Shear Strength of Sand: Integrated Analysis of Initial Porosity and Stress Effects

Abstract

1. Introduction

2. Materials and Methods

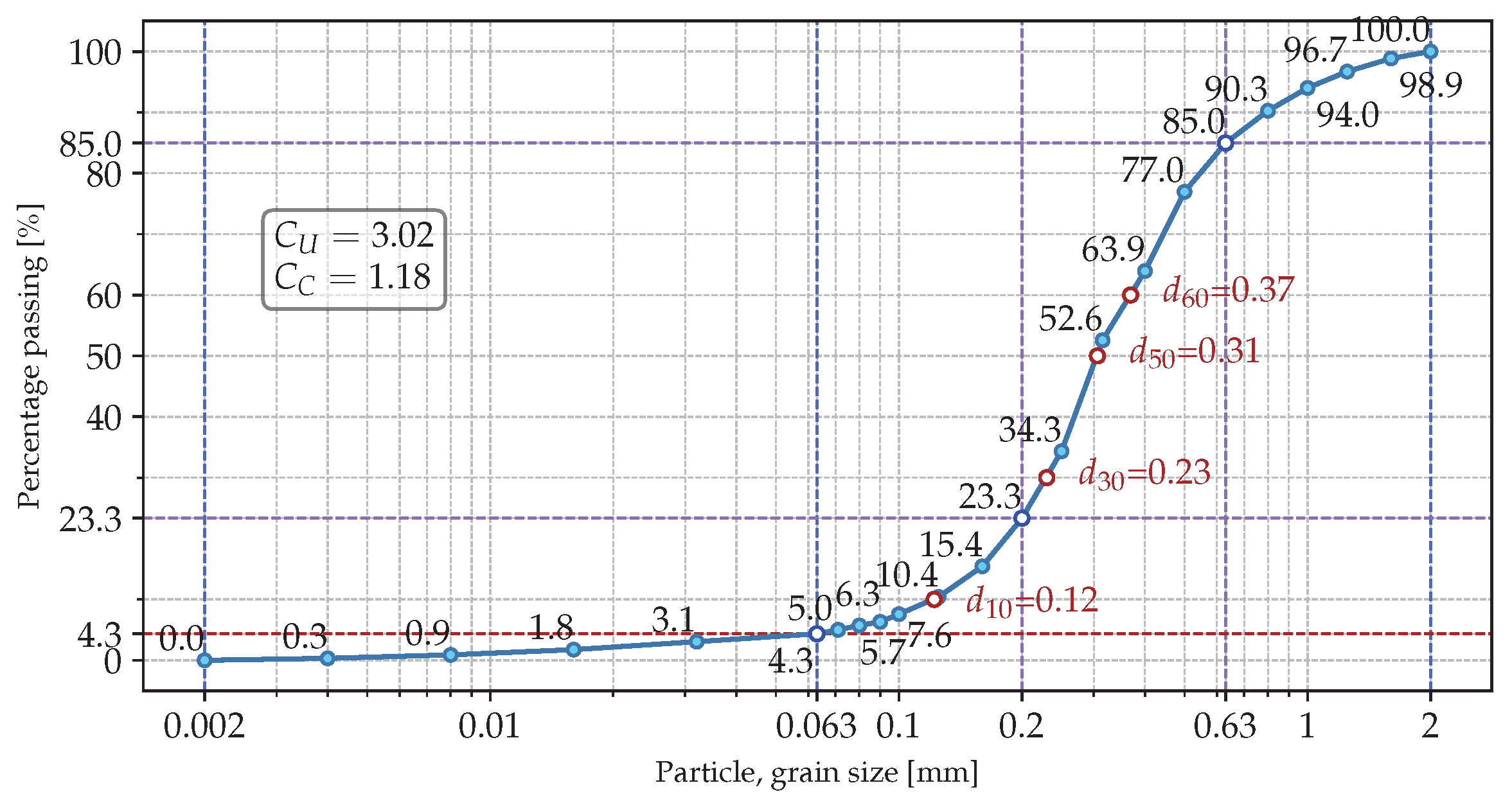

2.1. Soil Samples

2.2. Test Procedure

3. Results

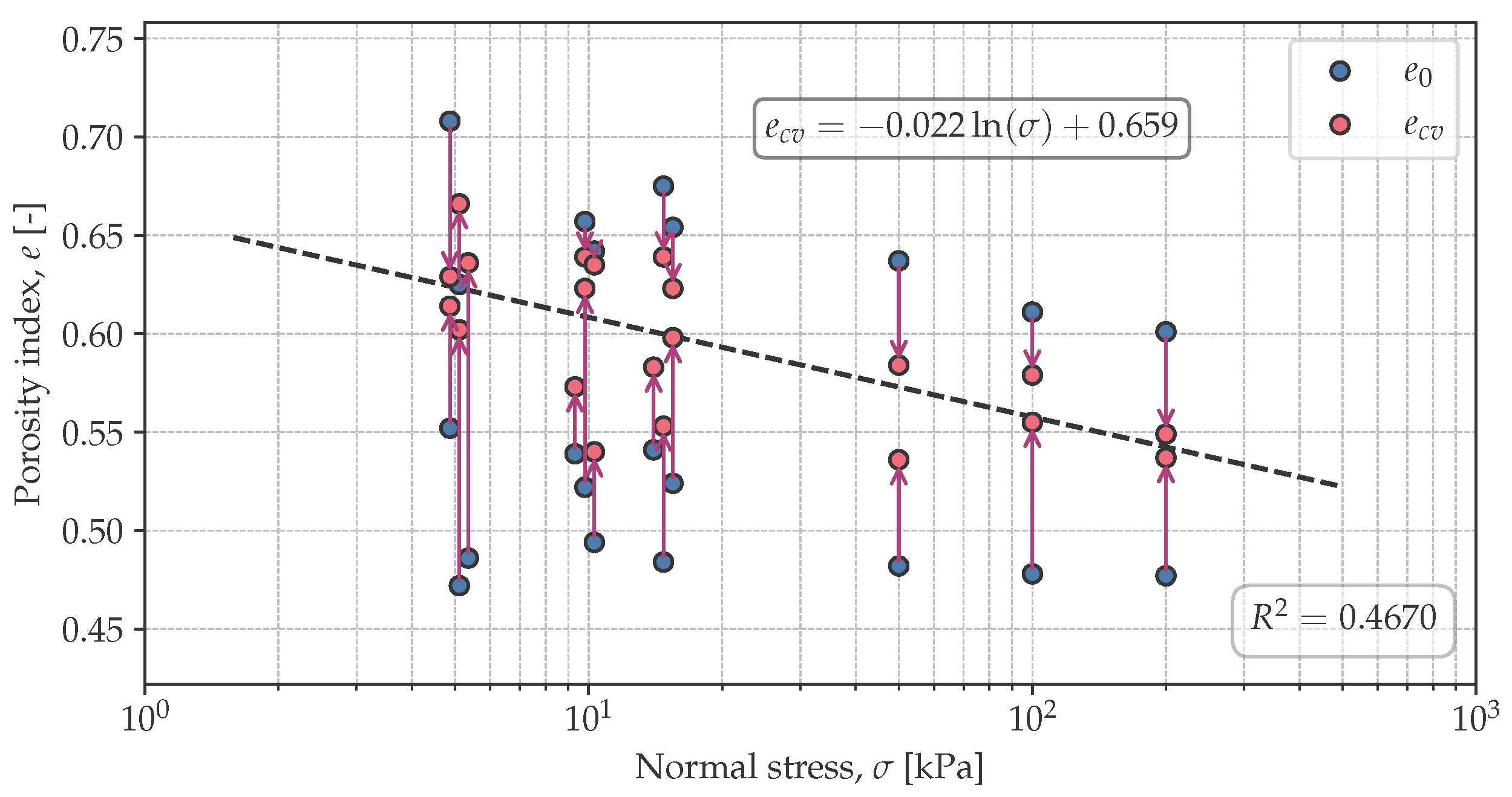

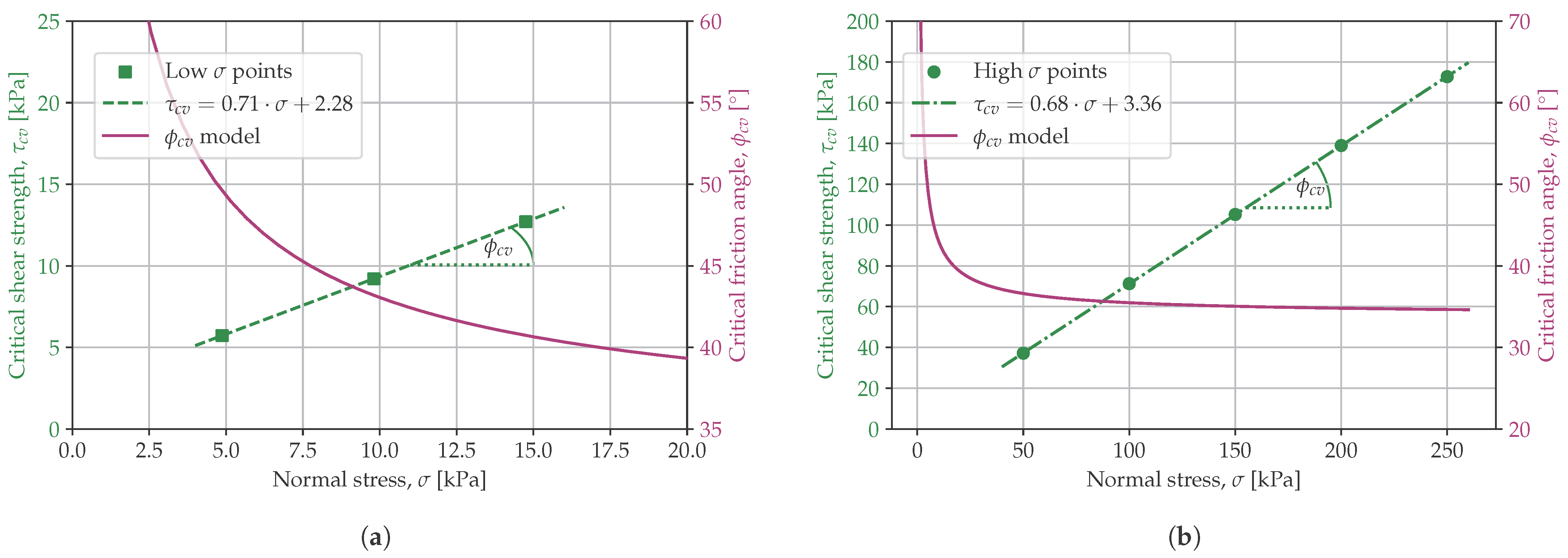

3.1. Critical State of Shearing

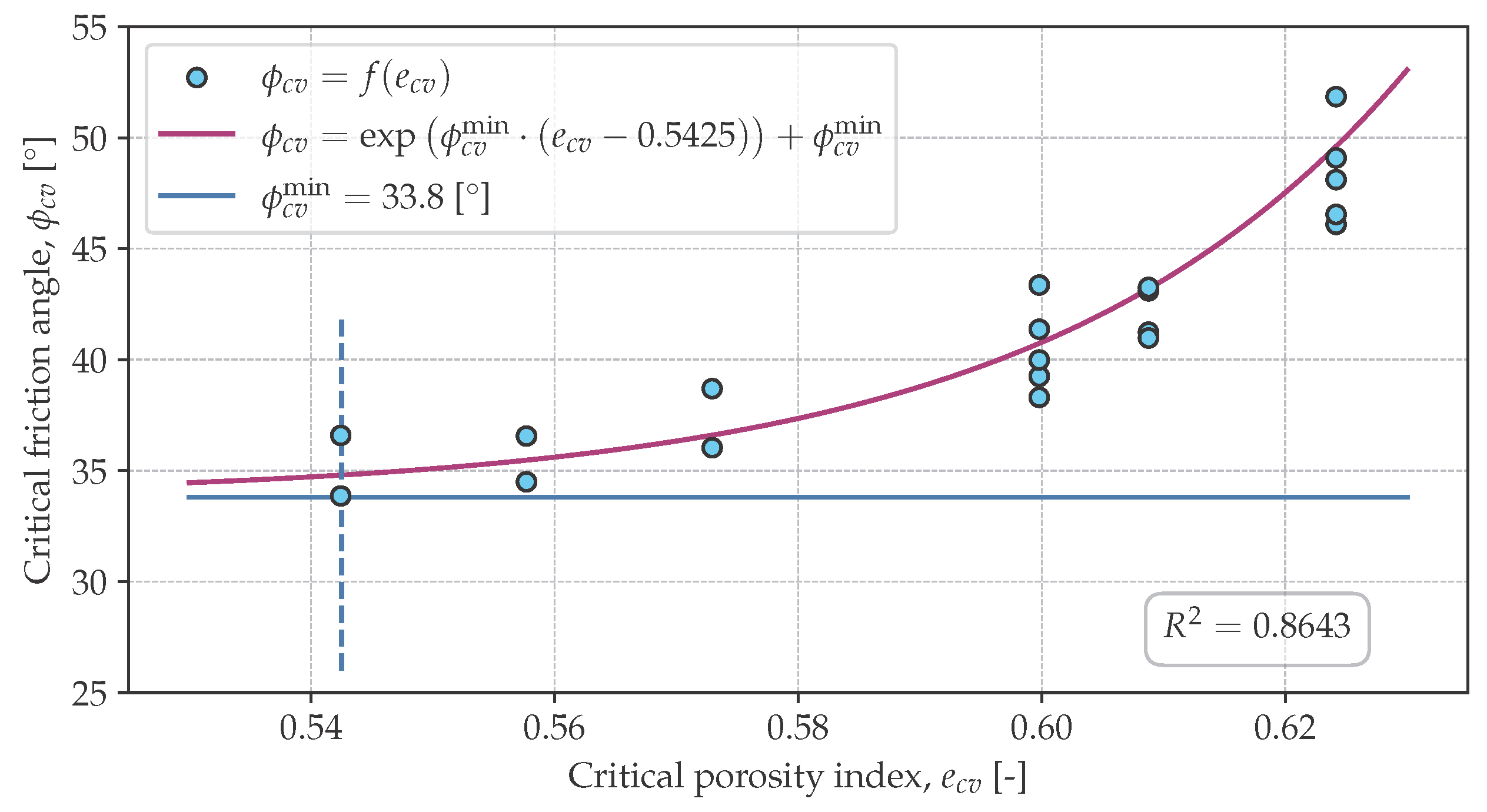

3.2. Critical Friction Angle

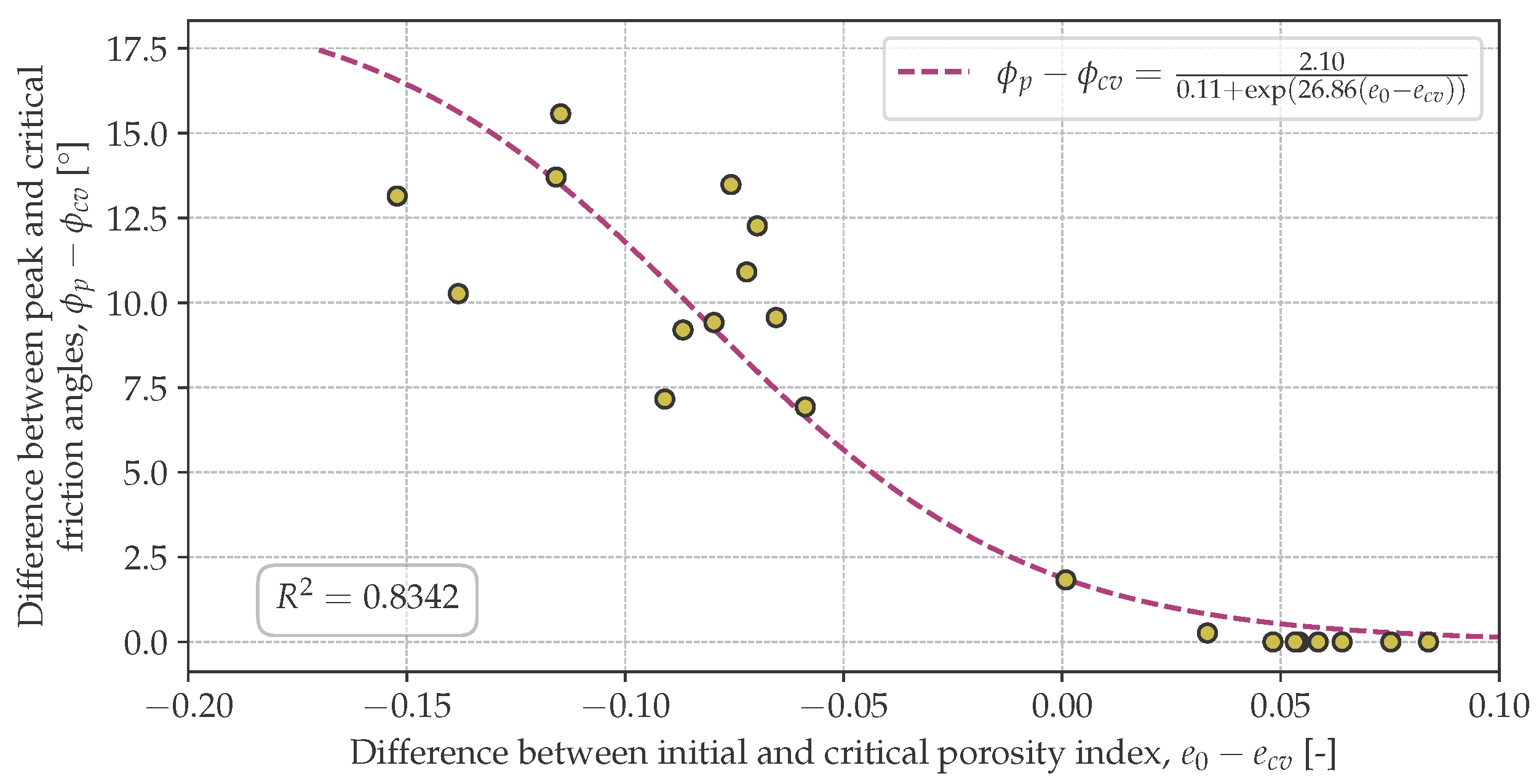

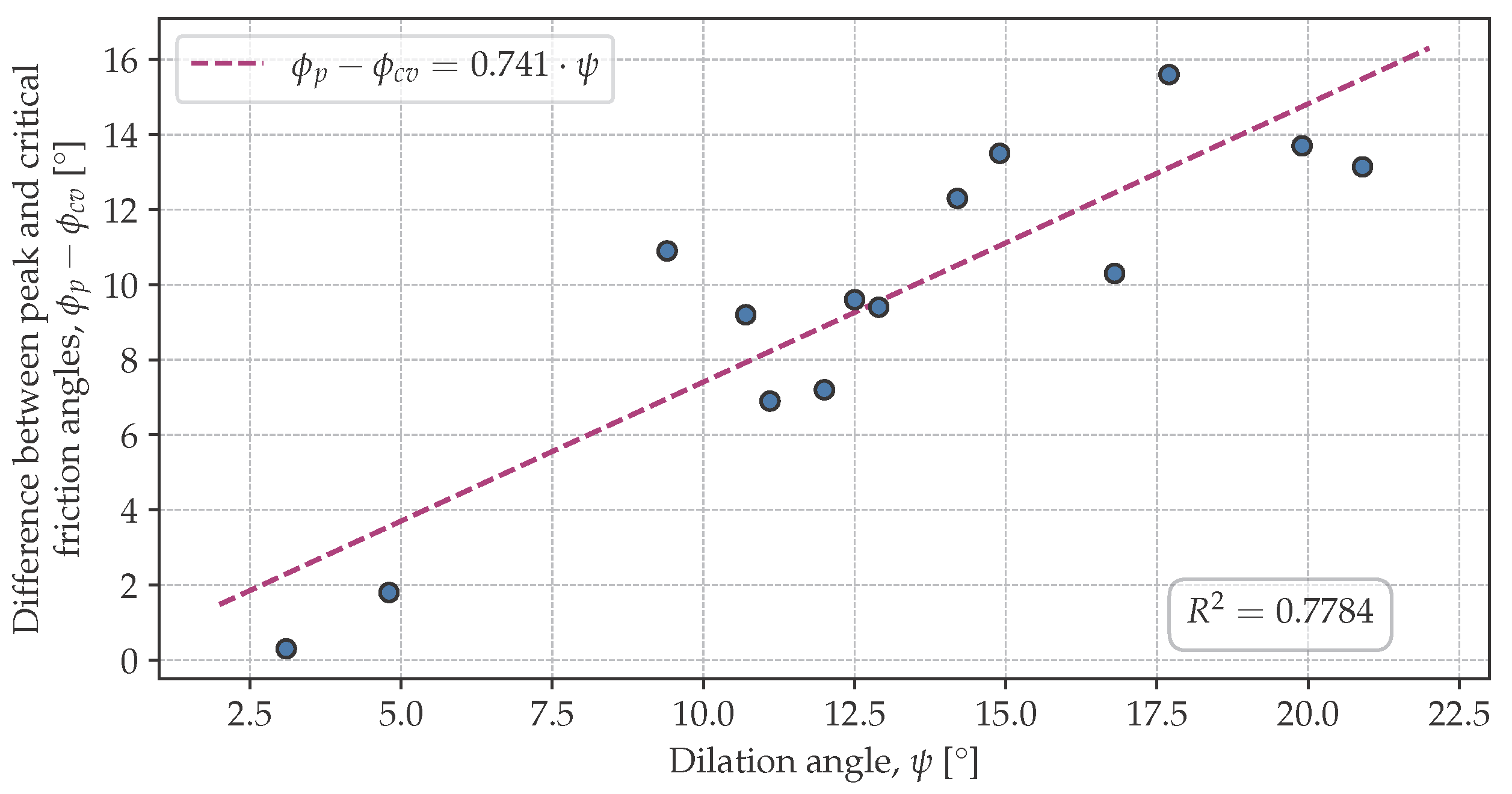

3.3. Peak Friction Angle

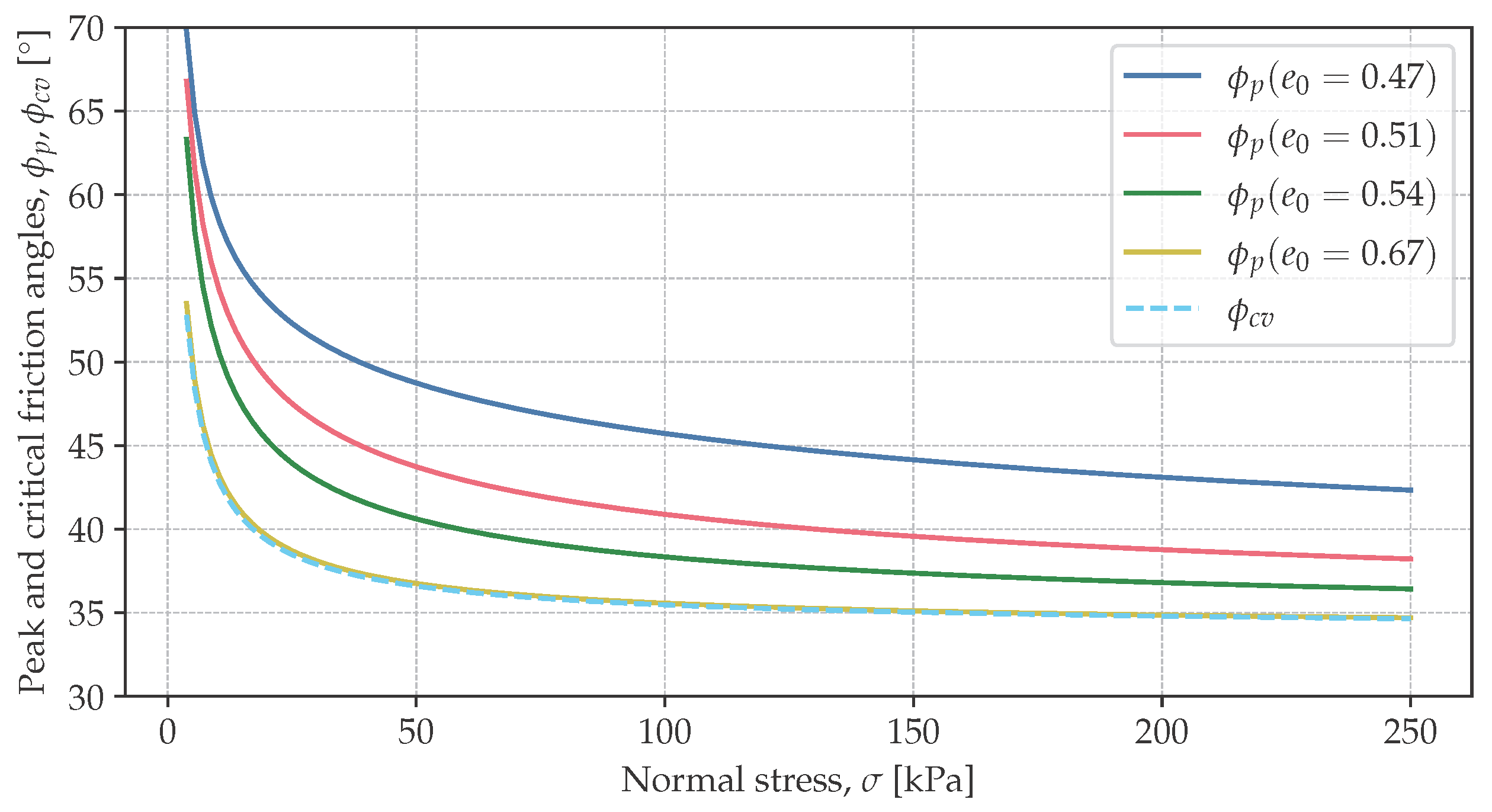

3.4. Critical and Peak Friction Angles in Relation to Stress Range and Initial Porosity Index

4. Conclusions

- Considering the soil friction angle, it is important to specify whether it is the peak or critical soil friction angle because they apply to different deformation ranges and, in many cases, especially in dilative soils, they differ considerably.

- The peak soil friction angle increased with decreasing initial soil porosity index.

- The critical soil friction angle was independent of the initial porosity index.

- Both the peak and the critical soil friction angle depended on the stress state. The lower the stress, the larger the soil friction angle. This might have been due to the lower energy required to induce shear deformation of the specimen, which was also indicated by the decreasing critical porosity index with increasing stress. At high stresses, grain breakage became more important, which also resulted in a reduction in the strength described by the internal friction angle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Stefanow, D.; Dudziński, P.A. Soil shear strength determination methods – State of the art. Soil Tillage Res. 2021, 208, 104881. [Google Scholar] [CrossRef]

- Castellanos, B.A.; Brandon, T.L. A comparison between the shear strength measured with direct shear and triaxial devices on undisturbed and remolded soils. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering: Challenges and Innovations in Geotechnics, ICSMGE 2013, Paris, France, 2–6 September 2013; Volume 1, pp. 317–320. [Google Scholar]

- Szypcio, Z. Relation between the Friction Angle of Sand at Triaxial Compression and Triaxial Extension and Plane Strain Conditions. Geosciences 2020, 10, 29. [Google Scholar] [CrossRef]

- Dołżyk-Szypcio, K. Direct Shear Test for Coarse Granular Soil. Int. J. Civil Eng. 2019, 17, 1871–1878. [Google Scholar] [CrossRef]

- Chakraborty, T.; Salgado, R. Dilatancy and shear strength behavior of sand at low confining pressures. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering: The Academia and Practice of Geotechnical Engineering; IOS Press: Amsterdam, The Netherlands, 2009; Volume 1, pp. 652–655. [Google Scholar] [CrossRef]

- Yang, J.; Luo, X.D. Exploring the relationship between critical state and particle shape for granular materials. J. Mech. Phys. Solids 2015, 84, 196–213. [Google Scholar] [CrossRef]

- Wood, D.M. Soil Behaviour and Critical State Soil Mechanics; Cambidge University Press: New York, NY, USA, 1992. [Google Scholar] [CrossRef]

- Truyen, P.N.; Thinh, P.N.D.; Hung, H.T.; Phong, L.T.; Nhat, V.D. Evaluation of the Shear Strength and Dilatancy Behavior of Sand-Clay Mixtures Under Direct Shear Tests. In Proceedings of the 7th International Conference on Geotechnics, Civil Engineering and Structures, CIGOS 2024, Ho Chi Minh City, Vietnam, 4–5 April 2024; pp. 823–832. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M. Stress-dilatancy in very loose sand. Can. Geotech. J. 2004, 41, 972–989. [Google Scholar] [CrossRef]

- Sawicki, A.; Świdziński, W. Drained against undrained behaviour of sand. Arch. Hydroengineering Environ. Mech. 2007, 54, 207–222. [Google Scholar]

- Dołżyk-Szypcio, K. Naturalny Parametr Stanu. Grunty Niesposite; Oficyna Wydawnicza Politechniki Białostockiej: Białystok, Poland, 2021. [Google Scholar] [CrossRef]

- Been, K.; Hachey, J.; Jefferies, M.G. The critical state of sands. Geotechnique 1991, 41, 365–381. [Google Scholar] [CrossRef]

- Bolton, M.D. The strength and dilatancy of sands. Geotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Simoni, A.; Houlsby, G.T. The direct shear strength and dilatancy of sand-gravel mixtures. Geotech. Geol. Eng. 2006, 24, 523–549. [Google Scholar] [CrossRef]

- Bouri, D.; Krim, A.; Brahim, A.; Arab, A. Shear strength of compacted Chlef sand: Effect of water content, fines content and others parameters. Stud. Geotech. Mech. 2019, 42, 18–35. [Google Scholar] [CrossRef]

- Rasti, A.; Adarmanabadi, H.R.; Pineda, M.; Reinikainen, J. Evaluating the Effect of Soil Particle Characterization on Internal Friction Angle. Am. J. Eng. Appl. Sci. 2021, 14, 129–138. [Google Scholar] [CrossRef]

- Yang, J.; Luo, X.D. The critical state friction angle of granular materials: Does it depend on grading? Acta Geotech. 2018, 13, 535–547. [Google Scholar] [CrossRef]

- Stacho, J.; Sulovska, M. Shear Strength Properties of Coarse-Grained Soils Determined Using Large-Size Direct Shear Test. Civ. Environ. Eng. 2022, 18, 244–257. [Google Scholar] [CrossRef]

- Żarkiewicz, K.; Qatrameez, W. Assessment of Stress in the Soil Surrounding the Axially Loaded Model Pile by Thin, Flexible Sensors. Sensors 2021, 21, 7214. [Google Scholar] [CrossRef]

- Zhu, Q.Z.; Shao, J.F.; Mainguy, M. A micromechanics-based elastoplastic damage model for granular materials at low confining pressure. Int. J. Plast. 2010, 26, 586–602. [Google Scholar] [CrossRef]

- Carlos Santamarina, J.; Park, J.; Terzariol, M.; Cardona, A.; Castro, G.M.; Cha, W.; Garcia, A.; Hakiki, F.; Lyu, C.; Salva, M.; et al. Soil Properties: Physics Inspired, Data Driven; Number May; Springer International Publishing: Cham, Switzerland, 2019; pp. 67–91. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, F.; Zhang, Y.; Dan, H.; Liu, W. Effects of shear strength reduction strategies on safety factor of homogeneous slope based on a general nonlinear failure criterion. Comput. Geotech. 2015, 63, 215–228. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Pletzer, C.; Marcher, T.; Schneider-Muntau, B. Investigation on shear strength parameters of soil and soft rock material in the low stress range. Int. J. Geotech. Eng. 2024, 18, 66–74. [Google Scholar] [CrossRef]

- Al Tarhouni, M.A.; Hawlader, B. Monotonic and cyclic behaviour of sand in direct simple shear test conditions considering low stresses. Soil Dyn. Earthq. Eng. 2021, 150, 106931. [Google Scholar] [CrossRef]

- Tim, H. The Effects of Suppression of Dilation on the Shear Strength of Sands Tim House a Thesis Submitted To the Faculty of Graduate Studies in Partial Fulfillment of the Requirements for the Degree of Master of Science Graduate Program in Civil Engineering Toro. Ph.D. Thesis, York University, Toronto, ON, Canada, 2019. [Google Scholar]

- Rousé, P.C. Relation between the critical state friction angle of sands and low vertical stresses in the direct shear test. Soils Found. 2018, 58, 1282–1287. [Google Scholar] [CrossRef]

- Rad, M.M.; Ibrahim, S.K. Optimal plastic analysis and design of pile foundations under reliable conditions. Period. Polytech. Civ. Eng. 2021, 65, 761–767. [Google Scholar] [CrossRef]

- Benmebarek, M.A.; Benmebarek, S.; Rad, M.M.; Ray, R. Pile optimization in slope stabilization by 2D and 3D numerical analyses. Int. J. Geotech. Eng. 2022, 16, 211–224. [Google Scholar] [CrossRef]

- Sfriso, A.O. The friction angle and critical state void ratio of sands. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering: The Academia and Practice of Geotechnical Engineering; IOS Press: Amsterdam, The Netherlands, 2009; Volume 1, pp. 433–435. [Google Scholar] [CrossRef]

| No. | nr | [kPa] | [- ] | [kPa] | [kPa] | [- ] |

|---|---|---|---|---|---|---|

| 1 | ln-1-A | 4.87 | 0.708 | 5.06 | 5.06 | 0.629 |

| 2 | ln-1-B | 9.81 | 0.657 | 9.18 | 9.18 | 0.639 |

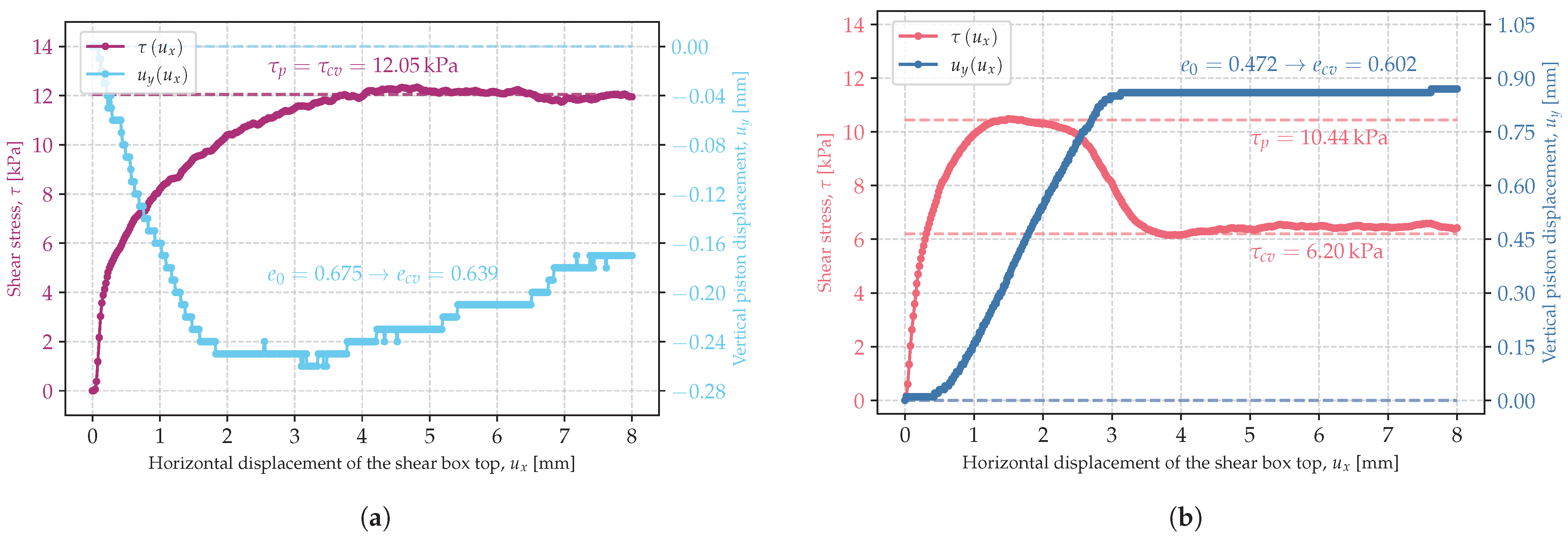

| 3 | ln-1-C | 14.75 | 0.675 | 12.05 | 12.05 | 0.639 |

| 4 | zg-1-A | 4.87 | 0.472 | 10.44 | 6.2 | 0.602 |

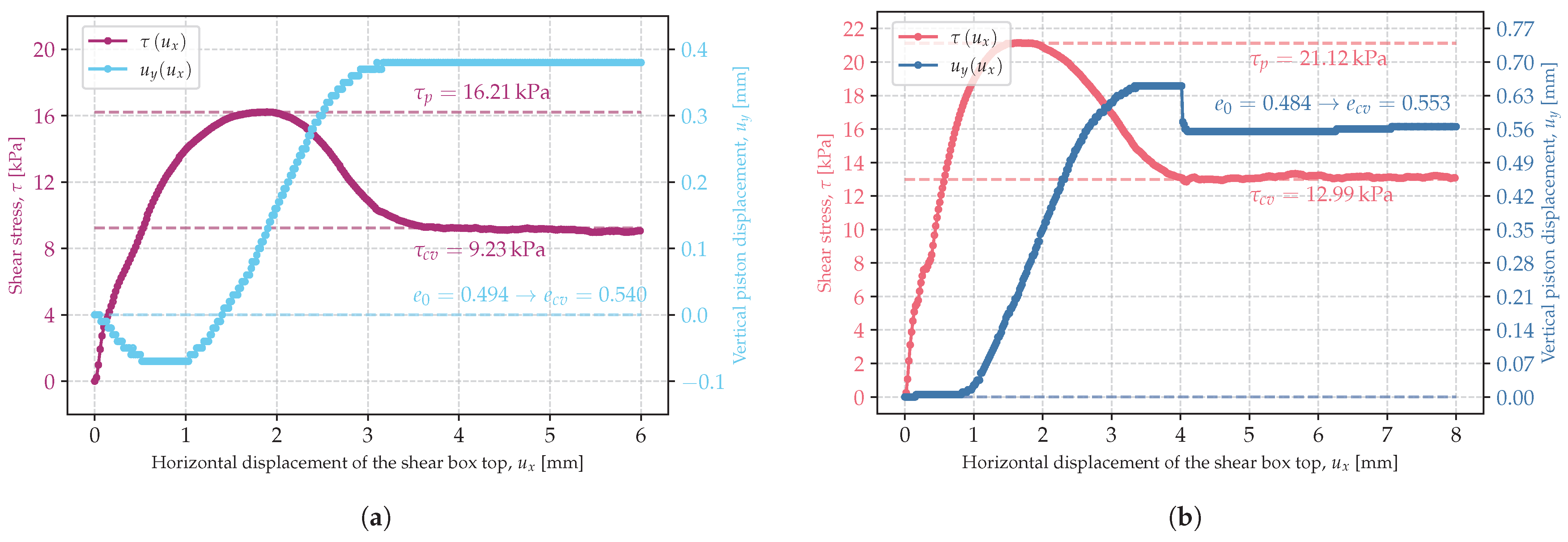

| 5 | zg-1-B | 9.81 | 0.494 | 16.21 | 9.23 | 0.54 |

| 6 | zg-1-C | 14.75 | 0.484 | 21.12 | 12.99 | 0.553 |

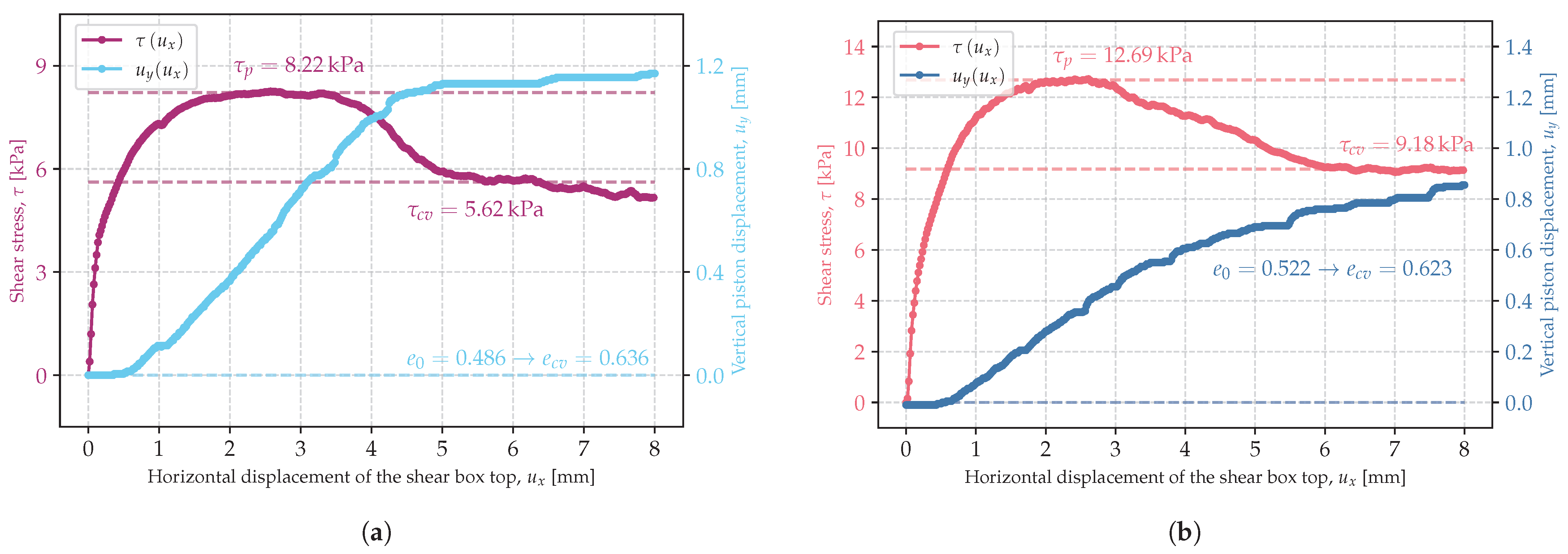

| 7 | szg-1-A | 4.87 | 0.486 | 8.22 | 5.62 | 0.636 |

| 8 | szg-1-B | 9.81 | 0.522 | 12.69 | 9.18 | 0.623 |

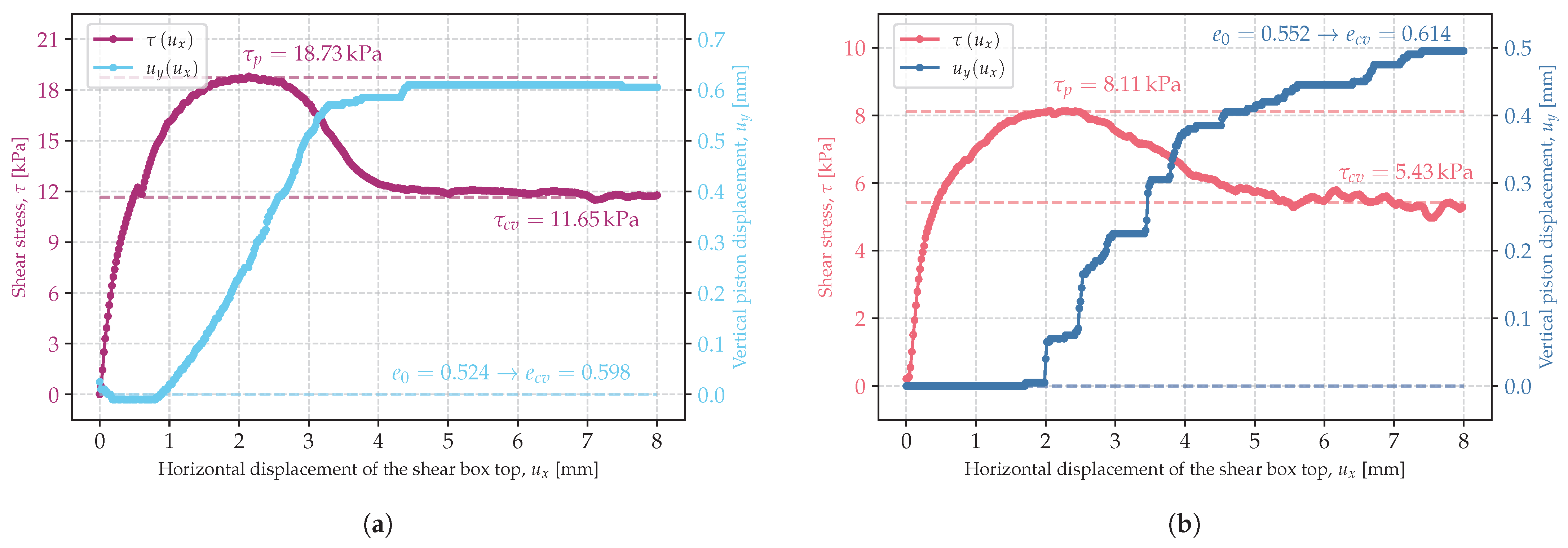

| 9 | szg-1-C | 14.75 | 0.524 | 18.73 | 11.65 | 0.598 |

| 10 | szg-2-A | 4.87 | 0.552 | 8.11 | 5.43 | 0.614 |

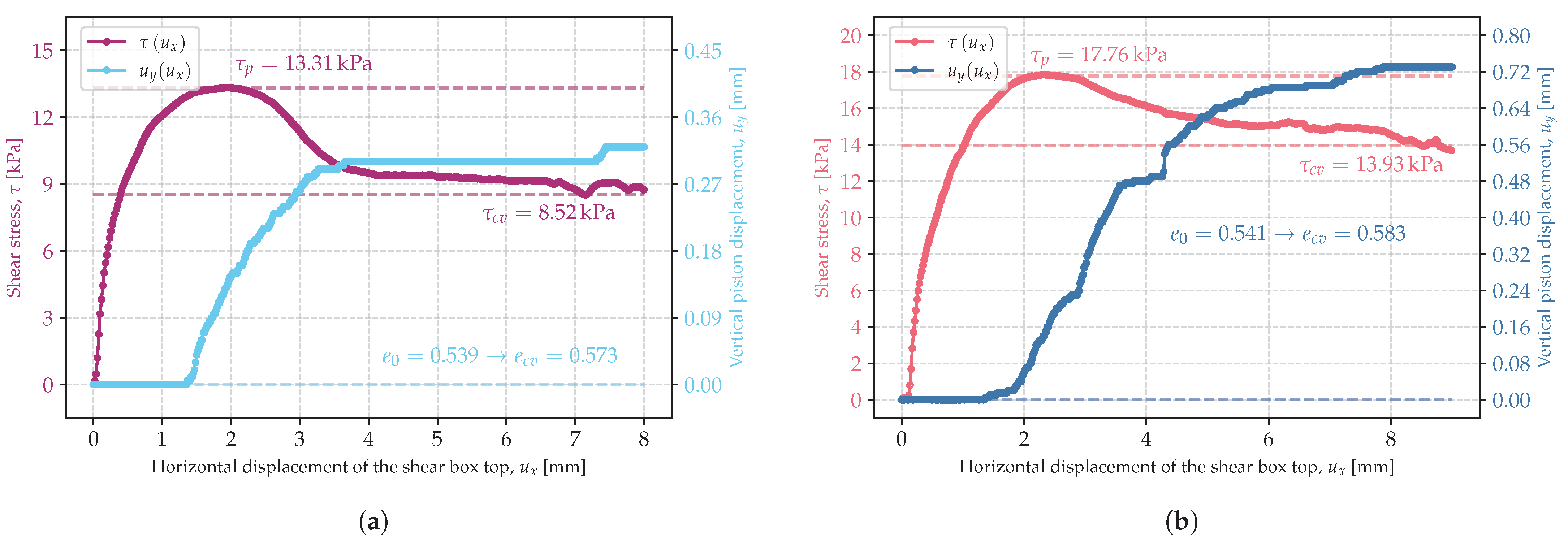

| 11 | szg-2-B | 9.81 | 0.539 | 13.31 | 8.52 | 0.573 |

| 12 | szg-2-C | 14.75 | 0.541 | 17.76 | 13.93 | 0.583 |

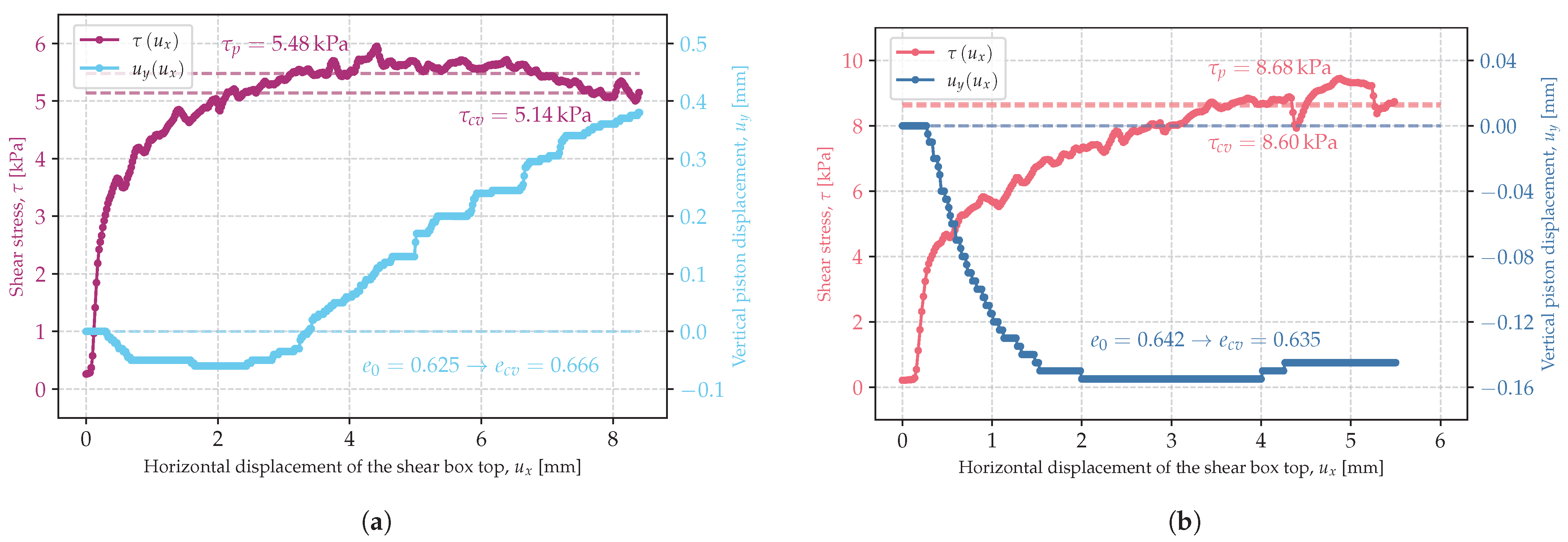

| 13 | ln-2-A | 4.87 | 0.625 | 5.48 | 5.14 | 0.666 |

| 14 | ln-2-B | 9.81 | 0.642 | 8.68 | 8.6 | 0.635 |

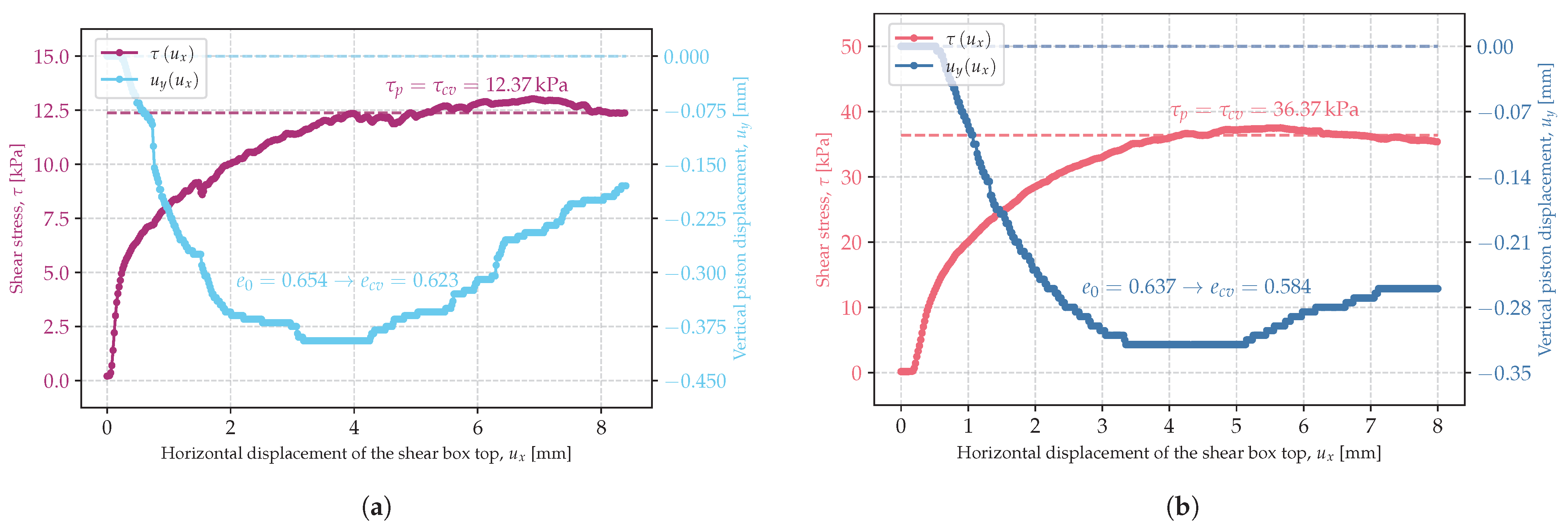

| 15 | ln-2-C | 14.75 | 0.654 | 12.37 | 12.37 | 0.623 |

| 16 | ln-3-A | 50 | 0.637 | 36.37 | 36.37 | 0.584 |

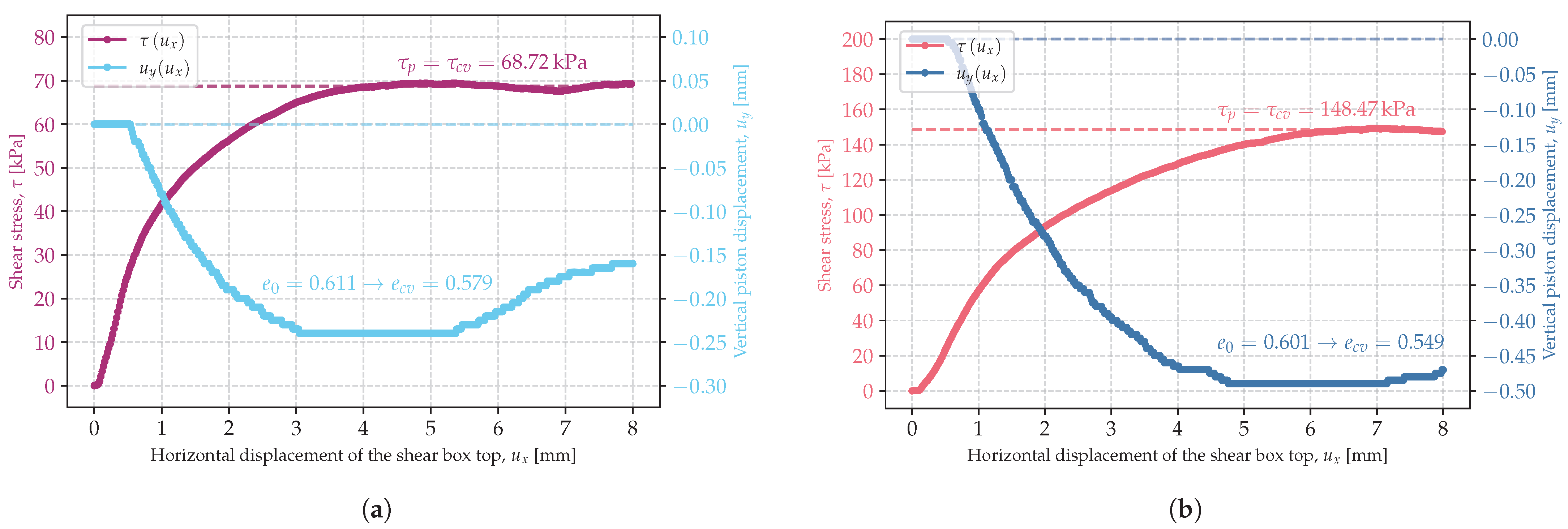

| 17 | ln-3-B | 100 | 0.611 | 68.72 | 68.72 | 0.579 |

| 18 | ln-3-C | 200 | 0.601 | 148.47 | 148.47 | 0.549 |

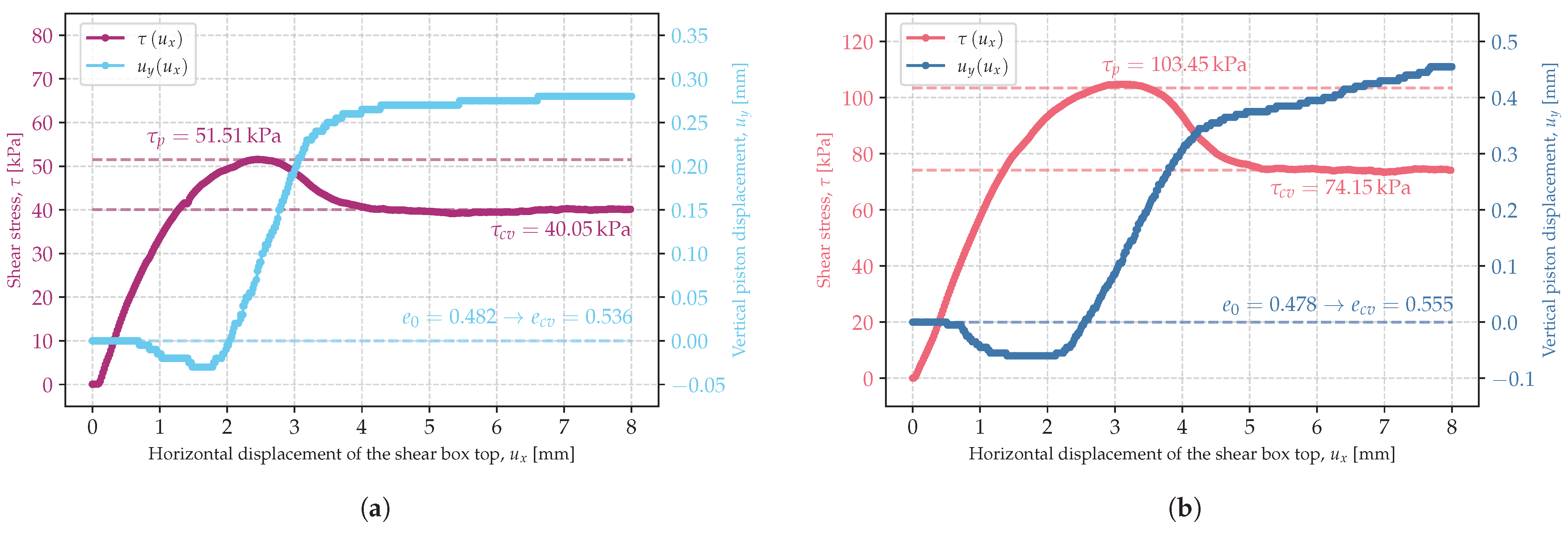

| 19 | zg-2-A | 50 | 0.482 | 51.51 | 40.05 | 0.536 |

| 20 | zg-2-B | 100 | 0.478 | 103.45 | 74.15 | 0.555 |

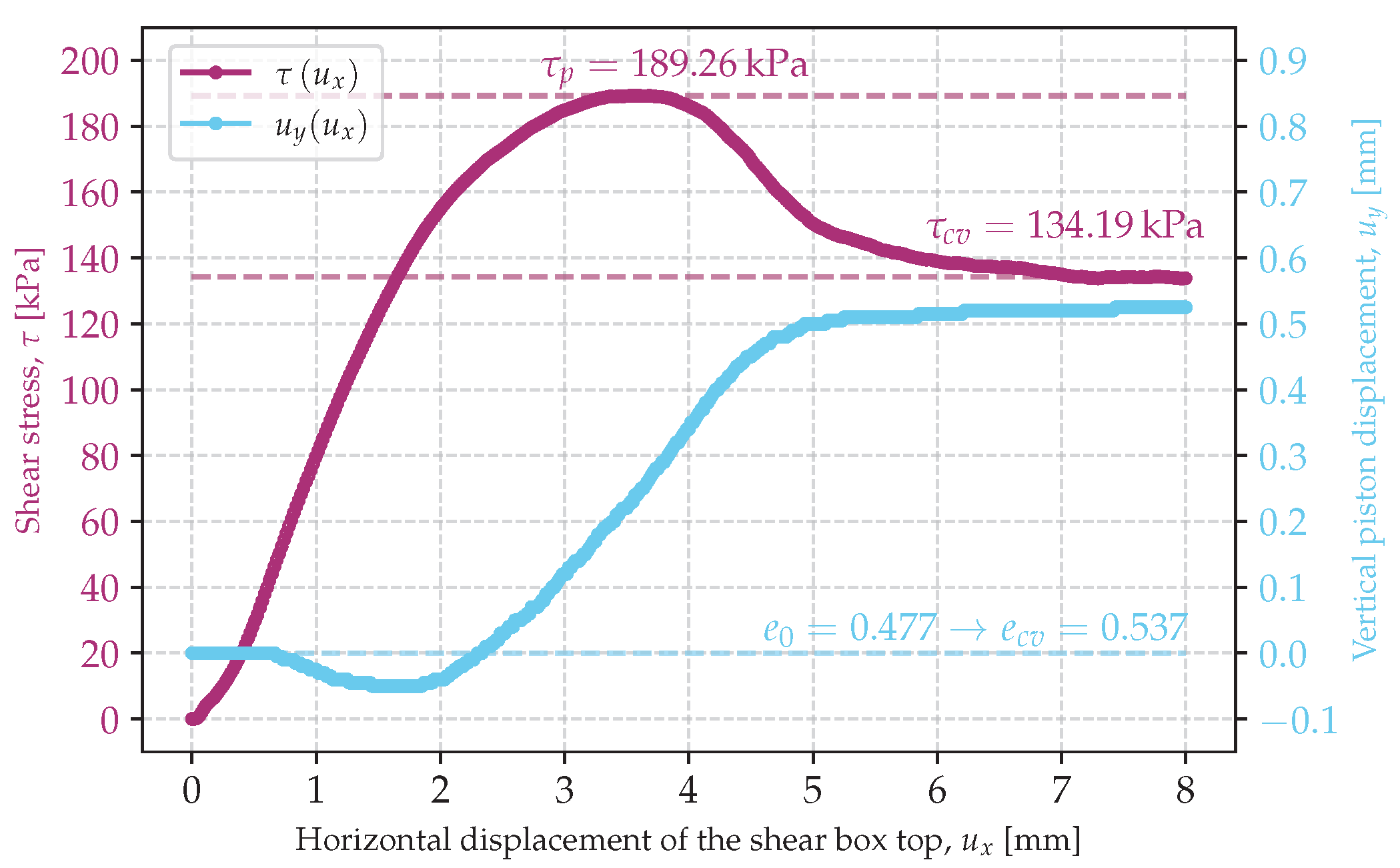

| 21 | zg-2-C | 200 | 0.477 | 189.26 | 134.19 | 0.537 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żarkiewicz, K.; Bednarek, R. Shear Strength of Sand: Integrated Analysis of Initial Porosity and Stress Effects. Appl. Sci. 2025, 15, 5902. https://doi.org/10.3390/app15115902

Żarkiewicz K, Bednarek R. Shear Strength of Sand: Integrated Analysis of Initial Porosity and Stress Effects. Applied Sciences. 2025; 15(11):5902. https://doi.org/10.3390/app15115902

Chicago/Turabian StyleŻarkiewicz, Krzysztof, and Roman Bednarek. 2025. "Shear Strength of Sand: Integrated Analysis of Initial Porosity and Stress Effects" Applied Sciences 15, no. 11: 5902. https://doi.org/10.3390/app15115902

APA StyleŻarkiewicz, K., & Bednarek, R. (2025). Shear Strength of Sand: Integrated Analysis of Initial Porosity and Stress Effects. Applied Sciences, 15(11), 5902. https://doi.org/10.3390/app15115902