Empowering Optimal Operations with Renewable Energy Solutions for Grid Connected Merredin WA Mining Sector

Abstract

1. Introduction

2. Methodology and Materials

2.1. Site Feasibility

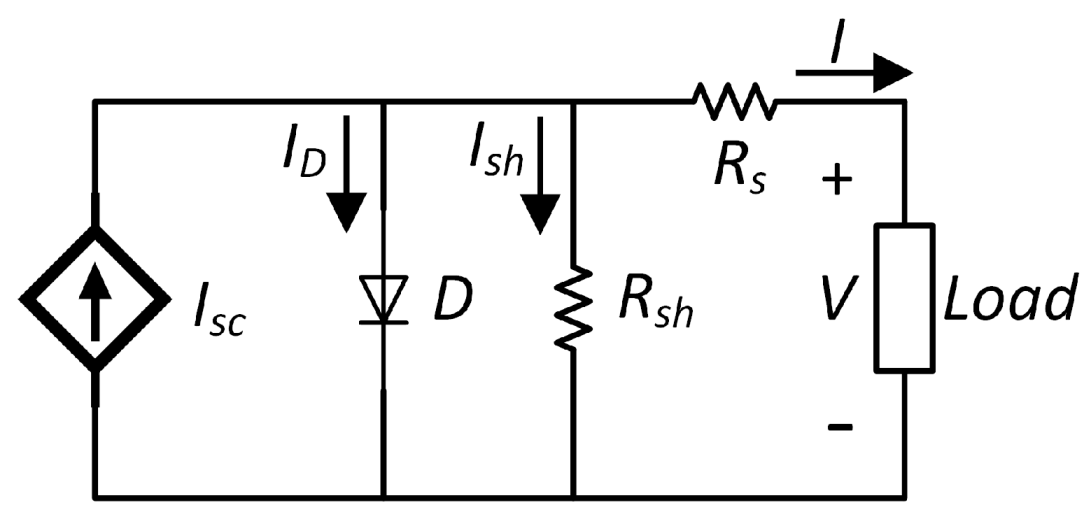

2.2. Solar PV Modeling

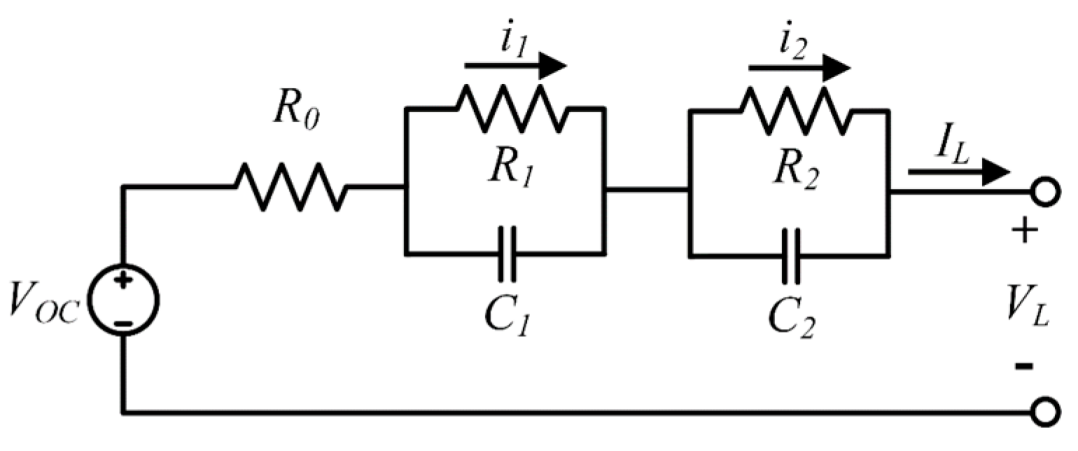

2.3. Battery Energy Storage System (BESS)

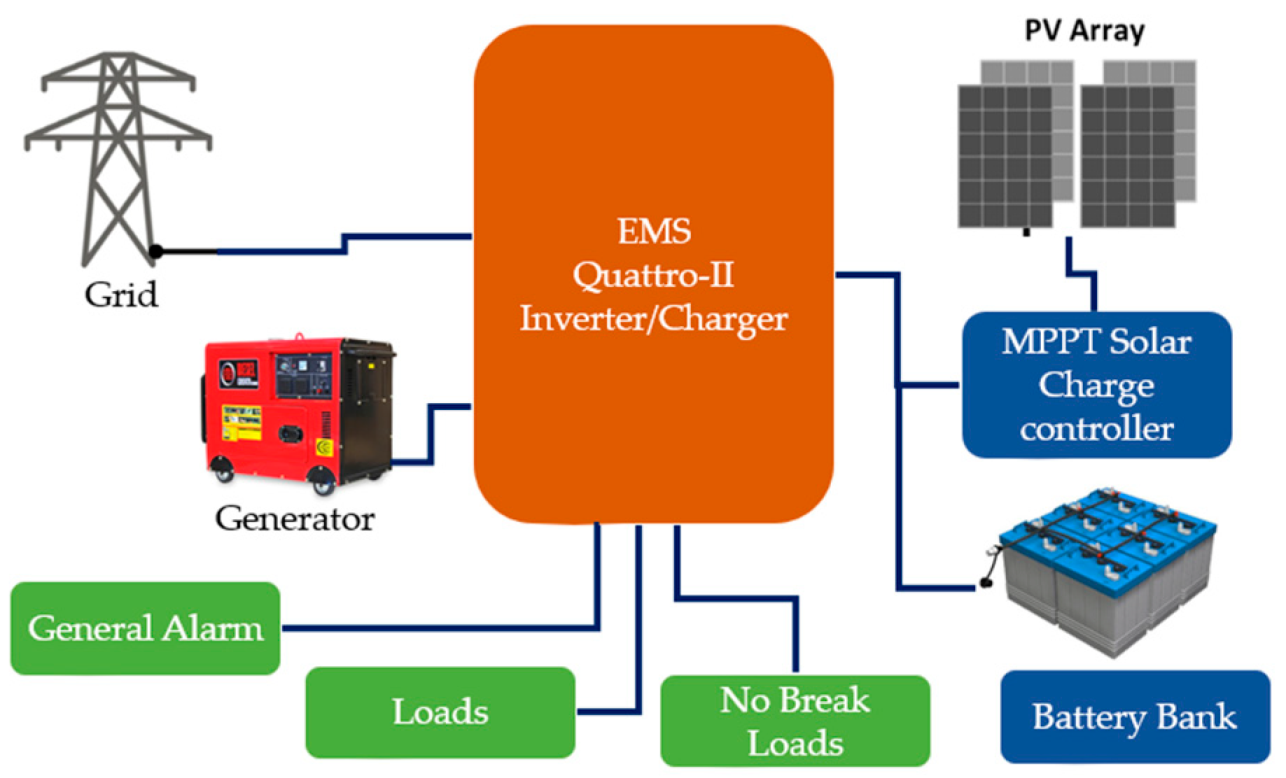

2.4. Implementation Plan

2.5. Data Collection and Performance Monitoring

2.5.1. Performance Monitoring

2.5.2. Environmental Impact Monitoring

2.6. Cost Savings

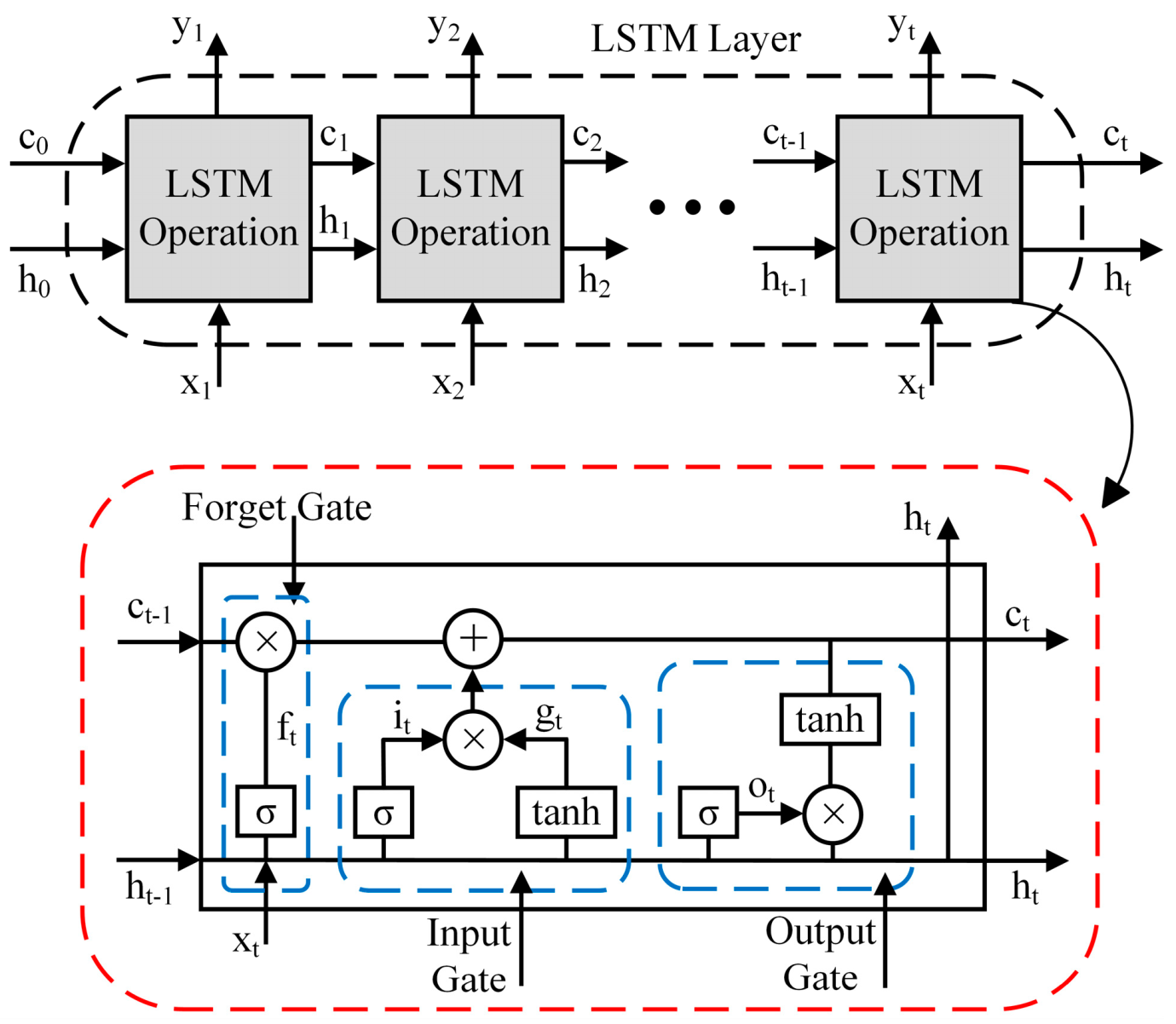

2.7. Optimization Method

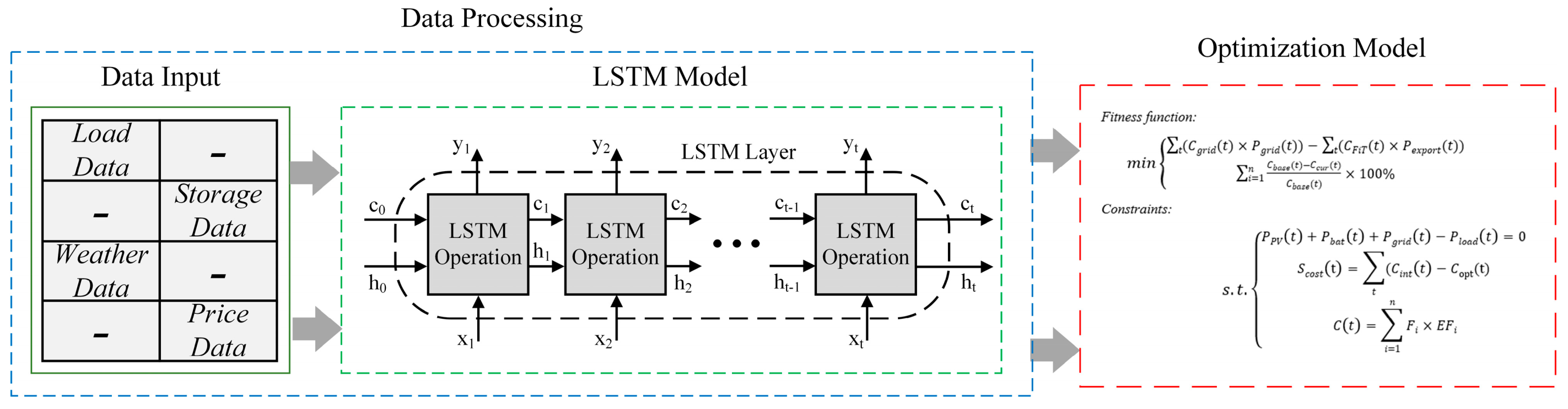

2.7.1. Data Processing

2.7.2. Data Optimization

| Algorithm 1: Optimization Formula |

| Input: Merredin WA Power Grid information Output: Cost savings optimal results and carbon emission reduction Begin optimization method: Start analysis and checking parameters Analyze performance Data Processing LSTM model: Optimization Model Fitness function: Constraints: Optimization complete if Constraints are satisfied then Update parameters from the optimization models and if suit the optimization problem then return and end if end if |

3. Results and Discussion

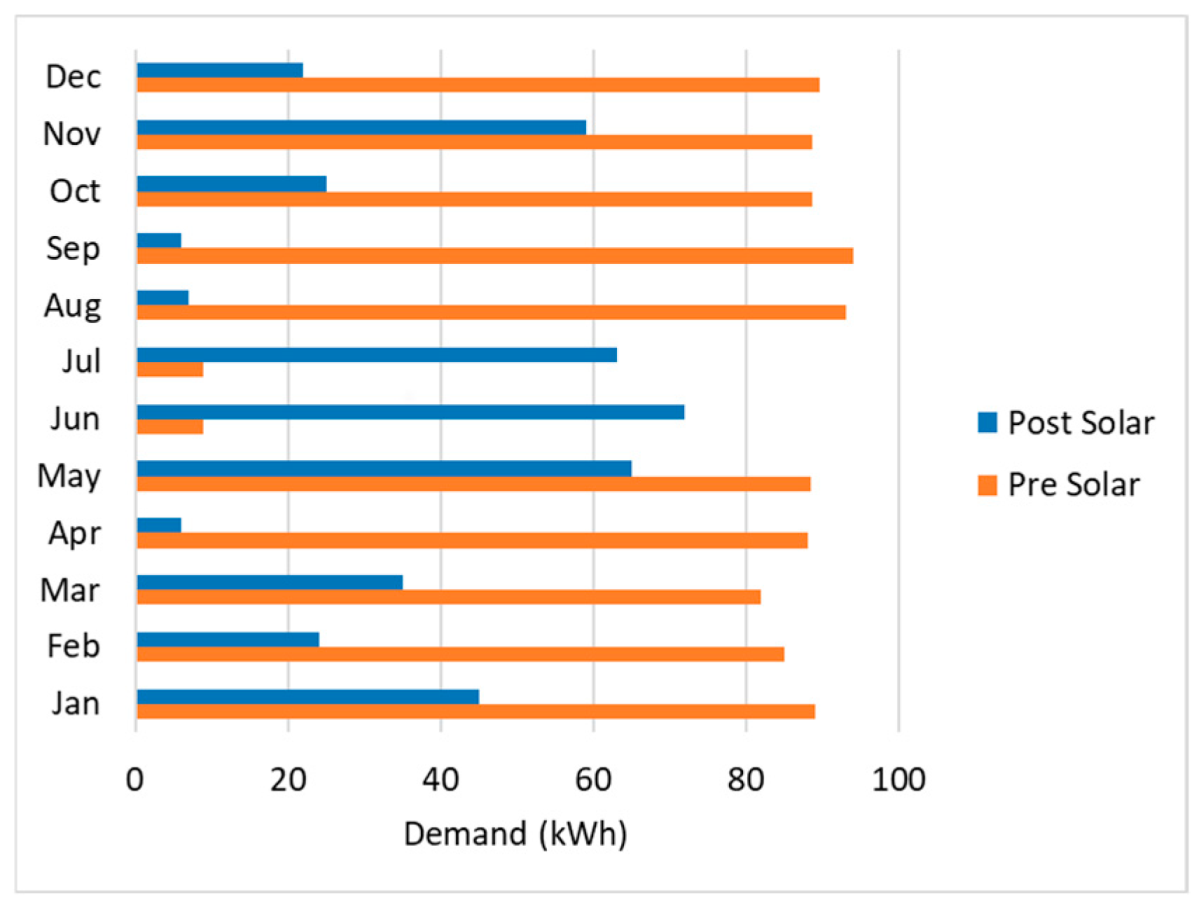

3.1. Energy Independence

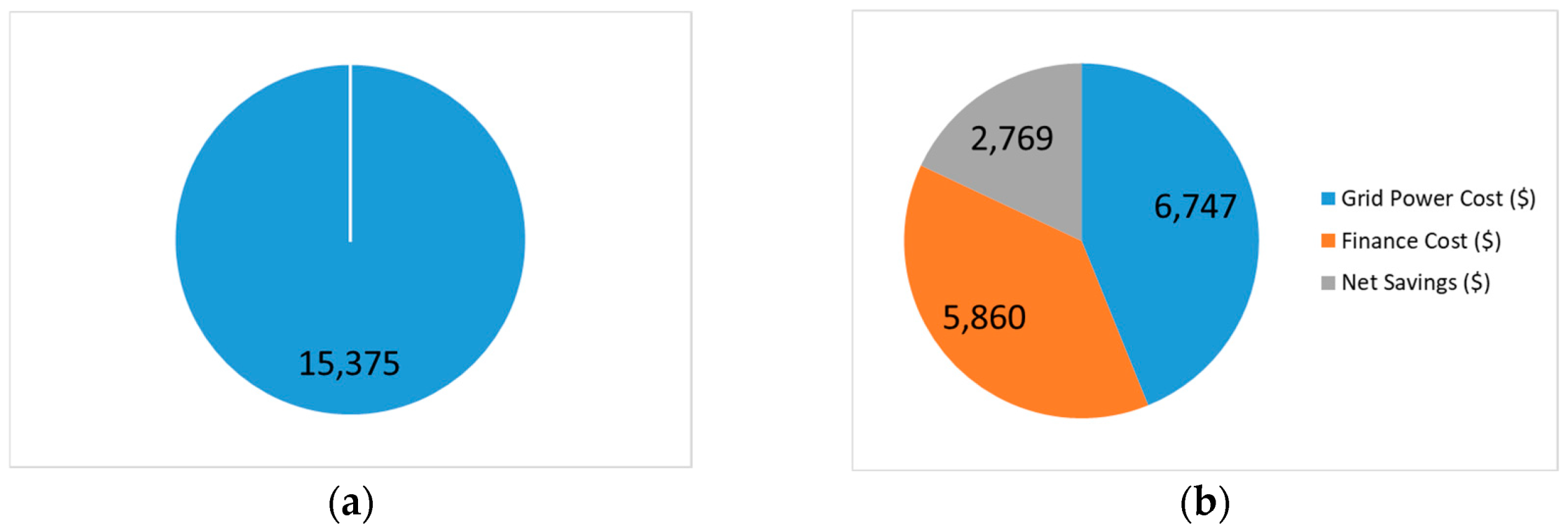

3.2. Cost Reduction

3.3. Environmental Sustainability

- The project achieved a 67% reduction in carbon emissions, primarily due to the shift from fossil fuel-based electricity to solar power.

- Although diesel-powered, the backup generator, was used sparingly, further minimizing greenhouse gas emissions.

- By utilizing RE for the majority of its power needs, the mining site positioned itself as a leader in environmental responsibility within industry.

3.4. System Performance and Resilience

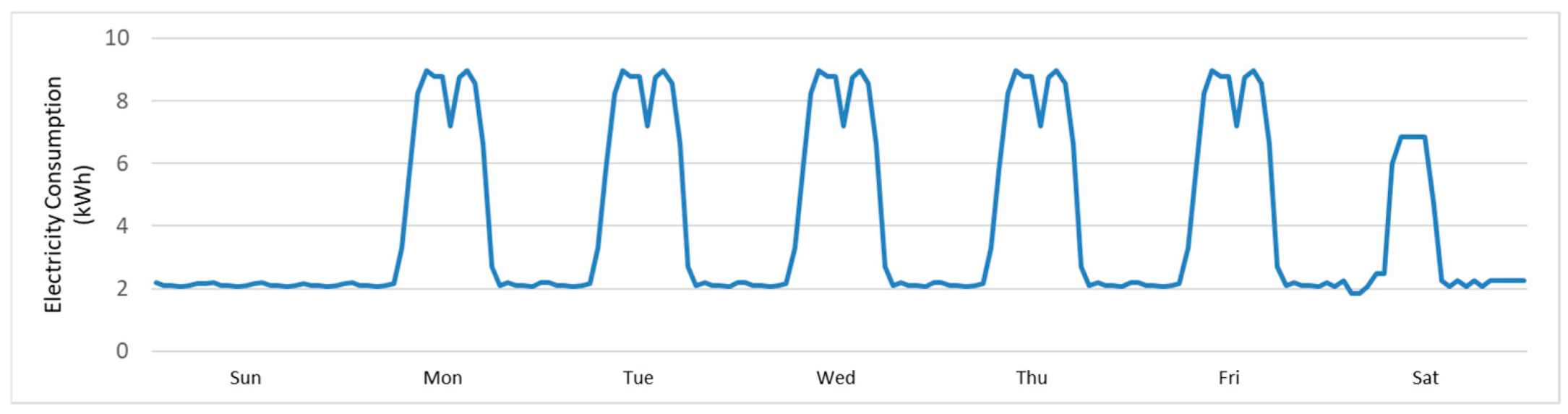

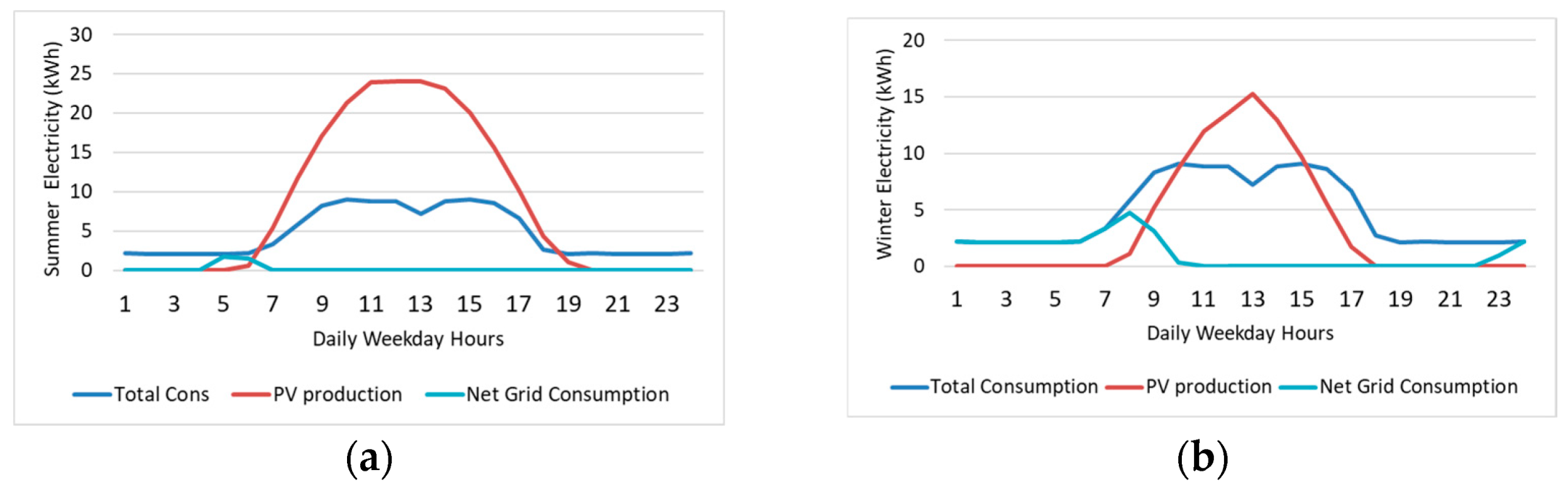

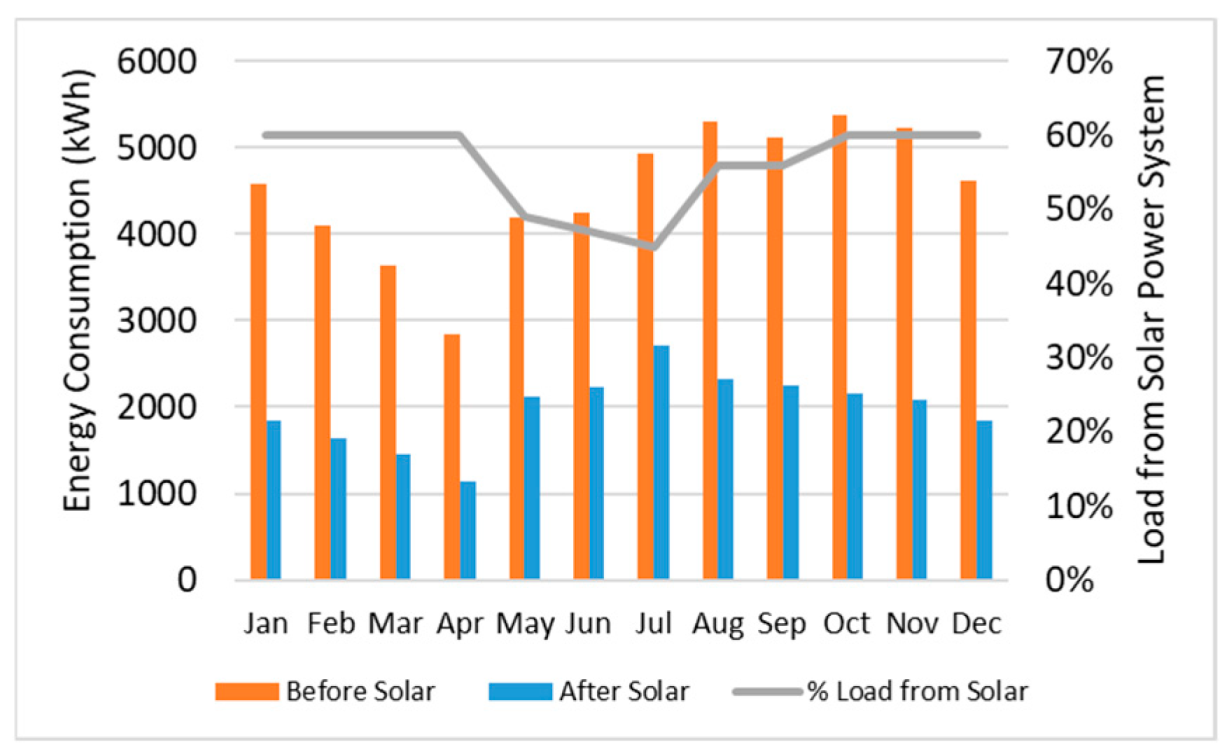

3.5. Energy Consumption Analysis

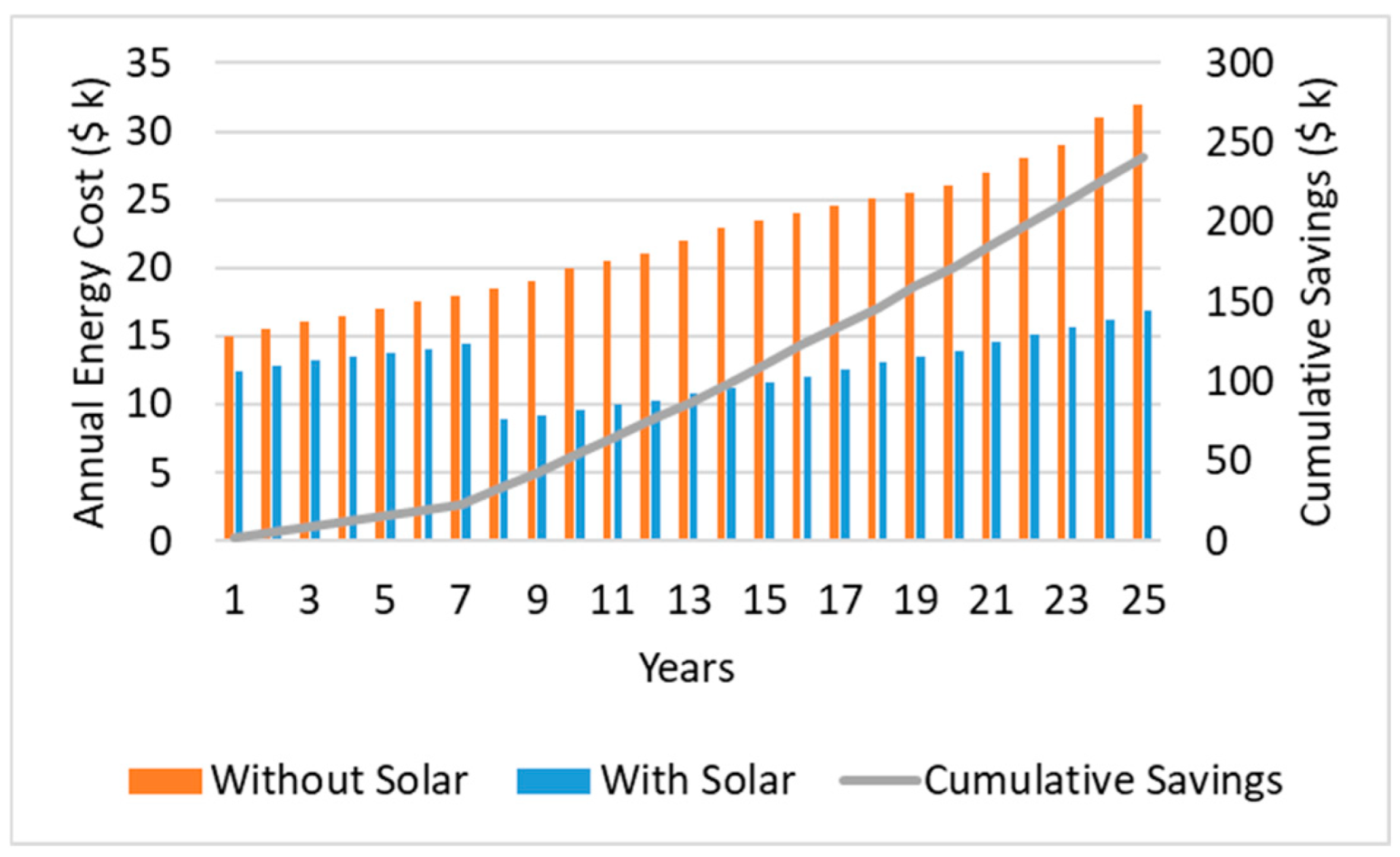

3.6. Future Savings Estimations

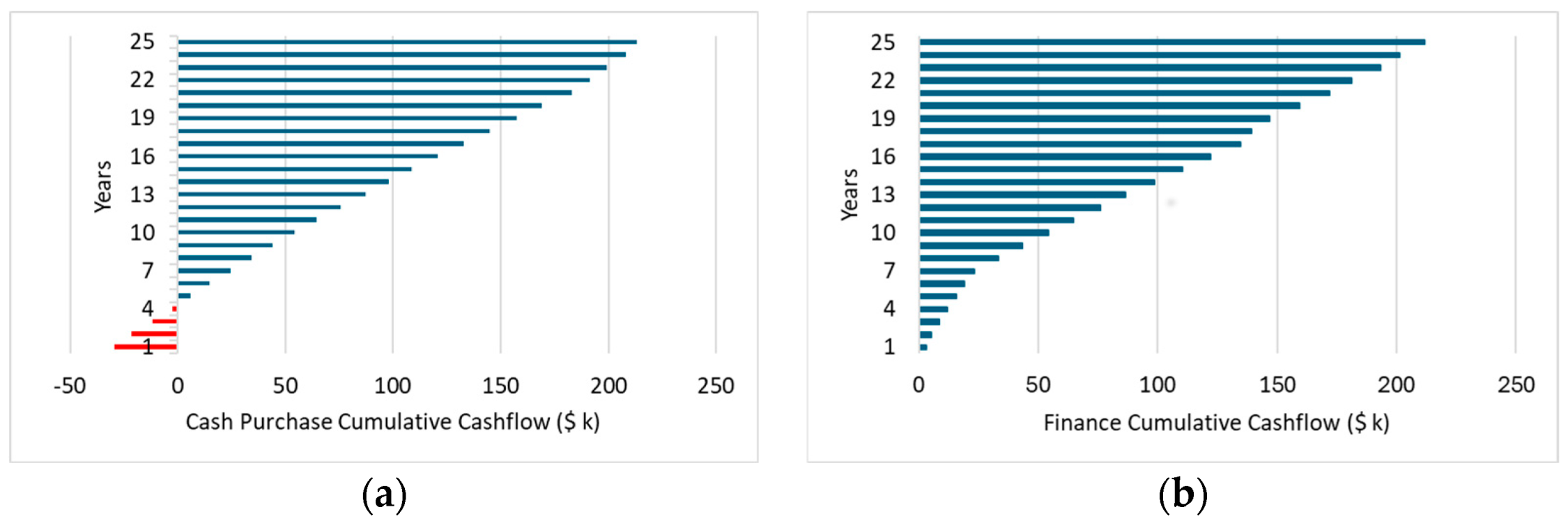

3.7. Cash Flow and Investment Analysis

3.8. Long-Term Cost Projection

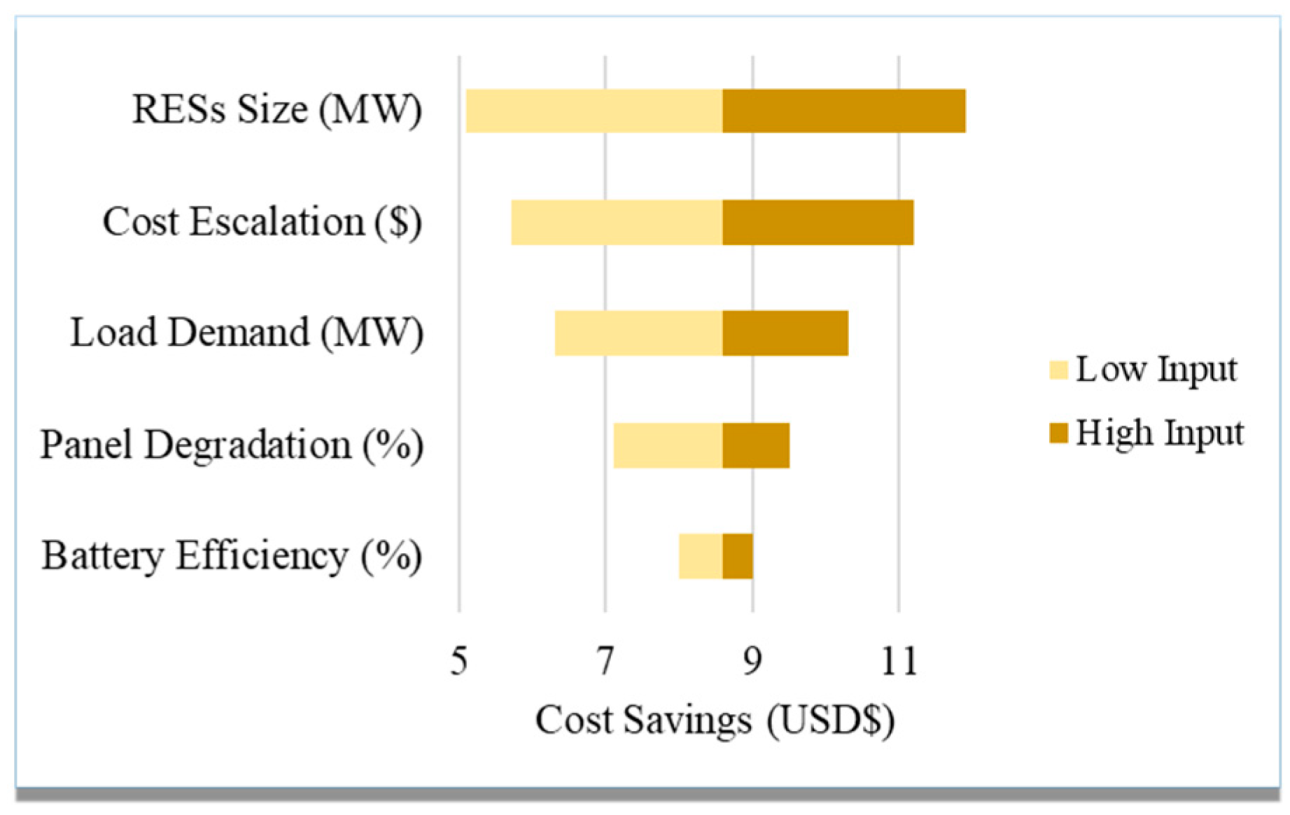

3.9. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Methods | Parameters |

|---|---|

| LSTM | Layers: 2 Neurons: 69 Training Epochs: 107 Learning Rate: 0.0014 Dropout Rate: 0.3 Batch Size: 41 Optimization Method: Adam optimizer |

| TF | Layers: 2 Neurons: 76 Training Epochs: 125 Learning Rate: 0.0013 Dropout Rate: 0.17 Batch Size: 49 Model Size: 128 Feed-forward Network Size: 512 |

| RL | Layers: 2 Neurons: 79 Training Epochs: 137 Learning Rate: 0.0019 Batch Size: 51 Entropy Coefficient: 0.015 |

| GA | Population size: 170 Number of Iterations: 125 Selection method: Tournament Crossover rate: 0.71 Mutation rate: 0.0085 |

| TS | Tabu list size: 30 Number of iterations: 155 Aspiration criteria: Fitness Threshold Neighborhood size: 65 Stopping criteria: 155 (iterations) |

| PSO | Swarm size: 45 Inertia weight: 0.83 Cognitive Coefficient: 2.31 Social Coefficient: 2.19 Velocity Limits: 7 Maximum iterations: 160 |

| GWO | Number of wolves: 70 Encircling behavior (Decreasing A Parameter): [1.93, 0] Wolves’ movement (Increasing C Parameter): [0, 2.17] Maximum iterations: 130 |

| ACO | Number of ants: 95 Pheromone evaporation rate: 0.31 Pheromone deposit amount: 2.75 Exploration vs exploitation: 5 Importance of pheromone: 3 Maximum iterations: 155 |

| BA | Population size: 80 Initial loudness: 0.63 Initial pulse rate: 1 Frequency range: [0, 1] Velocity: 5 Maximum iterations: 140 |

References

- Tan, V.; Deng, R.; Egan, R. Solar photovoltaic waste and resource potential projections in Australia, 2022–2050. Resour. Conserv. Recycl. 2024, 202, 107316. [Google Scholar] [CrossRef]

- Linden, S. Electricity Generation Licence; Merredin Project Company Pty Ltd: Subiaco, Australia, 2021; pp. 1–44. [Google Scholar]

- Khan, S.A.; Tao, Z.; Agyekum, E.B.; Fahad, S.; Tahir, M.; Salman, M. Sustainable rural electrification: Energy-economic feasibility analysis of autonomous hydrogen-based hybrid energy system. Int. J. Hydrogen Energy 2024, 9, 1–14. [Google Scholar] [CrossRef]

- Khan, T.; Waseem, M.; Tahir, M.; Liu, S.; Yu, M. Autonomous hydrogen-based solar-powered energy system for rural electrification in Balochistan, Pakistan: An energy-economic feasibility analysis. Energy Convers. Manag. 2022, 271, 116284. [Google Scholar] [CrossRef]

- Shakya, B.D.; Aye, L.; Musgrave, P. Technical feasibility and financial analysis of hybrid wind–photovoltaic system with hydrogen storage for Cooma. Int. J. Hydrogen Energy 2005, 30, 9–20. [Google Scholar] [CrossRef]

- Beasy, K.; Lodewyckx, S.; Gale, F. An Analysis of Emerging Renewable Hydrogen Policy through an Energy Democracy Lens: The Case of Australia. Sustainability 2024, 16, 2226. [Google Scholar] [CrossRef]

- Burton, J.; Kemp, D.; Barnes, R.; Parmenter, J. Mapping critical minerals projects and their intersection with Indigenous peoples’ land rights in Australia. Energy Res. Soc. Sci. 2024, 113, 103556. [Google Scholar] [CrossRef]

- Department of Primary Industries and Regional Development. Climate Change in the Merredin Area, Western Australia. Available online: https://www.agric.wa.gov.au/climate-change/climate-change-merredin-area-western-australia (accessed on 11 September 2024).

- Ralph, N.; Hancock, L. Energy security, transnational politics, and renewable electricity exports in Australia and Southeast Asia. Energy Res. Soc. Sci. 2019, 49, 233–240. [Google Scholar] [CrossRef]

- Hossain, E.; Zawad, M.; Rakibul Islam, K.H.; Akash, M.Q. Design a Novel Controller for Stability Analysis of Microgrid by Managing Controllable Load using Load Shaving and Load Shifting Techniques; and Optimizing Cost Analysis for Energy Storage System. Int. J. Renew. Energy Res. 2016, 6, 772–786. [Google Scholar] [CrossRef]

- Worlanyo, A.S.; Jiangfeng, L. Evaluating the environmental and economic impact of mining for post-mined land restoration and land-use: A review. J. Environ. Manag. 2021, 279, 1–16. [Google Scholar] [CrossRef]

- Strazzabosco, A.; Gruenhagen, J.H.; Cox, S. A review of renewable energy practices in the Australian mining industry. Renew. Energy 2022, 187, 135–143. [Google Scholar] [CrossRef]

- Velasquez, N.; Anani, A.; Munoz-Gama, J.; Pascual, R. Towards the Application of Process Mining in the Mining Industry—An LHD Maintenance Process Optimization Case Study. Sustainability 2023, 15, 7974. [Google Scholar] [CrossRef]

- Corrigan, C.C.; Ikonnikova, S.A. A review of the use of AI in the mining industry: Insights and ethical considerations for multi-objective optimization. Extr. Ind. Soc. 2024, 17, 101440. [Google Scholar] [CrossRef]

- Brzychczy, E.; Gackowiec, P.; Liebetrau, M. Data Analytic Approaches for Mining Process Improvement—Machinery Utilization Use Case. Resources 2020, 9, 17. [Google Scholar] [CrossRef]

- Bhimaraju, A.; Mahesh, A.; Nirbheram, J.S. Feasibility study of solar photovoltaic/grid-connected hybrid renewable energy system with pumped storage hydropower system using abandoned open cast coal mine: A case study in India. J. Energy Storage 2023, 72, 108206. [Google Scholar] [CrossRef]

- Brueckner, M.; Durey, A.; Mayes, R.; Pforr, C. The mining boom and Western Australia’s changing landscape: Towards sustainability or business as usual? Rural Soc. 2013, 22, 111–124. [Google Scholar] [CrossRef]

- Riedemann, J.; Reyes, E.; Sarasiri, N.; Pena, R.; Andrade, I. Renewable Source-Based Water Pumping Electrification in Mines: Current technologies and future trends. IEEE Electrif. Mag. 2024, 12, 38–44. [Google Scholar] [CrossRef]

- Pouresmaieli, M.; Ataei, M.; Nouri Qarahasanlou, A.; Barabadi, A. Integration of renewable energy and sustainable development with strategic planning in the mining industry. Results Eng. 2023, 20, 101412. [Google Scholar] [CrossRef]

- Laslett, D.; Carter, C.; Creagh, C.; Jennings, P. A large-scale renewable electricity supply system by 2030: Solar, wind, energy efficiency, storage and inertia for the South West Interconnected System (SWIS) in Western Australia. Renew. Energy 2017, 113, 713–731. [Google Scholar] [CrossRef]

- Huang, H.; Ata, S.; Rougieux, F.; Kay, M. Decarbonising mining of Australia’s critical mineral deposits: Opportunities for sustainable mining through solar photovoltaics and wind energy integration. J. Clean. Prod. 2024, 455, 142300. [Google Scholar] [CrossRef]

- Mariutti, E. The Limits of the Current Consensus Regarding the Carbon Footprint of Photovoltaic Modules Manufactured in China: A Review and Case Study. Energies 2025, 18, 1178. [Google Scholar] [CrossRef]

- Qays, O.; Buswig, Y.; Basri, H.; Hossain, L.; Abu-siada, A.; Rahman, M.M.; Muyeen, S.M. An Intelligent Controlling Method for Battery Lifetime Increment Using State of Charge Estimation in PV-Battery Hybrid System. Appl. Sci. 2020, 10, 8799. [Google Scholar] [CrossRef]

- Chander, S.; Purohit, A.; Sharma, A.; Arvind; Nehra, S.P.; Dhaka, M.S. A study on photovoltaic parameters of mono-crystalline silicon solar cell with cell temperature. Energy Rep. 2015, 1, 104–109. [Google Scholar] [CrossRef]

- Ohirul Qays, M.; Buswig, Y.; Hossain, M.L.; Abu-Siada, A. Active Charge Balancing Strategy Using the State of Charge Estimation Technique for a PV-Battery Hybrid System. Energies 2020, 13, 3434. [Google Scholar] [CrossRef]

- Chatzigeorgiou, N.G.; Theocharides, S.; Makrides, G.; Georghiou, G.E. A review on battery energy storage systems: Applications, developments, and research trends of hybrid installations in the end-user sector. J. Energy Storage 2024, 86, 111192. [Google Scholar] [CrossRef]

- Hutton & Northey Merredin on Google Maps. Available online: https://www.google.com/maps/ (accessed on 31 October 2024).

- Sørensen, B. The Energy Conversion Processes. In Renewable Energy; Academic Press: Cambridge, MA, USA, 2011; pp. 337–531. [Google Scholar]

- Ansari, S.; Ayob, A.; Lipu, M.S.H.; Saad, M.H.M.; Hussain, A. A Review of Monitoring Technologies for Solar PV Systems Using Data Processing Modules and Transmission Protocols: Progress, Challenges and Prospects. Sustainability 2021, 13, 8120. [Google Scholar] [CrossRef]

- ENF Solar Panel Directory. Available online: https://www.enfsolar.com/pv/panel-datasheet/crystalline/48172 (accessed on 2 November 2024).

- Evoenergy. BIS Oxford Economics Australia: Electricityrelated Labour Escalation Forecasts to 2028/29; 11; BIS Oxford Economics Pty Limited: Sydney, Australia, 2023; pp. 1–40. [Google Scholar]

- Honnurvali, M.S.; Gupta, N.; Goh, K.; Umar, T.; Kabbani, A.; Nazeema, N. Case study of PV output power degradation rates in Oman. IET Renew. Power Gener. 2018, 13, 352–360. [Google Scholar] [CrossRef]

- Zhao, Q.; Huang, S.; Wang, T.; Yu, Y.; Wang, Y.; Li, Y.; Gao, W. The Influencing Factors and Future Development of Energy Consumption and Carbon Emissions in Urban Households: A Review of China’s Experience. Appl. Sci. 2025, 15, 2961. [Google Scholar] [CrossRef]

- Jiménez García, C.; Porres de la Haza, M.J.; Coll Aliaga, E.; Lerma-Arce, V.; Lorenzo-Sáez, E. Methodology for Measuring Mobility Emissions with High Spatial Resolution: Case Study in Valencia, Spain. Appl. Sci. 2025, 15, 669. [Google Scholar] [CrossRef]

- Early Townsite of Merredin. Available online: https://catalogue.data.wa.gov.au/dataset/early-townsite-of-merredin (accessed on 2 November 2024).

- Qays, M.O.; Ahmad, I.; Habibi, D.; Masoum, M.A.S. Forecasting data-driven system strength level for inverter-based resources-integrated weak grid systems using multi-objective machine learning algorithms. Electr. Power Syst. Res. 2024, 238, 111112. [Google Scholar] [CrossRef]

| Module Type | SRP-425-BMZ-HV | SRP-430-BMZ-HV | SRP-435-BMZ-HV | SRP-440-BMZ-HV |

|---|---|---|---|---|

| STC | STC | STC | STC | |

| at STC | 425 | 430 | 435 | 440 |

| 52.1 | 52.2 | 52.4 | 52.6 | |

| 10.31 | 10.40 | 10.47 | 10.53 | |

| 43.8 | 43.9 | 44.1 | 44.3 | |

| 9.71 | 9.80 | 9.87 | 9.93 | |

| Efficiency (μm) | 19.46 | 19.69 | 19.91 | 20.14 |

| Tolerance Power | (0, +4.99) | |||

| System Voltage (max) | 1500 VDC | |||

| Series Fuse Rating (max) | 20 A | |||

| Energy-Consumption Split | |||

|---|---|---|---|

| Total | Solar | Grid | |

| kWh | 35,694 | 31,132 | 4561 |

| % | 100% | 87% | 13% |

| Optimization Method | Cost (USD$) | Computation Time (s) | Cost Reduction (%) | Accuracy (%) |

|---|---|---|---|---|

| LSTM-Classical | 2769 | 1.153 | 57.03 | 99.247 |

| TF | 2733 | 1.164 | 56.21 | 99.015 |

| RL | 2681 | 1.169 | 55.67 | 98.832 |

| GA | 2643 | 1.172 | 55.28 | 98.541 |

| TS | 2591 | 1.181 | 54.71 | 98.043 |

| PSO | 2583 | 1.972 | 54.21 | 97.682 |

| GWO | 2547 | 2.014 | 53.89 | 97.429 |

| ACO | 2522 | 2.029 | 53.31 | 97.156 |

| BA | 2499 | 2.048 | 52.95 | 95.025 |

| Solar Projections | Value (kWh) | Cost from Grid ($) |

|---|---|---|

| System Suggested | 33 kW | - |

| 33 kW solar system annual energy production (CEC Average) | 31,132 | - |

| Conservative annual estimate at site due to PV system orientation | 54,240 | - |

| Usage estimates based on a 5.5-day week with some standing power usage | ||

| Peak Usage substituted by Solar | 27,373 | 7765.87 |

| Off-Peak Usage substituted by Solar | 3041 | 862.86 |

| Potential excess solar production feed in | 23,825 | - |

| Total Savings | 54,240 | 8627.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qays, M.O.; Kumar, R.; Ahmed, M.; Lachowicz, S.; Amin, U. Empowering Optimal Operations with Renewable Energy Solutions for Grid Connected Merredin WA Mining Sector. Appl. Sci. 2025, 15, 5516. https://doi.org/10.3390/app15105516

Qays MO, Kumar R, Ahmed M, Lachowicz S, Amin U. Empowering Optimal Operations with Renewable Energy Solutions for Grid Connected Merredin WA Mining Sector. Applied Sciences. 2025; 15(10):5516. https://doi.org/10.3390/app15105516

Chicago/Turabian StyleQays, Md Ohirul, Ravi Kumar, Minhaz Ahmed, Stefan Lachowicz, and Uzma Amin. 2025. "Empowering Optimal Operations with Renewable Energy Solutions for Grid Connected Merredin WA Mining Sector" Applied Sciences 15, no. 10: 5516. https://doi.org/10.3390/app15105516

APA StyleQays, M. O., Kumar, R., Ahmed, M., Lachowicz, S., & Amin, U. (2025). Empowering Optimal Operations with Renewable Energy Solutions for Grid Connected Merredin WA Mining Sector. Applied Sciences, 15(10), 5516. https://doi.org/10.3390/app15105516