The Health-Promoting Potential of Fruit Pomace and Its Application in the Confectionery Industry

Abstract

1. Introduction

2. Confectionery Industry

| Country | Confectionery Market Value | Non-Chocolate Confectionery Segment | Key Trends | Reference |

|---|---|---|---|---|

| Global | EUR 265.61 billion (2023) | No detailed data available | Growing demand for premium products, rising environmental awareness, and interest in healthier alternatives. | [9] |

| China | EUR 69.87 billion (2023) | No data available | The growing middle class increases confectionery consumption, raising interest in premium products. | [14] |

| United States | EUR 69.62 billion (2023) | No data available | Increasing popularity of functional and eco-friendly products; rising interest in sugar-free alternatives. | [14] |

| Germany | EUR 8.64 billion (2023) | No data available | Stable market with a slight value decline (−1.68%); consumers seek high-quality products. | [15] |

| France | EUR 6.37 billion (2023) | No data available | Slight market growth (+0.38%); increasing interest in artisanal products. | [15] |

| United Kingdom | EUR 6.09 billion (2023) | No data available | Stable market with slight growth (+0.46%); consumers focus on ingredients and product origin. | [15] |

| Poland | EUR 2.11 billion (2023) | EUR 6.02 million | Growth in gummy sales (43.4% of the non-chocolate confectionery market) and hard candies (12.4%); rising interest in functional and eco-friendly products. | [9] |

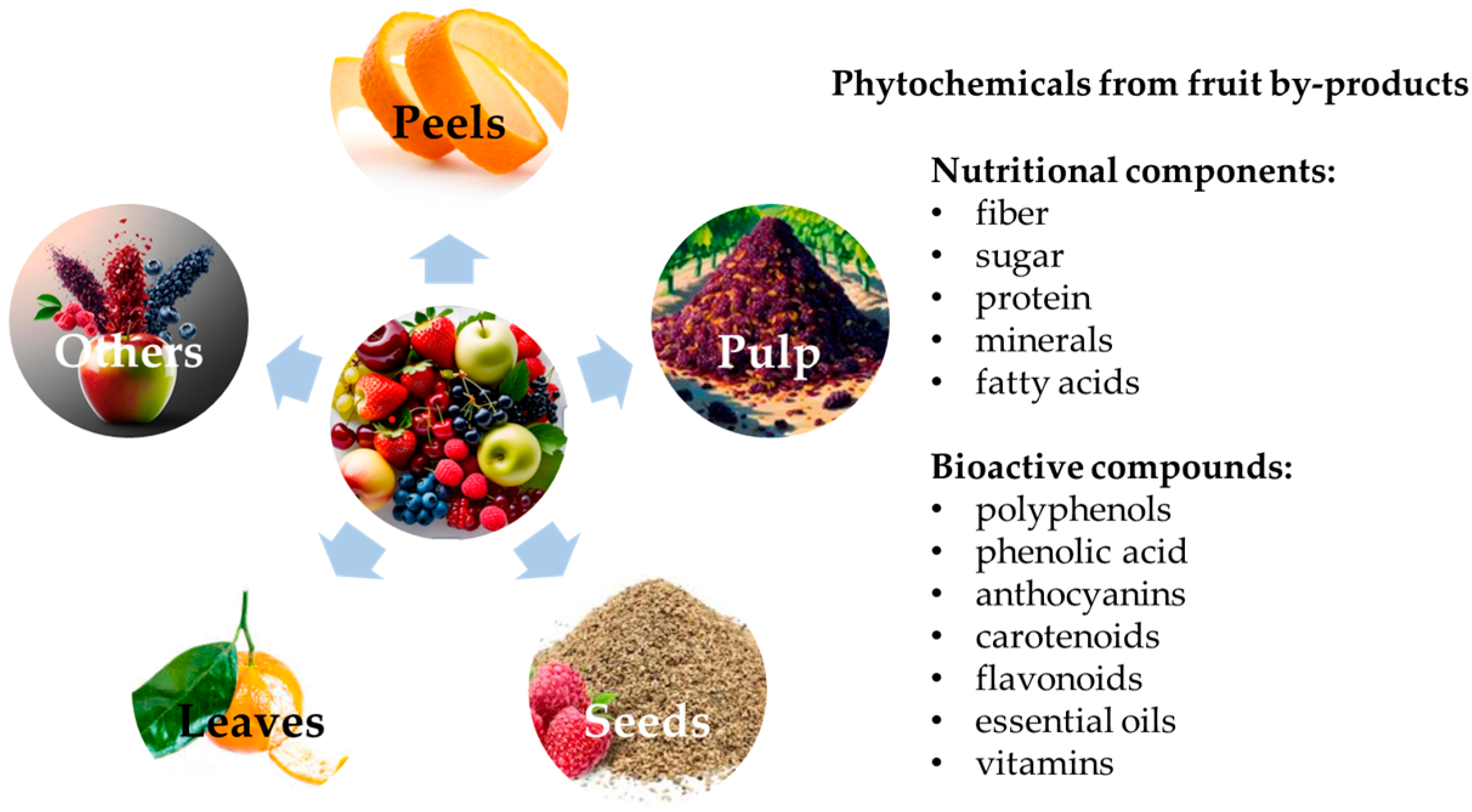

3. Fruit Pomace: A Nutrient-Rich By-Product with Potential in Food Technology

Characteristics of Selected Fruit Pomace—Ingredients and Properties

| Sources of Pomace | Bioactive Compounds | Health Benefits | Reference |

|---|---|---|---|

| Apple | Phenolic acids (52.3–2453.76 mg/100 g): chlorogenic acid, hydroxycinnamic acids, ferulic acid, p-coumaric acid, sinapic acid, p-coumaroyl-quinic acid, caffeic acid, 2-hydroxybenzoic acid, gallic acid, gallic acid-glucoside, gentisic acid, vanillic acid, cinnamic acid, protocatechuic acid; Flavonoids (2.153–120.96 mg/g): quercetin, catechins, epicatechin, phloridzin, isorhamnetin, kaempferol, myricetin, rutin; Anthocyanins (5.0–13.0 mg/100 g): cyanidin-3-O-galactoside; Triterpenes: oleanolic acid, maslinic acid, ursolic acid; Dietary Fiber (36.5–57.9%). | digestive health; blood sugar regulation; prebiotic, antimicrobial, anti-inflammatory, anticancer, antioxidant, and cardio-protective effects | [24,25,28,29,30,31,32,33] |

| Grape | Stilbenes: resveratrol (0.052–0.160 mg/g); Phenolic Acids: gallic acid (0.116–0.729 mg/g), protocatechuic acid, p-hydroxyphenylacetic acid, vanillic acid, homovanillic acid, homoprotocatechic acid, protocatechuic acid, gentisic acid, syringic acid, 4-O-methylgallic acid, 3-O-methylgallic acid, dihydro-3-coumaric acid, hydroferulic acid, hydrocaffeic acid, isoferulic acid; Flavanols: epigallocatechin, catechins, epicatechin, procyanidin B2; Flavonoid (9.87–50.32 mg CE/g); Flavonoid Glycosides: hyperoside, isoquercitrin, rutin, quercitrin; Flavonoid Aglycons: quercetin (0.047–0.557 mg/g), luteolin; Flavonols: myricetin-3-O-rhamnoside; Anthocyanins (375–4527): 3-O-glucosides of delphinidin, cyanidin, petunidin, pelargonidin, peonidin, malvidin. | heart, gut, and skin health; anti-aging, anti-inflammatory, antioxidant, antitumor, antimicrobial, anti-diabetic, anti-hyperlipidemic effects | [37,38,39,40,41,42] |

| Mandarin orange | Phenolic Acids: gallic acid (0.232–0.307 mg/g), p-coumaric acid, chlorogenic acid, ferulic acid; Flavonoid: hesperidin, quercetin; TPC (41.26–46.17 mg GAE/g); TFC (28.17–33.21 mg QE/g); TCC (1.91–1.97 mg β-carotene/g). | antioxidant activity | [36] |

| Orange | TPC (2.41 g GAE/100 g); TFC (1.36 g RE/100 g); Proanthocyanidins (0.003 mg CyE/100 g). | antioxidant and anti-inflammatory activities | [34] |

| Lemon | TPC (2.46 g GAE/100 g); TFC (1.53 g RE/100 g); Proanthocyanidins (0.004 mg CyE/100 g). | ||

| Chokeberry | TPC (9.01–51.1 mg GAE/g): 3-hydroxybenzoic acid, vanillic acid, ellagic acid, gallic acid, chlorogenic acid, methoxycinnamic acid, ferulic acid; TFC (1.89 mg QE/g): epicatechin, quercetin, resveratrol; Xanthophylls: lutein and zeaxanthin, canthaxanthin; Tocopherols: α-tocopherol, γ-tocopherol, δ-tocopherol; Total anthocyanins (1.58–3.05 mg/g): cyanidin-3-O-galactoside; cyanidin-3-O-glucoside, cyanidin 3-O-arabinoside, cyanidin 3-O-xyluside. | anti-inflammatory, anticancer, antiproliferative, and antioxidative activities | [45,48] |

| Blueberry | TPC (3.8–19.54 mg GAE/g): chlorogenic acid, caffeic acid, 4-hydroxycinnamic acid; Flavanols: catechin, epicatechin, procyanidin B2, myricetin, kaempferol, quercetin; Total anthocyanins (0.83–5.65 mg/g): delphinidin 3-O-galactoside, cyanidin-3-O-galactoside, cyanidin-3-O-glucoside, petunidin-3-O-glucoside, petunidin-3-galactoside, malvidin-3-O-glucoside, malvidin-3-O-galactoside, pelargonidin-3-O-galactoside. | anti-inflammatory, anticancer, antiproliferative, antioxidative, antimicrobial, antitumor effects | [45,46,47] |

| Raspberry | TPC (0.633–20.15 mg/g GAE): gallic acid, caffeic acid, p-coumaric acid, chlorogenic acid, ellagic acid (49.15–105.52 µg/g); TFC (3.16–8.02 mg/g QE; 0.592–45.51 mg/g RE): quercetin; Total anthocyanins (0.65–12.61 mg/g C3G): cyanidin-3-O-sophoroside, cyanidin-3-O-glucoside. | antioxidative, anti-inflammatory, anticancer, antimicrobial | [47,49,50,51] |

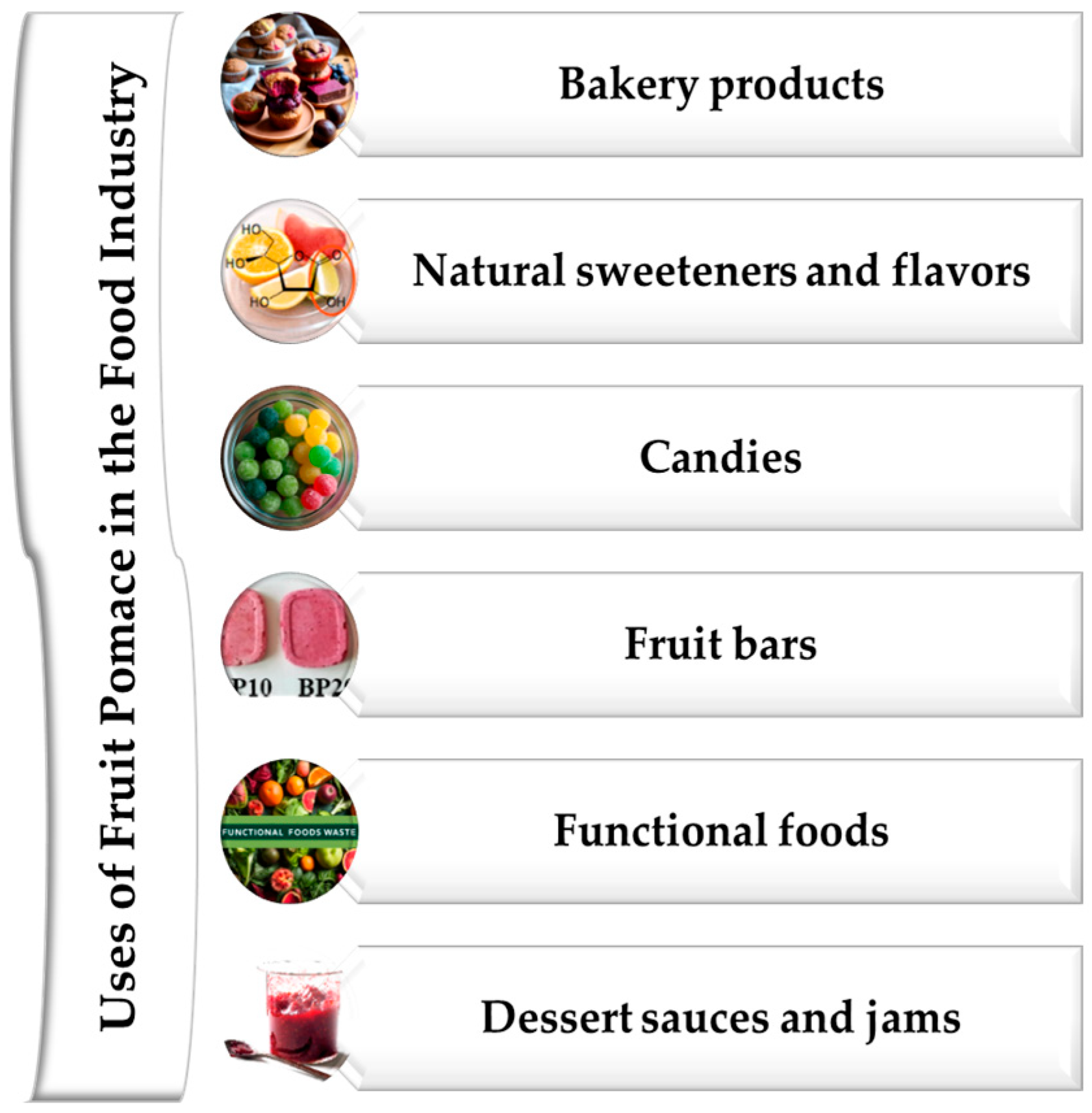

4. The Use of Pomace in the Confectionery Industry

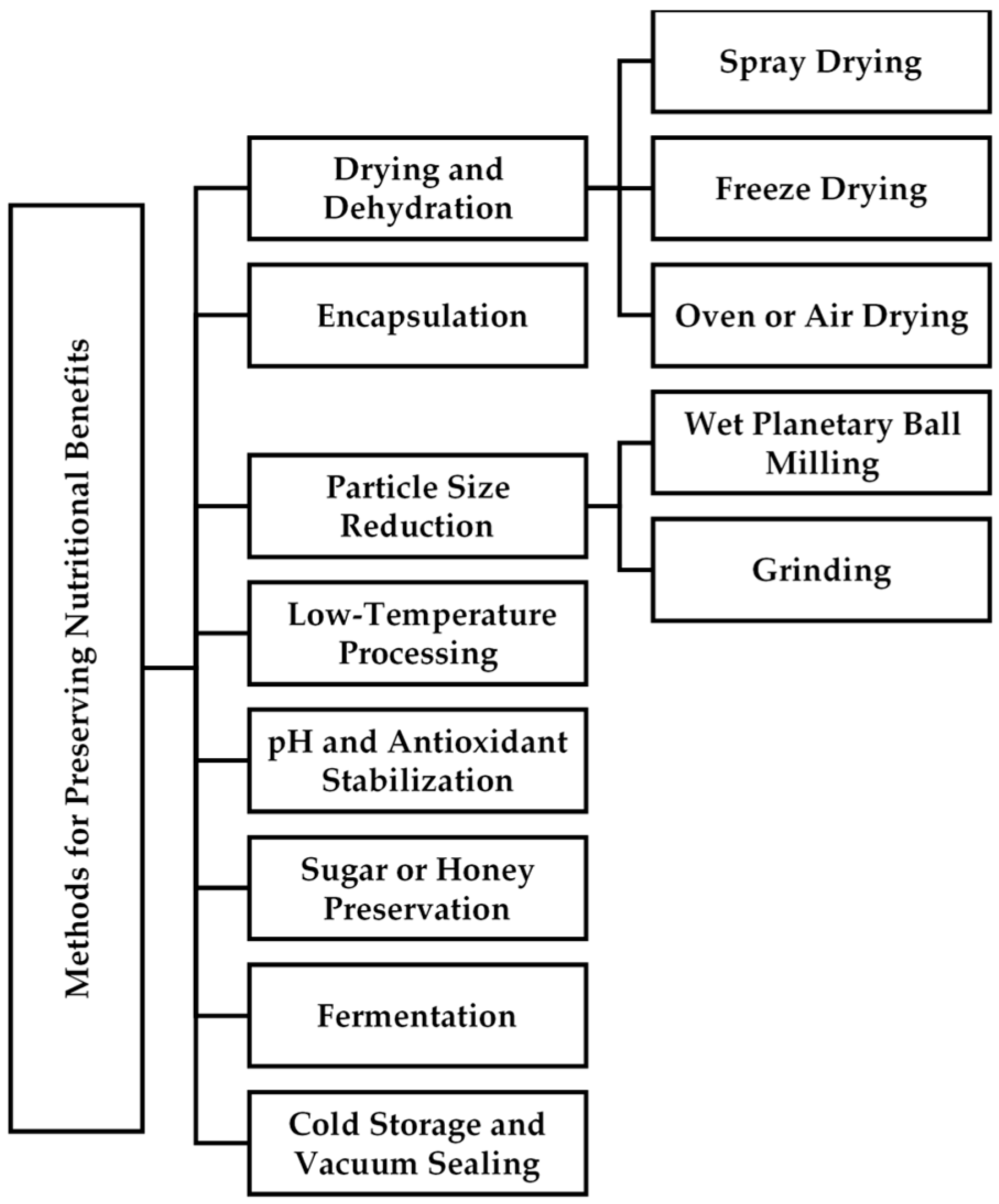

5. The Methods Used for Preserving the Nutritional Benefits of Pomace as Candy Fillings

5.1. Extraction Techniques

5.2. Spray Drying

5.3. Freeze Drying

5.4. Oven or Air Drying

5.5. Wet Planetary Ball Milling

5.6. Grinding

5.7. Enzymatic Treatments

5.8. Infrared and Heat Treatments

6. Risks and Difficulties Resulting from the Use of Pomace in Food

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gupta, R.K.; Ali, E.A.E.; Abd El Gawad, F.; Daood, V.M.; Sabry, H.; Karunanithi, S.; Srivastav, P.P. Valorization of fruits and vegetables waste by-products for development of sustainable food packaging applications. Waste Manag. Bull. 2024, 2, 21–40. [Google Scholar] [CrossRef]

- Miah, J.H.; Griffiths, A.; McNeill, R.; Halvorson, S.; Schenker, U.; Espinoza-Orias, N.D.; Morse, S.; Yang, A.; Sadhukhan, J. Environmental management of confectionery products: Life cycle impacts and improvement strategies. J. Clean. Prod. 2018, 177, 732–751. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, H.; Bhatt, S.; Deutsch, J.; Suri, R. Addressing food waste: How to position upcycled foods to different generations. J. Consum. Behav. 2021, 20, 242–250. [Google Scholar] [CrossRef]

- Sudha, M.L.; Priyanka, R. Fruit and Vegetable Waste (by-Product) Utilization in Bakery Products Review. Nov. Tech. Nutr. Food Sci. 2023, 6, 636–644. [Google Scholar]

- Szymanowska, U.; Karaś, M.; Bochnak-Niedźwiecka, J. Antioxidant and Anti-Inflammatory Potential and Consumer Acceptance of Wafers Enriched with Freeze-Dried Raspberry Pomace. Appl. Sci. 2021, 11, 6807. [Google Scholar] [CrossRef]

- Sharma, C.; Sherman, R.; Deutsch, J. Opportunities for Upcycled Ingredients in the Confectionery Industry: Appealing to Consumers While Reducing Food Waste. Manuf. Confect. 2022, 13–18. [Google Scholar]

- Ozkan, G.; Günal-Köroğlu, D.; Capanoglu, E. Chapter One—Valorization of fruit and vegetable processing by-products/wastes. In Advances in Food and Nutrition Research; Academic Press: San Diego, CA, USA, 2023; Volume 107, pp. 1–39. [Google Scholar]

- Mildner-Szkudlarz, S.; Bajerska, J.; Górnaś, P.; Segliņa, D.; Pilarska, A.; Jesionowski, T. Physical and Bioactive Properties of Muffins Enriched with Raspberry and Cranberry Pomace Powder: A Promising Application of Fruit By-Products Rich in Biocompounds. Plant Foods Hum. Nutr. 2016, 71, 165–173. [Google Scholar] [CrossRef] [PubMed]

- Straits Research. Confectionery Market Size, Share & Trends Analysis Report By Product Type (Hard-Boiled Sweets, Mints, Gums & Jellies, Chocolate, Caramels & Toffees, Medicated Confectionery, Fine Bakery Wares, Others), By Age Group (Children, Adult, Geriatric), By Price Point (Economy, Mid-Range, Luxury), By Distribution Channel (Supermarket/Hypermarket, Convenience Stores, Pharmaceutical & Drug Stores, Food Services, Duty-Free Outlets, E-Commerce, Others) and By Region (North America, Europe, APAC, Middle East and Africa, LATAM) Forecasts, 2024–2032. SRFB3446DR. 2024. Available online: https://www.fortunebusinessinsights.com/industry-reports/confectionery-market-100542 (accessed on 3 March 2025).

- Ciurlă, L.; Enache, I.M.; Buțerchi, I.; Mihalache, G.; Lipșa, F.D.; Patraș, A. A New Approach to Recover Bioactive Compounds from Apple Pomace: Healthy Jelly Candies. Foods 2024, 14, 39. [Google Scholar] [CrossRef]

- Myers, A. How Natural Sweeteners Became a Gamechanger for Confectionery. Confectionery News, 8 September 2022. Available online: https://www.confectionerynews.com/Article/2022/09/08/how-natural-sweeteners-became-a-gamechanger-for-confectionery/ (accessed on 3 March 2025).

- Sayas-Barberá, E.; Paredes, C.; Salgado-Ramos, M.; Pallarés, N.; Ferrer, E.; Navarro-Rodríguez de Vera, C.; Pérez-Álvarez, J.Á. Approaches to Enhance Sugar Content in Foods: Is the Date Palm Fruit a Natural Alternative to Sweeteners? Foods 2023, 13, 129. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Daily, R. Sugar Reduction in 2024: How Consumer Demands, Health Policies Will Influence Product Launches. Bakery and Snacks, 7 December 2023. Available online: https://www.bakeryandsnacks.com/Article/2023/12/07/Sugar-reduction-in-2024-How-consumer-demands-health-policies-will-influence-product-launches/ (accessed on 3 March 2025).

- Wunsch, N.G. Global Confectionery Market Revenue by Country. Statista, 9 December 2024. Available online: https://www.statista.com/statistics/758648/revenue-of-the-confectionery-market-worldwide-by-country/ (accessed on 16 May 2025).

- European Confectionery Market Value by Country. Report Linker. 2023. Available online: https://www.reportlinker.com/dataset/3e6b7ca0f43cf7209888528783ded426fcad8244 (accessed on 3 March 2025).

- Galanakis, C.M. Valorization of Fruit Processing By-Products; Academic Press: San Diego, CA, USA, 2019. [Google Scholar]

- Galanakis, C.M. Food Waste Recovery: Processing Technologies and Industrial Techniques; Academic Press: San Diego, CA, USA, 2015. [Google Scholar]

- Kawecka, L.; Galus, S. Wytłoki owocowe—Charakterystyka i możliwości zagospodarowania. Postępy Tech. Przetwórstwa Spożywczego 2021, 1, 156–167. [Google Scholar]

- Piasecka, I.; Górska, A. Possible uses of fruit pomaces in food technology as a fortifying additive—A review. Zesz. Probl. Postępów Nauk. Rol. 2020, 600, 43–54. [Google Scholar] [CrossRef]

- Iqbal, A.; Schulz, P.; Rizvi, S.S.H. Valorization of bioactive compounds in fruit pomace from agro-fruit industries: Present Insights and future challenges. Food Biosci. 2021, 44, 101384. [Google Scholar] [CrossRef]

- Hussain, A.; Rehman, A.; Kauser, S.; Ali, A.; Arif, M.R.; Fatima, H.; Korma, S.A. Evaluation of peel, flesh, and kernel of mango (Mangifera indica L.) for phytochemicals and application as functional ingredients in bakery formulation. Nutrire 2024, 49, 45. [Google Scholar] [CrossRef]

- Netreba, N.; Sergheeva, E.; Gurev, A.; Dragancea, V.; Codină, G.G.; Sturza, R.; Ghendov-Mosanu, A. The Influence of Pomace Powder of Musky Squash on the Characteristics of Foamy Confectionery Products during Storage. Appl. Sci. 2024, 14, 6671. [Google Scholar] [CrossRef]

- Šeremet, D.; Mandura, A.; Cebin, A.V.; Martinić, A.; Galić, K.; Komes, D. Challenges in confectionery industry: Development and storage stability of innovative white tea-based candies. J. Food Sci. 2020, 85, 2060–2068. [Google Scholar] [CrossRef]

- Lin, L.; Peng, A.; Yang, K.; Zou, Y. Monomeric phenolics in different parts of high-acid apple (Malus sieversii f. niedzwetzkyana (Dieck) Langenf): A promising source of antioxidants for application in nutraceuticals. Int. J. Food Sci. Technol. 2018, 53, 1503–1509. [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple pomace as a functional and healthy ingredient in food products: A review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- Fraterrigo Garofalo, S.; Demichelis, F.; Peletti, V.; Picco, L.; Tommasi, T.; Fino, D. Comparative study of polyphenol extraction using physical techniques and water as a solvent: A sustainable approach for the valorization of apple pomace. Environ. Sci. Pollut. Res. 2024, 1–14. [Google Scholar] [CrossRef]

- Wadhwa, M.; Bakshi, M. Utilization of Fruit and Vegetable Wastes as Livestock Feed and as Substrates for Generation of Other Value-Added Products; RAP Publication; FAO: Bangkok, Thailand, 2013. [Google Scholar]

- Barreira, J.C.; Arraibi, A.A.; Ferreira, I.C. Bioactive and Functional Compounds in Apple Pomace from Juice and Cider Manufacturing: Potential Use in Dermal Formulations. Trends Food Sci. Technol. 2019, 90, 76–87. [Google Scholar] [CrossRef]

- Pascoalino, L.A.; Barros, L.; Barreira, J.C.; Oliveira, M.B.P.; Reis, F.S. Closing the loop: Exploring apple pomace as a source of bioactive compounds in the framework of circular economy. Sustain. Food Technol. 2025, 3, 81–95. [Google Scholar] [CrossRef]

- Rabeeah, I.; Gruber-Schmidt, V.; Murray, H.; Afsharzadeh, N.; Paltram, R.; Marinovic, S.; Haselmair-Gosch, C. Apple pomace as a potential source of oxidative stress-protecting dihydrochalcones. Antioxidant 2024, 13, 1159. [Google Scholar] [CrossRef] [PubMed]

- Plamada, D.; Simon, E.; Nemes, S.A.; Teleky, B.E.; Odocheanu, R.; Szabo, K.; Vodnar, D.C. Exploring the in vitro prebiotic potential of two different freeze-dried apple pomace cultivars. Food Biosci. 2025, 64, 105892. [Google Scholar] [CrossRef]

- Duggan, J.; Yu, L.; Fitter, S.; Kumorkiewicz-Jamro, A.; Vandyke, K.; Bulone, V.; Zannettino, A. Apple Pomace Polyphenols Extracted by Deep Eutectic Solvent Ameliorate Lipopolysaccharide-Induced Inflammation in RAW264.7 Murine Macrophages and Human Monocyte-Derived Macrophages. ACS Food Sci. Technol. 2025, 5, 1354–1364. [Google Scholar] [CrossRef]

- Ingegneri, M.; Braghini, M.R.; Piccione, M.; De Stefanis, C.; Mandrone, M.; Chiocchio, I.; Trombetta, D. Citrus Pomace as a Source of Plant Complexes to Be Used in the Nutraceutical Field of Intestinal Inflammation. Antioxidants 2024, 13, 869. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Ye, Z.; Ji, C.; Zhou, Z. Antioxidant, Anti-Inflammatory, and Anticancer Activities of Five Citrus Peel Essential Oils. Antioxidants 2024, 13, 1562. [Google Scholar] [CrossRef] [PubMed]

- Kaur, S.; Panesar, P.S.; Chopra, H.K.; Singh, V. Exploring the Bioactive Potential of Citrus reticulata Pomace: Extraction, Characterization, and Applications. Food Humanit. 2025, 4, 100518. [Google Scholar] [CrossRef]

- Karastergiou, A.; Gancel, A.L.; Jourdes, M.; Teissedre, P.L. Valorization of grape pomace: A review of phenolic composition, bioactivity, and therapeutic potential. Antioxidants 2024, 13, 1131. [Google Scholar] [CrossRef]

- Almanza-Oliveros, A.; Bautista-Hernández, I.; Castro-López, C.; Aguilar-Zárate, P.; Meza-Carranco, Z.; Rojas, R.; Martínez-Ávila, G.C.G. Grape pomace—Advances in its bioactivity, health benefits, and food applications. Foods 2024, 13, 580. [Google Scholar] [CrossRef]

- Wang, C.; You, Y.; Huang, W.; Zhan, J. The high-value and sustainable utilization of grape pomace: A review. Food Chem. 2024, 24, 101845. [Google Scholar] [CrossRef]

- Cappa, C.; Lavelli, V.; Mariotti, M. Fruit candies enriched with grape skin powders: Physicochemical properties. LWT Food Sci. Technol. 2015, 62, 569–575. [Google Scholar] [CrossRef]

- Yang, C.; Han, Y.; Tian, X.; Sajid, M.; Mehmood, S.; Wang, H.; Li, H. Phenolic composition of grape pomace and its metabolism. Crit. Rev. Food Sci. Nutr. 2024, 64, 4865–4881. [Google Scholar] [CrossRef] [PubMed]

- da Lopes, J.C.; Madureira, J.; Margaça, F.M.A.; Cabo Verde, S. Grape Pomace: A Review of Its Bioactive Phenolic Compounds, Health Benefits, and Applications. Molecules 2025, 30, 362. [Google Scholar] [CrossRef]

- Bojang, K.P.; Varalakshmi, M. Effectiveness of Grape-Based Interventions on Cognitive and Mental Health: Evidence from Human Trials. Curr. Nutr. Rep. 2025, 14, 19. [Google Scholar] [CrossRef]

- Cichowska, J.; Kowalska, H.; Czajkowska, K.; Hankus, M. Using the potential of osmotic dehydration and health-promoting properties of fruits in creating new food products. Adv. Food Process. Technol. 2016, 2, 103–107. [Google Scholar]

- Stanca, L.; Bilteanu, L.; Bujor, O.C.; Ion, V.A.; Petre, A.C.; Bădulescu, L.; Geicu, O.I.; Pisoschi, A.M.; Serban, A.I.; Ghimpeteanu, O.-M. Development of functional foods: A comparative study on the polyphenols and anthocyanins content in chokeberry and blueberry pomace extracts and their antitumor properties. Foods 2024, 13, 2552. [Google Scholar] [CrossRef] [PubMed]

- Lončarić, A.; Celeiro, M.; Jozinović, A.; Jelinić, J.; Kovač, T.; Jokić, S.; Lores, M. Green extraction methods for extraction of polyphenolic compounds from blueberry pomace. Foods 2020, 9, 1521. [Google Scholar] [CrossRef]

- Jara-Palacios, M.J.; Santisteban, A.; Gordillo, B.; Hernanz, D.; Heredia, F.J.; Escudero-Gilete, M.L. Comparative study of red berry pomaces (blueberry, red raspberry, red currant and blackberry) as sources of antioxidants and pigments. Eur. Food Res. Technol. 2019, 245, 1–9. [Google Scholar] [CrossRef]

- Saracila, M.; Untea, A.E.; Oancea, A.G.; Varzaru, I.; Vlaicu, P.A. Comparative Analysis of Black Chokeberry (Aronia melanocarpa L.) Fruit, Leaves, and Pomace for Their Phytochemical Composition, Antioxidant Potential, and Polyphenol Bioaccessibility. Foods 2024, 13, 1856. [Google Scholar] [CrossRef]

- Brodowska, A.J. Raspberry pomace—Composition, properties and application. J. Biol. Res. 2017, 7, 86–96. [Google Scholar]

- Krivokapić, S.; Vlaović, M.; Damjanović Vratnica, B.; Perović, A.; Perović, S. Biowaste as a potential source of bioactive compounds—A case study of raspberry fruit pomace. Foods 2021, 10, 706. [Google Scholar] [CrossRef]

- Četojević-Simin, D.D.; Ranitović, A.S.; Cvetković, D.D.; Markov, S.L.; Vinčić, M.N.; Đilas, S.M. Bioactivity of blackberry (Rubus fruticosus L.) pomace: Polyphenol content, radical scavenging, antimicrobial and antitumor activity. Acta Period. Technol. 2017, 48, 63–76. [Google Scholar] [CrossRef]

- Petrov Ivanković, A.; Ćorović, M.; Milivojević, A.; Simović, M.; Banjanac, K.; Veljković, M.; Bezbradica, D. Berries Pomace Valorization: From Waste to Potent Antioxidants and Emerging Skin Prebiotics. Int. J. Fruit Sci. 2024, 24, 85–101. [Google Scholar] [CrossRef]

- Górnaś, P.; Juhnevica-Radenkova, K.; Radenkovs, V.; Mišina, I.; Pugajeva, I.; Soliven, A.; Seglina, D. The impact of different baking conditions on the stability of the extractable polyphenols in muffins enriched by strawberry, sour cherry, raspberry or black currant pomace. Lebensm.-Wiss. Technol. 2015, 65, 946–953. [Google Scholar] [CrossRef]

- Raczkowska, E.; Serek, P. Health-Promoting Properties and the Use of Fruit Pomace in the Food Industry—A Review. Nutrients 2024, 16, 2757. [Google Scholar] [CrossRef]

- Iervese, F.; Flamminii, F.; D’Alessio, G.; Neri, L.; De Bruno, A.; Imeneo, V.; Di Mattia, C.D. Flavonoid-and limonoid-rich extracts from lemon pomace by-products: Technological properties for the formulation of o/w emulsions. Food Biosci. 2024, 59, 104030. [Google Scholar] [CrossRef]

- Gargouri, B.; Ammar, S.; Verardo, V.; Besbes, S.; Segura-Carretero, A.; Bouaziz, M. RP-HPLC–DAD-ESI-TOF–MS Based Strategy for New Insights into the Qualitative and Quantitative Phenolic Profile in Tunisian Industrial Citrus limon by-Product and Their Antioxidant Activity. Eur. Food Res. Technol. 2017, 243, 2011–2024. [Google Scholar] [CrossRef]

- Magalhães, D.; Vilas-Boas, A.A.; Teixeira, P.; Pintado, M. Functional ingredients and additives from lemon by-products and their applications in food preservation: A review. Foods 2023, 12, 1095. [Google Scholar] [CrossRef]

- Lucarini, M.; Durazzo, A.; Bernini, R.; Campo, M.; Vita, C.; Souto, E.B.; Lombardi-Boccia, G.; Ramadan, M.F.; Santini, A.; Romani, A. Fruit Wastes as a Valuable Source of Value-Added Compounds: A Collaborative Perspective. Molecules 2021, 26, 6338. [Google Scholar] [CrossRef]

- Grevtseva, N.; Gorodyska, O.; Brykova, T.; Gubsky, S. The use of wine waste as a source of biologically active substances in confectionery technologies. In Bioconversion of Wastes to Value-Added Products; CRC Press: Boca Raton, FL, USA, 2023; pp. 69–111. [Google Scholar]

- Mildner-Szkudlarz, S.; Bajerska, J.; Zawirska-Wojtasiak, R.; Górecka, D. White grape pomace as a source of dietary fibre and polyphenols and its effect on physical and nutraceutical characteristics of wheat biscuits. J. Sci. Food Agric. 2013, 93, 389–395. [Google Scholar] [CrossRef]

- Ashoush, I.S.; Gadallah, M.G.E. Utilization of Mango Peels and Seed Kernels Powders as Sources of Phytochemicals in Biscuit. World J. Dairy Food Sci. 2011, 6, 35–42. [Google Scholar]

- Jurkiewicz, P.; Szlachtowicz, A.; Wdowiak, N. Sensory Analysis as a Tool in the Design of Innovative Food Products of the Biscuit Industry. Product & Process Management. Environmental Focus, Poznań. 2016. Available online: https://www.researchgate.net/publication/268190395_Sensory_analysis_as_a_tool_in_the_new_food_product_development (accessed on 3 March 2025).

- Tańska, M.; Roszkowska, B.; Czaplicki, S.; Borowska, E.J.; Bojarska, J.; Dąbrowska, A. Effect of Fruit Pomace Addition on Shortbread Cookies to Improve Their Physical and Nutritional Values. Plant Foods Hum. Nutr. 2016, 71, 307–313. [Google Scholar] [CrossRef] [PubMed]

- Zlatanović, S.; Kalušević, A.; Micić, D.; Laličić-Petronijević, J.; Tomić, N.; Ostojić, S.; Gorjanović, S. Functionality and Storability of Cookies Fortified at the Industrial Scale with up to 75% of Apple Pomace Flour Produced by Dehydration. Foods 2019, 8, 561. [Google Scholar] [CrossRef] [PubMed]

- Bajerska, J.; Mildner-Szkudlarz, S.; Górnaś, P.; Seglina, D. The effects of muffins enriched with sour cherry pomace on acceptability, glycemic response, satiety, and energy intake: A randomized crossover trial. J. Sci. Food Agric. 2016, 96, 2486–2493. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, V.; Aggarwal, P.; Singh, G. Valorization of citrus residue for the development of phytochemical enriched candy: Textural, bioactive, molecular, and structural characterization. Biomass Convers. Biorefin. 2023, 15, 2805–2816. [Google Scholar] [CrossRef]

- Kamboj, S.; Bandral, J.D.; Sood, M.; Gupta, N. Utilization of waste unripe mango for preparation of candy with enhanced bioactive and mineral composition. Indian J. Ecol. 2023, 50, 1569–1574. [Google Scholar]

- Spinei, M.; Oroian, M. Characterization of Băbească Neagră Grape Pomace and Incorporation into Jelly Candy: Evaluation of Phytochemical, Sensory, and Textural Properties. Foods 2024, 13, 98. [Google Scholar] [CrossRef]

- Jagelavičiūtė, J.; Čižeikienė, D.; Bašinskienė, L. Enzymatic modification of apple pomace and its application in conjunction with probiotics for jelly candy production. Appl. Sci. 2025, 15, 599. [Google Scholar] [CrossRef]

- Heidari, M.; Pezeshki, A.; Ghanbarzadeh, B.; Hamishehkar, H.; Ahmadzadeh Nobari Azar, F.; Mohammadi, M.; Ghorbani, M. Microencapsulation of Vitis vinifera grape pulp phenolic extract using maltodextrin and its application in gummy candy enrichment. Food Sci. Nutr. 2024, 12, 3405–3416. [Google Scholar] [CrossRef]

- Piñón-Balderrama, C.I.; Leyva-Porras, C.; Terán-Figueroa, Y.; Espinosa-Solís, V.; Álvarez-Salas, C.; Saavedra-Leos, M.Z. Encapsulation of Active Ingredients in Food Industry by Spray-Drying and Nano Spray-Drying Technologies. Processes 2020, 8, 889. [Google Scholar] [CrossRef]

- Jofre, C.M.; Campderros, M.E.; Rinaldoni, A.N. Integral use of grape: Clarified juice production by microfiltration and pomace flour by freeze-drying. Development of gluten-free filled cookies. Food Chem. Adv. 2024, 4, 100583. [Google Scholar] [CrossRef]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef] [PubMed]

- Reißner, A.M.; Rohm, H.; Struck, S. Sustainability on Bread: How Fiber-Rich Currant Pomace Affects Rheological and Sensory Properties of Sweet Fat-Based Spreads. Foods 2023, 12, 1315. [Google Scholar] [CrossRef] [PubMed]

- Gorjanović, S.; Zlatanović, S.; Laličić-Petronijević, J.; Dodevska, M.; Micić, D.; Stevanović, M.; Pastor, F. Enhancing composition and functionality of jelly candies through apple and beetroot pomace flour addition. npj Sci. Food 2024, 8, 85. [Google Scholar] [CrossRef]

- Sobczak, P.; Nadulski, R.; Kobus, Z.; Zawiślak, K. Technology for Apple Pomace Utilization within a Sustainable Development Policy Framework. Sustainability 2022, 14, 5470. [Google Scholar] [CrossRef]

- Prosapio, V.; Norton, I.; De Marco, L. Optimization of freeze-drying using a Life Cycle Assessment approach: Strawberries’ case study. J. Clean. Prod. 2017, 168, 1171–1179. [Google Scholar] [CrossRef]

- Jabłońska-Ryś, E. Zawartość polifenoli w czekoladach. Nauka Przyr. Technol. 2012, 6, 30. [Google Scholar]

- Galus, S.; Trojanowska, M.; Wójcik, J.; Ciurzyńska, A.; Janowicz, M. Biodegradowalne Opakowania Jadalne z Odpadów Przetwórstwa Owocowo-Warzywnego. Ważenie, Dozowanie, Pakowanie. 2022. Available online: https://wdp.com.pl/presentation,biodegradowalne-opakowania-jadalne-z-odpadow-przetworstwa-owocowo-warzywnego,0hwb639jRX9Rvy31zPkZ82fEf06dR5bt28YpfpNhvWD8bT1DV9.html (accessed on 3 March 2025).

- Antonic, B.; Jancikova, S.; Dordevic, D.; Tremlova, B. Apple pomace as food fortification ingredient: A systematic review and meta-analysis. J. Food Sci. 2020, 85, 2977–2985. [Google Scholar] [CrossRef]

- Socas-Rodríguez, B.; Álvarez-Rivera, G.; Valdés, A.; Ibáñez, E.; Cifuentes, A. Food by-products and food wastes: Are they safe enough for their valorization? Trends Food Sci. Technol. 2021, 114, 133–147. [Google Scholar] [CrossRef]

- Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety. Official Journal. L 031, 01/02/2002 P. 0001–0024. Available online: https://eur-lex.europa.eu/eli/reg/2002/178/oj/eng (accessed on 3 March 2025).

| Product | Type of Added Fruit By-Products | Properties | Sensory Impact | References | |

|---|---|---|---|---|---|

| Bakery | Biscuits | 10, 20, and 30% white grape pomace | Antioxidant activity, rheological, nutraceutical, physical, and sensory properties | 10%—acceptable | [59] |

| Mango seeds and peel | Antioxidant activity, technological, and sensory properties | 10%—acceptable | [60] | ||

| Muffins | 10, 20, 30, and 40% cherry pomace | Antioxidant activity, antidiabetic, and sensory properties | 20% or 30% of pomace additive—acceptable | [64] | |

| 10%, 20% raspberry pomace and 10%, 20% cranberry pomace | Antioxidant activity, textural properties | No data | [8] | ||

| Cookies | 25, 50, and 75% apple pomace flour | Antioxidant activity, sensory properties | 25% and 50% coarse flours adding—more acceptable | [63] | |

| 20% rosehip, rowan, blackcurrant, and elderberry pomace | Antioxidant activity, textural properties | 20%—acceptable | [62] | ||

| 10–30% strawberry, raspberry, chokeberry, blackcurrant, and apple pomace | Antioxidant activity, sensory and storage properties, nutritional | 20%—acceptable | [61] | ||

| Cookies, gingerbread, waffles | Grape seed and skin powder | Antioxidant activity, technological properties | Larger additions (10%) of grape seed flour—unacceptable | [58] | |

| Wafers | 10, 20, 30, 50, and 75% raspberry pomace (RP) | Antioxidant activity, anti-inflammatory | 20% RP—more acceptable, 75%—unacceptable | [5] | |

| Candies | Candies | Citrus peel | Antioxidant activity, antidiabetic | Sucralose-based—more acceptable | [65] |

| Mango pomace | Antioxidant activity, sensory properties | Overall acceptability decreases with storage period | [66] | ||

| Fruity candies | Red skin grapes | Antioxidant activity, textural, and physicochemical properties | No data | [39] | |

| Jelly candies | Neagra grape pomace (GP) | Antioxidant activity, phytochemical, and sensory properties | Acceptance depends on the particle size of GP | [67] | |

| Apple pomace aqua extract (APE) | Antioxidant and antidiabetic activities, sensory properties | Jellies with APE—more acceptable | [10] | ||

| Apple pomace (AP) with probiotic | Increases soluble dietary fiber, sensory properties | Jellies with AP—more acceptable | [68] | ||

| Method | Description | Nutritional Impact | Technological Feasibility | Reference |

|---|---|---|---|---|

| Aqueous Extraction | Extracts bioactives (e.g., phenolics, carotenoids) from pomace. | Improves antioxidant and antidiabetic properties. | Simple, suitable for clean-label products. | [10] |

| Spray Drying | Converts extract into powder using low-temp drying. | Preserves antioxidants, improves sensory properties. | Scalable, cost-efficient, industrial-friendly. | [69,70] |

| Freeze Drying | Low-temp dehydration preserving structure and compounds. | Retains color, flavor, fiber, and polyphenols. | Premium quality, higher cost, aseptic. | [71] |

| Oven/Air Drying | Drying at 58–60 °C; used for pomace flour production. | Some nutrient loss, but increased fiber and phenolics remain. | Economical, slower, widely accessible. | [72] |

| Wet Planetary Ball Milling | Reduces particle size in oil suspension. | Maintains fiber and polyphenol stability. | Industrially viable, enhances texture and shelf-life. | [73] |

| Grinding | Fine powder preparation from dried pomace. | Increases polyphenol, flavonoid, and betalain content; retains stability. | Simple, compatible with standard confectionery processing. | [74] |

| Enzymatic Treatment | Enzymes break down polysaccharides to increase solubility and fiber content. | Enhances probiotic viability; improves swelling and hydration capacity. | Scalable, low-cost, functionally beneficial. | [68] |

| Heat and Infrared Treatment | Infrared at 140–150 °C for 10 min with wheat bran. | Increases fiber and polyphenols with minimal degradation. | Easy to implement in small-scale settings, eco-friendly. | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tama, A.; Karaś, M. The Health-Promoting Potential of Fruit Pomace and Its Application in the Confectionery Industry. Appl. Sci. 2025, 15, 5790. https://doi.org/10.3390/app15105790

Tama A, Karaś M. The Health-Promoting Potential of Fruit Pomace and Its Application in the Confectionery Industry. Applied Sciences. 2025; 15(10):5790. https://doi.org/10.3390/app15105790

Chicago/Turabian StyleTama, Anna, and Monika Karaś. 2025. "The Health-Promoting Potential of Fruit Pomace and Its Application in the Confectionery Industry" Applied Sciences 15, no. 10: 5790. https://doi.org/10.3390/app15105790

APA StyleTama, A., & Karaś, M. (2025). The Health-Promoting Potential of Fruit Pomace and Its Application in the Confectionery Industry. Applied Sciences, 15(10), 5790. https://doi.org/10.3390/app15105790