1. Introduction

Under-body blast (UBB) events caused by buried landmines or improvised explosive devices (IEDs) can produce rapid vertical accelerations transmitted through the vehicle floor into the occupant’s lower limbs, pelvis, and ultimately the spine, resulting in complex and severe loading of the head–neck system. The vertical accelerations can result in compressive axial loads and inertial bending moments in the cervical spine, increasing the risk of skull base fractures, cervical vertebral damage, and traumatic brain injury (TBI). Non-penetrative occupant injuries represent the common casualty pattern in armored vehicles surviving mine detonations, where hull integrity remains preserved. In this scenario, the blast wave fails to penetrate the vehicle hull to directly injure occupants. Primary injury mechanisms originate from vehicle transmissibility, generating traumatic impacts through structural vibration. The simulation and analysis of selected blast scenarios have been the focus of several studies. Danelson [

1] developed a blast buck (Accelerative Loading Fixture, or ALF) for studying under-body blast events in a laboratory to compare the responses of Hybrid III and PMHS in the explosion. Trajkovski [

2] conducted a finite element analysis to investigate the blast response of the V-shaped hull structure in light armored vehicles. Espinoza-Garcés [

3] developed a finite element model of the Hybrid III dummy under pipeline explosion environment and established the relationship between head injury and the blast propagation radius.

The use of dummies for testing the non-penetrative occupant injuries of landmine explosions holds significant scientific value and practical importance. A dummy can simulate the biomechanical responses of the human body under blast impacts, thereby providing injury data. Through dummy testing, it is possible to quantify the extent of damage caused to occupants by blast impacts, evaluate the effectiveness of vehicle protection systems, and provide a basis for improving vehicle design and materials.

Due to the high biofidelity of the dummy, it is already widely used in automobile, manned spaceflight, and military protection tests. For example, Hybrid III 50th ATD (Anthropomorphic Test Device) is used by the North Atlantic Treaty Organization (NATO) as a dummy to test explosion damage to occupants, so it is currently a mature means of explosion-damage test [

4,

5]. Many scholars have studied the response of Hybrid III under impact. Ott [

6] and Marie Bailey [

7,

8] compared the response of the Hybrid III and the PHMS in under-body high-velocity impact. Using the Hybrid III dummy, Horst analyzed occupant safety in blast-mine loading under vehicles [

9], and Bass investigated the protective effects of different protective clothing on the head and neck under a C4 explosion [

10]. Yin conducted a study on the influence of wearing protective equipment on the injuries sustained by vehicle occupants during vertical under-vehicle blast impacts [

11]. Subsequently, the higher biofidelity dummies, Thor and WIAMan, were launched. Compared with Hybrid III, the flexibility of thoracic and vertebral joints and chest and shoulder restraints of THOR were increased. WIAMan is designed to be more suitable for testing under-body explosion damage, as its structure and materials more closely resemble human characteristics [

12]. Zeng compared the response of Thor, WIAMan, and Hybrid III in under-body blast impact [

13]. These high biofidelity dummies make the structure and size and biomechanical response as similar as possible to the human body, but the manufacturing cost is high. However, high biofidelity dummies are very expensive. For example, a full Hybrid III 50th percentile male ATD generally costs approximately

$250,000, depending on configuration and sensor instrumentation. When large-scale use of dummies is required—such as assessing occupant injuries at multiple seating positions within a vehicle—the use of high-fidelity dummies inevitably leads to substantial cost. The aim of this study is to reduce the cost associated with occupant injury testing.

To enhance engineers’ analysis of occupant biological response through force distribution visualization and reduce cost, a finite element model of a dummy has been introduced. LSTC and the University of Washington have jointly developed the Hybrid III finite element model (FEM). Scholars optimized the material properties of the Hybrid III numerical model under high-speed impact conditions by taking into account the strain rate effects. Lou validated the mechanical behavior of the lumbar spine by introducing a stiffer viscoelastic material card [

14]. Zhu validated the material properties of the pelvis flesh, lower leg flesh, heel foam, and lower leg skin under the high rate [

15]. Then, Suhaimi conducted high-speed impact tests to validate that the computational results of the optimized Hybrid III 50th FEM are in good agreement with the test results of the physical model [

16,

17] (The correlation and analysis score ranged from 0.653 to 0.901, and the differences in peak response ranged from 1.5% to 12.7%). In terms of applications, Sławiński [

18], Suhaimi [

19], and Wang [

20] used Hybrid III 50th FEM to analyze the human damage under blast. Roberts studied the effect of shock waves on the human head–neck based on Hybrid III 50th FEM [

21]. However, the coupling situations between the occupant and the vehicle are complex and varied. Ensuring that the transmission of explosion impacts within vehicles matches actual conditions is extremely difficult in the finite element model. The proposal of the new method can simplify these analyses. In the paper, the finite element model was utilized under simplified conditions to conduct a comparative validation of the new method.

Mapping the test model using one-dimensional convolutional neural networks (1D-CNNs) constitutes a major contribution of this work, and prior studies have explored similar approaches in data calibration and damage assessment. Park explored the feasibility of using 1D-CNN for vibration-based structural damage assessment. By analyzing the vibration signals, the 1D-CNN model can effectively identify structural damage, improving the accuracy and efficiency of the evaluation [

22]. Ail calibrated the low-cost carbon monoxide sensor using 1D-CNN. This method improves the accuracy and reliability of the sensor and demonstrates the potential of 1D-CNN in the calibration of sensor data [

23]. Lanning proposed a CNN-based framework to calibrate parameters of nonlinear structural models using time-history data of loads and displacements [

24].

This paper aims to investigate a unique testing method that is cost-effective, capable of yielding rapid results, and incorporates a simplified physical dummy model installed on-site. The paper established a simplified physical model of the head–neck structure. Then, we built the mapping test model based on 1D-CNN. Through the fusion of virtual and real testing, the damage to occupants caused by explosions is assessed. The method holds certain significance for the cost-effectiveness testing of dummies. The head–neck part of the dummy is the research content of this paper.

1.1. Injury Criterion

In automotive crash safety assessment, injury criteria are quantitative metrics used to evaluate the likelihood of occupant injury under various impact conditions. Commonly used criteria include the Head Injury Criterion (HIC), which evaluates the risk of traumatic brain injury based on head acceleration; the Neck Injury Index (Nij), which combines axial force and bending moment at the neck; the Chest Deflection and Viscous Criterion (VC) for assessing thoracic injury; and femur loads and tibia indices for lower extremity evaluation. These criteria were originally developed for use in automotive crash testing to assess the risk of human injuries under high-acceleration, short-duration impacts. With the growing need to evaluate occupant responses in under-body blast (UBB) scenarios—especially due to landmine and IED threats—these criteria have been widely adopted in blast biomechanics research. HIC and Nij remain commonly used due to their simplicity and extensive validation history. NATO, for example, references HIC in its military vehicle occupant protection guidelines, including the HFM-090 [

4] and the AEP-55 [

5] for blast testing and evaluation. Moreover, finite element human body models, such as those used in studies funded by the NATO Research Task Groups, commonly utilize HIC and Nij as benchmark outputs to evaluate head and neck loading under under-body blast and overpressure scenarios [

25]. While these criteria are not specifically designed for blast loading, their adoption reflects a practical need for standardized, quantitative injury measures in blast biomechanics.

For under-body blast events, vertical acceleration of the head and neck axial compression are considered the principal contributors to injury. In consideration of space limitations, selected aspects of the vertical acceleration of the head and the axial compression force of the upper neck are considered in this work.

1.1.1. Neck Injury

Nij is a biomechanical injury criterion developed to evaluate the risk of cervical spine injury under combined axial loading and bending conditions. It was introduced by the National Highway Traffic Safety Administration (NHTSA) and standardized by the Society of Automotive Engineers (SAE J1727) to assess neck injury potential in frontal vehicle collisions [

26]. Nij is calculated as a linear combination of normalized axial force and sagittal plane bending moment measured at the occipital condyle of anthropomorphic test devices (ATDs), such as the Hybrid III dummy:

where

is the axial force,

is the sagittal plane moment (flexion/extension),

and

are injury threshold values. For the 50th percentile male, the critical compressing force is

, the critical tensile force is

, the critical flexion moment is

, the critical extension moment is

.

The Hybrid III ATD measures and using a six-axis load cell mounted at the upper neck, which are then substituted into the Nij equation to assess injury risk.

1.1.2. Head Injury

The HIC criterion was adopted in 1998 by the NHTSA [

27]. The commonly used time window limits for the HIC standard are 15 ms or 36 ms. Explosions generate extremely rapid shock waves, with the primary loading on the human body typically occurring within just a few to several milliseconds. Therefore, using HIC

36 may include smaller but longer-duration accelerations, which dilutes the peak impact and underestimates the actual injury risk. HIC

15 is more suitable for identifying short-duration, high-acceleration impacts—precisely the type of injury mechanism explosions typically cause to the human body. NATO reports, such as the HFM-090 [

4] and the AEP-55 [

5], commonly use HIC

15 when evaluating explosive or short-duration high-load events such as blasts and falls. The HIC

15 value can be obtained by the following formula:

where

is the resultant acceleration of the center of gravity of the head in

(

).

and

are the moments in time during the event, where HIC

15 is at a maximum. Time shall be specified in seconds [s].

The Hybrid III ATD evaluates head injury risk using HIC, with acceleration signals measured by accelerometers mounted at the center of gravity of the head.

2. Methodology

The initial step to build the system involves designing a cost-effective dummy that preserves the segmental mass distribution and center-of-mass locations characteristic of human surrogates. Additionally, the dummy should feature a modular design for ease of assembly and disassembly, while maintaining low manufacturing costs. The primary focus of this study is the head–neck region of the dummy. The head–neck structure consists of alternating aluminum vertebral analogs and silicone intervertebral discs, secured by latex straps simulating ligaments. This design enables basic mobility and injury recognition. Although the segmental mass and center of gravity of the simplified dummy were designed to approximate those of the Hybrid III 50th percentile model, notable differences persist due to the use of cost-effective materials and the omission of moment of inertia considerations. To address these discrepancies, a mapping model based on 1D-CNN is developed.

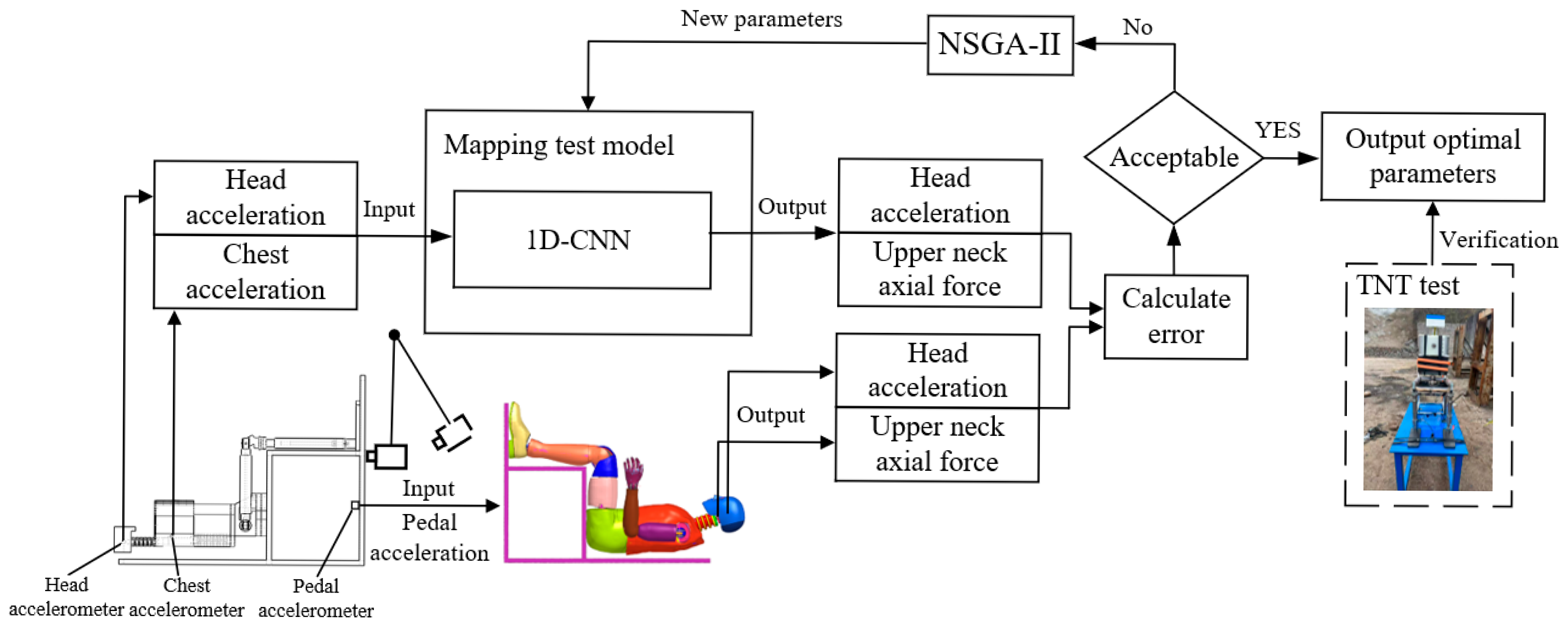

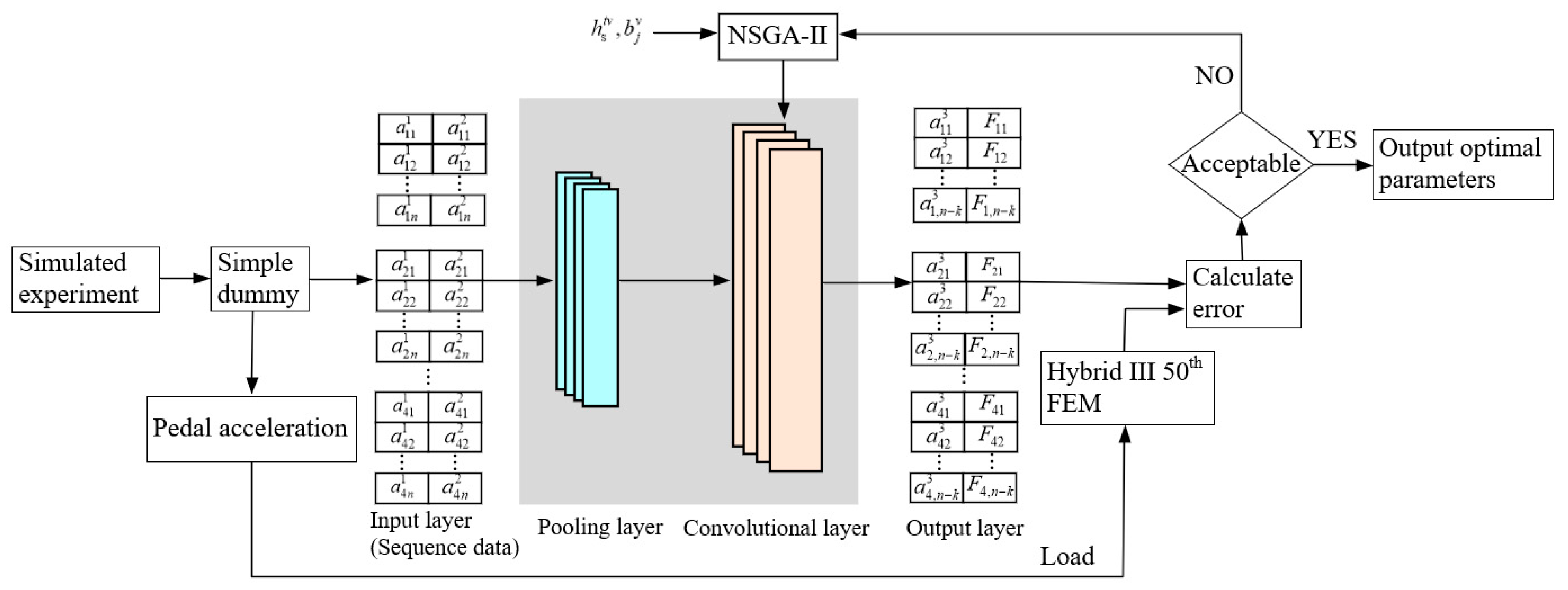

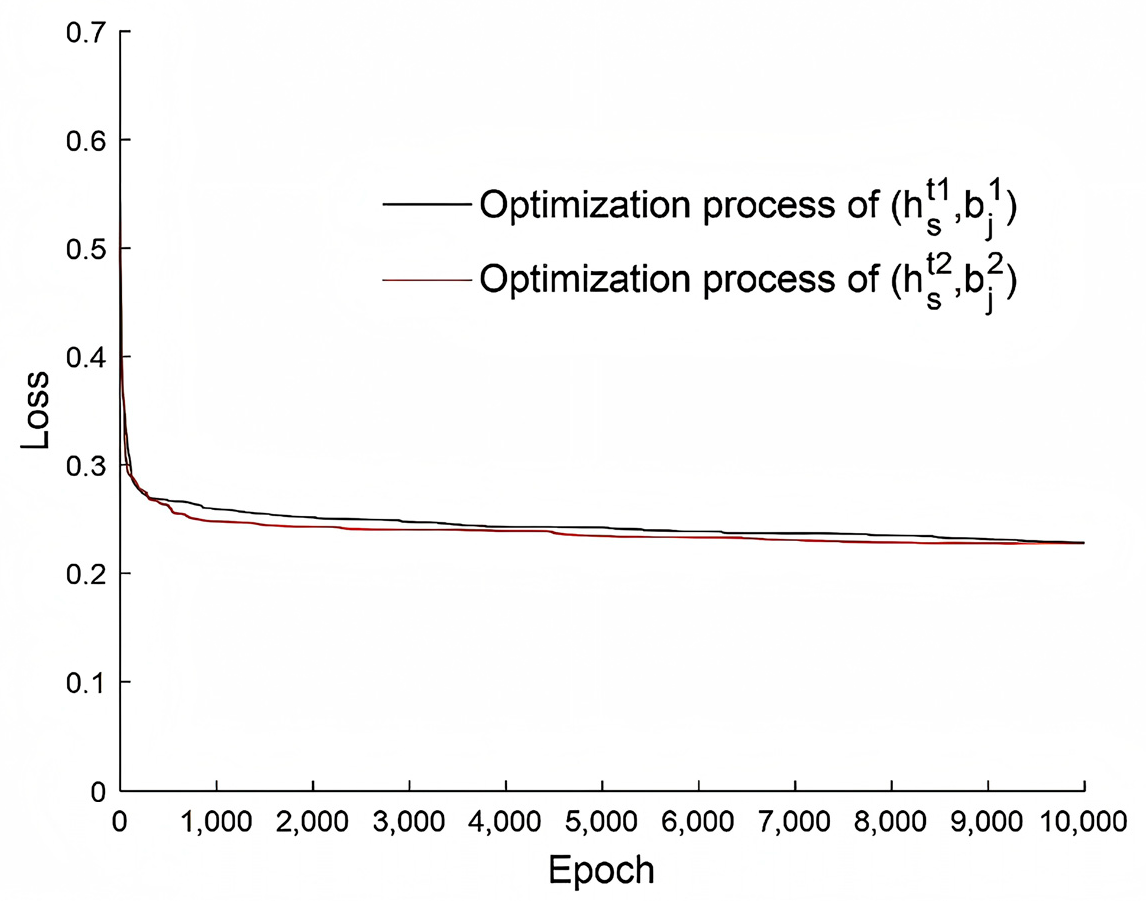

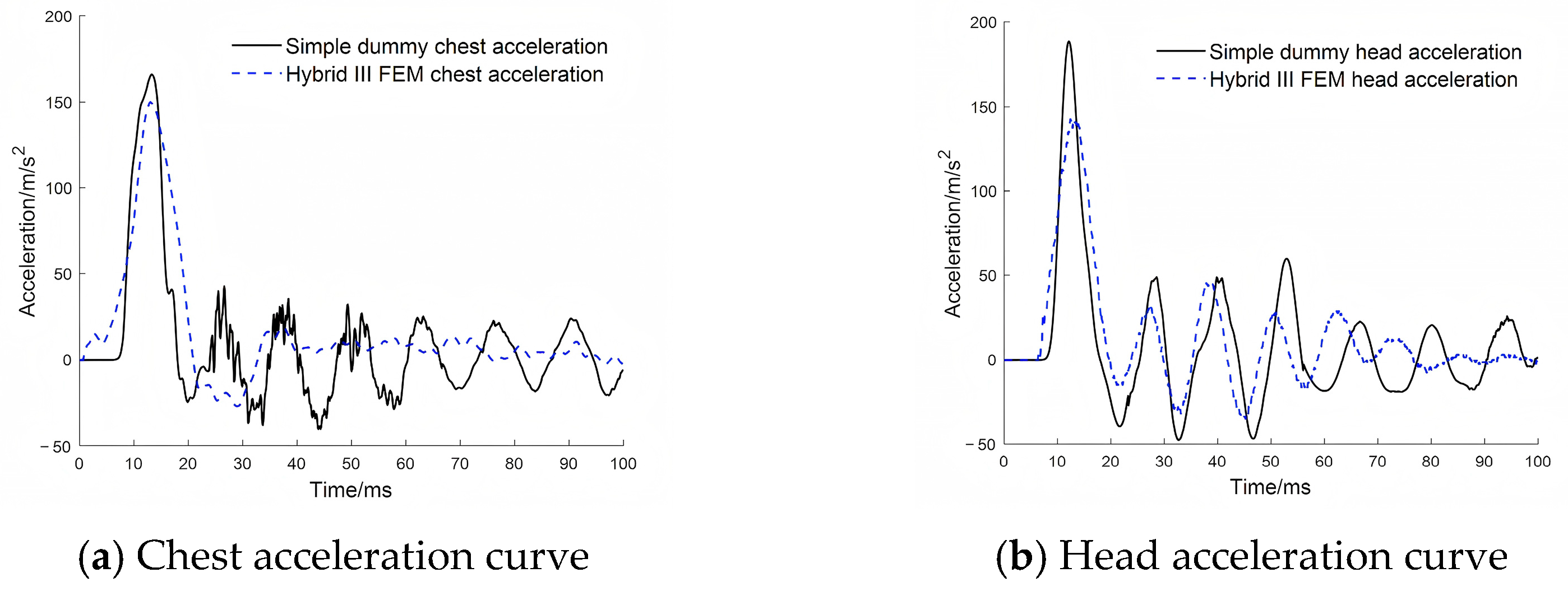

In the second step, the 1D-CNN network is trained to address the discrepancy between the simplified dummy and the high-fidelity dummy. While the simplified dummy replicates segmental mass and center-of-mass distributions, its response still deviates from that of the high-biofidelity dummy due to the use of low-cost materials and simplified joint connections. The mapping model aims to minimize this deviation. The training dataset for the model was obtained through a repeatable and controlled pendulum experiment. Section Relationship Between the Pendulum and Explosive Impact investigates the relationship between pendulum impact and simulated explosions using empirical formulas for blast overpressure. An overview of the model-training procedure is presented as follows: As illustrated in

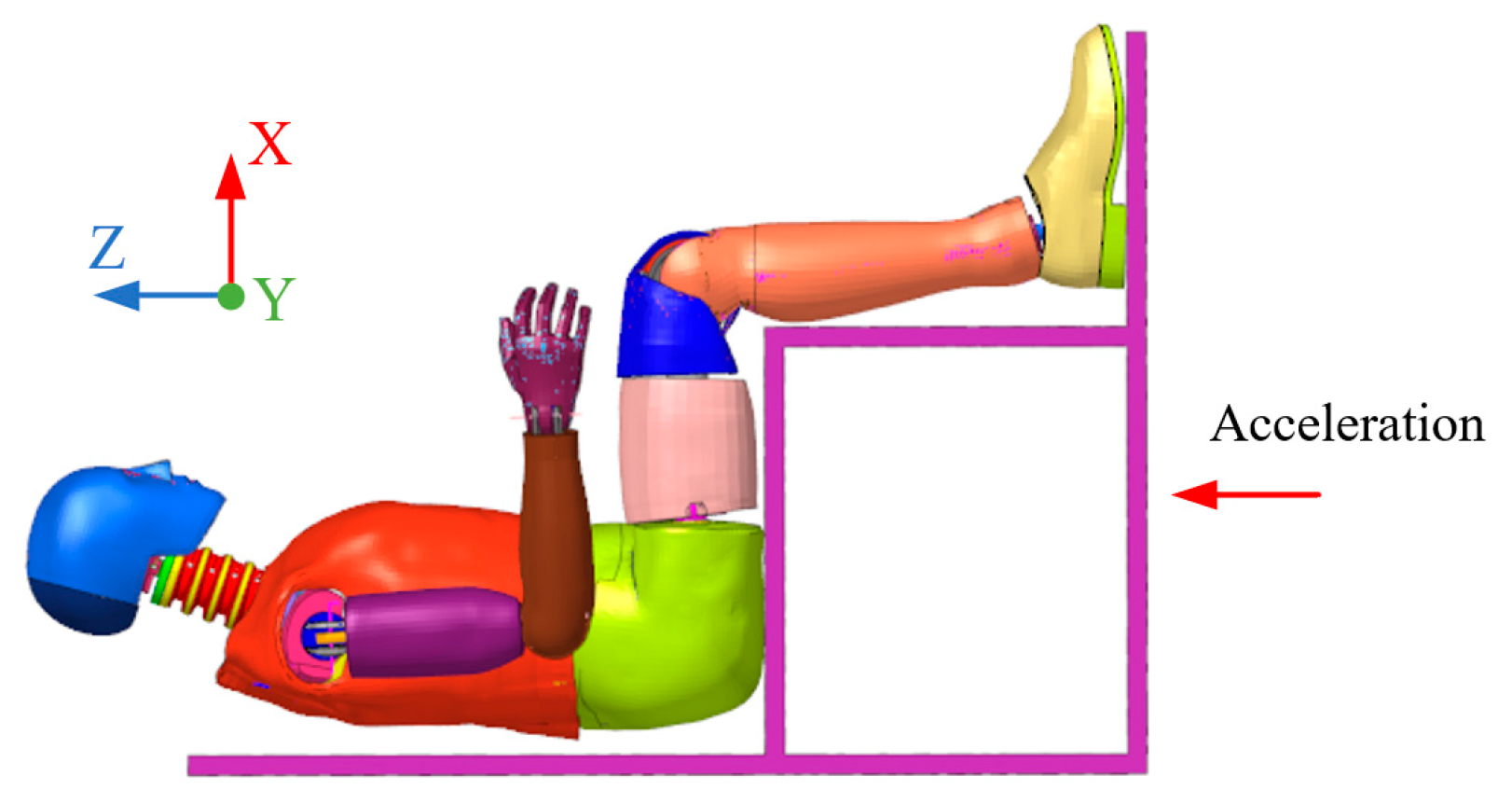

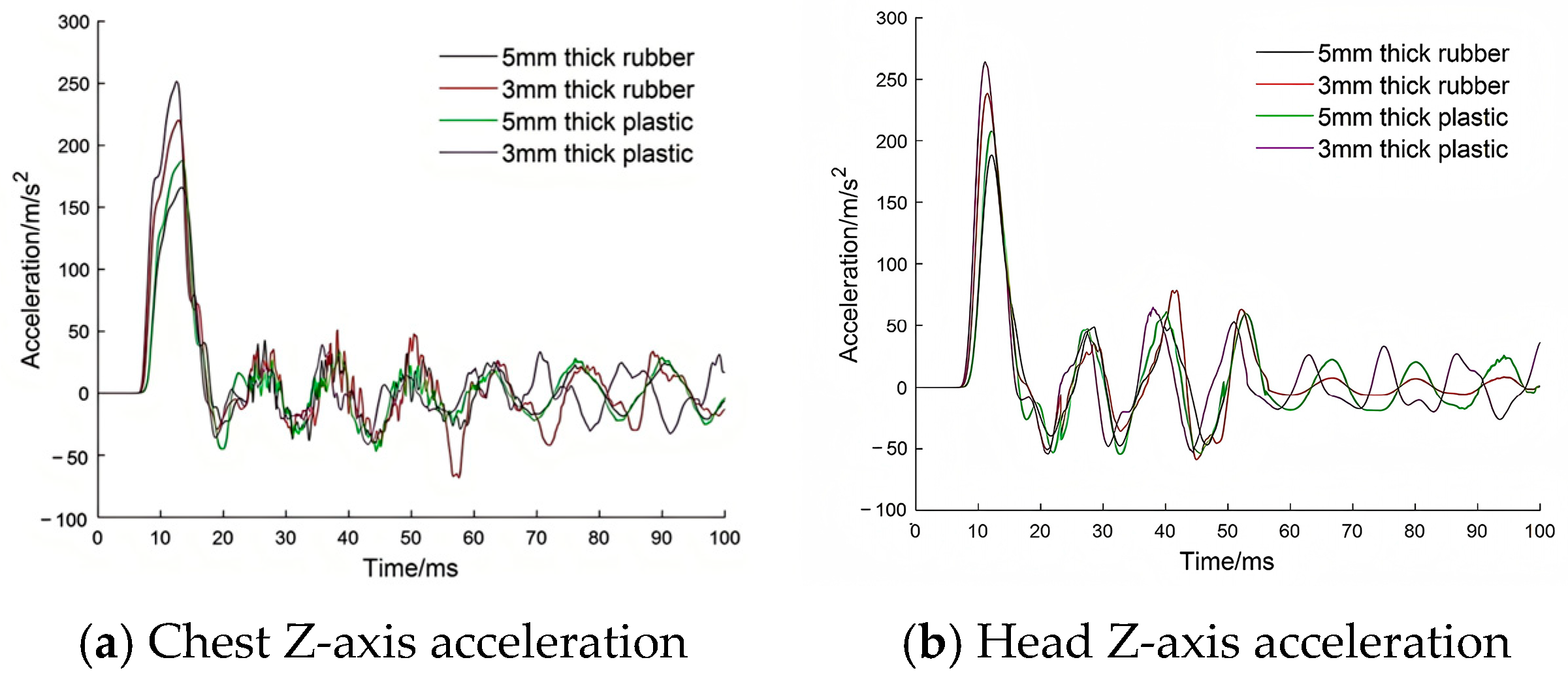

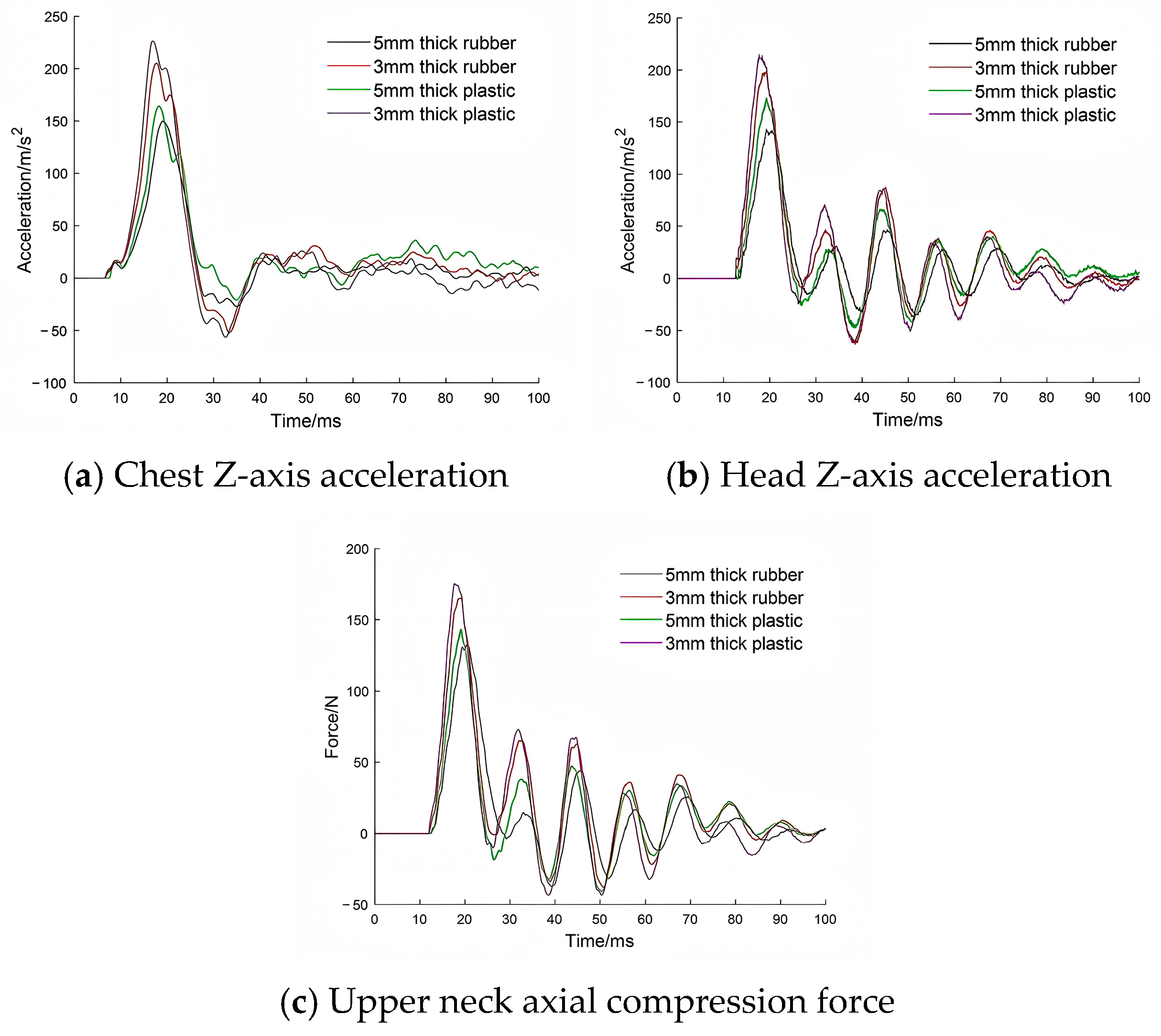

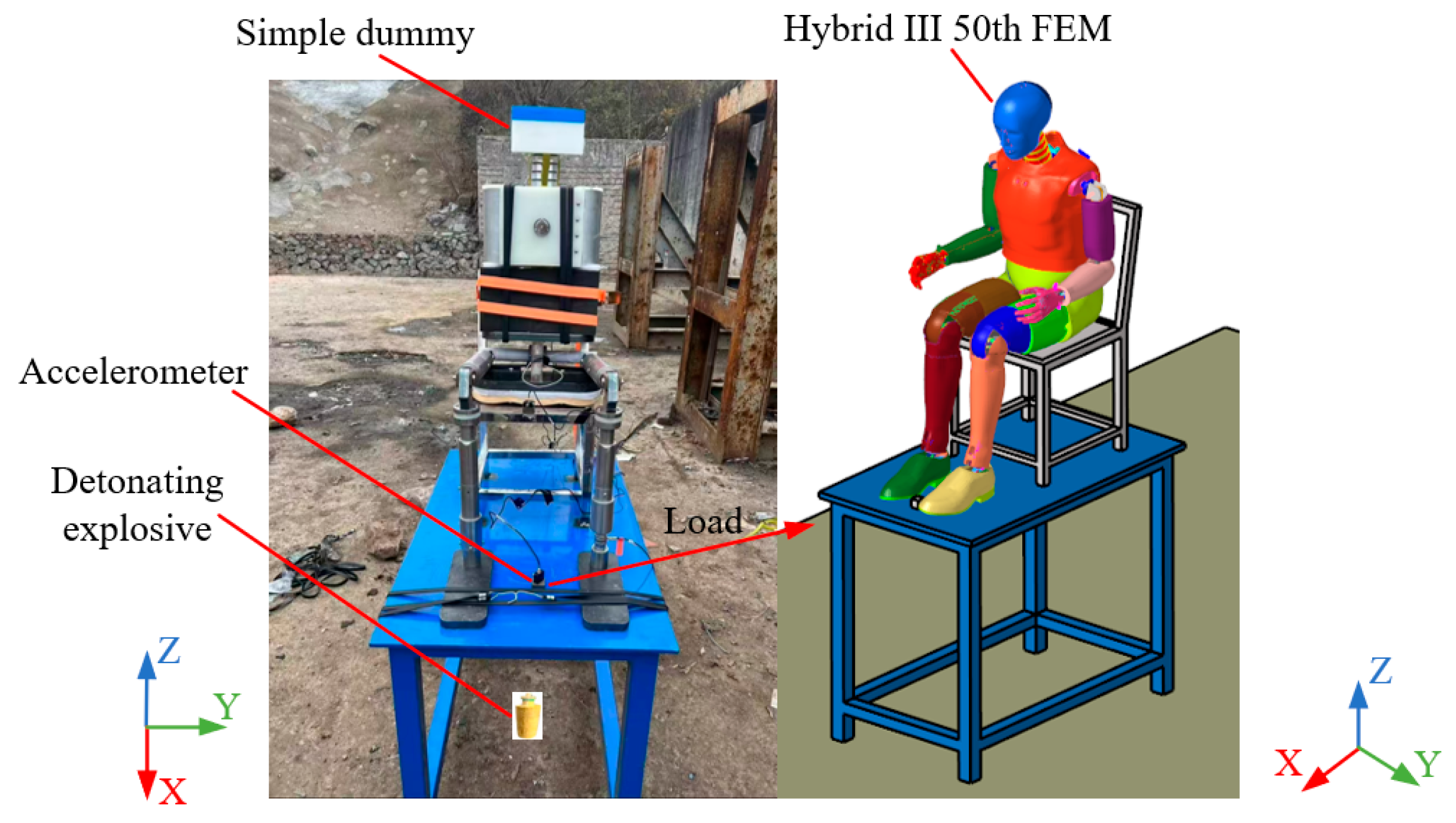

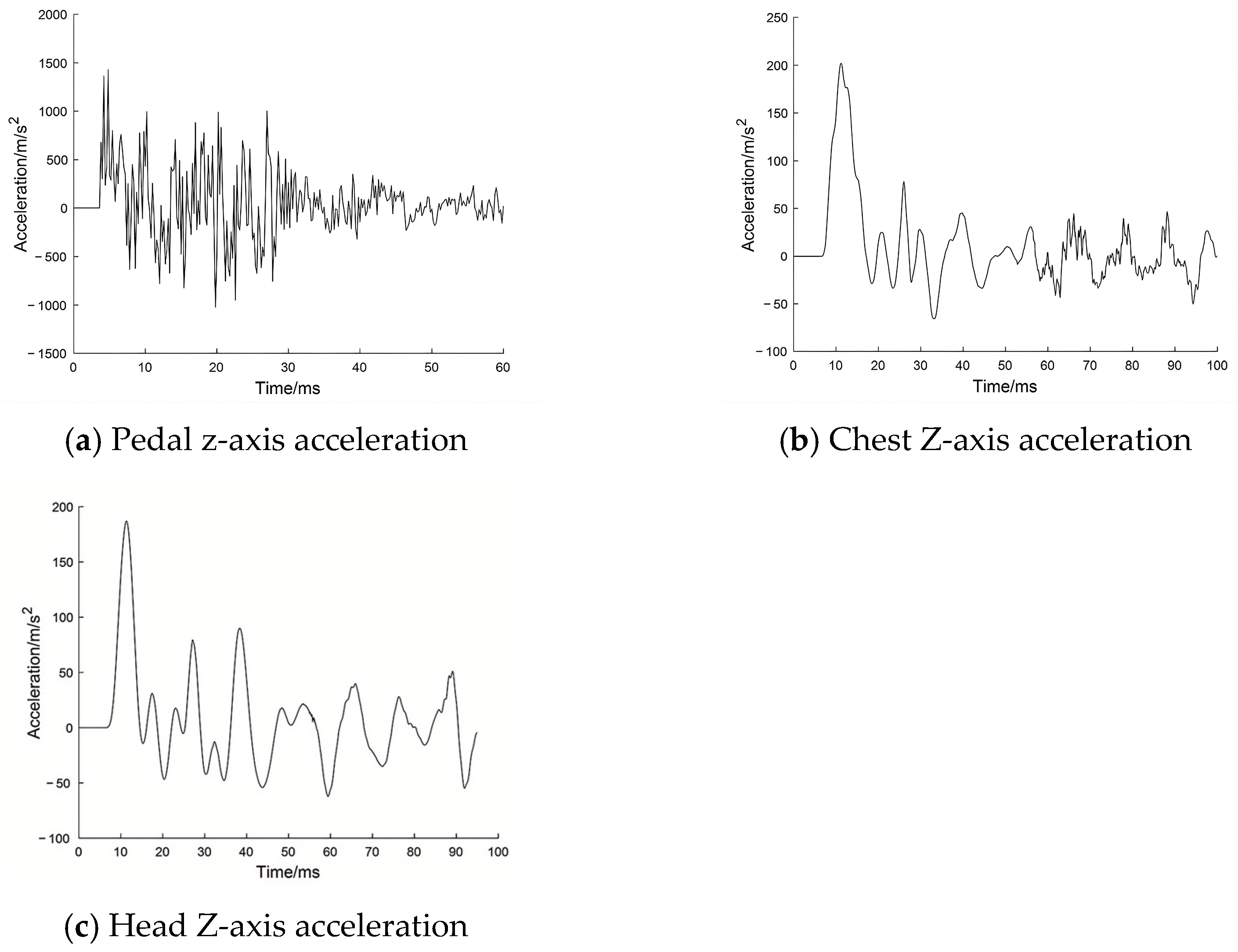

Figure 1, loading is applied to the pedal of the simplified dummy using the pendulum. Acceleration signals from the chest and head of the simplified dummy serve as inputs for the 1D-CNN, while the signals from the accelerometer mounted on the pedal are used as inputs for the Hybrid III FEM. The calibrated head acceleration and upper neck axial force are derived from the computations performed by the 1D-CNN. A comparison is made with the results from the Hybrid III model, and the error is computed. If the error is within acceptable limits, the optimal parameters of the modified model are retained. Otherwise, NSGA-II generates a new set of parameters (CNN’s filters and biases), and the process is repeated. The model is ultimately validated using TNT explosion test. The simple dummy tests the response in an explosive environment, and after the network with training parameters calculates and outputs the calibration value. The accelerometer signals from the test rig are used as inputs for the Hybrid III FEM, with the Hybrid III FEM serving as the reference.

Although the simple dummy is not equipped with a neck force transducer, making it impossible to test neck forces, the relative movement changes of the chest and head can reflect the changes in upper neck force. The mapping test model can map the acceleration of the chest and head to the axial compression force of the upper neck of Hybrid III 50th FEM.

Due to the inherent instability of energy release in explosive detonations, using explosive charge as input for finite element models introduces considerable uncertainty. As a result, this study focuses on the measured pedal acceleration as the key input parameter. Although using the pedal acceleration measured during testing as the input for the finite element model neglects the impact of local pedal deformation, since the head and neck do not directly interact with the pedal, the effect of local pedal deformation on the head–neck response is negligible.

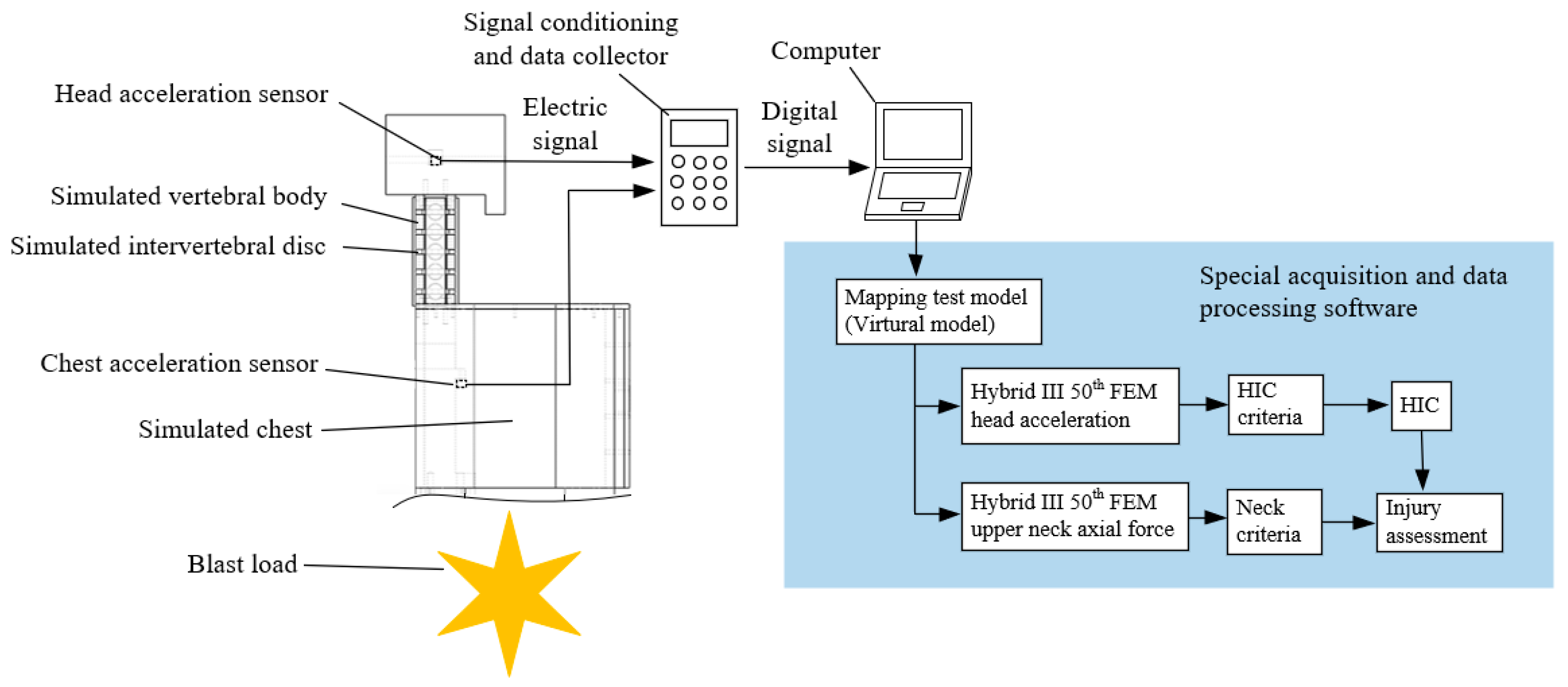

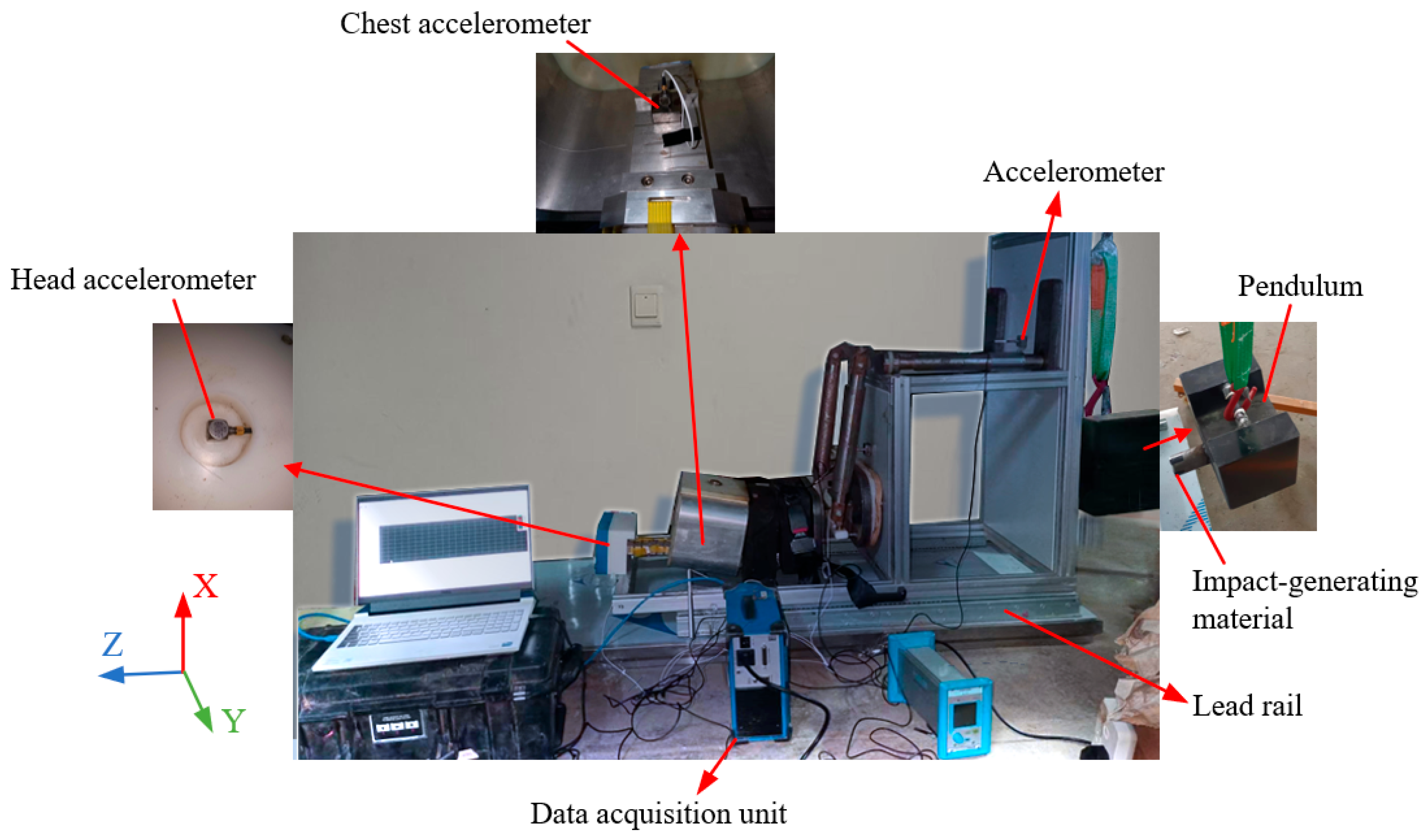

In the practical application of this system. The composition of the test system is shown in

Figure 2. The system includes a simple dummy (built-in head–neck physical model), accelerometers, signal conditioning and data collector, and special data acquisition and processing software. The software integrates a virtual model- head–neck injury mapping test model. When the explosion occurs, it will impact the dummy, resulting in a violent movement of the chest and head. The acceleration sensors installed at the centroids of the chest and head record the acceleration signals. These acceleration signals are transmitted through the signal line to the signal conditioning and data collector, and converted into digital signals. Then they are passed to the special data acquisition and processing software. Through the mapping test model in the software, the measured chest and head acceleration signals are mapped to high biofidelity dummy head–neck response, which is the head acceleration and upper neck axial compression force of Hybrid III 50th FEM. Finally, the injury results were evaluated according to the HIC criterion and the neck injury criterion.

Relationship Between the Pendulum and Explosive Impact

Pendulum impact tests can generate short-duration, high-intensity impact forces, making them suitable for studying the response of structures or the human body under instantaneous loading. In certain cases, this loading method can approximately simulate the effects of blast impacts. Draganić [

28] introduced various methods and devices for blast load testing and impact simulation, including laboratory techniques such as pendulum impact testing.

Pendulum-based simulation of blast loading relies on the assumption that the force applied by the pendulum to the pedal is equivalent to the force generated by the explosive event. The force exerted by the explosion on the pedal is estimated using the following method.

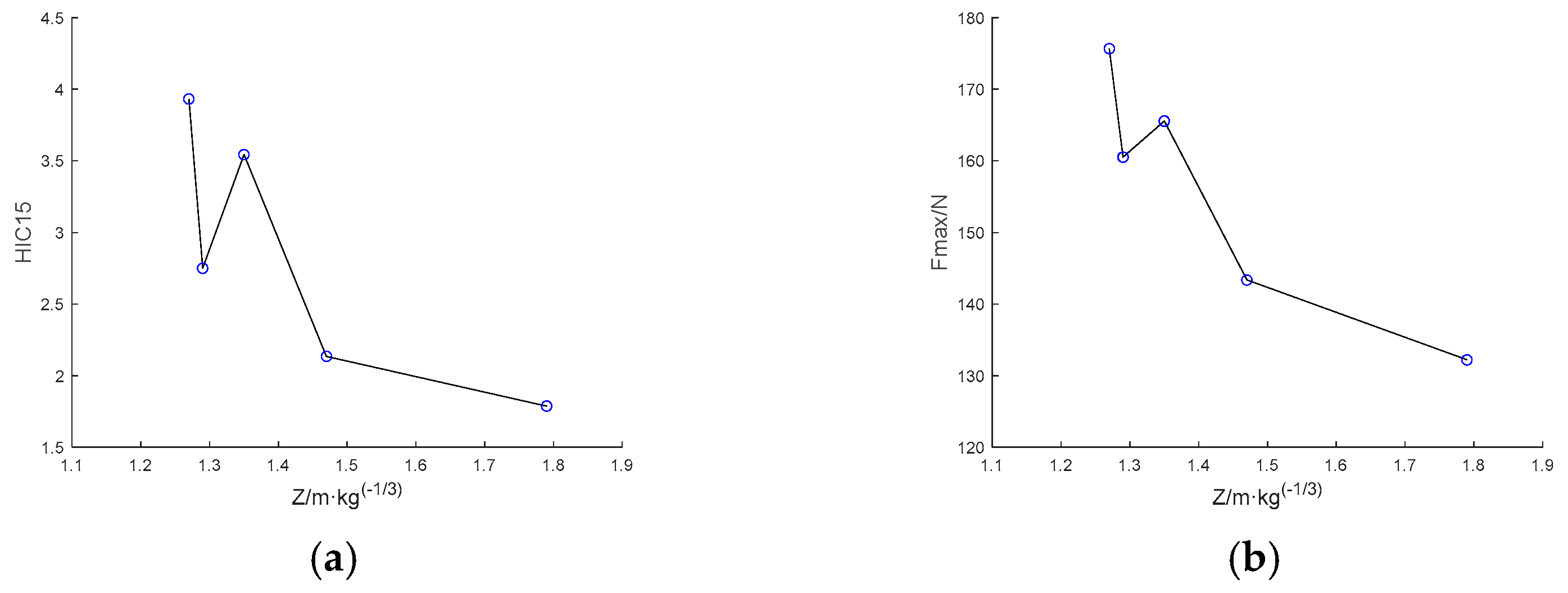

The following results show the peak impact force exerted on the bottom of the human corresponding to the simulated explosion.

Hopkinson, in his investigation of explosive phenomena, identified that blast effects scale with the cube root of the charge mass, thereby introducing [

29]:

Here,

is the TNT equivalent in kg, and

is the distance from the detonation point in m.

For hemispherical surface bursts, the empirical formulae for the peak overpressure (in MPa) was proposed by Newmark and Hansen [

30]. This equation applies to surface bursts, where the peak overpressure is typically higher than that of air bursts due to the enhancement caused by reflected waves and ground coupling effects.

This study focuses on scenarios with sufficiently large scaled distances, where the shock front may be reasonably approximated as planar. For simplification, the blast load on the vehicle bottom was assumed to be uniformly distributed, the force peak (in N) of blast acting on the pedal is given by

S represents the surface area of the bottom of the vehicle that is exposed to the blast in mm

2.

The following derivation establishes the relationship between the impact force exerted by the pendulum on the pedal and the pendulum parameters. Applying the law of conservation of energy yields the velocity of the pendulum at its lowest position:

The pendulum’s kinetic energy at the lowest point can be calculated as follows:

According to the impulse–momentum theorem, the average force acting on the pedal can be calculated by dividing the total impulse by the contact time:

where

is the mass of the pendulum in kg,

is the drop height of the pendulum in m,

is the force duration (or contact time) in s.

Assume that the maximum force is related to the average force by the following expression:

The value of is determined by the material properties and shape of the pendulum head.

By equating the maximum force generated by the explosive impact to the maximum impact force of the pendulum, we obtain

The Equation (11) indicates that, for a fixed explosion distance, increasing either the pendulum mass or its release height results in a higher equivalent simulated explosive yield.

Given the difficulty in determining the coefficient

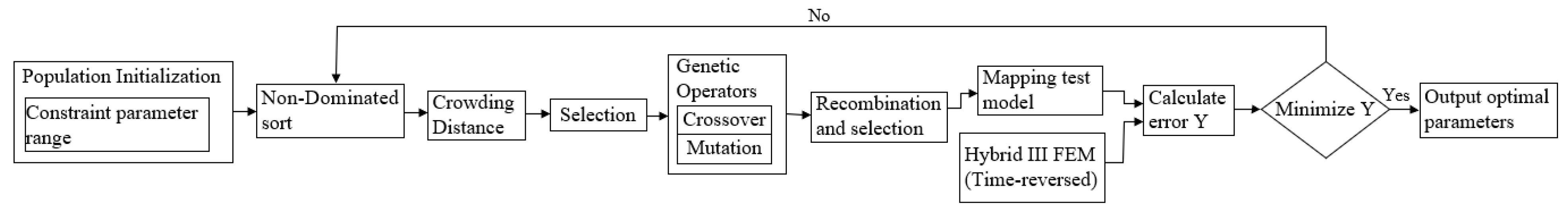

, an accelerometer is installed on the pedal to measure the acceleration peak. Subsequently, the peak force can be calculated as induced by the pendulum, and the scaled distance corresponding to the simulated blast is subsequently calculated using the Expression (10). The schematic diagram of the pendulum impact is shown in

Figure 3.

3. Head–Neck Physical Model

The structure of the human head–neck is complex, comprising cervical vertebrae, muscle groups, blood vessels, lymphatic tissues, and other anatomical constituents. It is considerably difficult to fully replicate the structure of the head–neck. The head–neck structure of a simple dummy should have the ability to recognize damage while having a relatively simple structure. The component primarily responsible for head–neck movement is taken into consideration. The cervical spine, serving as the principal load-bearing structure of the neck, is composed of seven cervical vertebrae, six intervertebral discs, and ligaments [

31]. The intervertebral discs separate the vertebrae and possess a high degree of compressibility, which endows the cervical spine with flexibility. In addition, the intervertebral discs function as a damping mechanism.

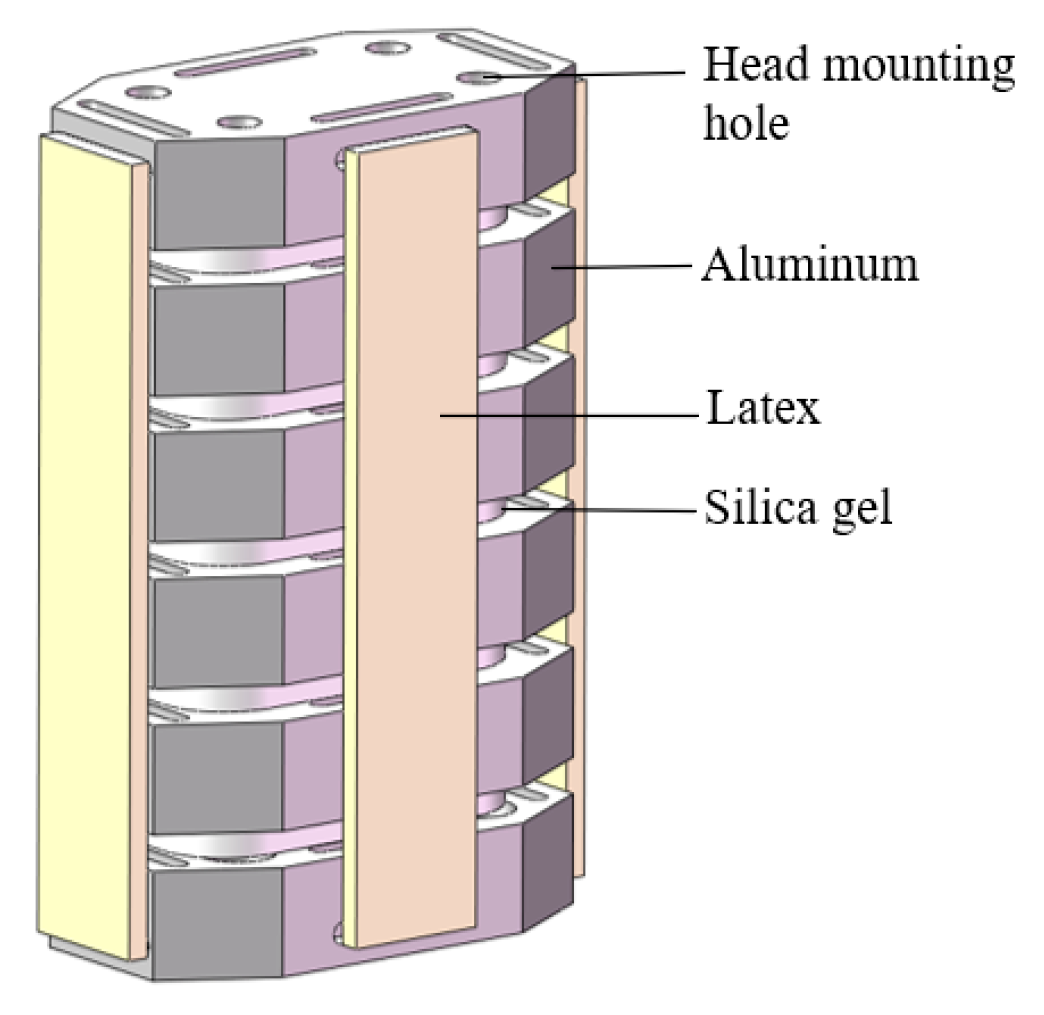

3.1. Structure and Material

Mature dummies on the market, such as the Hybrid III and Thor. Necks are constructed from alternating layers of rubber and metal components, which facilitates the neck’s bending and stretching motions, while a steel cable positioned within the central bore of the neck ensures the overall structural integrity. Guided by the characteristics of the human and mature dummy neck, efforts are made to ensure that the simplified dummy’s head–neck structure is capable of recognizing damage while remaining easy to manufacture, assemble, and disassemble.

Figure 4 shows the neck structure of the simplified dummy, which is composed of simulated vertebral bodies and intervertebral discs stacked together and surrounded by four symmetrically distributed latex straps with simulated ligaments. The simulated vertebral bodies are made of aluminum with high rigidity. The simulated intervertebral discs are made of silicone, which offers greater elasticity and damping compared to aluminum. These components are tightly fit and secured by latex straps. The latex straps allow for the adjustment of the overall equivalent stiffness and damping of the cervical spine within a small range by varying their tension.

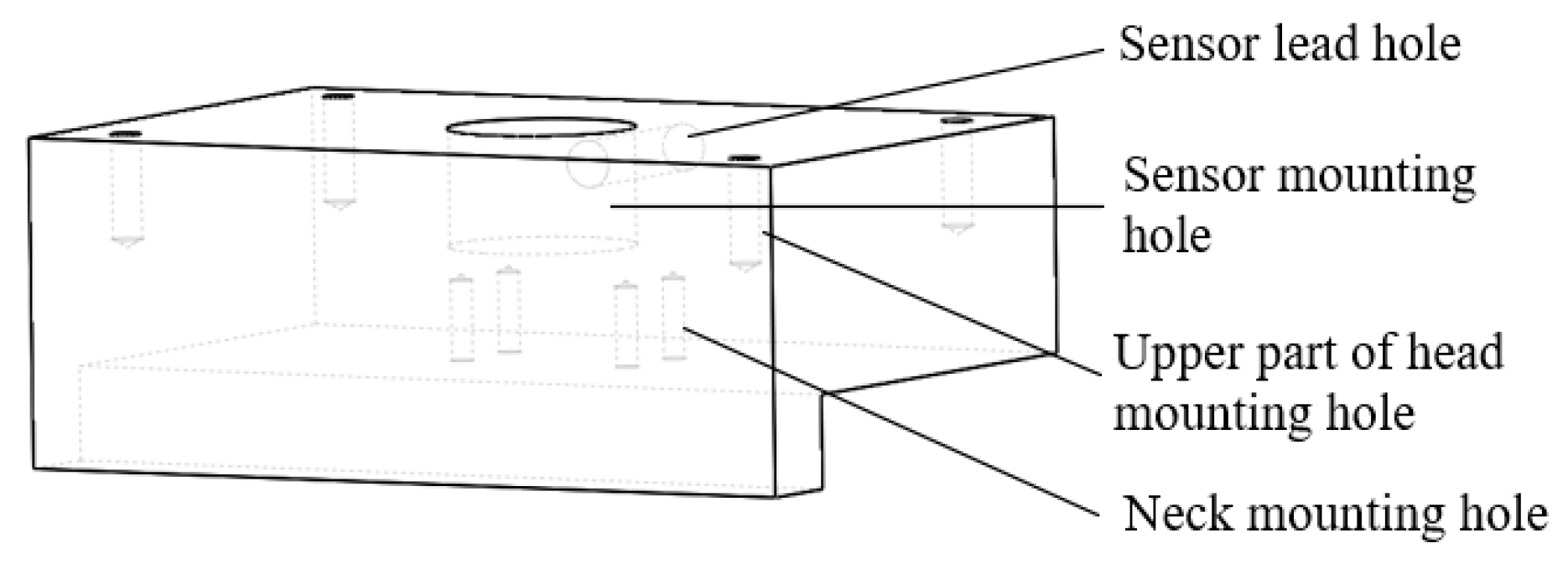

The head of the simplified dummy is primarily designed to simulate the mass of the human head. The head is constructed from PVC with a mass of 4.5 kg. As shown in

Figure 5, the head consists of upper and lower segments connected by screws, which can be disassembled for sensor installation. A threaded mounting hole is provided at the center of mass to accommodate an accelerometer. This accelerometer is used to measure the head’s acceleration under impact loading. A dedicated hole is included for routing the signal lines from the accelerometer.

Figure 6 displays the physical model of the head–neck structure. Four threaded counterbores are machined into the topmost and bottom vertebral bodies, serving as reserved screw holes for threaded connections between the neck and the head and thorax.

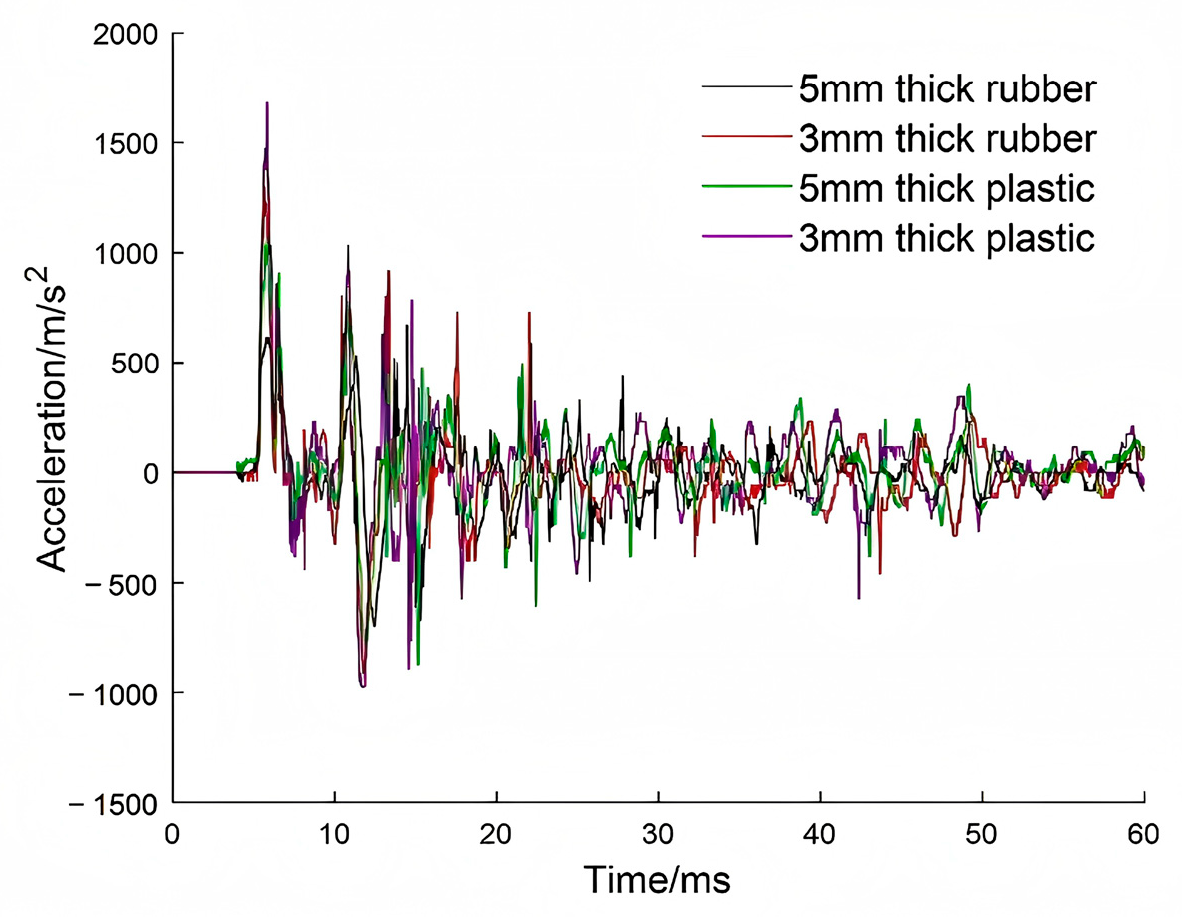

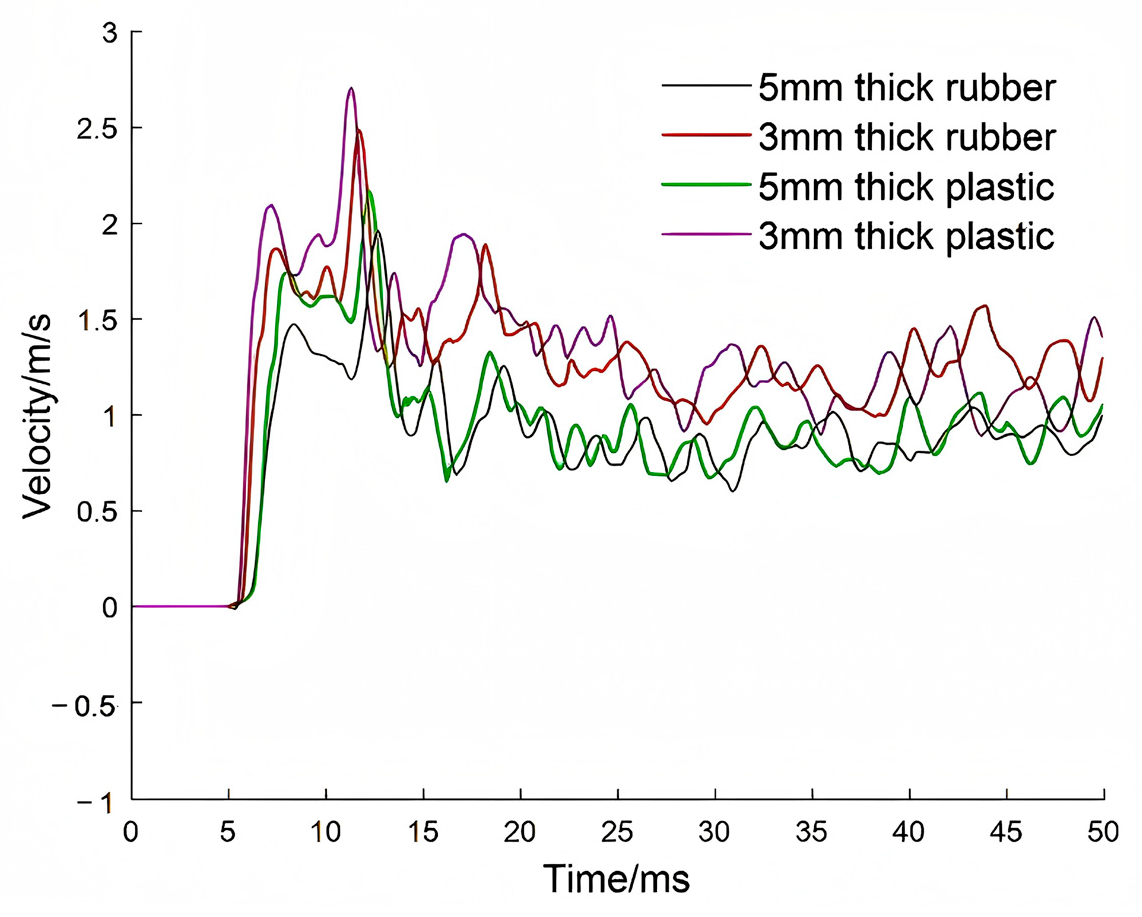

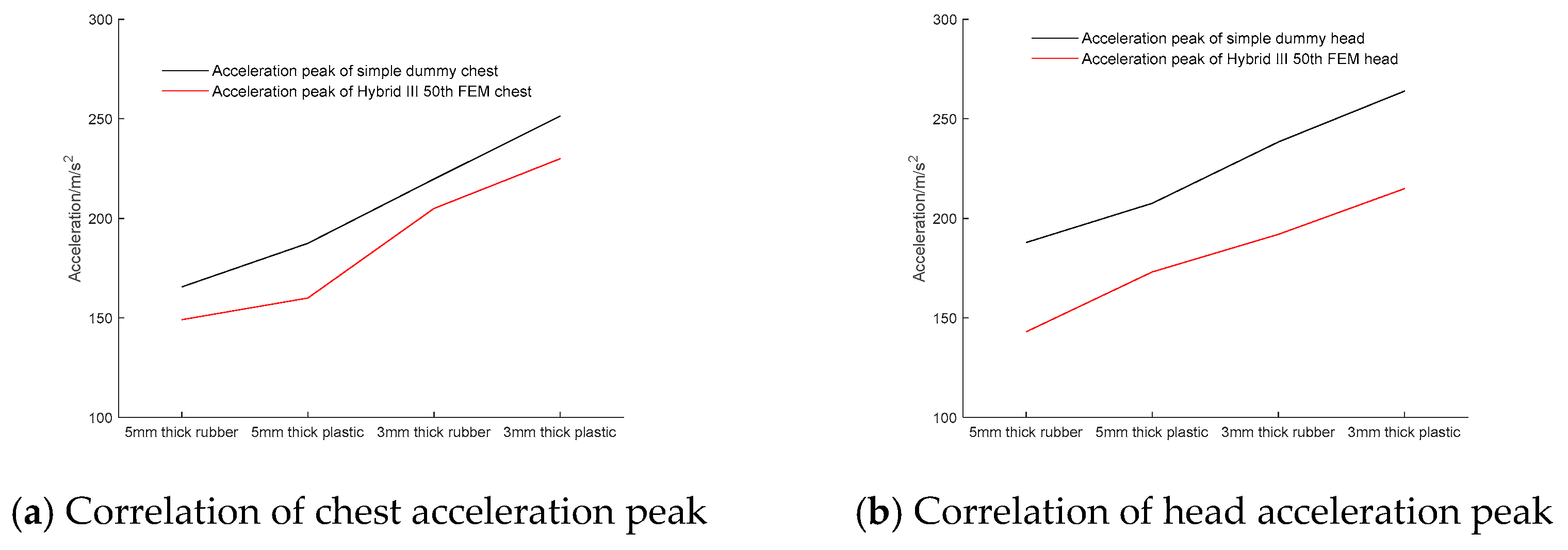

Section 5.4 will verify the structure’s ability to identify response variation by calculating the correlation.

3.2. Physical Model Properties

Given that the Hybrid III 50th high-biofidelity dummy serves as the reference in this work, the simplified dummy is designed to replicate its characteristics as closely as possible. In 1988, Kaleps conducted measurements of the mass, moments of inertia, center of gravity, and joint coordinates of various segments of the Hybrid III 50th dummy [

32]. The study included the joints’ local coordinates defined relative to the segmental center of gravity and the corresponding transformation matrices from the principal to the local reference coordinate systems. The global coordinate system was defined with its origin at the center of gravity of the thorax, and the global coordinates of all body segments were subsequently calculated.

Table 1 compares the mass, center of gravity, and joint coordinates of each segment in the head–neck structure between the simplified dummy and the Hybrid III. The deviation in segmental mass remains below 12.3%, while the discrepancies in center of gravity and joint locations are within 17.1%.

In head–neck biomechanical analysis, the neck is a critical structure for force transmission and kinematic coupling between the head and torso. Its mechanical properties significantly influence the head’s inertial response and injury risk. As a result, accurate representation of neck characteristics is essential for reliable evaluation of head–neck dynamics under impact or blast conditions. Material properties for the vertebral bodies and intervertebral discs were obtained from the LSTC Hybrid III FEM and compared against those of the simplified dummy, whose parameters were supplied by the manufacturer. In the finite element model, the vertebral bodies are made of aluminum and modeled using a linear elastic constitutive equation, while the intervertebral discs are represented by rubber with a viscoelastic constitutive model. In the simplified dummy, the vertebral bodies are also made of aluminum, whereas the intervertebral discs are made of silicone. According to the comparison results in

Table 2, the material properties of the vertebral bodies are identical, as both use aluminum. However, significant differences are observed in the intervertebral discs: the simplified discs are softer and exhibit greater damping. To achieve a balance, the thickness of the simplified discs was reduced.

Although the segmental mass and center of gravity of the simplified dummy were designed to closely match those of the Hybrid III 50th, significant differences remain due to the use of low-cost materials, and moments of inertia were not considered. Therefore, a mapping model based on a 1D-CNN was developed to reduce these discrepancies.

7. Discussion

The present study proposes a novel method for simulating blast-induced biomechanical responses using a simplified dummy and mapping test model calibration based on 1d-CNN. The primary contribution of this study lies in the proposal and validation of the method; however, certain limitations remain and will be addressed in future research.

First, future investigations should consider scenarios involving greater TNT equivalents or variations in blast angle to fully assess the model’s performance under extreme or oblique loading. In accordance with AEP-55 [

5] standards, the reference equivalent for armored vehicle underbelly mine testing is specified as 6, 8, and 10 kg TNT, and the blast tests should incorporate five critical impact orientations: frontal (0°), lateral (90°), rear (180°), anterolateral (45°), and posterolateral (135°) relative to the occupant position. Due to safety constraints at our testing facility and the use of a simplified rig simulating the vehicle’s under-body structure, high-yield explosives were not employed in this phase. The primary objective of this study was to develop and validate the proposed methodology. Future work will incorporate large-yield detonations and multi-directional blast testing to fully evaluate system performance. For the simulated explosion test, Krayterman [

44] and Cheng [

45] used a vertical shock machine to generate impulses representative of under-body blast loading. Somasundaram employs a hydraulic mechanism to accelerate the dummy-mounted sled, enabling controlled impact with a barrier for dynamic testing [

19]. A pressurized cylinder was employed by Marie Bailey to drive a hammer sled into the dummy-mounted floor and seat platen [

7,

8]. These methods can serve as references for future high-impact loading applications on the simplified dummy. To date, the simulated explosion test of varying impact angles on human body responses remains largely unexplored. Future research could aim to develop experimental blast simulation techniques capable of adjusting the impact trajectory angle.

Second, while the laboratory-based pendulum experiments offer controllable and repeatable conditions, they inherently differ from real explosive environments. Actual blast scenarios may involve multidirectional forces, complex fluid-structure interactions, and secondary effects such as fragment impacts, none of which are replicated in the current setup. These differences should be taken into account when interpreting the validity and generalizability of the results. While the problem of uniaxial loading has been mitigated in recent research, the complex multidirectional characteristics of blast waves and secondary phenomena remain challenging to reproduce. It is necessary to develop an experimental apparatus that can replicate the coupled effects of blast overpressure and fragment impact to better simulate real-world explosive loading conditions.

Third, the validation cases remain relatively limited in number and diversity. The current framework does not account for alternative loading configurations, such as varying occupant postures or different seat structures, which may significantly influence biomechanical outcomes. Expanding the experiment and simulation to encompass a broader range of real-world conditions would enhance the method’s robustness.

Future work will aim to address these limitations by expanding the methodology to other anatomical regions, such as the lumbar spine or lower limbs. A methodology similar to that presented in this study could be adopted for spinal injury assessment. Using the Driz criterion as a basis, the input to the mapping model can be set as the pelvic acceleration of the simplified dummy, while the output corresponds to the pelvic acceleration obtained from a high-biofidelity dummy or finite element model. Moreover, comparing the proposed 1D-CNN architecture with alternative deep learning models will help further validate the rationale behind the chosen calibration approach and potentially improve its accuracy and generalizability. For example, Mirhashemi [

46] utilized artificial neural networks (ANNs) to calibrate and simplify the data acquisition process for multi-hole probes. ANNs can establish complex mapping relationships between input data and output results, which meets our requirements. According to Wang’s review, machine learning algorithms—including random forests, support vector regression (SVR), and neural networks—have been shown to significantly enhance the performance and reliability of low-cost gas sensor systems [

47]. In future research, efforts will be made to identify and evaluate alternative algorithms that may outperform the current 1D-CNN architecture.

8. Conclusions

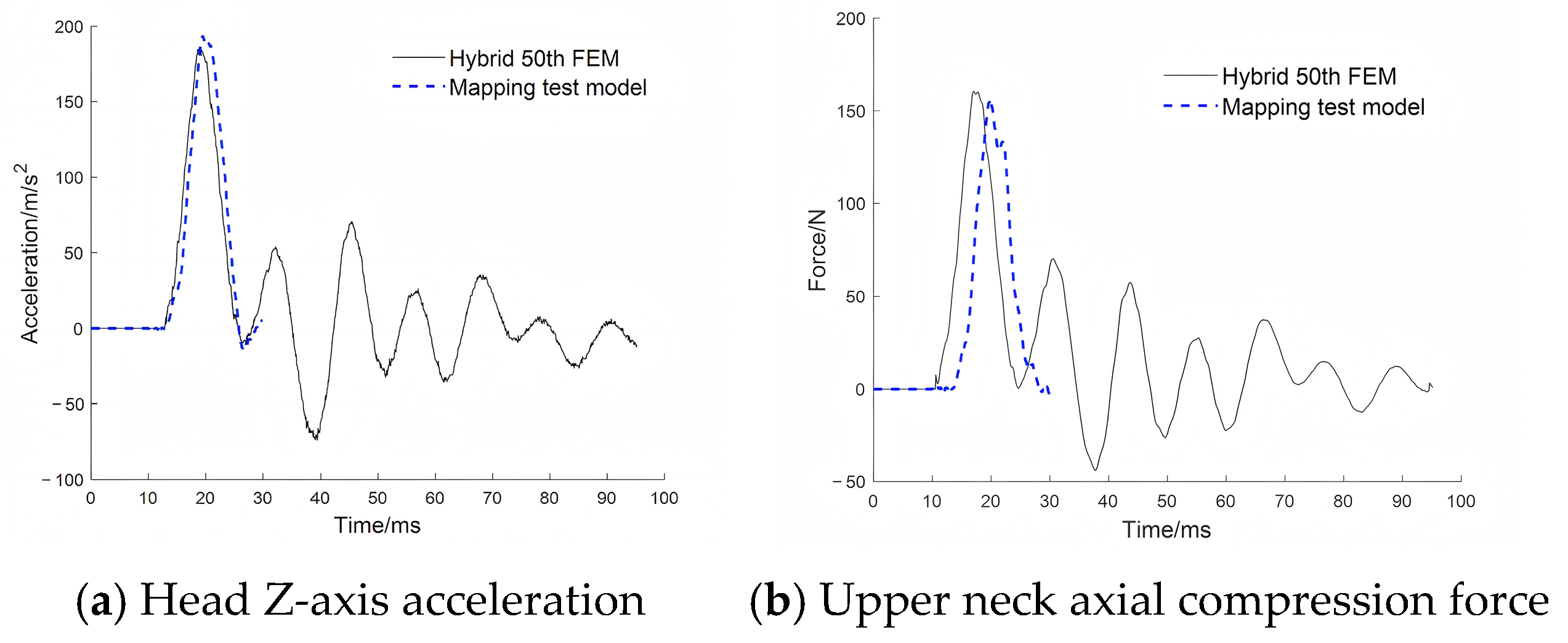

To address the trade-off between biofidelity and the cost associated with anthropomorphic test devices, a novel test methodology for evaluating head–neck injuries in blast environments was developed, leveraging a synergy of virtual and physical testing paradigms. A low-cost simplified dummy was designed to test human body responses, and a mapping test model based on 1D-CNN was proposed to calibrate the measured data.

(1) A head–neck physical model is proposed, replicating the segmental mass and center of gravity distribution of the Hybrid III 50th percentile dummy. Its cervical spine is composed of stacked simulated vertebral bodies and intervertebral discs. By calculating the correlation between the chest and head acceleration peak of the simplified dummy and those of the Hybrid III 50th FEM under the same loads, it is demonstrated that the head–neck response of the simplified dummy physical model exhibits a strong positive correlation with the response of the Hybrid III 50th FEM. This indicates that the head–neck physical model of the simplified dummy possesses the capability to identify response variation.

(2) The mapping relationship between the responses of the simplified dummy and the Hybrid III FEM was established through NSGA-II to train the parameters of 1D-CNN. The training data were acquired by employing the pendulum collision to simulate the under-body blast impact on the dummy. The explosion test verification was conducted, and the responses of the Hybrid III 50th numerical model under the same load were taken as a benchmark. The relative error of HIC output by this test method is 10.9%, and the relative error of maximum axial compression force of the upper neck is 2.4%, affirming the efficacy of the combined physical dummy and surrogate model in assessing blast-induced trauma.