Technology–Economy–Policy: Biochar in the Low-Carbon Energy Transition—A Review

Abstract

1. Introduction

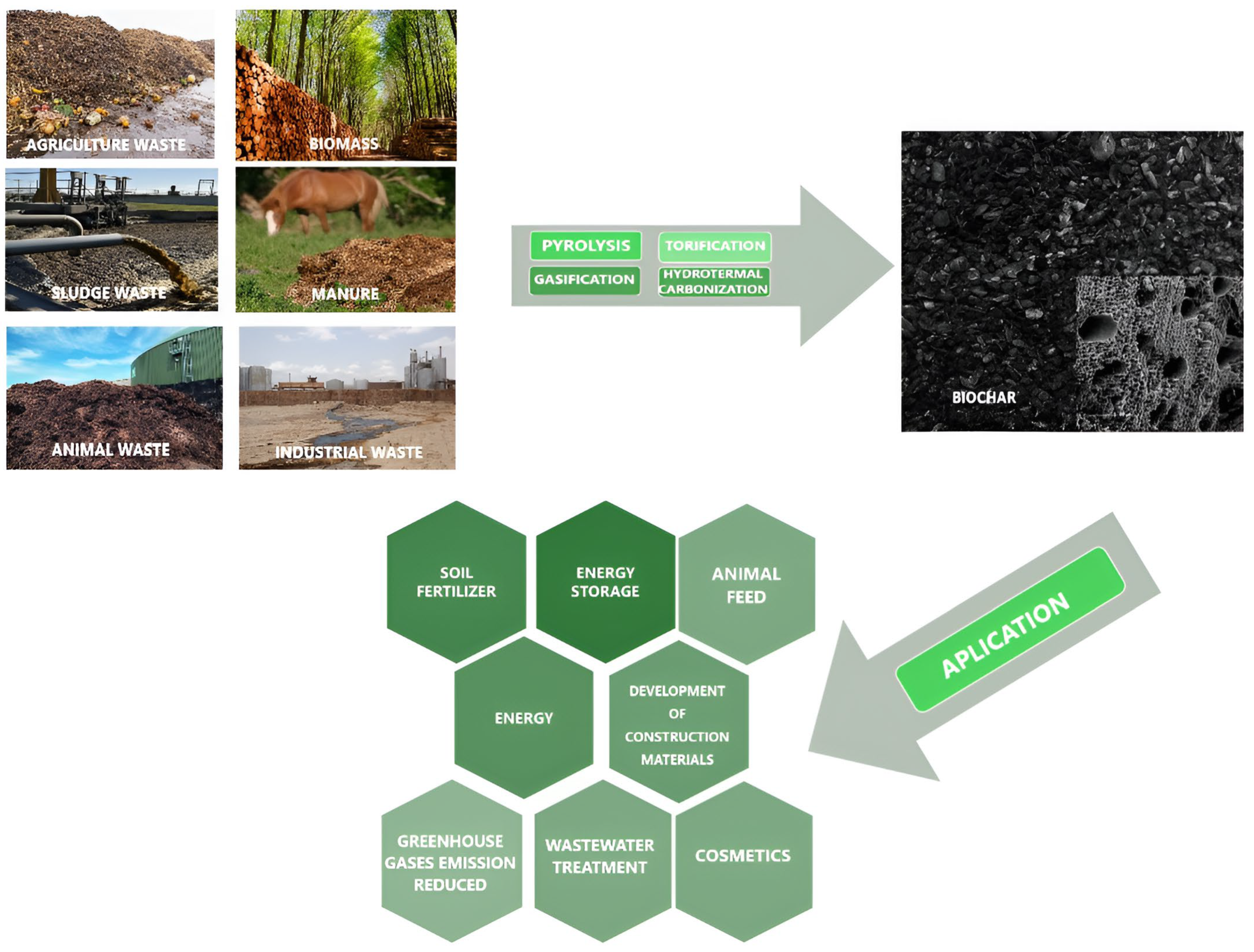

2. Biomass

3. Biochar

4. Technologies: Biochar Production

4.1. Pyrolysis

4.2. Gasification

4.3. Torrefaction

4.4. Hydrothermal Technology

5. Policy: Support for Biochar

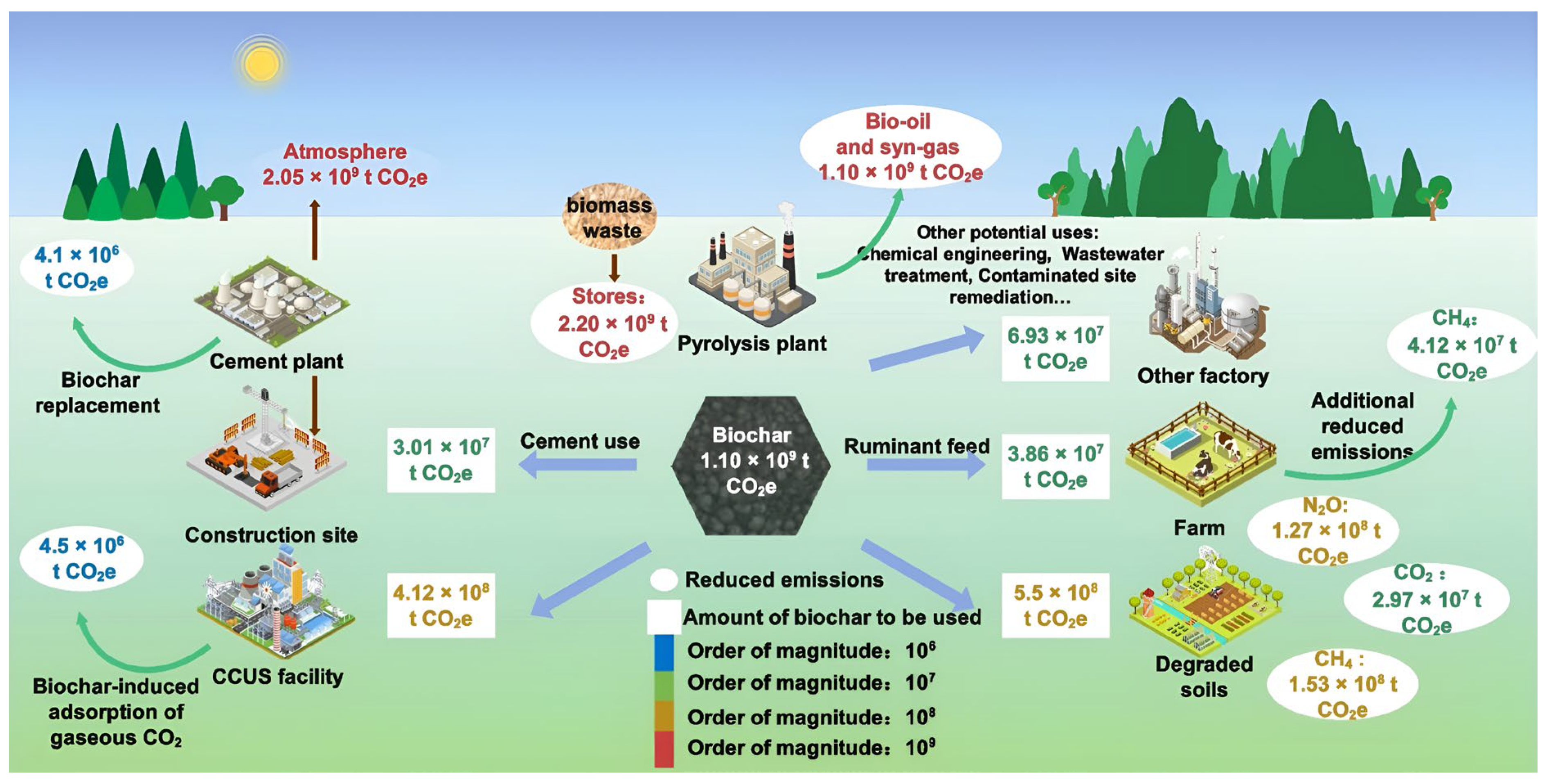

5.1. Biochar in Negative Emission Technologies (NETs) and Carbon Dioxide (CO2) Greenhouse Gases (GHGs)

5.2. The European Biochar Industry

6. Economy: Application of Biochar

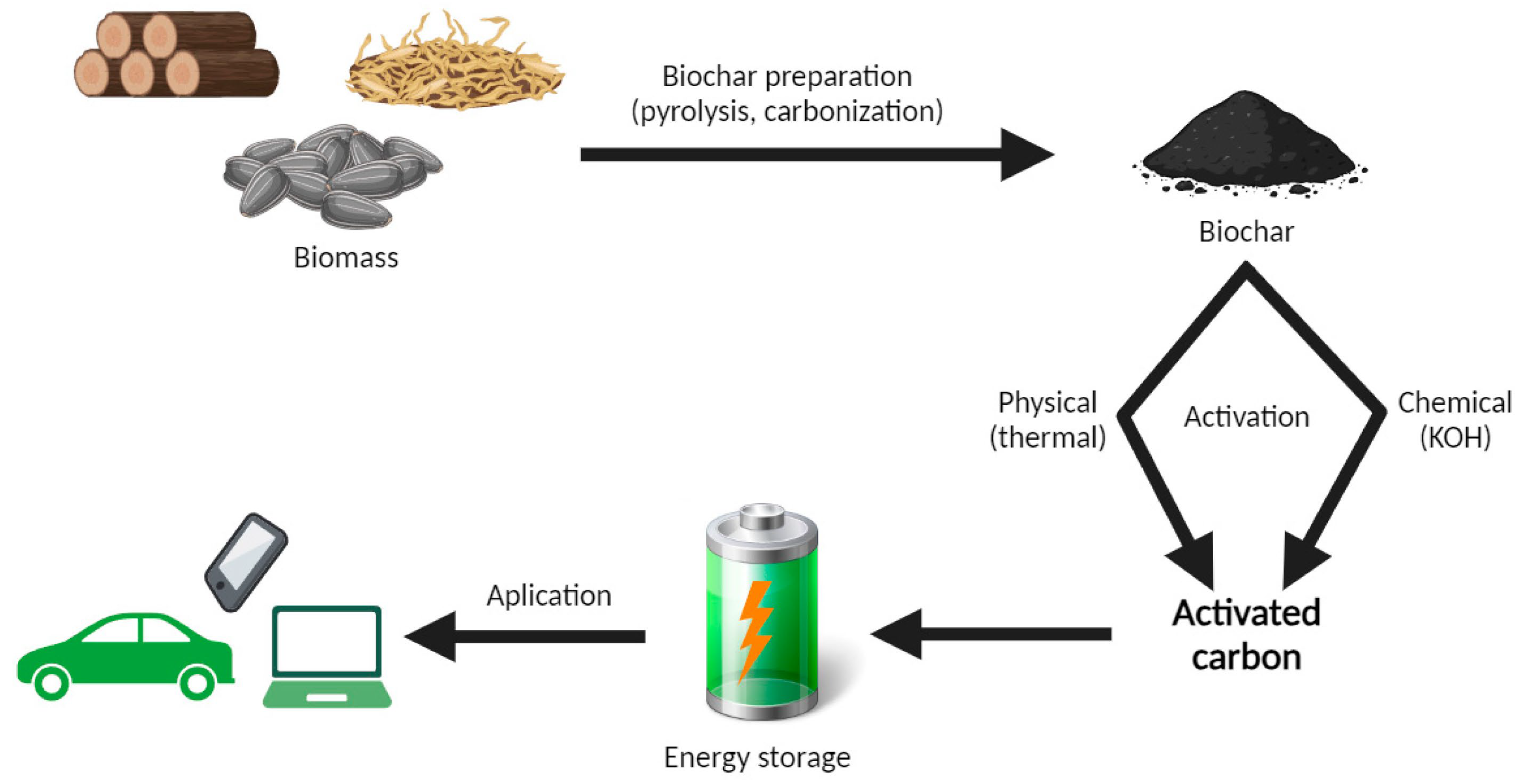

6.1. Application of Biochar in the Renewable Energy Sector

6.1.1. Renewable Energy

6.1.2. Biomaterials in MFCs for Bioelectricity Production

6.1.3. Application of Biochar in Biorefinery

6.1.4. Biochar as a Material for Batteries and Supercapacitors

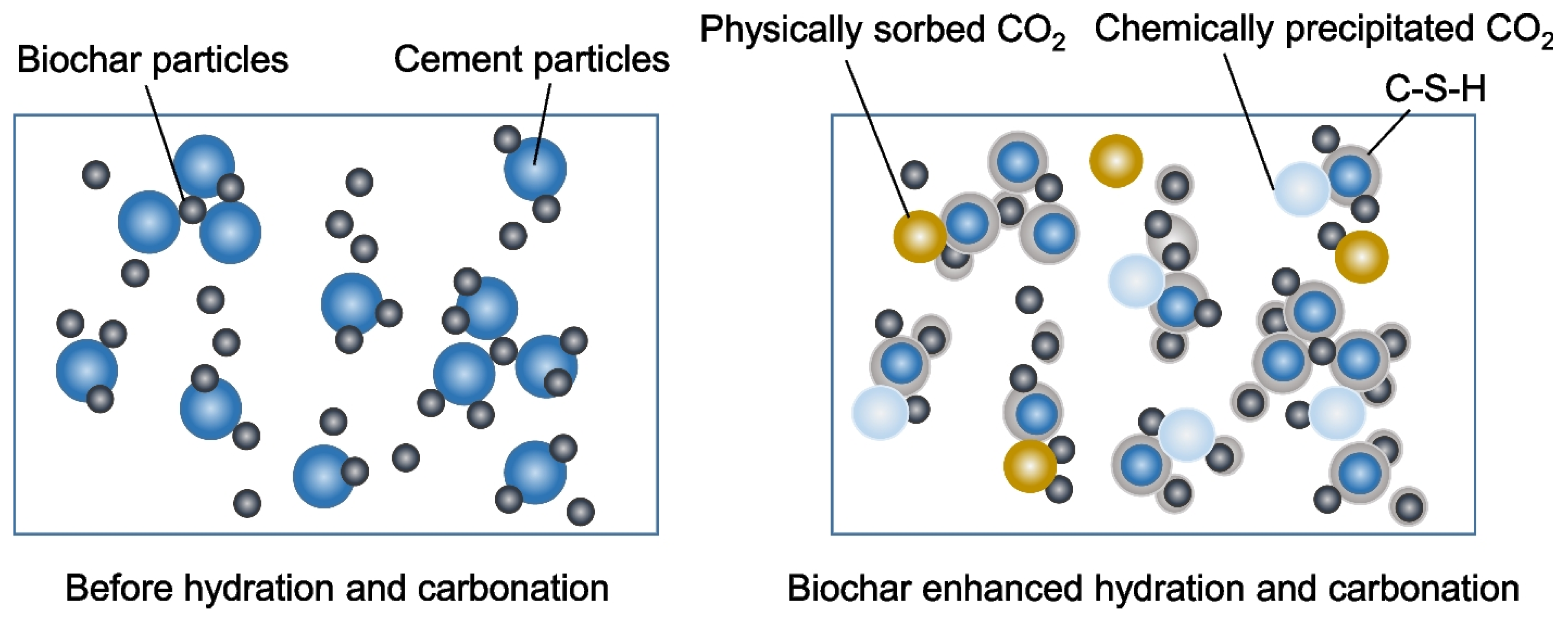

6.1.5. Biochar as a Building Material to Achieve Carbon Neutrality

6.1.6. Biochar-Based Composites

6.2. LCA as a Tool for Calculating the Actual Production Efficiency and Environmental Impact of a Product

7. Economic Assessment

8. Conclusions and Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vicente-Serrano, S.M.; Quiring, S.M.; Peña-Gallardo, M.; Yuan, S.; Domínguez-Castro, F. A review of environmental droughts: Increased risk under global warming? Earth-Sci. Rev. 2020, 201, 102953. [Google Scholar] [CrossRef]

- Rayan, R.A.; Choudhury, M.; Deb, M.; Chakravorty, A.; Devi, R.M.; Mehta, J. Climate change: Impact on waterborne infectious diseases. In Water Conservation in the Era of Global Climate Change; Elsevier: Amsterdam, The Netherlands, 2021; pp. 213–228. [Google Scholar]

- Yoro, K.O.; Daramola, M.O. CO2 emission sources, greenhouse gases, and the global warming effect. In Advances in Carbon Capture; Woodhead Publishing; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–28. [Google Scholar]

- Abbass, K.; Qasim, M.Z.; Song, H.; Murshed, M.; Mahmood, H.; Younis, I. A review of the global climate change impacts, adaptation, and sustainable mitigation measures. Environ. Sci. Pollut. Res. 2022, 29, 42539–42559. [Google Scholar] [CrossRef] [PubMed]

- Akanyange, S.N.; Nie, W.; Mwabaima, F.I.; Liu, F.; Niu, W.; Jiang, S.Q.; Zhang, Y.; Adom-Asamoah, G.; Yeboah, M.L.; Qiu, B.; et al. A systematic review of the physiological and environmental impacts of coal dust and its control technologies. Fuel 2024, 371, 131876. [Google Scholar] [CrossRef]

- Xue, Y.; Zhou, Z.; Nie, T.; Wang, K.; Nie, L.; Pan, T.; Wu, X.; Tian, H.; Zhong, L.; Li, J.; et al. Trends of multiple air pollutants emissions from residential coal combustion in Beijing and its implication on improving air quality for control measures. Atmos. Environ. 2016, 142, 303–312. [Google Scholar] [CrossRef]

- Kirsch, S. Running out? Rethinking resource depletion. Extr. Ind. Soc. 2020, 7, 838–840. [Google Scholar] [CrossRef]

- Afshar, M.; Mofatteh, S. Biochar for a sustainable future: Environmentally friendly production and diverse applications. Results Eng. 2024, 23, 102433. [Google Scholar] [CrossRef]

- Silva, L.F.O.; Wolfe, A.L. Coal energy and environmental impacts: Introduction. Energy Geosci. 2021, 2, 87–89. [Google Scholar] [CrossRef]

- Abbas, Y.; Yun, S.; Wang, Z.; Zhang, Y.; Zhang, X.; Wang, K. Recent advances in bio-based carbon materials for anaerobic digestion: A review. Renew. Sustain. Energy Rev. 2021, 135, 110378. [Google Scholar] [CrossRef]

- Adger, W.N.; Arnell, N.W.; Tompkins, E.L. Successful adaptation to climate change across scales. Glob. Environ. Change 2005, 15, 77–86. [Google Scholar] [CrossRef]

- Leal Filho, W.; Azeiteiro, U.M.; Balogun, A.L.; Setti, A.F.F.; Mucova, S.A.; Ayal, D.; Oguge, N.O. The influence of ecosystems services depletion to climate change adaptation efforts in Africa. Sci. Total Environ. 2021, 779, 146414. [Google Scholar] [CrossRef]

- Feliciano, D.; Recha, J.; Ambaw, G.; MacSween, K.; Solomon, D.; Wollenberg, E. Assessment of agricultural emissions, climate change mitigation and adaptation practices in Ethiopia. Clim. Policy 2022, 22, 427–444. [Google Scholar] [CrossRef]

- Rising, N.R. Why the crisis engulfing nature matters for business and the economy. In World Economic Forum; TNFD: London, UK, 2020. [Google Scholar]

- European Commission. Communication for the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. In Proceedings of the the European Green Deal European Commission, Brussels, Belgium, 11 December 2019; p. 24.

- Sharma, R. Impacts on human health of climate and land use change in the Hindu Kush–Himalayan region. Mt. Res. Dev. 2012, 32, 480–486. [Google Scholar] [CrossRef]

- Sharif, A.; Mishra, S.; Sinha, A.; Jiao, Z.; Shahbaz, M.; Afshan, S. The renewable energy consumption-environmental degradation nexus in Top-10 polluted countries: Fresh insights from quantile-on-quantile regression approach. Renew. Energy 2020, 150, 670–690. [Google Scholar] [CrossRef]

- Izaguirre, C.; Losada, I.; Camus, P.; Vigh, J.; Stenek, V. Climate change risk to global port operations. Nat. Clim. Chang. 2021, 11, 14–20. [Google Scholar] [CrossRef]

- Jurgilevich, A.; Räsänen, A.; Groundstroem, F.; Juhola, S. A systematic review of dynamics in climate risk and vulnerability assessments. Environ. Res. Lett. 2017, 12, 013002. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy-and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Martiskainen, M.; Hook, A.; Baker, L. Decarbonization and its discontents: A critical energy justice perspective on four low-carbon transitions. Clim. Change 2019, 155, 581–619. [Google Scholar] [CrossRef]

- Bimbela, F.; Abrego1, J.; Gonzalo1, A.; Sánchez1, J.L.; Arauzo1, J. Biomass pyrolysis liquids. Fundamentals, technologies and new strategies. Boletín Del Grupo Español Del Carbón 2014, 33, 11–14. [Google Scholar]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef]

- Mehedintu, A.; Sterpu, M.; Soava, G. Estimation and forecasts for the share of renewable energy consumption in final energy consumption by 2020 in the european union. Sustainability 2018, 10, 1515. [Google Scholar] [CrossRef]

- Muresan, A.A.; Attia, S. Energy efficiency in the romanian residential building stock: A literature review. Renew. Sustain. Energy Rev. 2017, 74, 349–363. [Google Scholar] [CrossRef]

- Contescu, C.I.; Adhikari, S.P.; Gallego, N.C.; Evans, N.D.; Biss, B.E. Activated Carbons Derived from High-Temperature Pyrolysis of Lignocellulosic Biomass. C J. Carbon Res. 2018, 4, 51. [Google Scholar] [CrossRef]

- Saletnik, B.A.; Fiedur, M.; Saletnik, A.; Bajcar, M.; Zaguła, G.; Puchalski, C.; Lipa, T.; Dobrzański, B., Jr. Pyrolysis as a method of refining plant biomass residues from poppy (Papaver somniferum L.) and buckwheat (Fagopyrum esculentum) crops. Int. Agrophysics 2025, 39, 113–124. [Google Scholar] [CrossRef]

- Piekarczyk, M.; Kotwica, K.; Jaskulski, D. Wpływ stosowania popiołu ze słomy jęczmienia jarego na chemiczne właściwości gleby lekkiej. Fragm. Agron. 2011, 28, 91–99. [Google Scholar]

- Wacławowicz, R. The effect of ashes from biomass combustion on infection of spring wheat by Gaeumannomyces graminis. Prog. Plant Prot. 2012, 52, 2. [Google Scholar]

- Li, Y.; Rezgui, Y.; Zhu, H. District heating and cooling optimization and enhancement—Towards integration of renewables, storage and smart grid. Renew. Sustain. Energy Rev. 2017, 72, 281–294. [Google Scholar] [CrossRef]

- Kılkış, Ş.; Krajačić, G.; Duić, N.; Rosen, M.A.; Al-Nimr, A. Advancements in sustainable development of energy, water and environment systems. Energy Convers. Manag. 2018, 176, 164–183. [Google Scholar] [CrossRef]

- Zhou, Y.; Qin, S.; Verma, S.; Sar, T.; Sarsaiya, S.; Ravindran, B.; Liu, T.; Sindhu, R.; Patel, A.K.; Binod, P.; et al. Production and beneficial impact of biochar for environmental application: A comprehensive review. Bioresour. Technol. 2021, 337, 125451. [Google Scholar] [CrossRef]

- Donner, M.; Verniquet, A.; Broeze, J.; Kayser, K.; De Vries, H. Critical success and risk factors for circular business models valorising agricultural waste and by-products. Resour. Conserv. Recycl. 2021, 165, 105236. [Google Scholar] [CrossRef]

- AEBIOM European Biomass Association. Statistical Report 2018; AEBIOM European Biomass Association: Brussels, Belgium, 2019. [Google Scholar]

- Yang, Q.; Mašek, O.; Zhao, L.; Nan, H.; Yu, S.; Yin, J.; Li, Z.; Cao, X. Country-level potential of carbon sequestration and environmental benefits by utilizing crop residues for biochar implementation. Appl. Energy 2021, 282, 116275. [Google Scholar] [CrossRef]

- Yang, X.; Igalavithana, A.D.; Oh, S.E.; Nam, H.; Zhang, M.; Wang, C.H.; Kwon, E.E.; Tsang, D.C.; Ok, Y.S. Characterization of bioenergy biochar and its utilization for metal/metalloid immobilization in contaminated soil. Sci. Total Environ. 2018, 640, 704–713. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Feng, G.; Miles, D.; Gao, L.; Jia, Y.; Li, C.; Qu, Z. Impact of biochar on greenhouse gas emissions and soil carbon sequestration in corn grown under drip irrigation with mulching. Sci. Total Environ. 2020, 729, 138752. [Google Scholar] [CrossRef] [PubMed]

- Zakaria, M.R.; Farid, M.A.A.; Andou, Y.; Ramli, I.; Hassan, M.A. Production of biochar and activated carbon from oil palm biomass: Current status, prospects, and challenges. Ind. Crops Prod. 2023, 199, 116767. [Google Scholar] [CrossRef]

- Nuanhchamnong, C.; Kositkanawuth, K.; Wantaneeyakul, N. Granular waterworks sludge-biochar composites: Characterization and dye removal application. Results Eng. 2022, 14, 100451. [Google Scholar] [CrossRef]

- Suman, S. Conversion of Solid Biomass into Biochar: Act as a Green, Eco-Friendly Energy Source and a Substitute of Fossil Fuel Inputs. Proceedings 2020, 58, 34. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for environmental management: An introduction. In Biochar for Environmental Management Science and Technology; Lehmann, J., Joseph, S., Eds.; Earthscans: London, UK, 2009; pp. 1–12. [Google Scholar]

- Shackley, S.; Carter, S.; Knowles, T.; Middelink, E.; Haefele, S.; Sohi, S.; Cross, A.; Haszeldine, S. Sustainable gasification-biochar systems? A case-study of rice-husk gasification in Cambodia, Part 1: Context, chemical properties, environmental and health and safety issues. Energy Policy 2012, 42, 49–58. [Google Scholar] [CrossRef]

- Verheijen, F.; Jeffery, S.; Bastos, A.C.; Van Der Velde, M.; Diafas, I. Biochar Application to Soils: A Critical Scientific Review of Effects on Soil Properties; Processes and Functions; European Commission: Ispra, Italy, 2010. [Google Scholar]

- Kapoor, R.T.; Ahmad, P.; Rafatullah, M. Insights into biochar applications: A sustainable strategy toward carbon neutrality and circular economy. In Catalytic Applications of Biochar for Environmental Remediation: Sustainable Strategies Towards a Circular Economy; American Chemical Society: Washington, DC, USA, 2024; Volume 2, pp. 1–30. [Google Scholar]

- Bolan, N.; Hoang, S.A.; Beiyuan, J.; Gupta, S.; Hou, D.; Karakoti, A.; Joseph, S.; Jung, S.; Kim, K.-H.; Kirkham, M.; et al. Multifunctional applications of biochar beyond carbon storage. Int. Mater. Rev. 2022, 67, 150–200. [Google Scholar] [CrossRef]

- Lu, Y.; Silveira, M.L.; O’Connor, G.A.; Vendramini, J.M.B.; Li, Y.C. Biochar type and application methods affected nitrogen and phosphorus leaching from a sandy soil amended with inorganic fertilizers and biosolids. Agrosyst. Geosci. Environ. 2022, 5, e20236. [Google Scholar] [CrossRef]

- Hou, R.; Wang, L.; O’Connor, D.; Rinklebe, J.; Hou, D. Natural field freezethaw process leads to different performances of soil amendments towards cd immobilization and enrichment. Sci. Total Environ. 2022, 831, 154880. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Liu, B.; Su, Z. A critical review on the application and recent developments of post-modified biochar in supercapacitors. J. Clean. Prod. 2021, 310, 127428. [Google Scholar] [CrossRef]

- Saletnik, B.; Zaguła, G.; Saletnik, A.; Bajcar, M.; Puchalski, C. Biochar and Ash Fertilization Alter the Chemical Properties of Basket Willow (Salix viminalis L.) and Giant Miscanthus (Miscanthus x giganteus). Agronomy 2020, 10, 660. [Google Scholar] [CrossRef]

- Kosov, V.F.; Lavrenov, V.A.; Zaichenko, V.M. Simulation of a process for the two-stage thermal conversion of biomass into the synthesis gas. J. Phys. Conf. Ser. 2015, 653, 012031. [Google Scholar] [CrossRef]

- Bartoli, M.; Troiano, M.; Giudicianni, P.; Amato, D.; Giorcelli, M.; Solimene, R.; Tagliaferro, A. Effect of heating rate and feedstock nature on electrical conductivity of biochar and biochar-based composites. Appl. Energy Combust. Sci. 2022, 12, 100089. [Google Scholar] [CrossRef]

- Muzyka, R.; Misztal, E.; Hrabak, J.; Banks, S.W.; Sajdak, M. Various biomass pyrolysis conditions influence the porosity and pore size distribution of biochar. Energy 2023, 263, 126128. [Google Scholar] [CrossRef]

- Sharma, A.K.; Ghodke, P.K.; Goyal, N.; Bobde, P.; Kwon, E.E.; Lin, K.Y.A.; Chen, W.H. A critical review on biochar production from pine wastes, upgradation techniques, environmental sustainability, and challenges. Bioresour. Technol. 2023, 387, 129632. [Google Scholar] [CrossRef]

- Leng, L.; Xiong, Q.; Yang, L.; Li, H.; Zhou, Y.; Zhang, W.; Jiang, S.; Li, H.; Huang, H. An overview on engineering the surface area and porosity of biochar. Sci. Total Environ. 2021, 763, 144204. [Google Scholar] [CrossRef]

- Mierzwa-Hersztek, M.; Gondek, K.; Jewiarz, M.; Dziedzic, K. Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. J. Mater. Cycles Waste Manag. 2019, 21, 786–800. [Google Scholar] [CrossRef]

- Diao, R.; Zhu, X.; Wang, C.; Zhu, X. Synergistic effect of physicochemical properties and reaction temperature on gasification reactivity of walnut shell chars. Energy Convers. Manag. 2020, 204, 112313. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A.J.B.R. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Bruun, E.W.; Ambus, P.; Egsgaard, H.; Hauggaard-Nielsen, H. Effects of slow and fast pyrolysis biochar on soil C and N turnover dynamics. Soil Biol. Biochem. 2012, 46, 73–79. [Google Scholar] [CrossRef]

- Verma, M.; Godbout, S.; Brar, S.K.; Solomatnikova, O.; Lemay, S.P.; Larouche, J.P. Biofuels Production from Biomass by Thermochemical Conversion Technologies. Int. J. Chem. Eng. 2012, 2012, 542426. [Google Scholar] [CrossRef]

- Fu, P.; Hu, S.; Xiang, J.; Sun, L.; Su, S.; Wang, J. Evaluation of the porous structure development of chars from pyrolysis of rice straw: Effects of pyrolysis temperature and heating rate. J. Anal. Appl. Pyrolysis 2012, 98, 177–183. [Google Scholar] [CrossRef]

- Mohanty, P.; Pant, K.K.; Naik, S.N.; Parikh, J.; Hornung, A.; Sahu, J.N. Synthesis of green fuels from biogenic waste through thermochemical route—The role of heterogeneous catalyst: A review. Renew. Sustain. Energy Rev. 2014, 38, 131–153. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Palai, A.K.; Kumar, A.; Bhatia, R.K.; Patel, A.K.; Thakur, V.K.; Yang, Y.H. Trends in renewable energy production employing biomass-based biochar. Bioresour. Technol. 2021, 340, 125644. [Google Scholar]

- Liu, R.; Liu, G.; Yousaf, B.; Abbas, Q. Operating conditions-induced changes in product yield and characteristics during thermal-conversion of peanut shell to biochar in relation to economic analysis. J. Clean. Prod. 2018, 193, 479–490. [Google Scholar] [CrossRef]

- He, M.; Xu, Z.; Hou, D.; Gao, B.; Cao, X.; Ok, Y.S.; Rinklebe, J.; Bolan, N.S.; Tsang, D.C.W. Waste-derived biochar for water pollution control and sustainable development. Nat. Rev. Earth Environ. 2022, 3, 444–460. [Google Scholar] [CrossRef]

- Supraja, K.V.; Kachroo, H.; Viswanathan, G.; Verma, V.K.; Behera, B.; Doddapaneni, T.R.K.C.; Kaushal, P.; Ahammad, S.Z.; Singh, V.; Awasthi, M.K.; et al. Biochar production and its environmental applications: Recent developments and machine learning insights. Bioresour. Technol. 2023, 387, 129634. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Z.F.; Zhang, C.C.; Nan, J.; Ren, N.Q.; Lee, D.J.; Chen, C. Advances in pretreatment of lignocellulosic biomass for bioenergy production: Challenges and perspectives. Bioresour. Technol. 2022, 343, 126123. [Google Scholar] [CrossRef]

- James, A.; Sánchez, A.; Prens, J.; Yuan, W. Biochar from agricultural residues for soil conditioning: Technological status and life cycle assessment. Curr. Opin. Environ. Sci. Health 2022, 25, 100314. [Google Scholar] [CrossRef]

- Patel, S.; Kundu, S.; Halder, P.; Ratnnayake, N.; Marzbali, M.H.; Aktar, S.; Selezneva, E.; Paz-Ferreiro, J.; Surapaneni, A.; de Figueiredo, C.C.; et al. A critical literature review on biosolids to biochar: An alternative biosolids management option. Rev. Environ. Sci. Bio/Technol. 2020, 19, 807–841. [Google Scholar] [CrossRef]

- Alvarez, J.; Amutio, M.; Lopez, G.; Barbarias, I.; Bilbao, J.; Olazar, M. Sewage sludge valorization by flash pyrolysis in a conical spouted bed reactor. Chem. Eng. J. 2015, 273, 173–183. [Google Scholar] [CrossRef]

- Makepa, D.C.; Chihobo, C.H.; Musademba, D. Advances in sustainable biofuel production from fast pyrolysis of lignocellulosic biomass. Biofuels 2023, 14, 529–550. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Radziemska, E.; Ryms, M.; Ostrowski, P. Modern methods of thermochemical biomass conversion into gas, liquid and solid fuels. Proc. ECOpole 2010, 4, 2. [Google Scholar]

- Malińska, K. Biochar-a response to current environmental issues. Eng. Prot. Environ. 2012, 15, 387–403. [Google Scholar]

- Patel, S.; Kundu, S.; Halder, P.; Marzbali, M.H.; Chiang, K.; Surapaneni, A.; Shah, K. Production of hydrogen by catalytic methane decomposition using biochar and activated char produced from biosolids pyrolysis. Int. J. Hydrogen Energy 2020, 45, 29978–29992. [Google Scholar] [CrossRef]

- Chi, N.T.L.; Anto, S.; Ahamed, T.S.; Kumar, S.S.; Shanmugam, S.; Samuel, M.S.; Mathimani, T.; Brindhadevi, K.; Pugazhendhi, A. A review on biochar production techniques and biochar based catalyst for biofuel production from algae. Fuel 2021, 287, 119411. [Google Scholar] [CrossRef]

- Akinfalabi, S.I.; Rashid, U.; Ngamcharussrivichai, C.; Nehdi, I.A. Synthesis of reusable biobased nano-catalyst from waste sugarcane bagasse for biodiesel production. Environ. Technol. Innov. 2020, 18, 100788. [Google Scholar] [CrossRef]

- Suthar, R.G.; Wang, C.; Nunes, M.C.N.; Chen, J.; Sargent, S.A.; Bucklin, R.A.; Gao, B. Bamboo Biochar Pyrolyzed at Low Temperature Improves Tomato Plant Growth and Fruit Quality. Agriculture 2018, 8, 153. [Google Scholar] [CrossRef]

- Farrokh, N.T.; Suopajärvi, H.; Mattila, O.; Umeki, K.; Phounglamcheik, A.; Romar, H.; Sulasalmi, P.; Fabritius, T. Slow pyrolysis of by-product lignin from wood-based ethanol production–A detailed analysis of the produced chars. Energy 2018, 164, 112–123. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, Z.; Yao, Y.; Wang, X.; Tian, S. Spectral characterization of the impact of modifiers and different prepare temperatures on snow lotus medicinal residue-biochar and dissolved organic matter. Sci. Rep. 2024, 14, 8493. [Google Scholar] [CrossRef] [PubMed]

- Frainetti, A.J.; Klinghoffer, N.B. Recent experimental advances on the utilization of biochar as a tar reforming catalyst: A review. Int. J. Hydrogen Energy 2023, 48, 8022–8044. [Google Scholar] [CrossRef]

- Schilling, C.; Mola-Yudego, B.; Marinescu, M.; Gaston, C.; Röser, D. Biomass Gasification as a Viable Alternative for Small-scaled Combined Heat and Power Technologies in Remote Communities in Canada. BioEnergy Res. 2025, 18, 19. [Google Scholar] [CrossRef]

- Prabakar, D.; Manimudi, V.T.; Sampath, S.; Mahapatra, D.M.; Rajendran, K.; Pugazhendhi, A. Advanced biohydrogen production using pretreated industrial waste: Outlook and prospects. Renew. Sustain. Energy Rev. 2018, 96, 306–324. [Google Scholar] [CrossRef]

- Peterson, S.C.; Jackson, M.A. Simplifying pyrolysis: Using gasification to produce corn stover and wheat straw biochar for sorptive and horticultural media. Ind. Crops Prod. 2014, 53, 228–235. [Google Scholar] [CrossRef]

- Yao, Z.; You, S.; Ge, T.; Wang, C.H. Biomass gasification for syngas and biochar co-production: Energy application and economic evaluation. Appl. Energy 2018, 209, 43–55. [Google Scholar] [CrossRef]

- James, R.A.M.; Yuan, W.; Wang, D.; Wang, D.; Kumar, A. The effect of gasification conditions on the surface properties of biochar produced in a top-lit updraft gasifier. Appl. Sci. 2022, 10, 688. [Google Scholar] [CrossRef]

- Ahmad, J.; Patuzzi, F.; Rashid, U.; Shahabz, M.; Ngamcharussrivichai, C.; Baratieri, M. Exploring untapped effect of process conditions on biochar characteristics and applications. Environ. Technol. Innov. 2021, 21, 101310. [Google Scholar] [CrossRef]

- Ganesapillai, M.; Mehta, R.; Tiwari, A.; Sinha, A.; Bakshi, H.S.; Chellappa, V.; Drewnowski, J. Waste to energy: A review of biochar production with emphasis on mathematical modelling and its applications. Heliyon 2023, 9, e14873. [Google Scholar] [CrossRef]

- Yu, K.L.; Lau, B.F.; Show, P.L.; Ong, H.C.; Ling, T.C.; Chen, W.H.; Ng, E.P.; Chang, J.S. Recent developments on algal biochar production and characterization. Bioresour. Technol. 2017, 246, 2–11. [Google Scholar] [CrossRef]

- Choo, M.Y.; Oi, L.E.; Ling, T.C.; Ng, E.P.; Lin, Y.C.; Centi, G.; Juan, J.C. Deoxygenation of triolein to green diesel in the H2-free condition: Effect of transition metal oxide supported on zeolite Y. J. Anal. Appl. Pyrolysis 2020, 147, 104797. [Google Scholar] [CrossRef]

- Chen, W.H.; Lin, B.J.; Lin, Y.Y.; Chu, Y.S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B.; et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Yek, P.N.Y.; Cheng, Y.W.; Liew, R.K.; Mahari, W.A.W.; Ong, H.C.; Chen, W.H.; Peng, W.; Park, Y.-K.; Sonne, C.; Kong, S.H.; et al. Progress in the torrefaction technology for upgrading oil palm wastes to energy-dense biochar: A review. Renew. Sustain. Energy Rev. 2021, 151, 111645. [Google Scholar] [CrossRef]

- Bach, Q.V.; Skreiberg, Ø. Upgrading biomass fuels via wet torrefaction: A review and comparison with dry torrefaction. Renew. Sustain. Energy Rev. 2016, 54, 665–677. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, Z.; Huang, M.; Peng, H.; Zhang, W.; Chen, D.; Ma, Z. Valorisation of cotton stalk toward bio-aromatics: Effect of wet torrefaction deoxygenation and deminerization pretreatment on catalytic fast pyrolysis using Ga modified hierarchical zeolite. Fuel 2022, 330, 125571. [Google Scholar] [CrossRef]

- Bajcar, M.; Zardzewiały, M.; Saletnik, B.; Zaguła, G.; Puchalski, C.; Gorzelany, J. Torrefaction as a Way to Remove Chlorine and Improve the Energy Properties of Plant Biomass. Energies 2023, 16, 7365. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Volpe, M.; Messineo, A. Hydrothermal carbonization as a valuable tool for energy and environmental applications: A review. Energies 2020, 13, 4098. [Google Scholar] [CrossRef]

- Sharma, H.B.; Sarmah, A.K.; Dubey, B. Hydrothermal carbonization of renewable waste biomass for solid biofuel production: A discussion on process mechanism, the influence of process parameters, environmental performance and fuel properties of hydrochar. Renew. Sustain. Energy Rev. 2020, 123, 109761. [Google Scholar] [CrossRef]

- Ahmed, I.; Zia, M.A.; Afzal, H.; Ahmed, S.; Ahmad, M.; Akram, Z.; Sher, F.; Iqbal, H.M.N. Socio-economic and environmental impacts of biomass valorisation: A strategic drive for sustainable bioeconomy. Sustainability 2021, 13, 4200. [Google Scholar] [CrossRef]

- Wang, X.; Yun, S.; Fang, W.; Zhang, C.; Liang, X.; Lei, Z.; Liu, Z. Layer-stacking activated carbon derived from sunflower stalk as electrode materials for high-performance supercapacitors. ACS Sustain. Chem. Eng. 2018, 6, 11397–11407. [Google Scholar] [CrossRef]

- Oumabady, S.; Selvaraj, P.S.; Kamaludeen, S.P.; Ettiyagounder, P.; Suganya, K. Application of sludge-derived KOH-activated hydrochar in the adsorptive removal of orthophosphate. RSC Adv. 2021, 11, 6535–6543. [Google Scholar] [CrossRef] [PubMed]

- Verde, S.F.; Chiaramonti, D. The Biochar System in the EU: The Pieces Are Falling into Place, but Key Policy Questions Remain; Policy Briefs, Florence School of Regulation; European University Institute: Florence, Italy, 2021. [Google Scholar]

- European Commission. The European Green Deal. In Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2019) 640 final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Parliament and Council. Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 Laying Down Rules on the Making Available on the Market of EU Ferti Lising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2. Available online: https://eur-lex.europa.eu/eli/reg/2019/1009/oj/eng (accessed on 17 December 2024).

- European Commission. A new Circular Economy Action Plan—For a cleaner and more competitive Europe. In Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2020) 98 final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. A Farm to Fork Strategy for a fair, healthy and environmentally friendly food system. In Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2020) 381 final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Stepping up Europe’s 2030 climate ambition—Investing in a climate-neu tral future for the benefit of our people. In Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2020) 562 final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Parliament and Council. Regula tion (EU) 2018/841 of the European Parliament and of the Council of 30 May 2018 on the inclu sion of GHG emissions and removals from Land Use; In Land Use Change and Forestry into the 2030 Climate and Energy Framework and amending Regulation (EU) No. 525/2013 and Decision No. 529/2013/EU; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Parliament and Council. Regula tion (EU) 2018/842 of the European Parliament and of the Council of 30 May 2018 on Binding Annual Greenhouse Gas Emission Reductions by Member States from 2021 to 2030 Contributing to Climate Action to Meet Commitments under the Paris Agreement and Amending Regulation (EU) No 525/2013; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Bloomberg Cities Initiative: Biochar Projects in Urban Areas. Environmental Sustainability in Urban Development; Bloomberg Philanthropies: New York, NY, USA, 2021; Available online: https://apnews.com/article/1aa6324cecbff25b0fd15eeec12c8a7f (accessed on 25 April 2025).

- Biochar Policy Project: Advancing Biochar in U.S. Agriculture. NCAT Policy Report. NCAT. 2020. Available online: https://www.ncat.org/biochar-policy-project/?utm_source=chatgpt.com (accessed on 25 April 2025).

- Great Plains Biochar Initiative: Workshops and Grants for Biochar Development. Great Plains Biochar Conference; University of Nebraska-Lincoln: Lincoln, Nebraska, 2022; Available online: https://agronomy.unl.edu/great-plains-biochar-conference/?utm_source=chatgpt.com (accessed on 25 April 2025).

- CARBONITY Biochar Plant Development: A Step Toward Carbon Neutrality. Canadian Government Report, Economic Development Canada. 2023. Available online: https://www.canada.ca/en/economic-development-quebec-regions/news/2023/07/largest-biochar-production-plant-in-north-america-contributes-to-canadian-netzero-goals.html (accessed on 25 April 2025).

- Biochar Policy Development: Case Study in Vietnam. UNIDO Policy Brief, UNIDO. 2021. Available online: https://biocharvietnam.org/portfolio/unido-projects/?utm_source=chatgpt.com (accessed on 25 April 2025).

- BIO4Africa: Advancing Biochar Technologies in African Agriculture. African Agricultural Sustainability Report, BIO4Africa. 2020. Available online: https://www.bio4africa.eu/?utm_source=chatgpt.com (accessed on 25 April 2025).

- Biochar Plus Project: ECREEE’s Technical Assistance was requested for the Elaboration of an Action Plan Framework on the Biochar System for the Biochar Plus Project. Available online: https://www.ecreee.org/ecreees-technical-assistance-was-requested-for-the-elaboration-of-an-action-plan-framework-on-the-biochar-system-for-the-biochar-plus-project/ (accessed on 25 April 2025).

- Biochar for Sustainable Soils (B4SS): Project in Peru. ECHO Community Technical Report, ECHO Community. 2021. Available online: https://www.echocommunity.org/en/resources/ebbd436d-d4b3-49cf-9b37-b558d4a14318?utm_source=chatgpt.com (accessed on 25 April 2025).

- Fragkos, P. Global energy system transformations to 1.5 °C: The impact of revised Intergovern mental Panel on Climate Change carbon budgets. Energy Technol. 2020, 8, 2000395. [Google Scholar] [CrossRef]

- Minx, J.C.; Lamb, W.F.; Callaghan, M.W.; Fuss, S.; Hilaire, J.; Creutzig, F.; Amann, T.; Beringer, T.; Garcia, W.d.O.; Hartmann, J.; et al. Negative emissions—Part 1: Research landscape and synthesis. Environ. Res. Lett. 2018, 13, 63001. [Google Scholar] [CrossRef]

- Morgan, H.; Sohi, S.; Shackley, S. Biochar: An Emerging carbon abatement and soil management strategy. In Oxford Research Encyclopedia of Environmental Science; Oxford University Press: Oxford, UK, 2020. [Google Scholar]

- IPCC. Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Shukla, P.R., Skea, J., Buendia, E.C., Masson-Delmotte, Pörtner, H.-O., Roberts, D.C., Zhai, P., Slade, R., Connors, S., van Diemen, R., et al., Eds.; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- IPCC. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Delmotte, V.M., Zhai, P., Pörtner, H.O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Bruun, E.; Cross, A.; Hammond, J.; Nelissen, V.; Rasse, D.P.; Houggaard-Nielsen, H. Biochar Carbon Stability and Effect on Greenhouse Gas Emissions. In Biochar in European Soils and Agriculture—Science and Practice; Shackley, S., Ruysschaert, G., Zwart, K., Glaser, B., Eds.; Routledge: Oxfordshire, UK, 2016. [Google Scholar]

- Bossio, D.A.; Cook-Patton, S.C.; Ellis, P.W.; Fargione, J.; Sanderman, J.; Smith, P.; Wood, S.; Zomer, R.J.; von Unger, M.; Emmer, I.M.; et al. The role of soil carbon in natural climate solutions. Nat. Sustain. 2020, 3, 391–398. [Google Scholar] [CrossRef]

- Smith, P.; Davis, S.; Creutzig, F.; Fuss, S.; Minx, J.; Benoit, G.; Kato, E.; Jackson, R.B.; Cowie, A.; Kriegler, E.; et al. Biophysical and economic limits to negative CO2 emissions. Nat. Clim. Change 2016, 6, 42–50. [Google Scholar] [CrossRef]

- Olivier, J.G.J.; Peters, J.A.H.W. Trends in global CO2 and total greenhouse gas emissions: 2020 report. PBL Neth. Environ. Assess. Agency 2020, 5, 1–11. [Google Scholar]

- Lima, M.D.R.; Patrício, E.P.S.; Junior, U.D.O.B.; de Assis, M.R.; Xavier, C.N.; Bufalino, L.; Trugilho, P.F.; Hein, P.R.G.; Protásio, T.d.P. Logging wastes from sustainable forest management as alternative fuels for thermochemical conversion systems in Brazilian Amazon. Biomass Bioenergy 2020, 140, 105660. [Google Scholar]

- Chen, L.; Zhang, Y.; Wang, L.; Ruan, S.; Chen, J.; Li, H.; Yang, J.; Mechtcherine, V.; Tsang, D.C. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2022, 431, 133946. [Google Scholar] [CrossRef]

- Neogi, S.; Sharma, V.; Khan, N.; Chaurasia, D.; Ahmad, A.; Chauhan, S.; Singh, A.; You, S.; Pandey, A.; Bhargava, P.C. Sustainable biochar: A facile strategy for soil and environmental restoration, energy generation, mitigation of global climate change and circular bioeconomy. Chemosphere 2022, 293, 133474. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in climate change mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Smith, P.; Adams, J.; Beerling, D.J.; Beringer, T.; Calvin, K.V.; Fuss, S.; Griscom, B.; Hagemann, N.; Kammann, C.; Kraxner, F.; et al. Land-management options for greenhouse gas removal and their impacts on ecosystem services and the Sustainable Development Goals. Annu. Rev. Environ. Resour. 2019, 44, 255–286. [Google Scholar] [CrossRef]

- Jeffery, S.; Verheijen, F.G.A.; van der Velde, M.; Bastos, A.C. A quantitative review of the effects of biochar application to soils on crop pro ductivity using meta-analysis, Agriculture. Eco Syst. Environ. 2011, 144, 175–187. [Google Scholar]

- O’Toole, A.; Andersson, D.; Gerlach, A.; Glaser, B.; Kammann, C.; Kern, J.; Kuoppamäki, K.; Mumme, J.; Schmidt, H.-P.; Schulze, M. Current and Future Applications for Biochar; Routledge: New York, NY, USA, 2016. [Google Scholar]

- Dal Ferro, N.; Piccoli, I.; Berti, A.; Polese, R.; Morari, F. Organic carbon storage potential in deep agricultural soil layers: Evidence from long-term experiments in northeast Italy. Agric. Ecosyst. Environ. 2020, 300, 106967. [Google Scholar] [CrossRef]

- Geden, O.; Schenuit, F. Unconventional mitigation: Carbon dioxide removal as a new approach in EU climate policy. In SWP Research Papers 8/2020, Stiftung Wissenschaft und Politik (SWP); German Institute for International and Security Affairs: Berlin, Germany, 2020. [Google Scholar]

- Wang, L.; Deng, J.; Yang, X.; Hou, R.; Hou, D. Role of biochar toward carbon neutrality. Carbon Res. 2023, 2, 2. [Google Scholar] [CrossRef]

- EBI (European Biochar Industry) European Biochar Market Report 2023/2024. Available online: https://old.biochar-industry.com/2024/european-biochar-market-report-2023-2024-available-now/ (accessed on 12 February 2025).

- Do, Q.C.; Tran, T.N.; Tran, T.H.; La, D.D.; Ngo, H.H.; Thanh, B.X.; Chang, S.W.; Nguyen, D.D. Sustainable production and application of biochar for energy storage and conversion. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2023; pp. 333–364. [Google Scholar]

- Jiang, J.; Zhang, L.; Wang, X.; Holm, N.; Rajagopalan, K.; Chen, F.; Ma, S. Highly ordered macroporous woody biochar with ultra-high carbon content as supercapacitor electrodes. Electrochim. Acta. 2013, 113, 481–489. [Google Scholar] [CrossRef]

- Zhang, M.; Shu, L.; Shen, X.; Guo, X.; Tao, S.; Xing, B.; Wang, X. Characterization of nitrogen-rich biomaterial-derived biochars and their sorption for aromatic compounds. Environ. Pollut. 2014, 195, 84–90. [Google Scholar] [CrossRef]

- Plaza, M.G.; González, A.S.; Pis, J.J.; Rubiera, F.; Pevida, C. Production of microporous biochars by single-step oxidation: Effect of activation conditions on CO2 capture. Appl. Energy 2014, 114, 551–562. [Google Scholar] [CrossRef]

- Nasri, N.S.; Hamza, U.D.; Ismail, S.N.; Ahmed, M.M.; Mohsin, R. Assessment of porous carbons derived from sustainable palm solid waste for carbon dioxide capture. J. Clean. Prod. 2014, 71, 148–157. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, F.; Kang, W.; Shen, Q. Encapsulating selenium into macro-/micro-porous biochar-based framework for high-performance lithium-selenium batteries. Carbon 2015, 95, 354–363. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Yang, H.; Shao, J.; Chen, Y.; Feng, Y.; Wang, X.; Chen, H. Effects of hydrofluoric acid pre-deashing of rice husk on physicochemical properties and CO2 adsorption performance of nitrogen-enriched biochar. Energy 2015, 91, 903–910. [Google Scholar] [CrossRef]

- Nguyen, M.V.; Lee, B.K. A novel removal of CO2 using nitrogen doped biochar beads as a green adsorbent. Process Saf. Environ. Prot. 2016, 104, 490–498. [Google Scholar] [CrossRef]

- Dehkhoda, A.M.; Gyenge, E.; Ellis, N. A novel method to tailor the porous structure of KOH-activated biochar and its application in capacitive deionization and energy storage. Biomass Bioenergy 2016, 87, 107–121. [Google Scholar] [CrossRef]

- Chen, H.; Awasthi, S.K.; Liu, T.; Duan, Y.; Ren, X.; Zhang, Z.; Pandey, A.; Awasthi, M.K. Effects of microbial culture and chicken manure biochar on compost maturity and greenhouse gas emissions during chicken manure composting. J. Hazard. Mater. 2020, 389, 121908. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Duan, Y.; Awasthi, S.K.; Liu, T.; Zhang, Z. Influence of bamboo biochar on mitigating greenhouse gas emissions and nitrogen loss during poultry manure composting. Bioresour. Technol. 2020, 303, 122952. [Google Scholar] [CrossRef]

- Trinh, T.K.; Nguyen, T.T.; Nguyen, T.N.; Wu, T.Y.; Meharg, A.A.; Nguyen, M.N. Characterization and dissolution properties of phytolith occluded phosphorus in rice straw. Soil Tillage Res. 2017, 171, 19–24. [Google Scholar] [CrossRef]

- He, T.; Yuan, J.; Luo, J.; Lindsey, S.; Xiang, J.; Lin, Y.; Liu, D.; Chen, Z.; Ding, W. Combined application of biochar with urease and nitrification inhibitors have synergistic effects on mitigating CH4 emissions in rice field: A three-year study. Sci. Total Environ. 2020, 743, 140500. [Google Scholar] [CrossRef]

- Case, S.D.; McNamara, N.P.; Reay, D.S.; Stott, A.W.; Grant, H.K.; Whitaker, J. Biochar suppresses N2O emissions while maintaining N availability in a sandy loam soil. Soil Biol. Biochem. 2015, 81, 178–185. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Dixit, A.; Gupta, S.; Dai Pang, S.; Kua, H.W. (Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Sirico, A.; Belletti, B.; Bernardi, P.; Malcevschi, A.; Pagliari, F.; Fornoni, P.; Moretti, E. Effects of biochar addition on long-term behavior of concrete. Theor. Appl. Fract. Mech. 2022, 122, 103626. [Google Scholar] [CrossRef]

- Tan, K.; Pang, X.; Qin, Y.; Wang, J. Properties of cement mortar containing pulverized biochar pyrolyzed at different temperatures. Constr. Build. Mater. 2020, 263, 120616. [Google Scholar] [CrossRef]

- Chen, L.; Wang, L.; Zhang, Y.; Ruan, S.; Mechtcherine, V.; Tsang, D.C. Roles of biochar in cement-based stabilization/solidification of municipal solid waste incineration fly ash. Chem. Eng. J. 2022, 430, 132972. [Google Scholar] [CrossRef]

- Han, Y.; Xu, Y.; Shi, S.Q.; Li, J.; Fang, Z. Cuttlebone-inspired magnesium oxychloride cement reinforced by biochar as green adhesive for wood industry. J. Clean. Prod. 2022, 370, 133365. [Google Scholar] [CrossRef]

- Gomes, S.D.C.; Zhou, J.L.; Zeng, X.; Long, G. Water treatment sludge conversion to biochar as cementitious material in cement composite. J. Environ. Manag. 2022, 306, 114463. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Duan, H. Improvement effect of pyrolyzed agro-food biochar on the properties of magnesium phosphate cement. Sci. Total Environ. 2020, 718, 137422. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Ryu, C.; Gang, K.S.; Yang, W.; Park, Y.K.; Jung, J.; Hyun, S. Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500 °C. Bioresour. Technol. 2013, 148, 196–201. [Google Scholar] [CrossRef]

- Wang, S.S.; Gao, B.; Zimmerman, A.R.; Li, Y.C.; Ma, L.N.; Harris, W.G.; Migliaccio, K.W. Physicochemical and sorptive properties of biochars derived from woody and herbaceous biomass. Chemosphere 2015, 134, 257–262. [Google Scholar] [CrossRef]

- Mohan, D.; Rajput, S.; Singh, V.K.; Steele, P.H.; Pittman, C.U. Modelling and evaluation of chromium remediation from water using low cost bio-char, a green adsorbent. J. Hazard. Mater. 2011, 188, 319–333. [Google Scholar] [CrossRef]

- Palsan, S.A.; Lim, J.Y.; Nor Asfaliza, A. Synthesis and Characterization of Active Biocarbon Material for Use in Cosmetics and Personal Care Products. Key Eng. Mater. 2020, 841, 266–272. [Google Scholar]

- Jingjian, P.; Jun, J.; Renkou, X. Adsorption of Cr(III) from acidic solutions by crop straw derived biochars. J. Environ. Sci. China 2013, 25, 1957–1965. [Google Scholar]

- Mohammed, N.A.S.; Abu-Zurayk, R.A.; Hamadneh, I.; Al-Dujaili, A.H. Phenol adsorption on biochar prepared from the pine fruit shells: Equilibrium, kinetic and thermodynamics studies. J. Environ. Manag. 2018, 226, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Thang, P.Q.; Jitae, K.; Giang, N.M.V.B.L.; Huong, P.T. Potential application of chicken manure biochar towards toxic phenol and 2, 4-dinitrophenol in wastewaters. J. Environ. Manag. 2019, 251, 109556. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Dai, Y.; Zhang, M.; Feng, C.; Qin, B.; Zhang, W.; Zhao, N.; Li, Y.; Ni, Z.; Xu, Z.; et al. Mechanisms of Pb and/or Zn adsorption by different biochars: Biochar characteristics, stability, and binding energies. Sci. Total Environ. 2020, 717, 136894. [Google Scholar] [CrossRef] [PubMed]

- IRENA International Renewable Energy Agency Renewable Energy Highlights; July 2024. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2022/Jul/IRENA_Renewable_energy_highlights_July_2022.pdf (accessed on 16 March 2025).

- Davenport, J.; Wayth, N. Statistical Review of World Energy; Energy Institute: London, UK, 2023. [Google Scholar]

- Do, M.H.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Sharma, P.; Pandey, A.; Bui, X.T.; Zhang, X. Performance of a dual-chamber microbial fuel cell as biosensor for on-line measuring ammonium nitrogen in synthetic municipal wastewater. Sci. Total Environ. 2021, 795, 148755. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, D.S.; Yang, J.H.; Chun, Y.; Yoo, H.Y.; Han, S.O.; Lee, J.; Park, C.; Kim, S.W. Enhanced electron transfer mediator based on biochar from microalgal sludge for application to bioelectrochemical systems. Bioresour. Technol. 2018, 264, 387–390. [Google Scholar] [CrossRef]

- Gebreslassie, T.R.; Nguyen, P.K.T.; Yoon, H.H.; Kim, J. Co-production of hydrogen and electricity from macroalgae by simultaneous dark fermentation and microbial fuel cell. Bioresour. Technol. 2021, 336, 125269. [Google Scholar] [CrossRef]

- Chakraborty, I.; Sathe, S.M.; Dubey, B.K.; Ghangrekar, M.M. Waste-derived biochar: Applications and future perspective in microbial fuel cells. Bioresour. Technol. 2020, 312, 123587. [Google Scholar] [CrossRef]

- Hemalatha, M.; Sravan, J.S.; Min, B.; Mohan, S.V. Concomitant use of Azolla derived bioelectrode as anode and hydrolysate as substrate for microbial fuel cell and electro-fermentation applications. Sci. Total Environ. 2020, 707, 135851. [Google Scholar] [CrossRef]

- Cao, C.; Wei, L.; Su, M.; Wang, G.; Shen, J. Low-cost adsorbent derived and in situ nitrogen/iron co-doped carbon as efficient oxygen reduction catalyst in microbial fuel cells. Bioresour. Technol. 2016, 214, 348–354. [Google Scholar] [CrossRef]

- PYREG GmbH. PYREG Carbonization–Our Technology Our Solutions. Available online: https://www.pyreg.com/our-technology/ (accessed on 25 April 2025).

- Nettenergy, B.V. Mobile Flash Pyrolysis Technology. Available online: https://www.nettenergy.com (accessed on 25 April 2025).

- Meyer, S.; Glaser, B.; Quicker, P. Technical, economical, and climate-related aspects of biochar production technologies: A literature review. Environ. Sci. Technol. 2011, 45, 9473–9483. [Google Scholar] [CrossRef]

- Lu, H.R.; El Hanandeh, A. Life cycle perspective of bio-oil and biochar production from hardwood biomass; what is the optimum mix and what to do with it? J. Clean. Prod. 2019, 212, 173–189. [Google Scholar] [CrossRef]

- Sekar, M.; Mathimani, T.; Alagumalai, A.; Chi, N.T.L.; Duc, P.A.; Bhatia, S.K.; Brindhadevi, K.; Pugazhendhi, A. A review on the pyrolysis of algal biomass for biochar and bio-oil-bottlenecks and scope. Fuel 2021, 283, 119190. [Google Scholar] [CrossRef]

- Gupta, S.; Mondal, P.; Borugadda, V.B.; Dalai, A.K. Advances in upgradation of pyrolysis bio-oil and biochar towards improvement in biorefinery economics: A comprehensive review. Environ. Technol. Innov. 2021, 21, 101276. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Anyalewechi, C.L.; Okieimen, C.O.; Kusuma, H.S. Biomass pyrolysis technologies for value-added products: A state-of-the-artreview. Environ. Dev. Sustain. 2021, 23, 14324–14378. [Google Scholar] [CrossRef]

- Roy, P.; Dias, G. Prospects for pyrolysis technologies in the bioenergy sector: A review. Renew. Sustain. Energy Rev. 2017, 77, 59–69. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, S.W.; Tsang, Y.F.; Kim, Y.T.; Lee, J. Engineered rice-straw biochar catalysts for the production of value-added chemicals from furan. Chem. Eng. J. 2020, 387, 124194. [Google Scholar] [CrossRef]

- Hazmi, B.; Rashid, U.; Ibrahim, M.L.; Nehdi, I.A.; Azam, M.; Al-Resayes, S.I. Synthesis and characterization of bifunctional magnetic nano-catalyst from rice husk for production of biodiesel. Environ. Technol. Innov. 2021, 21, 101296. [Google Scholar] [CrossRef]

- Wang, Y.; Chang, H.; Ma, T.; Deng, H.; Zha, Z. Effect of cotton stalk particle size on the structure of biochar and the performance of anode for lithium-ion battery. J. Phys. Chem. Solid 2022, 169, 110845. [Google Scholar] [CrossRef]

- Nie, S.; Li, R.; Xin, Y.; Tan, Y.; Miao, C.; Xiang, Y.; Xiao, W. Enhanced cycling performance of Sn nanoparticles embedded into the pyrolytic biochar from tea-seed shells as composite anode materials for lithium ions batteries. Solid State Ion. 2021, 368, 115703. [Google Scholar] [CrossRef]

- Lei, W.; Wang, X.; Zhang, Y.; Luo, Z.; Xia, P.; Zou, Y.; Ma, Z.; Pan, Y.; Lin, S. Facile synthesis of Fe3C nano-particles/porous biochar cathode materials for lithium sulfur battery. J. Alloys Compd. 2021, 853, 157024. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhang, C.; Kong, F.; Zhao, Q.; Kong, A.; Shan, Y. Activated biochar derived from peanut shells as the electrode materials with excellent performance in Zinc-air battery and supercapacitance. Waste Manag. 2021, 125, 257–267. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Canche, N.G.; Carrillo, J.G.; Escobar-Morales, B.; Salgado-Tránsito, I.; Pacheco, N.; Pech-Cohuo, S.C.; Peña-Cruz, M.I. Physicochemical and optical characterization of citrus aurantium derived biochar for solar absorber applications. Materials 2021, 14, 4756. [Google Scholar] [CrossRef] [PubMed]

- Tiihonen, A.; Siipola, V.; Lahtinen, K.; Pajari, H.; Widsten, P.; Tamminen, T.; Kallio, T.; Miettunen, K. Biocarbon from brewery residues as a counter electrode catalyst in dye solar cells. Electrochim. Acta 2021, 368, 137583. [Google Scholar] [CrossRef]

- Rawat, S.; Mishra, R.K.; Bhaskar, T. Biomass derived functional carbon materials for supercapacitor applications. Chemosphere 2022, 286, 131961. [Google Scholar] [CrossRef] [PubMed]

- Nirmaladevi, S.; Boopathiraja, R.; Kandasamy, S.K.; Sathishkumar, S.; Parthibavarman, M. Wood based biochar supported MnO2 nanorods for high energy asymmetric supercapacitor applications. Surf. Interfaces 2021, 27, 101548. [Google Scholar] [CrossRef]

- Kwarciany, R.; Fiedur, M.; Saletnik, B. Opportunities and Threats for Supercapacitor Technology Based on Biochar—A Review. Energies 2024, 17, 4617. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.; Guo, B.; Yang, J.; Shen, Z.; Hou, D.; Ok, Y.S.; Poon, C.S. Biochar as green additives in cement-based composites with carbon dioxide curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Praneeth, S.; Guo, R.; Wang, T.; Dubey, B.; Sarmah, A.K. Accelerated carbonation of biochar reinforced cement-fly ash composites: Enhancing and sequestering CO2 in building materials. Constr. Build. Mater. 2020, 244, 118363. [Google Scholar] [CrossRef]

- Danish, A.; Ali Mosaberpanah, M.; Usama Salim, M.; Ahmad, N.; Ahmad, F.; Ahmad, A. Reusing biochar as a filler or cement replacement material in cementitious composites: A review. Constr. Build. Mater. 2001, 300, 124295. [Google Scholar] [CrossRef]

- Reis, D.C.; Abrao, P.C.R.A.; Sui, T.; John, V.M. Influence of cement strength class on environmental impact of concreto. Resour. Conserv. Recycl. 2020, 163, 105075. [Google Scholar] [CrossRef]

- Praneeth, S.; Saavedra, L.; Zeng, M.; Dubey, B.K.; Sarmah, A.K. Biochar admixtured lightweight, porous and tougher cement mortars: Mechanical, durability and micro computed tomography analysis. Sci. Total Environ. 2021, 750, 142327. [Google Scholar] [CrossRef] [PubMed]

- Dixit, A.; Verma, A.; Pang, S.D. Dual waste utilization in ultra-high performance concrete using biochar and marine clay. Cem. Concr. Compos. 2021, 120, 104049. [Google Scholar] [CrossRef]

- Maljaee, H.; Madadi, R.; Paiva, H.; Tarelho, L.; Ferreira, V.M. Incorporation of biochar in cementitious materials: A roadmap of biochar selection. Constr. Build. Mater. 2021, 283, 122757. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Du, X.; Zhang, Y.; Pan, X.; Meng, F.; You, J.; Wang, Z. Preparation and properties of modified porous starch/carbon black/natural rubber composites. Compos. Part B Eng. 2019, 156, 1–7. [Google Scholar] [CrossRef]

- Jong, L.; Peterson, S.C.; Jackson, M.A. Utilization of porous carbons derived from coconut shell and wood in natural rubber. J. Polym. Environ. 2014, 22, 289–297. [Google Scholar] [CrossRef]

- Cui, P.; Schito, G.; Cui, Q. VOC emissions from asphalt pavement and health risks to construction workers. J. Clean. Prod. 2020, 244, 118757. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, Y.U.; Jeon, J.; Yun, B.Y.; Kang, Y.; Kim, S. Analysis of biochar-mortar composite as a humidity control material to improve the building energy and hygrothermal performance. Sci. Total Environ. 2021, 775, 145552. [Google Scholar] [CrossRef]

- Tan, K.; Qin, Y.; Du, T.; Li, L.; Zhang, L.; Wang, J. Biochar from waste biomass as hygroscopic filler for pervious concrete to improve evaporative cooling performance. Constr. Build. Mater. 2021, 287, 123078. [Google Scholar] [CrossRef]

- Rodier, L.; Bilba, K.; Onesippe, C.; Arsene, M.A. Utilization of bio-chars from sugarcane bagasse pyrolysis in cement-based composites. Ind. Crops Prod. 2019, 141, 111731. [Google Scholar] [CrossRef]

- Lee, H.; Yang, S.; Wi, S.; Kim, S. Thermal transfer behavior of biochar-natural inorganic clay composite for building envelope insulation. Constr. Build. Mater. 2019, 223, 668–678. [Google Scholar] [CrossRef]

- Zhang, X.; Duan, P.; Wu, Z.; Xiong, Z. Aged biochar stimulated ammonia oxidizing archaea and bacteria-derived N2O and NO production in an acidic vegetable soil. Sci. Total Environ. 2019, 687, 433–440. [Google Scholar] [CrossRef] [PubMed]

- Nematian, M.; Keske, C.; Ng’ombe, J.N. A Techno-Economic Analysis of Biochar Production and the Bioeconomy for Orchard Biomass. Waste Manag. 2021, 135, 467–477. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, J.; Nascimento, L.; Soares, M.; Valério, N.; Ribeiro, A.; Faria, L.; Silva, A.; Pacheco, N.; Araújo, J.; Vilarinho, C. Life Cycle Assessment (LCA) of Biochar Production from a Circular Economy Perspective. Processes 2022, 10, 2684. [Google Scholar] [CrossRef]

- Matuštík, J.; Hnátková, T.; Kočí, V. Life cycle assessment of biochar-to-soil systems: A review. J. Clean. Prod. 2020, 259, 120998. [Google Scholar] [CrossRef]

- Zhu, X.; Labianca, C.; He, M.; Luo, Z.; Wu, C.; You, S.; Tsang, D.C.W. Life-cycle assessment of pyrolysis processes for sustainable production of biochar from agro-residues. Bioresour. Technol. 2022, 360, 127601. [Google Scholar] [CrossRef] [PubMed]

- Miller-Robbie, L.; Ulrich, B.A.; Ramey, D.F.; Spencer, K.S.; Herzog, S.P.; Cath, T.Y.; Higgins, C.P. Life cycle energy and greenhouse gas assessment of the co-production of biosolids and biochar for land application. J. Clean. Prod. 2015, 91, 118–127. [Google Scholar] [CrossRef]

- Tiegam, R.F.T.; Tchuifon Tchuifon, D.R.; Santagata, R.; Kouteu Nanssou, P.A.; Anagho, S.G.; Ionel, I.; Ulgiati, S. Production of activated carbon from cocoa pods: Investigating benefits and environmental impacts through analytical chemistry techniques and life cycle assessment. J. Clean. Prod. 2021, 288, 125464. [Google Scholar] [CrossRef]

- Yang, X.; Han, D.; Zhao, Y.; Li, R.; Wu, Y. Environmental evaluation of a distributed-centralized biomass pyrolysis system: A case study in Shandong, China. Sci. Total. Environ. 2020, 716, 136915. [Google Scholar] [CrossRef]

- Ayaz, M.; Feizienė, D.; Tilvikienė, V.; Akhtar, K.; Stulpinaitė, U.; Iqbal, R. Biochar Role in the Sustainability of Agriculture and Environment. Sustainability 2021, 13, 1330. [Google Scholar] [CrossRef]

- Latawiec, A.E.; Koryś, A.; Koryś, K.A.; Kuboń, M.; Sadowska, U.; Gliniak, M.; Sikora, J.; Drosik, A.; Niemiec, M.; Klimek-Kopyra, A.; et al. Economic Analysis of Biochar Use in Soybean Production in Poland. Agronomy 2021, 11, 2108. [Google Scholar] [CrossRef]

- Aguirre, J.L.; Martín, M.T.; González, S.; Peinado, M. Effects and Economic Sustainability of Biochar Application on Corn Production in a Mediterranean Climate. Molecules 2021, 26, 3313. [Google Scholar] [CrossRef] [PubMed]

- Aguirre, J.L.; González-Egido, S.; González-Lucas, M.; González-Pernas, F.M. Medium-Term Effects and Economic Analysis of Biochar Application in Three Mediterranean Crops. Energies 2023, 16, 4131. [Google Scholar] [CrossRef]

| Continent | Program/Initiative | Description | References |

|---|---|---|---|

| North America | Bloomberg Cities Idea Exchange (USA) | Initiative supporting cities in solving issues like climate change, including the biochar project in Lincoln, Nebraska. | [108] |

| North America | Biochar Policy Project (USA) | Project advancing the biochar industry in the USA, supporting farmers and removing investment barriers. | [109] |

| North America | Great Plains Biochar Initiative (USA) | Initiative supporting the biochar market in the USA, offering workshops and grants. | [110] |

| North America | CARBONITY Biochar Plant (Canada) | The largest biochar facility in North America, supported by the Canadian government. | [111] |

| Asia | Biochar Policy Project (Vietnam) | UNIDO project developing policy and action plans for biochar in Vietnam. | [112] |

| Africa | BIO4Africa | Project supporting agriculture in Africa using biochar technology. | [113] |

| Africa | Biochar Plus Project | EU project advancing biochar technology in Africa, the Caribbean, and the Pacific. | [114] |

| South America | Biochar for Sustainable Soils (B4SS) (Peru) | Project developing biochar from green waste in Lima, Peru, reducing emissions. | [115] |

| Biomass Feedstock | Pyrolysis Temperature (°C) | Applications | Ref. |

|---|---|---|---|

| Red cedar wood | 750 | Energy storage | [137] |

| Cotton stalk | 600 | CO2 capture | [138] |

| Almond shells and olive stones | 400–650 | CO2 capture | [139] |

| Palm kernel shell | 700 | CO2 capture | [140] |

| Pomelo pericarp inner spongy layer | 400 | Energy | [141] |

| Rice husk | 600 | CO2 capture | [142] |

| Chicken manure | 450 | CO2 capture | [143] |

| Spruce whitewood | 600 | Energy storage | [144] |

| Chicken manure | Mitigation of greenhouse gas emissions reduced N2O, CH4, and NH3 production | [145] | |

| Bamboo | Mitigation of greenhouse gas emissions reduced NH3 | [146] | |

| Rice straw | CH4 and N2O | [147] | |

| Wheat straw | CH4 | [148] | |

| Hardwood tree | N2O | [149] | |

| Wood | 300 | Development of construction materials | [150] |

| 400 | [151] | ||

| 500 | [152] | ||

| 700 | [153,154] | ||

| Maize straw | 400 | Development of construction materials | [155] |

| Sewage sludge | 700 | Development of construction materials | [156] |

| Wheat straw | 650 | Development of construction materials | [157] |

| Basket willow | 500 | Soil fertilizer | [50] |

| Giant miscanthus | 500 | Soil fertilizer | [50] |

| Wood bark | 500 | Soil fertilizer | [158] |

| Pinewood | 500–600 | Soil fertilizer | [159] |

| Oak wood | 400–500 | Soil fertilizer | [160] |

| Coconut shell | 800 | Cosmetics and personal care products | [161] |

| Canda straw Rice straw Soybean straw Peanut straw | 400 | Wastewater treatment | [162] |

| Pine fruit shells | 900–600 | Wastewater treatment | [163] |

| chicken manure | 200–600 | Wastewater treatment | [164] |

| Rice straw Chicken manure Sewage sludge | 550 | Wastewater treatment | [165] |

| Application/Device | Biochar Function | Modification | Performance/Parameters | Ref. |

|---|---|---|---|---|

| Lithium-ion battery | Anode | Pure biochar | Enhanced Li+ transfer | [184] |

| Biochar with Ni and Sn | Higher reusability and discharge capacity | [185] | ||

| Cathode | Fe3C–biochar composite | 555 mAh/g after 250 cycles | [186] | |

| Zinc–air battery | KCl-activated biochar | Higher capacitance and peak power density vs. Pt/C | [187] | |

| Solar absorber coatings | Pigment material | Pure biochar | Reduced reflectance | [188] |

| Dye-sensitized solar cell (DSSC) | Catalyst (counter electrode) | Biochar replacing Pt | Effective Pt replacement | [189] |

| Electrochemical double-layer capacitor (EDLC) | Electrode | High-temperature pyrolyzed biochar | High conductivity and graphite-like structure | [190] |

| Composite supercapacitor | Electrode | Biochar with MnO2, NiO, and polyaniline | Increased capacitance and cycling stability | [191] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saletnik, A.; Saletnik, B. Technology–Economy–Policy: Biochar in the Low-Carbon Energy Transition—A Review. Appl. Sci. 2025, 15, 5882. https://doi.org/10.3390/app15115882

Saletnik A, Saletnik B. Technology–Economy–Policy: Biochar in the Low-Carbon Energy Transition—A Review. Applied Sciences. 2025; 15(11):5882. https://doi.org/10.3390/app15115882

Chicago/Turabian StyleSaletnik, Aneta, and Bogdan Saletnik. 2025. "Technology–Economy–Policy: Biochar in the Low-Carbon Energy Transition—A Review" Applied Sciences 15, no. 11: 5882. https://doi.org/10.3390/app15115882

APA StyleSaletnik, A., & Saletnik, B. (2025). Technology–Economy–Policy: Biochar in the Low-Carbon Energy Transition—A Review. Applied Sciences, 15(11), 5882. https://doi.org/10.3390/app15115882