1. Introduction

Crane systems are used in various industries, including transportation and construction, and are specifically made to make handling large weights easier. These systems use high-strength structural elements and rigid cables (ropes) since they are made to support heavy loads. This ensures a safe operational process by decreasing adverse effects such as vibrations and deformations [

1]. However, the limited performance of rigid cable systems in responding to sudden impacts, dynamic load variations, and complex motion paths has made it necessary to develop and find alternative solutions [

2]. In this context, elastic cable winch systems have been designed to address the lack of traditional rigid cable systems. Elastic cables enhance adaptability to dynamic loads, sudden movements, and environmental factors. Their energy absorption capacity significantly improves system stability during sudden load changes and prevents failures caused by excessive stress [

3]. The advantages of elastic cable systems, such as low inertia, large working area, high speed, and acceleration, provide a competitive edge over rigid arm systems, particularly in cable-operated robotic systems [

4,

5]. However, challenges such as tension control, sagging due to flexibility, and the complexity of control algorithms make control problems more prominent in these systems [

4,

5].

Various studies have been conducted on crane systems’ horizontal and vertical movements. Most researchers have focused on controlling horizontal oscillations in rotating cranes through horizontal movement [

6,

7,

8]. Studies have typically been conducted on vertical movement on elevator systems [

9] and offshore crane systems [

10]. In these studies, the rope is often assumed to be non-extensible. Research on elevator systems has focused on longitudinal vibrations, and the equations of motion have been derived using Hamilton’s principle and subsequently converted into ordinary differential equations through the Galerkin method. Methods such as Lyapunov control have dissipated vibrational energy in these models [

11]. Moon et al. [

12] demonstrated that the rope parameters, such as time-varying stiffness, damping constant, and rope mass, evolve. Therefore, measuring the load position is crucial for load position control during vertical movements. Furthermore, N.B. Le et al. developed a simple mathematical model for a nonlinear elastic cable winch system. They applied input–output feedback linearization theory to control winch movement without requiring load position information [

13].

The sliding mode control (SMC) method has emerged as a preferred control strategy for such nonlinear systems due to its robustness against varying parameters and external disturbances [

14]. To mitigate the phenomenon known as “chattering,” which manifests as high-frequency oscillations in the control signal, the Equivalent Sliding Mode Control (ESMC) method has been employed, ensuring system stability against external effects [

15,

16,

17]. For instance, the dynamics of nonlinear plants have been analyzed using ESMC, demonstrating simplified stability proofs [

18]. Additionally, integrating SMC with the equivalent input disturbance approach has enhanced disturbance rejection capabilities in Stewart platform control systems [

19]. In the study conducted by Wang et al., the Global Equivalent Sliding Mode Control (GESMC) method was shown through simulations to provide faster and more stable performance with less chattering compared to conventional sliding mode control (SMC) and PID control in bridge crane systems [

20]. Similarly, Zhang et al. applied a Disturbance Evaluating Sliding Mode Control (DESMC) method to a four-degree-of-freedom tower crane system, incorporating the beneficial aspects of disturbance effects into the control design, thereby achieving superior control performance as demonstrated in simulations [

21]. In this context, the present study advances beyond the simulation studies in [

20,

21] by analyzing the real-time performance of SMC approaches. The study by Xia and Ouyang implemented a super-twisting algorithm-based SMC approach in tower cranes, achieving vibration suppression and precise control while offering high robustness against external disturbances [

22]. Likewise, Li et al. designed a variable structure sliding mode controller for bridge cranes to suppress load oscillations and achieve precise positioning, effectively reducing chattering in the control input [

23]. Furthermore, the work by Kui et al. introduced a hybrid integral sliding mode control scheme for cable-driven parallel robots, improving tracking accuracy and mitigating vibration issues [

24]. Recent studies have also suggested fixed-time controllers, which guarantee convergence within a specified time regardless of initial conditions, despite the robustness and finite-time convergence characteristics of sliding mode controllers [

25,

26]. These methods may be very promising for this work’s future development. The present study applies the SMC method to elastic cable winch systems to enhance tracking and position control performance.

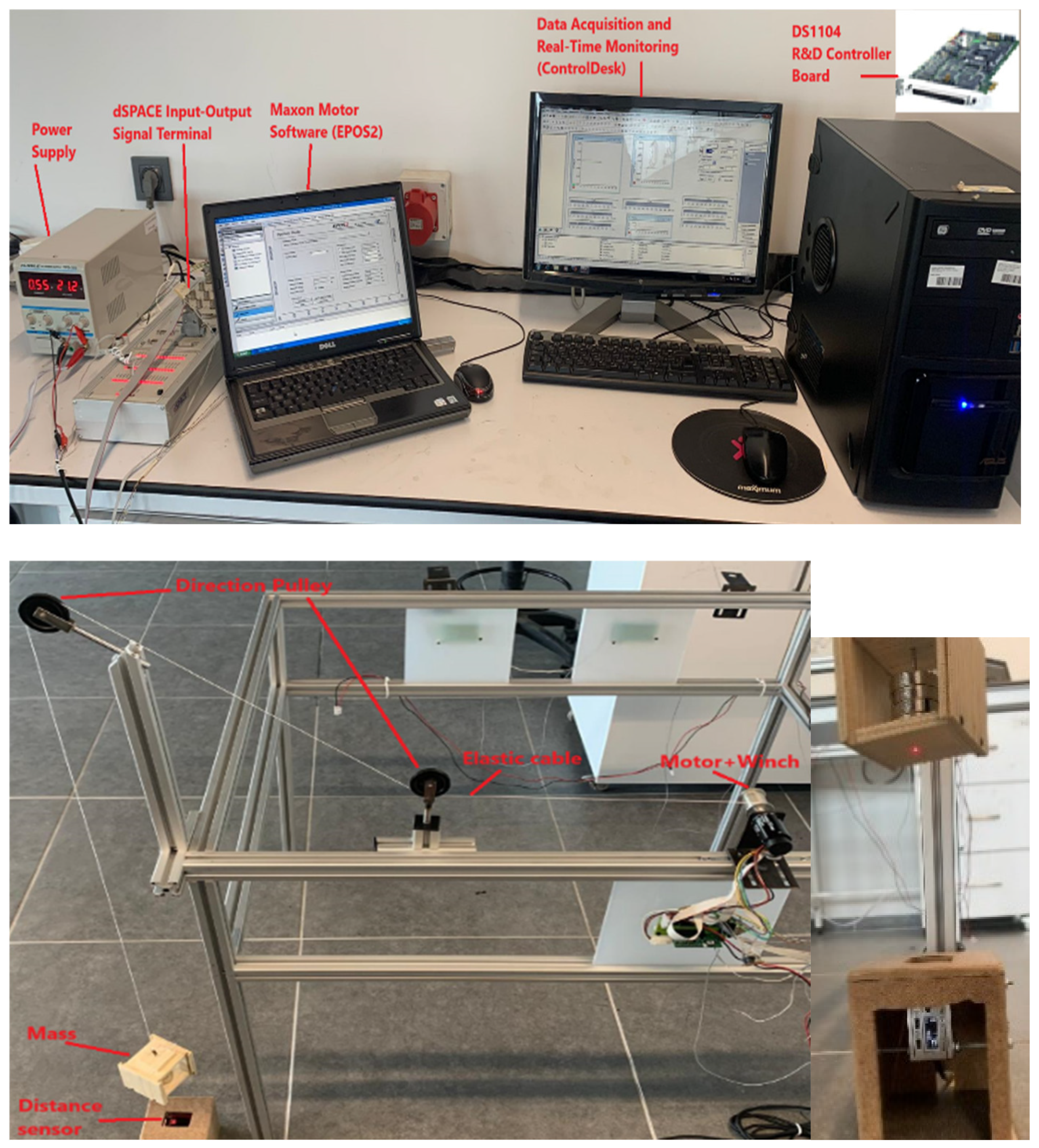

Control engineering studies aim to find practical methods to solve problems. Electromechanical systems, in particular, involve numerous uncertainties, unknown parameters, and disturbances during operation. Thus, all these factors must be considered in controlling design. In this applied engineering field, experimental studies are more convincing than pure simulation analyses. Fortunately, today’s technological advances offer experimental methods such as hardware-in-the-loop simulation or animation for real-time testing and analysis of a controller. Real-time control systems play a critical role in experimental studies. For example, using dSPACE, various control methods have been implemented in real time, verifying the performance of artificial intelligence-based asynchronous motor drives [

27]. In this context, the opportunities provided by real-time control systems not only enhance the reliability of experimental studies but also optimize design processes, significantly contributing to the field of control engineering.

The contribution of this study to the literature stands out in two main aspects. First, a realistic model with four degrees of freedom was developed by considering the elastic cable stretching between the winch drum and the guide pulleys and in the vertical direction. Second, through the real-time implementation of the developed controller, the SMC controller has demonstrated superior performance with ESMC compared to the PD method. This paper presents the mathematical modeling, control design, simulation, and experimental results of an elastic cable winch system. An experimental setup was designed on a smaller scale compared to actual crane mechanisms. While cable deformations are typically negligible in real-world applications due to high load-to-cable weight ratios, this study specifically aims to examine in detail the effects of system elasticity on control performance using elastic polyester cables and light loads. This approach will make significant contributions to developing control strategies for innovative applications requiring multiple elastic cables, such as mobile compact winch systems and unmanned aerial vehicle payload transport.

The remainder of the paper is structured as follows:

Section 2 presents the detailed mathematical modeling of an elastic cable crane system.

Section 3 discusses the design principles and analysis of the SMC controller developed for the system.

Section 4 covers the results of the experimental study and their discussion. Finally,

Section 5 provides an overall evaluation of the study and offers recommendations for future research.

2. Mathematical Model of an Elastic Cable Winch System

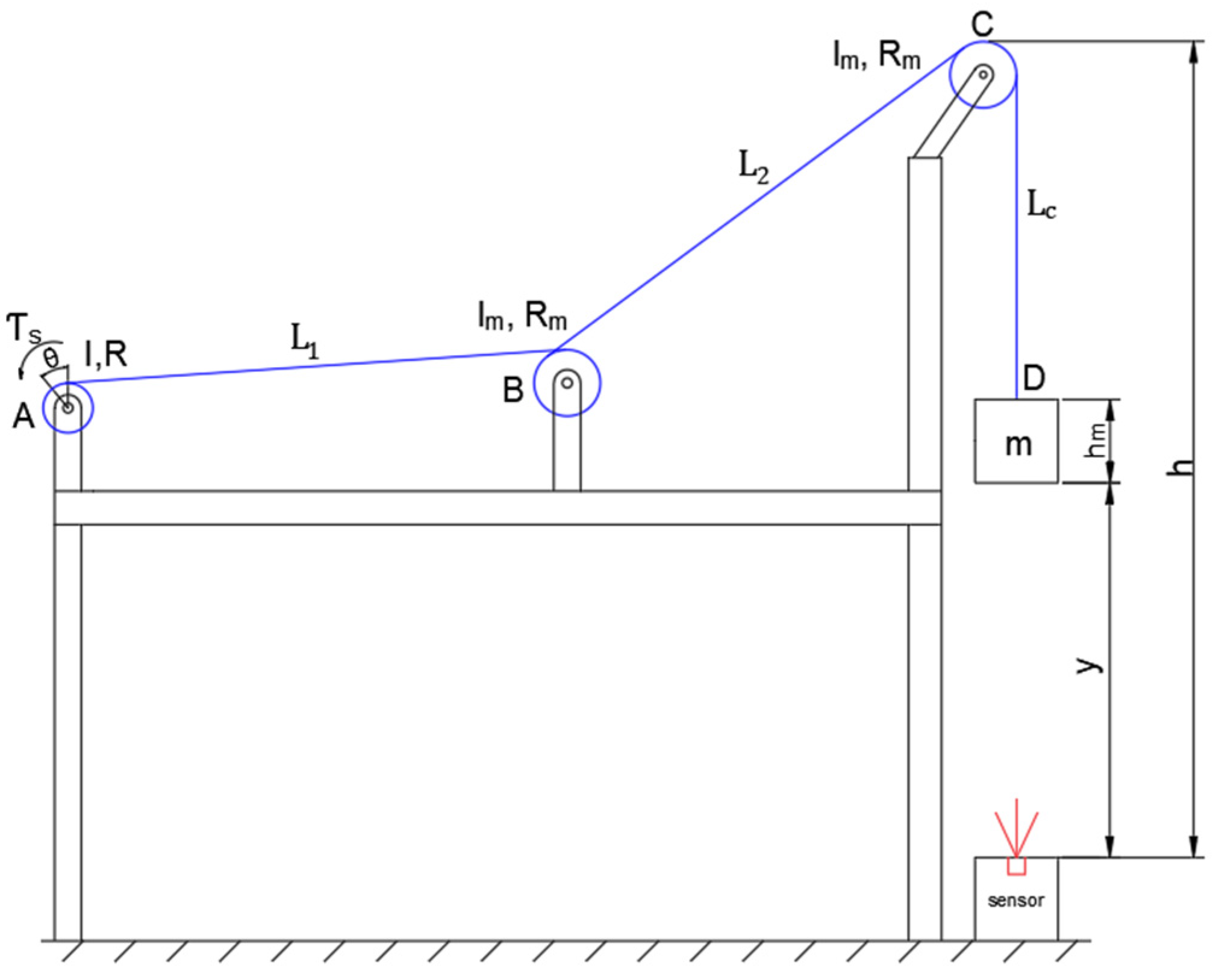

As illustrated in

Figure 1, a seemingly simple system consisting of a motor and a mass is modeled more realistically by incorporating the cable’s elasticity.

For mathematical modeling of the winch system, the definition of the system is as follows: the radius of the drum and the direction pulleys are defined as R and Rm, and the moments of inertia are defined as I and Im, respectively. The cable is determined to be homogeneous and elastic, and its mass is mc. The load consists of the combined mass of the carrier box and any additional weights. The system is structured so that the load moves vertically with the change in cable length.

The angular velocity and acceleration of the drum are demonstrated by and , respectively. A cable system where the segment between points A and B has a length denoted by and stiffness , while the segment between points B and C has a length with stiffness. These stiffness parameters are defined as follows: , .

E represents the Young’s modulus and A is the cross-sectional area of the cable.

Assuming no slippage occurs between the cable and the pulleys, one full turn of the cable is wrapped around the directional pulleys located at points B and C. Due to the elasticity of the cable segments, the rotation angles of the pulleys at points B and C will not necessarily be identical, even if the pulleys share the same diameter. This characteristic introduces additional degrees of freedom to the system.

In this revised configuration, the system exhibits four degrees of freedom: the rotational motions of the pulleys at points A, B, and C, denoted by , , and , and the vertical translation of the attached mass, represented by .

The linear velocities of the cable at these points can be expressed as follows:

,

where

and

denote the radii of the respective pulleys, and the overdot indicates the time derivative.

To calculate the kinetic energy of the unwound portion of the cable, it is essential to determine the linear velocity of its center of mass. The length of the unwound segment is given by , with mass , and the distance of its center of mass from the sensor is .

The velocity of the center of mass is thus .

Accordingly, the kinetic energy of this segment is approximately .

The linear velocity of the center of mass of the AB cable can be considered the average of these (). Thus, the kinetic energy of the AB segment is approximately .

The total kinetic energy of the system is as follows:

In this formula, and are constants and is variable. The difference in the translations at the ends of the AB cable is and the potential energy of this part is , for the BC cable and , and for the CD cable and where .

The potential energy of the CD part of the cable is .

The total potential energy is

The motion equations of the crane system are derived using Lagrangian mechanics. The Lagrangian function of the system is defined as the difference between the kinetic energy

T and the potential energy

U:

The equations of motion of the system are derived using the Lagrange equation.

The generalized coordinates are

,

,

and

resulting in a total of four equations of motion.

The system was initially modeled as a four-degree-of-freedom (4-DOF) structure to reflect its physical characteristics accurately. However, the experimental setup includes only a single motor integrated with an encoder and a laser distance sensor for measuring the vertical position of the load. Since no sensors are available to measure the angular positions of the guide pulleys, the motions of these components cannot be directly observed. As a result, the 4-DOF model contains unobservable states, limiting its practical applicability for control design. Therefore, a reduced two-degree-of-freedom (2-DOF) model, incorporating only the measurable variables (the drum angle and the vertical position of the load) has been adopted.

The elongation occurring in the cable segments between the winch drum at point A and the guide pulley at point B, as well as between the guide pulleys at points B and C, is negligible compared to the elongation observed between the pulley at point C and the load. Therefore, the stretching behavior of the cable is primarily considered over the segment between the pulley and the load. This assumption enables the derivation of a simplified mathematical model, which forms the theoretical basis for subsequent controller design and analysis.

The stretching of the cable takes place mainly between the directional pulley and the mass. For this reason, the elongation of the cable is expressed as . If the initial height of the cable is denoted by , its height at any given moment can be expressed as The stiffness of the cable is given by . Assuming both pulleys rotate equally, the relationship between the drum’s and pulley’s angular velocities is .

Within the framework of simplified system dynamics modeling, the original kinetic energy expression Equation (2) has been reduced to Equation (8), while the potential energy expression Equation (4) has been simplified to Equation (9), resulting in a more streamlined formulation.

In this system, there are two generalized coordinates:

, which defines the vertical position of the load, and

, which defines the angular position of the drum. Thus, the generalized coordinates in Equation (7) are

and

, respectively. On the other hand, the generalized force is composed of the frictional force at the direction pulleys and the driving torque.

As a result, the equations of motion of the two-degree-of-freedom winch system with elastic cable are as follows, where nonlinear effects due to the cable elasticity are noticeable.

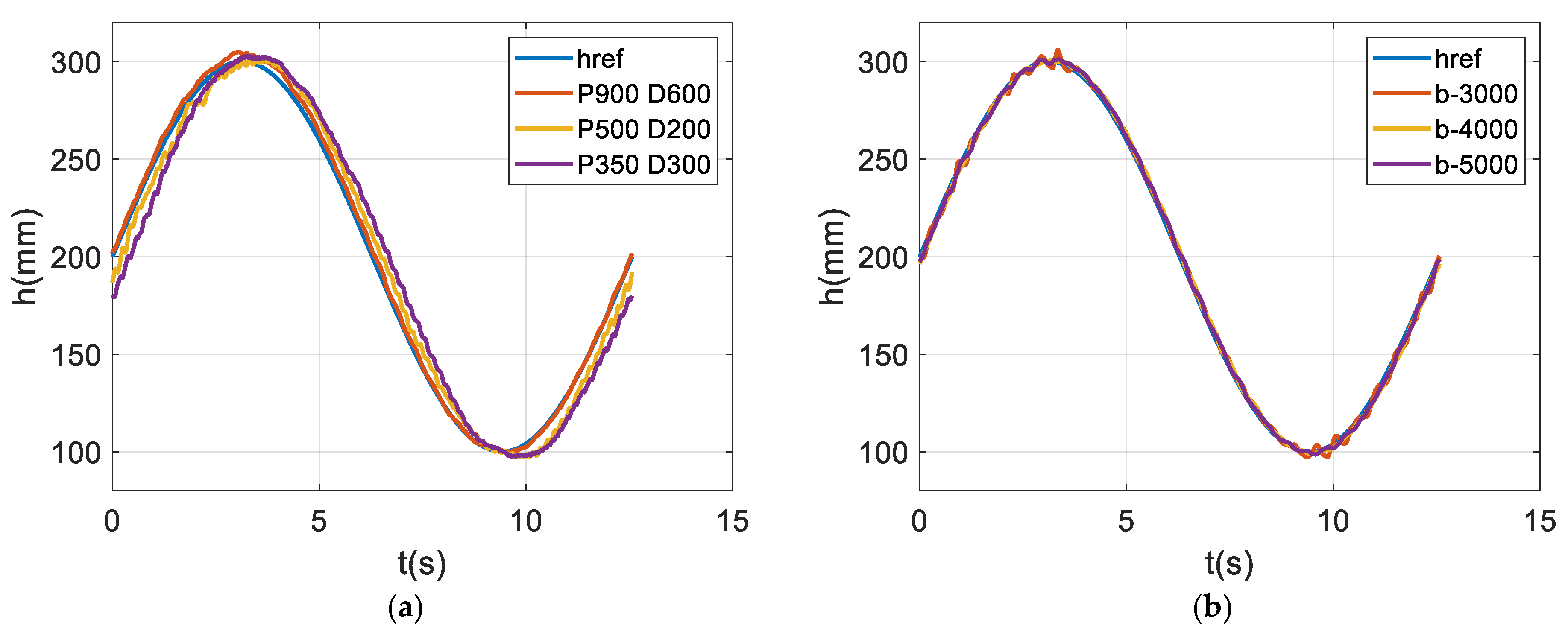

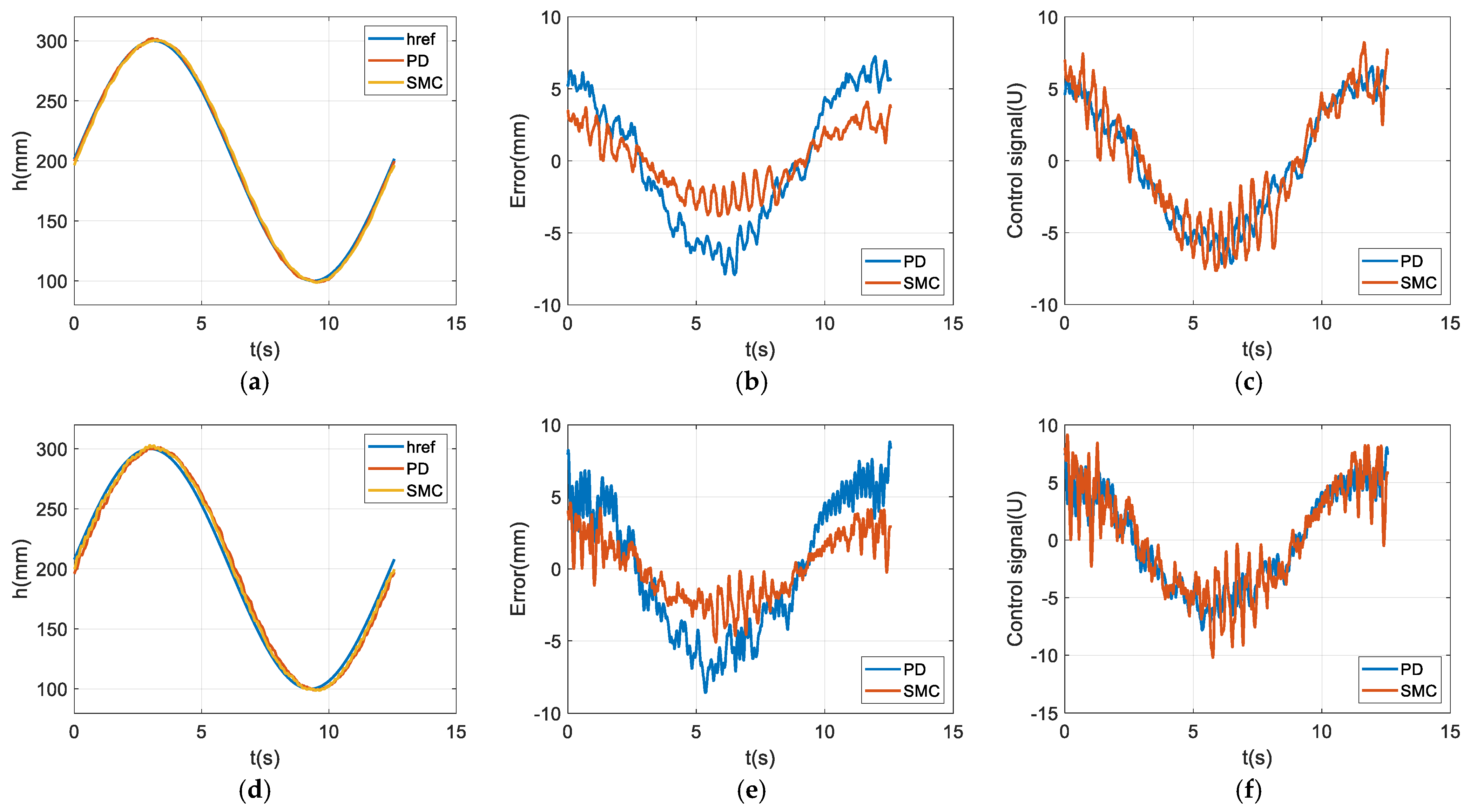

4. Simulation Results

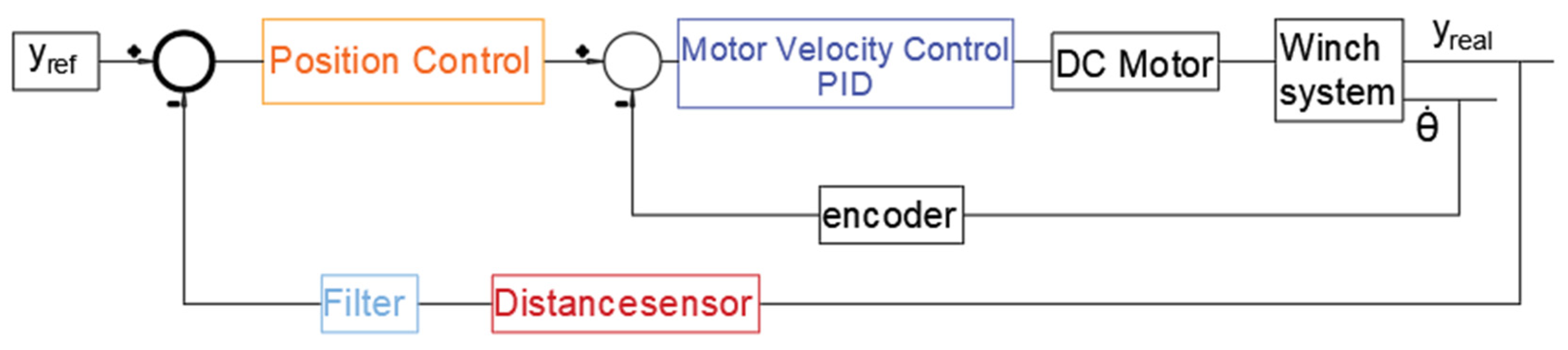

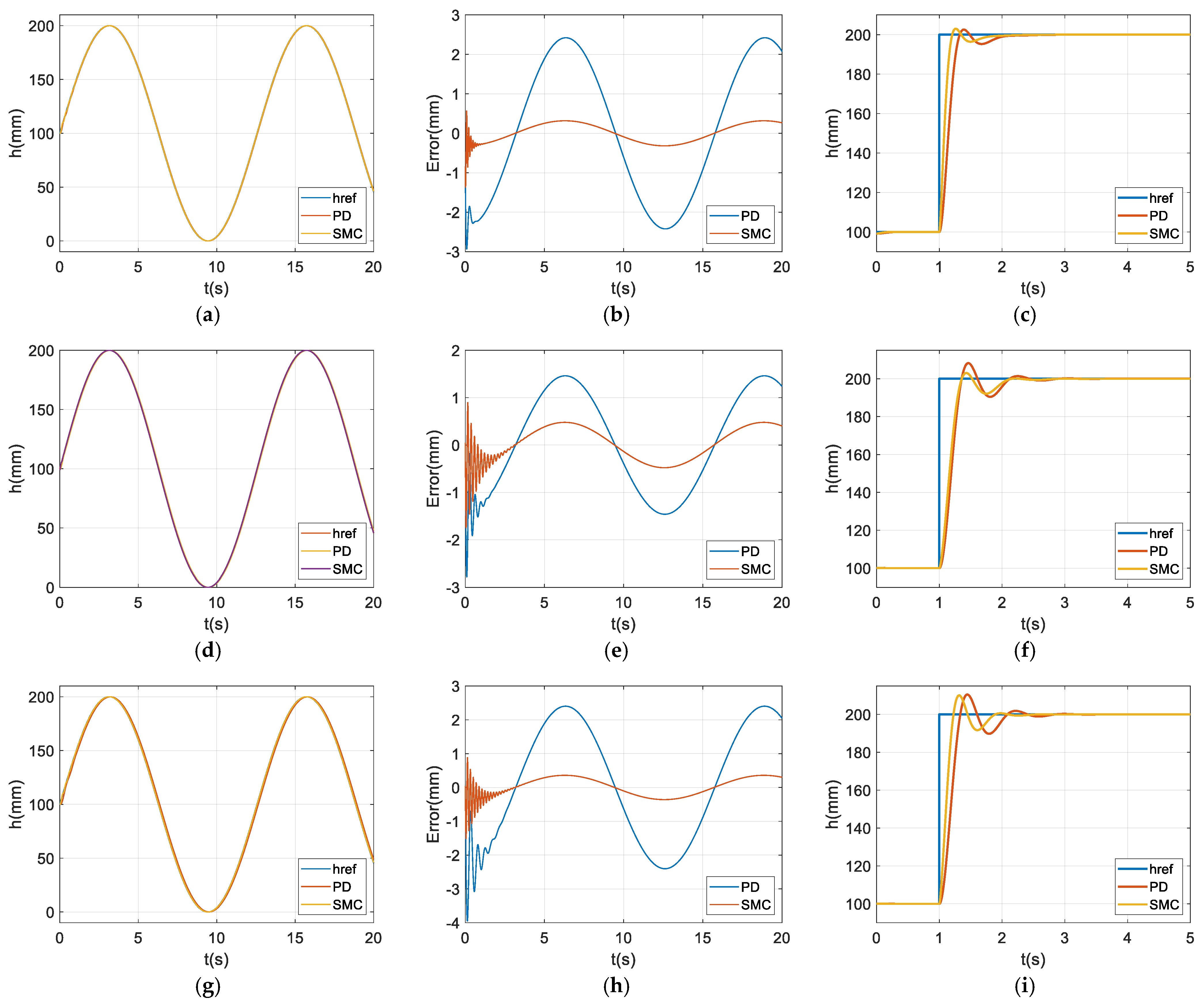

The simulation results obtained in the MATLAB/Simulink environment are presented in

Figure 3. In this section, the performance of the proposed control methods is evaluated under different test cases. Test cases include the minimum, medium, and maximum load conditions shown in

Figure 3.

Subfigures (a), (d), and (g) illustrate the trajectory tracking performance;

Subfigures (b), (e), and (h) present the tracking error between the reference trajectory and the controller output;

Subfigures (c), (f), and (i) depict the position control performance.

In all the scenarios, the ESMC method demonstrates a more successful performance compared to PD control, withfewer errors and a faster settling time.

These simulations contributed to a better understanding of the system dynamics and enabled the validation of the control algorithms as well as a preliminary evaluation of the system behavior prior to the implementation of real-time experiments.

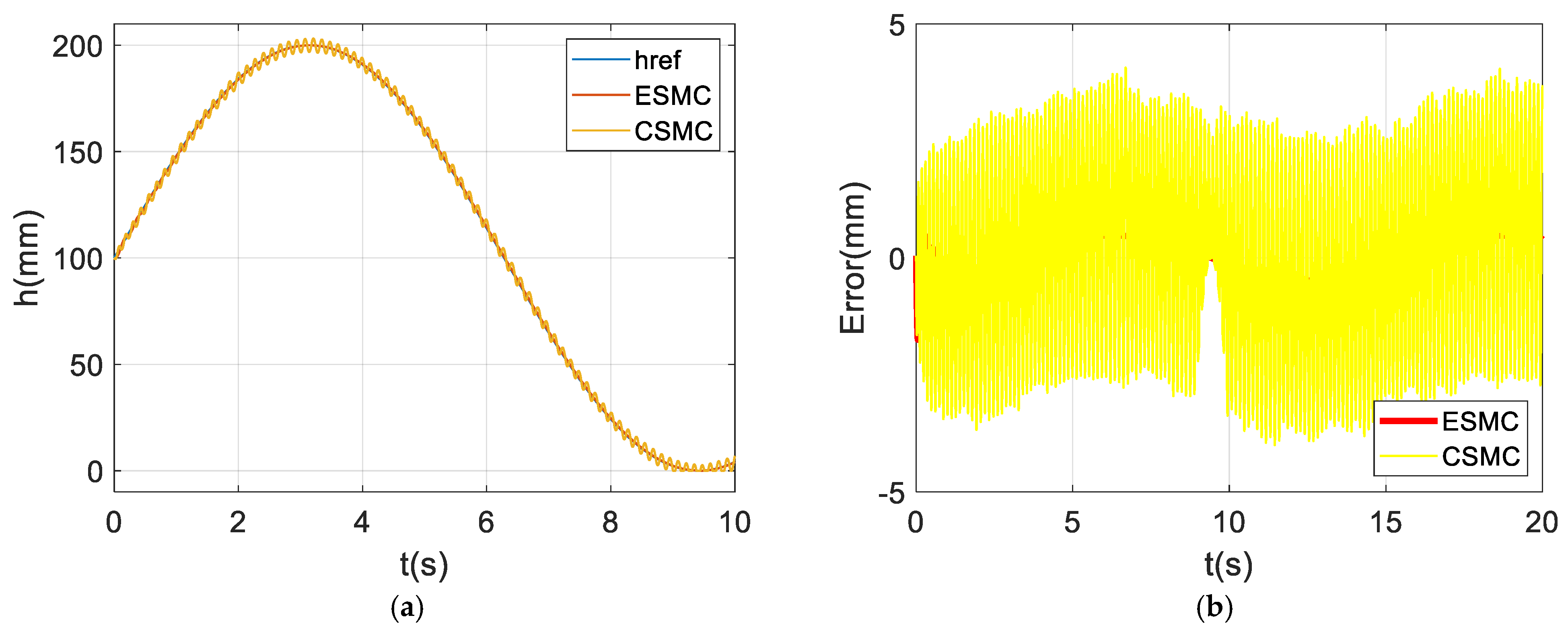

Moreover, the ESMC method and the classical SMC approach are presented in

Figure 4.

In this comparison, it is observed that ESMC provides a smoother and more continuous convergence to the sliding surface. This characteristic significantly reduces the high-frequency switching (chattering) often encountered in classical SMC, thereby enhancing the system’s stability. In this respect, ESMC offers a more stable and practically applicable control structure compared to the conventional SMC. Furthermore, in the experimental studies, only the ESMC method was implemented, and the obtained results support the effectiveness of the proposed control approach.

6. Conclusions

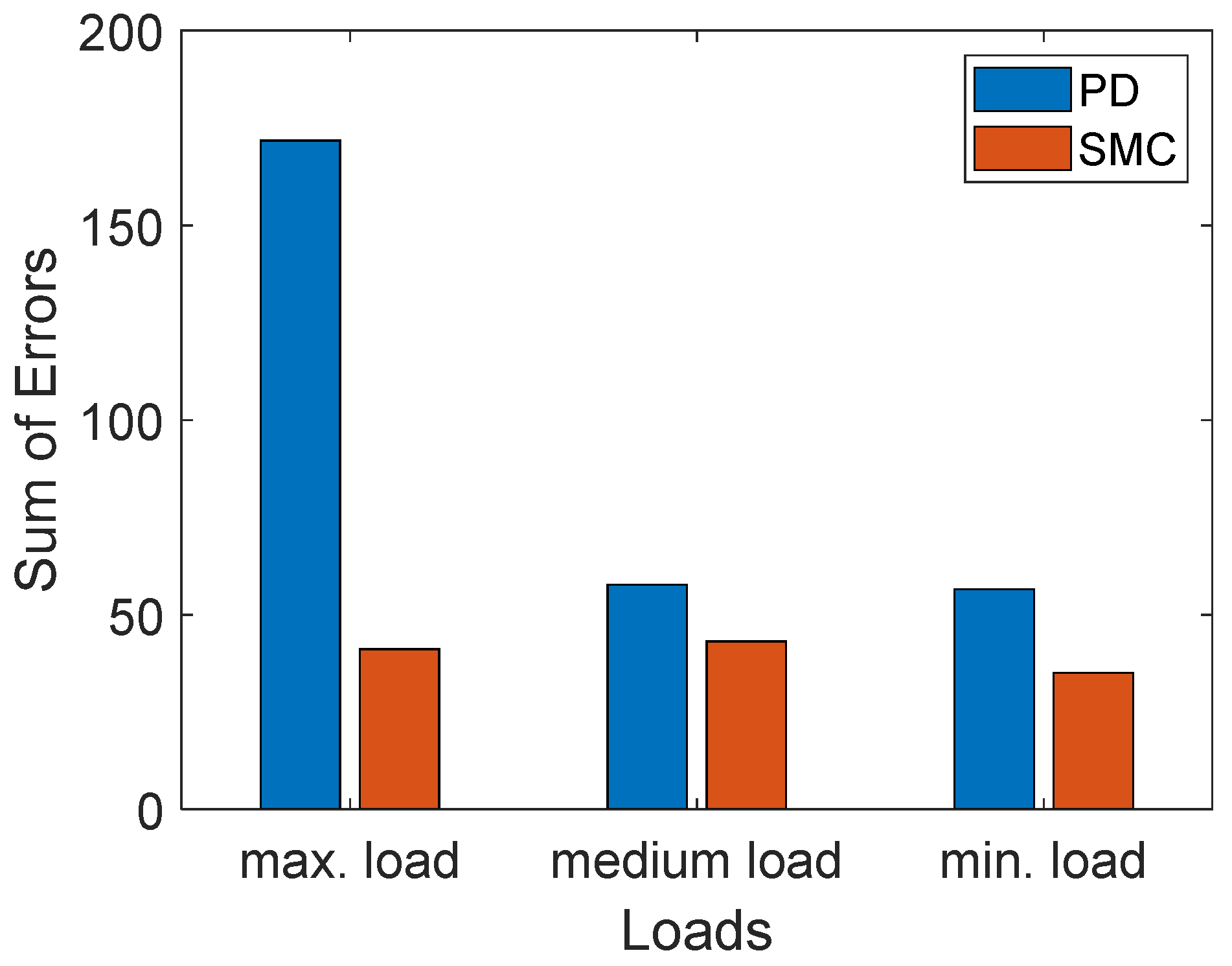

In this study, a comparative analysis of PD and SMC methods was conducted for an elastic cable-driven winch system through both simulations and real-time experiments. The simulation results demonstrated that the SMC algorithm exhibited superior positioning accuracy, reduced overshoot, and enhanced tracking performance compared to the PD controller.

Similarly, in real-time experiments, the SMC algorithm achieved higher accuracy than the PD controller in both step displacement and sinusoidal trajectory tracking tasks. Under varying load conditions, the PD controller exhibited instability at maximum load, whereas the SMC algorithm successfully maintained stable system behavior across all tested scenarios. The nonlinear structure of SMC provides increased robustness against modeling inaccuracies and parameter uncertainties, offering a significant advantage for systems operating under variable loads.

Moreover, the SMC algorithm proved more effective in minimizing torque ripple observed at the motor shaft. The analysis indicated that the SMC systematically reduced acceleration ripple amplitude at specific frequencies, while the PD controller maintained generally higher and more consistent levels of ripple.

Furthermore, during real-time experiments, only the PD controller failed to maintain control under high-load conditions, despite functioning adequately in simulation. This highlights the limitations of evaluating system performance based solely on simulations and underscores the importance of real-time testing.

Future research could concentrate on enhancing the SMC algorithm to improve motor torque ripple behavior and investigate its use in more complex systems with multiple degrees of freedom. Specifically, efforts can be focused on developing control strategies for innovative applications that involve multiple elastic cables, such as those used with unmanned aerial vehicles. Additionally, fixed-time control strategies will be compared to the sliding mode control approach used in this study, in terms of convergence time, robustness, and implementation complexity.