Abstract

To investigate the anchoring performance of self-drilling anchors in gravel-cobble strata, this study conducted indoor orthogonal tests based on soil grouting experiments to simulate actual construction conditions. The influence of fine particle content, grouting pressure, and water-cement ratio on anchoring parameters was analyzed. Additionally, a grouting simulation model was developed using PFC2D 5.0 numerical software to examine the effects of grouting pressure, drilling speed, and grout viscosity on the grout diffusion radius through orthogonal and single-factor experimental schemes. The results demonstrate that: fine particle content exerts the most significant impact on anchoring performance, with higher content reducing peak pullout resistance; the grout diffusion radius exhibits a positive correlation with grouting pressure but a negative correlation with drilling speed and grout viscosity, with viscosity having the strongest influence, followed by pressure and speed; the diffusion pattern follows a gradually decreasing trend along the drilling direction, while the radius increases at a diminishing rate with elevated pressure; when viscosity ranges from 83.3 to 833.3 mPa·s, the diffusion radius decreases by 72%; and multivariate regression analysis indicates a power function relationship between the diffusion radius and these three parameters.

1. Introduction

With the rapid advancement of urban construction, a variety of deep foundation pit projects have proliferated, with an increasing number of such projects extending into sandy pebble strata [1,2,3,4]. Soil nailing and anchor support are commonly employed in foundation pit engineering. However, the sandy pebble stratum is characterized by its susceptibility to hole collapse and challenges in hole formation, often leading to construction issues such as borehole instability and drill rod sticking. Consequently, casing wall protection drilling technology is frequently utilized in these strata, despite its low construction efficiency. In areas with a high content of large-sized pebbles, achieving a satisfactory drilling rate is often unfeasible, and drill bit wear becomes a significant concern. The self-drilling anchor bolt, which integrates drilling, grouting, and anchoring into a single system, offers an effective solution to the challenges of hole formation and collapse in sandy pebble strata.

Currently, most indoor experimental studies on anchor bolts involve prefabricated anchor solids, which are subsequently embedded in soil for curing and pull-out testing [5,6,7,8]. However, due to the unique construction technology of self-drilling anchor bolts, the shape of the anchorage body cannot be predetermined, making it impractical to conduct indoor tests using prefabricated rods. As a result, research on self-drilling anchor bolts predominantly relies on field tests [9]. To address this limitation, the three stages of drilling, grouting, and anchoring in the construction process of self-drilling anchor bolts are separated, and indoor tests are conducted in conjunction with soil grouting experiments [10,11,12]. For instance, Liu conducted indoor grouting tests using custom-designed grouting equipment to determine the horizontal grouting diffusion patterns in shallow sandy pebble layers. The study examined the effects of grouting duration, grouting pressure, water-cement ratio, and permeability coefficient on grouting diffusion [13]. Similarly, Yu performed indoor grouting tests using a self-designed grouting model system, analyzing the influence of parameters such as grouting volume and grouting pressure on tunnel mechanical deformation [14]. Additionally, Chen utilized a self-developed grouting model test apparatus to simulate the crack grouting process, enhancing the understanding of crack propagation mechanisms during grouting [15].

In recent years, with the continuous advancement of the PFC numerical simulation system based on Mesomechanics theory, researchers have explored methods to analyze slurry diffusion and its coupling with the injected medium from a microscopic perspective. This approach has opened new avenues for studying the grouting process of self-drilling bolts [16,17,18]. The sandy pebble stratum, characterized by large pores, can be effectively simulated and analyzed using the “pipe domain” model derived from particle flow theory. Initially developed to study sandstone permeability, this model has been progressively refined and widely applied in fields such as hydraulic fracturing and fluid injection in granular media [19,20]. For example, based on a loess fissure grouting model test, Zhang utilized PFC particle flow software to simulate the slurry diffusion process in loess [21]. Zhou employed PFC numerical simulations to investigate the reinforcement effects of cement slurry injection in soil, analyzing the influence of cement particle size distribution, soil particle size distribution, and parallel bond strength between particles on the mechanical properties of cement-reinforced soil [22]. Wang established a discrete element fluidization gangue model using PFC, examining the diffusion and rock movement of fluidized gangue under varying grouting speeds, void ratios, and gangue particle sizes [23]. Additionally, Sun applied PFC to derive flow and pressure calculation formulas for particle flow, simulating the grouting process in soil cracks within a coupled environment from a microscopic perspective. Their study analyzed the initiation and propagation of cracks, as well as grouting pressure, under different grouting pressures and soil properties [24].

In this study, indoor pull-out tests of self-drilling anchor bolts were conducted in Luoyang sandy cobble strata, integrated with soil grouting experiments. To simulate the field construction effects of self-drilling anchor bolts, the three stages of drilling, grouting, and anchoring in the construction process were performed separately within a short timeframe. The research investigated the influence of varying grouting pressures, fine particle ratios in sandy cobble, and different water-cement ratios on the peak pull-out force, ultimate displacement, and anchor diameter. Additionally, a numerical model of self-drilling anchor bolt grouting in sandy cobble strata was established using PFC numerical simulation software. The study further examined the effects of different grouting pressures, drilling speeds, and slurry viscosities on the slurry diffusion radius.

2. Experimental Study on Slurry Diffusion

2.1. Testing Material

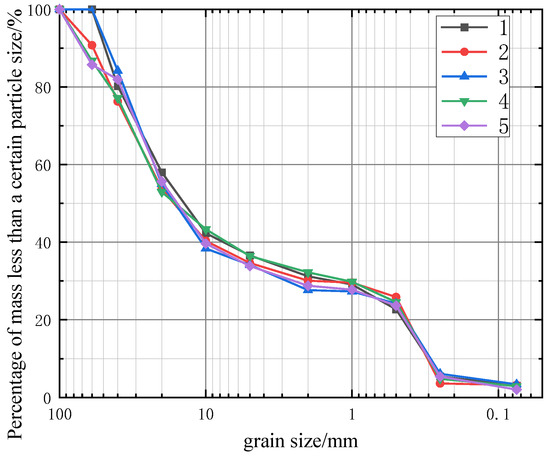

The anchor rods utilized in the experiment were HER38N self-drilling anchor rods with a diameter of 38 mm, manufactured by Luoyang Hengnuo Anchoring Technology Co., Ltd. (Luoyang, China). These rods feature an outer wall thickness of 8 mm, a yield force of 450 kN, a tensile force of 550 kN, and an elongation of 8%. The cement used was composite Portland cement P C 42.5, also produced by the same company. The soil samples were collected from a foundation pit project in the new district of Luoyang City. Five groups of soil samples were sieved, and their detailed parameters are presented in Table 1 and Figure 1.

Table 1.

Particle size gradation test results.

Figure 1.

Undisturbed particle size gradation curve.

2.2. Testing Equipment

The experimental setup comprises grouting equipment, pull-out equipment and data acquisition systems.

The grouting equipment includes an air compressor, a pressure barrel, and a slurry pipe, as illustrated in Figure 2a. The air compressor is capable of delivering a maximum pressure of 0.6 MPa, while the pressure barrel, with a capacity of 8 L for cement slurry, can withstand a maximum pressure of 0.8 MPa. The slurry pipe, measuring 580 mm in length, is connected to an 8 mm Teflon pipe that extends from the pressure barrel.

Figure 2.

Indoor test equipment: (a) grouting equipment; (b) drawing equipment.

The pull-out equipment consists of a jack and a manual pump. The jack, model RCH-60100, can apply a load of up to 600 kN and has a maximum stroke of 100 mm, as depicted in Figure 2b.

The data acquisition system is equipped with a pressure sensor, two dial indicators, two cable displacement sensors, an XL2101B5G static strain gauge, and its accompanying data acquisition and analysis software. The pressure sensor has a capacity of 50 T.

2.3. Specimen Making

When the specimen is made, the soil is first filled in the mold, and the grouting hole is reserved, as shown in Figure 3a. Then, the cement slurry is injected into the soil with different grouting pressures through the grouting equipment. After the grouting is completed, the bolt is quickly inserted into the reserved hole, as shown in Figure 3b. The shell of the specimen is a PVC pipe with a diameter of 320 mm. After 28 days of curing period, pull out and disassemble to observe the shape of anchorage body.

Figure 3.

Specimen pouring: (a) Filling completed; (b) Pouring completed.

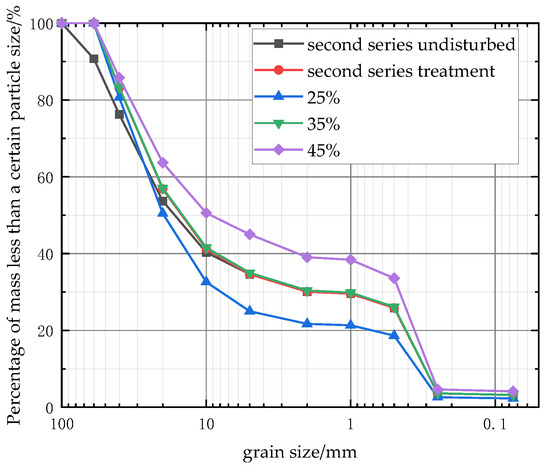

During the experiment, the proportion of fine particles in the soil was treated as one of the independent variables. To ensure the soil samples more accurately reflect real-world conditions, the collected soil samples were scaled using the equivalent substitution method. The particle size gradation data of the soil and the three independent variable gradations after scaling are presented in Table 2, while the corresponding particle size gradation curve is illustrated in Figure 4.

Table 2.

The particle size gradation of soil after treatment and the particle size gradation of three independent variables.

Figure 4.

Treatment and indoor test soil particle size gradation curve.

2.4. Test Scheme

In this experiment, an orthogonal test scheme was designed, with a total of 9 groups and an anchorage length of 500 mm. The experimental research was carried out from three aspects: grouting pressure, water-cement ratio and proportion of fine particles in soil. The specimens were named in the order of “Fine particle proportion-Grouting pressure-Water cement ratio”. The drawing was carried out by step loading method, according to 0→5→10→15→20→25→30 kN. Loading is carried out until the specimen is destroyed. The observation time and failure standard are consistent with the field test, and judged according to the “Technical Specification for Building Foundation Pit Support” (JGJ120-2012) [25].

3. Analysis of Slurry Diffusion Test Results

3.1. Test Result Analysis

The test scheme and test results are shown in Table 3. A total of 9 sets of effective data were obtained in this test. From the test results, the failure mode is mainly the slip between the anchorage body and the soil. The specimen with a large diffusion range has broken anchorage body, and the anchorage body is inverted cone as a whole, as shown in Figure 5.

Table 3.

Indoor orthogonal test scheme and results data.

Figure 5.

The shape of anchorage body after pull-out of specimen.

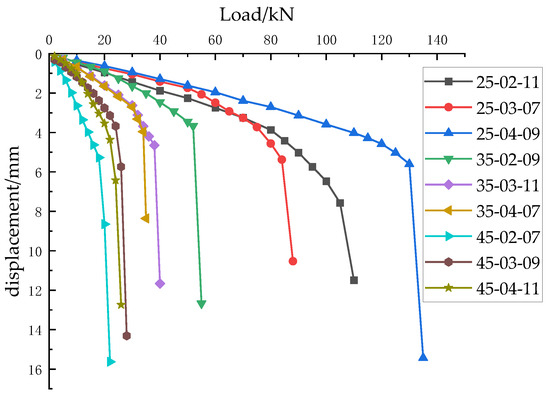

The load-displacement curve of the anchor bolt provides a macroscopic reflection of the load transfer characteristics and failure mechanisms under varying pull-out forces, as illustrated in Figure 6. The load-displacement curves of the nine self-drilling bolts exhibit a similar trend, demonstrating a linear relationship prior to reaching the ultimate load. However, upon reaching the ultimate load, the displacement does not undergo an abrupt change; instead, the load remains constant despite further increases in displacement. Consequently, the load value at this stage is defined as the peak pull-out force.

Figure 6.

Load-displacement curve of indoor test.

This trend can be attributed to the fact that, during the initial loading stage, the cohesive force at the interface between the anchorage body and the soil predominantly restricts the displacement of the bolt. As the applied load increases, it surpasses the bearing capacity of the interfacial bonding force, leading to localized relative sliding at the interface and a subsequent decline in the bonding force of the anchorage body. Upon reaching the ultimate load, the bond strength of the anchorage body can no longer resist the pull-out load. However, since the pull-out load at this stage has not yet exceeded the failure strength of the anchorage body, the anchorage body is uniformly pulled out, resulting in increased displacement while the load remains constant.

3.2. Analysis of the Influence Degree of Independent Variables

3.2.1. Extremum Difference Analysis

Through the range analysis, the influence order of each factor on the peak value of drawing force, ultimate displacement and anchor diameter can be obtained. As shown in Table 4, Table 5 and Table 6. is the sum of the test results corresponding to the number I level of each factor; is the average value of the test results corresponding to the number I level of a factor; L is the range of the average value of the test results corresponding to each level of a factor.

Table 4.

Pullout peak range analysis of bolt.

Table 5.

Analysis of limit displacement range of anchor rod.

Table 6.

Analysis of anchor solid diameter range.

Through range analysis of the indoor test results for the self-drilling anchor bolts, the relative influence of each factor on the outcomes was determined. For the peak pull-out force, the order of influence is as follows: fine particle proportion > water-cement ratio > grouting pressure. For the ultimate displacement and the diameter of the anchorage body, the order of influence is: fine particle proportion > grouting pressure > water-cement ratio.

3.2.2. Analysis of Variance

On the basis of range analysis, the significance level of each factor was further studied by variance analysis, as shown in Table 7, Table 8 and Table 9. In this orthogonal experiment, the degree of freedom of each factor is 2, and the significance level = 0.01, 0.1 is selected. By calculating the statistics of each factor and comparing with the critical value, the significance level of each factor on the peak value of drawing force, ultimate displacement, anchorage diameter and equivalent bond strength is determined. Among them, “**” is very significant, “*” is significant, and “—” is not significant.

Table 7.

Anchor pullout peak variance analysis.

Table 8.

Analysis of variance of ultimate displacement of bolt.

Table 9.

Anchor body diameter variance analysis.

From the data presented in the table, it is evident that the proportion of fine particles exerts a highly significant influence on both the peak pull-out force and the diameter of the anchorage body, while its impact on the ultimate displacement is also significant. This suggests that self-drilling anchors exhibit superior anchoring performance in soil layers with a lower proportion of fine particles. The influence of grouting pressure is only significant in relation to the diameter of the anchorage body, with no notable impact on other factors. This indicates that controlling grouting pressure primarily affects the size of the anchorage body, with limited contribution to enhancing the overall anchorage performance of self-drilling bolts. The water-cement ratio significantly influences the peak pull-out force and the diameter of the anchorage body, but its effect on the ultimate displacement is negligible. It is postulated that the strength of the interface between the anchorage body and the soil is affected by variations in the water-cement ratio. By optimizing this ratio, interfacial strength can be increased, leading to improved performance of self-drilling anchors.

The primary and secondary factors identified through variance analysis align with the results of the range analysis, confirming the scientific validity and significance of the findings regarding the influence of each factor on the peak pull-out force, ultimate displacement, and anchor diameter. It is evident that the proportion of fine particles exerts the most substantial influence in this experiment. A lower proportion of fine particles enables the anchoring performance of self-drilling bolts to be more fully realized. This implies that self-drilling anchors can provide robust support capacity in soil layers characterized by uneven particle dispersion.

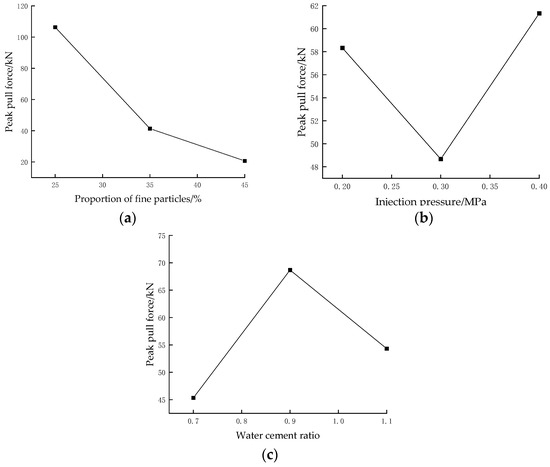

3.2.3. Variable Sensitivity Analysis

The predominant failure mode observed in the test specimens is the sliding failure at the interface between the anchorage body and the soil. Consequently, an in-depth investigation into the mechanical parameters of this interface is crucial for enhancing the anchoring performance of self-drilling anchors and for establishing design specifications for their application. Based on the results of the comprehensive comparative tests, a sensitivity analysis was conducted to evaluate the influence of each factor on the peak pull-out force, guided by the findings of the range analysis. This analysis provides a more intuitive understanding of the trends in how each factor affects the peak pull-out force, as illustrated in Figure 7.

Figure 7.

Analysis of the influence of various factors on the drawing peak value: (a) Proportion of fine particles; (b) Injection pressure; (c) Water cement ratio.

As illustrated in Figure 7, the proportion of fine particles, grouting pressure, and water-cement ratio all influence the peak pull-out force. The peak pull-out force decreases as the proportion of fine particles increases. With increasing grouting pressure, it initially decreases and then rises. The water-cement ratio exhibits a critical value, similar to the anchorage length observed in field tests. Within this critical range, the peak pull-out force increases with a higher water-cement ratio; however, beyond this threshold, it decreases as the water-cement ratio continues to rise.

Among these factors, the proportion of fine particles exerts the most significant influence on the peak pull-out force. When the proportion of fine particles is relatively low, the soil exhibits higher porosity, allowing for more uniform and extensive slurry diffusion during grouting. This results in a larger contact area between the anchorage body and the soil, thereby increasing the pull-out resistance of the bolt. Conversely, as the proportion of fine particles increases, the soil porosity decreases, and the distribution of large and small pebbles in the sandy pebble stratum becomes more irregular. This irregularity hinders effective slurry circulation during diffusion, leading to inconsistent diffusion ranges within the same horizontal plane. Consequently, the bonding force at the interface between the anchorage body and the soil becomes uneven. When a failure point emerges at the interface, it accelerates the failure of the entire anchorage system.

4. Basic Theory of Grouting Simulation

4.1. Flow Equation

In PFC, the “tube domain” model is employed to simulate fluid-solid coupling. The actual pores between particles are defined as fluid “domains” using the FISH language, and these “domains” are interconnected via “pipes”. Assuming that each “pipe” functions as a parallel plate with a specific length and aperture, and that the fluid flow adheres to the cubic law, the flow rate through the parallel plate can be expressed as:

In the above equation, is the flow, m3/s−1; is the opening degree, m; is the coefficient of fluid viscosity, Pa·s; (p2 − p1) is the pressure differential between neighboring fluid domains, Pa; is the length of the pipe, m; is the thickness of the sample, m.

If the particles on either side of the pipe remain bonded, the parameter a can be calculated using the following equation:

In the above equation, is the initial opening, m; is the normal force when the opening of the fluid pipeline is reduced to half, N; is the normal force, N.

When the force on both sides of the pipeline is 0 or tension, the calculation formula of a is:

In the above equation, is the displacement proportional multiplier; is the normal displacement of pipeline particles, m.

4.2. Pressure Equation

Each “domain” continuously updates the fluid pressure by obtaining the flow through the surrounding pipeline, and the fluid pressure acts on the particles in the “domain” in the form of volume force. The fluid pressure increment generated in unit time is:

In the above equation, is the bulk modulus of fluid, Pa; is the apparent volume of the fluid domain, m3; Σq is the sum of the flow obtained through the surrounding pipeline, m3/s; is the volume change of fluid domain caused by the stress between particles, m3.

4.3. Solution Method

After each calculation step, the geometry of the “domain” will change, resulting in changes in the opening of the surrounding pipeline and affecting the flow in the pipeline. The change of flow rate will cause the change of pressure in the “domain”, and the change of pressure will change the geometry of the “domain” again through mechanical calculation, so as to realize the coupling calculation. In order to obtain the critical time step required for the coupling calculation, assuming that there is a disturbance pressure, the flow rate generated by the disturbance can be obtained from the Equation (1):

In the above equation, N is the total number of pipes connecting the “domain”; r is the average radius of particles around the “domain”, m.

The response pressure variation resulting from fluid inflow can be calculated based on the pressure equation.

When the response pressure change is equal to the disturbance pressure (i.e., ), the critical time step can be obtained by the simultaneous Equations (5) and (6):

5. Simulation Calculation Model of Grouting

5.1. Modelling

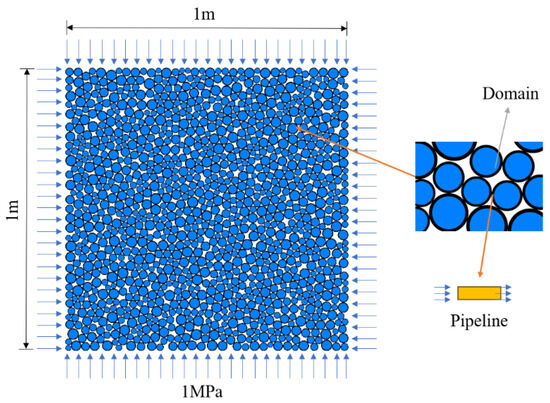

The model has a length and width of 1 m, with a total of 1145 particles automatically generated, as depicted in Figure 8. To optimize computational efficiency while considering the limitations of computer processing power, the particle radius was enlarged to reduce the total number of particles. The particle radii are uniformly distributed between a maximum value of 4 cm and a minimum value, with a ratio of 2 between the largest and smallest radii. The interparticle connections are established using the Parallel Bond model.

Figure 8.

Numerical simulation diagram of grouting in sandy pebble stratum.

5.2. Particle Parameters

Through on-site geological exploration and laboratory testing, the fundamental parameters of sandy pebble stratum particles were determined by calibrating the mesoscopic parameters, as detailed in Table 10.

Table 10.

Basic parameters of particles.

5.3. Analysis of Influencing Factors of Slurry Diffusion Radius

This experiment primarily investigates the slurry diffusion of self-drilling anchors during the drilling and grouting process in sandy pebble strata, with the grouting effect preliminarily assessed through the slurry diffusion radius. The slurry diffusion radius is typically influenced by factors such as the grouting process and stratum conditions. To account for the construction conditions of various factors in real-world scenarios and to facilitate precise control and implementation in particle flow software, this study selected three relatively significant and controllable factors: grouting pressure (p), drilling speed (s), and slurry viscosity (μ). Under a confining pressure of 1 MPa, the simulation scheme included grouting pressures of 0.2 MPa, 0.3 MPa, and 0.4 MPa. Considering the drilling efficiency of self-drilling anchor equipment during construction, drilling speeds of 0.2 m/min, 0.3 m/min, and 0.4 m/min were selected. In accordance with the Technical Specification for Building Foundation Pit Support (JGJ120-2012), the water-cement ratio for cement slurry in engineering construction ranges from 0.5 to 0.55. However, based on actual construction and site conditions, the water-cement ratio typically ranges from 0.7 to 1. Therefore, slurry viscosities of 83.3 mPas, 138.9 mPas, and 416.6 mPas were chosen. By generating a Scalar to represent pore pressure, the program identifies the abscissa values of the Scalar at the farthest left and right points at the final time step, and the average of these values is taken as the slurry diffusion radius.

This simulation employs an orthogonal test design, comprising a total of nine groups. Assuming no interaction between the factors, the three selected factors-grouting pressure, drilling speed, and slurry viscosity—were arranged according to a three-level, three-factor orthogonal analysis table, denoted as L9(33). The factors were labeled in the order of “Grouting pressure-Drilling speed-Slurry viscosity”. The orthogonal test design and corresponding calculation results are presented in Table 11.

Table 11.

Numerical simulation test scheme and simulation results.

It can be seen from the relevant research results [13], the slurry diffusion range has a power function relationship with grouting pressure, grouting time and slurry viscosity. In this simulation process, the grouting time can be expressed by the drilling speed, so it is assumed to obey the function equation:

In the above equation, is the grouting diffusion radius, m; p is grouting pressure, MPa; s is drilling rate, m/min; is slurry viscosity, mPa·s; A, B, C, D is undetermined coefficients.

The equation is a nonlinear equation, which can be transformed into a linear equation after taking logarithms on both sides. The experimental data are analyzed by multiple linear regression method, and the constant A and partial regression coefficients B, C and D can be obtained. However, the partial regression coefficient is affected by the corresponding factor units and values, and cannot directly reflect the relative importance of the independent variables. Therefore, the regression coefficient βi is often obtained after standardization. The greater the absolute value of βi, the greater the influence of this factor on the grouting diffusion radius. Through the above method, the empirical formula between the diffusion radius R and the three influencing factors can be obtained:

In the above equation, βp, βs, βμ is the standardized regression coefficients of grouting diffusion radius to grouting pressure, drilling speed and slurry viscosity; is the multiple correlation coefficient.

The results indicate that slurry viscosity has the greatest impact on the grouting diffusion radius, with grouting pressure being the second most influential factor, whereas drilling speed contributes relatively little to the slurry diffusion radius.

5.4. The Impact of Various Factors on the Slurry Diffusion Radius

5.4.1. The Influence of Different Grouting Pressure on Slurry Diffusion Radius

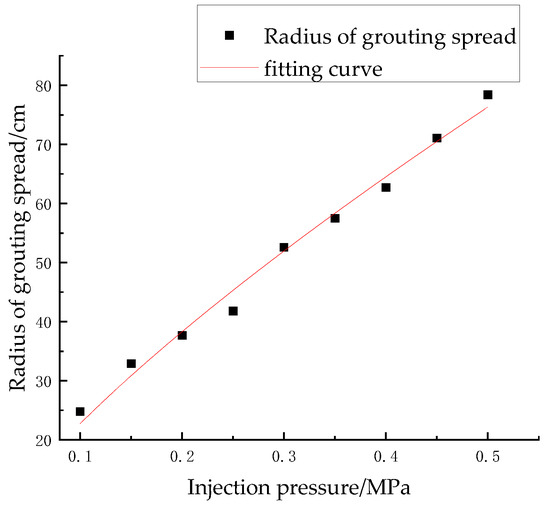

To isolate the influence of individual parameters on slurry diffusion characteristics, a series of controlled single-factor experiments were conducted. Under constant conditions of drilling speed (0.3 m/min) and slurry viscosity (138.9 mPa·s), the grouting pressure was systematically varied from 0.1 to 0.5 MPa to investigate its specific effects on diffusion radius. The resultant pressure-dependent diffusion patterns are presented in Figure 9.

Figure 9.

The correlation between the slurry diffusion radius and grouting pressure.

Based on regression analysis of the results, the correlation between the slurry diffusion radius and grouting pressure is established as follows:

From the Equation (10), it can be seen that the slurry diffusion radius has a power function relationship with the grouting pressure, and the slurry diffusion radius increases with the increase of the grouting pressure. When the grouting pressure is 0.1 MPa, the slurry diffusion radius is 24.8 cm. When the grouting pressure increases to 0.3 MPa, the slurry diffusion radius is 52.6 cm, which is expanded by 112.1%. When the grouting pressure increases from 0.3 MPa to 0.5 MPa, the slurry diffusion radius is 78.4 cm, which is expanded by 49.1%. It can be seen that the slurry diffusion radius will increase with the increase of grouting pressure, but the rate of increase will gradually decrease. Therefore, too large grouting pressure will not significantly increase the slurry diffusion radius. Field applications require adjustments for anchor length and in situ heterogeneity.

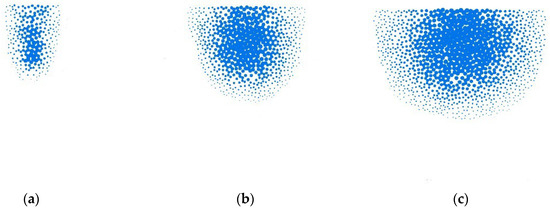

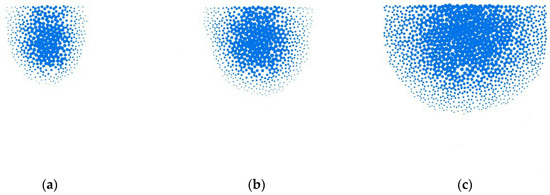

Figure 10 presents the slurry diffusion patterns under varying grouting pressures, revealing two key phenomena: (1) the diffusion radius exhibits positive pressure-dependence while maintaining downward progression, and (2) pronounced slurry concentration gradients emerge, with the grouting port region showing significantly higher density than peripheral zones. Notably, the observed diffusion demonstrates preferential lateral expansion—a deviation from conventional vertical-dominated penetration patterns. While laboratory-scale constraints may accentuate this lateral effect, future work will investigate scale dependencies through either three-dimensional numerical simulations or field-scale validation tests.

Figure 10.

Slurry diffusion at different grouting pressure levels: (a) 0.1 MPa; (b) 0.3 MPa; (c) 0.5 MPa.

5.4.2. The Influence of Different Drilling Speed on Slurry Diffusion Radius

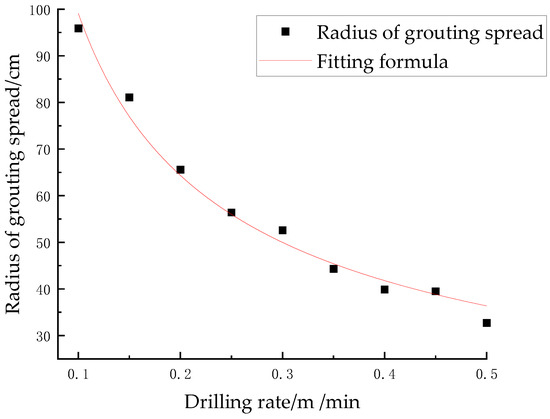

The numerical simulations were conducted under constant grouting pressure (0.3 MPa) and slurry viscosity (138.9 mPa·s) conditions, while varying the drilling speed across a range of 0.1–0.5 m/min to systematically investigate its influence on slurry diffusion radius. The resultant diffusion patterns are presented in Figure 11.

Figure 11.

The correlation between the slurry diffusion radius and drilling speed.

The relationship between slurry diffusion radius and drilling speed is obtained by regression analysis of the results:

It can be seen from Equation (11) and Figure 10 that the slurry diffusion radius has a power function relationship with the drilling speed, and the slurry diffusion radius decreases with the increase of the drilling speed. When the drilling speed is 0.5 m/min, the slurry diffusion radius is the smallest, which is 32.7 cm. When the drilling speed is reduced to 0.3 m/min, the slurry diffusion radius increases to 52.6 cm, an increase of 60.9%. When the drilling speed decreases from 0.3 m/min to 0.1 m/min, the slurry diffusion radius increases to 95.9 cm, an increase of 82.3%. It can be seen that in the actual construction process on site, different construction conditions have different optimal drilling speeds. The pursuit of too fast drilling speed will make the self-drilling anchor performance of the bolt not fully utilized, thus wasting construction resources. The slurry diffusion under different drilling speeds is shown in Figure 12. The smaller the drilling speed, the more uniform the slurry distribution.

Figure 12.

Slurry diffusion at different drilling speeds levels: (a) 0.5 m/min; (b) 0.3 m/min; (c) 0.1 m/min.

5.4.3. The Influence of Different Slurry Viscosity on Slurry Diffusion Radius

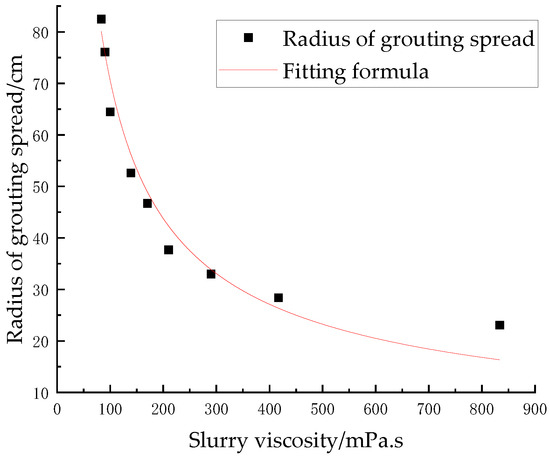

The study employed fixed parameters of 0.3 MPa grouting pressure and 0.3 m/min drilling speed while varying slurry viscosity between 83.3–833.3 mPa·s to investigate its influence on slurry diffusion radius. The corresponding simulation results are presented in Figure 13.

Figure 13.

The correlation between the slurry diffusion radius and slurry viscosity.

It can be seen from Figure 13 that when the slurry viscosity is 83.3 mPas, the maximum slurry diffusion radius is 82.5 cm, and when the slurry viscosity is 416.6 mPas, the slurry diffusion radius is 28.4 cm. As the slurry viscosity increases, the slurry diffusion radius gradually decreases. When the slurry viscosity increases to 833.3 mPas, the slurry diffusion radius decreases to 23.1 cm, the slurry viscosity increases by 9 times, and the slurry diffusion radius decreases by 72%. The relationship between slurry diffusion radius and slurry viscosity is obtained by regression analysis of the results:

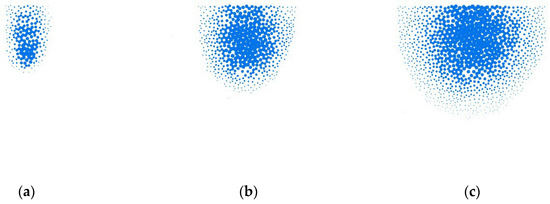

Equation (12) establishes a power-law relationship between slurry diffusion radius and viscosity, with Figure 14 illustrating the corresponding diffusion patterns across different viscosity values. The results demonstrate significant variations in diffusion range, where the highest viscosity (833.3 mPa·s) produces the most constrained diffusion, primarily localized near the outlet with minimal radial penetration. These findings indicate that highly viscous slurries exhibit poor permeability during field applications, ultimately compromising anchoring effectiveness due to insufficient grout dispersion.

Figure 14.

Slurry diffusion at different slurry viscosity level: (a) 833.3 mPas; (b) 167 mPas; (c) 83.3 mPas.

6. Nonlinear Fitting of Indoor Test Results

The preceding analysis demonstrates that the slurry diffusion radius follows a power-law relationship with grouting pressure, grouting time, and slurry viscosity. In our laboratory experiments, the investigated independent variables were fine particle ratio, grouting pressure, and water-cement ratio. Given that water-cement ratio fundamentally determines slurry viscosity, we propose that the slurry diffusion radius (equivalent to anchor body diameter) similarly obeys a power-law relationship with these three parameters, as expressed by the following function:

In the above equation, is the diameter of anchor body, m; is the proportion of fine particles, %; is grouting pressure, MPa; is water-cement ratio; E, F, G, H is the undetermined coefficients.

After the linear transformation of the nonlinear Equation (13), the multiple linear regression analysis of the indoor test data is carried out, and the standardized regression coefficient βi is obtained, as shown in Equation (14):

In the above equation, βk, βp, βa is the standardized regression coefficient of grouting diffusion radius to grouting pressure, drilling speed and slurry viscosity; is the multiple correlation coefficient.

The analysis reveals that the diameter of the anchorage body is most significantly influenced by the fine particle ratio, followed by grouting pressure, while the water-cement ratio exhibits the least effect. These findings are consistent with both range and variance analyses from previous laboratory tests, thereby validating the reliability of the proposed equation.

7. Conclusions

Through systematic laboratory experiments, this study investigated the effects of fine particle ratio, grouting pressure, and water-cement ratio on three key performance parameters of self-drilling anchors in sandy pebble strata: peak pull-out force, ultimate displacement, and anchor diameter. Furthermore, employing PFC-based discrete element numerical simulations of the self-drilling anchor grouting process, we examined how grouting pressure, drilling speed, and slurry viscosity influence the slurry diffusion radius. The main findings of this investigation are summarized as follows:

- The orthogonal test results revealed the following order of influencing factors on peak pull-out force: fine particle ratio > water-cement ratio > grouting pressure. A similar dominance pattern was observed for ultimate displacement and anchorage body diameter: fine particle ratio > grouting pressure > water-cement ratio. Through optimization of water-cement ratio and grouting pressure according to particle size gradation in sandy pebble strata, the stability of self-drilling anchor bolts can be substantially improved.

- The peak pull-out force exhibits three distinct characteristic relationships with the investigated parameters: it decreases monotonically with increasing fine particle content; it demonstrates a convex relationship with grouting pressure, initially decreasing before reaching a minimum value and subsequently increasing; and it follows a threshold-dependent behavior with respect to water-cement ratio, showing an increasing trend below a critical ratio but decreasing progressively when this threshold is exceeded.

- The slurry diffusion radius of self-drilling bolts exhibits distinct relationships with three key parameters: it increases proportionally with grouting pressure while decreasing with both drilling speed and slurry viscosity. Among these factors, sensitivity analysis reveals slurry viscosity as the most influential parameter, followed by grouting pressure, with drilling speed demonstrating the least impact. Based on these observed relationships, we establish that the diffusion radius follows a power-law function of grouting pressure, drilling speed, and slurry viscosity, from which we derive the following empirical formula.

- The overall diffusion form of the slurry is large in the upper part and gradually decreases along the drilling direction, but the slurry is mainly concentrated in the outlet area. The slurry diffusion radius will increase with the increase of grouting pressure, but the rate of increase will gradually decrease. When the drilling speed is 0.5 m/min, the slurry diffusion radius is the smallest, which is 32.7 cm. When the drilling speed decreases to 0.3 m/min, the slurry diffusion radius increases to 52.6 cm, an increase of 60.9%. When the drilling speed decreases from 0.3 m/min to 0.1 m/min, the slurry diffusion radius increases to 95.9 cm, an increase of 82.3%. When the slurry viscosity increases from 83.3 mPa·s to 833.3 mPa·s, the slurry diffusion radius decreases by 72%.

This study investigates the grouting diffusion characteristics and anchoring performance of self-drilling anchors in sandy cobble strata through laboratory pull-out tests and the development of a grouting model. While the experimental procedures and modeling approach were designed to closely simulate actual construction processes of self-drilling anchors, certain idealized assumptions were necessarily incorporated, which may introduce some discrepancies compared to real-world field conditions. Prior to this investigation, field tests were conducted to examine the anchoring performance of self-drilling anchors in sandy cobble strata. Future research will comprehensively account for natural environmental factors affecting slurry diffusion and anchoring behavior, with particular emphasis on the unique characteristics of self-drilling anchors and their practical engineering applications.

Author Contributions

Conceptualization, X.G. and C.W.; methodology, X.G. and C.W.; software, M.Z.; validation, X.G., M.Z. and C.W.; formal analysis, X.G. and C.W.; investigation, X.C. and Y.Z.; resources, X.G. and C.W.; data curation, M.Z., X.C. and Y.Z.; writing—original draft preparation, X.G.; writing—review and editing, X.G. and M.Z.; visualization, X.G.; supervision, X.G.; project administration, C.W.; funding acquisition, X.G. and C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This article was funded by the National Natural Science Foundation of China (Grant No. 52104082).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sun, Y. Surface subsidence of pit-in-pit foundation in sand–cobble stratum in Beijing area. Proc. Inst. Civ. Eng.-Ground Improv. 2018, 172, 96–107. [Google Scholar] [CrossRef]

- Huang, J.; Xu, P.; Huang, Z. Settlement Analysis of Mud-Water Shield Passing Full-Face Water-Rich Sand and Cobble Stratum Under Luo River. Geotech. Geol. Eng. 2023, 42, 535–542. [Google Scholar] [CrossRef]

- Jin, Z.; Sun, F.; Zhu, Y.; Yang, L.; Yu, B.; Yan, Y.; Du, Y.; Ge, G. An Experimental Study on the Shear Characteristics of Typical Colluvial Soil with Gravel and the Stability of Slopes in Wenzhou, China. Indian Geotech. J. 2020, 51, 627–646. [Google Scholar] [CrossRef]

- Zhao, P.; Ma, W. Study on the correlation of macro-fine parameters of surrounding rock in sand and cobble tunnel based on discrete element. Mater. Res. Express 2022, 9, 095502. [Google Scholar] [CrossRef]

- Ubaid, H.; Amanpreet, T. Pullout behavior of helical soil nails in cohesionless soil: A laboratory investigation. IOP Conf. Ser. Earth Environ. Sci. 2023, 1110, 012006. [Google Scholar] [CrossRef]

- Jiang, X.; Qin, Y.; Li, W.-T.; Xiang, P.-F.; Zhang, S.-S.; Chen, C. Experimental study on grouting mortar GFRP anchor rod pulling test. J. Phys. Conf. Ser. 2021, 2044, 012161. [Google Scholar] [CrossRef]

- Małkowski, P.; Feng, X.; Niedbalski, Z.; Żelichowski, M. Laboratorial Tests and Numerical Modeling of Rock Bolts Bonded by Different Materials. Rock Mech. Rock Eng. 2022, 56, 2589–2606. [Google Scholar] [CrossRef]

- Buragadda, V.; Orekanti, R.E.; Kompala, P.M. Influence of type of geosynthetic material interaction on shallow anchor pullout capacity. Mater. Today Proc. 2024, 103, 277–281. [Google Scholar] [CrossRef]

- Chen, J.; Ma, S.; Guo, Z.; Liu, H.; Liu, A.; Lan, J. Mechanical Behavior and Parameter Effects of a Novel Cross-Sectional Self-Drilling Bolt Under Tension. Geotech. Geol. Eng. 2025, 43, 95. [Google Scholar] [CrossRef]

- Zhong, Z.; Li, J.; Bie, C. Theoretical Approach to Predicting the Diffusion Radius of Fracture Grouting in Soil–Rock Mixtures. Appl. Sci. 2023, 13, 4730. [Google Scholar] [CrossRef]

- Zhuo, Z.; Rentai, L. Theoretical and experimental study on one dimensional fracture grouting in soil medium. Sādhanā 2020, 45, 232–242. [Google Scholar] [CrossRef]

- Kim, D.; Park, K. Evaluation of the grouting in the sandy ground using bio injection material. Geomech. Eng. 2017, 12, 739–752. [Google Scholar] [CrossRef]

- Liu, S.; Xie, Z.; Zhang, J.; Sun, J.; Tian, Q.; Yu, Z.; An, X.; Wu, W. Experimental Study on the Diffusion Law of Horizontal Grouting in Shallow Sand Gravel Layer. KSCE J. Civ. Eng. 2024, 28, 3192–3207. [Google Scholar] [CrossRef]

- Hua, S.Y.; Zhang, M.D.; Huang, W.H. Model test study of soil grouting effect on shield tunnel longitudinal structural behavior. Eng. Geol. 2025, 347, 107912. [Google Scholar] [CrossRef]

- Cheng, S.; Yang, F.; Dai, Y.; Yang, Z.; Shi, Y. An Experimental Research on Crack Propagation Regularity During Fracture Grouting. IOP Conf. Ser. Earth Environ. Sci. 2021, 651, 032047. [Google Scholar] [CrossRef]

- Fu, J.; Haeri, H.; Sarfarazi, V.; Zadeh, R.K.; Amini, E.; Amini, M.S.; Karimi, L. Computational and experimental analysis of failure characteristics in geogrid-reinforced pre-holed subsurface materials. Eng. Fract. Mech. 2025, 315, 110857. [Google Scholar] [CrossRef]

- Li, J.; Hu, J.; Zhao, Y.; Zhao, Z.; Chen, Y.; Li, B. Failure characteristics of tunnel under the true triaxial condition: Role of a prefabricated flaw. Theor. Appl. Fract. Mech. 2024, 130, 104327. [Google Scholar] [CrossRef]

- Xiao, Q.; Gao, B.; Deng, H.; Zhao, J. Study on the performance of pervious concrete under freeze–thaw cycle based on PFC3D. Front. Phys. 2025, 12, 1466191. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, F.; Furtney, J.; Damjanac, B. A review of methods, applications and limitations for incorporating fluid flow in the discrete element method. J. Rock Mech. Geotech. Eng. 2022, 14, 1005–1024. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, W.; Chen, J.; Xiao, X.; Li, Y.; Zhao, X. Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int. J. Coal Geol. 2014, 121, 1–13. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, Z.; Fang, X.; Liang, X. Research on the Fracture Grouting Mechanism and PFC Numerical Simulation in Loess. Adv. Mater. Sci. Eng. 2018, 2018, 4784762. [Google Scholar] [CrossRef]

- Zhou, J.; Fang, K.; Zhao, T. Reinforcement effect of cement grout on soil based on granular flow theory. In Proceedings of the 2016 4th International Conference on Advanced Materials and Information Technology Processing (AMITP 2016), Guilin, China, 24–25 September 2016. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Li, M.; Sartaj, M.; Wang, Y. A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method. Sustainability 2022, 14, 12838. [Google Scholar] [CrossRef]

- Sun, F.; Pan, R.; Zhu, X.Y.; Chen, T.L. Meso-Mechanical Simulation of Fracture Grouting under Fluid-Solid Coupling Environment and Engineering Applications. Appl. Mech. Mater. 2013, 477–478, 485–491. [Google Scholar] [CrossRef]

- JGJ120-2012; Technical Specification for Building Foundation Pit Support. China Standards Press: Beijing, China, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).