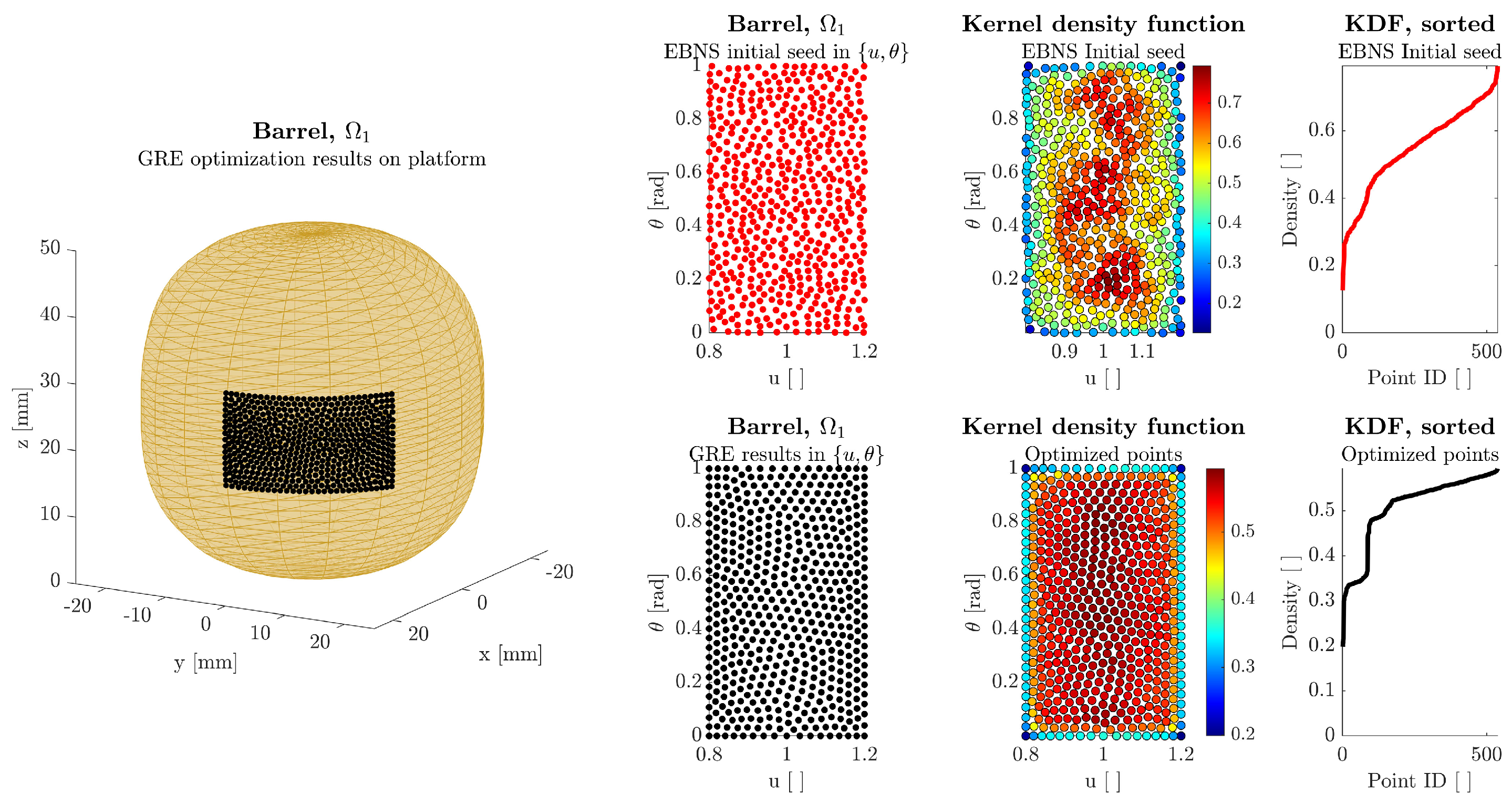

3.2. Results of the Repulsion Energy Minimization Algorithm and Validation of the Uniform Density Hypothesis

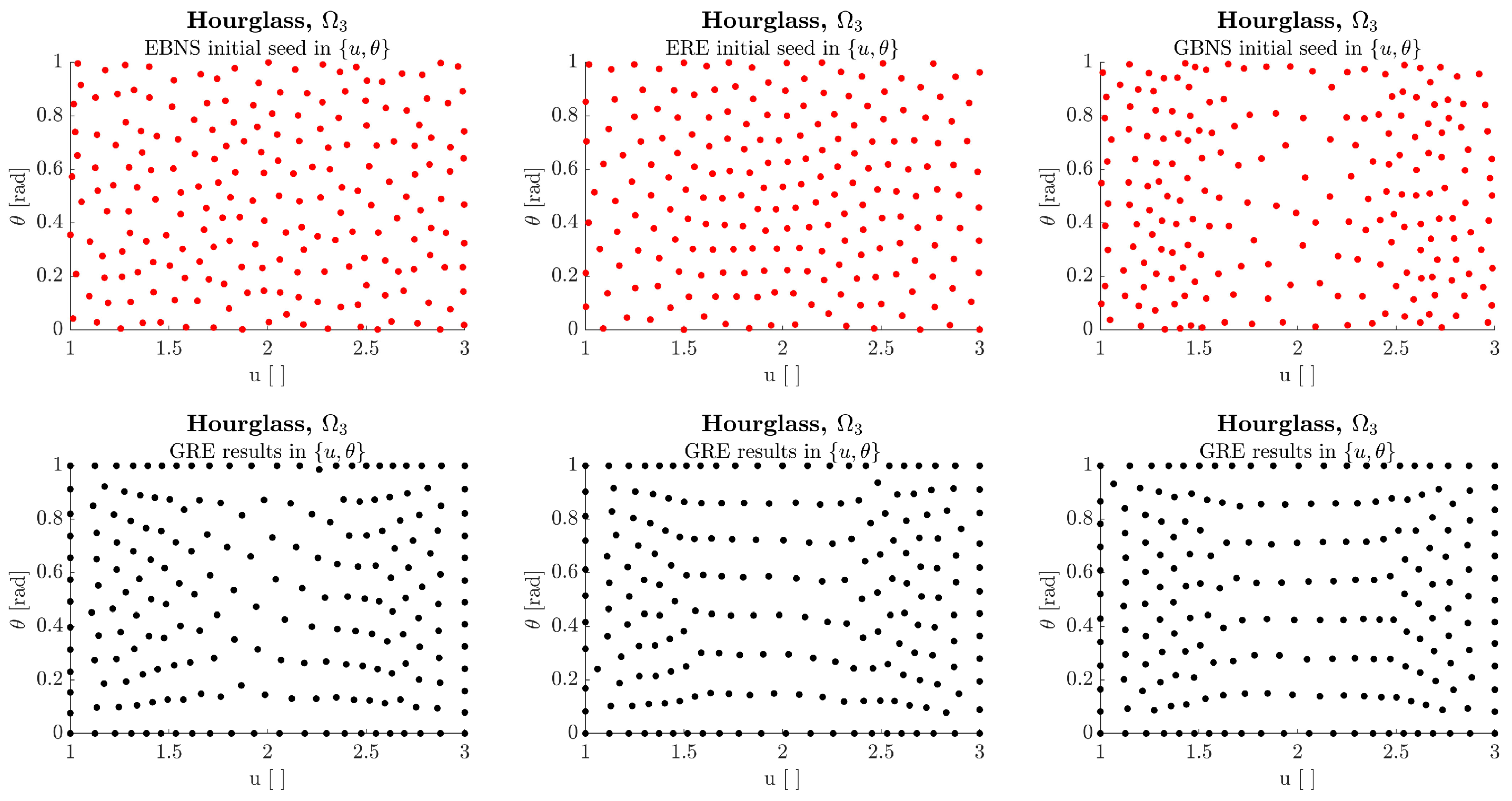

3.3. Comparison of Initial Seed Methods

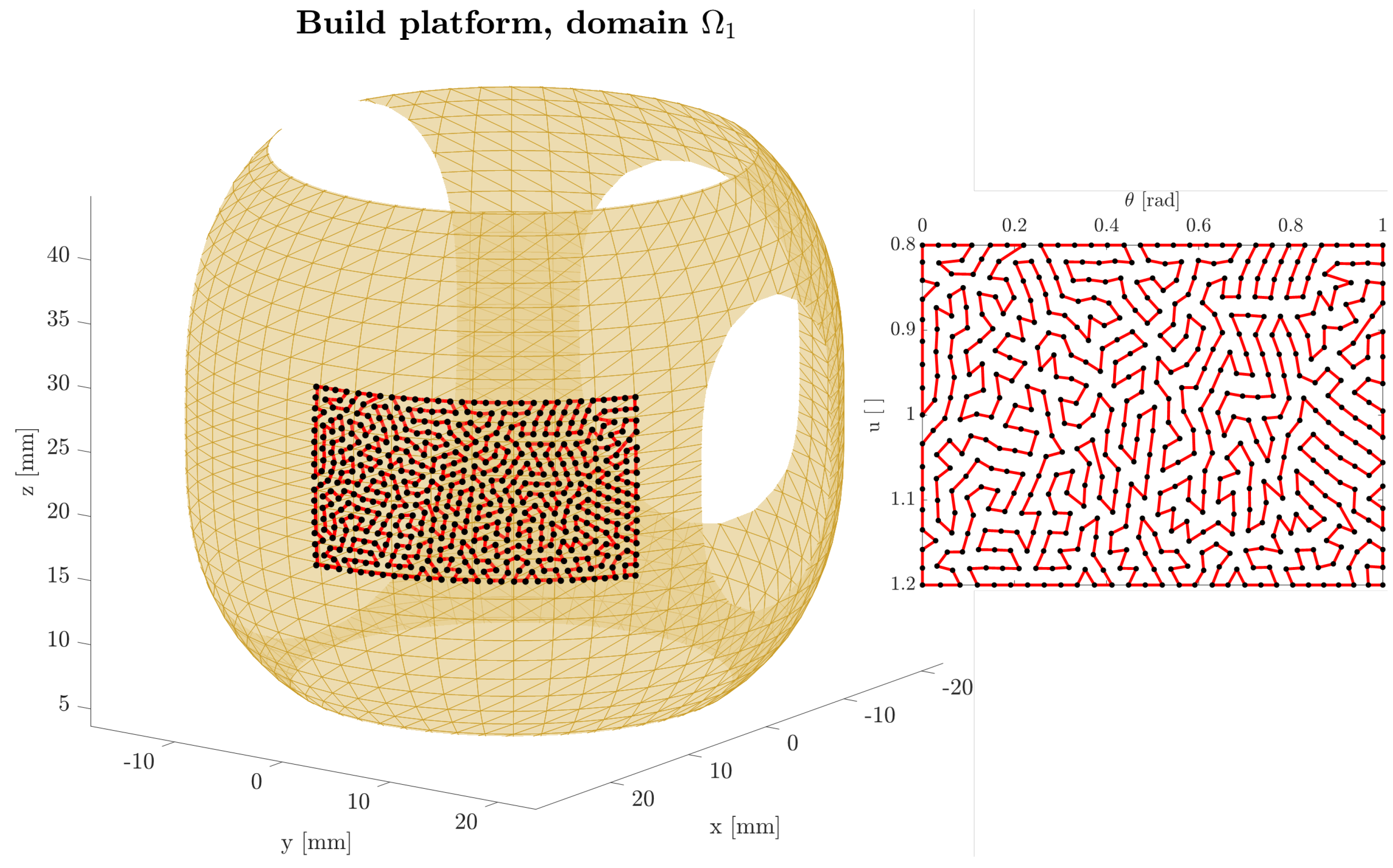

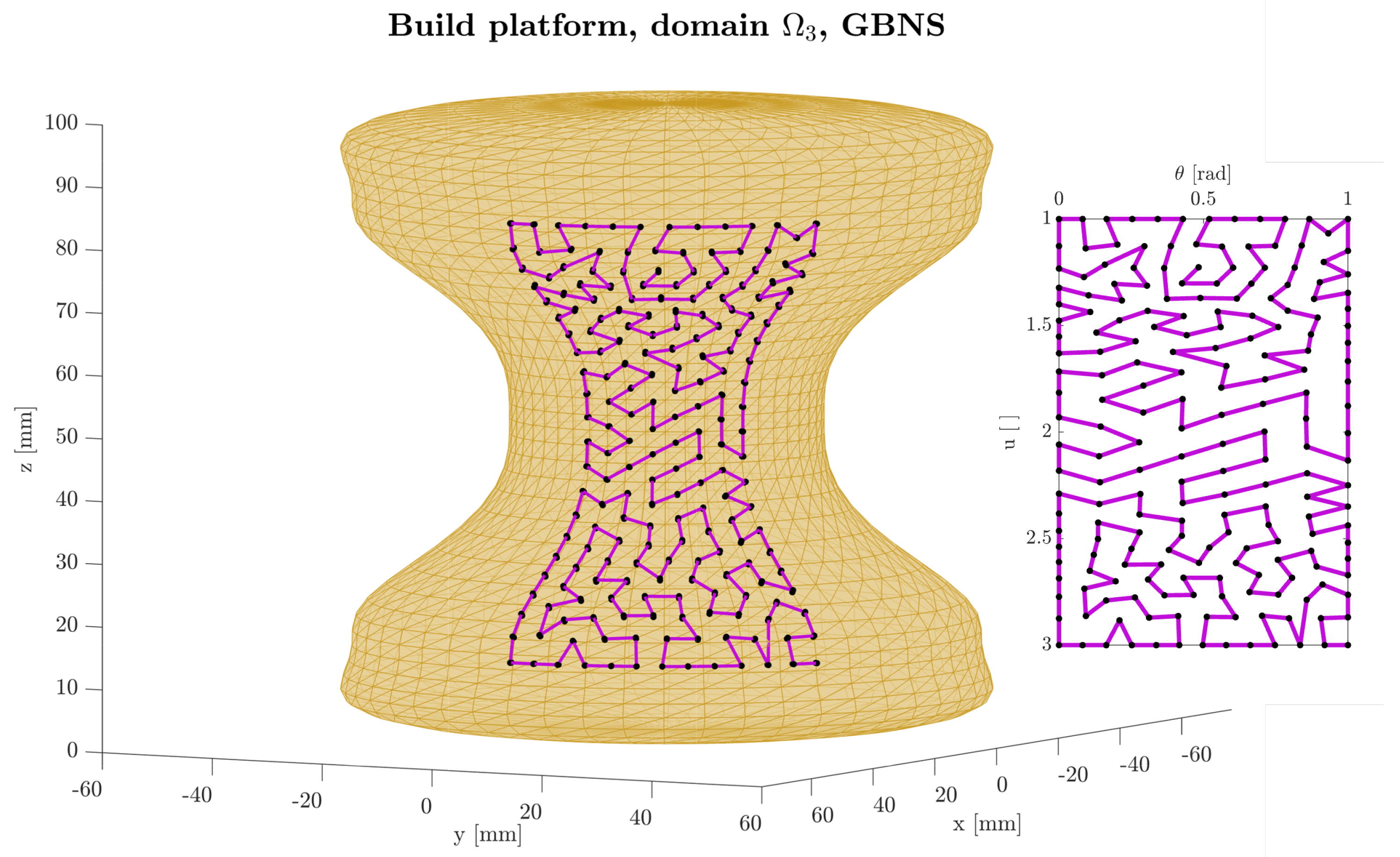

3.4. Path Planning Examples with the 2-Opt Nearest Neighbor Algorithm

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | additive manufacturing |

| MEX | material extrusion |

| DED | directed energy deposition |

| NPAM | Non-Planar Additive Manufacturing |

| RbNPAM | Robot-based Non-Planar Additive Manufacturing |

| TPMSs | Triply Periodic Minimal Surfaces |

| GRE | geodesic repulsion energy |

| GBNS | geodesic blue noise sampling |

| ERE | Euclidean repulsion energy |

| EBNS | Euclidean blue noise sampling |

| KDF | kernel density function |

References

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- ISO/ASTM Standard 52900:2021(E); Additive Manufacturing—General Principles—Fundamentals and Vocabulary. 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 15 February 2025).

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, Y.; Yu, K.; Dong, G. Innovative polymer-based composite materials in additive manufacturing: A review of methods, materials, and applications. Polym. Compos. 2024, 45, 15389–15420. [Google Scholar] [CrossRef]

- Forés-Garriga, A.; Pérez, M.A.; Gómez-Gras, G.; Reyes-Pozo, G. Role of infill parameters on the mechanical performance and weight reduction of PEI Ultem processed by FFF. Mater. Des. 2020, 193, 108810. [Google Scholar] [CrossRef]

- Tang, P.; Zhao, X.; Shi, H.; Hu, B.; Ding, J.; Yang, B.; Xu, W. A review of multi-axis additive manufacturing: Potential, opportunity and challenge. Addit. Manuf. 2024, 83, 104075. [Google Scholar] [CrossRef]

- Urhal, P.; Weightman, A.; Diver, C.; Bartolo, P. Robot assisted additive manufacturing: A review. Robot. Comput.-Integr. Manuf. 2019, 59, 335–345. [Google Scholar] [CrossRef]

- Stano, G.; Sayah, N.; Smith, D.E.; Fleck, T.J. Effect of Process Parameters in Additively Manufactured Sensors prepared via Material Extrusion Processes: Correlation among Electrical, Mechanical and Microstructure Properties. Addit. Manuf. Lett. 2024, 9, 100194. [Google Scholar] [CrossRef]

- Ballesteros, L.M.; Cano, D.; García, C.A.; Giraldo, L.V.; Jiménez, L.F.; Rave, E.; Rudas, J.S.; M, C.A.I.; Toro, A. Comparison of textured nylon surfaces manufactured by CNC micromachining and 3D printing. Surf. Topogr. Metrol. Prop. 2024, 12, 012001. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Aamir, M.; Tolouei-Rad, M. Effect of 3D Printing Parameters on the Fatigue Properties of Parts Manufactured by Fused Filament Fabrication: A Review. Appl. Sci. 2023, 13, 904. [Google Scholar] [CrossRef]

- Tunc, L.T.; Sheikhi, M.; Moldovan, C.; Gutiu, E.; Balc, N. Non-planar 5-axis directional additive manufacturing of plastics: Machine, process, and tool path. Manuf. Lett. 2024, 41, 959–964. [Google Scholar] [CrossRef]

- Liu, G.; Huang, W.; Wang, Y.; Ren, H.; Zhang, G.; Zhou, L.; Xiong, Y. Stress field-aware infill toolpath generation for additive manufacturing of continuous fiber reinforced polymer composites. Mater. Des. 2024, 239, 112756. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Liu, Q.; Wang, X.; Liu, J.; Li, L. Non-planar additive manufacturing of pre-impregnated continuous fiber reinforced composites using a three-axis printer. J. Mater. Res. Technol. 2024, 32, 4410–4419. [Google Scholar] [CrossRef]

- Yao, Y.; Cheng, L.; Li, Z. A comparative review of multi-axis 3D printing. J. Manuf. Process. 2024, 120, 1002–1022. [Google Scholar] [CrossRef]

- Štefčák, P.; Gajdoš, I.; Slota, J.; Varga, J.; Kimáková, Z.; Vrabeľ, M. Determination of Design Limitations of Curved Profiles Manufactured by Robotics Non-Planar Additive Manufacturing. Adv. Sci. Technol. Res. J. 2024, 18, 92–98. [Google Scholar] [CrossRef]

- Allum, J.; Kitzinger, J.; Li, Y.; Silberschmidt, V.V.; Gleadall, A. ZigZagZ: Improving mechanical performance in extrusion additive manufacturing by nonplanar toolpaths. Addit. Manuf. 2021, 38, 101715. [Google Scholar] [CrossRef]

- Nayyeri, P.; Zareinia, K.; Bougherara, H. Planar and nonplanar slicing algorithms for fused deposition modeling technology: A critical review. Int. J. Adv. Manuf. Technol. 2022, 119, 2785–2810. [Google Scholar] [CrossRef]

- Han, X.; Wu, G.; Liu, X.; Song, X.; Cui, L. Research on a Support-Free Five-Degree-of-Freedom Additive Manufacturing Method. Micromachines 2024, 15, 855. [Google Scholar] [CrossRef]

- Xie, F.; Chen, L.; Li, Z.; Tang, K. Path smoothing and feed rate planning for robotic curved layer additive manufacturing. Robot. Comput.-Integr. Manuf. 2020, 65, 101967. [Google Scholar] [CrossRef]

- Shan, Y.; Shui, Y.; Hua, J.; Mao, H. Additive manufacturing of non-planar layers using isothermal surface slicing. J. Manuf. Process. 2023, 86, 326–335. [Google Scholar] [CrossRef]

- Wei, D.; Zhu, G.; Shi, Z.; Gao, L.; Sun, B.; Gao, J. Isogeometric topology optimization for infill designs of porous structures with stress minimization in additive manufacturing. Int. J. Numer. Methods Eng. 2024, 125, e7391. [Google Scholar] [CrossRef]

- Munasinghe, N.; Paul, G. Radial slicing for helical-shaped advanced manufacturing applications. Int. J. Adv. Manuf. Technol. 2021, 112, 1089–1100. [Google Scholar] [CrossRef]

- Etienne, J.; Ray, N.; Panozzo, D.; Hornus, S.; Wang, C.C.; Martínez, J.; McMains, S.; Alexa, M.; Wyvill, B.; Lefebvre, S. Curvislicer: Slightly curved slicing for 3-axis printers. ACM Trans. Graph. 2019, 38, 1–11. [Google Scholar] [CrossRef]

- Liu, B.; Feng, J.; Lin, Z.; Wu, S.; He, Y.; Fu, J. Spherical path planning for multi axis support free additive manufacturing of truss structures. J. Manuf. Process. 2024, 109, 198–212. [Google Scholar] [CrossRef]

- Li, X.; Liu, W.; Hu, Z.; He, C.; Ding, J.; Chen, W.; Wang, S.; Dong, W. Supportless 3D-printing of non-planar thin-walled structures with the multi-axis screw-extrusion additive manufacturing system. Mater. Des. 2024, 240, 112860. [Google Scholar] [CrossRef]

- Zutin, G.C.; Pulquerio, E.C.; Pasotti, A.V.; Barbosa, G.F.; Shiki, S.B. Application of robotic manipulator technology and its relation to additive manufacturing process—A review. Int. J. Adv. Manuf. Technol. 2024, 133, 257–271. [Google Scholar] [CrossRef]

- Sun, X.; Mazur, M.; Cheng, C.T. A review of void reduction strategies in material extrusion-based additive manufacturing. Addit. Manuf. 2023, 67, 103463. [Google Scholar] [CrossRef]

- Cendrero, A.M.; Fortunato, G.M.; Munoz-Guijosa, J.M.; De Maria, C.; Díaz Lantada, A. Benefits of Non-Planar Printing Strategies Towards Eco-Efficient 3D Printing. Sustainability 2021, 13, 1599. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N. Adaptive path planning for wire-feed additive manufacturing using medial axis transformation. J. Clean. Prod. 2016, 133, 942–952. [Google Scholar] [CrossRef]

- Nguyen, L.; Buhl, J.; Bambach, M. Continuous Eulerian tool path strategies for wire-arc additive manufacturing of rib-web structures with machine-learning-based adaptive void filling. Addit. Manuf. 2020, 35, 101265. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Fu, G.; Zhang, A.; Du, J. A non-retraction path planning approach for extrusion-based additive manufacturing. Robot. Comput.-Integr. Manuf. 2017, 48, 132–144. [Google Scholar] [CrossRef]

- Michel, F.; Lockett, H.; Ding, J.; Martina, F.; Marinelli, G.; Williams, S. A modular path planning solution for Wire + Arc Additive Manufacturing. Robot. Comput.-Integr. Manuf. 2019, 60, 1–11. [Google Scholar] [CrossRef]

- Lin, S.; Xia, L.; Ma, G.; Zhou, S.; Xie, Y.M. A maze-like path generation scheme for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2019, 104, 1509–1519. [Google Scholar] [CrossRef]

- Gupta, P.; Krishnamoorthy, B.; Dreifus, G. Continuous toolpath planning in a graphical framework for sparse infill additive manufacturing. Comput. Aided Des. 2020, 127, 102880. [Google Scholar] [CrossRef]

- Li, Y.; Tang, K.; He, D.; Wang, X. Multi-Axis Support-Free Printing of Freeform Parts with Lattice Infill Structures. Comput. Aided Des. 2021, 133, 102986. [Google Scholar] [CrossRef]

- Vassilakos, A.; Giannatsis, J.; Dedoussis, V. Fabrication of parts with heterogeneous structure using material extrusion additive manufacturing. Virtual Phys. Prototyp. 2021, 16, 267–290. [Google Scholar] [CrossRef]

- Ibhadode, O.; Zhang, Z.; Sixt, J.; Nsiempba, K.M.; Orakwe, J.; Martinez-Marchese, A.; Ero, O.; Shahabad, S.I.; Bonakdar, A.; Toyserkani, E. Topology optimization for metal additive manufacturing: Current trends, challenges, and future outlook. Virtual Phys. Prototyp. 2023, 18, e2181192. [Google Scholar] [CrossRef]

- Feng, J.; Fu, J.; Yao, X.; He, Y. Triply periodic minimal surface (TPMS) porous structures: From multi-scale design, precise additive manufacturing to multidisciplinary applications. Int. J. Extreme Manuf. 2022, 4, 022001. [Google Scholar] [CrossRef]

- Teng, F.; Sun, Y.; Guo, S.; Gao, B.; Yu, G. Topological and Mechanical Properties of Different Lattice Structures Based on Additive Manufacturing. Micromachines 2022, 13, 1017. [Google Scholar] [CrossRef]

- Shaikh, A.; Saxena, A.; Griffis, J.; Shahed, K.; Manogharan, G. Functionally graded TPMS gyroid structures for additive manufacturing of non-pneumatic tires. Mater. Sci. Addit. Manuf. 2024, 3, 5022. [Google Scholar] [CrossRef]

- Wakjira, Y.; Cioni, A.; Lemu, H.G. Current status of the application of additive-manufactured TPMS structure in bone tissue engineering. Prog. Addit. Manuf. 2024, 10, 1085–1102. [Google Scholar] [CrossRef]

- Oh, S.H.; An, C.H.; Seo, B.; Kim, J.; Park, C.Y.; Park, K. Functional morphology change of TPMS structures for design and additive manufacturing of compact heat exchangers. Addit. Manuf. 2023, 76, 103778. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Wu, F.; Liu, Z.; Liu, L.; Wang, D. Design method of gyroid lattice structure based on the load paths direction and capacity. Addit. Manuf. 2025, 97, 104586. [Google Scholar] [CrossRef]

- Zhao, D.; Guo, W. Shape and Performance Controlled Advanced Design for Additive Manufacturing: A Review of Slicing and Path Planning. J. Manuf. Sci. Eng. 2020, 142, 010801. [Google Scholar] [CrossRef]

- López-Arrabal, A.; Guzmán-Bautista, Á.; Solórzano-Requejo, W.; Franco-Martínez, F.; Villaverde, M. Axisymmetric non-planar slicing and path planning strategy for robot-based additive manufacturing. Mater. Des. 2024, 241, 112915. [Google Scholar] [CrossRef]

- Wawryniuk, Z.; Brancewicz-Steinmetz, E.; Sawicki, J. Revolutionizing transportation: An overview of 3D printing in aviation, automotive, and space industries. Int. J. Adv. Manuf. Technol. 2024, 134, 3083–3105. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Liu, G. A Review of 3D Printed Bone Implants. Micromachines 2022, 13, 528. [Google Scholar] [CrossRef]

- Vijetha, K.; Lingaraju, D.; Satish, G.; Reddy, V.S.; Reddy, M.P.K. Fabrication of microchannel heat sink using additive manufacturing technology: A review. Proc. Inst. Mech. Eng. Part E 2024. [Google Scholar] [CrossRef]

- Sikulskyi, S.; Ren, Z.; Mekonnen, D.T.; Holyoak, A.; Govindarajan, R.S.; Kim, D. Additively manufactured unimorph dielectric elastomer actuators: Design, materials, and fabrication. Front. Robot. AI 2022, 9, 1034914. [Google Scholar] [CrossRef]

- Liao, C.Y.; Tseng, Y.W.; Wu, S.D.; Kang, L.Y.; Dai, N.T.; Hsu, S.H. Non-planar bioprinting with molding assistance for irregular wound shape. J. Mater. Res. Technol. 2023, 26, 1596–1608. [Google Scholar] [CrossRef]

- Cook, R.L. Stochastic sampling in computer graphics. ACM Trans. Graph. 1986, 5, 51–72. [Google Scholar] [CrossRef]

- Mitchell, D.P. Generating antialiased images at low sampling densities. In Proceedings of the SIGGRAPH ’87: Proceedings of the 14th Annual Conference on Computer Graphics and Interactive Techniques, Anaheim, CA, USA, 27–31 July 1987; Volume 21, pp. 65–72. [Google Scholar] [CrossRef]

- Croes, G.A. A Method for Solving Traveling-Salesman Problems. Oper. Res. 1958, 6, 791–812. [Google Scholar] [CrossRef]

- Yang, J.; Qi, Q.; Adili, A.; Ding, H. An analytical tool path smoothing algorithm for robotic machining with the consideration of redundant kinematics. Robot. Comput.-Integr. Manuf. 2024, 89, 102768. [Google Scholar] [CrossRef]

- Jiang, M.; Zhou, Y.; Wang, R.; Southern, R.; Zhang, J.J. Blue noise sampling using an SPH-based method. ACM Trans. Graph. 2015, 34, 1–11. [Google Scholar] [CrossRef]

- Shawe-Taylor, J.; Cristianini, N. Kernel Methods for Pattern Analysis; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar] [CrossRef]

- Franco-Martínez, F.; Solórzano-Requejo, W.; de Blas-de Miguel, A.; Vostatek, M.; Grasl, C.; Bonora, M.; Moscato, F.; Lantada, A.D. Design and Manufacturing of Microtextured Patient-Specific Coronary Stent. In Proceedings of the 16th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2023)—BIODEVICES, Lisbon, Portugal, 16–18 February 2023; pp. 142–149. [Google Scholar] [CrossRef]

- Chauvette, J.F.; Hia, I.L.; Farahani, R.D.; Plante, R.; Piccirelli, N.; Therriault, D. Non-planar multinozzle additive manufacturing of thermoset composite microscaffold networks. Compos. B Eng. 2023, 256, 110627. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef]

- Insero, F.; Furlan, V.; Giberti, H. Non-planar slicing for filled free-form geometries in robot-based FDM. J. Intell. Manuf. 2023, 36, 833–851. [Google Scholar] [CrossRef]

- Singh, S.; Singh, A.; Kapil, S.; Das, M. Generation of continuous and sparse space filling toolpath with tailored density for additive manufacturing of biomimetics. Comput. Aided Des. 2024, 173, 103718. [Google Scholar] [CrossRef]

| Domain | Build Platform | u-Range [ ] | -Range [rad] | Command Infill Density [%] | Rasters Traversing Each Point | Initial Seed Method |

|---|---|---|---|---|---|---|

| Barrel | EBNS | |||||

| Barrel | Actual slice polygon, from [57] | ERE | ||||

| Hourglass | EBNS, ERE, GBNS | |||||

| Barrel Control Polygon | |||

|---|---|---|---|

| Segment 1 | Segment 2 | ||

| [mm] | [mm] | [mm] | [mm] |

| 0 | 50 | 25 | 25 |

| 5 | 50 | 25 | 20 |

| 10 | 50 | 25 | 15 |

| 25 | 50 | 25 | 0 |

| 25 | 35 | 10 | 0 |

| 25 | 30 | 5 | 0 |

| 25 | 25 | 0 | 0 |

| Hourglass Control Polygon | |||||||

|---|---|---|---|---|---|---|---|

| Segment 1 | Segment 2 | Segment 3 | Segment 4 | ||||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] |

| 0 | 100 | 50 | 85 | 25 | 50 | 50 | 15 |

| 5 | 100 | 50 | 80 | 25 | 45 | 50 | 10 |

| 10 | 100 | 50 | 75 | 25 | 40 | 50 | 5 |

| 75 | 100 | 25 | 70 | 25 | 30 | 75 | 0 |

| 50 | 95 | 25 | 60 | 50 | 25 | 10 | 0 |

| 50 | 90 | 25 | 55 | 50 | 20 | 5 | 0 |

| 50 | 85 | 25 | 50 | 50 | 15 | 0 | 0 |

| Case | Mean [mm] | Standard Deviation [mm] | |

|---|---|---|---|

| EBNS initial seed GRE optimization | 0.740 0.848 | 0.106 0.030 | |

| ERE initial seed GRE optimization | 0.937 1.693 | 0.560 0.159 | |

| GBNS initial seed GRE optimization | 3.839 4.384 | 0.500 0.278 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzman-Bautista, A.; López-Arrabal, A.; Sanchez-Oro-Aguado, E.; Fernández Gorgojo, A.; García-Galán, R.; Badesa, F.J.; Vizan-Idoipe, A. Quasi-Uniform Density Non-Solid Infill Strategy for Axisymmetric Non-Planar Additive Manufacturing. Appl. Sci. 2025, 15, 5899. https://doi.org/10.3390/app15115899

Guzman-Bautista A, López-Arrabal A, Sanchez-Oro-Aguado E, Fernández Gorgojo A, García-Galán R, Badesa FJ, Vizan-Idoipe A. Quasi-Uniform Density Non-Solid Infill Strategy for Axisymmetric Non-Planar Additive Manufacturing. Applied Sciences. 2025; 15(11):5899. https://doi.org/10.3390/app15115899

Chicago/Turabian StyleGuzman-Bautista, Alvaro, Adrián López-Arrabal, Elio Sanchez-Oro-Aguado, Andrea Fernández Gorgojo, Ramiro García-Galán, Francisco J. Badesa, and Antonio Vizan-Idoipe. 2025. "Quasi-Uniform Density Non-Solid Infill Strategy for Axisymmetric Non-Planar Additive Manufacturing" Applied Sciences 15, no. 11: 5899. https://doi.org/10.3390/app15115899

APA StyleGuzman-Bautista, A., López-Arrabal, A., Sanchez-Oro-Aguado, E., Fernández Gorgojo, A., García-Galán, R., Badesa, F. J., & Vizan-Idoipe, A. (2025). Quasi-Uniform Density Non-Solid Infill Strategy for Axisymmetric Non-Planar Additive Manufacturing. Applied Sciences, 15(11), 5899. https://doi.org/10.3390/app15115899