Data Spaces in Manufacturing and Supply Chains: A Review and Insights from European Initiatives

Abstract

1. Introduction

- What are the bibliometric trends and patterns in the academic literature concerning data spaces in the context of manufacturing and supply chains?

- What are the main thematic contributions and conceptual perspectives in the existing scientific literature on data spaces in this context?

- What initial evidence and practical insights can be drawn from ongoing European initiatives developing and implementing data spaces in manufacturing and supply chains?

2. Materials and Methods

2.1. Literature Search and Selection

2.2. Bibliometric Analysis

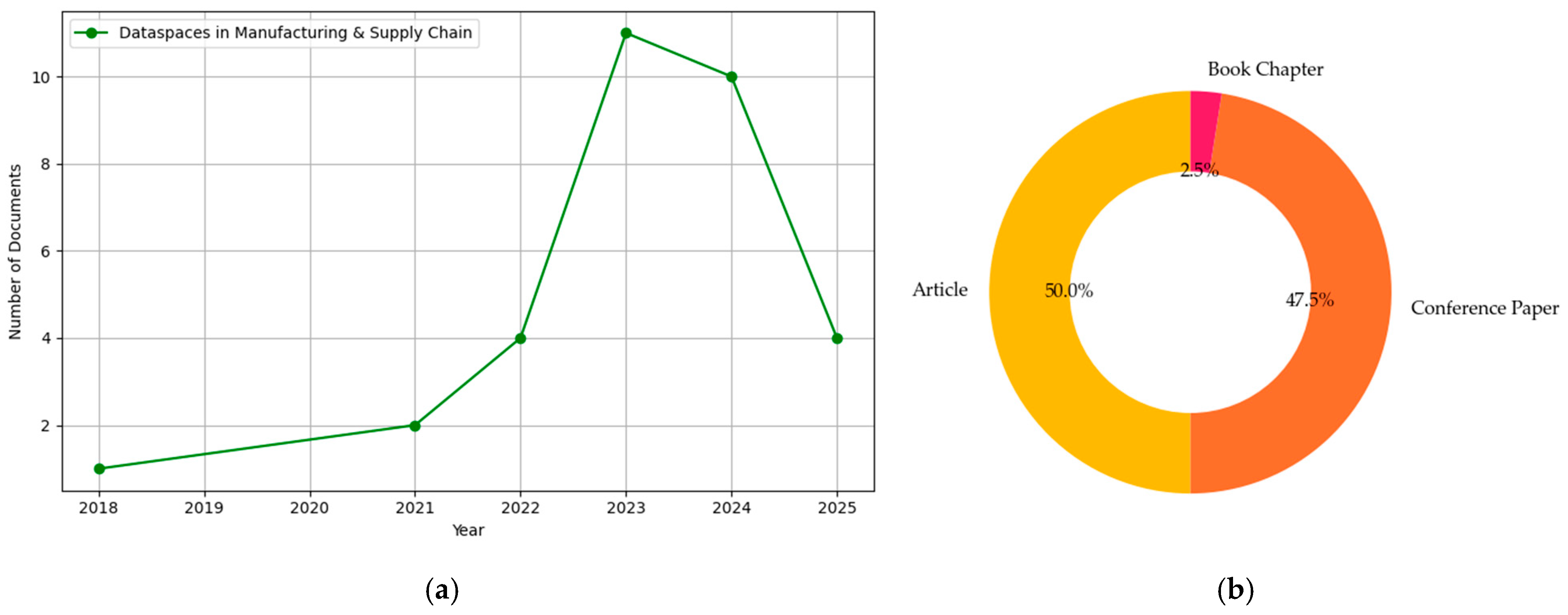

- Yearly publication trends: to track the growth and timing of scholarly interest in the topic.

- Distribution by document type: to assess the maturity of the field based on the balance between exploratory (conference) and consolidated (journal/review) outputs.

- Publishing sources: to identify core journals and conferences and understand the disciplinary orientation of the research.

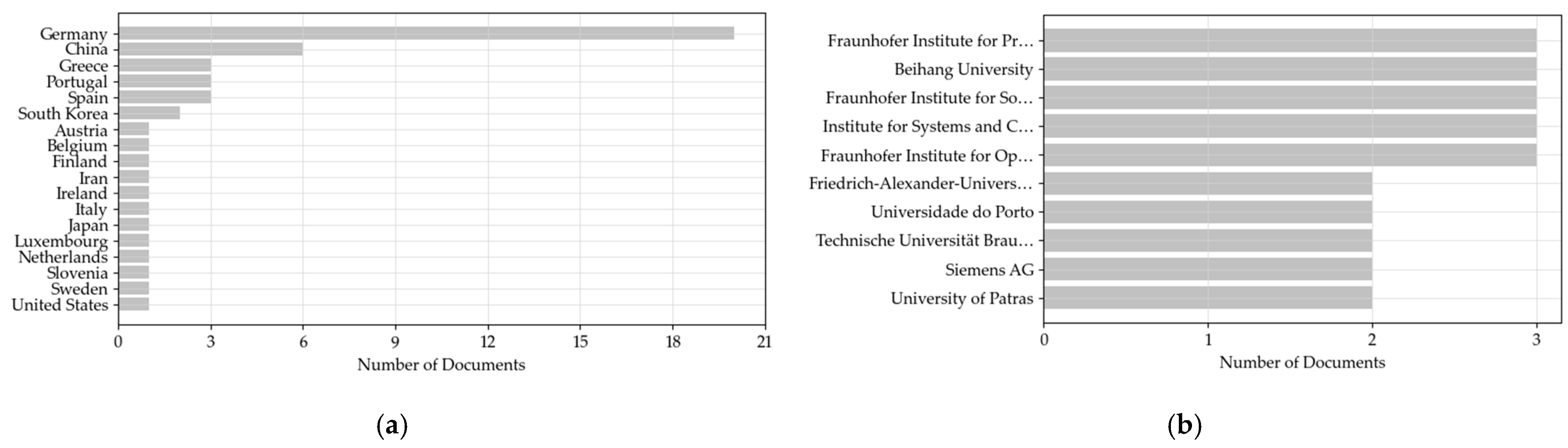

- Geographic and institutional affiliations: to map regional and institutional research activity and highlight key academic and industrial contributors.

- Most prolific authors: to recognize leading researchers shaping the field and influencing ongoing developments.

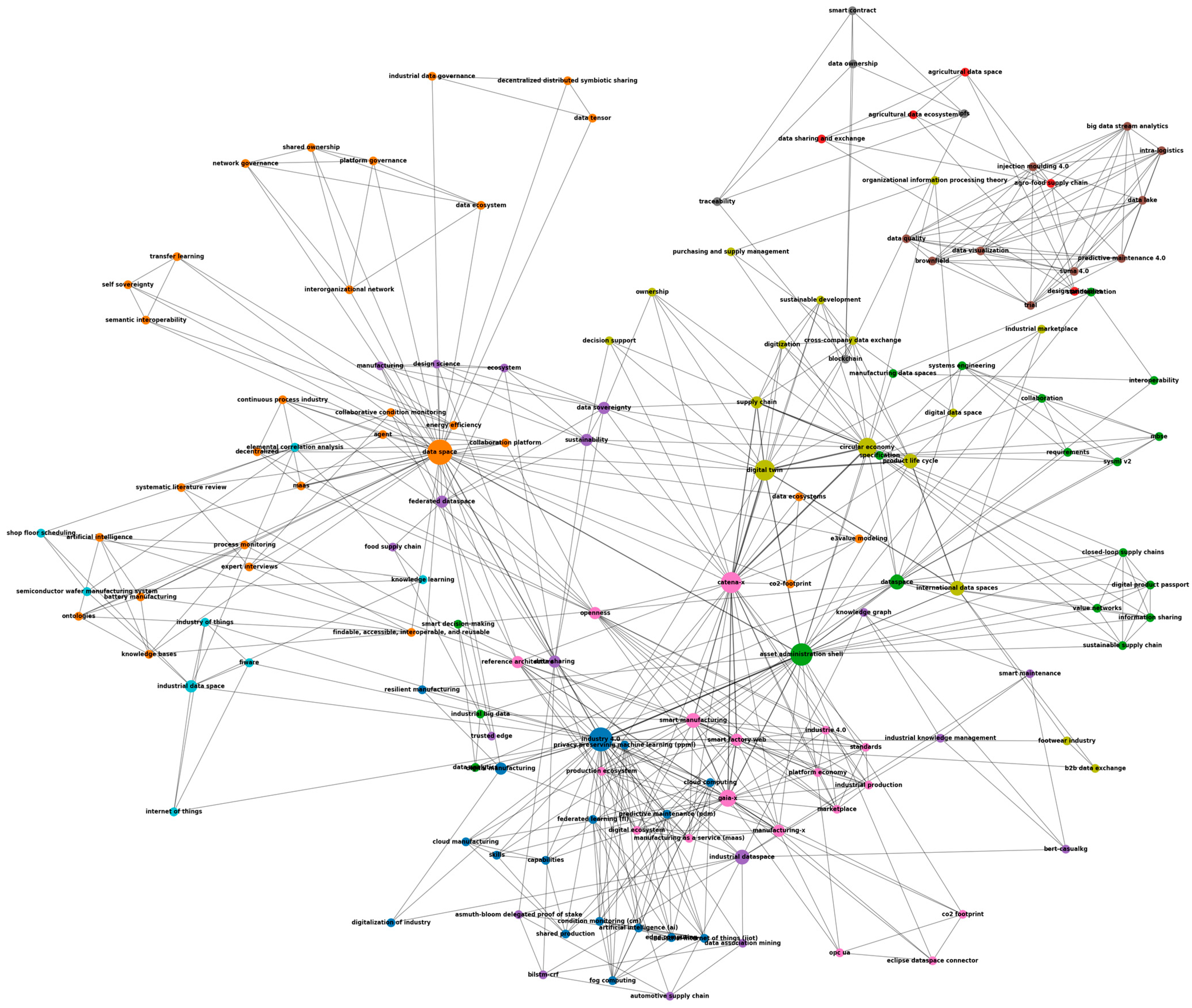

- Keyword co-occurrence analysis: to explore the thematic structure of the literature, identify dominant research clusters, and reveal how key concepts interconnect across publications.

2.3. Content Analysis of Scientific Contributions

- Industrial domain: to identify which sectors (e.g., automotive, energy, food) are leading or emerging in the adoption of data spaces and to assess cross-sectoral applicability.

- Operational objectives: to determine the operational focus of data space use (e.g., cost efficiency, sustainability, resilience).

- Type of integration: to distinguish between vertical integration (across supply chain tiers) and horizontal integration (among peer organizations), which reflect different collaboration models and data-sharing structures.

- Integrated technologies: to capture the technological ecosystems (e.g., IoT, digital twins, AI) that integrate with data space functionality and enable data-driven applications.

- Types of shared data: to analyze what categories of data (e.g., production metrics, maintenance logs, environmental indicators) are most commonly exchanged, indicating the functional scope of data spaces.

- Use of standards and architectures: to examine adherence to recognized frameworks (e.g., International Data Space (IDS), Gaia-X), which is essential for interoperability, scalability, and compliance with governance models.

2.4. Analysis of European Data Space Initiatives

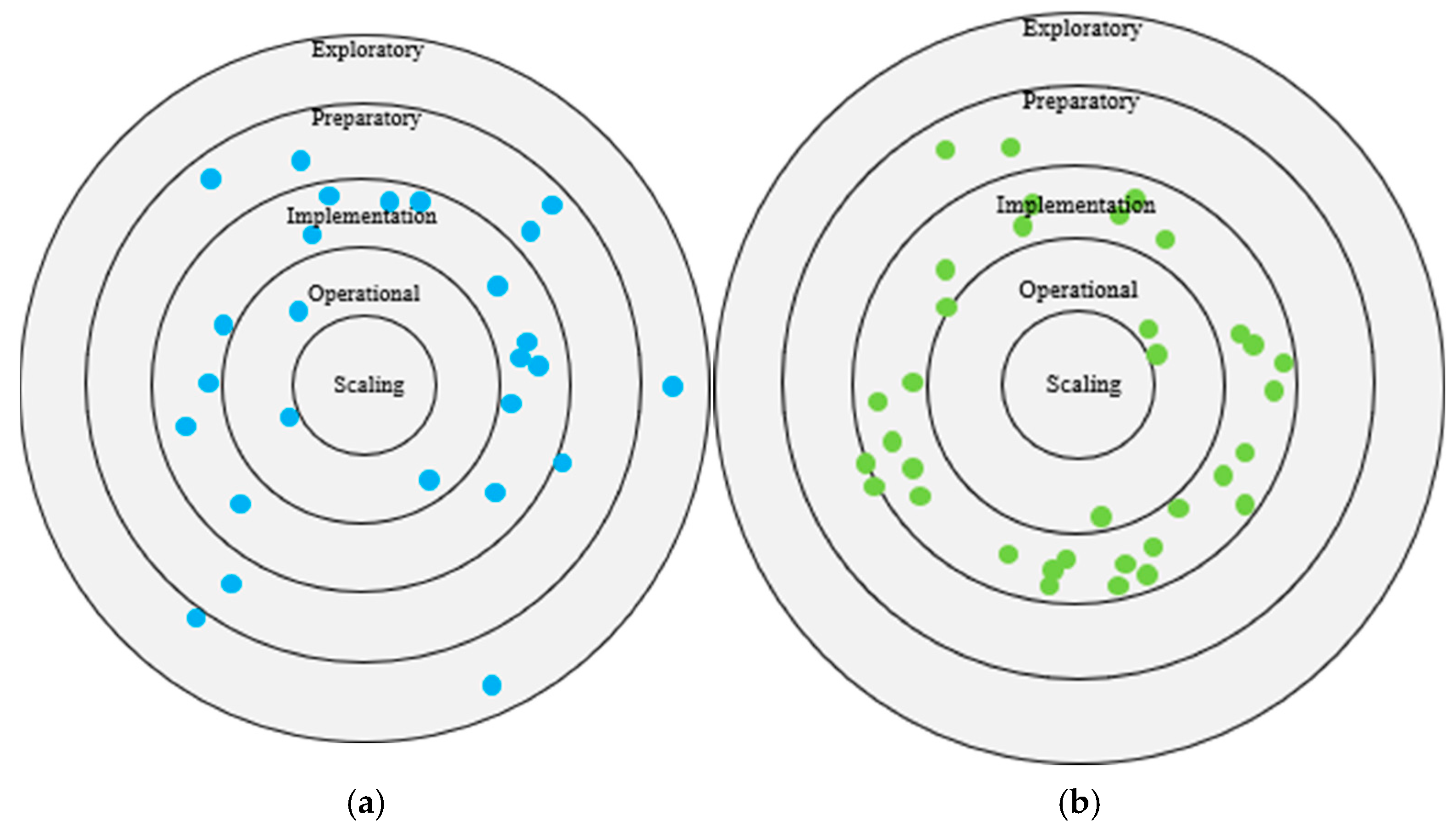

- Maturity levels: the five-stage model (Exploratory, Preparatory, Implementation, Operational, Scaling) captures the lifecycle progression of initiatives, indicating their readiness and deployment status.

- Architectural foundations: Identifying the use of frameworks like IDS or Gaia-X allows assessment of technical alignment with recognized standards and interoperability models.

- Design principles: core principles such as data sovereignty, interoperability, and trust reflect the governance philosophy and foundational values shaping each initiative.

- Funding sources: analyzing the role of EU, national, and private funding highlights the degree of public investment and institutional prioritization of data spaces.

- Business models: classification into patterns like joint innovation or marketplace structures provides insight into the economic rationale and collaboration modes behind the initiatives.

- Geographic distribution: mapping projects by country enables the identification of regional leadership, policy alignment, and cross-country engagement in data space development.

3. Results

3.1. What Are the Bibliometric Trends and Patterns in the Academic Literature Concerning Data Spaces in the Context of Manufacturing and Supply Chains?

3.2. What Are the Main Thematic Contributions and Conceptual Perspectives in the Existing Scientific Literature on Data Spaces in This Context?

3.3. What Initial Evidence and Practical Insights Can Be Drawn from Ongoing European Initiatives That Are Developing and Implementing Data Spaces in Manufacturing and Supply Chains?

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Paper | Examined Sector | Operational Objective | Integration Type | Integrated Technologies | Shared Data | Standards Architecture |

|---|---|---|---|---|---|---|

| [40] | Automotive | S, R | Within supply chain | DT | Product | Gaia-X, AAS, IDS, Catena-X |

| [41] | Automotive | R | Within supply chain | None | Production | Gaia-X |

| [42] | Automotive | R, S | Within supply chain | DT | Maintenance | IDS-RAM |

| [43] | Automotive | S | Within supply chain | None | Product, Maintenance | None |

| [44] | Automotive | R | Within supply chain | BC | Production, Quality, Inventory, Energy | AAS |

| [45] | Electronic, Automotive | E | Within company | IoT, ML, BDA | Quality, Maintenance | IDS |

| [46] | Food | S | Within supply chain | ML, IoT | Product | Gaia-X |

| [47] | Food | S | Within supply chain | BC | Product | None |

| [48] | Food | R | Within supply chain | IoT, BDA, ML | Maintenance | Gaia-X, IDS |

| [49] | Machining | R | Within supply chain | ML | Product, Production | AAS, IDS |

| [50] | Machining | E | Within company | IoT, BDA | Quality, Maintenance | IDS, FIWARE |

| [51] | Machining | E, R | Within supply chain | None | Product, Production | Gaia-X, AAS |

| [52] | Battery | S | Within supply chain | DT | Product, Sustainability | IDS, AAS |

| [53] | Battery | R | Within company | ML | Product | AAS |

| [54] | Aerospace | E | Within sector | None | Product | Gaia-X |

| [55] | Footwear | E | Within supply chain | IoT | Supply, Production | IDS |

| [56] | Nuclear | E | Within company | IoT, BDA, ML | Product, Production, Maintenance | None |

| [57] | Nuclear | R | Within company | IoT, ML | Maintenance | None |

| [58] | Semiconductor | E | Within company | IoT, DT | Production | None |

| [59] | Home Appliance | E, R | Within supply chain | None | Production | AAS |

| [60] | Heavy Equipment | R | Within company, within supply chain | None | Production | None |

| [61] | PrecisionEngineering | E | Within supply chain | None | Product | None |

| [62] | None | E | Within company | ML | Energy | None |

| [63] | Plastic/Metal | E | Within supply chain | DT, IoT | None | IDS |

| [64] | Steel casting/Oil refining | E | Within supply chain | BC | None | IDS |

| [65] | Not Specified | E, S | Within company | None | Quality | None |

| [66] | Not Specified | S, R | Within supply chain | None | Production, Demand, Sustainability | AAS, OPC UA, EDC |

| [67] | Not Specified | S | Within supply chain | None | Production | IDS, Gaia-X, AAS |

| [68] | Simulated | S, R | Within supply chain | IoT | Production, Product | IDS, Gaia-X |

| [69] | Electronic | R | Within company | None | Production | None |

| [70] | Steel | R | Within company | DT, ML, IoT | Production | AAS, IDS, Gaia-X |

| [71] | Simulated | R | Within supply chain | DT, ML, IoT | Production | IDS, Gaia-X, AAS |

References

- Omar, A.; Davis-Sramek, B.; Myers, M.B.; Mentzer, J.T. A global analysis of orientation, coordination, and flexibility in supply chains. J. Bus. Logist. 2012, 33, 128–144. [Google Scholar] [CrossRef]

- Mattsson, L.G. Reorganization of distribution in globalization of markets: The dynamic context of supply chain management. Supply Chain Manag. Int. J. 2003, 8, 416–426. [Google Scholar] [CrossRef]

- Erfurth, T.; Bendul, J. Integration of global manufacturing networks and supply chains: A cross case comparison of six global automotive manufacturers. Int. J. Prod. Res. 2018, 56, 7008–7030. [Google Scholar] [CrossRef]

- Bianchini, D.; Fapanni, T.; Garda, M.; Leotta, F.; Mecella, M.; Rula, A.; Sardini, E. Digital Thread for Smart Products: A Survey on Technologies, Challenges and Opportunities in Service-Oriented Supply Chains. IEEE Access 2024, 12, 125284–125305. [Google Scholar] [CrossRef]

- Spanaki, K.; Gürgüç, Z.; Adams, R.; Mulligan, C. Data supply chain (DSC): Research synthesis and future directions. Int. J. Prod. Res. 2018, 56, 4447–4466. [Google Scholar] [CrossRef]

- Chatfield, D.C.; Kim, J.G.; Harrison, T.P.; Hayya, J.C. The Bullwhip Effect-Impact of Stochastic Lead Time, Information Quality, and Information Sharing: A Simulation Study. Prod. Oper. Manag. 2004, 13, 340–353. [Google Scholar] [CrossRef]

- Leuschner, R.; Rogers, D.S.; Charvet, F.F. A meta-analysis of supply chain integration and firm performance. J. Supply Chain Manag. 2013, 49, 34–57. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Qin, L.; Menhas, R.; Lei, G. Strategic Sustainability and Operational Initiatives in Small- and Medium-Sized Manufacturers: An Empirical Analysis. Sustainability 2023, 15, 6330. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Zhang, Q. Impact of sustainable practices on sustainable performance: The moderating role of supply chain vis-ibility. J. Manuf. Technol. Manag. 2021, 32, 1421–1443. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Zhang, Q.; Ou, J.; Saqib, K.A.; Majeed, S.; Razzaq, A. Education for sustainable development in Pakistani higher education institutions: An exploratory study of students’ and teachers’ perceptions. Int. J. Sustain. High. Educ. 2020, 21, 1249–1267. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Ikram, M.; Qin, L. Mediating role of eWOM’s in green behavior interaction and corporate social responsibility: A stakeholder theory perspective. Int. J. Ethics Syst. 2025. ahead of print. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Xu, G.; Luo, Q. Green Manufacturing for a Green Environment from Manufacturing Sector in Guangdong Prov-ince: Mediating Role of Sustainable Operations and Operational Transparency. Appl. Sci. 2024, 14, 10637. [Google Scholar] [CrossRef]

- Gabellini, M.; Calabrese, F.; Regattieri, A.; Ferrari, E. Multivariate Multi-Output LSTM for Time Series Forecasting with In-termittent Demand Patterns. In Proceedings of the 27th Summer School Francesco Turco, Sanremo, Italy, 7–9 September 2022; 2022; pp. 1–7. [Google Scholar]

- Gabellini, M.; Civolani, L.; Regattieri, A.; Calabrese, F. A Data Model for Predictive Supply Chain Risk Management. In Proceedings of the CARV 2023, Bologna, Italy, 20–23 June 2023; Lecture Notes in Mechanical Engineering. pp. 365–372. [Google Scholar] [CrossRef]

- Gabellini, M.; Civolani, L.; Calabrese, F.; Bortolini, M. A Deep Learning Approach to Predict Supply Chain Delivery Delay Risk Based on Macroeconomic Indicators: A Case Study in the Automotive Sector. Appl. Sci. 2024, 14, 4688. [Google Scholar] [CrossRef]

- Gabellini, M.; Calabrese, F.; Civolani, L.; Regattieri, A.; Mora, C. A Data-Driven Approach to Predict Supply Chain Risk Due to Suppliers’ Partial Shipments. In Smart Innovation, Systems and Technologies; Scholz, S.G., Howlett, R.J., Setchi, R., Eds.; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2024; Volume 377, pp. 227–237. [Google Scholar] [CrossRef]

- Gabellini, M.; Mak, S.; Schoepf, S.; Brintrup, A.; Regattieri, A. A continuous training approach for risk informed supplier selection and order allocation. Prod. Manuf. Res. 2025, 13, 2447035. [Google Scholar] [CrossRef]

- Regattieri, A.; Gabellini, M.; Calabrese, F.; Civolani, L.; Galizia, F.G. Balancing Data Acquisition Benefits and Ordering Costs for Predictive Supplier Selection and Order Allocation. Appl. Sci. 2024, 14, 4306. [Google Scholar] [CrossRef]

- Mahmud, P.; Paul, S.K.; Azeem, A.; Chowdhury, P. Evaluating supply chain collaboration barriers in smalland medium-sized enterprises. Sustainability 2021, 13, 7449. [Google Scholar] [CrossRef]

- Shukla, R.K.; Garg, D.; Agarwal, A. Modeling barriers in supply chain coordination. Int. J. Manag. Sci. Eng. Manag. 2012, 7, 69–80. [Google Scholar] [CrossRef]

- Kembro, J.; Selviaridis, K. Exploring information sharing in the extended supply chain: An interdependence perspective. Supply Chain Manag. 2015, 20, 455–470. [Google Scholar] [CrossRef]

- Steinfield, C.; Markus, M.L.; Wigand, R.T. Through a glass clearly: Standards, architecture, and process transparency in global supply chains. J. Manag. Inf. Syst. 2011, 28, 75–108. [Google Scholar] [CrossRef]

- Yoon, J.; Talluri, S.; Rosales, C. Procurement decisions and information sharing under multi-tier disruption risk in a supply chain. Int. J. Prod. Res. 2020, 58, 1362–1383. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, F.; Tan, K.H. Effects of managerial ties and trust on supply chain information sharing and supplier opportunism. Int. J. Prod. Res. 2014, 52, 7046–7061. [Google Scholar] [CrossRef]

- Coche, E.; Kolk, A.; Ocelík, V. Unravelling cross-country regulatory intricacies of data governance: The relevance of legal insights for digitalization and international business. J. Int. Bus. Policy 2024, 7, 112–127. [Google Scholar] [CrossRef]

- Surucu-Balci, E.; Iris, Ç.; Balci, G. Digital information in maritime supply chains with blockchain and cloud platforms: Supply chain capabilities, barriers, and research opportunities. Technol. Forecast. Soc. Change 2024, 198, 122978. [Google Scholar] [CrossRef]

- Smith, K.; Seligman, L.; Swarup, V. Everybody Share: The Challenge of Data-Sharing Systems. Computer 2008, 41, 54–61. [Google Scholar] [CrossRef]

- Nylund, P.A.; Brem, A. Standardization in innovation ecosystems: The promise and peril of dominant platforms. Technol. Forecast. Soc. Change 2023, 194, 122714. [Google Scholar] [CrossRef]

- Damsgaard, J.; Truex, D. Binary trading relations and the limits of EDI standards: The Procrustean bed of standards. Eur. J. Inf. Syst. 2000, 9, 173–188. [Google Scholar] [CrossRef]

- Chandra, A.; Weissman, J.; Heintz, B. Decentralized edge clouds. IEEE Internet Comput. 2013, 17, 70–73. [Google Scholar] [CrossRef]

- Alsamhi, S.H.; Hawbani, A.; Kumar, S.; Timilsina, M.; Al-Qatf, M.; Haque, R.; Nashwan, F.; Zhao, L.; Curry, E. Empowering Dataspace 4.0: Unveiling Promise of Decentralized Data-Sharing. IEEE Access 2024, 12, 112637–112658. [Google Scholar] [CrossRef]

- Csernatoni, R. The EU’s hegemonic imaginaries: From European strategic autonomy in defence to technological sovereignty. Eur. Secur. 2022, 31, 395–414. [Google Scholar] [CrossRef]

- König, P.D. Fortress Europe 4.0? An analysis of EU data governance through the lens of the resource regime concept. Eur. Policy Anal. 2022, 8, 484–504. [Google Scholar] [CrossRef]

- Culotta, C.; Blome, C.; Henke, M. Theories of digital platforms for supply chain management: A systematic literature review. Int. J. Phys. Distrib. Logist. Manag. 2024, 54, 449–475. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, L. Digital twins for information-sharing in remanufacturing supply chain: A review. Energy 2021, 220, 119712. [Google Scholar] [CrossRef]

- Tiwari, S. Supply chain integration and Industry 4.0: A systematic literature review. Benchmarking 2021, 28, 990–1030. [Google Scholar] [CrossRef]

- Narayanan, S.; Marucheck, A.S.; Handfield, R.B. Electronic data interchange: Research review and future directions. Decis. Sci. 2009, 40, 121–163. [Google Scholar] [CrossRef]

- Cao, Q.; Schniederjans, D.G.; Schniederjans, M. Establishing the use of cloud computing in supply chain management. Oper. Manag. Res. 2017, 10, 47–63. [Google Scholar] [CrossRef]

- Wan, P.K.; Huang, L.; Holtskog, H. Blockchain-Enabled Information Sharing within a Supply Chain: A Systematic Literature Review. IEEE Access 2020, 8, 49645–49656. [Google Scholar] [CrossRef]

- Mügge, J.; Grosse Erdmann, J.; Riedelsheimer, T.; Manoury, M.M.; Smolka, S.O.; Wichmann, S.; Lindow, K. Empowering End-of-Life Vehicle Decision Making with Cross-Company Data Exchange and Data Sovereignty via Catena-X. Sustainability 2023, 15, 7187. [Google Scholar] [CrossRef]

- Schöppenthau, F.; Patzer, F.; Schnebel, B.; Watson, K.; Baryschnikov, N.; Obst, B.; Chauhan, Y.; Kaever, D.; Usländer, T.; Kulkarni, P. Building a Digital Manufacturing as a Service Ecosystem for Catena-X. Sensors 2023, 23, 7396. [Google Scholar] [CrossRef]

- Manoury, M.; Riedelsheimer, T.; Hellmeier, M.; Meyer, T. Supporting Changes in Digital Ownership and Data Sovereignty Across the Automotive Value Chain with Catena-X. Procedia Comput. Sci. 2025, 253, 374–383. [Google Scholar] [CrossRef]

- Steiner, B.; Münch, C. Leveraging digital data spaces in purchasing and supply management: Paving the way to the circular economy exemplified by Catena-X. J. Purch. Supply Manag. 2024, 30, 100951. [Google Scholar] [CrossRef]

- Liao, Y.; Kong, X.; Yin, L.; Gao, Y.; Dong, X. An industrial dataspace for automotive supply chain: Secure data sharing based on data association relationship. J. Ind. Inf. Integr. 2025, 44, 100778. [Google Scholar] [CrossRef]

- Lázaro, O.; Alonso, J.; Ohlsson, P.; Tijsma, B.; Lekse, D.; Volckaert, B.; Kerkhove, S.; Nielandt, J.; Masera, D.; Patrimia, G.; et al. Next-Generation Big Data-Driven Factory 4.0 Operations and Optimization: The Boost 4.0 Experience. In Technologies and Applications for Big Data Value; Springer: Berlin/Heidelberg, Germany, 2022; pp. 345–371. [Google Scholar]

- Tessmer, A.; Mast, J.; Loer, P.; Brunner, M.; Lippert, F.; Aschenbruck, N. An Open Source Trusted Edge Architecture of Federated Dataspaces for the Food Supply Chain. In Proceedings of the 7th IFIPIoT 2024 International IFIP WG 5.5 Work-shops, Nice, France, 6–8 November 2024; Springer: Berlin/Heidelberg, Germany, 2024; pp. 3–11. [Google Scholar]

- Abbasi, A.G.; Rydberg, A.; Altmann, P. Towards a verifiable and secure data sharing platform for livestock supply chain. In Proceedings of the 2022 IEEE Intl Conf on Dependable, Autonomic and Secure Computing, Intl Conf on Pervasive Intelligence and Computing, Intl Conf on Cloud and Big Data Computing, Intl Conf on Cyber Science and Technology Congress (DASC/PiCom/CBDCom/CyberSciTech), Falerna, Italy, 12–15 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Farahani, B.; Monsefi, A.K. Smart and collaborative industrial IoT: A federated learning and data space approach. Digit. Commun. Netw. 2023, 9, 436–447. [Google Scholar] [CrossRef]

- Usländer, T.; Schöppenthau, F.; Schnebel, B.; Heymann, S.; Stojanovic, L.; Watson, K.; Nam, S.; Morinaga, S. Smart factory web—A blueprint architecture for open marketplaces for industrial production. Appl. Sci. 2021, 11, 3585. [Google Scholar] [CrossRef]

- Alonso, Á.; Pozo, A.; Cantera, J.M.; de la Vega, F.; Hierro, J.J. Industrial data space architecture implementation using fiware. Sensors 2018, 18, 2226. [Google Scholar] [CrossRef]

- Volkmann, M.; Wagner, A.; Hermann, J.; Ruskowski, M. Asset Administration Shells and GAIA-X Enabled Shared Pro-duction Scenario. In Flexible Automation and Intelligent Manufacturing: Establishing Bridges for More Sustainable Manufacturing Systems; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Volz, F.; Sutschet, G.; Stojanovic, L.; Usländer, T. On the Role of Digital Twins in Data Spaces. Sensors 2023, 23, 7601. [Google Scholar] [CrossRef]

- Stier, S.P.; Xu, X.; Gold, L.; Möckel, M. Ontology-Based Battery Production Dataspace and Its Interweaving with Artificial Intelligence-Empowered Data Analytics. Energy Technol. 2024, 12, 2301305. [Google Scholar] [CrossRef]

- Theil, S.; Holtmann, M.; Reuter, N.; Reuter, M. Enabling Seamless Collaboration in AOCS/GNC Engineering: COOPERANTS Project’s Approach to Continuous Integration and Verification of Component Models. In Proceedings of the IAF Space Sys-tems Symposium, Milan, Italy, 14–18 October 2024. [Google Scholar]

- Pinto, P.; Sousa, C.; Cardeiro, C. Data spaces based approach for B2B data exchange: A footwear industry case. Procedia Comput. Sci. 2023, 219, 933–940. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y.; Zhu, Y.; Tao, F. Exploration on industrial system-aware dataspace towards smart manufacturing. In Proceedings of the 2022 IEEE 18th International Conference on Automation Science and Engineering (CASE), Mexico City, Mexico, 20–24 August 2022; IEEE Computer Society: Washington, DC, USA, 2022; pp. 1883–1889. [Google Scholar] [CrossRef]

- 57 Wang, Y.; Cheng, Y.; Qi, Q.; Tao, F. IDS-KG: An industrial dataspace-based knowledge graph construction approach for smart maintenance. J. Ind. Inf. Integr. 2024, 38, 100566. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, J.; Wu, L.; Zhang, P.; Wang, M. Industrial data space application framework for semiconductor wafer manufacturing system scheduling. J. Manuf. Syst. 2024, 77, 464–482. [Google Scholar] [CrossRef]

- Inigo, M.A.; Legaristi, J.; Larrinaga, F.; Perez, A.; Cuenca, J.; Kremer, B.; Montejo, E.; Porto, A. Towards Standardized Manufacturing as a Service through Asset Administration Shell and International Data Spaces Connectors. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, K.; Wang, M.; Wang, X.; Shen, Y. Towards Industry Data Governance: Construction of An Industrial Data Decentralized Distributed Symbiotic Sharing Space Based on Tensor. In Proceedings of the ICAC 2023—28th International Conference on Automation and Computing, Birmingham, UK, 30 August–1 September 2023; Institute of Electrical and Elec-tronics Engineers Inc.: Piscataway, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Li, Z.; Faheem, F.; Husung, S. Collaborative Model-Based Systems Engineering Using Dataspaces and SysML v2. Systems 2024, 12, 18. [Google Scholar] [CrossRef]

- Ranathunga, T.; McGibney, A.; Bharti, S. Enabling secure and self-sovereign machine learning model exchange in manu-facturing data spaces. J. Ind. Inf. Integr. 2024, 42, 100733. [Google Scholar] [CrossRef]

- Moreno, T.; Almeida, A.; Ferreira, F.; Caldas, N.; Toscano, C.; Azevedo, A. Digital twin for manufacturing equipment in industry 4.0. Adv. Transdiscipl. Eng. 2021, 15, 362–367. [Google Scholar] [CrossRef]

- Shin, M. Development of Collaboration Model for Data Space-Based Open Collaboration Platform in Continuous Process Industries. Sustainability 2025, 17, 126. [Google Scholar] [CrossRef]

- Hagenhoff, P.; Biehs, S.; Möller, F.; Otto, B. Designing a Reference Architecture for Collaborative Condition Monitoring Data Spaces: Design Requirements and Views. In Design Science Research for a Resilient Future; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Neubauer, M.; Steinle, L.; Reiff, C.; Ajdinović, S.; Klingel, L.; Lechler, A.; Verl, A. Architecture for manufacturing-X: Bringing asset administration shell, eclipse dataspace connector and OPC UA together. Manuf. Lett. 2023, 37, 1–6. [Google Scholar] [CrossRef]

- Jurmu, M.; Niskanen, I.; Kinnula, A.; Kääriäinen, J.; Ylikerälä, M.; Räsänen, P.; Tuikka, T. Exploring the Role of Federated Data Spaces in Implementing Twin Transition within Manufacturing Ecosystems. Sensors 2023, 23, 4315. [Google Scholar] [CrossRef] [PubMed]

- Kunz, L.; Reif, M.; Petzsche, T.; Schmallenbach, A.; Plociennik, C.; Ruskowski, M. Realizing Closed-Loop Supply Chain Networks based on Dataspaces and Manufacturing Marketplaces. IFAC-PapersOnLine 2024, 58, 235–240. [Google Scholar] [CrossRef]

- Guo, J.; Cheng, Y.; Wang, D.; Tao, F.; Pickl, S. Industrial Dataspace for smart manufacturing: Connotation, key technolo-gies, and framework. Int. J. Prod. Res. 2023, 61, 3868–3883. [Google Scholar] [CrossRef]

- Bakopoulos, E.; Sipsas, K.; Nikolakis, N.; Alexopoulos, K. A Digital Twin and Data Spaces framework towards Resilient Manufacturing Value Chains. IFAC-PapersOnLine 2024, 58, 163–168. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Weber, M.; Trautner, T.; Manns, M.; Nikolakis, N.; Weigold, M.; Engel, B. An industrial data-spaces framework for resilient manufacturing value chains. Procedia CIRP 2023, 116, 299–304. [Google Scholar] [CrossRef]

- Kari, A.; Bellin, P.; Matzner, M.; Gersch, M. Governing the emergence of network-driven platform ecosystems. Electron. Mark. 2025, 35, 4. [Google Scholar] [CrossRef]

- Mügge, J.; Hahn, I.R.; Riedelsheimer, T.; Chatzis, J.; Boes, J. End-of-life decision support to enable circular economy in the automotive industry based on digital twin data. Procedia CIRP 2023, 119, 1071–1077. [Google Scholar] [CrossRef]

- Gieß, A.; Neumann, J.; Jussen, I.; Schweihoff, J. Green data, green future? How data spaces enable the product carbon foot-print calculation for the automotive industry: A case study on Catena-X. In Proceedings of the INFORMATIK 2024, Wiesba-den, Germany, 26 September 2024; Lecture Notes in Informatics (LNI), Proceedings—Series of the Gesellschaft fur Informatik (GI). Gesellschaft fur Informatik (GI): Bonn, Germany, 2024; Volume 352, pp. 1799–1812. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabellini, M.; Civolani, L.; Ronchi, M.; Naldi, L.D.; Regattieri, A. Data Spaces in Manufacturing and Supply Chains: A Review and Insights from European Initiatives. Appl. Sci. 2025, 15, 5802. https://doi.org/10.3390/app15115802

Gabellini M, Civolani L, Ronchi M, Naldi LD, Regattieri A. Data Spaces in Manufacturing and Supply Chains: A Review and Insights from European Initiatives. Applied Sciences. 2025; 15(11):5802. https://doi.org/10.3390/app15115802

Chicago/Turabian StyleGabellini, Matteo, Lorenzo Civolani, Michele Ronchi, Ludovica Diletta Naldi, and Alberto Regattieri. 2025. "Data Spaces in Manufacturing and Supply Chains: A Review and Insights from European Initiatives" Applied Sciences 15, no. 11: 5802. https://doi.org/10.3390/app15115802

APA StyleGabellini, M., Civolani, L., Ronchi, M., Naldi, L. D., & Regattieri, A. (2025). Data Spaces in Manufacturing and Supply Chains: A Review and Insights from European Initiatives. Applied Sciences, 15(11), 5802. https://doi.org/10.3390/app15115802