Selective Laser-Melted Alloy 625: Optimization of Stress-Relieving and Aging Treatments

Abstract

1. Introduction

2. Materials and Method

3. Results and Discussion

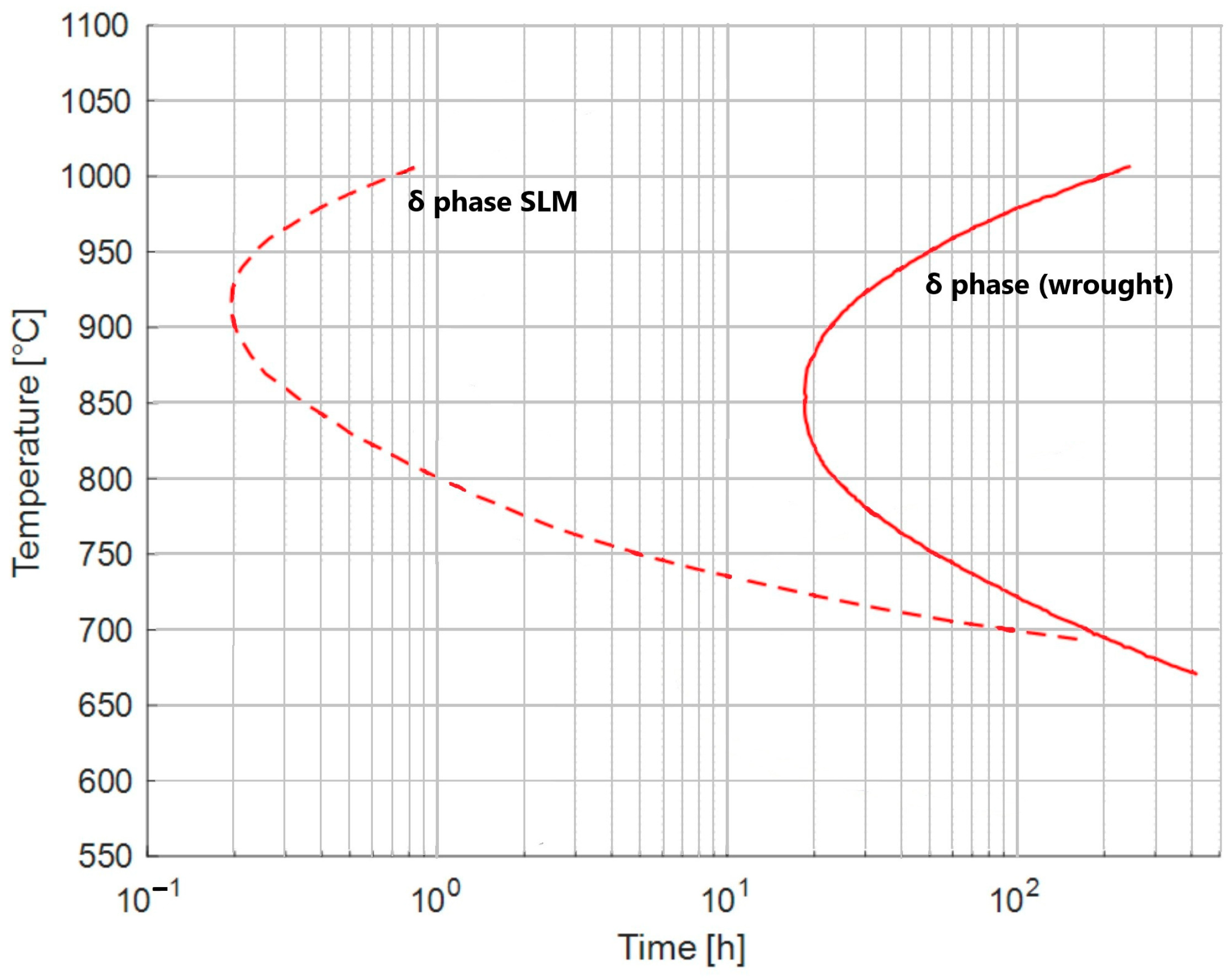

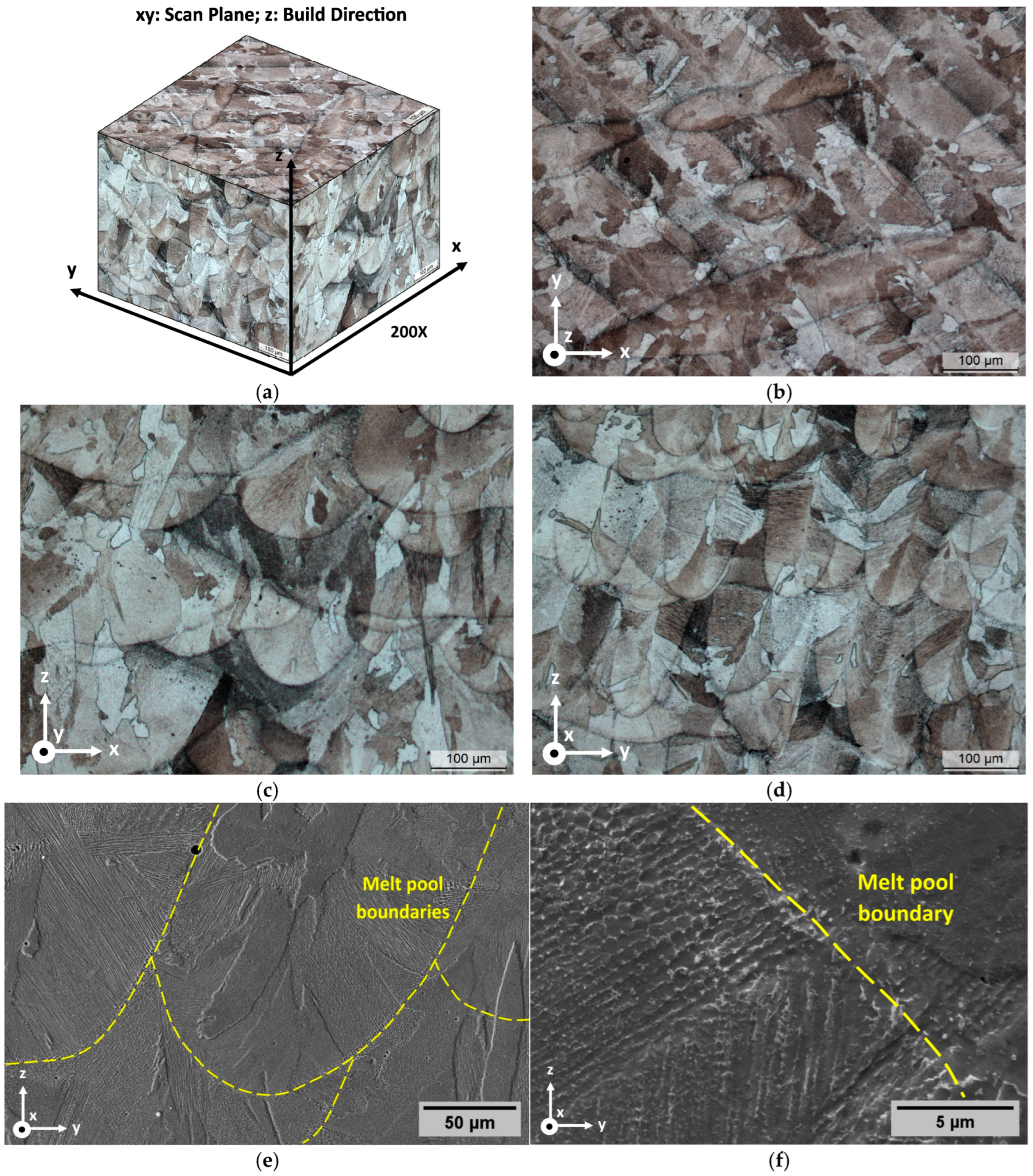

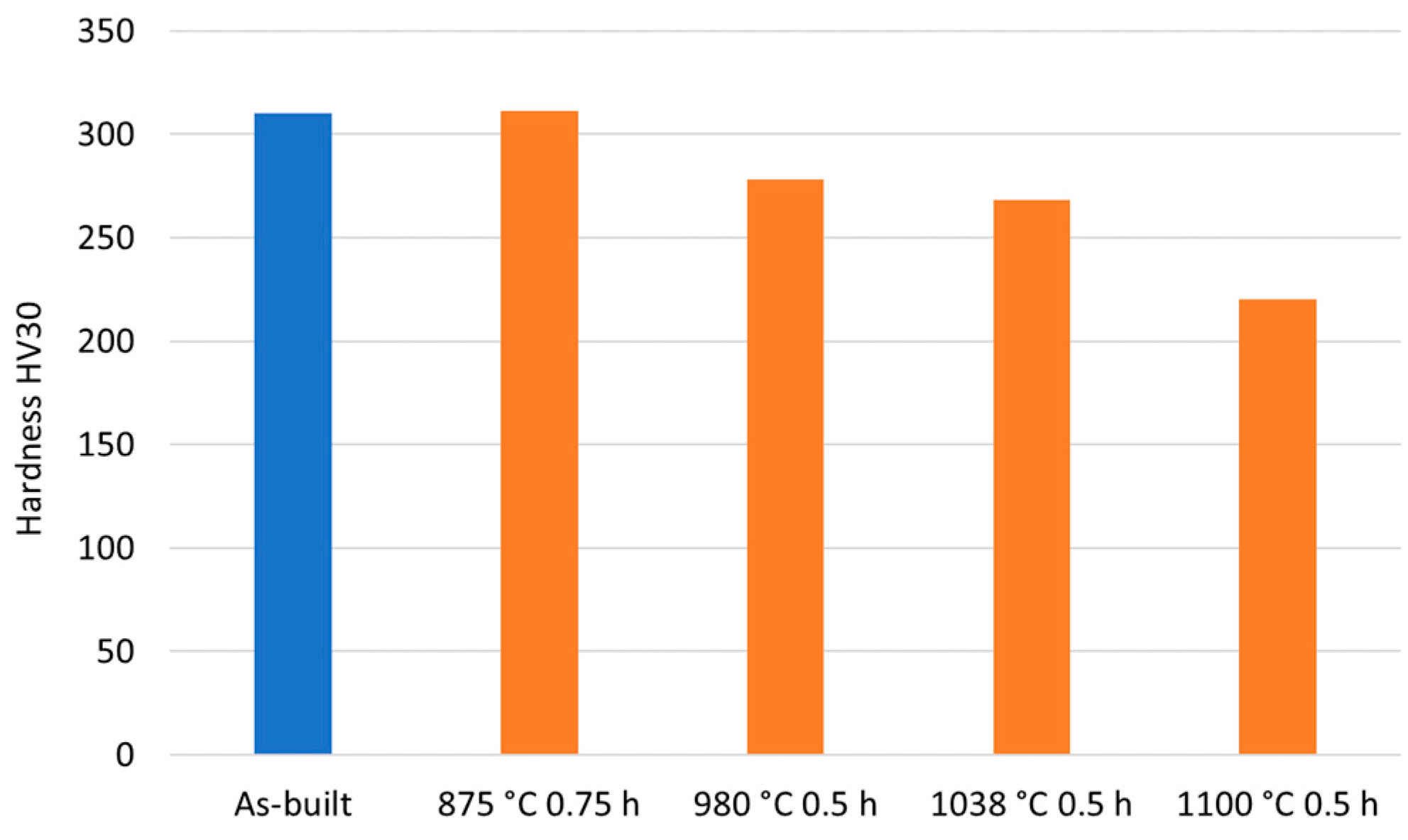

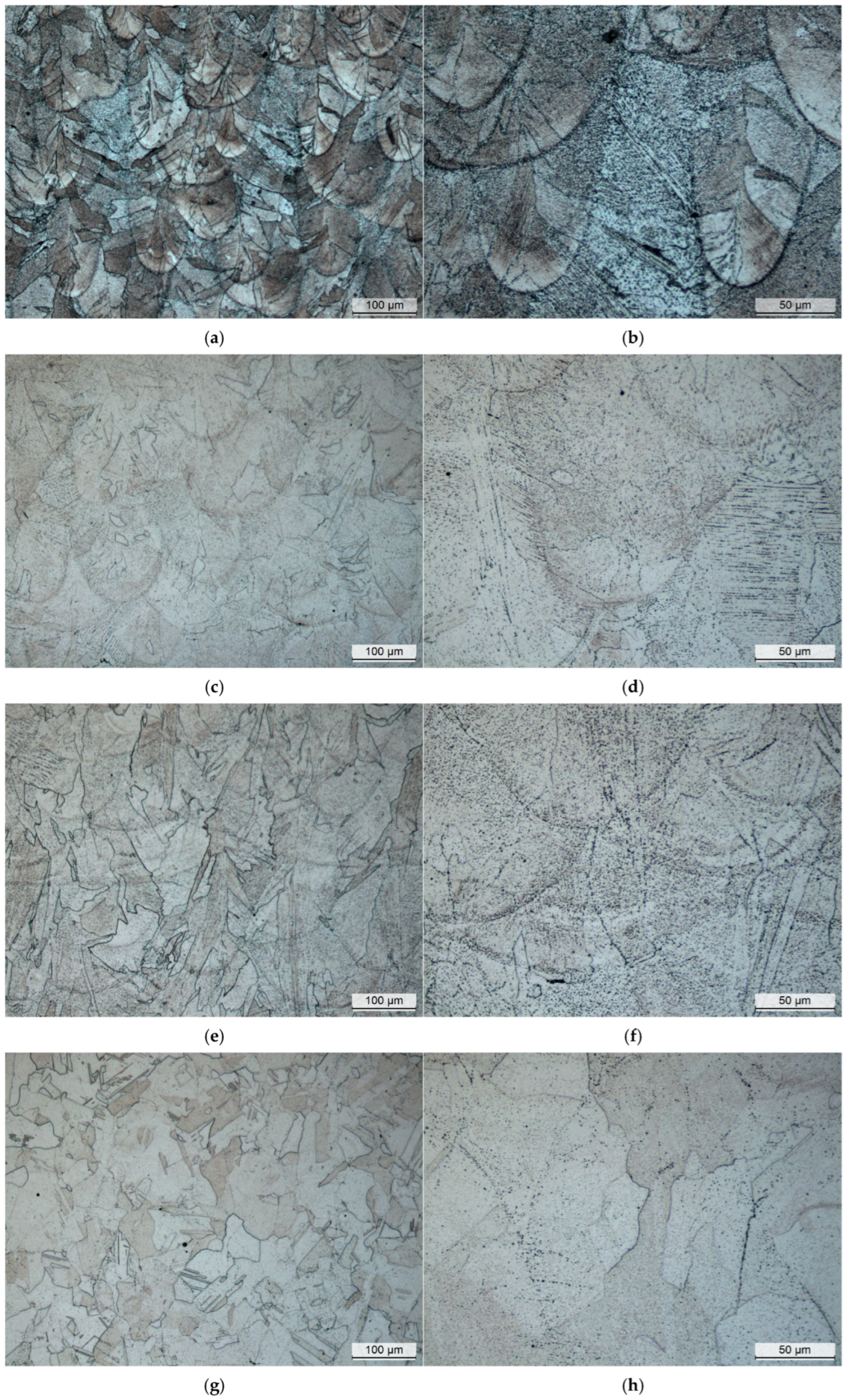

3.1. As-Built and Stress-Relieved Conditions

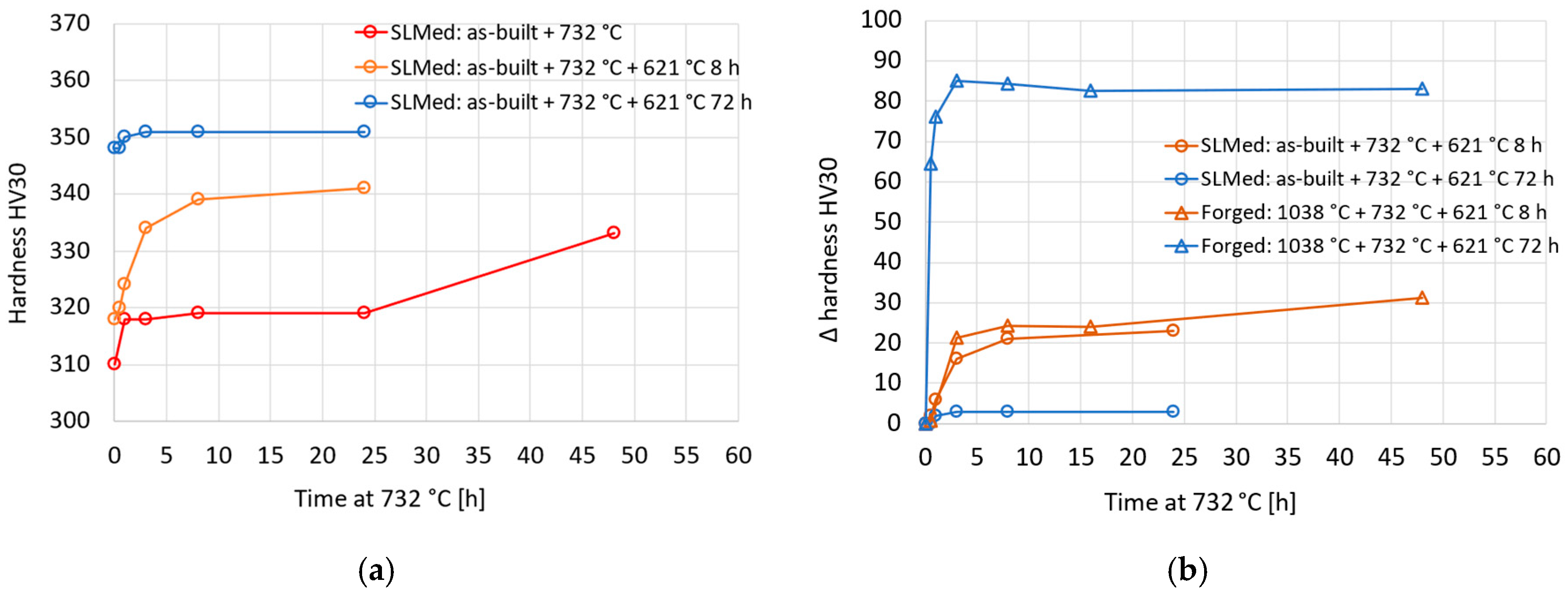

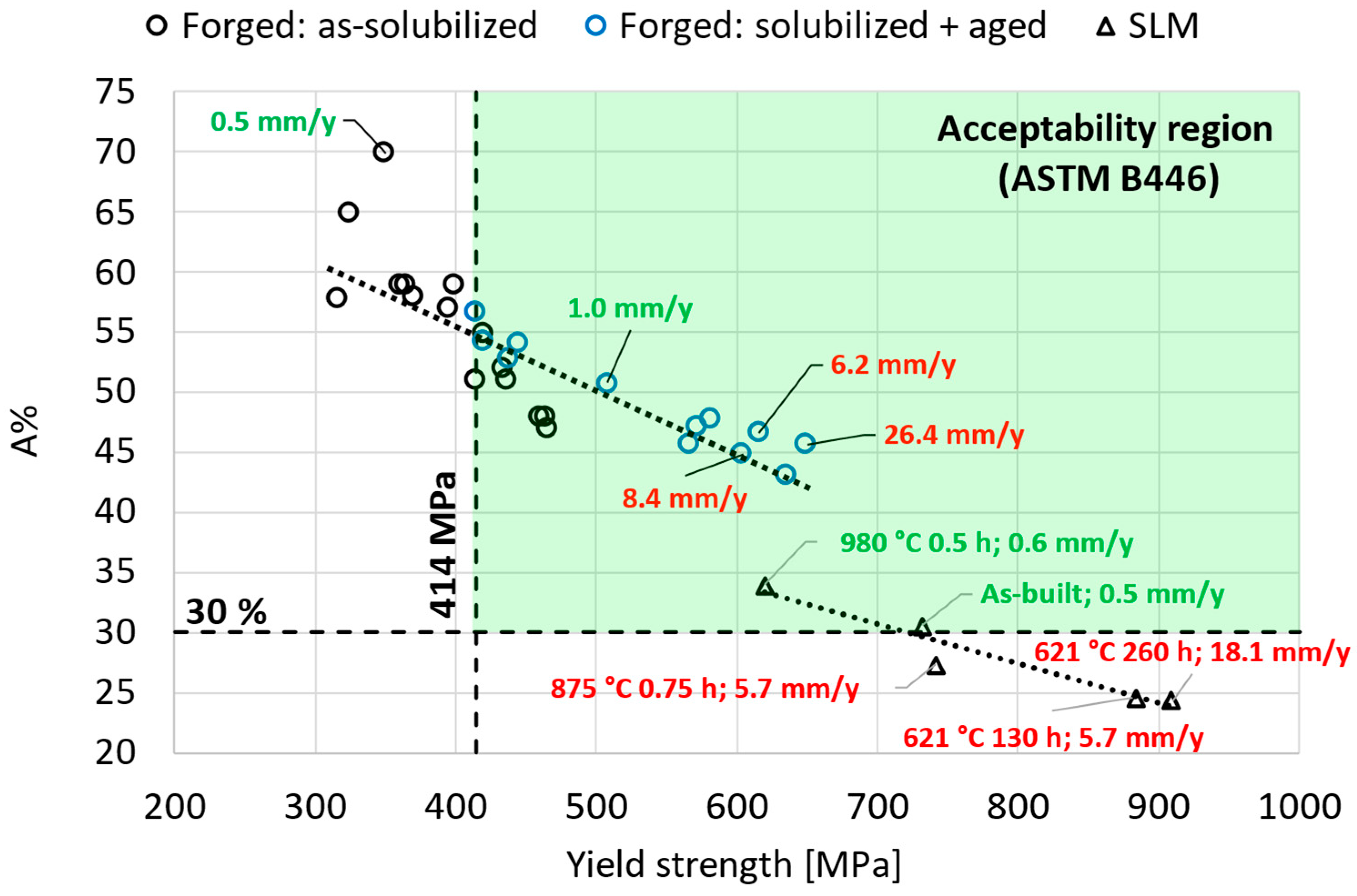

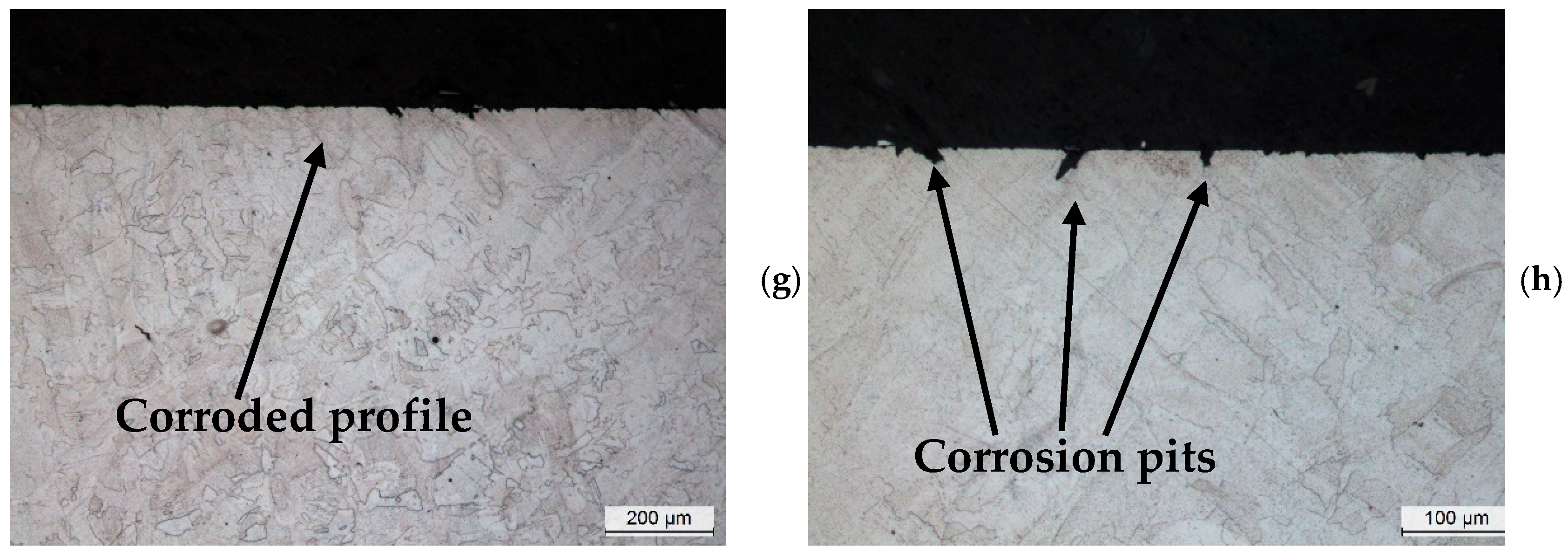

3.2. Single- and Double-Aging Treatments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suave, L.M.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Bertheau, D.; Laigo, J. Microstructural Evolutions During Thermal Aging of Alloy 625: Impact of Temperature and Forming Process. Metall. Mater. Trans. A 2014, 45, 2963–2982. [Google Scholar] [CrossRef]

- Shankar, V.; Bhanu Sankara Rao, K.; Mannan, S.L. Microstructure and Mechanical Properties of Inconel 625 Superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Sukumaran, A.; Gupta, R.K.; Anil Kumar, V. Effect of Heat Treatment Parameters on the Microstructure and Properties of Inconel-625 Superalloy. J. Mater. Eng. Perform. 2017, 26, 3048–3057. [Google Scholar] [CrossRef]

- Heubner, U.; Kloewer, J.; Alves, H.; Behrens, R.; Schindler, C.; Wahl, V.; Wolf, M. Nickel Alloys and High-Alloyed Special Stainless Steels: Properties-Manufacturing-Applications, 4th ed.; Expert-Verlag: Renningen, Germany; Stuttgart, Germany, 2012. [Google Scholar]

- ASM International. ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys; Davis, J., Ed.; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Eiselstein, H.L.; Tillack, D.J. The Invention and Definition of Alloy 625. In Proceedings on Superalloys 718, 625, and Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1991; pp. 1–14. [Google Scholar]

- Durand-Charre, M. The Microstructure of Superalloys, 1st ed.; Routledge: London, UK, 1968. [Google Scholar]

- Patel, S.J.; Smith, G.D. The Role of Niobium in Wrought Precipitation-Hardened Nickel-Base Alloys. In Proceedings on Superalloys 718, 625, 706 and Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2005; pp. 135–154. [Google Scholar]

- Floreen, S.; Fuchs, G.E.; Yang, W.J. The Metallurgy of Alloy 625. In Superalloys 718, 625, 706 and Derivatives; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1994; pp. 13–37. [Google Scholar]

- Rivolta, B.; Boniardi, M.V.; Gerosa, R.; Casaroli, A.; Panzeri, D.; Pizetta Zordão, L.H. Alloy 625 Forgings: Thermo-Metallurgical Model of Solution-Annealing Treatment. J. Mater. Eng. Perform. 2022, 32, 5785–5797. [Google Scholar] [CrossRef]

- ASTM B446-19; Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625), Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219), and Nickel-Chromium-Molybdenum-Tungsten Alloy (UNS N06650) Rod and Bar. ASTM International: West Conshohocken, PA, USA, 2019.

- Reed, R.C.; Rae, C.M.F. Physical Metallurgy of the Nickel-Based Superalloys. In Physical Metallurgy; Elsevier: Amsterdam, The Netherlands, 2014; pp. 2215–2290. [Google Scholar] [CrossRef]

- Vernot-Loier, C.; Cortial, F. Influence of Heat Treatments on Microstructure, Mechanical Properties and Corrosion Behaviour of Alloy 625 Forged Rod. In Proceedings on Superalloys 718, 625, and Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1991; pp. 409–422. [Google Scholar]

- Heubner, U.; Köhler, M. Effect of Carbon Content and Other Variables on Yield Strength, Ductility, and Creep Properties of Alloy 625. In Proceedings on Superalloys 718, 625, 706 and Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1994; pp. 479–488. [Google Scholar]

- Heubner, U.; Köhler, M. The Effect of Final Heat Treatment and Chemical Composition on Sensitization, Strength and Thermal Stability of Alloy 625. In Superalloys 718, 625, 706 and Derivatives; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1997; pp. 795–803. [Google Scholar]

- Lindwall, G.; Campbell, C.E.; Lass, E.A.; Zhang, F.; Stoudt, M.R.; Allen, A.J.; Levine, L.E. Simulation of TTT Curves for Additively Manufactured Inconel 625. Metall. Mater. Trans. A 2019, 50, 457–467. [Google Scholar] [CrossRef] [PubMed]

- Stoudt, M.R.; Lass, E.A.; Ng, D.S.; Williams, M.E.; Zhang, F.; Campbell, C.E.; Lindwall, G.; Levine, L.E. The Influence of Annealing Temperature and Time on the Formation of δ-Phase in Additively-Manufactured Inconel 625. Metall. Mater. Trans. A 2018, 49, 3028–3037. [Google Scholar] [CrossRef]

- Sitek, R.; Ciftci, J.; Moszczyńska, D.; Maj, P.; Ura-Bińczyk, E.; Warzybok, P.; Cieślik, I.; Wiśniewski, P.; Mizera, J. Effect of Annealing on the Microstructure and Properties of IN 625 Specimens Manufactured by Selective Laser Melting. Arch. Civil. Mech. Eng. 2022, 22, 207. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Mireles, J.; Stafford, S.W.; Perez, M.A.; Terrazas, C.A.; Wicker, R.B. Characterization of Inconel 625 Fabricated Using Powder-Bed-Based Additive Manufacturing Technologies. J. Mater. Process Technol. 2019, 264, 200–210. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.-W.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.-U.; Ugues, D.; et al. Influence of Heat Treatments on Microstructure Evolution and Mechanical Properties of Inconel 625 Processed by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2018, 729, 64–75. [Google Scholar] [CrossRef]

- Marchese, G.; Bassini, E.; Parizia, S.; Manfredi, D.; Ugues, D.; Lombardi, M.; Fino, P.; Biamino, S. Role of the Chemical Homogenization on the Microstructural and Mechanical Evolution of Prolonged Heat-Treated Laser Powder Bed Fused Inconel 625. Mater. Sci. Eng. A 2020, 796, 140007. [Google Scholar] [CrossRef]

- Lee, J.; Terner, M.; Jun, S.; Hong, H.-U.; Copin, E.; Lours, P. Heat Treatments Design for Superior High-Temperature Tensile Properties of Alloy 625 Produced by Selective Laser Melting. Mater. Sci. Eng. A 2020, 790, 139720. [Google Scholar] [CrossRef]

- Chen, F.; Wang, Q.; Zhang, C.; Huang, Z.; Jia, M.; Shen, Q. Microstructures and Mechanical Behaviors of Additive Manufactured Inconel 625 Alloys via Selective Laser Melting and Laser Engineered Net Shaping. J. Alloys Compd. 2022, 917, 165572. [Google Scholar] [CrossRef]

- Martucci, A.; Marchese, G.; Bassini, E.; Lombardi, M. Effects of Stress-Relieving Temperature on Residual Stresses, Microstructure and Mechanical Behaviour of Inconel 625 Processed by PBF-LB/M. Metals 2023, 13, 796. [Google Scholar] [CrossRef]

- Luna, V.; Trujillo, L.; Gamon, A.; Arrieta, E.; Murr, L.E.; Wicker, R.B.; Katsarelis, C.; Gradl, P.R.; Medina, F. Comprehensive and Comparative Heat Treatment of Additively Manufactured Inconel 625 Alloy and Corresponding Microstructures and Mechanical Properties. J. Manuf. Mater. Process. 2022, 6, 107. [Google Scholar] [CrossRef]

- Renishaw. In625-0402 Powder for Additive Manufacturing: Data Sheet. September 2017. Available online: https://www.renishaw.com/media/pdf/en/674a7fa1d94b4da3907f9a2275b6f46d.pdf (accessed on 18 January 2023).

- Concli, F.; Gerosa, R.; Panzeri, D.; Fraccaroli, L. High- and Low-Cycle-Fatigue Properties of Additively Manufactured Inconel 625. Progress. Addit. Manuf. 2024, 9, 1921–1940. [Google Scholar] [CrossRef]

- Marinucci, F.; Marchese, G.; Bassini, E.; Aversa, A.; Fino, P.; Ugues, D.; Biamino, S. Hardness Evolution of Solution-Annealed LPBFed Inconel 625 Alloy under Prolonged Thermal Exposure. Metals 2022, 12, 1916. [Google Scholar] [CrossRef]

- Kim, K.-S.; Kang, T.-H.; Kassner, M.E.; Son, K.-T.; Lee, K.-A. High-Temperature Tensile and High Cycle Fatigue Properties of Inconel 625 Alloy Manufactured by Laser Powder Bed Fusion. Addit. Manuf. 2020, 35, 101377. [Google Scholar] [CrossRef]

- Rivolta, B.; Gerosa, R.; Tavasci, F.; Ori Belometti, L. Mechanical and Microstructural Characterization of Forged Inconel 625 Ring Gaskets for Oil and Gas Application. Mater. Perform. Charact. 2017, 6, 20170030. [Google Scholar] [CrossRef]

- Rivolta, B.; Gerosa, R.; Tavasci, F.; Ori Belometti, L. Metallurgical Analysis of Inconel 625 Metallic Gaskets Produced by Centrifugal Casting. Mater. Perform. Charact. 2017, 6, 20170036. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Testa, C.; Brevi, F.; Biamino, S.; Fino, P.; Manfredi, D.; Marchese, G.; Calignano, F.; Pastore, T. Microstructure and Selective Corrosion of Alloy 625 Obtained by Means of Laser Powder Bed Fusion. Materials 2019, 12, 1742. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Williams, M.E.; Katz, M.B.; Levine, L.E.; Phan, T.Q.; Gnaeupel-Herold, T.H.; Ng, D.S. Formation of the Ni3Nb δ-Phase in Stress-Relieved Inconel 625 Produced via Laser Powder-Bed Fusion Additive Manufacturing. Metall. Mater. Trans. A 2017, 48, 5547–5558. [Google Scholar] [CrossRef] [PubMed]

- Dubiel, B.; Sieniawski, J. Precipitates in Additively Manufactured Inconel 625 Superalloy. Materials 2019, 12, 1144. [Google Scholar] [CrossRef]

- Tawancy, H.M.; Allam, I.M.; Abbas, N.M. Effect of Ni3Nb Precipitation on the Corrosion Resistance of Inconel Alloy 625. J. Mater. Sci. Lett. 1990, 9, 343–347. [Google Scholar] [CrossRef]

- Zhu, Z.; Sui, Y.; Dai, A.; Cai, Y.; Xu, L.-L.; Wang, Z.; Chen, H.; Shao, X.; Liu, W. Effect of Aging Treatment on Intergranular Corrosion Properties of Ultra-Low Iron 625 Alloy. Int. J. Corros. 2019, 2019, 9506401. [Google Scholar] [CrossRef]

- ASTM G28-02; Standard Test Methods for Detecting Susceptibility to Intergranular Corrosion in Wrought, Nickel-Rich, Chromium-Bearing Alloys. ASTM International: West Conshohocken, PA, USA, 2015.

- Carpenter Technology Corporation. CarTech® Custom Age 625 PLUS® Alloy: Technical Datasheet. Available online: www.carpentertechnology.com/alloy-finder/625-Plus (accessed on 25 August 2020).

- Carpenter Technology Corporation. A Guide to Etching Specialty Alloys for Microstructural Evaluation. Available online: https://carpentertechnology.com/blog/a-guide-to-etching-specialty-alloys (accessed on 14 November 2023).

- ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test. BSI Standards: London, UK, 2018.

- BS EN ISO 6892-1:2019; Metallic Materials—Tensile Testing. BSI Standards Limited: London, UK, 2020.

- Rivolta, B.; Gerosa, R.; Panzeri, D.; Nazim, A. Optimization of the Mechanical and Corrosion Resistance of Alloy 625 through Aging Treatments. Crystals 2024, 14, 139. [Google Scholar] [CrossRef]

- Rivolta, B.; Gerosa, R.; Panzeri, D. Influence of Single- and Double-Aging Treatments on the Mechanical and Corrosion Resistance of Alloy 625. Metals 2024, 14, 823. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Katz, M.B.; Williams, M.E. Precipitation and Dissolution of δ and Γ″ during Heat Treatment of a Laser Powder-Bed Fusion Produced Ni-Based Superalloy. Scr. Mater. 2018, 154, 83–86. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.Y.; Weaver, M.; Guo, Y.B. Microstructure Evolution Characteristics of Inconel 625 Alloy from Selective Laser Melting to Heat Treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Laser Aided Direct Metal Deposition of Inconel 625 Superalloy: Microstructural Evolution and Thermal Stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

| Condition | Hardness | YS [MPa] | UTS [MPa] | A% | Reference |

|---|---|---|---|---|---|

| As-built (SLM) | --- | 567–783 | 836–1041 | 10–57 | [19] |

| As-built (SLM) | --- | 350–400 | 840–910 | 56–62 | [20] |

| As-built (SLM) | 285 HBW | 618–783 | 891–1041 | 33–41 | [21,22] |

| As-built (SLM) | --- | 770 | 1039 | 40 | [23] |

| As-built (SLM) | --- | 709–859 | 1103–1242 | 27–30 | [24] |

| As-built (SLM) | 342 HV0.5 | 566 | 1087 | 29 | [25] |

| As-built (SLM) | 304 HV0.3 | --- | --- | --- | [26] |

| As-built (SLM) | 332 HV0.5 | 676–767 | 964–1055 | 34–42 | [27] |

| As-built (SLM) | 273–303 HV2 300–320 HV0.1 | 630 | 827 | --- | [28] |

| As-built (SLM) + 1038 °C | --- | 523–577 | 841–854 | --- | [19] |

| As-built (SLM) + 1038 °C | 253 HV0.5 | 598–633 | 955–1020 | 39–43 | [27] |

| As-built (SLM) + 1150 °C | --- | 379 | 851 | 55 | [22] |

| As-built (SLM) + 1150 °C | 190 HBW | 396 | 883 | 55 | [21] |

| As-built (SLM) + 1150 °C | 190 HBW | --- | --- | --- | [29] |

| Wrought (solubilized) | --- | 413 | 914 | 70 | [30] |

| Wrought (solubilized) | --- | 350 | 809 | 76 | [23] |

| Wrought (solubilized) | 169–275 HV30 | 317–460 | 751–910 | 47–70 | [11,31] |

| Centrifugally cast | 80–90 HRB 151–188 HV | 290–310 | 580–595 | 46–57 | [28,32] |

| Condition | YS [MPa] | UTS [MPa] | YS/UTS [-] | A% | |

|---|---|---|---|---|---|

| As-built (SLM) | Range | 350–859 | 827–1242 | 0.43–0.76 | 10–62 |

| Average | 653 | 990 | 0.66 | 38 | |

| As-built (SLM) + 1038 °C | Range | 523–633 | 841–1020 | 0.62–0.68 | 39–43 |

| Average | 583 | 918 | 0.64 | 41 | |

| As-built (SLM) + 1150 °C | Range | 379–396 | 851–883 | 0.45–0.45 | 55–55 |

| Average | 388 | 867 | 0.45 | 55 | |

| Wrought (solubilized) | Range | 317–460 | 751–914 | 0.43–0.47 | 47–76 |

| Average | 384 | 851 | 0.45 | 68 | |

| Centrifugally cast | Range | 290–310 | 580–595 | 0.50–0.52 | 46–57 |

| Average | 300 | 588 | 0.51 | 53 |

| Contour | Inner Area (Islands) | |

|---|---|---|

| Power [W] | 120 | 180 |

| Speed [mm/s] | 400 | 900 |

| Spot size [µm] | 50 | 150 |

| Plane | As-Built HV30 | Stress-Relieved (875 °C 45 min) HV30 |

|---|---|---|

| XY | 312 | 314 |

| YZ | 306 | 307 |

| ZX | 310 | 311 |

| Average | 309 | 311 |

| As-Built | Stress-Relieved (875 °C 45 min) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| YS [MPa] | UTS [MPa] | YS/UTS | A% | Z% | YS [MPa] | UTS [MPa] | YS/UTS | A% | Z% | |

| This work | 732 | 1041 | 0.70 | 31.0 | 38 | 742 | 1078 | 0.69 | 28.0 | 30 |

| Minimum ASTM B446 | 414 | 827 | --- | 30.0 | --- | 414 | 827 | --- | 30.0 | --- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivolta, B.; Gerosa, R.; Panzeri, D. Selective Laser-Melted Alloy 625: Optimization of Stress-Relieving and Aging Treatments. Appl. Sci. 2025, 15, 5441. https://doi.org/10.3390/app15105441

Rivolta B, Gerosa R, Panzeri D. Selective Laser-Melted Alloy 625: Optimization of Stress-Relieving and Aging Treatments. Applied Sciences. 2025; 15(10):5441. https://doi.org/10.3390/app15105441

Chicago/Turabian StyleRivolta, Barbara, Riccardo Gerosa, and Davide Panzeri. 2025. "Selective Laser-Melted Alloy 625: Optimization of Stress-Relieving and Aging Treatments" Applied Sciences 15, no. 10: 5441. https://doi.org/10.3390/app15105441

APA StyleRivolta, B., Gerosa, R., & Panzeri, D. (2025). Selective Laser-Melted Alloy 625: Optimization of Stress-Relieving and Aging Treatments. Applied Sciences, 15(10), 5441. https://doi.org/10.3390/app15105441