Interfacial Shear Properties of Red Clay and Polyurethane with Different Densities

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Test Pieces

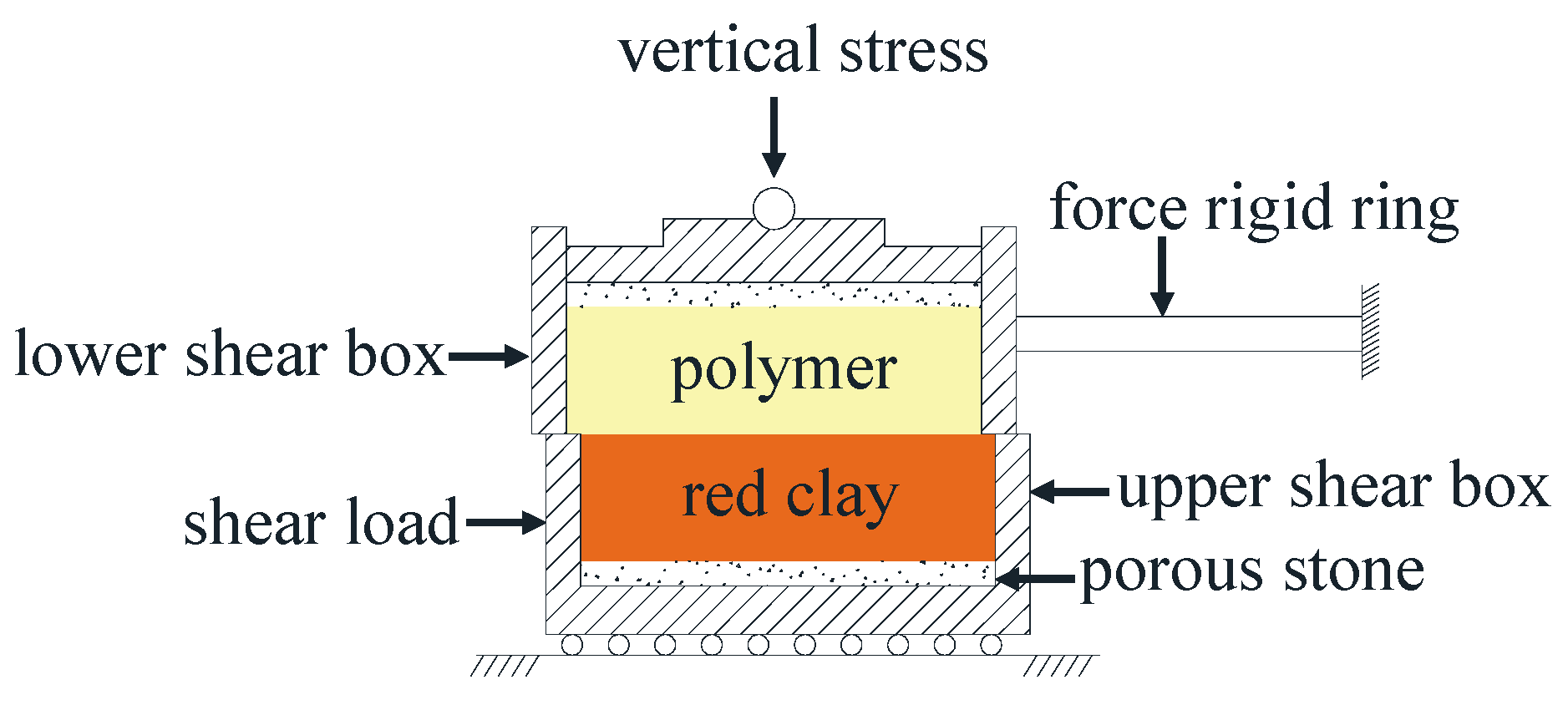

2.3. Experimental Method

3. Results and Discussion

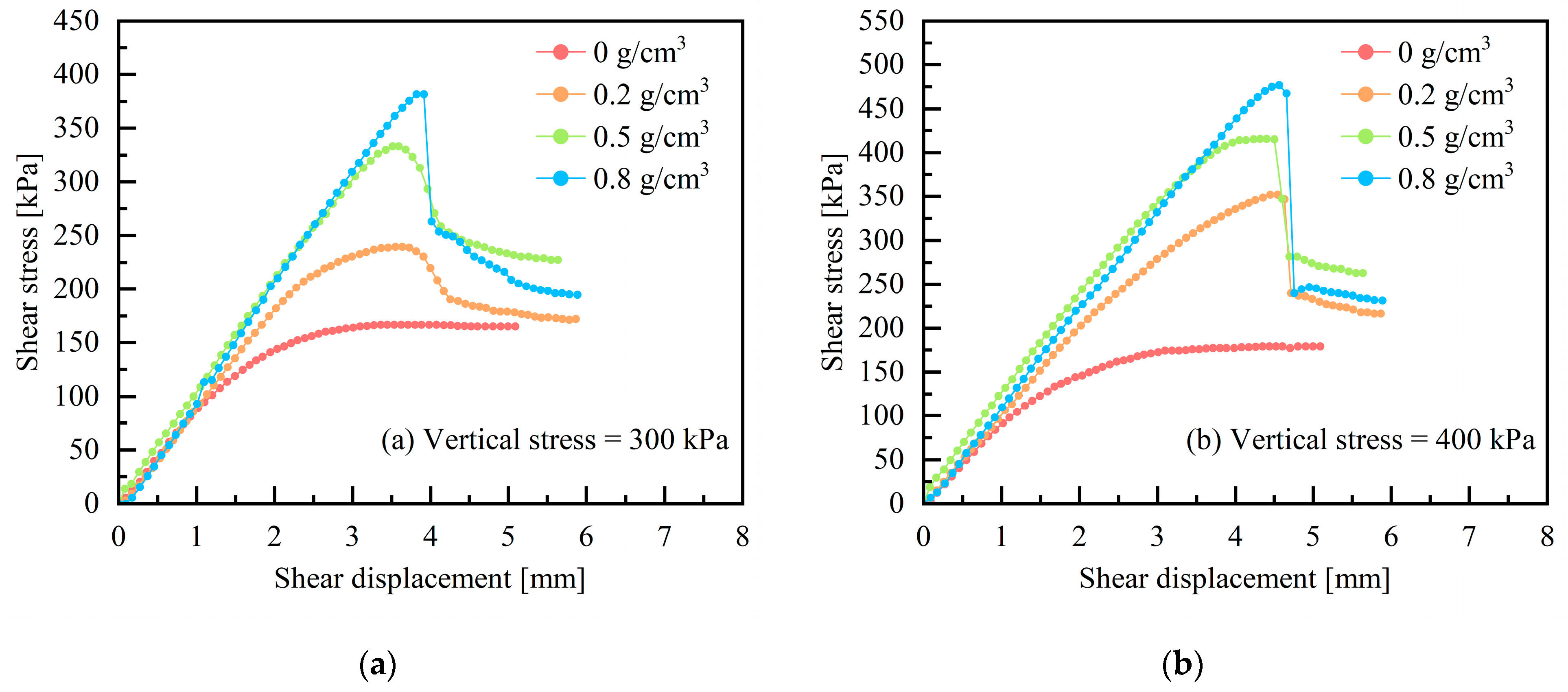

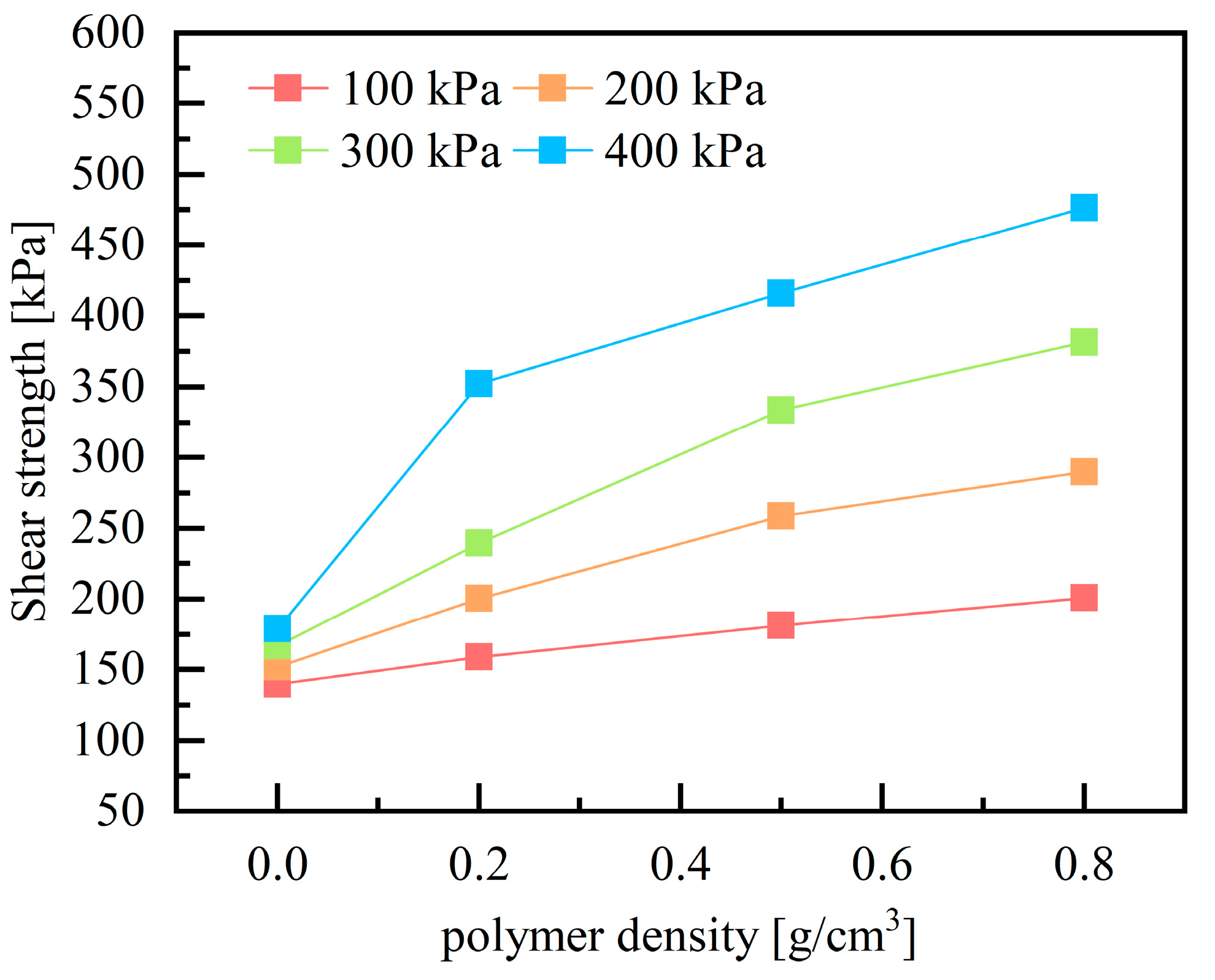

3.1. Effect of Polyurethane Density on Shear Stress-Shear Displacement Curve

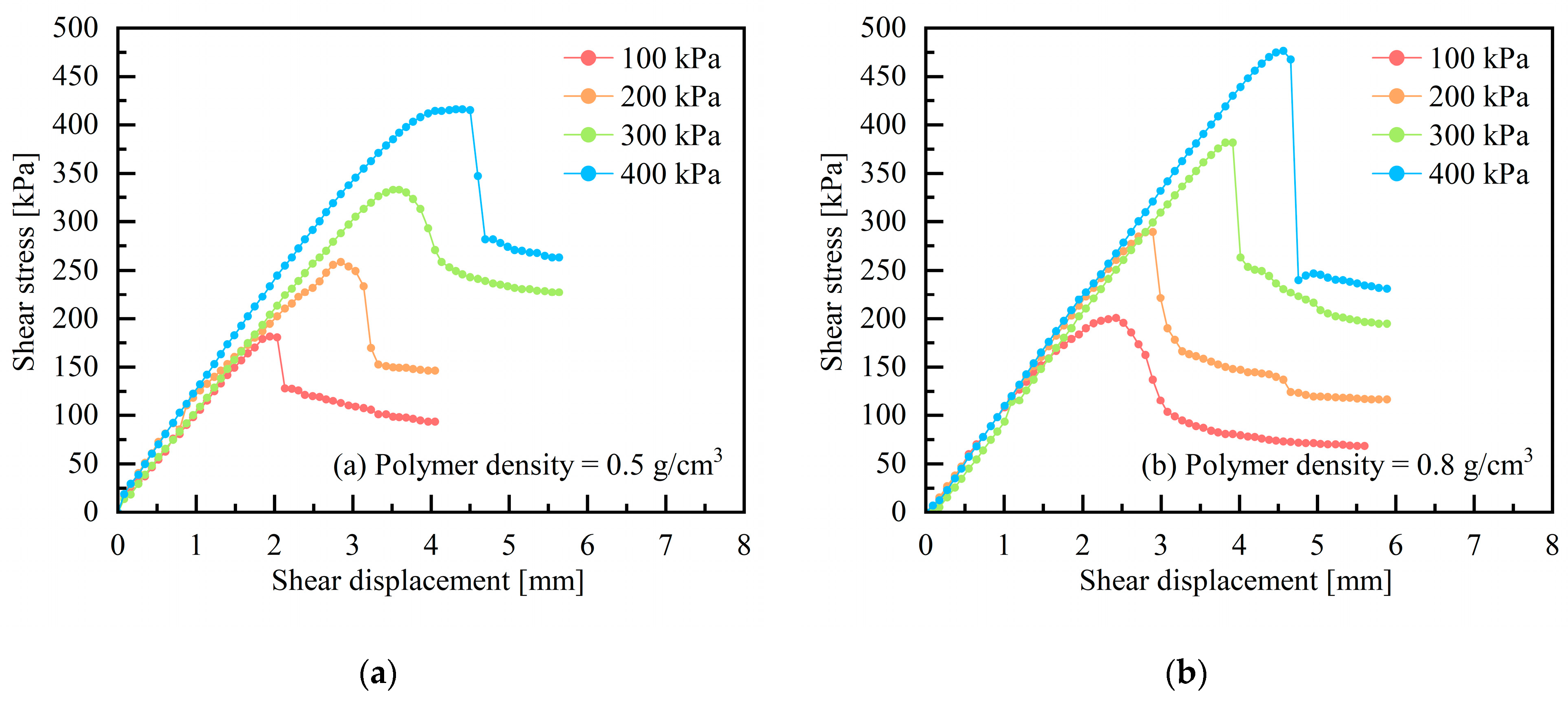

3.2. Effect of Normal Stress on Shear-Shear Displacement Curve

4. Model Validation

4.1. Definition of Material Parameters

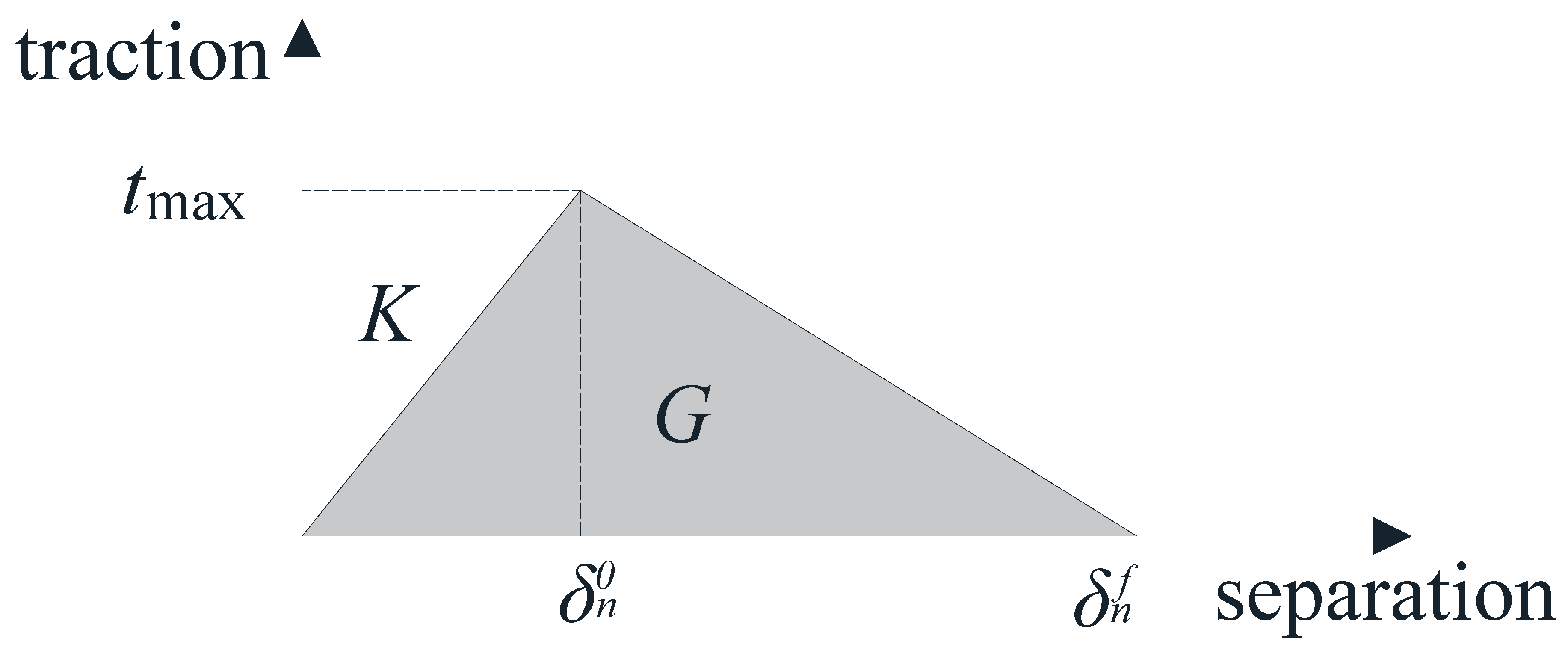

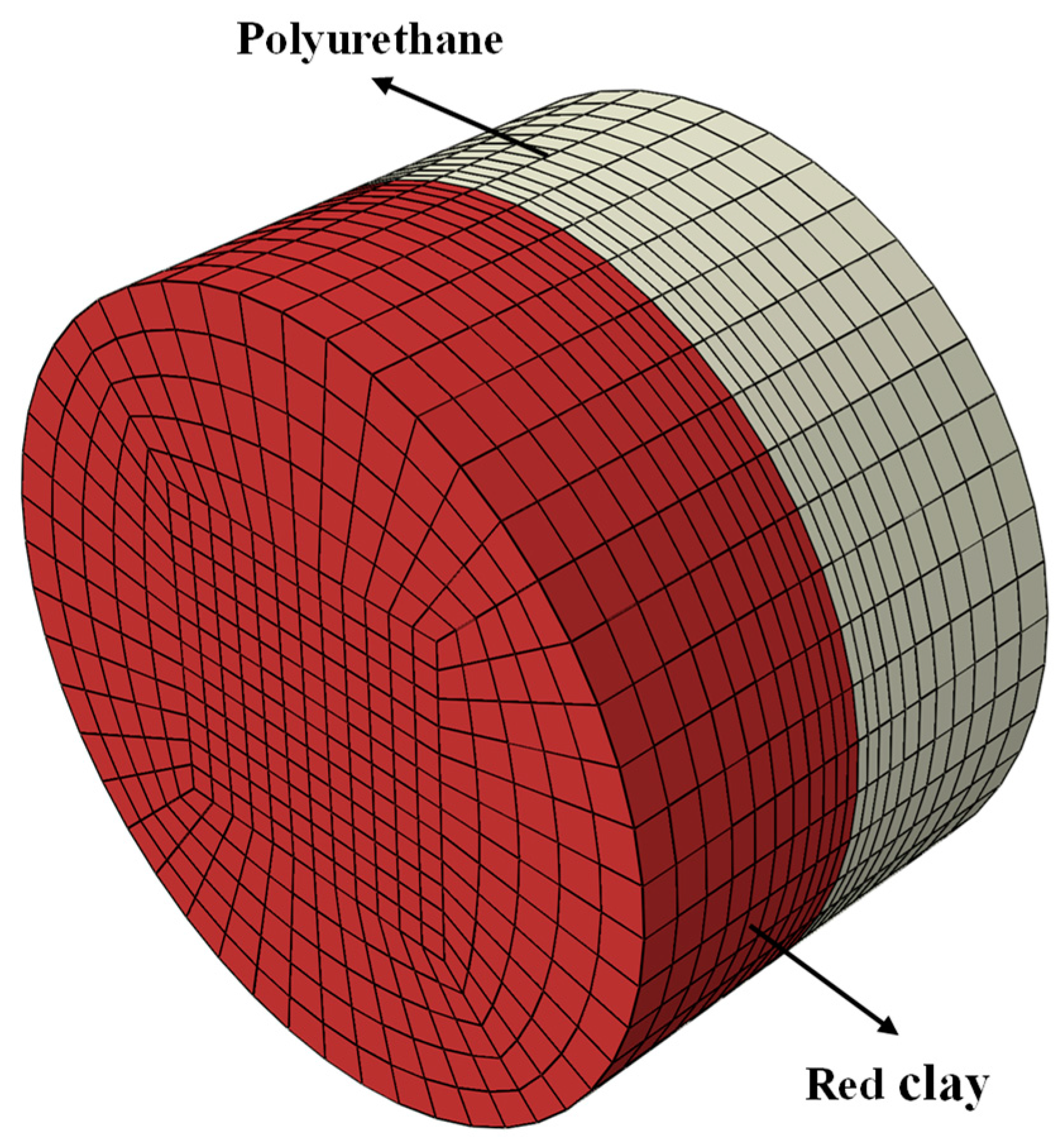

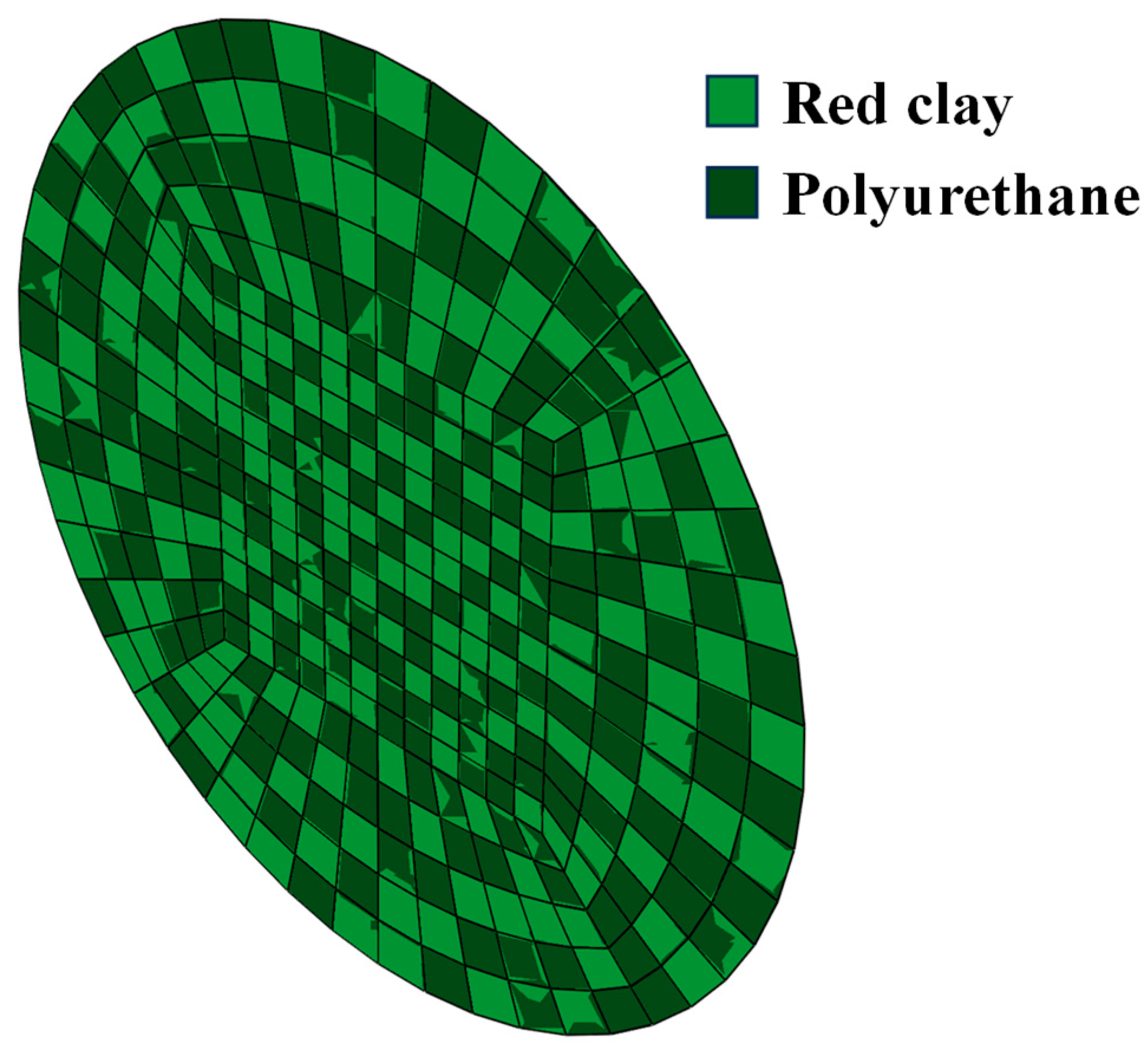

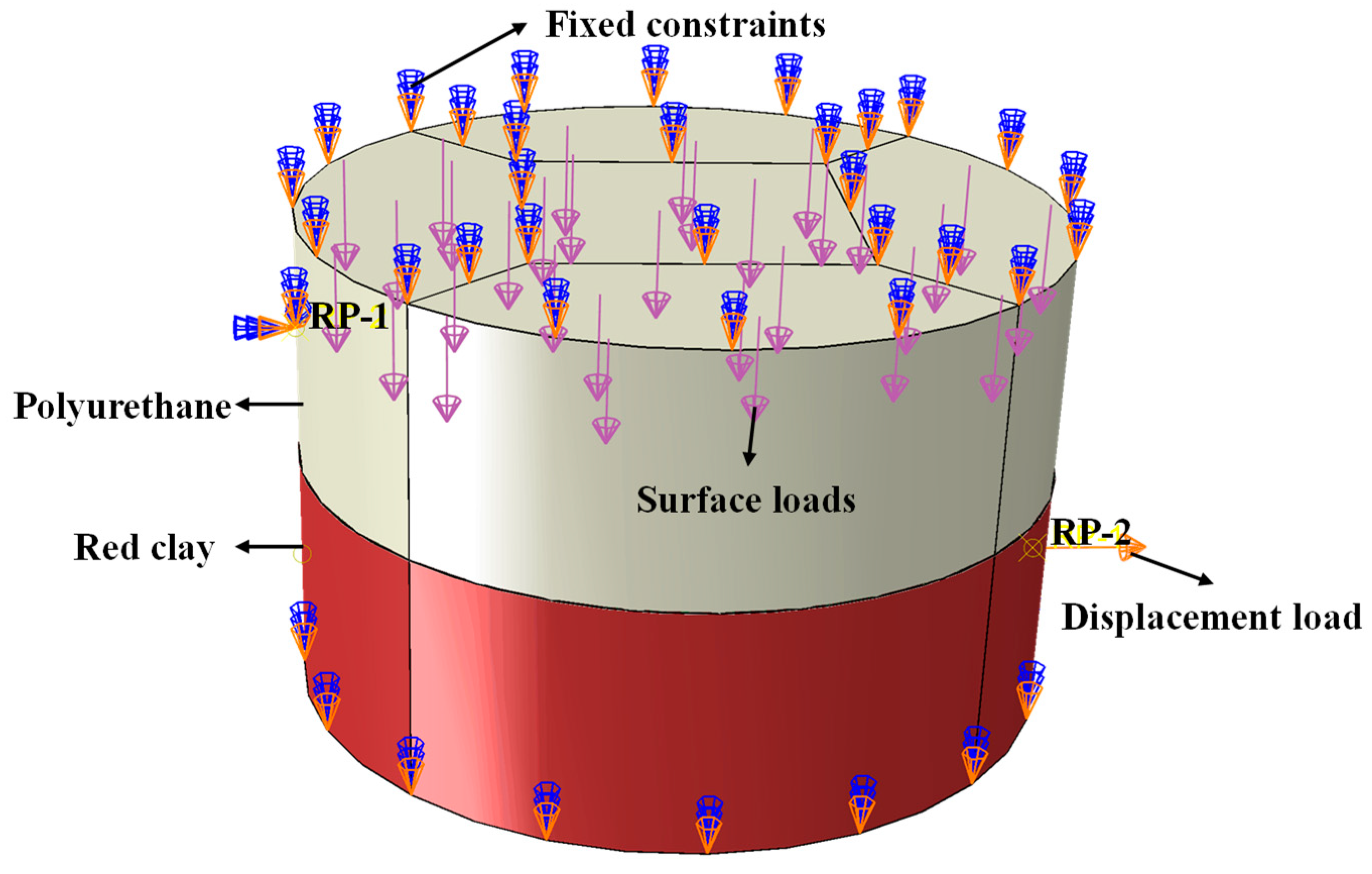

4.2. Finite Element Module Method

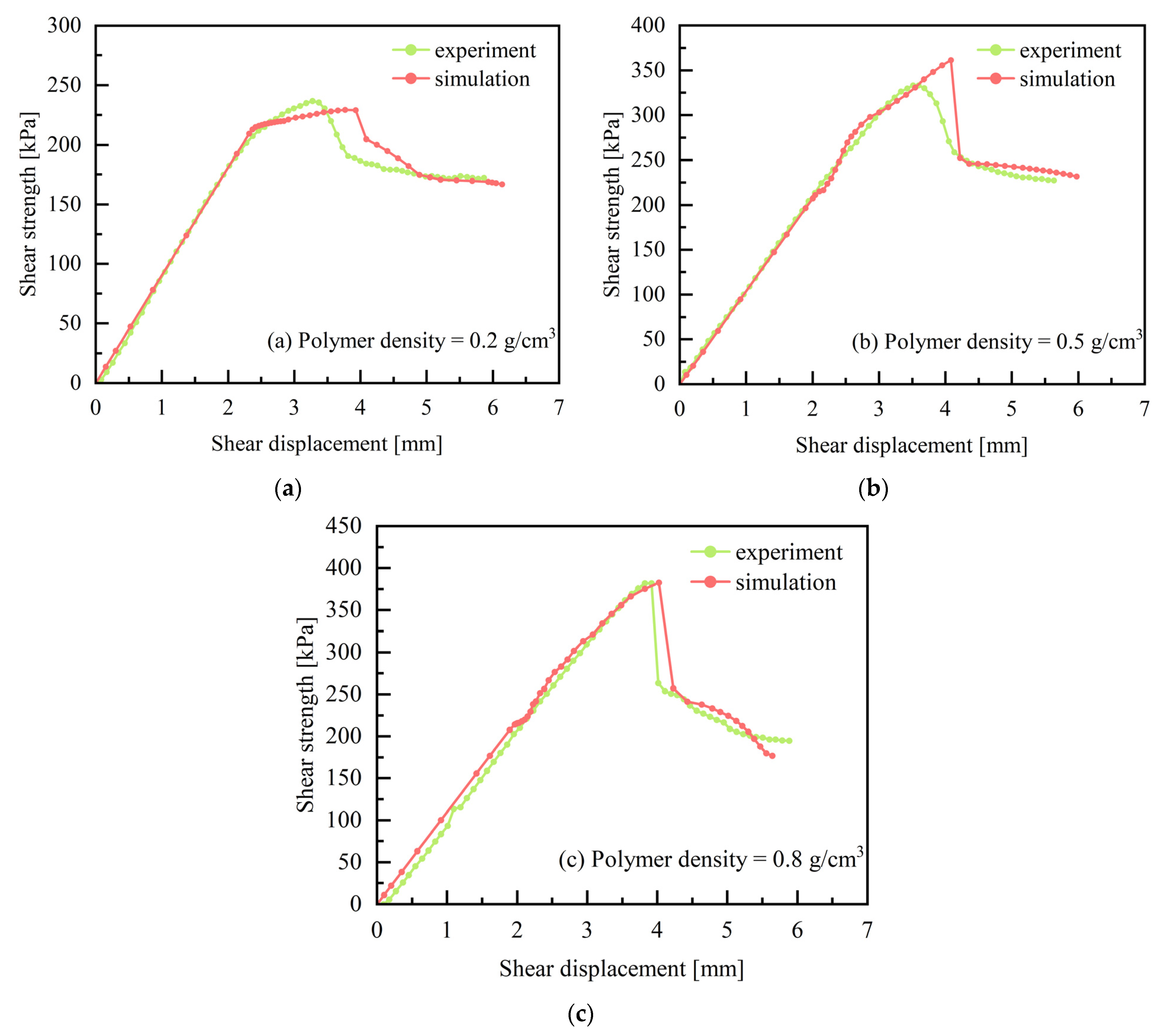

4.3. Analysis of Finite Element Simulation Results of Stress-Displacement Curve

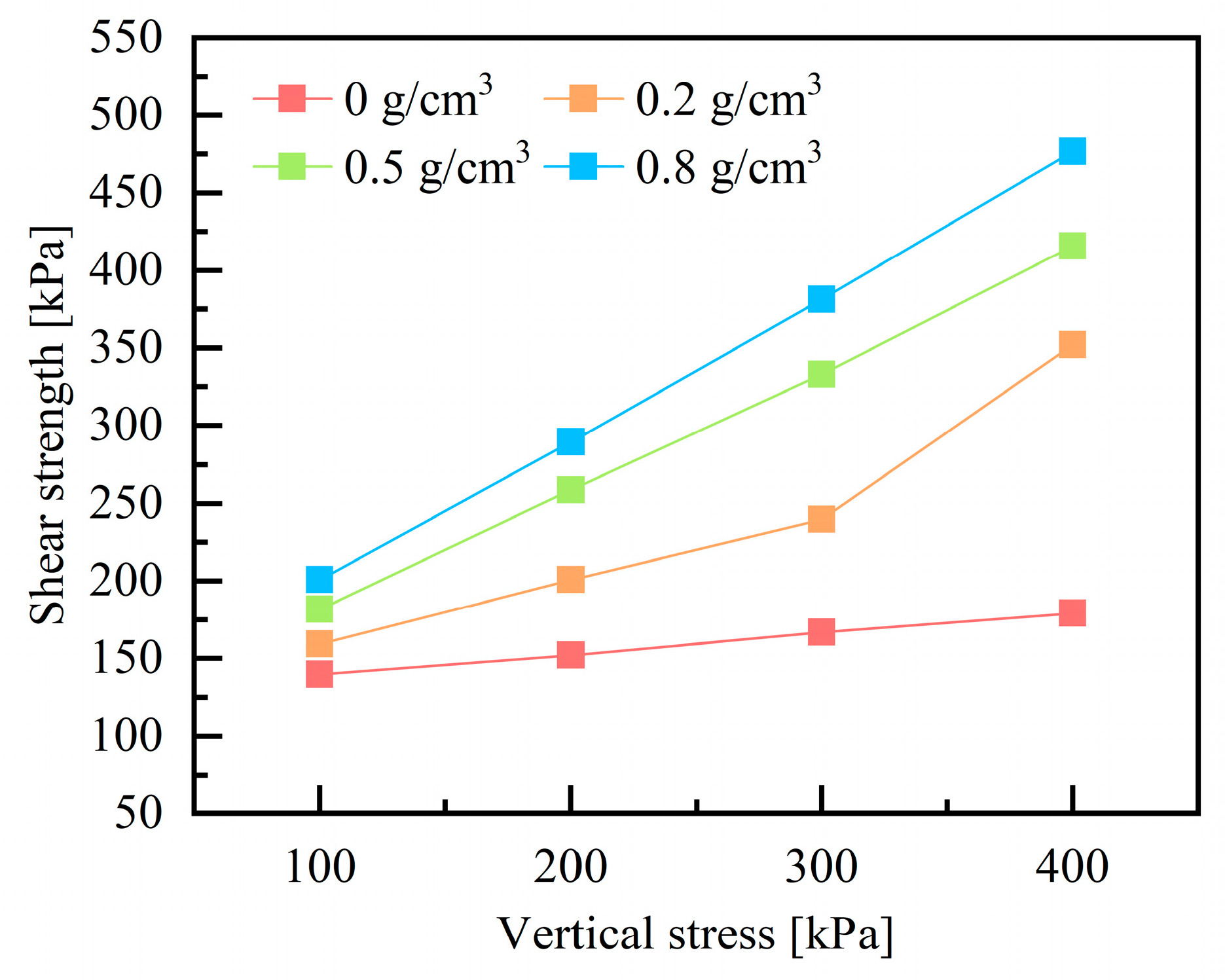

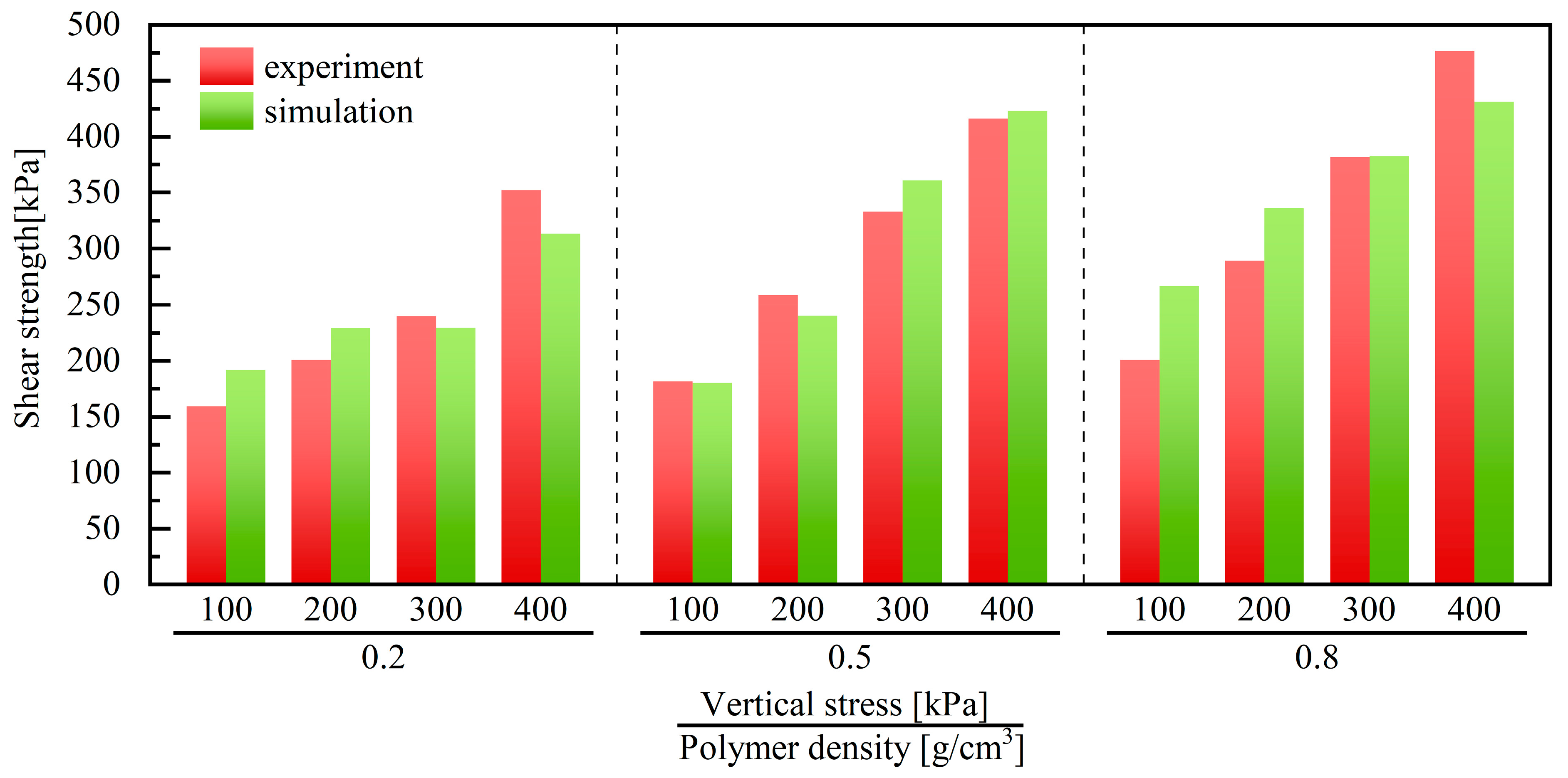

4.4. Analysis of Finite Element Simulation Results of Shear Strength

5. Conclusions

- The incorporation of polyurethane induces a transition in the shear stress-displacement curve of red clay from strain-hardening to strain-softening behavior. As the polyurethane density increases, the shear softening characteristics of polyurethane become more pronounced, though excessive density triggers abrupt interfacial softening. The shear strength exhibits a linear positive relationship with the density of polyurethane. Considering the changes in interfacial strength and ductility after the polyurethane infiltrates the red clay, the density of polyurethane can be controlled between 0.5 g/cm3 to 0.8 g/cm3, which provides critical guidance for determining the appropriate polyurethane content in red clay slope reinforcement projects.

- Normal stress has a significant impact on both the shear stress-strain curve and shear strength of polyurethane-red clay composites. As normal stress increases, the horizontal displacement at shear failure, peak shear stress, and residual stress all gradually increase, and the slope of the stress-rise stage also becomes steeper. Additionally, the interfacial shear strength increases linearly with normal stress.

- Simulation of direct shear tests using the ABAQUS cohesive element finite element model effectively captures the mechanical properties of the polyurethane-red clay interface. The simulation results align well with the experimental shear stress-displacement curve; For the simulation and modeling of shear strength values, the fitting results are better when the density of polyurethane is 0.5 g/cm3. However, there are certain errors when the density is 0.2 g/cm3 and 0.8 g/cm3, although these errors remain within an acceptable range.

6. Outlook

- The current finite element modeling approach treats the polyurethane material as an idealized linear-elastic isotropic constitutive model, which introduces notable limitations—particularly in accurately predicting the shear strength of high-density polyurethane composites. To address this, future work will adopt a hyperelastic-viscoelastic constitutive model that better captures the polyurethane’s deformation behavior.

- This study elucidates the intrinsic relationship between polyurethane density and interfacial shear behavior in red clay, establishing a theoretical benchmark for optimizing field slope stabilization strategies. Future work will extend these findings to practical engineering applications through integrated assessment of construction feasibility, long-term durability, and environmental compatibility.

- Subsequent studies will adopt the methodology established by Kraśkiewicz [49] for the linear relationship between polyurethane foam density and compressive stiffness, systematically compare the density-dependent mechanical behavior of polyurethane -red clay interfaces with other elastomer-soil systems, and validate the generalizability of this work’s conclusions. Correlation matrices and sensitivity analysis will be employed to quantify the interactions among polyurethane density, stiffness, environmental factors, and interfacial shear strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, L.; Yu, H.C.; Gao, Q.F.; Liu, J.; Liu, Z. Evolution of Tensile Properties of Compacted Red Clay Under Wet and Dry Cycles. KSCE J. Civ. Eng. 2022, 26, 606–618. [Google Scholar] [CrossRef]

- Ma, H.; Duan, Z.; Zhang, T.; Xu, S.; Lv, M. Micro-constructive Damage Model of Dry-Wet Cyclic Red Clay Based on Weibull Distribution. J. Test. Eval. 2024, 52, 1095–1108. [Google Scholar] [CrossRef]

- Li, H.; Chen, H.; Li, X.; Zhang, F. Design and construction application of concrete canvas for slope protection. Powder Technol. 2019, 334, 937–946. [Google Scholar] [CrossRef]

- Su, H.; Wu, D.; Lu, Y.; Peng, X.; Wang, X.; Chen, W.; Wang, S. Experimental and numerical study on stability performance of new ecological slope protection using bolt-hinge anchored block. Ecol. Eng. 2021, 172, 106409. [Google Scholar] [CrossRef]

- Han, L.; Long, J.; Song, Y. Study on bearing capacity characteristics and reinforcement measures of fill foundation in karst mountain area. Build. Struct. 2023, 53, 2326–2331. [Google Scholar]

- Chen, L.; Chen, X.; Wang, H.; Huang, X.; Song, Y. Mechanical Properties and Microstructure of Lime-Treated Red Clay. KSCE J. Civ. Eng. 2021, 25, 70–77. [Google Scholar] [CrossRef]

- Ma, H.; Pei, C.; Li, S.; Xu, S. Performance Evaluation and Modification Mechanism of Red Clay Treated with Lignosulfonate. Int. J. Civ. Eng. 2024, 22, 1961–1976. [Google Scholar] [CrossRef]

- Vilhena, R.M.; Mascarenha, M.M.d.A.; Angelim, R.R.; Simões, T.d.R.; Oliveira, R.B.d.; Luz, M.P.d. Evaluation of Lime-Treated Lateritic Soil for Reservoir Shoreline Stabilization. Water 2020, 12, 3141. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Chen, K.S. Research on Road Characteristics and the Microscopic Mechanism of Lime–Phosphogypsum-Stabilized Red Clay. Appl. Sci. 2023, 13, 8057. [Google Scholar] [CrossRef]

- Wang, L.; Weng, Z.; Qiang, L. Improving the Mechanical Properties of Red Clay Using Xanthan Gum Biopolymer. Int. J. Polym. Sci. 2021, 2021, 1535772. [Google Scholar] [CrossRef]

- Vydehi, K.V.; Moghal, A.A.B. Effect of Biopolymeric Stabilization on the Strength and Compressibility Characteristics of Cohesive Soil. J. Mater. Civ. Eng. 2021, 34, 04021428. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.H.; Aziz, M. Geotechnical behavior of high-plastic clays treated with biopolymer: Macro-micro-study. Environ. Earth Sci. 2023, 82, 91. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Kanungo, D.P.; Song, Z.; Bai, Y.; Wang, Y.; Li, D.; Qian, W. Topsoil reinforcement of sandy slope for preventing erosion using water-based polyurethane soil stabilizer. Eng. Geol. 2019, 252, 125–135. [Google Scholar] [CrossRef]

- Fang, H.Y.; Su, Y.J.; Du, X.M. xperimental and Numerical Investigation on Repairing Effect of Polymer Grouting for Settlement of High-Speed Railway Unballasted Track. Appl. Sci. Basel 2019, 9, 4496. [Google Scholar] [CrossRef]

- Xu, J.G.; Chen, Z.H.; Wang, R. Mechanical Characteristic Analysis of Buried Drainage Pipes After Polymer Grouting Trenchless Rehabilitation. Adv. Civ. Eng. 2021, 6, 679412. [Google Scholar] [CrossRef]

- Li, B.; Wang, F.M.; Fang, H.Y. Experimental and numerical study on polymer grouting pretreatment technology in void and corroded concrete pipes. Tunn. Undergr. Space Technol. 2021, 113, 103842. [Google Scholar] [CrossRef]

- Li, S.; Niu, Y.; Wang, B.; Gao, Y.; Zhu, Y. Research on Mechanical Response of Polymer Grouting Repair for Longitudinal Cracks in Reconstructed and Expanded Expressway Pavement. Math. Probl. Eng. 2022, 2022, 5760674. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Z.; Zhao, F.; Liu, F.; Wang, J. Improving the performance of RET modified asphalt with the addition of polyurethane prepolymer (PUP). Constr. Build. Mater. 2019, 206, 560–575. [Google Scholar] [CrossRef]

- Tao, G.; Yuan, J.; Chen, Q.; Peng, W.; Yu, R.; Basack, S. Chemical stabilization of calcareous sand by polyurethane foam adhesive. Constr. Build. Mater. 2021, 295, 123609. [Google Scholar] [CrossRef]

- Fang, H.; Su, Z.; Li, X.; Wang, F.; Fu, Y. Interfacial bond performance between self-expansion polymer and concrete. Constr. Build. Mater. 2021, 270, 121459. [Google Scholar] [CrossRef]

- Li, X.; Wang, M.; Zheng, D.; Fang, H.; Wang, F.; Wan, J. Study on the failure mechanism between polyurethane grouting material and concrete considering the effect of moisture by digital image correlation. J. Build. Eng. 2023, 67, 105948. [Google Scholar] [CrossRef]

- Fan, G.; Sha, F.; Yang, J.; Ji, X.; Lin, F.; Feng, C. Research on working performance of waterborne aliphatic polyurethane modified concrete. J. Build. Eng. 2022, 51, 104262. [Google Scholar] [CrossRef]

- Li, M.; Fang, H.; Du, M.; Zhang, C.; Su, Z.; Wang, F. The behavior of polymer-bentonite interface under shear stress. Constr. Build. Mater. 2020, 248, 118680. [Google Scholar] [CrossRef]

- Wang, Y.; Wan, Y.; Liu, Q.; Guo, C.; Shi, M. Interfacial Shear Properties of Non-water Reacted Polymer and Geomaterials. J. Build. Mater. 2021, 24, 115–120. [Google Scholar]

- Bai, Y.; Liu, J.; Song, Z.; Zhang, C.; He, C.; Deng, Y. Experimental study on strength and deformation characteristics of polymers treated sand. Acta Mater. Compos. Sin. 2024, 41, 4272–4286. [Google Scholar]

- Lin, P.; Guo, P.; Guo, C.; Chen, L.; Wang, F. Experimental study on interfacial shear properties of steel plate, polymer and soil. Chin. J. Geotech. Eng. 2023, 45, 85–93. [Google Scholar]

- Kim, J.; Choi, H.; Rye, H.-M.; Yoon, K.-B.; Lee, D.-E. A Study on the Red Clay Binder Stabilized with a Polymer Aqueous Solution. Polymers 2021, 13, 54. [Google Scholar] [CrossRef]

- Tan, P.; Wang, F.; Guo, C.; Liu, J.; Lei, Q.; Liu, Z. Performance evaluation and stabilization mechanism of red clay treated with polyurethane. Chemosphere 2023, 340, 139864. [Google Scholar] [CrossRef]

- Tan, P.; Wang, F.; Guo, C.; Liu, J. Cyclic stress–strain characteristics of red clay treated with permeable water-soluble polyurethane. Transp. Geotech. 2023, 42, 101072. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Ministry of Housing and Urban-Rural Development. Standard for Soil Test Method; China Planning Press: Beijing, China, 2019.

- Bai, Y.; Liu, J.; Cui, Y. Mechanical behavior of polymer stabilized sand under different temperatures. Constr. Build. Mater. 2021, 290, 123237. [Google Scholar] [CrossRef]

- Liu, W.; Ouyang, G.; Luo, X. Moisture content, pore-water pressure and wetting front in granite residual soil during collapsing erosion with varying slope angle. Geomorphology 2020, 362, 107210. [Google Scholar] [CrossRef]

- Lee, K.; Her, J.; Kwon, S. Red clay composites reinforced with polymeric binders. Constr. Build. Mater. 2008, 22, 2292–2298. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Kanungo, D.P. Study on the Brittleness Characteristics of Sand Reinforced with Polypropylene Fiber and Polyurethane Organic Polymer. Fibers Polym. 2019, 20, 620–632. [Google Scholar] [CrossRef]

- ShahriarKian, M.; Kabiri, S.; Bayat, M. Utilization of Zeolite to Improve the Behavior of Cement-Stabilized Soil. Int. J. Geosynth. Ground Eng. 2021, 7, 35. [Google Scholar] [CrossRef]

- Wang, Y.; Li, B.; Chen, C.; Fang, H.; Du, X.; Wang, N.; Zhai, K.; Di, D.; Du, M. Shear behavior of a two-component non-water reactive foamed polyurethane (TNFPU) grouting material under different stress levels. Constr. Build. Mater. 2024, 411, 134429. [Google Scholar] [CrossRef]

- Li, X.; Wan, J.; Zheng, D.; Fang, H.; Wang, F.; Hu, S. Compressive mechanical properties of self-expanding grouting materials with different densities. Constr. Build. Mater. 2022, 332, 127308. [Google Scholar] [CrossRef]

- Xu, J.; Hu, H.; Zhong, Y.; Wang, R.; Wang, B. Numerical Analysis on Underground Pipe Settlement and Vacancy Repairing with Polymer Injection. Chin. J. Undergr. Space Eng. 2017, 13, 1165–1172. [Google Scholar]

- Fang, H.; Li, B.; Wang, F. The mechanical behaviour of drainage pipeline under traffic load before and after polymer grouting trenchless repairing. Tunn. Undergr. Space Technol. 2018, 74, 185–194. [Google Scholar] [CrossRef]

- Goushis, R.; Mini, K.M. Finite element analysis of polymeric and cementitious materials to secure cracks in concrete. Mater. Today Proc. 2022, 49, 1599–1606. [Google Scholar] [CrossRef]

- Haruna, S.I.; Ibrahim, Y.E.; Han, Z.; Farouk, A.I.B. Flexural Response of Concrete Specimen Retrofitted with PU Grout Material: Experimental and Numerical Modeling. Polymers 2023, 15, 4114. [Google Scholar] [CrossRef]

- Hála, P.; Perrot, A.; Vacková, B. Experimental and numerical study on ballistic resistance of polyurethane-coated thin HPFRC plate. Mater. Today Proc. 2023, 93, 607–613. [Google Scholar] [CrossRef]

- Garbowski, T.; Pawlak, T.G.; Szymczak-Graczyk, A. Efficient Load-Bearing Capacity Assessment of a Degraded Concrete Manhole Using Sectional Homogenization. Materials 2024, 17, 5883. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Xue, B.; Fang, H. Variable angle shear test and finite element simulation of polyurethane—bentonite composite structure. Structures 2023, 48, 1722–1729. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, J. Introduction to partly soil models in ABAQUS Software and their application to the geotechnical engineering. Rock Soil Mech. 2004, 2, 144–148. [Google Scholar]

- Barbero, E.J. Finite Element Analysis of Composite Materials using Abaqus®; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Barenblatt, G.; Cherepanov, G. On the equilibrium and propagation of cracks in an ainisotropic medium. J. Appl. Math. Mech. 1961, 25, 61–74. [Google Scholar] [CrossRef]

- Dugdale, D. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Anysz, H.; Zbiciak, A.; Płudowska-Zagrajek, M.; abouni-Zawadzka, A.A. Artificial neural networks as a tool for selecting the parameters of prototypical under sleeper pads produced from recycled rubber granulate. J. Clean. Prod. 2023, 405, 136975. [Google Scholar] [CrossRef]

| Proportion [g/cm3] | Liquid Limit [%] | Plastic Limit [%] | Plasticity Index [%] | Optimum Water Content [%] | Maximum Dry Density [%] |

|---|---|---|---|---|---|

| 2.63 | 50.5 | 24.8 | 25.7 | 19 | 1.75 |

| Appearance | Specific Gravity [g/cm3] | Viscosity [mPa·s] | Hydroxyl Value [mgKOH/g] | Storage Temperature [°C] |

|---|---|---|---|---|

| Light yellow to brownish-yellow transparent liquid | 1.10–1.15 | 300–450 | 300–400 | 10–25 |

| Density [g/cm3] | Elastic Modulus [MPa] | Poisson’s Ratio |

|---|---|---|

| 0.2 | 128.5 | 0.2 |

| 0.5 | 292.4 | 0.2 |

| 0.8 | 487.3 | 0.2 |

| Density [g/cm3] | Elastic Modulus [kPa] | Poisson Ratio | Angle of Internal Friction [°] | Angle of Dilatancy [°] | Plastic Strain [kPa] |

|---|---|---|---|---|---|

| 1.75 | 198 | 0.35 | 14.35 | 0.1 | 0.1 |

| Density [g/cm3] | Normal Stress [kPa] | Shearing Rigidity [N/mm3] | Shearing Strength [kPa] | Shearing Displacement [mm] | Shear Damage Energy [N/mm] |

|---|---|---|---|---|---|

| 0.2 | 100 | 78.0 | 193.2 | 2.72 | 2.62 |

| 200 | 79.4 | 241.5 | 3.09 | 3.72 | |

| 300 | 92.9 | 239.8 | 3.55 | 4.26 | |

| 400 | 87.9 | 352.1 | 4.54 | 7.88 | |

| 0.5 | 100 | 996 | 181.6 | 1.94 | 1.76 |

| 200 | 99.3 | 258.6 | 2.84 | 3.68 | |

| 300 | 105.6 | 333.4 | 3.59 | 5.98 | |

| 400 | 111.5 | 416.0 | 4.32 | 8.99 | |

| 0.8 | 100 | 95.0 | 200.8 | 2.42 | 2.43 |

| 200 | 106.9 | 289.8 | 2.89 | 4.20 | |

| 300 | 112.3 | 381.7 | 3.82 | 7.29 | |

| 400 | 109.9 | 476.7 | 4.56 | 10.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, F.; Zhang, X.; Li, Q. Interfacial Shear Properties of Red Clay and Polyurethane with Different Densities. Appl. Sci. 2025, 15, 5501. https://doi.org/10.3390/app15105501

Cheng F, Zhang X, Li Q. Interfacial Shear Properties of Red Clay and Polyurethane with Different Densities. Applied Sciences. 2025; 15(10):5501. https://doi.org/10.3390/app15105501

Chicago/Turabian StyleCheng, Feng, Xinran Zhang, and Qingwang Li. 2025. "Interfacial Shear Properties of Red Clay and Polyurethane with Different Densities" Applied Sciences 15, no. 10: 5501. https://doi.org/10.3390/app15105501

APA StyleCheng, F., Zhang, X., & Li, Q. (2025). Interfacial Shear Properties of Red Clay and Polyurethane with Different Densities. Applied Sciences, 15(10), 5501. https://doi.org/10.3390/app15105501