1. Introduction

The emergence of intelligent manufacturing paradigms, exemplified by Germany’s “Industry 4.0” and China’s “Made in China 2025” [

1], necessitates the comprehensive modernization of traditional automobile wheel manufacturing to enhance efficiency and productivity. This transformation is crucial for the swift integration of digital and intelligent technologies. The digital twin methodology has gained prominence across various industries, enabling the development of virtual representations of physical entities and fostering real-time data connectivity, which subsequently aids in cost reduction and enhances operational efficiency [

2]. As a progressive aspect of industrial evolution, this methodology is driving advancements in manufacturing by incorporating essential information technologies such as robotics, the industrial internet, artificial intelligence, and big data analytics [

3]. The integration of digital tools and data significantly optimizes production processes, resulting in substantial improvements in efficiency. The primary objective of intelligent manufacturing is to establish a flexible and responsive production system capable of rapidly adapting to market fluctuations, addressing individual customer requirements, and delivering high-quality products and services at a lower cost [

4].

The concept of the digital twin has been documented in the international scientific literature for approximately two decades, highlighting its status as a relatively novel area of research. This field integrates advanced nonlinear multiscale and multiphysics models into a cohesive system, simulating the realistic responses of physical entities to varying environmental conditions. The initial reference to digital twinning can be traced back to 2002, when Michel Grieves proposed the idea that a digital informational representation of a physical system could exist as an independent entity. Initially applied within the context of product lifecycle management (PLM) [

5,

6], this concept has since expanded to encompass lean principles, as well as the roles of product manufacturers and consumer demands throughout the entire product lifecycle, which includes the stages of design, production, maintenance, and disposal [

7].

The United States Air Force Research Laboratory, in collaboration with NASA, introduced the concept of a digital twin in 2011 for the development of future aircraft. This concept is defined as a highly integrated simulation model that encompasses multiple physical phenomena, scales, and probabilities, specifically tailored to aircraft or systems. It utilizes physical models, sensor data, and historical data to replicate the functionality, real-time status, and evolutionary trends of the corresponding entity, thereby drawing significant attention to the digital twin [

8]. Since 2015, digital twin technology has experienced rapid development, and its scope of application has been expanding. Leading industrial enterprises worldwide, such as Siemens and General Electric (GE), have made substantial investments in the field of digital twins, driving the deep integration and widespread application of this technology across various industries [

9].

A digital twin is a technical framework that integrates multi-physical, multi-scale, and multi-disciplinary attributes. It possesses real-time synchronization capabilities, accurate mappings, and high-fidelity characteristics, enabling seamless interaction and fusion between the physical and digital worlds [

10]. Digital twin technology ensures the smooth integration of the digital and physical domains through the use of digital model simulations, analyses, and data aggregation, further enhanced by the capabilities of artificial intelligence and big data analytics [

11]. This technology not only facilitates the integration of the manufacturing information domain with the physical world but also has significant implications for the advancement of intelligent manufacturing. Its applications span numerous sectors, including industrial manufacturing [

12], health management [

13], energy management [

14], smart cities [

15], and aerospace [

16], it enhances efficiency, boosts performance, and nurtures innovation.

Digital twin technology is a fundamental component of smart manufacturing, enabling the creation of intricate virtual representations of production lines that enhance operational efficiency and product quality. These digital twins facilitate the simulation and optimization of manufacturing processes, effectively identifying potential issues and uncovering opportunities for improvement [

17]. As a result, they empower manufacturers to make more informed decisions regarding production planning and resource allocation, as evidenced by successful applications across various industries [

18]. The integration of sensor technology, the industrial internet, machine learning, and data analytics within digital twin technology establishes a closed-loop control system [

19]. Pei et al. [

20] introduced a quality monitoring methodology for production lines based on digital twin principles, where parameters indicative of quality performance are mapped to a virtual environment and optimized. Similarly, Cai et al. [

21] developed a quality management framework for the final assembly line of aircraft using digital twin technology, employing data mining tools to analyze real-time quality data to enhance assembly line quality. This system supports real-time monitoring and the optimization of industrial processes, as demonstrated by its effective implementation in smart factory management and zero-carbon industrial parks [

22]. Consequently, it significantly boosts production efficiency and elevates the level of intelligent operations.

The application of digital twin technology in intelligent manufacturing has become increasingly widespread, encompassing key areas such as the development of theoretical models, exploration of practical applications, fault detection techniques, health monitoring systems, and advanced production controls [

23]. Tao, F. et al. [

24] from Beihang University introduced the concept of a digital twin workshop and established a five-dimensional model along with a standardized architecture. Concurrently, scholars such as Wu, J. et al. [

25] have made significant contributions to digital twin modeling, technology development, and the construction of virtual machine tools.

Digital twin technology collects key parameters such as machine performance, temperature, and pressure, employing sensors and data acquisition tools to facilitate real-time data retrieval from physical systems and perform parallel analysis on digital counterparts, simultaneously offering manufacturers instruments for immediate visualization and analysis [

26]. This technology relies on modeling, simulation, and virtual reality technologies to dynamically replicate real-world elements and accomplish real-world regulation and control.

In the realm of intelligent production lines, digital twin technology not only facilitates the creation of virtual models prior to the establishment of new or revamped production lines but also ensures the comprehensive integration of all elements, processes, and business data. This technology encompasses simulation, predictive simulation, and equipment diagnostics throughout the production process [

27]. Furthermore, it demonstrates significant potential in monitoring line operations and maintenance through real-time data acquisition and simulation analysis, enabling the diagnosis of line health, the identification of faults, and the prediction of maintenance timing. Ren [

28] proposed an intelligent monitoring framework for product line reconstruction and the manual assembly of customized products based on digital twins, addressing issues related to misassembly and inefficiency. Chaux, J.D. [

29] introduced a digital twin architecture aimed at optimizing productivity within controlled-environment agriculture.

Despite its immense potential, the implementation of digital twin technology faces challenges in integrating various technologies, adhering to stringent professional standards, and ensuring seamless data acquisition. The integration of technologies such as modeling, simulation, data acquisition, transmission, and artificial intelligence necessitates a high level of enterprise digitization. At the operational and maintenance levels, professional quality and expertise are crucial; highly skilled personnel are required, and the successful completion of projects often depends on cross-departmental collaboration [

30]. Furthermore, acquiring data on physical entities, processing data fusion, and developing mapping mechanisms and interaction methods between virtual and real environments remain promising areas for further research.

The collaborative integration of digital twin technology within the manufacturing industry has led to significant advancements in three-dimensional visual monitoring for intelligent production systems. This is evidenced by its successful implementation across various sectors, including automotive, aerospace, and mechanical manufacturing [

31]. A major challenge in this context is the development of geometric, physical, logical, and data models that accurately represent the actual production line. Concurrently, it is essential to collect production data to facilitate real-time monitoring and synchronization between the physical and digital environments, thereby providing technical support for intelligent monitoring [

32].

This study focuses on the application of digital twin technology in intelligent manufacturing production lines. It examines the role of sensors and data acquisition tools in collecting real-time data from physical systems and operational processes while simultaneously simulating the behavior of these systems through digital models. This dual capability facilitates real-time visualization and analytical functions [

33]. Furthermore, the research explores the theoretical foundations of digital twin technology, its potential applications, and its significance in intelligent production. The objective of this paper is to develop a digital twin model that emphasizes critical condition monitoring elements within the manufacturing processes of intelligent production lines. Additionally, it investigates the architecture of a custom intelligent digital twin system specifically designed for automobile wheel production lines, ultimately providing innovative solutions and theoretical frameworks to enhance the intelligent manufacturing of automobile wheels.

2. Methods

Drawing upon the five-dimensional framework of digital twins—comprising the physical object, virtual model, twin data, service system, and connectivity, as articulated by Professor Tao F. [

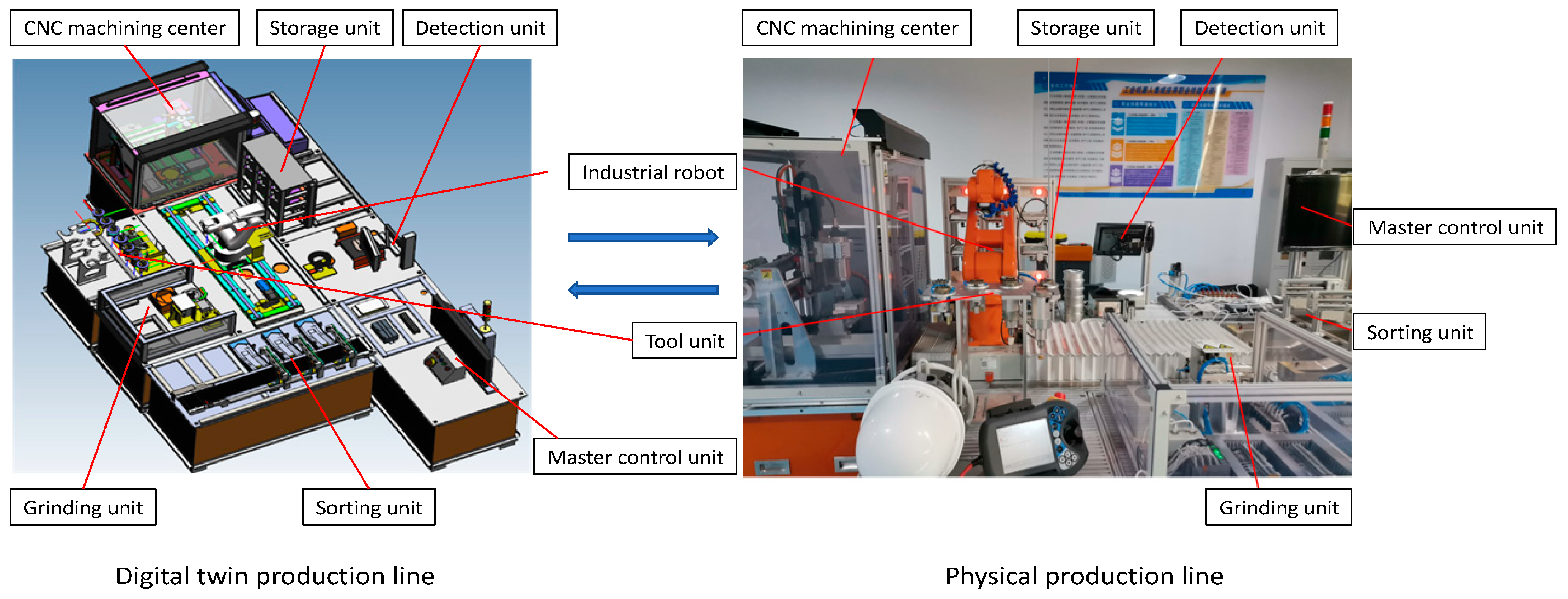

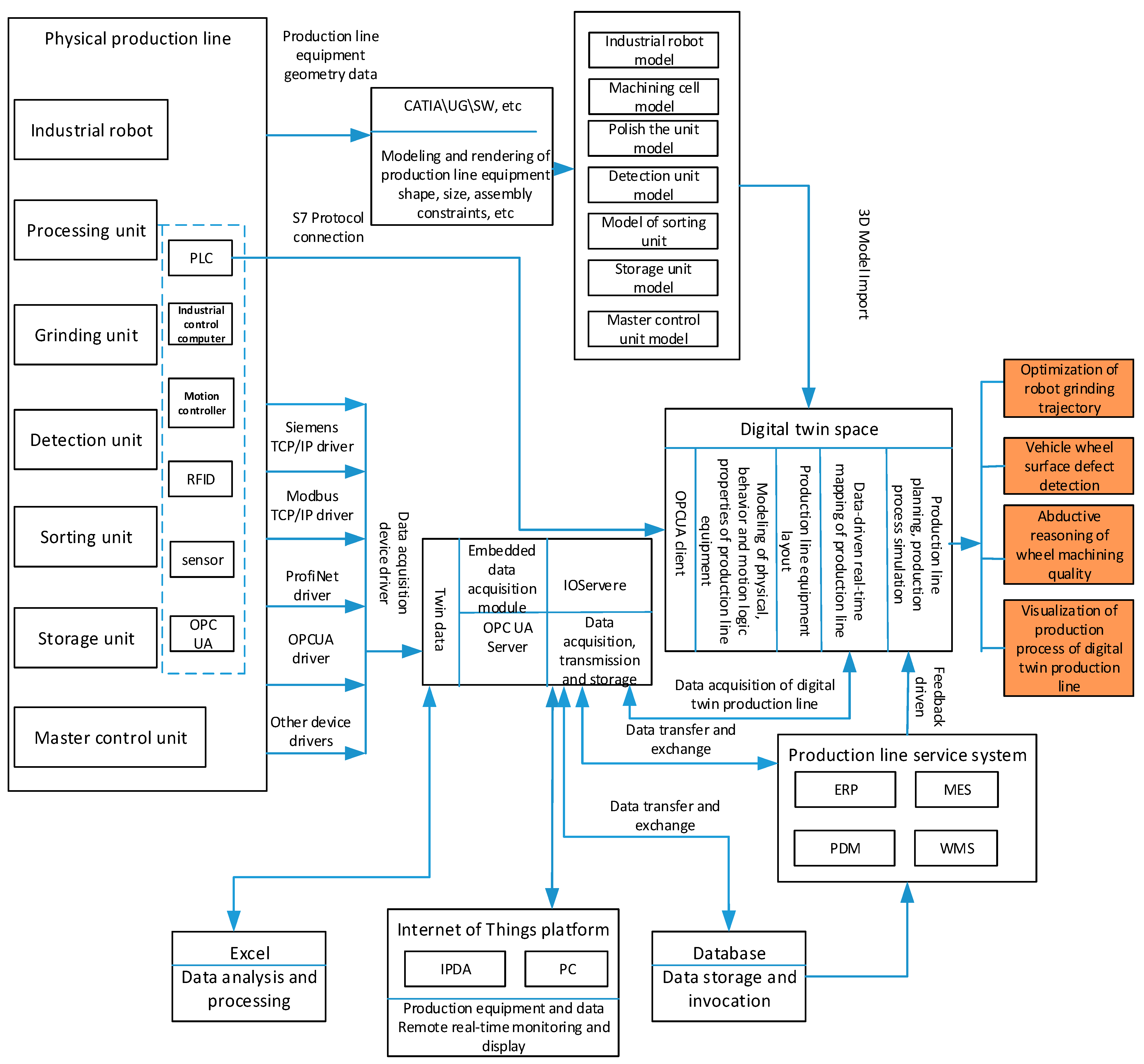

34]—this study presents a construction framework for a digital twin production line, as illustrated in

Figure 1. This research focuses on the processing, refinement, inspection, and management of automotive wheel components, aiming to enhance the automotive wheel production line by advancing it toward a more sophisticated paradigm of intelligent manufacturing through the development of a precise digital twin model.

The technological process of the intelligent automobile wheel production line consists of several key components: An industrial robot, operating according to a preprogrammed sequence, accurately grasps the tool unit and swiftly replaces the gripper. Simultaneously, the automated 3D warehouse within the storage unit retrieves the blank hub, preparing it for further processing. The industrial robot then transports the hub to the processing unit for CNC machining. Once the CNC machining is complete, the parts are conveyed to the grinding unit for a meticulous polishing process. Following image detection, the finished products are transported to the sorting unit, where they are categorized into either the qualified or unqualified areas based on established quality standards and inspection results.

This study examines the complexities of an intelligent manufacturing production line specifically designed for automotive wheels. It seamlessly integrates a diverse array of core components, including industrial robotic execution units, CNC machining centers, detection units, sorting units, storage units, tool units, and grinding units, all of which ultimately converge into a master control unit. Furthermore, the system harmoniously incorporates advanced technologies such as the industrial internet, PLC control, virtual debugging, machine vision recognition, industrial network communication protocols, the intricate programming logic of industrial robots, the MES management system, and artificial intelligence technology, thereby fully realizing the intelligence of automobile wheel production.

Figure 2 illustrates the model of each unit within the intelligent manufacturing line for automotive wheels.

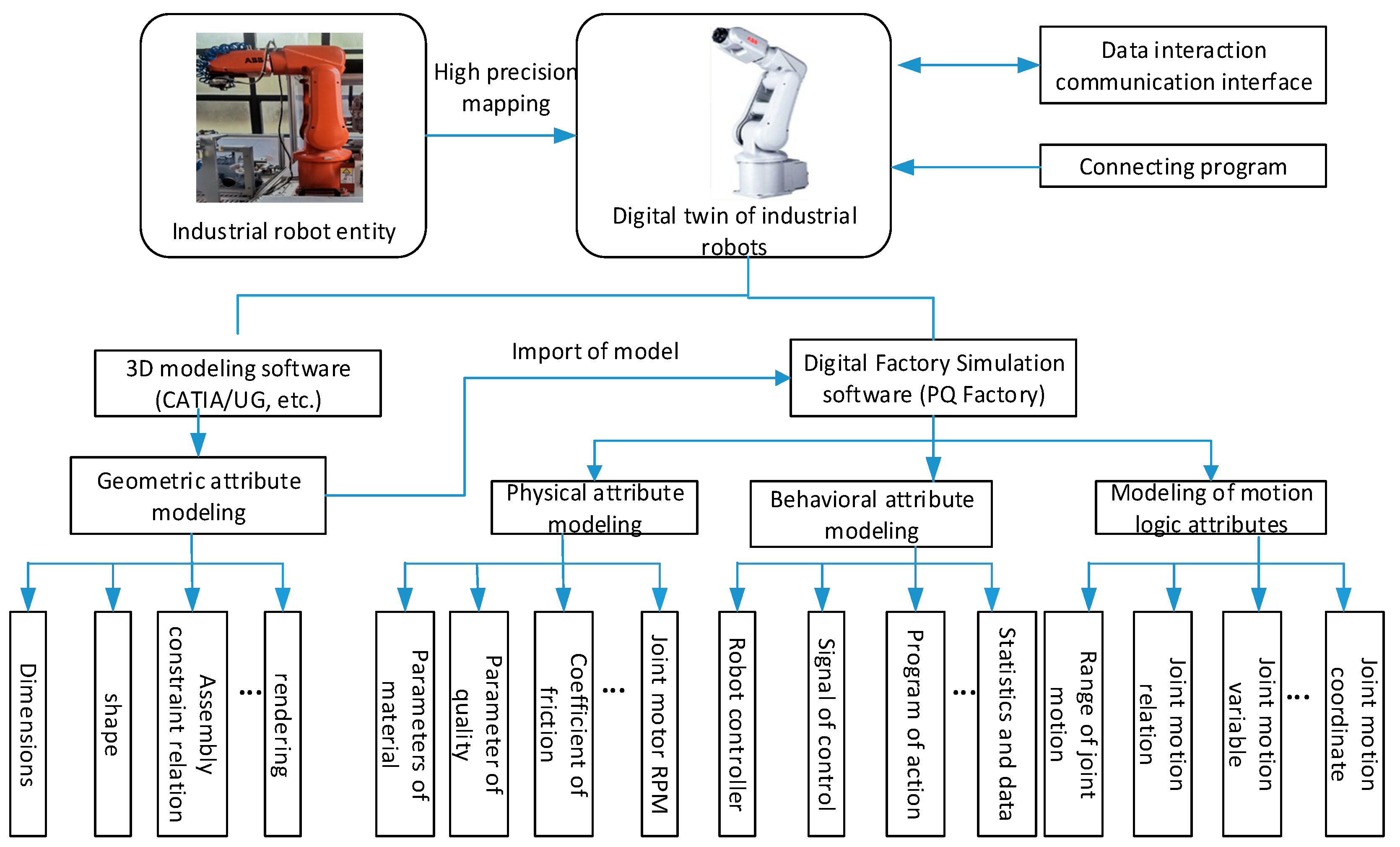

The critical aspect of developing a digital twin system for an intelligent automotive wheel production line is the precise modeling of each equipment unit, along with the integrated development of the entire digital twin production line. OPC UA technology facilitates the accurate acquisition and seamless integration of multi-source heterogeneous data. Furthermore, the virtual and physical production lines can achieve real-time synchronization. Deep learning and knowledge graph technologies have been integrated and applied to the fault diagnosis and maintenance strategies of the production line, accompanied by a real-time visual display of production operation data. The specific implementation method is as follows:

- (1)

Establish a digital twin model for each individual piece of equipment and develop a comprehensive digital twin of the entire production line.

- (2)

Using OPC UA technology, real-time data from the physical production line is collected and efficiently transmitted to both the digital twin of the production line and the application service layer.

- (3)

The communication interface and variable data connection technology facilitate seamless synchronous operation between the virtual workshop and the physical workshop.

- (4)

By leveraging artificial intelligence, deep learning algorithms, and knowledge graph technology, an efficient fault diagnosis and maintenance solution for intelligent production lines has been successfully developed. This solution significantly enhances the operational reliability and stability of the production line.

- (5)

Utilize the PQ Factory platform, Internet of Things (IoT) technology, Python v3.8.10 programming, Excel, and other tools to conduct comprehensive analyses and efficiently process production data. This approach ensures real-time visual monitoring of production operations.

Through the steps outlined above, as illustrated in

Figure 3, a successful mapping has been established between the physical production line and the digital twin of the automotive wheel hub production process.

3. Intelligent Production Line System Architecture Based on Digital Twin

This study examines an intelligent manufacturing line for automobile wheel hubs and presents the development of a digital twin system. It encompasses a physical production line layer, a data layer, a digital twin production line layer, and an application service layer, all organized through a hierarchical design methodology. The integration of the Industrial Internet of Things (IIoT) with digital twin technology establishes a novel framework that enables three-dimensional (3D) visual monitoring. The implementation of this system is expected to enhance production efficiency, reduce costs, and improve quality control, as evidenced by successful applications of digital twin technology in automotive manufacturing.

Figure 4 illustrates the architecture of the intelligent production line system, which utilizes digital twin technology to integrate functions across the various layers:

(1) Physical production line layer: This layer serves as the foundation of the digital twin production line system and is responsible for critical tasks such as 3D model construction and the collection of production data. It consists of two main modules: ① The physical equipment module, which integrates industrial robot execution units, CNC machining centers, tool units, sorting units, grinding units, testing units, storage units, a total control unit, and other core equipment, along with personnel and the production line environment, collectively constituting the physical entity of the production line. ② The data perception module, which includes sensors, programmable logic controllers (PLCs), industrial computers, motion controllers, and network infrastructure, is responsible for transmitting commands and collecting data to facilitate real-time communication and efficient data acquisition.

(2) Data layer: The data layer plays a central role in the digital twin production line system, ensuring efficient connectivity and stable operation among its components. Its primary function is to facilitate interconnectivity within the system by coordinating data collection, transmission, integration, and analysis, while simultaneously driving the system’s operations. The data layer consolidates real-time data from the physical production line, data generated by the digital twin, and information from the application service system. Comprehensive integration and thorough analysis of these data are crucial for the efficient functioning of the digital twin. The data layer is essential for uploading and storing data from the physical entity layer onto the server, subsequently distributing it to the digital twin production line layer, thereby enriching the twin model with valuable information. Additionally, it addresses the big data requirements of the application service layer and enhances capabilities for data visualization, status monitoring, and fault diagnosis.

(3) Digital twin production line layer: The digital twin production line layer facilitates the precise digital mapping of the physical production line, encompassing a comprehensive digital twin model that includes geometric models, assembly constraints, visual materials, behavioral and logical properties, and data interfaces. Within the framework of digital twin technology, the physical production line layer employs logical scripts and real-time data to drive a model that accurately emulates actual processing actions, signal transmission, and control logic. This model serves as a foundation for 3D visual monitoring [

35]. Furthermore, through bidirectional data interaction with the physical production line layer, the digital twin production line layer integrates with the application service layer to create a complete, real-time data-driven system, thereby enhancing the overall capabilities of production monitoring, diagnosis, analysis, and optimization.

(4) Application service layer: As the primary interactive interface within the digital twin system, the application service layer seamlessly integrates data visualization tools with various information management systems, including Manufacturing Execution Systems (MES), Product Data Management (PDM), Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP) systems, as well as decision support systems and databases. It provides comprehensive support for simulating, monitoring, evaluating, optimizing, predicting, and making decisions related to the production line. This layer facilitates user interaction with the digital twin system, enabling 3D visual monitoring to ensure a smooth and continuous flow of information and data. By conducting thorough analyses and optimizations of data from both physical and digital twin production lines, it integrates with systems such as MES, PDM, WMS, and ERP, thereby realizing a closed-loop optimization process through data fusion analysis and ongoing improvements. Simultaneously, the application service layer presents critical production information—including equipment status, utilization rates, process parameters, output, pass rates, logistics, and inventory—in an intuitive visual format [

36]. Furthermore, the application service layer utilizes extensive data sourced from the data layer to enhance functionalities such as historical scene recreation, remote oversight, instant alerts, and predictive analysis for diagnostics and maintenance tasks, thereby elevating the level of intelligence and automation in production management.

4. Construction of Digital Twin Production Line

4.1. Construction Process of Digital Twin Production Line

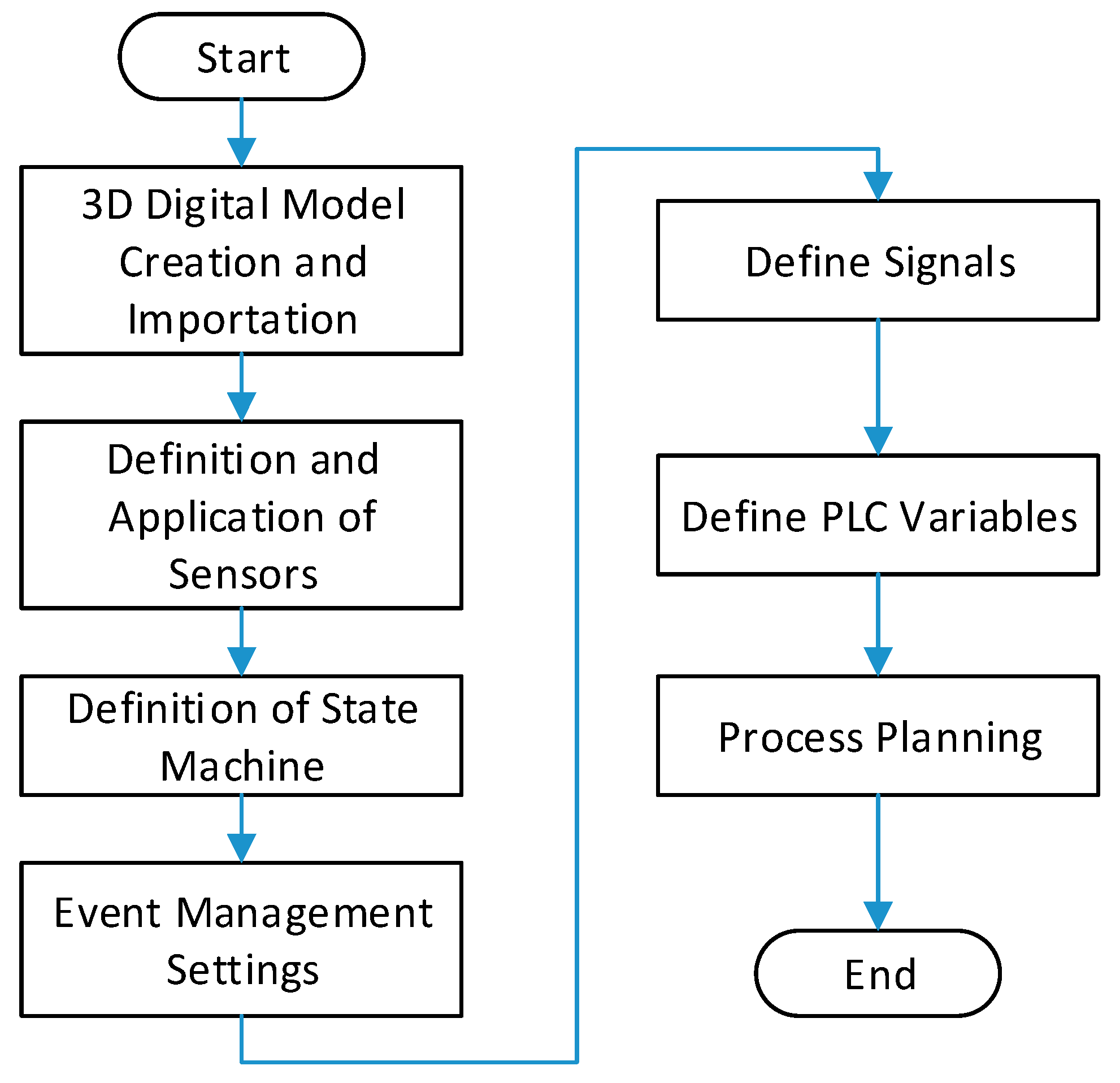

The specific method and flow of digital twin production line construction are shown in

Figure 5. By following a comprehensive process that includes data collection, model establishment, validation, and optimization, a digital twin model is created, accurately mirroring the actual production line within a virtual environment. This model offers powerful tools for the design and optimization of intelligent production lines, as it can simulate and predict the actual operation of the production line in real time, allowing for continuous improvement and efficiency gains. This is exemplified by the application of digital twin technology at the equipment level, which facilitates real-time monitoring and simulation, as well as the specific patent for a digital twin-based production line data mapping and integration system, which enhances the management and optimization of production line processes, as detailed below:

(1) 3D digital model creation and importation: Utilizing cutting-edge 3D modeling tools such as CATIA and UG to meticulously create 3D models that accurately represent essential equipment, including industrial robots, CNC machining centers, grinding machines, testing devices, sorters, storage systems, and integrated control systems. By converting these models into the .robp format, they become compatible with digital twin software. This compatibility facilitates the successful importation and precise virtual reproduction of the production line within the digital twin environment. Establishing a robust foundation for virtual debugging and digital twin modeling is crucial, as it enables the creation of accurate virtual counterparts of physical entities. This process significantly enhances the monitoring, simulation, forecasting, and improvement of real-world systems.

(2) Definition and application of sensors: Sensors, as essential detection devices in industrial automation, are adept at converting measured data into electrical signals or other output formats. This transformation facilitates the transmission, processing, storage, display, recording, and control of information, thereby enhancing production efficiency, quality assurance, and safety monitoring. They play a crucial role in industrial automation and are utilized across various sectors, including manufacturing, logistics, healthcare, and environmental monitoring. Advancements in technology, such as miniaturization, digitization, and the integration of artificial intelligence, have significantly improved the functionality and efficiency of sensors. In actual production lines, sensors monitor photoelectric signals to assess material conditions, employing signal blocks to confirm the presence of materials. Within the software system, the collision detection mechanism enhances the sensor’s detection capabilities, enabling the recognition of material presence through virtual collisions between the digital twin model of the sensor and the physical model.

(3) Definition of state machine: The concept of a state machine is fundamental in the definition of digital twin devices. Within the realm of digital twin software, this concept facilitates the characterization of mechanisms driven by primary actuators, such as motors and cylinders, as state machines. These state machines are predicated on two fundamental motion states: translation and rotation, which are expressed through actions such as the extension, rotation, clamping, and release of the mechanism. The operation and regulation of the state machine are primarily contingent upon trajectory points, which can be activated by custom events to ensure precise motion control. Each state is governed by the establishment of start and place variables, which function as the interface between the state machine and the external controller, responsible for initiating motion and providing state feedback. By configuring signals for various states and implementing event management systems, we can simulate mechanical effects, thereby augmenting the realism and interactivity of digital interactions and offering a highly realistic virtual testing environment for system development.

(4) Event management settings: In the physical production line, the fixture securely holds the object through the clamping action of the claw, utilizing both friction and clamping forces. However, accurately simulating this process in a virtual environment requires precise configurations to ensure that the software effectively replicates the grasping effect. In the digital twin production line, configuring events for the “state machine” object enables the simulation of the fixture’s physical actions and the solid connection of the material model; this process is referred to as “event management”. Event management is essential for creating an accurate virtual debugging environment. It ensures synchronization between the definitions of digital device actions and the event management settings, facilitating consistent alignment with the actual production line in the digital twin. This capability allows the jig in the virtual environment to replicate the grasping action observed in the real world.

(5) Define signals and PLC variables: In an advanced production line, synchronizing the digital twin with the physical entity in terms of motion posture requires the meticulous establishment and configuration of virtual signals. These signals delineate critical parameters such as motion trajectory, range limits, direction of movement, speed, displacement, and rotation angle, thereby accurately representing the real-time status of both the digital twin and the physical entity. The careful specification of Programmable Logic Controller (PLC) variables—including their names, data types, and addresses—constitutes a fundamental element for facilitating effective communication between PLC programs and the signals within the digital twin production line. Furthermore, smart production lines necessitate precise definitions for various components, including robots, devices, sensors, and button signals, which encompass signal names, types, addresses, external connections, and associated resources, thereby ensuring effective signal alignment. During the simulation debugging phase, the signals within the digital twin production line interact with those in the TIA Portal via the IO Server. Additionally, the PLC program, in conjunction with digital twin technology, plays a crucial role in the accurate control and optimization of the production line model.

(6) Process planning: Within the virtual environment, comprehensive planning of the processing technology is conducted based on the process flow and the trajectory of automobile wheel hubs. This planning encompasses critical steps such as path planning, collision detection, and reachability analysis for industrial robots. The quality of robot trajectories and the efficiency of production line construction can be enhanced by completing PLC program debugging and simulation verification processes prior to the establishment of the production line [

37].

4.2. Construction of Automobile Wheel Hub Digital Twin Production Line Model

The intelligent production line model at the automotive hub integrates several key components, including industrial robots, CNC machining centers, inspection systems, sorting mechanisms, storage solutions, tools, grinding apparatus, and a comprehensive control system. By leveraging industrial internet technology, PLC control, virtual debugging, machine vision, industrial networks, robot programming, and Manufacturing Execution Systems (MES), these technologies are seamlessly integrated to facilitate cross-disciplinary collaboration [

38].

Figure 6 illustrates the block diagram of the intelligent production line model for automobile wheels.

As illustrated in

Figure 6, the digital twin model of the intelligent production line for automobile wheel hubs can be described in detail as follows (1):

The formula represents the digital twin scene model of the intelligent production line for automobile wheels, where DTpl denotes the digital twin production line [

39]. This model serves as a sophisticated digital representation that facilitates the real-time monitoring and optimization of the production process. The abbreviations are defined as follows: EDM for the Execution Unit Model, TM for the Tool Unit Model, MM for the Machining Unit Model, GM for the Grinding Unit Model, DM for the Detection Unit Model, SM for the Sorting Unit Model, STM for the Storage Unit Model, CM for the Central Control Unit Model, and EM for the Environment Unit Model. The variables a, b, c, d, f, h, r, s, and t correspond to the quantities of each respective unit model.

4.3. Construction of Automobile Wheel Hub Digital Twin Production Line Based on PQ Factory

PQ Factory is an advanced software solution designed for the creation of production lines and the execution of virtual debugging. It facilitates real-time communication with various brands of Programmable Logic Controllers (PLCs). The software includes a comprehensive resource library that enables users to define production line equipment and supports a wide range of industrial devices, including industrial robots, cylinders, modules, conveyor belts, Automated Guided Vehicles (AGVs) [

40].

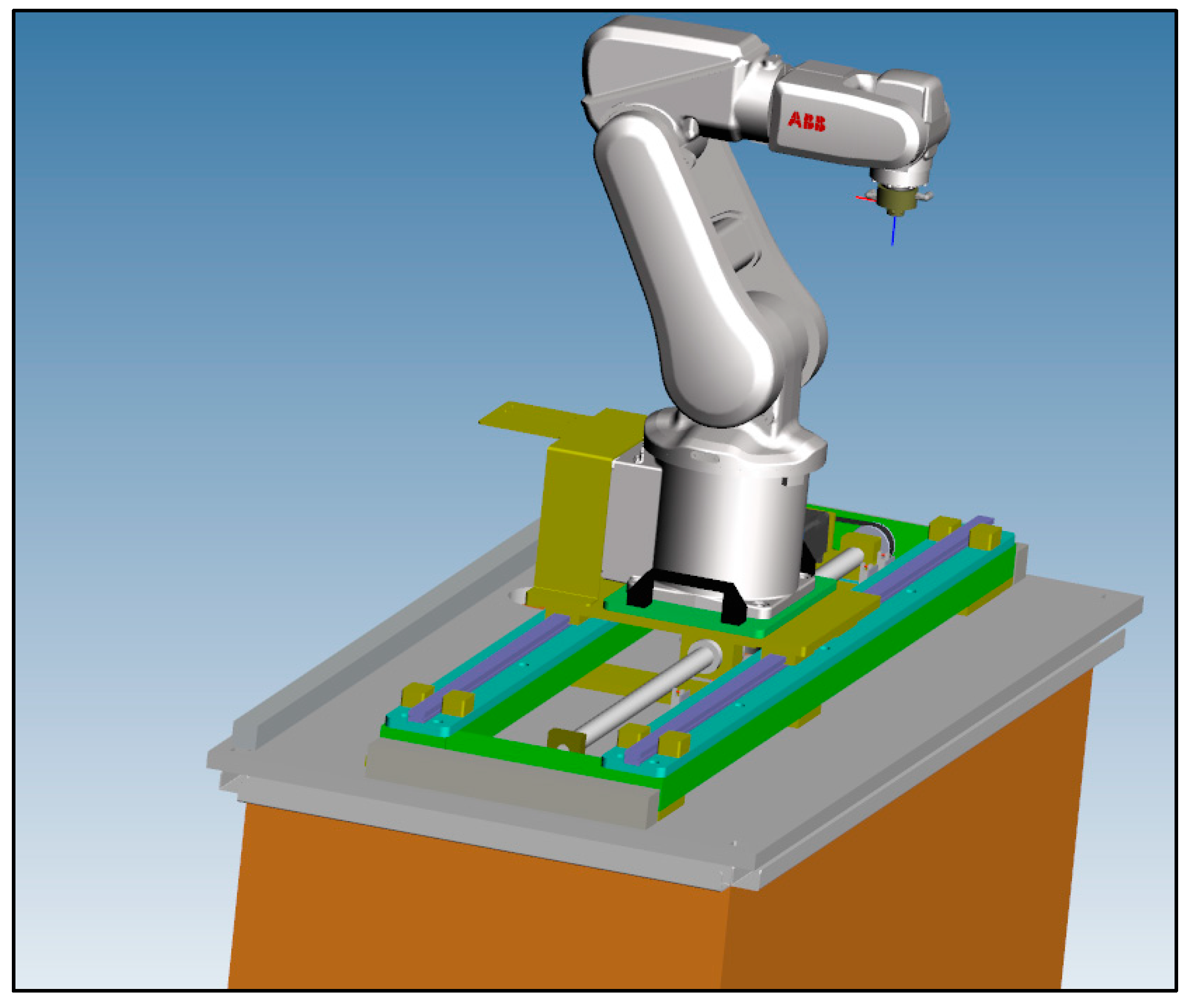

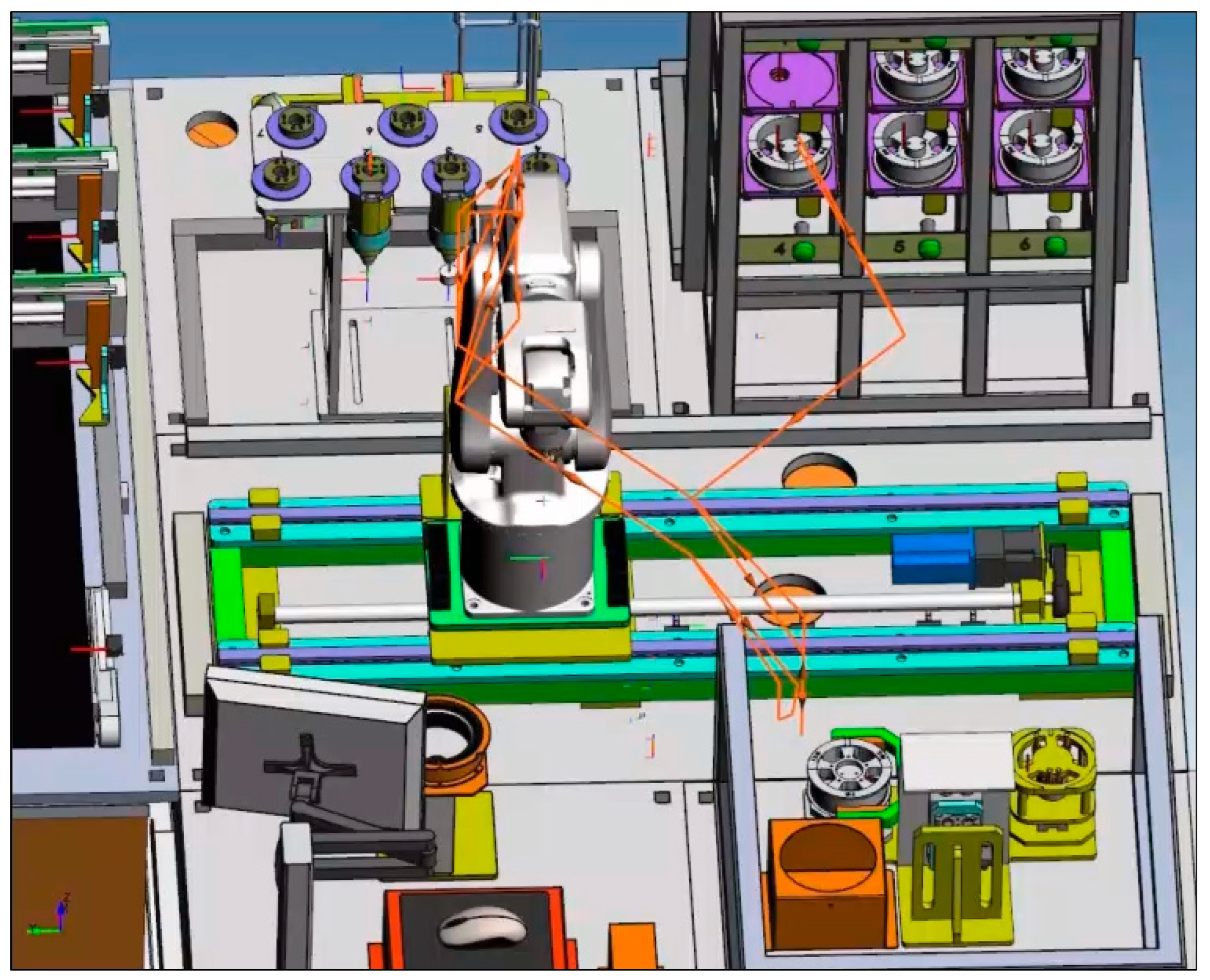

The following section uses the execution unit as an example to elaborate on the construction process and methodology of the automotive wheel hub digital twin production line based on PQ Factory [

41]. The execution unit consists of several key components: industrial robots, quick-change flange modules, translation slides, remote IO modules, and workbenches. By utilizing the quick-change tool, the execution unit effectively performs tasks such as removing, positioning, and grinding wheel hub components. The selected industrial robot is an ABB six-axis model, which integrates a seventh axis through the controller, enabling precise servo motion control of the external axis. By expanding its workspace, the robot can complete complex processes with additional functional units. The quick-change flange module, attached to the end flange of the industrial robot, aligns seamlessly with the tool end, facilitating uninterrupted automatic tool replacement by the robot. The motion parameters of the translation slide are transmitted from the industrial robot controller to the PLC via the field IO signal, allowing the servo motor to be controlled for linear motion. The process control signals from the execution unit communicate with the overall control unit through the remote IO module over industrial Ethernet, ensuring the smooth operation and accurate control of the production line. The following steps were conducted for this stage:

(1) Creation of a 3D digital model of production line equipment: Initially, we utilize 3D modeling software, such as CATIA, to accurately replicate the production line equipment, including its shape, size, position, and assembly interconnections. This process involves meticulous rendering to ensure that the digital twin model faithfully reflects the physical device’s attributes with the highest precision, as illustrated in

Figure 7. The digital twin 3D model of the execution unit employs techniques such as 3D scanning, sensor data modeling, CAD design, and point cloud reconstruction to provide a highly accurate virtual representation [

42].

The 3D models of the quick-change module flange end, translation slide, and table were developed using a consistent methodology, which established a foundation for simulation and integration. Subsequently, the refined model was integrated into PQ Factory’s digital simulation software, allowing for the detailed modeling of its physical attributes, behavioral patterns, and logical frameworks. This integration enhances the model’s accuracy within the simulated environment [

43], as illustrated in

Figure 8. Finally, to facilitate data interaction and connectivity, a data communication interface was established, along with the development of a driver connection script. This ensures seamless collaboration between the twin industrial robots and other system components, providing essential data support for the digital twin of the production line.

(2) Definition of production line equipment and motion parameter settings: Within the PQ Factory software environment, high-quality replication relies heavily on meticulously configured production line equipment, clearly defined mechanisms, and precise motion parameters. The process involves selecting the appropriate mechanism type, assigning it a unique name, specifying brand and model details, and establishing the device’s fundamental coordinate system. For instance, the six joint axes (J1 to J6) of an industrial robot are configured with detailed static parameters, including mechanical zero points, travel limits, and joint speeds. Motion parameters encompass linear velocity, angular velocity, and trajectory smoothing capabilities. Through these settings, the digital twin model of industrial robots can accurately replicate the motion characteristics of physical industrial robots in a virtual environment, thereby ensuring the accuracy and reliability of the twinning process. This is essential for subsequent simulation analysis, path planning, and dynamic interaction [

44].

(3) Definition of production line equipment status: In the PQ Factory v2024(64) software, the definitions of device states are based on the logical design of travel switches. This process involves naming sensor variables, selecting test objects, and ensuring that the roles of sensors in the virtual environment align with their functions in the real world. The definition utilizes a signal trigger mechanism to control the slide to a preset position and activate the sensor, thereby facilitating coordinated interaction between the guide rail and the robot. This coordination ensures the precision and uniformity of the production equipment’s operations. An accurate definition of production line equipment status serves as the foundation for achieving precise digital twinning. This state definition enables the digital twin to accurately reflect its operational performance and provides essential data support for the virtual commissioning of the production line.

(4) In the PQ Factory simulation environment, the precise management of grasp events is essential for accurately simulating the handling of workpieces, such as wheel hubs. This is achieved through comprehensive management settings for production line equipment events. It involves logically associating the workpiece with the industrial robot grippers, ensuring that the robot can initiate and execute the grasp action upon reaching the designated position. This simulation process replicates the grasping action in actual production and verifies the accuracy and reliability of the robot’s motion control logic.

(5) Definition of control signal: To meet the requirements of an intelligent production line process flow in the automotive industry, it is essential to precisely define the robot signals for the execution unit, the servo slide positioning movement signals, and the functional signals for the tool unit, among others. Additionally, a clear hardware address must be assigned to each signal based on the I/O signal parameters.

(6) In intelligent automobile wheel production lines, industrial robots play a crucial role in meticulously planning the handling and grinding processes, as well as executing these tasks efficiently. Their primary responsibilities include clamping parts from the machining area onto jigs and transporting them to subsequent stations for further processing and rigorous quality checks. To accomplish this, it is essential to first ascertain key information such as the position, shape, and size of the part, and to select the appropriate end-effector tools and teaching points for pick up and placement. Furthermore, the robot adjusts its posture to precisely meet handling specifications, facilitating a seamless transition from picking to placing, thereby ensuring that operations maintain both fluidity and precision. As the backbone of production control, industrial robots plan and send control instructions to each execution unit, including the tool unit, processing unit, grinding unit, sorting unit, testing unit, and storage unit. This coordination guarantees the efficient operation of the workpiece and the precise execution of the process flow through the tool’s pick-and-place operation.

Figure 9 illustrates the process planning for handling and grinding automobile wheel hubs.

5. Automobile Hub Intelligent Production Line System Data Acquisition and Transmission

The intelligent production line of the automotive hub integrates equipment and control systems from various manufacturers. These devices utilize diverse communication protocols and generate substantial amounts of heterogeneous data during operations, significantly increasing the complexity of data collection. To address these challenges, it is essential to implement effective data-gathering techniques and adopt standardized communication protocols. The OPC UA (Open Platform Communications Unified Architecture), as a standardized communication protocol, offers a solution for data exchange between different software systems and supports the collection and analysis of heterogeneous data from multiple sources. It facilitates data interaction and fusion between the physical production line and the digital twin production line.

In this study, the OPC UA, in conjunction with third-party IO server v3.8 software and an embedded OPC UA server, is utilized to develop a data perception platform framework for an intelligent production line system focused on automotive wheel hubs, based on digital twins. This approach effectively addresses the challenges of data acquisition and transmission from underlying equipment, as illustrated in

Figure 10.

By distinguishing between Ethernet communication and protocol-driven communication, the framework establishes external and embedded OPC UA servers to realize end-to-end functions of data acquisition and transmission [

45]. The OPC UA client built in the virtual workshop and information service layer, being at the receiving end of data transmission, forms a complete data transmission channel with the server.

In the implementation process, the first step involves establishing communication among the industrial Ethernet host computer, PLC, vision inspection system, sensors, and all relevant equipment. Secondly, by leveraging the integrated protocol driver in the IO Server software, the device data address is obtained via industrial Ethernet and then stored in the OPC UA server. Finally, offline simulation data for the virtual production line is acquired in real time through the employment of an emulation-driven protocol. These devices guarantee smooth communication and continuous data flow via seamless integration. Since data cannot be collected by third-party software, an embedded OPC UA server is used to collect and transmit data via the data acquisition development board and underlying protocol conversion program [

46]. The IO Server software summarizes and classifies the intelligent production line data, converts it into the format that conforms to the OPC UA protocol, and realizes real-time data transmission through the OPC UA server.

The study’s protocol-driven transmission method ensures seamless data integration across various systems, including MES, WMS, and ERP, as well as Excel and IoT platforms. This integration facilitates the real-time monitoring and analysis of production line data, enhancing the transparency and traceability of the manufacturing process. Additionally, it provides robust data support for production decision making, process optimization, and efficiency improvements, as demonstrated by the critical role of data in project management and the optimization of business operations.

7. Joint Virtual Debugging and Running Results

(1) Execute the PLC program: The connection to the actual PLC equipment is established through the “Connect PLC” function block of the IO Server, which enables synchronization between the variables in the PLC program and the software.

(2) Start the IO Server software: Before establishing a system connection, verify that the IP address and port number in the IO Server’s settings match those configured for PQ Factory’s connection to the PLC. This step ensures accurate communication. After confirming that there are no discrepancies, launch the engineering application files to establish real-time data acquisition and transmission between PQ Factory and the PLC. Next, initiate the virtual debugging process to simulate the actual operating environment and evaluate the system’s performance.

(3) Operate the digital twin production line: Once the connection between the PLC, IO Server, and PQ Factory is established, proceed with the commissioning and operation of the digital twin production line. Utilize the signal debugging panel to verify device actions by setting or resetting the signals to confirm their functionality. When the PLC connection status in PQ Factory indicates that the system is ready, you may initiate the operation of the digital twin production line.

Figure 13 illustrates the joint virtual commissioning status and schematic diagram of the digital twin smart production line for the automotive hub.

The intelligent production line system for automobile wheel hubs developed in this study and based on digital twin technology enables real-time monitoring and ensures seamless data synchronization between the physical and virtual environments. The IO Server acts as a vital conduit for information exchange.

Figure 14 illustrates the synchronized operation of the physical production line and its digital twin counterpart within the automotive hub intelligent digital twin system, clearly demonstrating the system’s effectiveness in enhancing production processes.

This integrated digital twin system significantly enhances the efficiency and accuracy of production monitoring, providing robust technical support along with practical examples to advance intelligent manufacturing. Furthermore, it fosters digital transformation and improves intelligence within the automotive wheel manufacturing sector.

8. Conclusions

This study provides a comprehensive analysis of the application of digital twin technology in intelligent manufacturing production lines for automotive hubs. The primary objective was to design and implement an intelligent production line based on the principles of digital twins. The specific contributions of this research are outlined as follows:

A comprehensive architecture for an intelligent production line system utilizing digital twin technology is proposed. This architecture employs a hierarchical design approach that encompasses four layers: the physical production line layer, the data layer, the digital twin production line layer, and the application service layer. By integrating industrial Internet of Things (IoT) technology, the framework facilitates real-time mapping and seamless integration between the physical production line and the digital environment.

Utilizing OPC UA technology, a data perception platform framework has been developed for the intelligent production line system of automotive wheels, based on the concept of digital twins. This framework effectively addresses the challenges related to data acquisition and transmission from the underlying equipment. It facilitates data interaction and fusion between the physical production line and the digital twin, thereby enhancing the visualization of the production process.

The operational application of the system, combined with collaborative debugging and simulation results, demonstrates its capability to achieve real-time data acquisition and visualization of the intelligent production line’s operations. The system fulfills the requirements for three-dimensional real-time monitoring of the production line, thereby confirming its feasibility.

The current research has successfully established capabilities for virtual simulation and virtual–real data acquisition and storage, as well as the three-dimensional real-time monitoring of an intelligent production line for automotive wheel hubs. Future investigations will further explore the integration of advanced technologies, such as big data analytics and artificial intelligence algorithms, to enhance quantitative analysis, diagnosis, evaluation, optimization, prediction, and decision-making processes, for the intelligent production line of automotive wheel hubs, with the aim of improving its performance and intelligence.