Featured Application

based on transparent soil, the interfacial characteristics of coir geotextiles are studied in this study. The results of this study can provide a reference for understanding the pullout behaviour of natural fiber geotextiles, especially coir geotextiles as alternative materials for geotechnical engineering.

Abstract

As green and low-carbon materials, coir geotextiles have a broad application prospect in soil strengthening. In order to clarify the interface characteristics of coir geotextiles, the pullout test is performed on coir geotextiles by using transparent soil technology. The transparent soil is prepared by using fused quartz as the skeleton particle and the mixture of No. 15 industrial white oil and No. 3 industrial white oil as the pore fluid. The results show that the mechanical response of different pullout tests is basically similar, that is, with the increase in pullout displacement, the pullout force first increases rapidly, then slowly increases to the peak value, and then gradually decreases with the fluctuation. The adhesion of coir-geotextile–soil interface is 5.68 kPa and the internal friction angle is 3.43°. The interfacial friction coefficient of the coir geotextiles is unstable, ranging from 0.2 to 0.6. With the increase in normal stress, anchorage length, and pullout rate, the peak pullout force and the thickness of the shear band increase gradually.

1. Introduction

Geosynthetic materials have been widely used in geotechnical engineering and other fields because of their low cost and good mechanical properties. Geosynthetic materials mainly rely on the interfacial friction between the reinforcement and the soil to play a role. Clarifying the interaction law between the reinforcement and the soil is crucial for clarifying the reinforcement mechanism. The pullout test is an important means to study the interfacial properties of the reinforcement and the soil.

Many researchers have studied the soil-geosynthetic interaction using the pullout test. Agarwal et al. [1] used Mixed Recycled Aggregate (MRA) and Polymer Strips (PS) as filler and found that the value of the apparent interfacial coefficient of friction was higher in dense conditions and decreased by 70–80% in loose conditions under a large pullout test. Abdi et al. [2] carried out pullout tests on geogrids reinforced with small metal plates, and the results showed that the pullout force increased significantly with the increase in the height of the small metal plates and the distance from the pullout load. Abdi and Zandieh [3] carried out pullout tests with sandy soils and clays, respectively, and analyzed the interfacial parameters between the geogrids and the different fillers. Cardile et al. [4] observed the rotational movement of sand and gravel during the test and explored the effect of the geogrid on the pullout force through a large number of pullout tests. Chen et al. [5] conducted a pull test on soil reinforced with geogrids with different apertures, and the results showed that, compared with the geogrids with small apertures, the geogrids with large apertures had a better reinforcement ability. Ferreira et al. [6] added three different reinforcement materials, namely geogrids, geotechnical composite reinforcement materials, and geotextiles, to the granite residual soil, and the research results showed that the peak pullout force of the geogrids was the highest. Xu et al. [7] studied the influence of the angle of geotextile wrapping anchorage on the pullout force through the pullout test and found that, as the base angle decreased, the initial pullout force formed in the early and middle stages of pullout became larger, and as the top angle increased, the final pullout force, reached at the end of the pullout test, became larger. Some scholars have used transparent soil technology to carry out pullout tests and study the interface characteristics of reinforced soil in the geogrid [8,9,10].

However, all the above studies are aimed at generally common geosynthetics, which produce pollution during the production process and do not degrade easily inside the soil body. In this paper, several studies on soil reinforcement with different fiber geotextiles are listed, as shown in Table 1 [11,12,13,14,15,16,17]. As an environmentally friendly material, natural fiber fabrics need to be promoted and developed. The coir geotextile, as a representative natural fiber fabric, has excellent mechanical properties and durability. Methods to improve the durability of coir fibers and protect natural materials from biodegradation include the application of kerosene [18], the application of cashew shell liquid oil [19,20], lime treatment [21], chemical reagent treatment [22], and so on. Scholars have already used coir geotextiles as reinforcing materials in geotechnical engineering. Lal et al. [23] studied the influence of different forms of coir geotextiles on the load settlement characteristics of a sand bed on a square foundation, and the results showed that, for the same amount of material, the performance of the geocell-reinforced soil improved more than that of the flat form. Vinod et al. [24] carried out monotonic loading tests of coir geotextiles reinforcing a very loose sand layer. The results of the tests showed that the coir geotextile improved the load-bearing capacity of the foundations to a great extent, but the reinforcement parameters needed to be optimized for the design of the reinforcement. Bhole et al. [25] found, through monotonic loading tests, that the addition of coir geotextiles at the interface of the subsoil and the subbase significantly reduced the settlement of highly plastic soils, and the settlement of two types of coir-geotextile-reinforced soils was reduced by 18% and 8%, respectively. Sudarsanan et al. [26] conducted a study on coir geotextiles and non-woven coir fibers where these were subjected to tensile tests and the results showed that the coir geotextiles were suitable as a reinforcing material for road base reinforcement, while non-woven coir fibers were not. Anusudha et al. [27] found, through field tests, that when the unit mass of the two coir geotextiles was 740 g/m2 and 365 g/m2, respectively, the elastic modulus of the reinforced roadbed of two kinds of coir geotextiles was 1.41 times and 1.25 times higher than the elastic modulus of the unreinforced soil body, respectively. Adajar et al. [22] used the Rocscience Slide2 version 9.017 software to carry out a numerical analysis, and the results showed that the strength performance of coir geotextiles in strengthening slopes was almost equivalent to that of synthetic geotextiles. Based on the California Bearing Ratio (CBR) test, Harinder and Shankar [28] found that, when the content of coir geotextiles increased, the stiffness and CBR value of the black cotton soil subgrade also increased.

Table 1.

Different fiber geotextiles.

In the context of the global push for low-carbon and environmentally sustainable practices, the use of renewable, biodegradable, and natural materials has received a great deal of attention. Coconut fiber, extracted from coconut shells, is one such material that offers a sustainable alternative to traditional non-renewable resources. Its development and utilization are of great significance for reducing environmental pressure and reducing dependence on synthetic materials.

However, the interaction mechanism between coir geotextiles and the subsoil is still poorly understood, especially in terms of interface pullout behavior that affects its performance in soil reinforcement applications. In this paper, the transparent soil technique is used to clarify the interface pullout mechanism between coir geotextiles and the soil. Transparent soil technology refers to the preparation of artificial soil by mixing solid particles with pore liquids with the same refractive index. The solid particles constituting the transparent soil can be fused quartz sand, etc., and the pore liquid constituting the transparent soil can be mineral oil, etc. Typically, researchers can use the PIV (Particle Image Velocimetry) software or the DIC (Digital Image Correlation) software to analyze the deformation displacement of transparent soil. Although the preparation cost of transparent soil is higher than that of natural soil, it has the advantages of non-invasiveness, integrity, whole process, and fine measurement. Based on the transparent soil technology, the mechanism of coir geotextile pullout behavior is analyzed, and the reinforcement effect of coir geotextiles is evaluated by using the interfacial friction coefficient. The results of this study are helpful to broaden the understanding of natural fiber reinforcement materials, provide certain guidance for the design and implementation of a soil system reinforced with coir geotextiles, and promote the application of natural fiber materials.

2. Materials and Methods

2.1. Test Materials

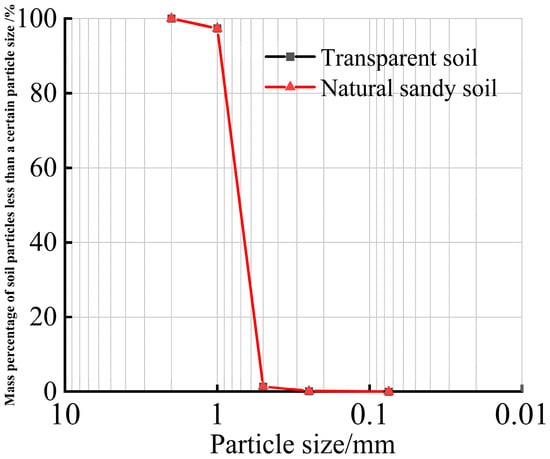

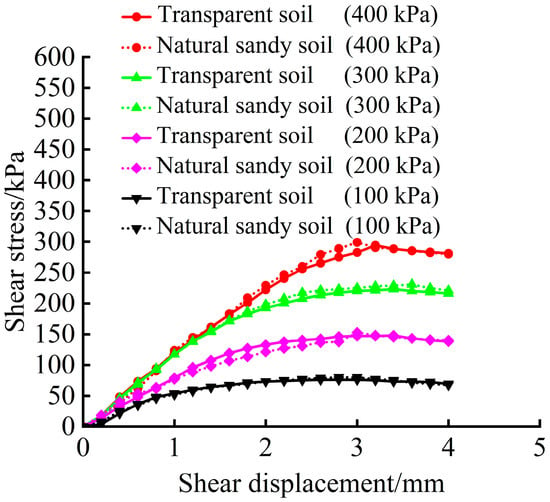

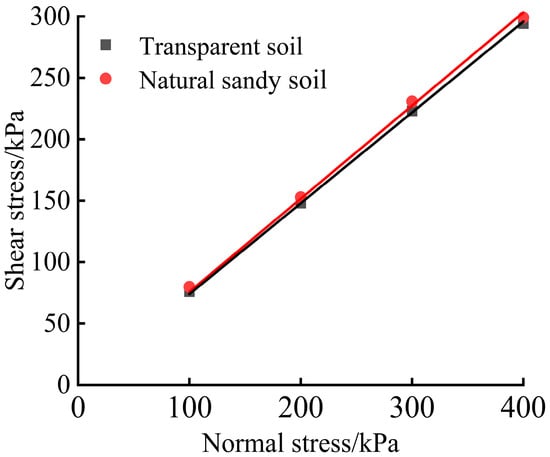

Transparent soil is a kind of artificial soil which is composed of solid particles and liquid with the same refractive index. In the present study, the solid particle material was fused quartz sand and the pore liquid was No. 15 and No. 3 industrial white oil mixed at a volume ratio of 1.5:1. Figure 1 shows the soil particle grading curves of transparent soil and natural sandy soil, and the particle grading curves of both were consistent. The shear strength characteristics of the transparent soil and the natural sandy soil were measured by a fast shear test. Figure 2 shows the shear-stress–shear-displacement relationship in the transparent soil and the natural sandy soil. It can be seen from Figure 2 that the characteristics of the transparent soil and the natural sandy soil were similar, and the shear strength increased with the increase in normal stress. Figure 3 shows the relationship between shear strength and normal stress in the transparent soil and natural sandy soil. As it can be seen from Figure 3, the internal friction angle of the natural sandy soil was about 37.16°, and that of the transparent soil was about 36.48°. The difference between transparent soil and natural sandy soil was only 0.68°, which is very close. It can be concluded that the transparent soil configured in the present study can be used to simulate natural sandy soil.

Figure 1.

The soil particle grading curves of transparent soil and natural sandy soil.

Figure 2.

The shear-stress–shear-displacement relationship of transparent soil and natural sandy soil.

Figure 3.

The relationship between shear strength and normal stress in the transparent soil and natural sandy soil.

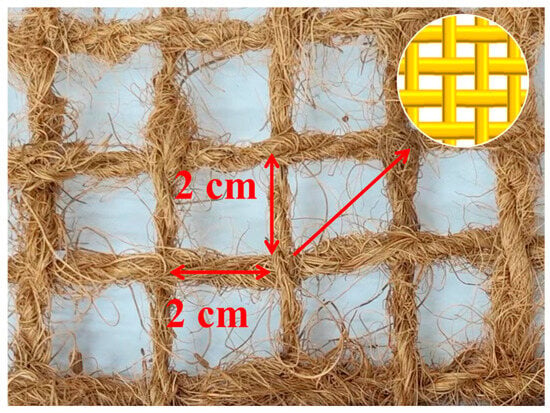

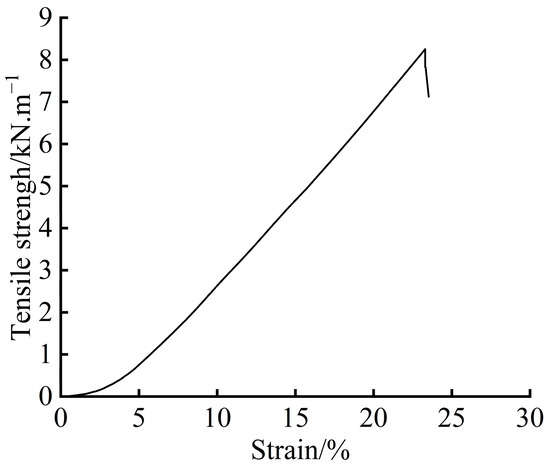

The coir geotextile was woven from the coconut shell fiber produced by the fruit of tall coconut trees. Figure 4 shows the physical picture of the coir geotextile, which had a grid-like structure similar to geogrids. Table 2 shows the basic physical characteristics of the coir geotextile, in which the linear density was mainly used to represent the thickness of the transverse and longitudinal ribs of the coir geotextile, while the gram weight was the mass of the coir geotextile per unit area. According to the research of Yang [29], when the width of the fabric was 3/4 of the width of the pullout test box, the friction effect on the side wall of the pullout test box could be minimized. Therefore, the width of the coir geotextile in this article was set to 300 mm. The reservation distance between the coir geotextile and the transparent glass side panels on both sides of the pullout test box was 50 mm. The lubrication of the mixed oil and the small friction coefficient of the left- and right-side walls can further reduce the impact of the boundary effect. Figure 5 shows the tensile test curve of the coir geotextile. The ultimate tensile strength of the coir geotextile was 8.25 kN/m and the peak strain was 23.31%. When the coir geotextile was subjected to a 5% strain, the tensile strength was 0.75 kN/m and the corresponding stiffness was 15 kN/m. When a 10% strain occurred on the coir geotextile, the tensile strength was 2.63 kN/m and the corresponding stiffness was 26.3 kN/m.

Figure 4.

The physical picture of the coir geotextile.

Table 2.

The basic physical characteristics of the coir geotextile.

Figure 5.

The tensile test curve of the coir geotextile.

2.2. Test Equipment

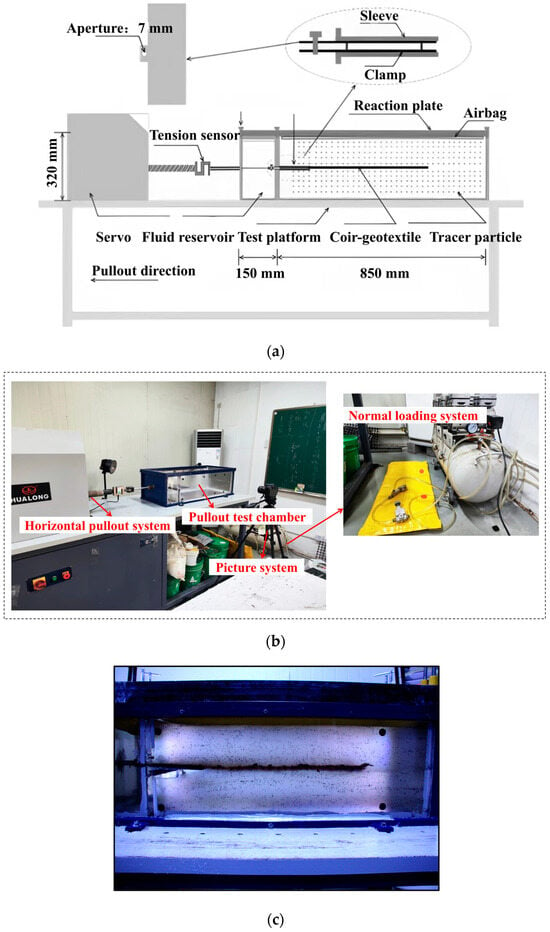

Figure 6 shows the test equipment. The test equipment mainly included a pullout test box, a horizontal pullout system, and an image system. Among them, the size of the pullout test box was 1000 mm (length) × 400 mm (width) × 300 mm (height). The pullout test chamber was divided into two parts, the liquid storage chamber on the left and the soil storage chamber on the right. The soil storage chamber was used to store the transparent soil and the coir geotextile and its size was 850 mm (length) × 400 mm (width) × 300 mm (height), while the liquid storage chamber was used to balance the liquid level of the transparent soil and its size was 150 mm (length) × 400 mm (width) × 300 mm (height). The soil storage chamber and the liquid storage chamber were separated by glass panels. There was a 10 mm narrow gap in the pullout of the glass plate.

Figure 6.

The test equipment. (a) Schematic diagram; (b) overall physical picture; (c) pullout test chamber filled with the transparent soil and the coir geotextile.

The horizontal pullout system was mainly powered by a closed-loop stepper motor, and then the pullout force was transmitted to the coir geotextile through the ball screw, so as to achieve the application of horizontal tension, and the high-precision tension and displacement sensors were arranged on it to realize the automatic measurement and recording of the force and displacement values during the pullout process. The normal loading system was mainly realized through the air bag loading, and the output pressure of the air compressor was transferred to the air bag so as to realize the application of normal load.

The image system was composed of an image acquisition system and an image analysis system, mainly including a digital single-lens reflex camera, a strong incandescent lamp, a portable computer, and other equipment. A strong incandescent lamp was used as a lighting device to irradiate the tracer particles to form a speckle surface. A digital single-lens reflex camera was used to continuously record the whole process of the pullout test, so as to complete the image data acquisition. The tracer particles were dyed using the fused quartz, and their particle size distribution and mechanical properties were consistent with those of transparent soil solid particles, as shown in Figure 6a,c. The digital single-lens reflex camera was a Canon EOS800D digital camera (Canon, Tokyo, Japan), which was placed on the front side of the pullout test box and fixed to the tripod. The camera was controlled wirelessly by a portable computer. The image analysis system was composed of two pieces of analysis software, PhotoInfor and PostViewer. The digital image processing technology based on the PhotoInfor version 2009 software and PostViewer version 2009 software has been widely used in geotechnical engineering. Some scholars have implemented this digital image processing technology with good results [30,31,32,33].

2.3. Test Plan

Table 3 shows the test scheme. Three groups of tests were conducted to study the effects of normal stress, anchorage length, and pullout rate on the interface characteristics of reinforced soil.

Table 3.

The test scheme.

2.4. Test Procedure

(1) The temperature and light of the laboratory were controlled. By controlling the air conditioning of the laboratory to maintain a constant temperature in the laboratory, the test was carried out under low light conditions.

(2) The packing of the lower part of the pullout box was filled and compacted. The mixed mineral oil, with a refractive index of 1.4585, was poured into the pullout box, and then the fused quartz was evenly spread in the mixed mineral oil. During the spreading process, the height of the mixed oil level was always maintained about 2 mm higher than the surface height of the fused quartz particles. When the height of each spreading of the transparent soil reached about 5 mm, a layer of tracer particles was laid. When the height of the transparent soil was about 50 mm, it was necessary to use rigid plates for compaction. According to Equation (1) and to the standard maximum dry density of the measured filler, the mass of the filler required for each fixed volume was calculated to ensure that the mass of each layer was the same, and the required compaction degree (90%) was obtained by layering compaction. The symbol of the compaction degree is K, and the equation is (1):

where K, ρd, and ρdmax are the compaction degree, the dry density of the fill, and the maximum dry density, respectively.

(3) The coir geotextile was laid. The lower layer of transparent soil filler was scraped and compacted, the pullout fixture was installed. The installed coir geotextile test piece was passed through the soil storage chamber sleeve unit to the liquid storage chamber. The coir geotextile fixture was connected to the force transfer rod with a nut.

(4) The upper packing was filled and compacted, and normal loads were applied. The transparent soil was filled, and the tracer particles were arranged in the same way as step (2). After filling, the air bag was placed on top of the pullout box, and the rigid steel plate was used as a reaction plate on the air bag. Three I-beams of No. 10 were placed above the reaction plate to provide sufficient stiffness for the pressure of the air bag. After the installation was completed, the normal load was applied through the air compressor, and when the air pressure of the air bag increased slowly from the initial value to the air pressure setting value, it was stabilized for about 300 s, and then the horizontal pull test was carried out.

(5) The device was installed and started. A bracket was installed, and the strong incandescent lamp was secured. The camera was turned on. The computer was connected, and the camera was adjusted. The horizontal loading device was turned on. Pullout tests on the coir geotextile were conducted at a set horizontal rate. Every test was interrupted when the pullout displacement reached 50 mm or when the pullout curve was seriously unstable. After the end of each group of tests, the air pressure of the air bag and the horizontal displacement of the return position were released, the strong incandescent lamp and the camera were turned off, the packing and coir geotextile were removed, the state of the coir geotextile was observed, and then the above steps were repeated for the next group of tests.

3. Results and Discussion

3.1. Influence of Normal Stress

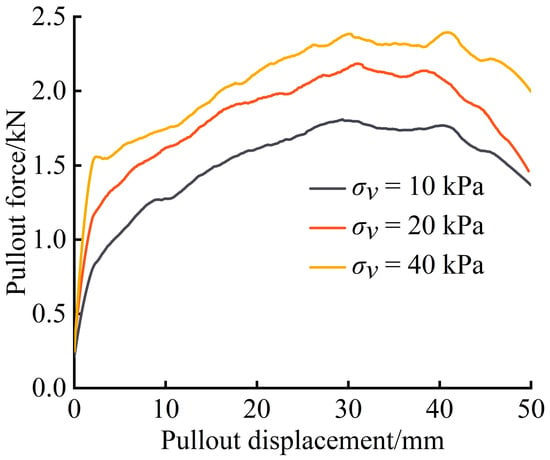

Figure 7 shows the relationship curve between the pullout force and the pullout displacement under different normal stresses. As it can be seen from Figure 7, with the increase in normal stress, the pullout force in the whole process increased significantly. The mechanical response of the pullout test was basically similar, that is, with the increase in pullout displacement, the pullout force first increased rapidly, then slowly increased to the peak value, and then gradually decreased with the fluctuation. A similar pattern appears in Figure 11 and Figure 13 below.

Figure 7.

The relationship curve between the pullout force and the pullout displacement under different normal stresses.

When the normal stress increased from 10 kPa to 40 kPa, the corresponding peak value of the pullout force increased from 1.8 kN to 2.2 kN and 2.4 kN, respectively. At the beginning of the pullout test, the greater the normal stress, the greater the slope of the pullout curve, because, when other things were equal, the greater the normal stress, the more soil entered the coir geotextile mesh. As the interlocking effect between the coir geotextile and the soil increased, the resistance to be overcome in the pullout test increased.

In order to evaluate the reinforcement effect of the coir geotextile, the shear strength and the friction coefficient of the reinforced soil interface were analyzed. The relevant calculation formulas of shear stress, normal stress, and interfacial friction coefficient of the reinforced soil are shown in Equations (2)–(4), respectively [34].

where Td and P are the horizontal tension and the normal load (kN), respectively, L and B are the length and width of the reinforcement, respectively, τ and σv are the shear stress and the normal stress (kPa), respectively, A is the horizontal area of the pullout box (m2), and fgs is the interfacial friction coefficient of the reinforced soil.

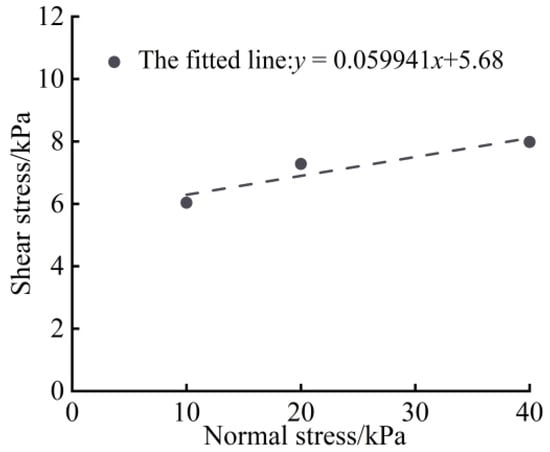

Figure 8 shows the relationship between the shear strength of the coir geotextile and the normal stress. The shear strength parameters of the coir geotextile interface can be obtained after linear fitting, in which the cohesion was 5.68 kPa and the internal friction angle was 3.43°.

Figure 8.

The relationship between the shear strength of the coir geotextile and the normal stress.

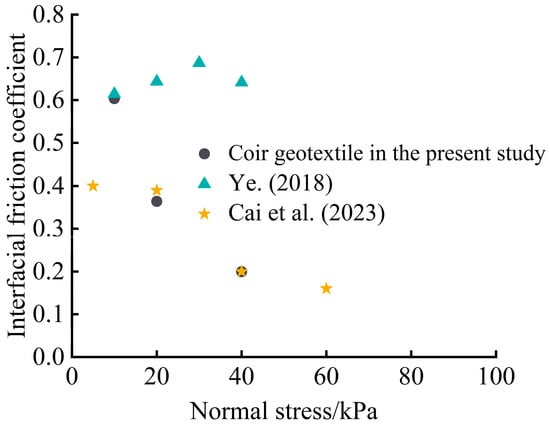

Figure 9 shows the relationship between the interfacial friction coefficient of the reinforced soil and normal stress. The interfacial friction coefficient of the reinforced soil is an important index of the comprehensive strength of the interfacial friction effect, which is the ratio of the interfacial shear stress to the normal stress. In general, the greater the interface friction coefficient, the better the reinforcement effect. Since the strain at each point of the reinforced material is not the same, the stress at the interface of the reinforced soil is not evenly distributed. Only when the reinforced material is pulled out, the friction resistance at the upper and lower interface can be considered to be evenly distributed.

Figure 9.

The relationship between the interfacial friction coefficient of the reinforced soil and normal stress [35,36].

As it can be seen from Figure 9, the interface friction coefficient was a quantity that changed with the change in normal stress, rather than a constant. The tests conducted by Ye [35] and Cai et al. [36] show a similar situation. Ye [35] conducted a pullout test on a geogrid with a tensile strength of 40 kN/m in transparent soil. It can be seen that, under a normal stress of 10 kPa, the interfacial friction coefficients of the coir geotextile and the geogrid were close to each other, and the gap between them began to appear as the normal stress increased. The interfacial friction coefficient between the geogrid and the transparent soil was always in the range of 0.6 to 0.7, while the interfacial friction coefficient between the coir geotextile and the transparent soil showed a decreasing trend. Because under the action of high normal stress the coir geotextile was more prone to deformation and destruction than the geogrid, then the reinforcement effect was weakened. Cai et al. [36] conducted a pullout test on gabion mesh standard sand with a tensile strength of 28.1 kN/m. At 20 kPa, the interfacial friction coefficient in the present study was slightly lower than that obtained by Cai et al. [36]. At 40 kPa, the interfacial friction coefficient in the present study basically coincided with the results obtained by Cai et al. [36]. As the normal stress increased to 40 kPa, the gabion mesh studied by Cai et al. [36] and the coir geotextile in the present study experienced a high degree of deformation and failure under high normal stress, and the interfacial friction coefficient of both materials dropped to a low level.

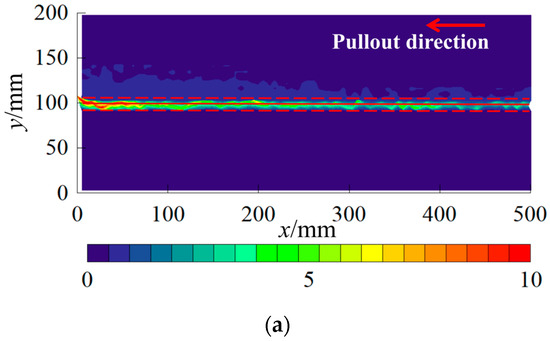

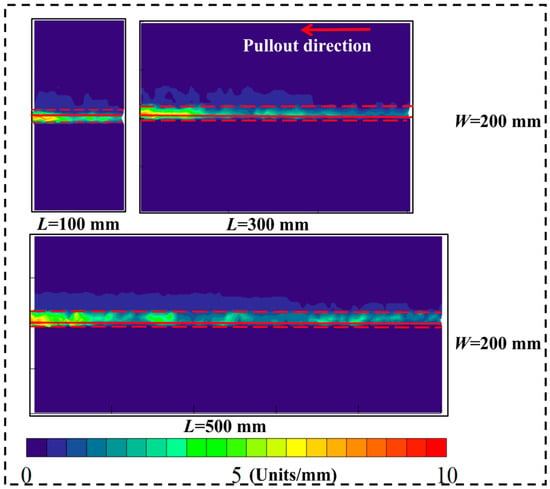

In order to further study the interfacial interaction between the coir geotextile and the subsoil, the displacement contour of the interfacial reinforcement and the soil was analyzed by using an image analysis technique. For the division processing of the displacement contour, this paper referred to the studies of Wang et al. [30] and Zhou et al. [37]. In the present study, the position around the reinforced soil interface was studied, and the place where the horizontal displacement of the particles was about 0 on the reinforced soil interface was selected as the upper and lower boundaries. For example, in Figure 10, the red dotted line is the upper and lower boundary of the shear band, and the red solid line in the middle represents the position of the coir geotextile. The thickness of the upper interface of the shear band was defined as the thickness between the coir geotextile and the upper boundary, and so on for the lower interface thickness of the shear band. There was a common control group, that is, the anchorage length was 500 mm, the normal stress was 20 kPa, and the pullout rate was 1 mm/min. In addition, Figure 10, Figure 12, and Figure 14 illustrate all the displacement contours that had formed an obviously stable contact area on the interface. Figure 10 shows the particle displacement contour under different normal stresses. It can be seen from Figure 10 that, when the normal stress increased from 10 kPa to 20 kPa successively, the corresponding thickness of the interfacial shear band increased from 13 mm to 16 mm successively. Moreover, when the normal stress further increased to 40 kPa, the thickness of the interfacial shear band also increased to 20 mm. In other words, the thickness of the interfacial shear band increased with the increase in normal stress, indicating that normal stress had a certain influence on the meso-motion behavior of the interfacial reinforced soil. When the normal stress increased, the reinforcement and the soil became closer, the driving effect of the coir geotextile on the surrounding soil particles was stronger, and the thickness of the shear band at the interface of the reinforcement and the soil was thicker.

Figure 10.

Contour of particle displacement under normal stresses. (a) 10 kPa; (b) 20 kPa; (c) 40 kPa.

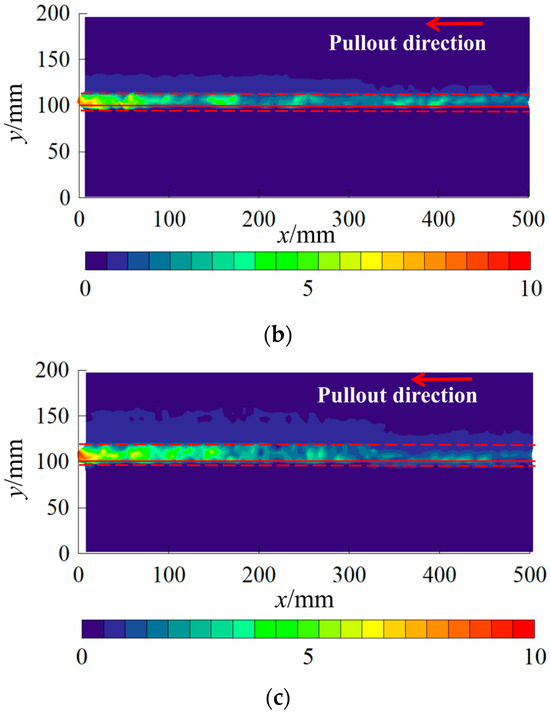

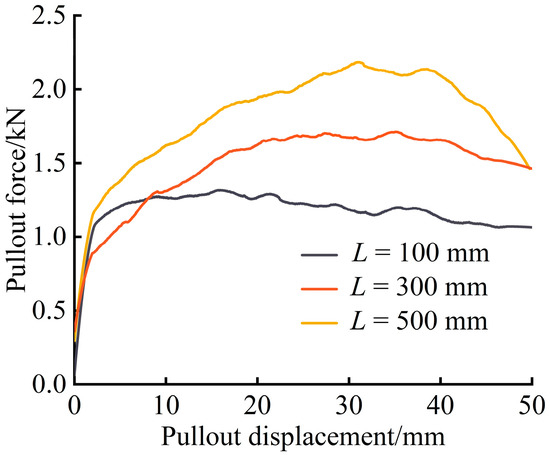

3.2. Influence of Anchorage Length

Figure 11 shows the relationship curve between the pullout force and the pullout displacement under different anchorage lengths. It can be seen from Figure 11 that, with the increase in anchorage length, the corresponding peak value of the pullout force increased from 1.3 kN to 1.6 kN and 2.2 kN successively. The coir geotextile in the present study was a planar mesh structure with a certain thickness. The resistance generated by the coir geotextile in the pullout process was mainly composed of the friction between the coir geotextile and the soil mass and the passive resistance of the transverse rib of the fabric. When the width of the coir geotextile was fixed, the longer the anchorage length of the coir geotextile, the longer the longitudinal rib of the coir geotextile and the more mesh and transverse rib the coir geotextile contained. Therefore, in the same case, the longer the anchorage length of the coir geotextile, the greater the scope of reinforcement and the stronger the spatial chain effect. The greater the resistance generated, the greater the peak pullout force required.

Figure 11.

The relationship curve between the pullout force and the pullout displacement under different anchorage lengths.

Figure 12 shows the contour of particle displacement under different anchorage lengths. In order to facilitate comparison, the displacement contour of the coir geotextile length’s corresponding position was analyzed. As it can be seen from Figure 12, when the anchorage length increased from 100 mm to 300 mm, the thickness of the interfacial shear band increased from 11 mm to 14 mm, and when the anchorage length further increased to 500 mm, the thickness of the interfacial shear band also increased to 16 mm. This indicates that the anchorage length had a great influence on the meso-motion behavior of the reinforced soil interface. In the pullout test, when the anchorage length of the coir geotextile was longer, its driving effect on the soil particles around the reinforced soil interface was stronger and the shear band thickness at the reinforced soil interface was thicker.

Figure 12.

The contour of particle displacement under different anchorage lengths.

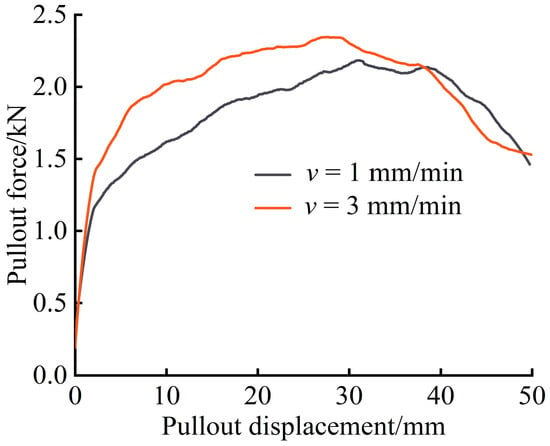

3.3. Influence of Pullout Rate

Figure 13 shows the relationship curve between the pullout force and the pullout displacement at different pullout rates. As it can be seen from Figure 13, at a higher pullout rate, the pullout test curve had a better stress–strain response in the initial stage of the pullout. With the increase in the pullout rate, the corresponding peak value of the pullout force increased from 2.2 kN to 2.4 kN successively. The pullout rate was positively correlated with the peak value of the pullout force. After reaching the peak of the pullout force, the pullout test curve dropped faster at high pullout rates, because, when the pullout rate of the coir geotextile was small in the pullout process, the transparent soil particles had enough time to rearrange. The stress distribution was more uniform during the pullout process, and the pullout force of the coir geotextile was small. When the pullout rate increased, the transparent soil particles did not have enough time to rearrange, which may produce a stress concentration effect, resulting in additional stress at the interface of the reinforced soil. When the coir geotextile was pulled, dilatation was more likely to occur, resulting in greater friction, which increased the pullout force. At the same time, under greater friction, the joints of the coir geotextile were more likely to be damaged, resulting in stress reduction. Therefore, at a higher pullout rate, that is, 3 mm/min, the rate of decline was faster after the pullout force had reached its peak.

Figure 13.

The relationship curve between the pullout force and the pullout displacement at different pullout rates.

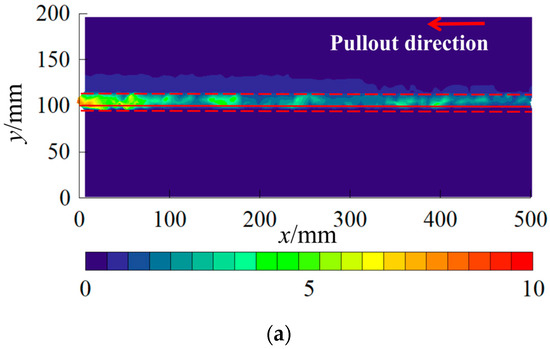

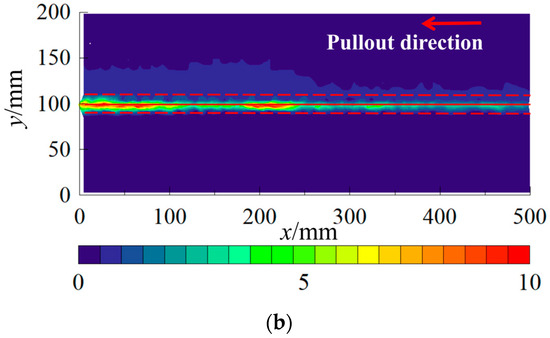

Figure 14 shows the contour of particle displacement at different pullout rates. As it can be seen from Figure 14, when the pullout rate changed, it affected the microscopic movement behavior of the reinforced soil interface. When the pullout rate increased from 1 mm/min to 3 mm/min, the thickness of the interface shear band increased from 16 mm to 18 mm. This indicates that the pullout rate affected the meso-behavior of the interfacial motion of the reinforced soil. With the increase in the pullout rate, the driving effect of the coir geotextile on the soil particles also was enhanced.

Figure 14.

The contour of particle displacement at different pullout rates. (a) 1 mm/min; (b) 3 mm/min.

In addition to the three factors of normal stress, anchorage length, and pullout rate, there are other factors worth considering. Mirzaalimohammadi et al. [38] found that the morphology of geosynthetics could lead to differences in their pullout behavior, and the morphology of the coir geotextile may also affect the pullout behaviour. In addition, the sensitivity of the measurement tool may introduce further uncertainty into the results. In the follow-up study, the author will take more strict and standardized measures to carry out the experiment, and the subsequent research will focus on considering influencing factors such as the morphology of the coir geotextile.

4. Conclusions

In the present study, transparent soil technology was used to carry out the interface pullout test between the coir geotextile and the transparent soil. The effects of normal stress, anchorage length, and pullout rate on the interface mechanical properties of reinforced soil were analyzed. The following conclusions were drawn:

- (1)

- The mechanical response of different pullout tests was basically similar, that is, with the increase in pullout displacement, the pullout force first increased rapidly, then slowly increased to the peak value, and then gradually decreased with the fluctuation.

- (2)

- The cohesion at the stiff–soil interface was 5.68 kPa, and the internal friction angle was 3.43°. The interfacial friction coefficient was in the range of 0.2–0.6.

- (3)

- With the normal stress increasing from 10 kPa to 20 kPa and 40 kPa successively, the peak value of the pullout force increased from 1.8 kN to 2.2 kN and 2.4 kN successively and the thickness of the shear band increased from 13 mm to 16 mm and 20 mm successively.

- (4)

- As the anchorage length increased from 100 mm to 300 mm and 500 mm successively, the peak pullout force increased from 1.3 kN to 1.6 kN and 2.2 kN successively and the thickness of the shear band increased from 11 mm to 14 mm and 16 mm successively.

- (5)

- As the pullout rate increased from 1 mm/min to 3 mm/min, the peak pullout force increased from 2.2 kN to 2.4 kN and the thickness of the shear band increased from 16 mm to 18 mm.

In the future, the application prospects of coir geotextiles are quite considerable. Coir geotextiles, as a renewable resource, have the characteristics of low carbon emission and high biodegradability compared with traditional geomaterials and can be used in ecological slope protection engineering, roadbed reinforcement engineering, and foundation reinforcement engineering. Subsequently, the relevant research of this subject can be planned from the following two aspects. First of all, in terms of material performance optimization, better weaving methods, physical modification methods, and chemical modification methods can be explored to improve the strengthening effect of coir geotextiles in the soil. Second, in terms of long-term performance evaluation, long-term field tests and monitoring can be carried out in the future to evaluate the reinforcement effect of coir geotextiles in complex environments, especially under different soil types. The application research of coir geotextiles is not limited to the above mentioned, and related research needs to be further expanded in the future.

Author Contributions

Conceptualization, L.L. and H.L.; data curation, L.L.; formal analysis, L.L., H.L. and W.C.; funding acquisition, L.L.; investigation, L.L.; methodology, L.L.; project administration, L.L.; resources, L.L.; software, H.L.; supervision, L.L.; validation, L.L., H.L. and W.C.; visualization, H.L.; writing—original draft, H.L.; writing—review and editing, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 42207190) and the Natural Science Foundation of Hainan Province, China. (Grant No. 122RC541).

Institutional Review Board Statement

Not appliable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Agarwal, A.; Ramana, G.V.; Datta, M.; Soni, N.K.; Satyakam, R. Pullout behaviour of polymeric strips embedded in mixed recycled aggregate (MRA) from construction & demolition (C&D) waste—Effect of type of fill and compaction. Geotext. Geomembr. 2023, 51, 405–417. [Google Scholar] [CrossRef]

- Abdi, M.R.; Mirzaeifar, H.; Asgardun, Y.; Hatami, K. Assessment of pegged geogrid (PG) pullout performance in coarse-grained soils using PIV analysis. Geotext. Geomembr. 2024, 52, 27–45. [Google Scholar] [CrossRef]

- Abdi, M.R.; Zandieh, A.R. Experimental and numerical analysis of large scale pull out tests conducted on clays reinforced with geogrids encapsulated with coarse material. Geotext. Geomembr. 2014, 42, 494–504. [Google Scholar] [CrossRef]

- Cardile, G.; Gioffrè, D.; Moraci, N.; Calvarano, L.S. Modelling interference between the geogrid bearing members under pullout loading conditions. Geotext. Geomembr. 2017, 45, 169–177. [Google Scholar] [CrossRef]

- Chen, C.; Duan, Y.; Rui, R.; Wang, L. Study of single and two-layer geogrid reinforced ballasted trackbed using pullout test and discrete element method. Rock. Soil. Mech. 2021, 42, 954–962. (In Chinese) [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Pullout behavior of different geosynthetics—Influence of soil density and moisture content. Front. Built Environ. 2020, 6, 12. [Google Scholar] [CrossRef]

- Xu, Y.; Williams, D.J.; Serati, M. Influence of anchorage angles on pull-out resistance of geotextile wrap around anchorage. Geosynth. Int. 2018, 25, 378–391. [Google Scholar] [CrossRef]

- Ezzein, F.M.; Bathurst, R.J. A new approach to evaluate soil-geosynthetic interaction using a novel pullout test apparatus and transparent granular soil. Geotext. Geomembr. 2014, 42, 246–255. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Ezzein, F.M. Geogrid pullout load–strain behaviour and modelling using a transparent granular soil. Geosynth. Int. 2016, 23, 271–286. [Google Scholar] [CrossRef]

- Derksen, J.; Ziegler, M.; Fuentes, R. Geogrid-soil interaction: A new conceptual model and testing apparatus. Geotext. Geomembr. 2021, 49, 1393–1406. [Google Scholar] [CrossRef]

- Dafalla, M.; Obaid, A. The Role of Polypropylene Fibers and Polypropylene Geotextile in Erosion Control. In Proceedings of the Second International Conference on Geotechnical and Earthquake Engineering, Lisboa, Portugal, 21–25 June 2013; pp. 669–676. [Google Scholar] [CrossRef]

- Agrawal, B.J. Geotextile: It’s application to civil engineering–overview. In Proceedings of the National Conference on Recent Trends in Engineering & Technology, Gujarat, India, 13–14 May 2011; pp. 1–6. [Google Scholar]

- Koerner, R.M. Early background and history of geotextiles. In Geotextiles: From Design to Applications; Koerner, R.M., Ed.; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 3–15. ISBN 9780081002346. [Google Scholar] [CrossRef]

- Kiffle, Z.B.; Steele, S.E.; Bhatia, S.K.; Smith, J.L. Use of Jute as a Sustainable Alternative for PP in Geotextile Tubes. In Proceedings of the Geotechnical Frontiers 2017, Orlando, FL, USA, 12–15 March 2017; pp. 369–378. [Google Scholar] [CrossRef]

- Chow, M.F.; Hashrim, H.; Chong, S.T.; Ng, Y.J. Investigating the effectiveness of Water Hyacinth Fiber Mat for Soil Erosion Control. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar] [CrossRef]

- Giménez-Morera, A.; Ruiz Sinoga, J.D.; Cerdà, A. The impact of cotton geotextiles on soil and water losses from mediterranean rainfed agricultural land. Land Degrad. Dev. 2010, 21, 210–217. [Google Scholar] [CrossRef]

- Artidteang, S.; Bergado, D.T.; Tanchaisawat, T.; Saowapakpiboon, J. Investigation of tensile and soil-geotextile interface strength of kenaf woven limited life geotextiles (llgs). Lowl. Technol. Int. 2012, 14, 1–8. [Google Scholar]

- Ramasubbarao, G. Strength behaviour of kerosene coated coir fiber-reinforced expansive soil. Facta Univ.—Ser. Arch. Eng. 2014, 12, 113–120. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Surface Modification of Coir Fibers for Extended Hydrophobicity and Antimicrobial Property for Possible Geotextile Application. J. Nat. Fibers. 2017, 14, 335–345. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Durability studies of surface-modified coir geotextiles. Geotext. Geomembr. 2018, 46, 699–706. [Google Scholar] [CrossRef]

- Marques, A.R.; Santiago de Oliveira Patrício, P.; Soares dos Santos, F.; Monteiro, M.L.; de Carvalho Urashima, D.; de Souza Rodrigues, C. Effects of the climatic conditions of the southeastern Brazil on degradation the fibers of coir-geotextile: Evaluation of mechanical and structural properties. Geotext. Geomembr. 2014, 42, 76–82. [Google Scholar] [CrossRef]

- Adajar, M.A.; Cutora, M.; Bolima, S.J.; Chua, K.J.; Isidro, I.A.; Ramos, J.V. Strength Performance of Nonwoven Coir Geotextiles as an Alternative Material for Slope Stabilization. Appl. Sci. 2023, 13, 7590. [Google Scholar] [CrossRef]

- Lal, D.; Sankar, N.; Chandrakaran, S. Effect of reinforcement form on the behaviour of coir geotextile reinforced sand beds. Soils Found. 2017, 57, 227–236. [Google Scholar] [CrossRef]

- Vinod, P.; Bhaskar, A.B.; Sreehari, S. Behaviour of a square model footing on loose sand reinforced with braided coir rope. Geotext. Geomembr. 2009, 27, 464–474. [Google Scholar] [CrossRef]

- Bhole, C.R.; Sunitha, V.; Mathew, S. Coir Geotextile Reinforcement for Sustainable Pavements: An Experimental Investigation into Structural Behavior. Int. J. Pavement Res. Technol. 2023, 1–14. Available online: https://link.springer.com/article/10.1007/s42947-023-00367-y (accessed on 1 January 2025). [CrossRef]

- Sudarsanan, N.; Mohapatra Sunil, R.; Karpurapu, R.; Amirthalingam, V. Use of Natural Geotextiles to Retard Reflection Cracking in Highway Pavements. J. Mater. Civ. Eng. 2018, 30, 04018036. [Google Scholar] [CrossRef]

- Anusudha, V.; Sunitha, V.; Mathew, S. Performance of coir geotextile reinforced subgrade for low volume roads. Int. J. Pavement Res. Technol. 2021, 14, 213–221. [Google Scholar] [CrossRef]

- Harinder, D.; Shankar, S. 10—Behavior assessment of poor subgrade soil using natural coir geotextile under static and repeated load condition. In Green Materials in Civil Engineering; GuhaRay, A., Hata, T., Iyer, N.R., Samui, P., Kumar, S., Eds.; Woodhead Publishing: Sawston, UK, 2024; pp. 153–164. [Google Scholar] [CrossRef]

- Yang, G. Lateral Deformation Characteristics of Geogrid Reinforced Earth Retaining Wall. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2005. (In Chinese). [Google Scholar]

- Wang, J.; Qi, H.; Lin, Z.; Tang, Y. Pullout test on geosynthetic reinforced sand based on digital image analysis. Rock. Soil. Mech. 2022, 43, 3259–3269. (In Chinese) [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.; Lin, Z.; Wang, X. Spatiotemporal evolution rule of rocks fracture surrounding gob-side roadway with model experiments. Int. J. Min. Sci. Technol. 2016, 26, 895–902. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, D.; Li, A.; Lu, S.; Tai, Q.; Chu, Z. Model test and numerical analysis for the face failure mechanism of large cross-section tunnels under different ground conditions. Tunn. Undergr. Space Technol. 2022, 130, 104735. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Q.; Ma, B.; Li, Z.; Yin, W.; Lou, Q. Study on surface roughness effect on shear behavior of concrete-soil interface. Eng. Fail. Anal. 2023, 145, 107050. [Google Scholar] [CrossRef]

- JTG E50-2006; Test Method of Geosynthetics for Highway Engineering. Research Institute of Highway Science Ministry of Transport: Beijing, China, 2006. (In Chinese)

- Ye, Y. Study on Pullout Test Based on Transparent Soil Technology. Master’s Thesis, Tongji University, Shanghai, China, 2018. (In Chinese). [Google Scholar]

- Cai, X.; Feng, J.; Liu, W.; Li, S.; Huang, X.; Xu, H. Experimental study on interface friction characteristics of geosynthetics. Build. Struct. 2023; in press. (In Chinese). [Google Scholar] [CrossRef]

- Zhou, J.; Chen, J.; Xue, J.; Wang, J. Micro-mechanism of the interaction between sand and geogrid transverse ribs. Geosynth. Int. 2012, 19, 426–437. [Google Scholar] [CrossRef]

- Mirzaalimohammadi, A.; Ghazavi, M.; Lajevardi, S.H.; Roustaei, M. Experimental Investigation on Pullout Behavior of Geosynthetics with Varying Dimension. Int. J. Geomech. 2021, 21, 04021089. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).