Investigation on the Role of Drying Air Humidity and Process Parameters in Shaping the Conditions of Spray Drying Using Model Feed Materials

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spray Drying

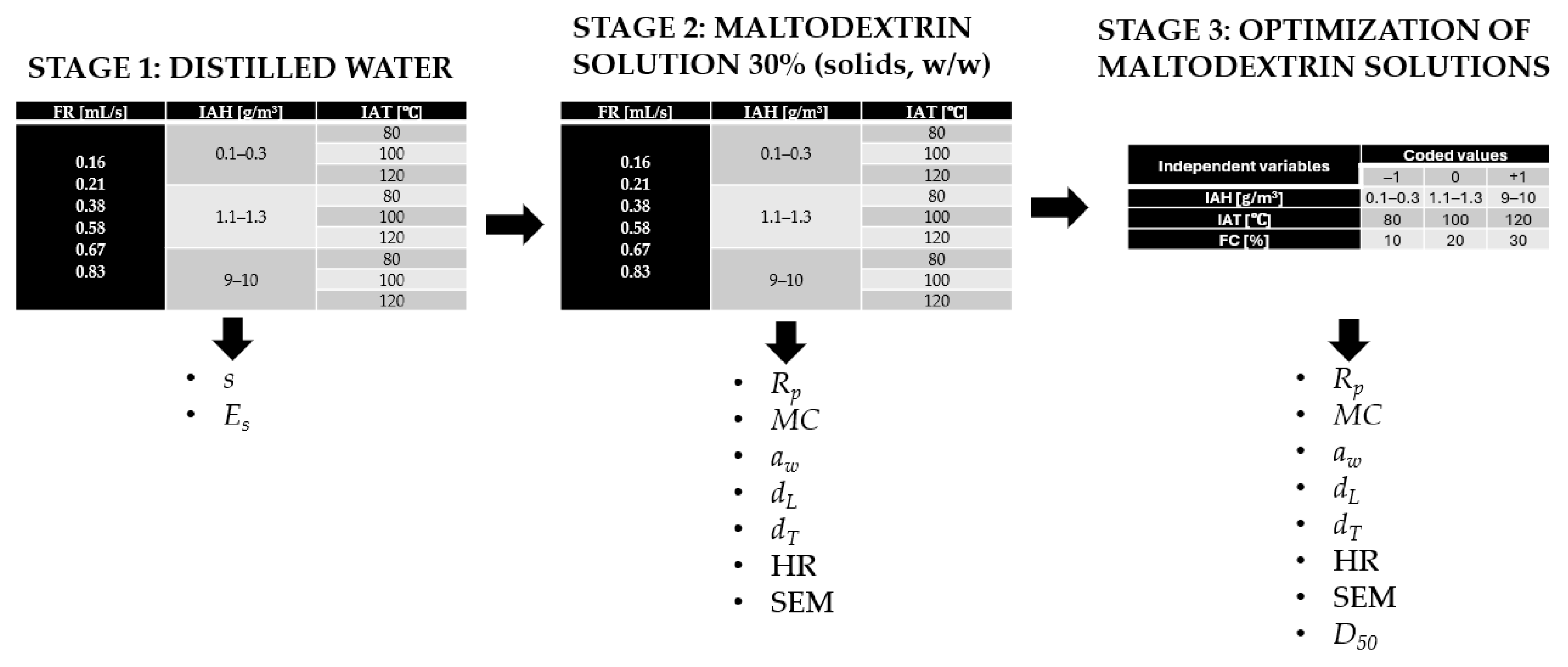

2.3. Experimental Plan

- -

- Stage I: Spray drying/evaporation of distilled water at variable feed rate (FR), inlet air humidity (IAH) and inlet air temperature (IAT) (54 experiments) (Table 1). During 10 min of the experiment, the outlet air temperature, the relative and absolute humidity of outlet air were measured every 1 min and documented (AZ9871 Data logging/Printing Anemometer, AZ Instrument Corp., Taichung, Taiwan). The process performance was also observed visually, and the time at which water evaporation stopped (the droplets appeared on the internal surface of a spray dryer’s window) was noted. Before running every experiment and during the experiment, the ambient temperature and humidity were monitored using thermo-hygrometer (testo 622 Scientific Ambient Monitor, Testo SE & Co. KGaA, Titisee (Neustadt, Germany)).

- -

- Stage II: Spray drying of 30% (solids, w/w) MD solutions at the same levels of independent variables and procedure of monitoring drying air parameters and ambient air parameters as in Stage I (54 experiments) (Table 1). Additionally, powder recovery (Rp), its moisture content (MC), water activity (aw), loose bulk and tapped densities (dL and dT), flowability (HR) were determined. The morphology of selected variants was analyzed as well.

- -

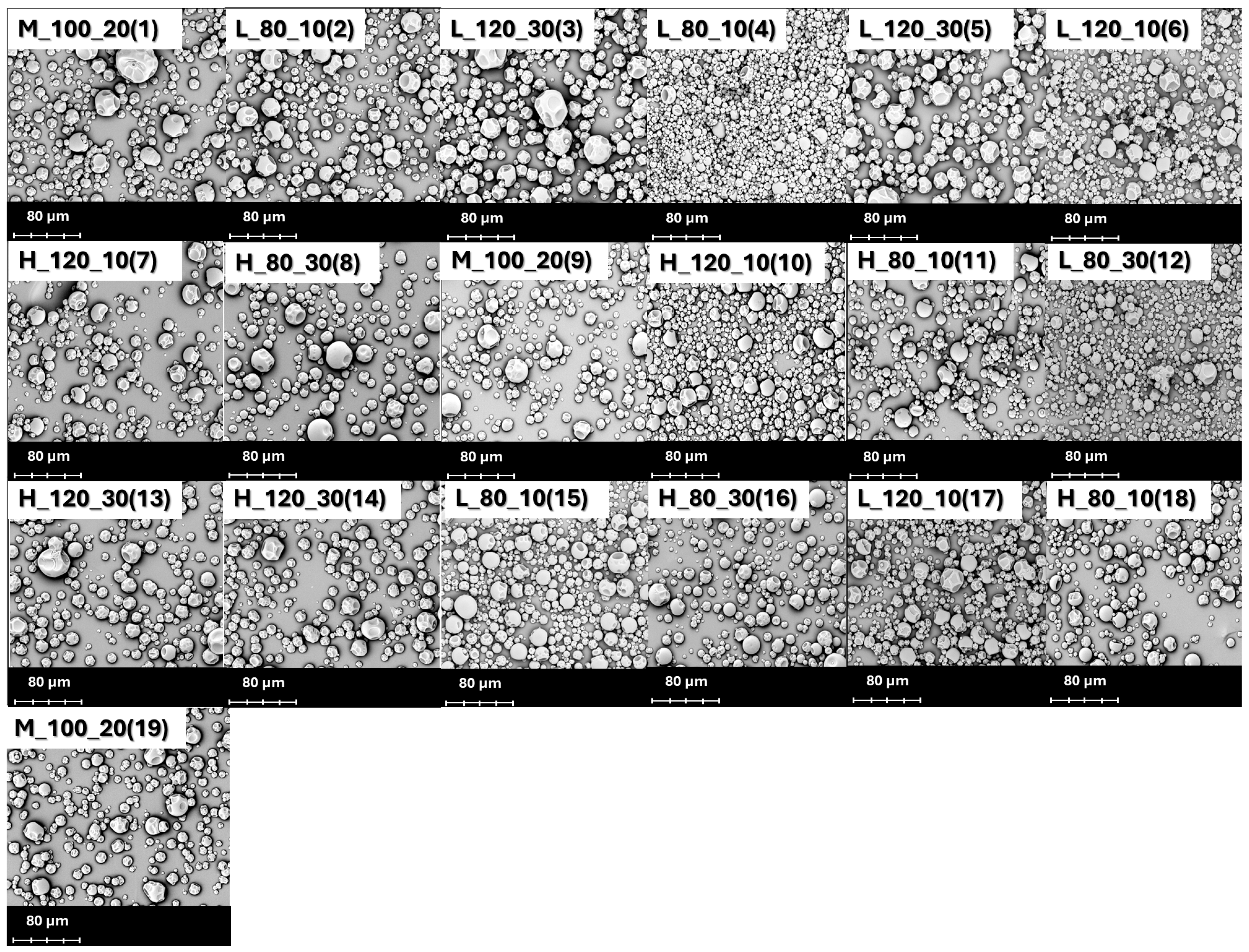

- Stage III: Optimization of MD solutions spray drying process variables (inlet air temperature (IAT), inlet air humidity (IA), feed solution concentration (FC)) for maximum powder recovery and powders of low moisture content and activity using response surface methodology (RSM) with random run order and center points runs added, with three coded levels for each variable: low (−1), standard (0), and high (+1) (Table 2). A total of 19 combinations of variables were considered: 8 factorial points in 2 replications and 3 center points runs placed in the beginning, middle and at the end of the experiment (Table 3). The levels of drying process variables were chosen based on the preliminary research and technical specification of air-dehumidification system. Additionally, particle morphology and particle size (D50), loose bulk and tapped densities (dL and dT), and flowability (HR) of obtained powders were determined. The procedure of monitoring drying air and ambient air parameters was the same as in Stage I and II of the research.

2.4. Analitycal Methods

2.4.1. Moisture Content and Water Activity

2.4.2. Bulk Density and Flowability

2.4.3. Particle Morphology

2.4.4. Particle Size

2.5. Data Collection and Analysis

2.6. Statistical Methods

2.6.1. Analysis of Variance (ANOVA)

2.6.2. Response Surface Methodology (RSM)

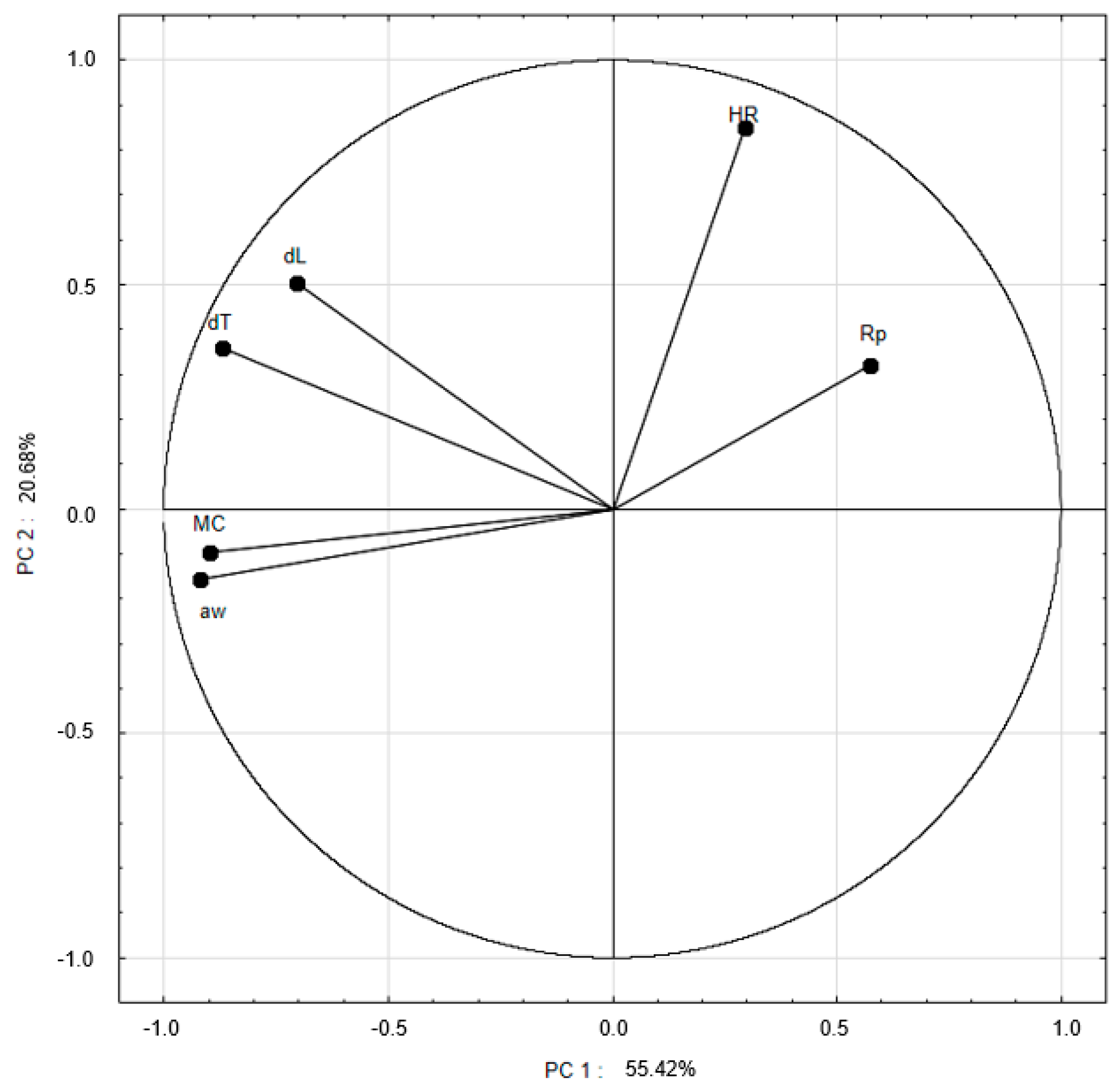

2.6.3. Principal Component Analysis (PCA) and Hierarchical Cluster Analysis (HCA)

3. Results and Discussion

3.1. Stage I

Drying Air Consumption and Specific Energy Consumption

3.2. Stage II

3.2.1. Powder Recovery

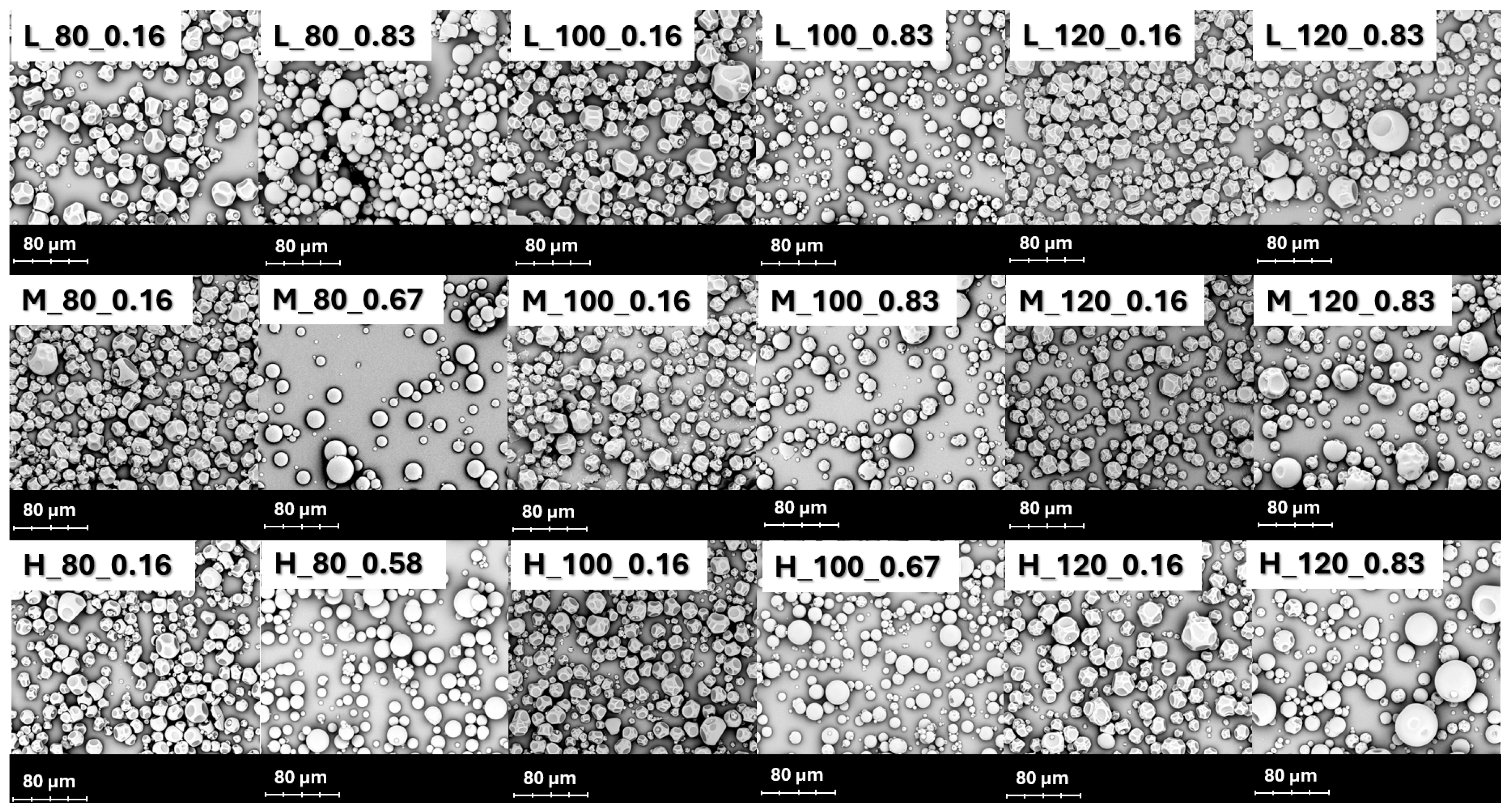

3.2.2. Particles Morphology

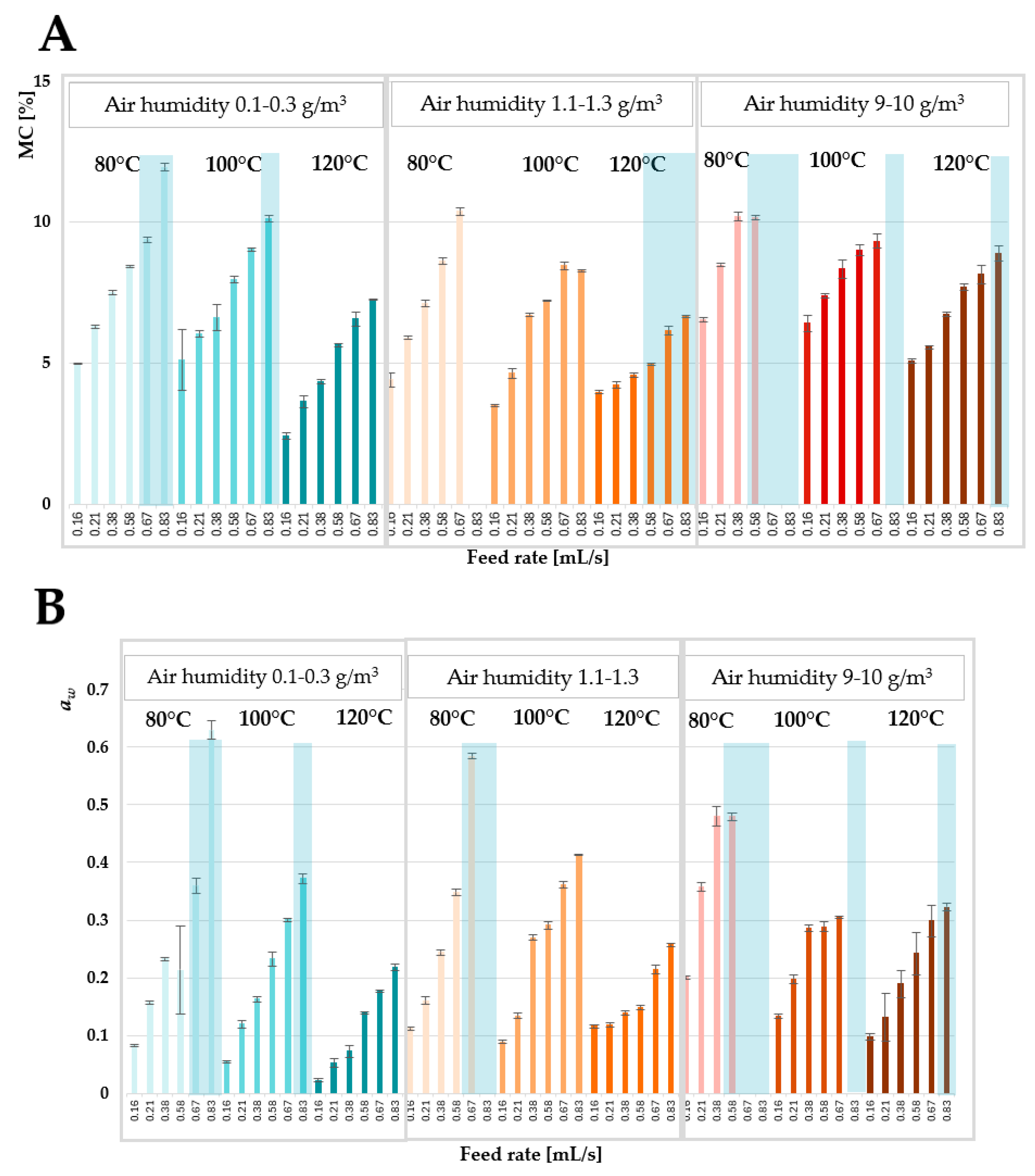

3.2.3. Moisture Content and Water Activity

3.2.4. Bulk Density

3.2.5. Flowability

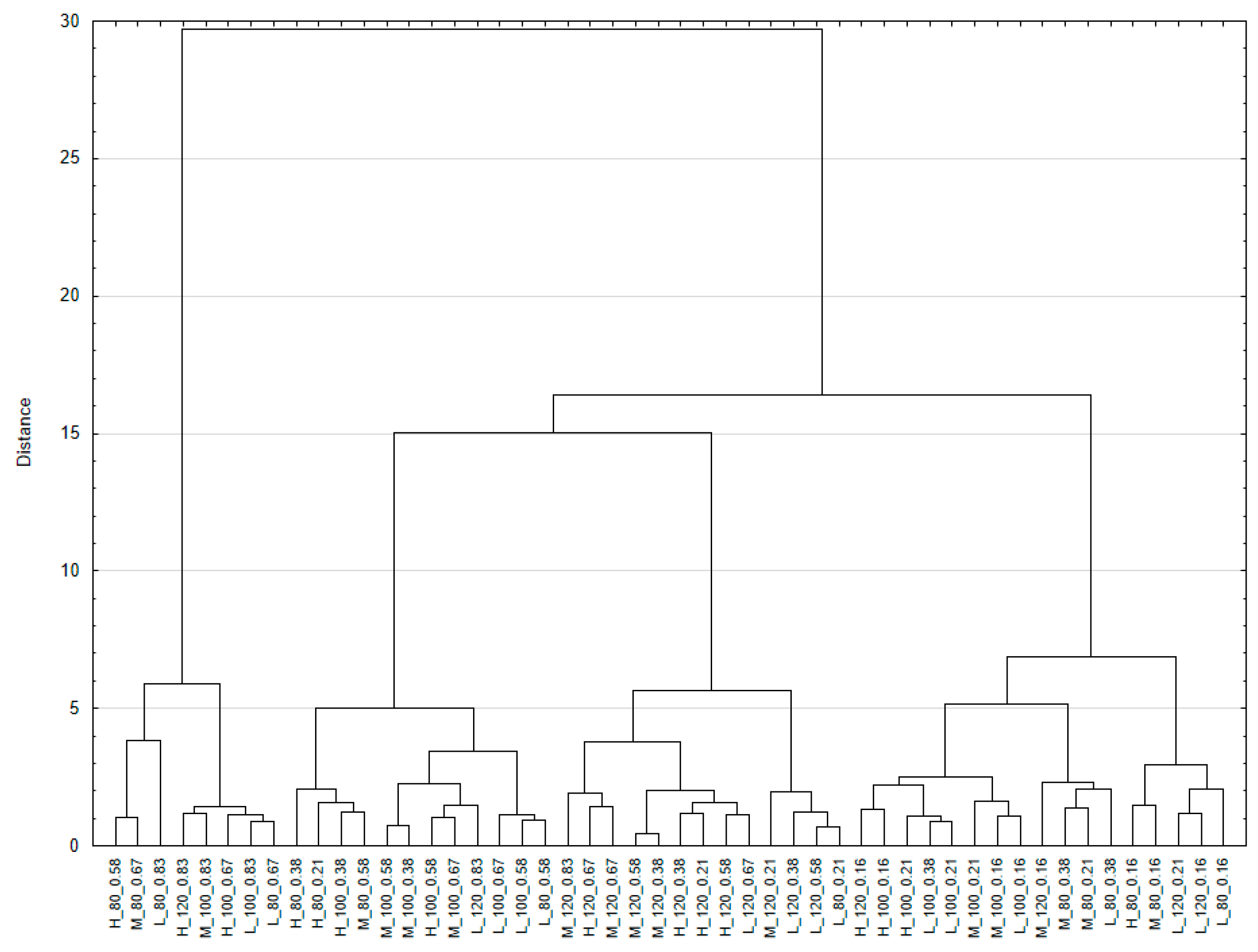

3.2.6. Hierarchical Clyster Analysis

3.3. Stage III

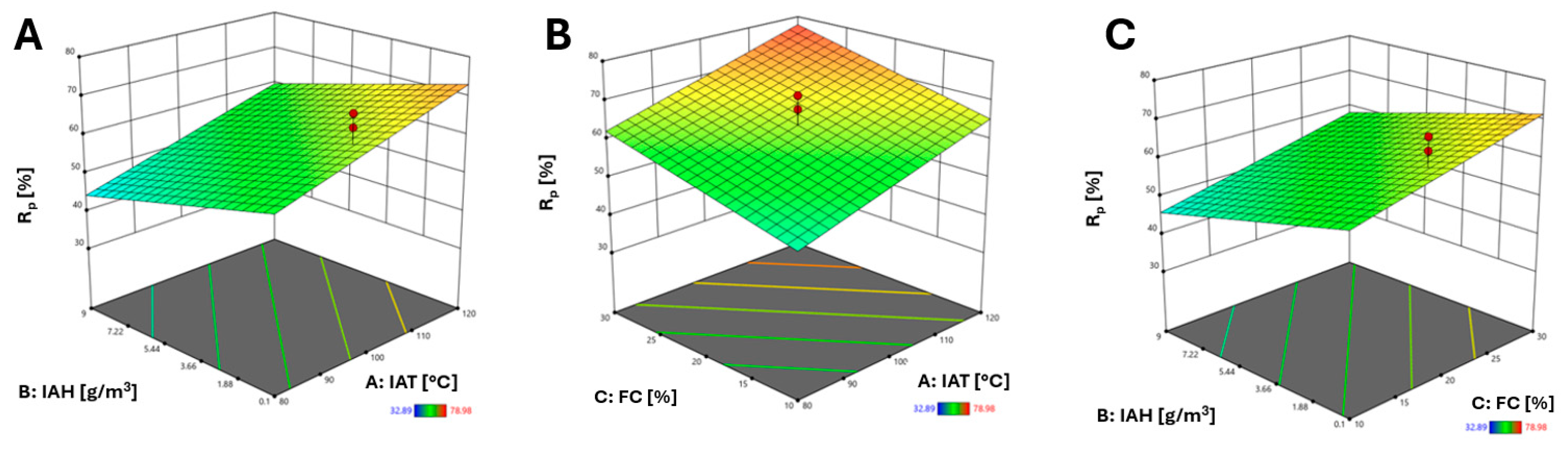

3.3.1. Powder Recovery

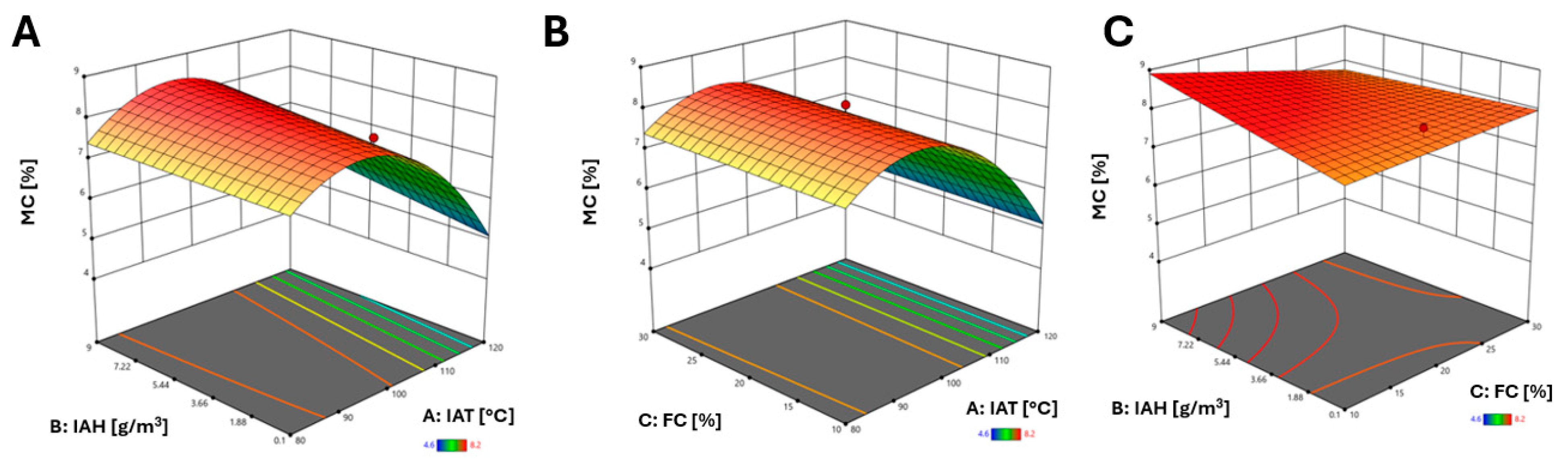

3.3.2. Moisture Content

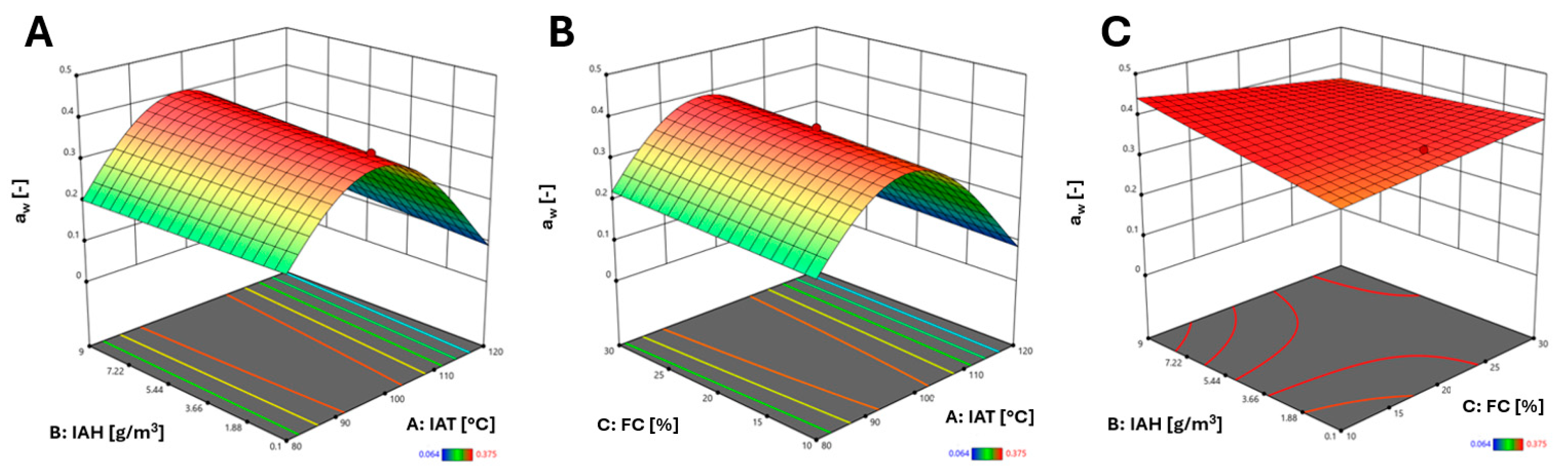

3.3.3. Water Activity

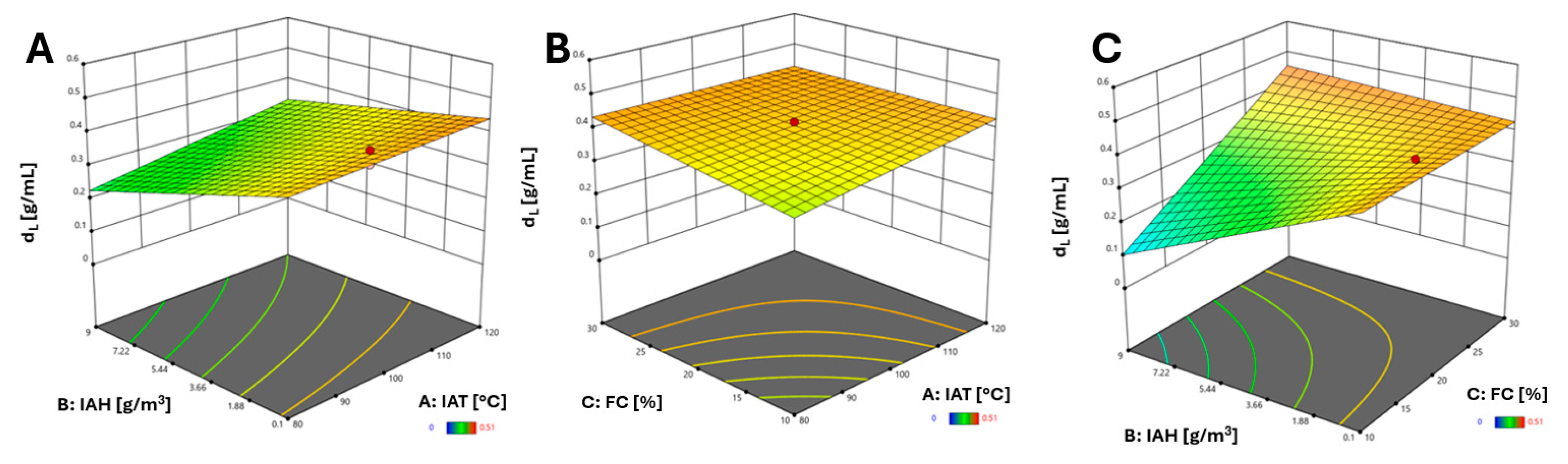

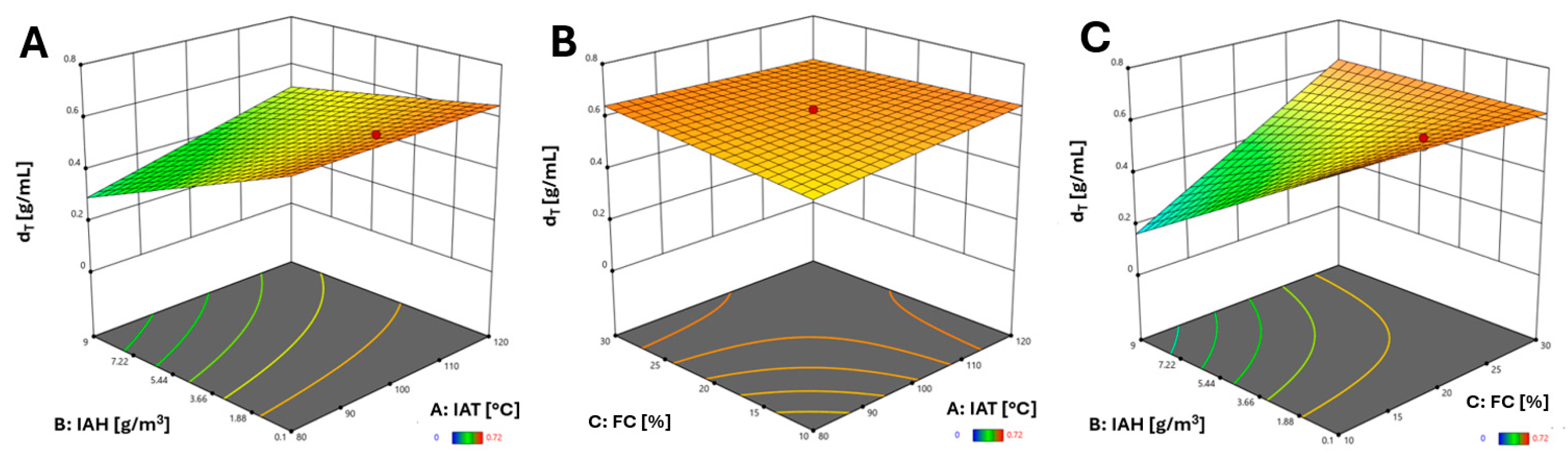

3.3.4. Loose Bulk and Tapped Density

3.3.5. Flowability

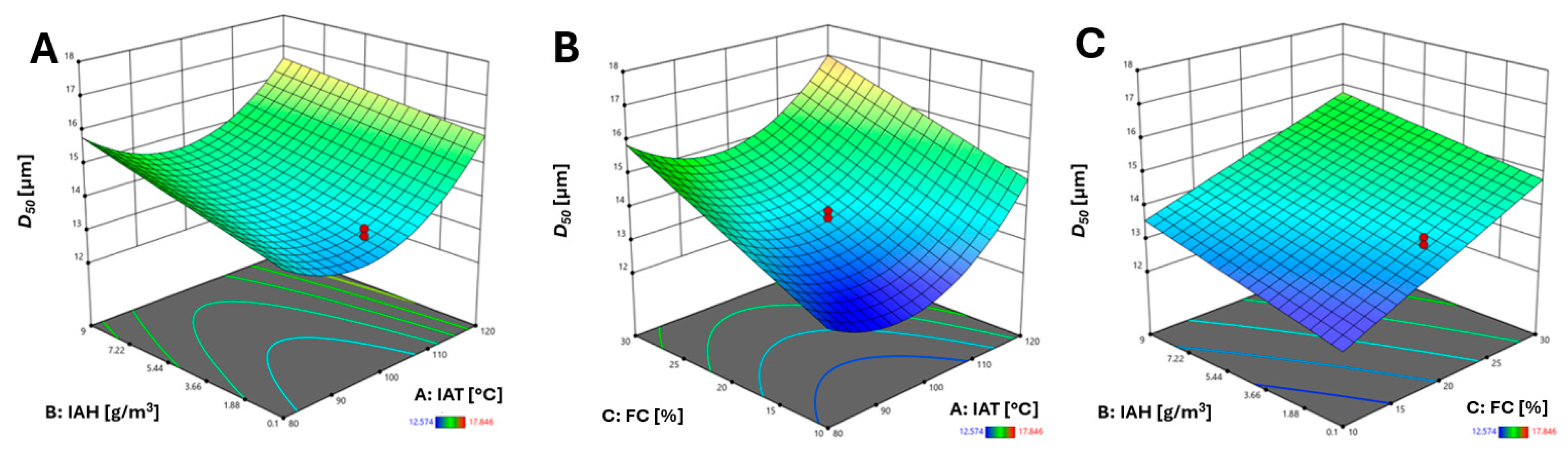

3.3.6. Particle Size and Particles Morphology

3.3.7. Process Optimization

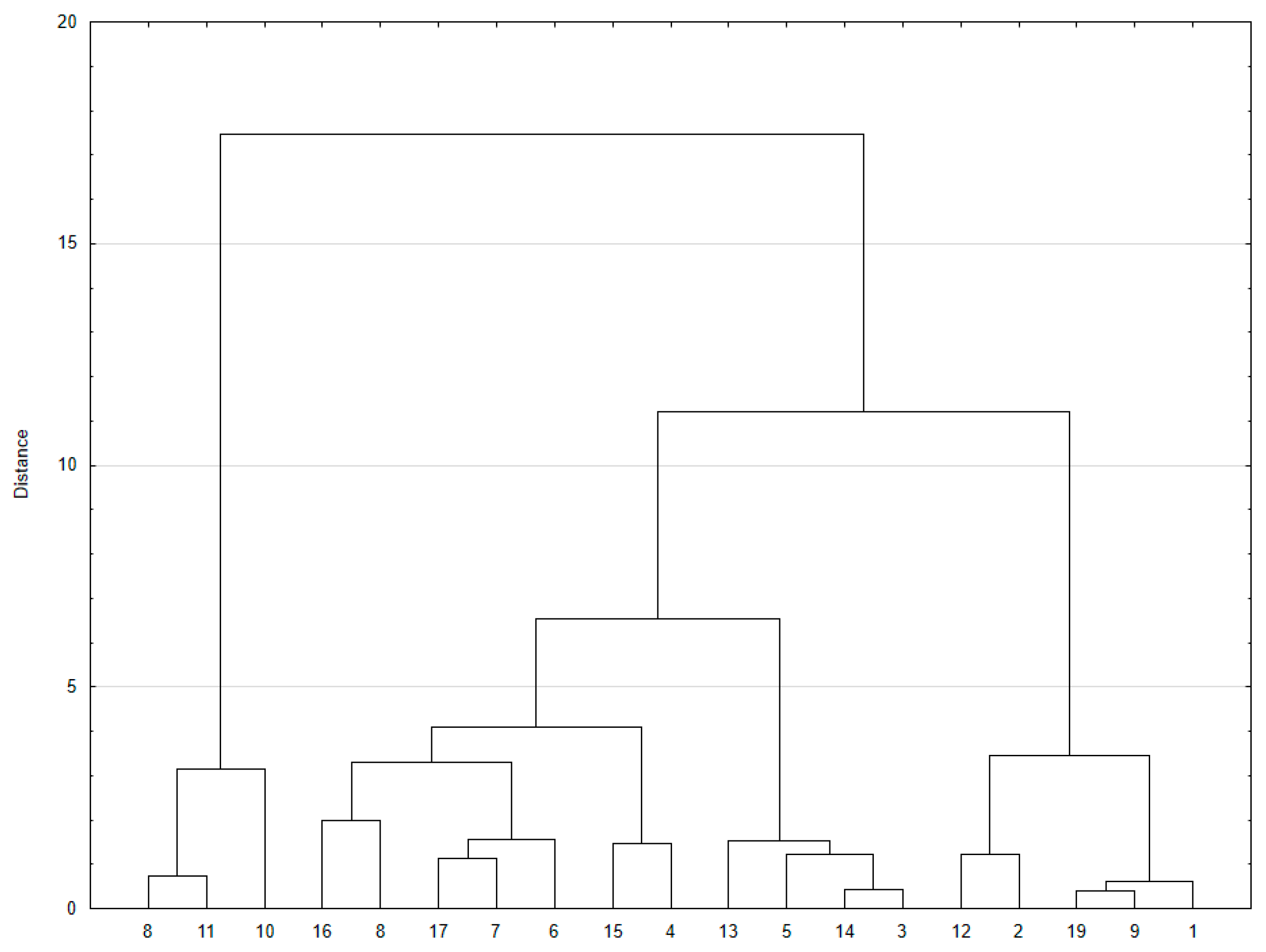

3.3.8. Hierarchical Clyster Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Order | Drying Parameters | Rp [%] | MC [%] | aw | dL [g/cm3] | dT [g/cm3] | HR [-] | D50 [µm] |

|---|---|---|---|---|---|---|---|---|

| 1 | M_100_20 | 67.86 | 7.8 ± 0.1 hi | 0.359 ± 0.010 j | 0.42 ± 0.04 ab | 0.60 ± 0.02 ab | 1.43 ± 0.10 ab | 13.91 ± 0.03 abc |

| 2 | L_80_10 | 69.91 | 7.2 ± 0.1 fgh | 0.230 ± 0.001 gh | 0.44 ± 0.02 abc | 0.63 ± 0.01 ab | 1.43 ± 0.10 ab | 15.43 ± 0.08 efg |

| 3 | L_120_30 | 67.39 | 5.2 ± 0.2 abc | 0.101 ± 0.005 bc | 0.45 ± 0.03 abc | 0.66 ± 0.03 abc | 1.47 ± 0.12 ab | 16.80 ± 0.12 ghij |

| 4 | L_80_10 | 54.07 | 6.3 ± 0.2 def | 0.136 ± 0.003 e | 0.42 ± 0.00 ab | 0.65 ± 0.01 abc | 1.54 ± 0.00 b | 12.57 ± 0.23 a |

| 5 | L_120_30 | 78.98 | 4.9 ± 0.1 ab | 0.079 ± 0.013 a | 0.46 ± 0.02 bc | 0.62 ± 0.06 ab | 1.34 ± 0.09 ab | 17.17 ± 0.39 hij |

| 6 | L_120_10 | 59.44 | 4.6 ± 0.1 a | 0.064 ± 0.002 a | 0.45 ± 0.02 abc | 0.66 ± 0.04 bc | 1.47 ± 0.06 ab | 14.38 ± 0.12 bcde |

| 7 | H_120_10 | 49.12 | 6.1 ± 0.4 cde | 0.116 ± 0.001 cd | 0.42 ± 0.02 ab | 0.66 ± 0.01 abc | 1.58 ± 0.07 b | 15.36 ± 0.45 def |

| 8 | H_80_30 | 32.89 | 6.9 ± 0.1 efg | 0.167 ± 0.003 f | 0.40 ± 0.01 ab | 0.57 ± 0.02 a | 1.43 ± 0.00 ab | 17.52 ± 1.34 ij |

| 9 | M_100_20 | 71.26 | 7.8 ± 0.2 hi | 0.375 ± 0.001 j | 0.40 ± 0.05 ab | 0.63 ± 0.03 abc | 1.61 ± 0.25 b | 13.22 ± 0.21 ab |

| 10 | H_120_10 | 59.89 | 6.7 ± 0.1 ef | 0.164 ± 0.005 f | - | - | - | 16.17 ± 0.29 fgh |

| 11 | H_80_10 | 38.65 | 8.3 ± 0.6 i | 0.274 ± 0.002 i | - | - | - | 13.99 ± 0.53 abcd |

| 12 | L_80_30 | 60.91 | 8.2 ± 0.2 i | 0.265 ± 0.008 i | 0.38 ± 0.01 a | 0.62 ± 0.03 ab | 1.62 ± 0.07 b | 15.94 ± 0.23 fgh |

| 13 | H_120_30 | 74.83 | 6.0 ± 0.9 cde | 0.164 ± 0.004 f | 0.48 ± 0.05 bc | 0.65 ± 0.04 abc | 1.37 ± 0.05 ab | 17.85 ± 0.85 j |

| 14 | H_120_30 | 68.76 | 5.2 ± 0.0 abc | 0.096 ± 0.007 b | 0.44 ± 0.04 abc | 0.72 ± 0.03 c | 1.62 ± 0.07 b | 17.11 ± 0.80 hij |

| 15 | L_80_10 | 50.85 | 7.8 ± 0.4 ghi | 0.215 ± 0.004 g | 0.42 ± 0.00 ab | 0.66 ± 0.05 bc | 1.59 ± 0.14 b | 12.69 ± 0.34 a |

| 16 | H_80_30 | 55.67 | 6.4 ± 0.1 def | 0.143 ± 0.004 e | 0.51 ± 0.01 c | 0.61 ± 0.02 ab | 1.20 ± 0.04 a | 16.79 ± 1.16 ghij |

| 17 | L_120_10 | 63.67 | 5.7 ± 0.2 bcd | 0.118 ± 0.001 d | 0.42 ± 0.01 ab | 0.66 ± 0.02 bc | 1.58 ± 0.07 b | 15.03 ± 0.04 cdef |

| 18 | H_80_10 | 34.62 | 8.2 ± 0.1 i | 0.234 ± 0.003 h | - | - | - | 14.88 ± 0.43 cdef |

| 19 | M_100_20 | 71.37 | 8.1 ± 0.1 hi | 0.368 ± 0.003 j | 0.38 ± 0.02 a | 0.60 ± 0.01 ab | 1.58 ± 0.07 b | 13.69 ± 0.21 abc |

| Response | Model | R2 | CV [%] | p-Value (Model) | p-Value (Lack of Fit) |

|---|---|---|---|---|---|

| Rp | Linear | 0.7265 | 12.90 | 0.0002 | 0.2160 |

| MC | Quadratic | 0.8754 | 8.13 | 0.0003 | 0.1950 |

| aw | Transformed quadratic (square root) | 0.8840 | 11.29 | 0.0002 | 0.0656 |

| D50 | Quadratic | 0.9610 | 2.75 | <0.0001 | 0.7811 |

| dL | 2FI | 0.7691 | 26.68 | 0.0027 | 0.5085 |

| dT | 2FI | 0.7726 | 26.22 | 0.0025 | 0.7196 |

| HR | 2FI | 0.7510 | 27.71 | 0.0041 | 0.7139 |

References

- Bhandari, B.R.; Datta, N.; Howes, T. Problems associated with spray drying of sugar-rich foods. Dry. Technol. 1997, 15, 671–684. [Google Scholar] [CrossRef]

- Hayashi, H. Drying Technologies of Foods-Their History and Future. Dry. Technol. 1989, 7, 315–369. [Google Scholar] [CrossRef]

- Ameri, M.; Maa, Y.F. Spray drying of biopharmaceuticals: Stability and process considerations. Dry. Technol. 2006, 24, 763–768. [Google Scholar] [CrossRef]

- Babalis, S.J.; Belessiotis, V.G. Influence of the drying conditions on the drying constants and moisture diffusivity during the thin-layer drying of figs. J. Food Eng. 2004, 65, 449–458. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Spray drying of tomato pulp in dehumidified air: I. The effect on product recovery. J. Food Eng. 2005, 66, 25–34. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. powder properties. Dry. Technol. 2008, 26, 726–737. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. A new technique for spray drying orange juice concentrate. Innov. Food Sci. Emerg. Technol. 2010, 11, 342–351. [Google Scholar] [CrossRef]

- Jedlińska, A.; Samborska, K.; Wieczorek, A.; Wiktor, A.; Ostrowska-Ligęza, E.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Błażowski, Ł.; Tułodziecki, M.; et al. The application of dehumidified air in rapeseed and honeydew honey spray drying-Process performance and powders properties considerations. J. Food Eng. 2019, 245, 80–87. [Google Scholar] [CrossRef]

- Samborska, K.; Sarabandi, K.; Tonon, R.; Topuz, A.; Eroğlu, E.; Kaymak-Ertekin, F.; Malekjani, N.; Jafari, S.M. Recent progress in the stickiness reduction of sugar-rich foods during spray drying. Dry. Technol. 2023, 41, 2566–2585. [Google Scholar] [CrossRef]

- Samborska, K. Powdered honey-drying methods and parameters, types of carriers and drying aids, physicochemical properties and storage stability. Trends Food Sci. Technol. 2019, 88, 133–142. [Google Scholar] [CrossRef]

- Samborska, K.; Edris, A.; Jedlińska, A.; Barańska, A. The production of white mulberry molasses powders with prebiotic carrier by dehumidified air-assisted spray drying. J. Food Process Eng. 2021, 45, e13928. [Google Scholar] [CrossRef]

- Barańska, A.; Jedlińska, A.; Samborska, K. Is it Possible to Produce Carrier-Free Fruit and Vegetable Powders by Spray Drying? Pol. J. Food Nutr. Sci. 2023, 73, 214–223. [Google Scholar] [CrossRef]

- Velić, D.; Bilić, M.; Tomas, S.; Planinić, M. Simulation, calculation and possibilities of energy saving in spray drying process. Appl. Therm. Eng. 2003, 23, 2119–2131. [Google Scholar] [CrossRef]

- Bimbenet, J.J.; Schuck, P.; Roignant, M.; Brulé, G.; Méjean, S. Heat balance of a multistage spray-dryer: Principles and example of application. Lait 2002, 82, 541–551. [Google Scholar] [CrossRef][Green Version]

- Kosasih, E.A.; Rafdi, M.; Firdaus, F. Experimental investigation of vitamin C yield of tomatoes and vitamin C essence by spray drying and dehumidifying the drying air: Product quality and energy consumption. In Proceedings of the 9th International Conference on Thermofluids, Yogyakarta, Indonesia, 9–10 November 2017; Pranoto, I., Deendarlianto, Widyaparaga, A., Majid, A.I., Wiranata, A., Takei, M., Höhne, T., Eds.; AIP Publishing: Melville, NY, USA, 2018. [Google Scholar]

- Samborska, K.; Barańska, A.; Szulc, K.; Jankowska, E.; Truszkowska, M.; Ostrowska-Ligęza, E.; Wołosiak, R.; Szymańska, E.; Jedlińska, A. Reformulation of spray-dried apple concentrate and honey for the enhancement of drying process performance and the physicochemical properties of powders. J. Sci. Food Agric. 2020, 100, 2224–2235. [Google Scholar] [CrossRef]

- Nguyen, D.Q.; Mounir, S.; Allaf, K. Optimization of the spray drying operating conditions for producing the powder mixture of gum Arabic and maltodextrin. Int. J. Food Eng. 2017, 13, 20160271. [Google Scholar] [CrossRef]

- Ravichandran, K.S.; Silva, E.S.; Moncada, M.; Perkins-Veazie, P.; Lila, M.A.; Greenlief, C.M.; Thomas, A.L.; Hoskin, R.T.; Krishnaswamy, K. Spray drying to produce novel phytochemical-rich ingredients from juice and pomace of American elderberry. Food Biosci. 2023, 55, 102981. [Google Scholar] [CrossRef]

- Gavarić, A.; Vladić, J.; Ambrus, R.; Jokić, S.; Szabó-Révész, P.; Tomić, M.; Blažić, M.; Vidović, S. Spray drying of a subcritical extract using Marrubium vulgare as a method of choice for obtaining high quality powder. Pharmaceutics 2019, 11, 523. [Google Scholar] [CrossRef]

- Siemons, I.; Politiek, R.G.A.; Boom, R.M.; van der Sman, R.G.M.; Schutyser, M.A.I. Dextrose equivalence of maltodextrins determines particle morphology development during single sessile droplet drying. Food Res. Int. 2020, 131, 108988. [Google Scholar] [CrossRef]

- Gouaou, I.; Shamaei, S.; Koutchoukali, M.S.; Bouhelassa, M.; Tsotsas, E.; Kharaghani, A. Impact of operating conditions on a single droplet and spray drying of hydroxypropylated pea starch: Process performance and final powder properties. Asia Pac. J. Chem. Eng. 2019, 14, e2268. [Google Scholar] [CrossRef]

- Boel, E.; Koekoekx, R.; Dedroog, S.; Babkin, I.; Vetrano, M.R.; Clasen, C.; van der Mooter, G. Unraveling particle formation: From single droplet drying to spray drying and electrospraying. Pharmaceutics 2020, 12, 625. [Google Scholar] [CrossRef] [PubMed]

- Žugić, A.; Krgović, N.; Mudrić, J.; Kostov, M.T.; Tomović, M.; Medarević, D.; Nešić, I.; Tadić, V. Pectin as the carrier for the spray drying of green tea extracts: Tailoring microencapsulation to obtain a prospective nutraceutical. Int. J. Biol. Macromol. 2025, 306, 141514. [Google Scholar] [CrossRef]

- Schuck, P.; Dolivet, A.; Méjean, S.; Jeantet, R. Relative humidity of outlet air: The key parameter to optimize moisture content and water activity of dairy powders. Dairy Sci. Technol. 2008, 88, 45–52. [Google Scholar] [CrossRef]

- Keshani, S.; Daud, W.R.W.; Woo, M.W.; Talib, M.Z.M.; Chuah, A.L.; Russly, A.R. Artificial neural network modeling of the deposition rate of lactose powder in spray dryers. Dry. Technol. 2012, 30, 386–397. [Google Scholar] [CrossRef]

- Juarez-Enriquez, E.; Olivas, G.I.; Zamudio-Flores, P.B.; Perez-Vega, S.; Salmeron, I.; Ortega-Rivas, E.; Sepulveda, D.R. A review on the influence of water on food powder flowability. J. Food Process Eng. 2022, 45, e14031. [Google Scholar] [CrossRef]

- Koç, B.; Koç, M.; Baysan, U. Food Powders Bulk Properties. In Food Powders Properties and Characterization; Ermiş, E., Ed.; Springer: Cham, Switzerland, 2021; pp. 1–36. [Google Scholar]

- Barbosa-Cánovas, G.V.; Ortega-Rivas, E.; Juliano, P.; Yan, H. Bulk properties. In Food Powders: Physical Properties, Processing, and Functionality; Barbosa-Cánovas, G.V., Ed.; Springer: Boston, MA, USA, 2005; pp. 55–90. [Google Scholar]

- Suhag, R.; Kellil, A.; Razem, M. Factors Influencing Food Powder Flowability. Powders 2024, 3, 65–76. [Google Scholar] [CrossRef]

- Juarez-Enriquez, E.; Olivas, G.I.; Zamudio-Flores, P.B.; Ortega-Rivas, E.; Perez-Vega, S.; Sepulveda, D.R. Effect of water content on the flowability of hygroscopic powders. J. Food Eng. 2017, 205, 12–17. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Spray drying of tomato pulp: Effect of feed concentration. Dry. Technol. 2004, 22, 2309–2330. [Google Scholar] [CrossRef]

- van Boven, A.P.; Calderon Novoa, S.M.; Kohlus, R.; Schutyser, M.A.I. Investigation on nozzle zone agglomeration during spray drying using response surface methodology. Powder Technol. 2023, 429, 118910. [Google Scholar] [CrossRef]

- Both, E.M.; Boom, R.M.; Schutyser, M.A.I. Particle morphology and powder properties during spray drying of maltodextrin and whey protein mixtures. Powder Technol. 2020, 363, 519–524. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Cuevas-Glory, L.F.; Pino, J.A.; Sosa-Moguel, O.; Sauri-Duch, E.; Bringas-Lantigua, M. Optimization of the spray-drying process for developing stingless bee honey powder. Int. J. Food Eng. 2017, 13, 20160217. [Google Scholar] [CrossRef]

- Himmetagaoglu, A.B.; Erbay, Z. Effects of spray drying process conditions on the quality properties of microencapsulated cream powder. Int. Dairy J. 2019, 88, 60–70. [Google Scholar] [CrossRef]

- Chegini, G.R.; Ghobadian, B. Effect of spray-drying conditions on physical properties of orange juice powder. Dry. Technol. 2005, 23, 657–668. [Google Scholar] [CrossRef]

- George, S.; Kumar, M.V.P.; Kumar, B.R. Investigating the impact of spray drying parameters on milk powder bio fortification with curcumin and veld grape (Cissus quadrangularis) extract. Food Hum. 2025, 4, 100572. [Google Scholar] [CrossRef]

- Tao, Y.; Tang, Z.; Huang, Q.; Xu, X.; Cheng, X.; Zhang, G.; Jing, X.; Li, X.; Liang, J.; Granato, D.; et al. Effects of spray drying temperature on physicochemical properties of grapeseed oil microcapsules and the encapsulation efficiency of pterostilbene. Lebensm. Wiss. Technol. 2024, 193, 115779. [Google Scholar] [CrossRef]

- Littringer, E.M.; Mescher, A.; Eckhard, S.; Schröttner, H.; Langes, C.; Fries, M.; Griesser, U.; Walzel, P.; Urbanetz, N.A. Spray drying of mannitol as a drug carrier—The impact of process parameters on product properties. Dry. Technol. 2012, 30, 114–124. [Google Scholar] [CrossRef]

| Feed Rate [mL/s] | Inlet Air Humidity [g/m3] | Inlet Air Temperature [°C] |

|---|---|---|

| 0.16 0.21 0.38 0.58 0.67 0.83 | 0.1–0.3 | 80 |

| 100 | ||

| 120 | ||

| 1.1–1.3 | 80 | |

| 100 | ||

| 120 | ||

| 9–10 | 80 | |

| 100 | ||

| 120 |

| Independent Variables | Symbol | Coded Values | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| Inlet air absolute humidity [g/m3] | X1 | 0.1–0.3 | 1.1–1.3 | 9–10 |

| Inlet air temperature [°C] | X2 | 80 | 100 | 120 |

| Feed solution concentration [%] | X3 | 10 | 20 | 30 |

| Random Order | X1 | X2 | X3 |

|---|---|---|---|

| 1 | 0 | 0 | 0 |

| 2 | −1 | −1 | +1 |

| 3 | −1 | +1 | +1 |

| 4 | −1 | −1 | −1 |

| 5 | −1 | +1 | +1 |

| 6 | −1 | +1 | −1 |

| 7 | +1 | +1 | −1 |

| 8 | +1 | −1 | +1 |

| 9 | 0 | 0 | 0 |

| 10 | +1 | +1 | −1 |

| 11 | +1 | −1 | −1 |

| 12 | −1 | −1 | +1 |

| 13 | +1 | +1 | +1 |

| 14 | +1 | +1 | +1 |

| 15 | −1 | −1 | −1 |

| 16 | +1 | −1 | +1 |

| 17 | −1 | +1 | −1 |

| 18 | +1 | −1 | −1 |

| 19 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barańska-Dołomisiewicz, A.; Jedlińska, A.; Samborska, K. Investigation on the Role of Drying Air Humidity and Process Parameters in Shaping the Conditions of Spray Drying Using Model Feed Materials. Appl. Sci. 2025, 15, 5761. https://doi.org/10.3390/app15105761

Barańska-Dołomisiewicz A, Jedlińska A, Samborska K. Investigation on the Role of Drying Air Humidity and Process Parameters in Shaping the Conditions of Spray Drying Using Model Feed Materials. Applied Sciences. 2025; 15(10):5761. https://doi.org/10.3390/app15105761

Chicago/Turabian StyleBarańska-Dołomisiewicz, Alicja, Aleksandra Jedlińska, and Katarzyna Samborska. 2025. "Investigation on the Role of Drying Air Humidity and Process Parameters in Shaping the Conditions of Spray Drying Using Model Feed Materials" Applied Sciences 15, no. 10: 5761. https://doi.org/10.3390/app15105761

APA StyleBarańska-Dołomisiewicz, A., Jedlińska, A., & Samborska, K. (2025). Investigation on the Role of Drying Air Humidity and Process Parameters in Shaping the Conditions of Spray Drying Using Model Feed Materials. Applied Sciences, 15(10), 5761. https://doi.org/10.3390/app15105761