Research on the Deformation and Failure Mechanism of Flexible Formwork Walls in Gob-Side-Entry Retaining of Ultra-Long Isolated Mining Faces and Pressure Relief-Control Technology via Roof Cutting

Abstract

1. Introduction

2. Engineering Geological Background

2.1. Study Area Characterization

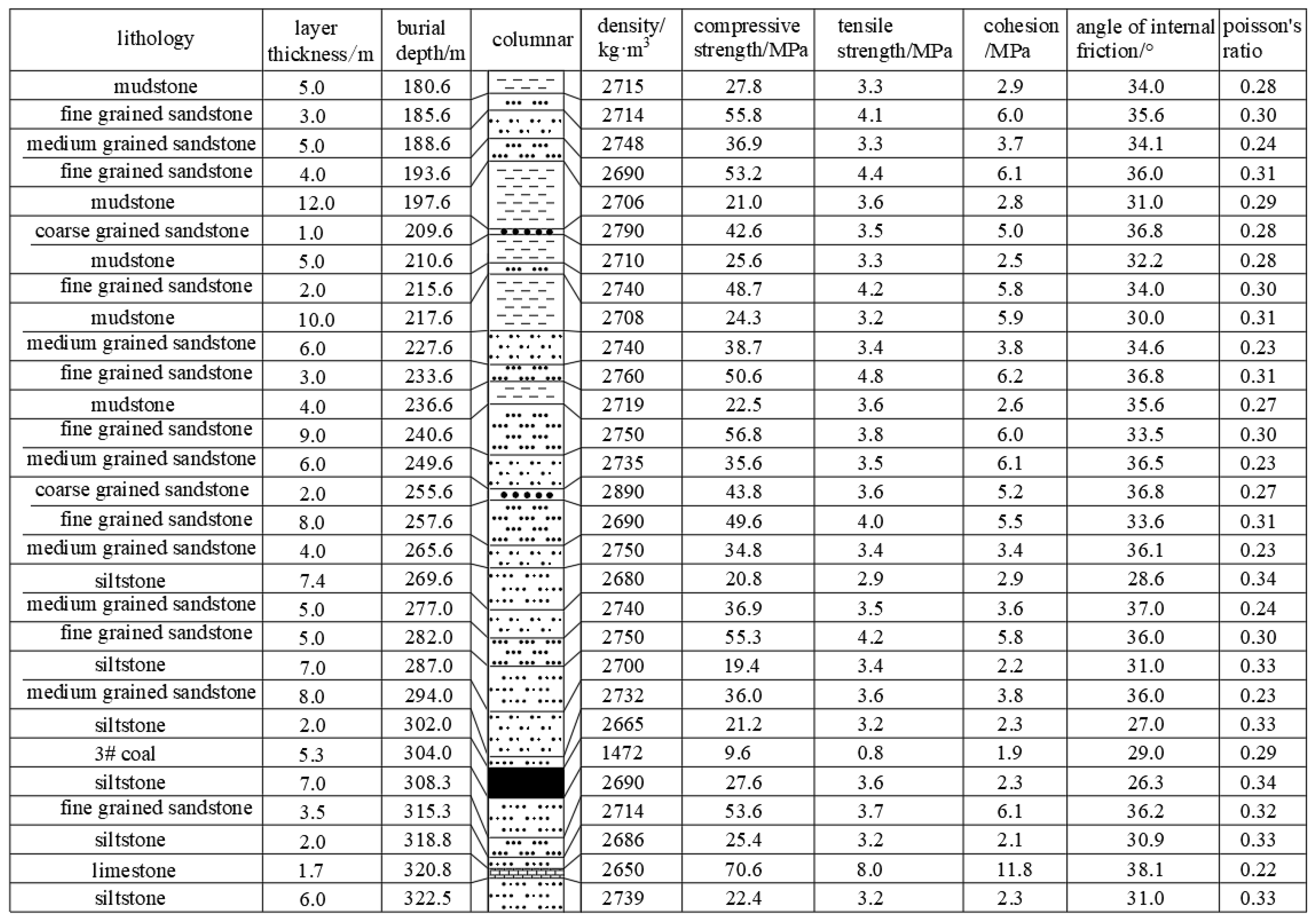

2.2. Geomechanical Characteristics

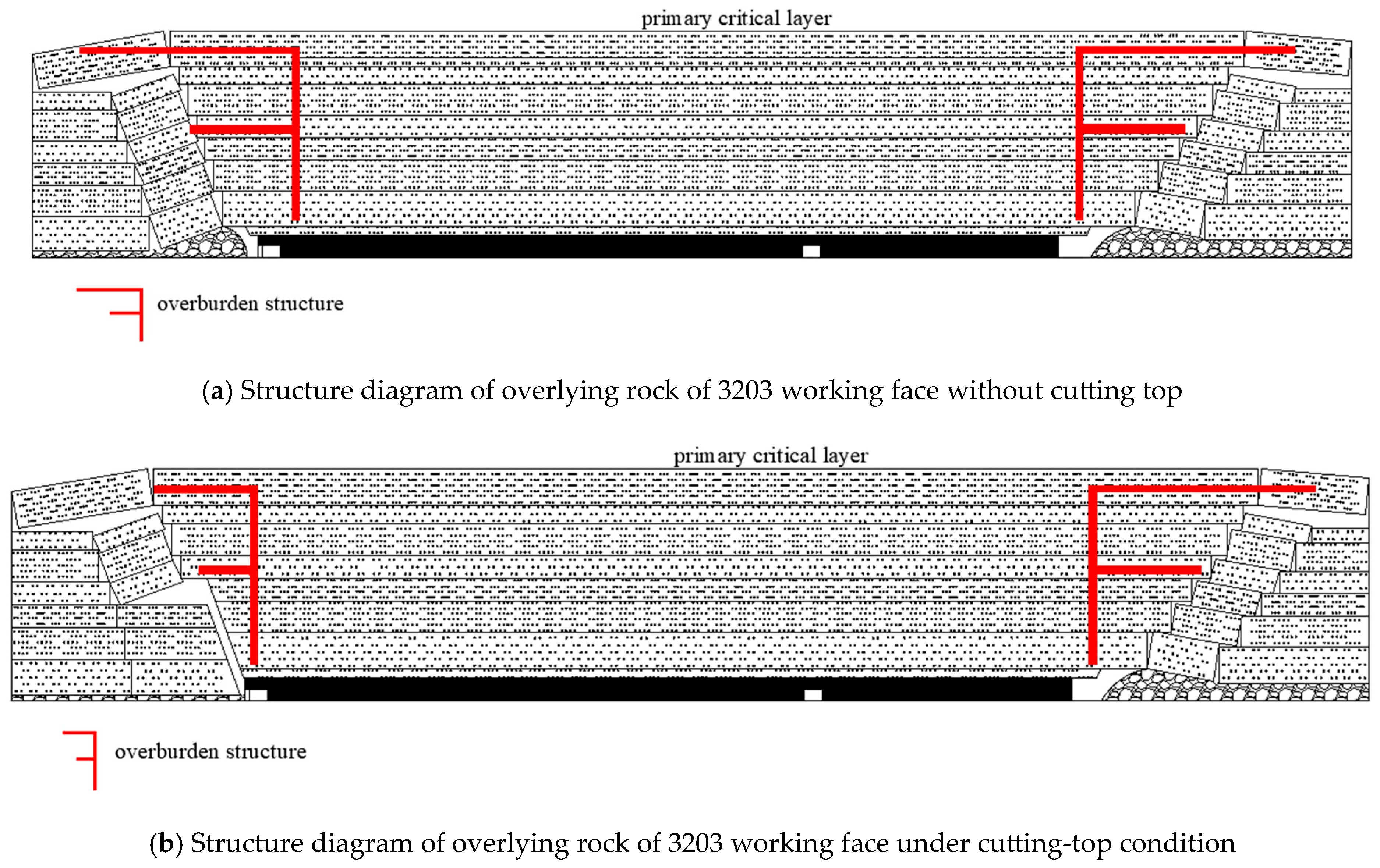

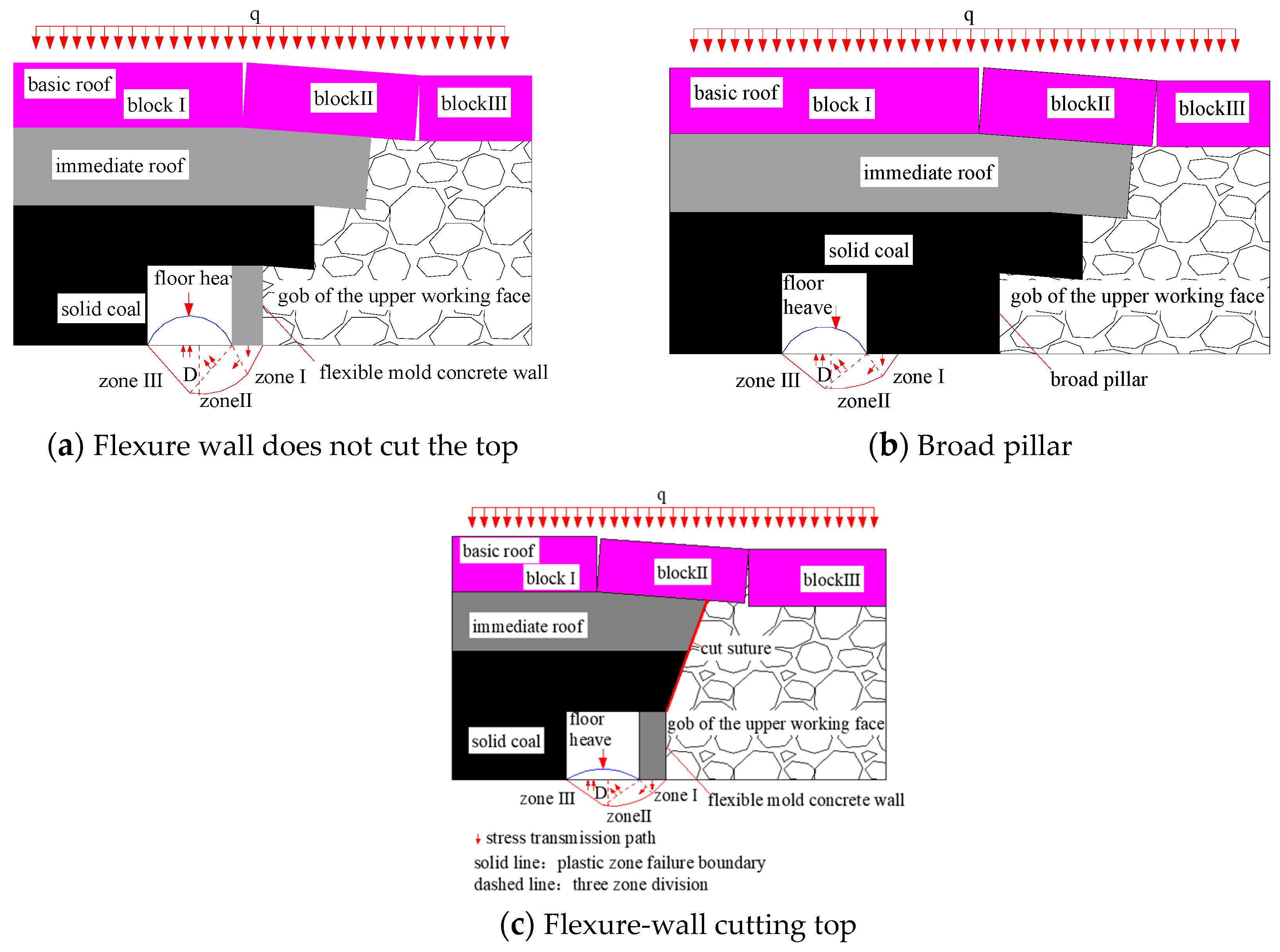

3. Mechanism of Entry Instability in Advance Region and Principle of Surrounding Rock Control by Roof Cutting for Pressure Relief

4. Determination of Blasting Top-Cutting Pressure-Relief Parameters

5. Numerical Simulation of Ore Pressure Characteristics of Concrete Wall of Overlong Fully Mechanized Caving Island Face Before and After Cutting Top

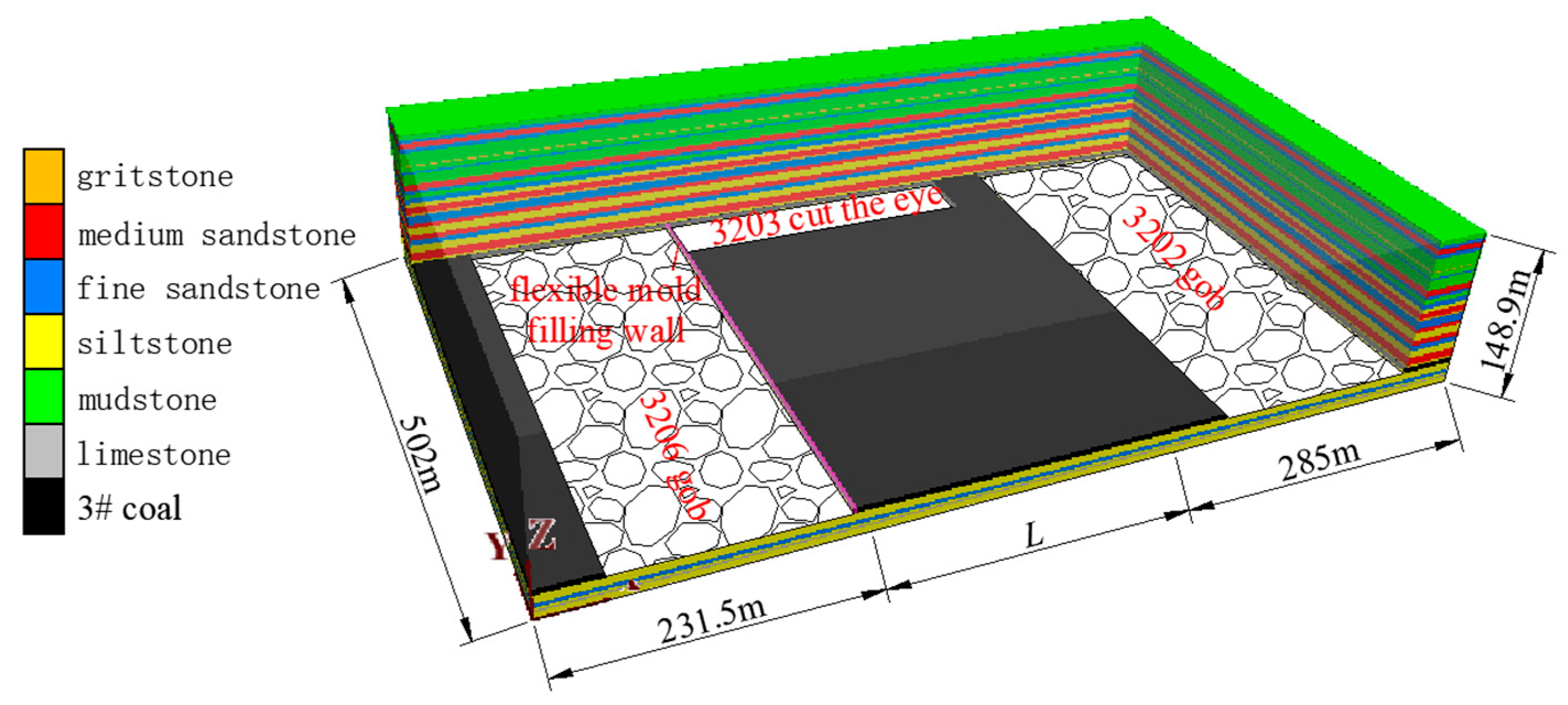

5.1. The Establishment of Numerical Model

5.2. Numerical Simulation Process

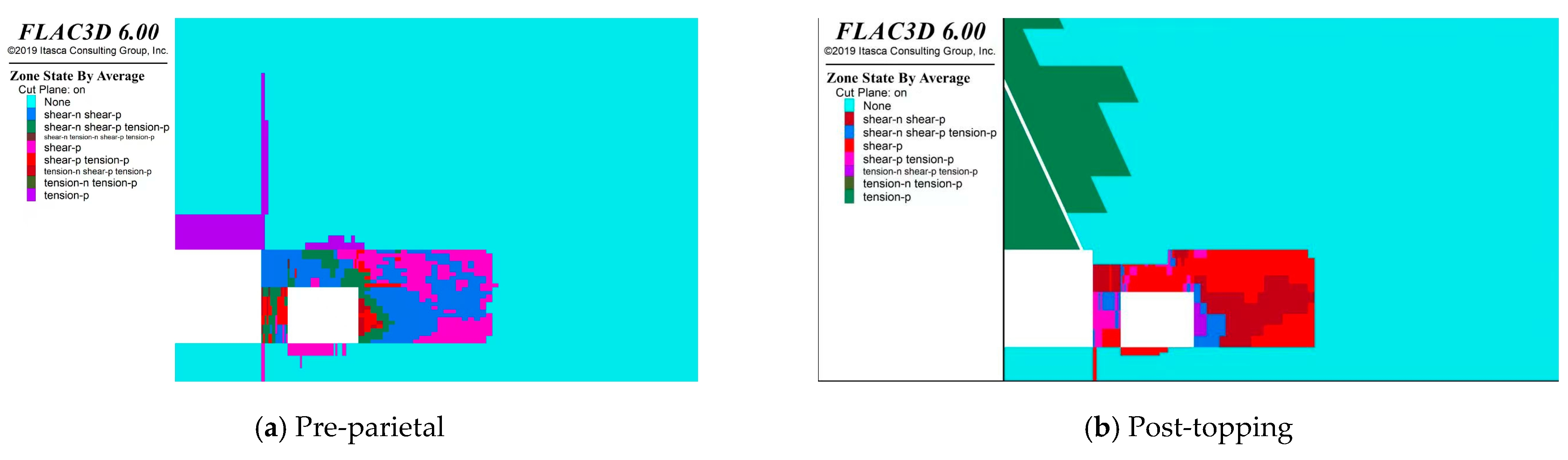

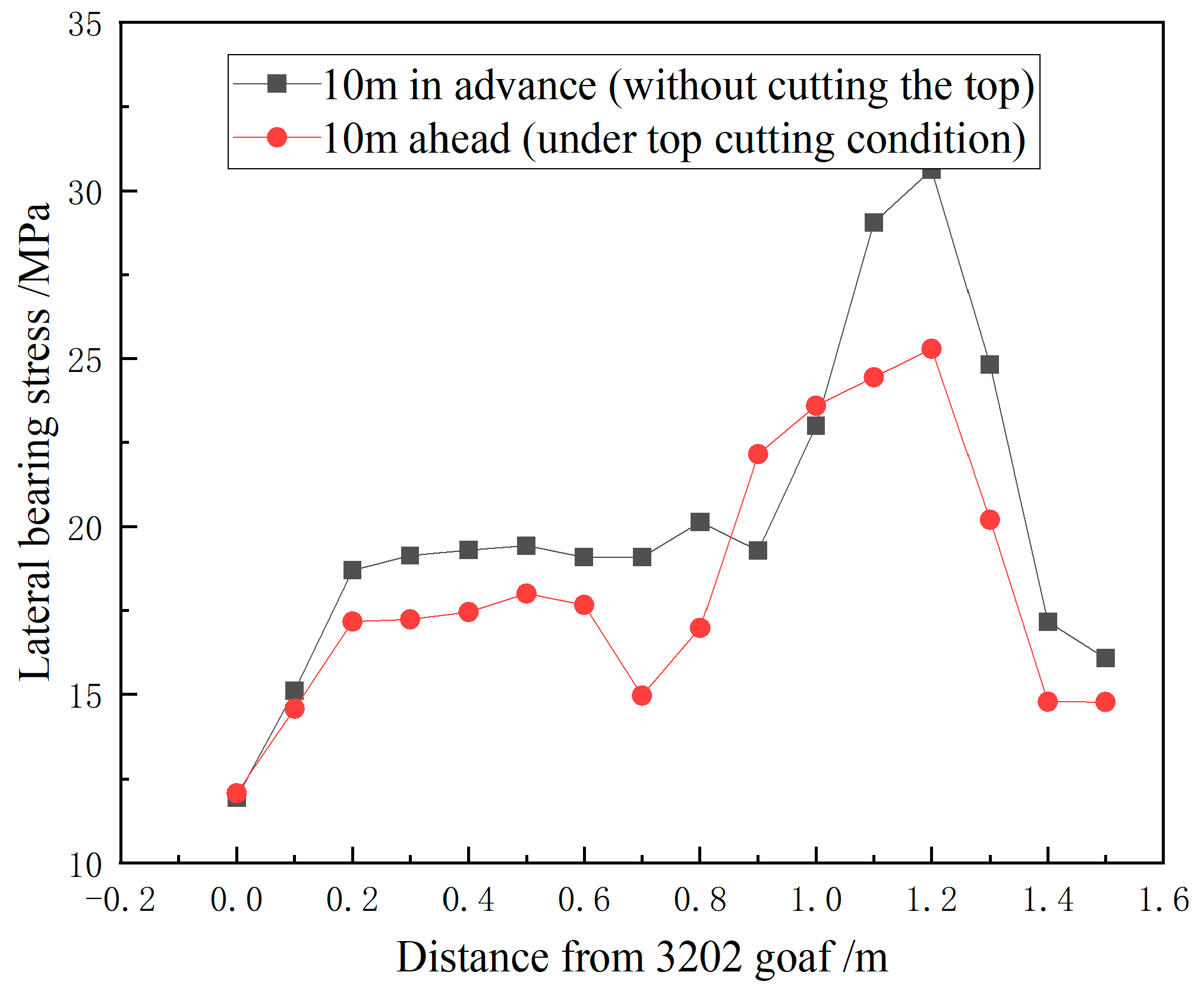

5.3. Numerical Simulation Analysis of Flexographic Concrete-Wall Side Before and After Top Cutting

6. Field Industrial Test

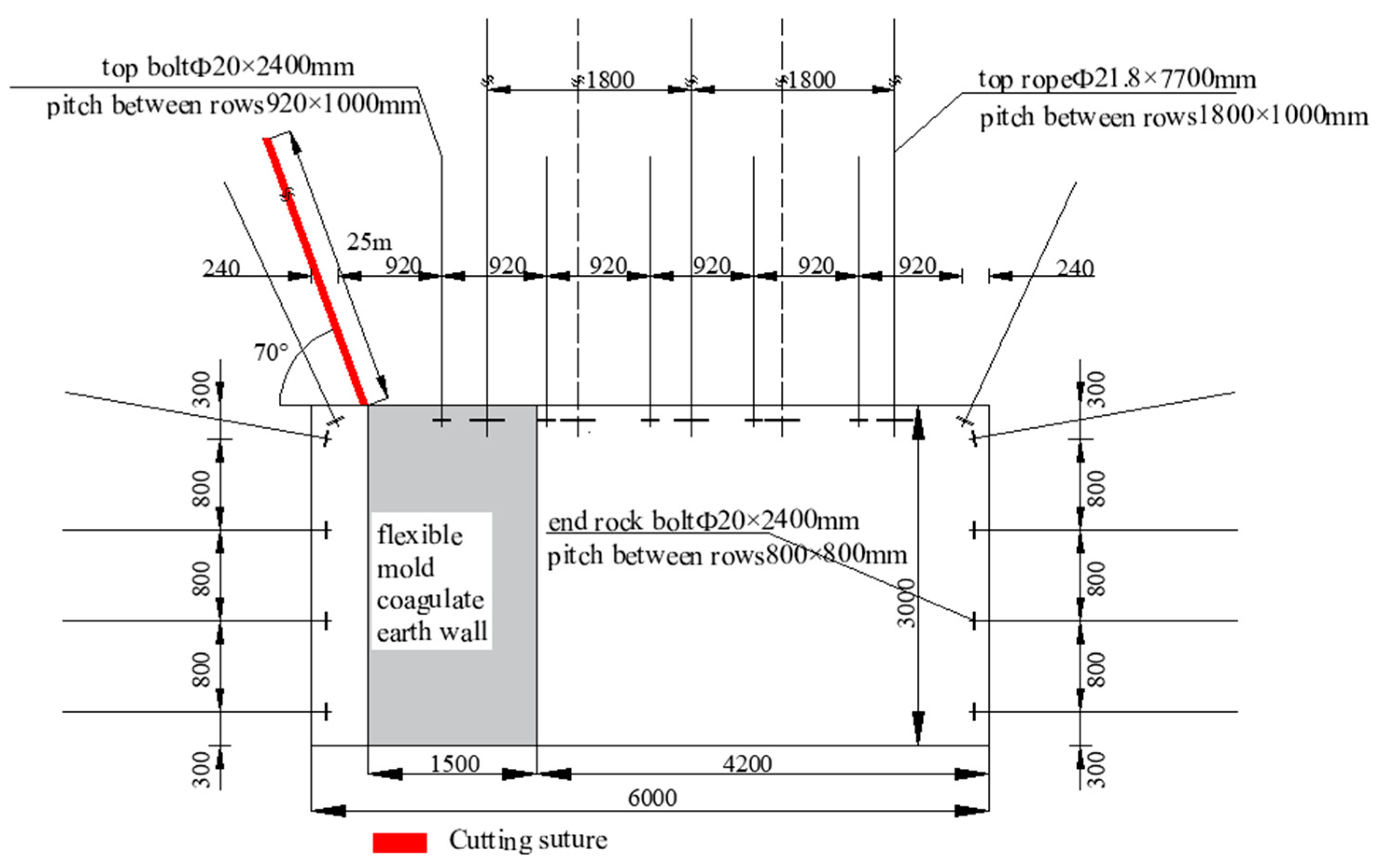

6.1. Top-Cutting Scheme

6.2. Mine Pressure Monitoring-Point Layout

6.3. Observation Result

6.3.1. Working Resistance Analysis of End Hydraulic Support

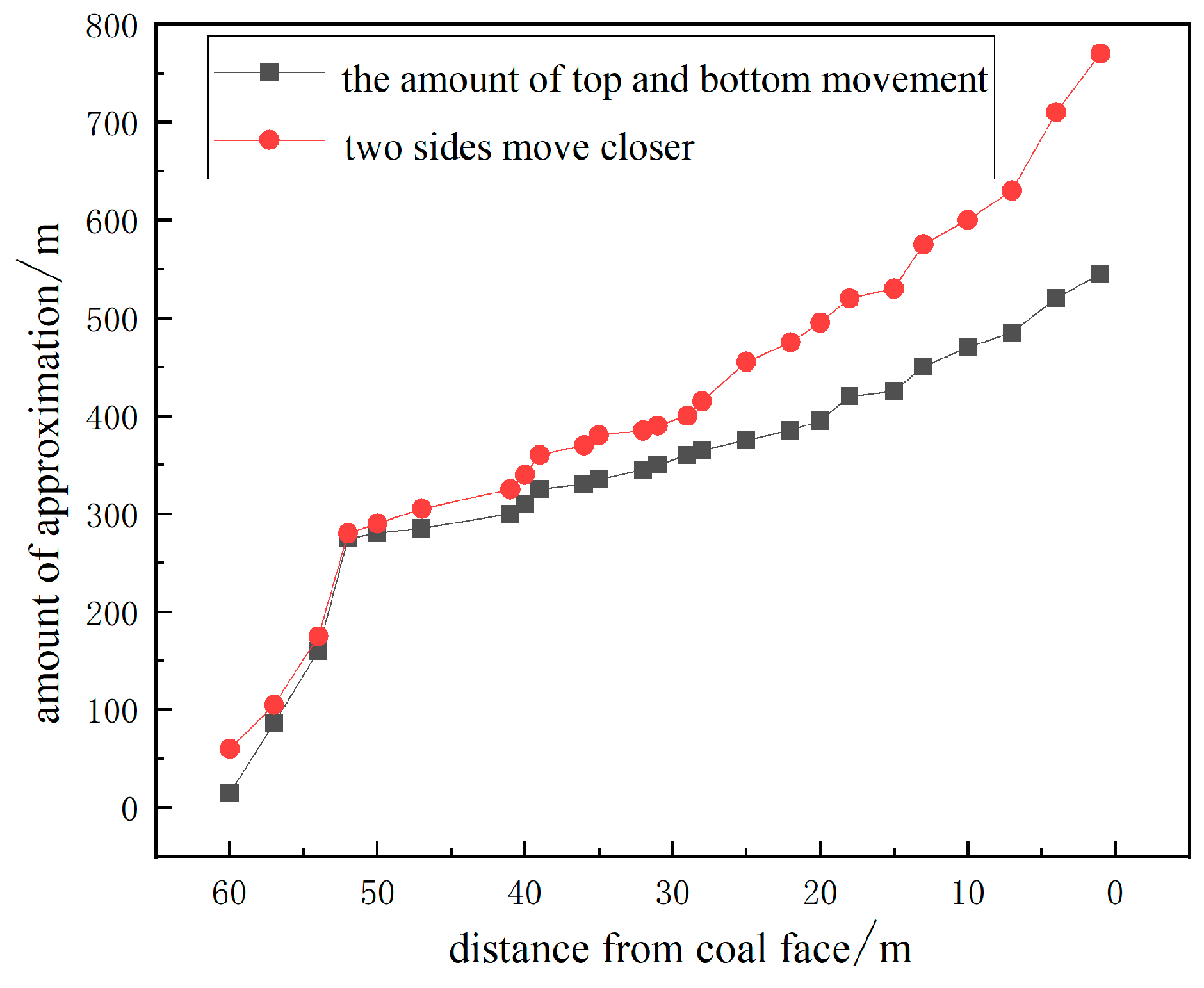

6.3.2. Observation Results of Roadway Deformation

7. Conclusions

- (1)

- Blast-induced roof cutting effectively reduces the length of the cantilever beam on the flexible formwork wall side, transforming the overlying strata boundary structure from a large-scale F-type configuration to a small-scale F-type configuration. This structural modification decreases the load per unit area acting on the flexible concrete wall, thereby mitigating lateral abutment stress and reducing the load imposed on the floor heave-affected zone. Consequently, these mechanisms synergistically achieve robust control over roadway surrounding rock deformation.

- (2)

- Compared with non-cutting scenarios, roof cutting significantly reduces plastic zone damage in the roof strata adjacent to the cutting line of the flexible concrete wall gob-side entry retaining roadway. Quantitatively, the floor plastic zone area decreases by 48.0%, the solid coal rib plastic zone diminishes by 18.8%, and the average vertical stress is reduced by 11.7%. These metrics conclusively demonstrate the pronounced pressure relief effect of roof cutting on the flexible concrete wall side.

- (3)

- Compared to the wide coal pillar side, the face-end hydraulic supports on the pillarless gob-side entry retaining side after roof cutting exhibit distinct differences in the distribution patterns and magnitudes of working resistance. As the interval resistance increases, the average working resistance of hydraulic supports on the wide coal pillar side demonstrates uniform distribution, ranging from 2635 to 4455 kN. In contrast, the pillarless side post-cutting shows a declining trend in the frequency distribution of average working resistance, with values ranging from 1403 to 4356 kN, resulting in an average reduction of 30% compared to the non-cutting scenario.

- (4)

- After roof cutting for pressure relief, the surrounding rock deformation control effects of the track entry on the gob-side entry side and the transportation entry on the 50 m wide coal pillar side are comparable. Although the convergence of the two sidewalls in the track entry on the gob-side entry side remains higher than that on the wide coal pillar side, the average convergence of the roof and floor is controlled within 300 mm, the floor heave convergence is within 240 mm, and the average convergence of the two sidewalls is within 350 mm. This effectively ensures safe production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, M.; Gao, Y.; Gai, Q.; Yang, J. Mechanical principle and mining methods of automagical entry formation without coal pillars. Coal Sci. Technol. 2023, 51, 19–30. [Google Scholar]

- Lang, D.; Chen, S.; Yuan, H.; Yu, J.; Yu, Y.; Luo, S.; Hu, B.; Xie, P. Study of Reasonable Roof Cutting Parameters of Dense-Drilling Roof Cutting and Pressure Relief Self-Forming Roadway in Non-Pillar Mining. Appl. Sci. 2025, 15, 2685. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Ma, Q.; Zheng, Y.; Song, G.; Yan, W.; Zhang, Y.; Hu, L. The Floor Heave Mechanism and Control Technology of Gob-Side Entry Retaining of Soft Rock Floor. Sustainability 2023, 15, 6074. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Bai, J.B.; Wang, X.G.; Xu, Y.; Yan, S.; Liu, H.L.; Wu, W.; Zhang, W.G. Review and development of surrounding rock control technology for gob-side entry retaining in China. J. China Coal Soc. 2023, 48, 3979–4000. [Google Scholar]

- Qiang, X.; Li, J.; Chen, C.; Dong, J.; Zheng, Y.; Chen, Z. Nonuniform Deformation Instability Mechanism of Gob-Side Entry Retained in Inclined Coal Seam and Stability Control. Appl. Sci. 2023, 13, 8727. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Kamenets, V. Stress environment around head entries with pillarless gobside entry retaining through numerical simulation incorporating the two type of filling wall. IOP Conf. Ser. Earth Environ. Sci. 2022, 1049, 012011. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Skrzypkowski, K.; Isaienkov, O.; Zagórski, K.; Zagórska, A. Floor Heave Control in Gob-Side Entry Retaining by Pillarless Coal Mining with Anti-Shear Pile Technology. Appl. Sci. 2024, 14, 4992. [Google Scholar] [CrossRef]

- Sakhno, I.; Isayenkov, O.; Rodzin, S. Local reinforcing of footing supported in the destroyed rock massif. Min. Miner. Depos. 2017, 11, 9–16. [Google Scholar] [CrossRef]

- Huang, B.X.; Liu, C.Y.; Zhen, B.S.; Cheng, Q.Y. Distribution abutment pressures on laneway pillars for superwide isolated fully mechanized top coal caving face. Chin. J. Geotech. Eng. 2007, 29, 932–937. [Google Scholar]

- Liu, C.Y.; Huang, B.X.; Meng, X.J.; Yang, P.J.; Chen, L.G. Research on abutment pressure distribution law overlength isolated fully-mechanized top coal caving face. Chin. J. Rock Mech. Eng. 2007, 26, 2761–2766. [Google Scholar]

- Fan, Z.; Fu, S.; Pan, L. Study on caving structure characteristics of overlying strata in deep super long island working face. Coal Eng. 2020, 52, 86–90. [Google Scholar]

- Miao, X.X.; Qian, M.G. Broken feature of key strata and its influence on rock pressure in super-length fully-mechanized coal face. Chin. J. Rock Mech. Eng. 2003, 22, 45–47. [Google Scholar]

- Zhao, T. Application Research on the Flexible Formwork of Pumped-concrete Support in Gob-side Entry Retaining in Shallow Coal Seam. Master’s Thesis, Xi’an University Of Science And Technology, Xi’an, China, 2014. [Google Scholar]

- Wu, S. Study on deformation mechanism and construction technology of surrounding rock of gob side entry retaining with flexible formwork wall. Coal Sci. Technol. 2022, 50, 127–135. [Google Scholar]

- Pang, D.; Zhou, Y.; Niu, X.; He, K.; Li, C.; Chen, Z. Research on the Mechanical Properties of Flexible Material Backfilling Wall in Gob-Side Entry Retaining. Minerals 2022, 12, 1020. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Cao, X. Design of small coal pillar reinforcement and double flexible-formwork wall support for retained entry in extra thick coal seam. Coal Eng. 2022, 54, 46–51. [Google Scholar]

- Malashkevych, D.; Petlovanyi, M.; Sai, K.; Zubko, S. Research into the coal quality with a new selective mining technology of the waste rock accumulation in the mined-out area. Min. Miner. Depos. Sci. 2022, 16, 103–114. [Google Scholar] [CrossRef]

- Kostecki, T.; Spearing, A.J.S. Spearing, Influence of backfill on coal pillar strength and floor bearing capacity in weak floor conditions in the Illinois Basin. Int. J. Rock Mech. Min. Sci. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- Habib, K.M.; Vennes, I.; Mitri, H. Laboratory investigation into the use of soundless chemical demolitions agents for the breakage of hard rock. Int. J. Coal Sci. Technol. 2022, 9, 70. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S. Directional fracturing of rock by soundless chemical demolition agents. Heliyon Sci. 2024, 104, e26068. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, X. Stability analysis and numerical simulation of hinged arch structure forfractured beam in super-long mining workface under shallow seam. Rock Soil Mech. 2016, 37, 203–209. [Google Scholar]

- Li, H.; Zhang, B.; Guo, J.; Yang, Y.; Cui, J. Surrounding rock control technology of roof cutting for pressure relief insmall coal pillar roadway under secondary mining. Min. Saf. Environ. Prot. 2024, 51, 90–97. [Google Scholar]

- Zhu, G.A.; Dou, L.M.; Ding, Z.W.; Xie, J.H. Pre-evaluation for rock burst risks in island longwall panel before mining. Chin. J. Geotech. Eng. 2018, 40, 819–827. [Google Scholar]

- Dou, L.; He, H. Study of OX-F-T spatial structure evolution of overlying strata in coal mine. Chin. J. Rock Mech. Eng. 2012, 31, 453–460. [Google Scholar]

- Huang, P.; Li, M.; Xie, J.; Ren, G.; Zhao, C.; Simao, F.C. Mechanics Model of Floor Heave: Case Study on Thin Coal Seam with Soft Roof and Floor. Appl. Sci. 2023, 13, 9102. [Google Scholar] [CrossRef]

- Mo, S.; Sheffield, P.; Corbett, P.; Ramandi, H.L.; Oh, J.; Canbulat, I.; Saydam, S. A numerical investigation into floor buckling mechanisms in underground coal mine roadways. Tunn. Undergr. Space Technol. 2020, 103, 103497. [Google Scholar] [CrossRef]

- Yang, P.; Liu, C. Structure Forms of Basic Roof and Reasonable Supporting Parameters in Ends of Fully-Mechanized Top Caving Face. J. Min. Saf. Eng. 2012, 29, 26–32. [Google Scholar]

- Pang, Y.H.; Gong, S.X.; Liu, Q.B.; Wang, H.B.; Lou, J.F. Overlying strata fracture and instability process andsupport loading prediction in deep working face. J. Min. Saf. Eng. 2021, 38, 304–316. [Google Scholar]

| Density/kg·10−3 | Poisson’s ratio | Tensile Strength/MPa | Compressive Strength/MPa | Cohesion/MPa | Internal Friction Angle/° | |

|---|---|---|---|---|---|---|

| Flexible formwork wall | 2360 | 0.20 | 2.0 | 30 | 3.2 | 38.9 |

| Strain | Stress/MPa | Strain | Stress/MPa | Strain | Stress/MPa | Strain | Stress/MPa |

|---|---|---|---|---|---|---|---|

| 0.00 | 0.00 | 0.09 | 0.37 | 0.18 | 1.16 | 0.27 | 4.21 |

| 0.01 | 0.03 | 0.10 | 0.42 | 0.19 | 1.31 | 0.28 | 5.18 |

| 0.02 | 0.06 | 0.11 | 0.49 | 0.20 | 1.48 | 0.29 | 6.61 |

| 0.03 | 0.10 | 0.12 | 0.56 | 0.21 | 1.68 | 0.30 | 8.89 |

| 0.04 | 0.13 | 0.13 | 0.63 | 0.22 | 1.92 | 0.31 | 13.12 |

| 0.05 | 0.17 | 0.14 | 0.71 | 0.23 | 2.20 | 0.32 | 23.69 |

| 0.06 | 0.22 | 0.15 | 0.81 | 0.24 | 2.54 | 0.33 | 97.74 |

| 0.07 | 0.26 | 0.16 | 0.91 | 0.25 | 2.96 | ||

| 0.08 | 0.31 | 0.17 | 1.03 | 0.26 | 3.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Guo, J. Research on the Deformation and Failure Mechanism of Flexible Formwork Walls in Gob-Side-Entry Retaining of Ultra-Long Isolated Mining Faces and Pressure Relief-Control Technology via Roof Cutting. Appl. Sci. 2025, 15, 5833. https://doi.org/10.3390/app15115833

Wang H, Guo J. Research on the Deformation and Failure Mechanism of Flexible Formwork Walls in Gob-Side-Entry Retaining of Ultra-Long Isolated Mining Faces and Pressure Relief-Control Technology via Roof Cutting. Applied Sciences. 2025; 15(11):5833. https://doi.org/10.3390/app15115833

Chicago/Turabian StyleWang, Heng, and Junqing Guo. 2025. "Research on the Deformation and Failure Mechanism of Flexible Formwork Walls in Gob-Side-Entry Retaining of Ultra-Long Isolated Mining Faces and Pressure Relief-Control Technology via Roof Cutting" Applied Sciences 15, no. 11: 5833. https://doi.org/10.3390/app15115833

APA StyleWang, H., & Guo, J. (2025). Research on the Deformation and Failure Mechanism of Flexible Formwork Walls in Gob-Side-Entry Retaining of Ultra-Long Isolated Mining Faces and Pressure Relief-Control Technology via Roof Cutting. Applied Sciences, 15(11), 5833. https://doi.org/10.3390/app15115833