Nutritional Profiling of Underutilised Citrullus lanatus mucosospermus Seed Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Source of Egusi Seed, Chemicals, and Reagents

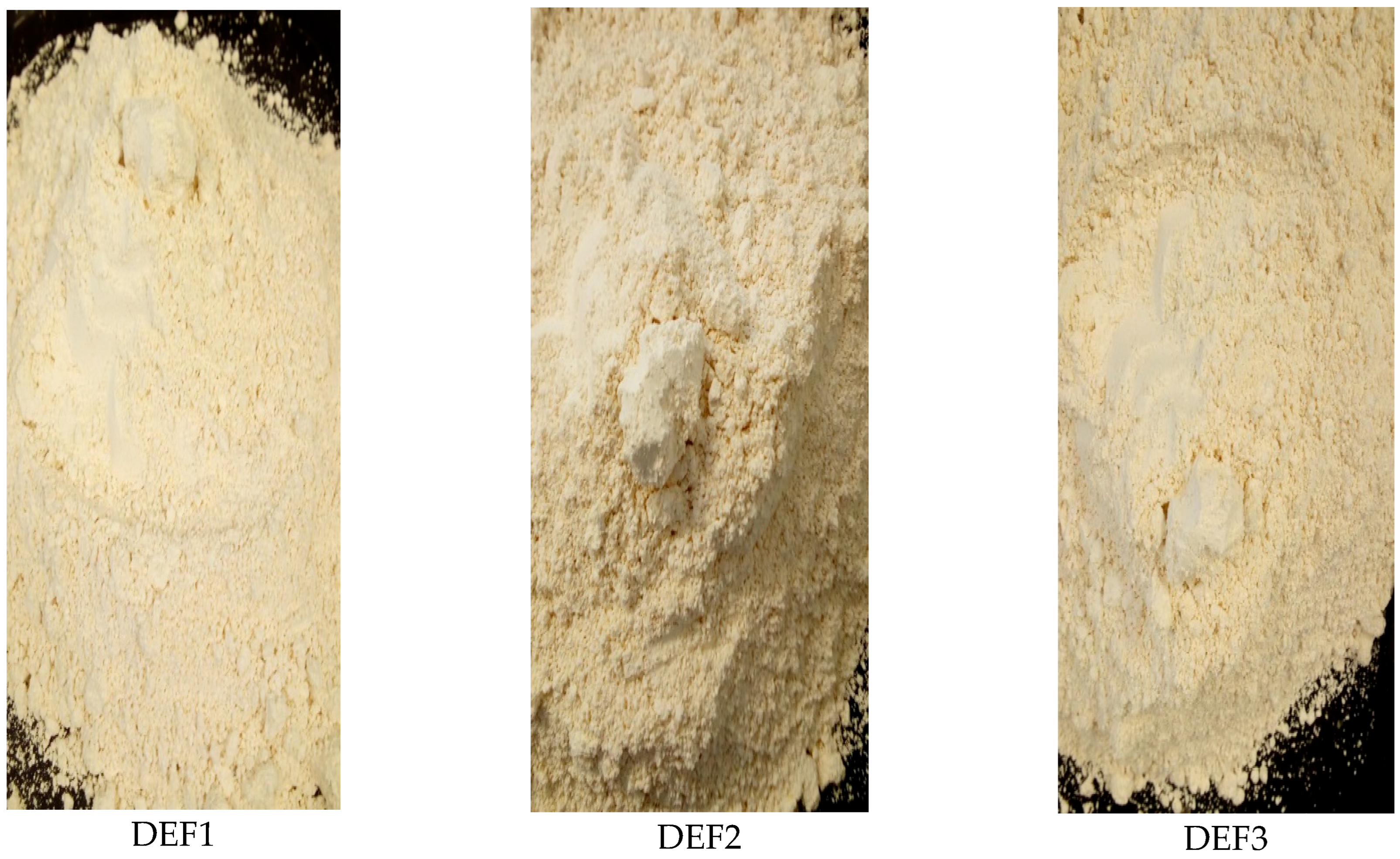

2.2. Production of Defatted Egusi Flour Using Supercritical CO2 Extraction

2.3. Macro and Micronutrient Composition of Defatted Egusi Flour

2.3.1. Proximate Analysis of Defatted Egusi Flour

2.3.2. Amino Acid Profiling of Defatted Egusi Flour

Reagent Preparation

Derivatisation Procedure of Amino Acids

Chromatographic Analysis of Amino Acids

2.3.3. The Mineral Content of Defatted Egusi Flour

Sample Digestion

Trace Element Analysis

Major Element Analysis

2.3.4. Sugars in Defatted Egusi Flour

2.4. Functional Properties of Defatted Egusi Flour

2.4.1. Water Absorption and Solubility Index of Defatted Egusi Flour

2.4.2. Pasting Properties of Defatted Egusi Flour

2.5. Statistical Data Analysis

3. Results and Discussion

3.1. Effect of Supercritical CO2 Extraction on the Proximate Composition of Egusi Flour

3.2. Effect of Supercritical CO2 Defatting on the Amino Acid Composition of Defatted Egusi Flour

3.3. Mineral Composition of Defatted Egusi Flour

3.4. Sugars of Defatted Egusi Flour

3.5. Effect of Extraction Condition on Functional Properties of Defatted Egusi Flour

3.6. Effect of Extraction Condition on Pasting Properties of Defatted Egusi Flour

3.7. Conclusions

3.8. Significance Statement

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paudel, L.; Clevenger, J.; McGregor, C. Refining of the egusi locus in watermelon using KASP assays. Sci. Hortic. 2019, 257, 108665. [Google Scholar] [CrossRef]

- Frazzoli, C.; Mazzanti, F.; Achu, M.B.; Pouokam, G.B.; Fokou, E. Elements of kitchen toxicology to exploit the value of traditional (African) recipes: The case of Egusi Okra meal in the diet of HIV+/AIDS subjects. Toxicol. Rep. 2017, 4, 474–483. [Google Scholar] [CrossRef]

- Olubi, O.; Felix-minnaar, J.V.; Jideani, V.A. Physicochemical, mineral and sensory characteristics of Instant Citrullus lanatus mucosospermus (Egusi) Soup. Foods 2021, 10, 1817. [Google Scholar]

- Mashilo, J.; Shimelis, H.; Ngwepe, R.M. Genetic resources of bottle gourd (Lagenaria siceraria (Molina) Standl.] and citron watermelon (Citrullus lanatus var. citroides (L.H. Bailey) Mansf. ex Greb.)-implications for genetic improvement, product development and commercialization: A review. S. Afr. J. Bot. 2022, 145, 28–47. [Google Scholar] [CrossRef]

- Efavi, J.; Kanbogtah, D.; Apalangya, V.; Nyankson, E.; Tiburu, E.; Dodoo-Arhin, D.; Onwona-Agyeman, B.; Yaya, A. The effect of NaOH catalyst concentration and extraction time on the yield and properties of Citrullus vulgaris seed oil as a potential biodiesel feed stock. S. Afr. J. Chem. Eng. 2018, 25, 98–102. [Google Scholar] [CrossRef]

- Liu, X.; Jia, X.; Liu, W.; Nie, B.; Zhang, C.; Song, D. Geoenergy Science and Engineering Mechanical strength and porosity changes of bituminous coal induced by supercritical CO2 interactions: Influence of saturation pressure. Geoenergy Sci. Eng. 2023, 225, 211691. [Google Scholar] [CrossRef]

- Liu, H.; Ye, C.; Zhao, Y.; Li, G.; Xu, Y.; Tang, Y. Chemical Engineering and Processing—Process Intensification Performance analysis of biomass gasification coupled with ultra-supercritical power generation system. Chem. Eng. Process—Process Intensif. 2022, 179, 109093. [Google Scholar] [CrossRef]

- Guzmán-Albores, J.M.; Bojórquez-Velázquez, E.; De León-Rodríguez, A.; de Jesús Calva-Cruz, O.; de la Rosa, A.P.B.; Ruíz-Valdiviezo, V.M. Comparison of Moringa oleifera oils extracted with supercritical fluids and hexane and characterization of seed storage proteins in defatted flour: Moringa seed characterization. Food Biosci. 2021, 40, 100830. [Google Scholar] [CrossRef]

- Vatansever, S.; Whitney, K.; Ohm, J.B.; Simsek, S.; Hall, C. Physicochemical and multi-scale structural alterations of pea starch induced by supercritical carbon dioxide + ethanol extraction. Food Chem. 2021, 344, 128699. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Chen, L.; Zang, J.; Huang, Y.; Chen, H. The Journal of Supercritical Fluids Experimental characterization and analysis of supercritical jet dynamics by phase-shifting interferometer system. J. Supercrit. Fluids 2022, 189, 105724. [Google Scholar] [CrossRef]

- Huang, C.; Li, Z. Data-driven modeling of ultra-supercritical unit coordinated control system by improved transformer network. Energy 2023, 266, 126473. [Google Scholar] [CrossRef]

- Sharma, A.; Ray, A.; Singhal, R.S. A biorefinery approach towards valorization of spent coffee ground: Extraction of the oil by supercritical carbon dioxide and utilizing the defatted spent in formulating functional cookies. Futur. Foods 2021, 4, 100090. [Google Scholar] [CrossRef]

- Olubi, O.; Felix-Minnaar, J.; Jideani, V. Physicochemical and fatty acid profile of egusi oil from supercritical carbon dioxide extraction. Heliyon 2019, 5, e01083. [Google Scholar] [CrossRef] [PubMed]

- Bulbul, V.J.; Bhushette, P.R.; Zambare, R.S.; Deshmukh, R.R.; Annapure, U.S. Effect of cold plasma treatment on Xanthan gum properties. Polym. Test. 2019, 79, 106056. [Google Scholar] [CrossRef]

- Li, C.; He, M.; Yun, Y.; Peng, Y. Co-infection with Wolbachia and Cardinium may promote the synthesis of fat and free amino acids in a small spider, Hylyphantes graminicola. J. Invertebr. Pathol. 2020, 169, 107307. [Google Scholar] [CrossRef] [PubMed]

- ISO 9001; Quality Management Systems. International Organization for Standardization: Geneva, Switzerland, 2015.

- Tyagi, R.; Sharma, P.; Nautiyal, R.; Lakhera, A.K.; Kumar, V. Synthesis of quaternised guar gum using Taguchi L(16) orthogonal array. Carbohydr. Polym. 2020, 237, 116136. [Google Scholar] [CrossRef] [PubMed]

- Nour, A.A.M.; Mohamed, A.R.; Adiamo, O.Q.; Babiker, E.E. Changes in protein nutritional quality as affected by processing of millet supplemented with Moringa seed flour. J. Saudi Soc. Agric. Sci. 2018, 17, 275–281. [Google Scholar]

- Famakinwa, A.; Shuttleworth, A.; Lubisi, S.; Olubi, O.; Oguntibeju, O.O.; Obilana, A. Chemical and Functional Properties of Snacks Produced from Wheat Flour Fortified with Moringa Oleifera Leaf Powder. Afr. J. Food Agric. Nutr. Dev. 2023, 23, 24467–24486. [Google Scholar] [CrossRef]

- Yousaf, L.; Hou, D.; Liaqat, H.; Shen, Q. Millet: A review of its nutritional and functional changes during processing. Food Res. Int. 2021, 142, 110197. [Google Scholar] [CrossRef]

- Gomez, L.; Alvarez, C.; Zhao, M.; Tiwari, U.; Curtin, J.; Garcia-Vaquero, M.; Tiwari, B. Innovative processing strategies and technologies to obtain hydrocolloids from macroalgae for food applications. Carbohydr. Polym. 2020, 248, 116784. [Google Scholar] [CrossRef]

- Bindereif, B.; Karbstein, H.P.; van der Schaaf, U.S. Sugar beet pectins for the formulation of dressings and soft drinks: Understanding the complexity of charged hydrocolloids in industrial food emulsions. Food Hydrocoll. 2023, 135, 108054. [Google Scholar] [CrossRef]

- Kumar, S.; Haq R ul Prasad, K. Studies on physico-chemical, functional, pasting and morphological characteristics of developed extra thin flaked rice. J. Saudi Soc. Agric. Sci. 2018, 17, 259–267. [Google Scholar] [CrossRef]

- El-Adawy, T.A.; Taha, K.M. Characteristics and composition of watermelon, pumpkin, and paprika seed oils and flours. J. Agric. Food Chem. 2001, 49, 1253–1259. [Google Scholar] [CrossRef] [PubMed]

- Santamaria, M.; Garzon, R.; Rosell, C.M. Impact of starch-hydrocolloid interaction on pasting properties and enzymatic hydrolysis. Food Hydrocoll. 2023, 142, 108764. [Google Scholar] [CrossRef]

- Veli, D. Effects of supercritical CO2 extraction parameters on Stela Joki. Food Bioprod. Process 2012, 90, 693–699. [Google Scholar]

- Ehsan, M.M.; Awais, M.; Lee, S.; Salehin, S.; Guan, Z.; Gurgenci, H. Potential prospects of supercritical CO2 power cycles for commercialisation: Applicability, research status, and advancement. Renew. Sustain. Energy Rev. 2023, 172, 113044. [Google Scholar] [CrossRef]

- Irondi, E.A.; Imam, Y.T.; Ajani, E.O.; Alamu, E.O. Natural and modified food hydrocolloids as gluten replacement in baked foods: Functional benefits. Grain Oil Sci. Technol. 2023, 6, 163–171. [Google Scholar] [CrossRef]

- Li, J.; Yadav, M.P.; Li, J. Effect of different hydrocolloids on gluten proteins, starch and dough microstructure. J. Cereal Sci. 2019, 87, 85–90. [Google Scholar] [CrossRef]

- Lamminen, M.; Halmemies-beauchet-filleau, A.; Kokkonen, T.; Jaakkola, S. Different microalgae species as a substitutive protein feed for soya bean meal in grass silage based dairy cow diets. Anim. Feed. Sci. Technol. 2019, 247, 112–126. [Google Scholar] [CrossRef]

- Hedayati, S.; Niakousari, M.; Babajafari, S.; Mazloomi, S.M. Ultrasound-assisted extraction of mucilaginous seed hydrocolloids: Physicochemical properties and food applications. Trends Food Sci. Technol. 2021, 118, 356–361. [Google Scholar] [CrossRef]

- Alves-Santos, A.M.; Sugizaki, C.S.A.; Lima, G.C.; Naves, M.M.V. Prebiotic effect of dietary polyphenols: A systematic review. J. Funct. Foods. 2020, 74, 104169. [Google Scholar] [CrossRef]

- Zhou, S.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Effect of heat-moisture treatment on the in vitro digestibility and physicochemical properties of starch-hydrocolloid complexes. Food Hydrocoll. 2020, 104, 105736. [Google Scholar] [CrossRef]

- Praveen, M.A.; Parvathy, K.R.K.; Jayabalan, R.; Balasubramanian, P. Dietary fiber from Indian edible seaweeds and its in-vitro prebiotic effect on the gut microbiota. Food Hydrocoll. 2019, 96, 343–353. [Google Scholar] [CrossRef]

- de Oliveira, D.C.; Santos, E.W.; Nogueira-Pedro, A.; Xavier, J.G.; Borelli, P.; Fock, R.A. Effects of short-term dietary restriction and glutamine supplementation in vitro on the modulation of inflammatory properties. Nutrition 2018, 48, 96–104. [Google Scholar] [CrossRef] [PubMed]

- Olubi, O.; Obilana, A.; Tshilumbu, N.; Fester, V.; Jideani, V. Physicochemical and Functional Properties of Citrullus mucosospermus, Citroides, and Moringa oleifera Seeds’ Hydrocolloids. Foods 2024, 13, 1131. [Google Scholar] [CrossRef]

- Akande, K.E. Proximate and Amino acid Analyses of Full-fat Sunflower (Helianthus annuus L.). Seed Meal. Singap. J. Sci. Res. 2011, 1, 179–183. [Google Scholar] [CrossRef]

- Wang, P.; Gao, Y.; Wang, D.; Huang, Z.; Fei, P. Amidated pectin with amino acids: Preparation, characterization and potential application in Hydrocolloids. Food Hydrocoll. 2022, 129, 107662. [Google Scholar] [CrossRef]

- John, S. The Recent WHO/FAO/UNU Requirement Pattern for Indispensable Amino Acids and Their Implication. J. Nutr. 2008, 138, 130–140. [Google Scholar]

- Astorga-españa, M.S.; Rodríguez-galdón, B.; Rodríguez-rodríguez, E.M.; Díaz-romero, C. Amino acid content in seaweeds from the Magellan Straits (Chile). J. Food Compos. Anal. 2016, 53, 77–84. [Google Scholar] [CrossRef]

- Gouda, N.; Singh, R.K.; Meher, S.N.; Panda, A.K. Production and characterization of bio oil and bio char from flax seed residue obtained from supercritical fluid extraction industry. J. Energy Inst. 2017, 90, 265–275. [Google Scholar] [CrossRef]

- Perakis, C.; Louli, V.; Magoulas, K. Supercritical fluid extraction of black pepper oil. J. Food Eng. 2005, 71, 386–393. [Google Scholar] [CrossRef]

- Gravelle, A.J.; Marangoni, A.G. Effect of matrix architecture on the elastic behavior of an emulsion-filled polymer gel. Food Hydrocoll. 2021, 119, 106875. [Google Scholar] [CrossRef]

- Grasso, S.; Liu, S.; Methven, L. Quality of mu ffi ns enriched with upcycled defatted sun flower seed flour. LWT—Food Sci. Technol. 2020, 119, 108893. [Google Scholar] [CrossRef]

- Nkoana, D.K.; Mashilo, J.; Shimelis, H.; Ngwepe, R.M. Nutritional, phytochemical compositions and natural therapeutic values of citron watermelon (Citrullus lanatus var. citroides): A Review. S. Afr. J. Bot. 2022, 145, 65–77. [Google Scholar] [CrossRef]

- Al-Farga, A.; Zhang, H.; Siddeeg, A.; Shamoon, M.; Chamba, M.V.; Al-Hajj, N. Proximate composition, functional properties, amino acid, mineral and vitamin contents of a novel food: Alhydwan (Boerhavia elegana Choisy) seed flour. Food Chem. 2016, 211, 268–273. [Google Scholar] [CrossRef] [PubMed]

- Famakinwa, A.; Ngcoko, A.; Nicholas, E.; Olubi, O.; Oguntibeju, O.O.; Van Wyk, J.; Obilana, A. Chemical and functional properties of Nutrient dense beverages develpoed from underutilised crop. Plant Sci. Today 2023, 46, 649–656. [Google Scholar]

- Fiori, L. Supercritical extraction of sunflower seed oil: Experimental data and model validation. J. Supercrit. Fluids 2009, 50, 218–224. [Google Scholar] [CrossRef]

- Hamdani, A.M.; Wani, I.A.; Bhat, N.A. Sources, structure, properties and health benefits of plant gums: A review. Int. J. Biol. Macromol. 2019, 135, 46–61. [Google Scholar] [CrossRef]

- Spies, R.D.; Hoseney, R.C. Effect of sugars on starch gelatinization. Cereal Chem. 1982, 59, 128. [Google Scholar]

- Abudayeh ZH, M.; Lamazian, H.R.; Sereda, P.; Chekman, I.; Khalifa, I.; Azzam, K.M.A.; Hassouneh, L.K.M. Comparative Study of Amino Acid Composition in the Seeds, Pulp and Rind from Citurllus colocynthis Fruits. Int. J. Pharmacogn. Phytochem. Res. 2016, 8, 433–437. [Google Scholar]

- Bemiller, J.N. Pasting, paste, and gel properties of starch-hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

| Defatted Egusi Flour 1,2 | ||||

|---|---|---|---|---|

| Proximate (%) | Raw Egusi | DEF1 | DEF2 | DEF3 |

| Moisture | 8.1 ± 0.0 a | 10.1 ± 0.0 a | 6.6 ± 0.5 b | 5.3 ± 0.0 c |

| Crude protein | 28.4 ± 0.0 a | 60.4 ± 0.1 a | 48.4 ± 0.4 b | 60.1 ± 0.6 a |

| Crude fat | 52.0 ± 0.0 a | 0.6 ± 0.0 b | 0.4 ± 0.0 b | 0.7 ± 0.0 b |

| Carbohydrate | 5.2 ± 0.0 a | 19.5 ± 1.3 b | 34.9 ± 1.7 c | 23.4 ± 2.3 c |

| Fibre | 2.7 ± 0.1 a | 4.4 ± 0.3 a | 3.4 ± 0.3 b | 4.4 ± 0.4 a |

| Ash | 3.6 ± 0.0 a | 5.0 ± 1.3 a | 6.3 ± 1.9 a | 6.1 ± 2.5 a |

| Defatted Egusi Flour 1,2 | |||

|---|---|---|---|

| Amino Acids (g/100 g) | DEF1 | DEF2 | DEF3 |

| Essential | |||

| Histamine | 1.5 ± 0.0 a | 1.4 ± 0.1 b | 1.1 ± 0.0 c |

| Methionine | 1.9 ± 0.3 a | 1.8 ± 0.1 ab | 2.3 ± 0.1 c |

| Valine | 2.9 ± 0.1 a | 2.7 ± 0.1 b | 7.64 ± 0.3 b |

| Isoleucine | 2.2 ± 0.2 a | 2.1 ± 0.1 b | 2.8 ±0.2 c |

| Threonine | 1.5 ± 1.4 a | 2.0 ± 0.2 a | 4.4 ± 0.2 c |

| Leucine | 4.31 ± 0.1 a | 4.21 ± 0.0 b | 1.1 ± 1.0 a |

| Phenylalanine | 3.09 ± 0.3 a | 2.95 ± 0.1 b | 2.4 ± 0.1 a |

| Non-Essential | |||

| Glutamic | 12.9 ± 1.0 a | 11.8 ± 1.0 c | 2.1 ± 0.2 a |

| Proline | 2.4 ± 0.2 a | 2.2 ± 0.1 b | 1.4 ± 0.1 a |

| Defatted Egusi Flour 1,2 | |||

|---|---|---|---|

| Mineral (mg/100 g) | DEF1 | DEF2 | DEF3 |

| B | 2.7 ± 0.11 a | 3.3 ± 0.045 b | 3.6 ± 0.22 b |

| Al | 17.1 ± 0.29 a | 8.6 ± 0.07 c | 11.0 ± 0.02 b |

| Ti | 0.7 ± 0.01 a | 0.5 ± 0.01 b | 0.6 ± 0.02 c |

| Cr | 0.3 ± 0.00 a | 0.1 ± 0.00 b | 0.1 ± 0.00 a |

| Mn | 7.7 ± 0.12 a | 7.8 ± 0.05 b | 8.5 ± 0.14 c |

| Fe | 44.4 ± 0.54 a | 26.7 ± 0.11 c | 33.0 ± 0.56 b |

| Ni | 0.5 ± 0.01 a | 0.4 ± 0.01 a | 0.5 ± 0.01 b |

| Cu | 3.7 ± 0.07 a | 3.9 ± 0.06 b | 4.1 ± 0.08 c |

| Zn | 9.6 ± 0.15 a | 12.0 ± 0.16 b | 12.8 ± 0.21 c |

| Sr | 0.9 ± 0.00 a | 1.1 ± 0.01 b | 1.2 ± 0.02 c |

| Mo | 0.2 ± 0.00 a | 0.3 ± 0.01 b | 0.4 ± 0.01 c |

| Ba | 0.8 ± 0.07 a | 0.8 ± 0.05 a | 0.8 ± 0.02 a |

| Si | 14.0 ± 0.11 a | 10.7 ± 0.04 b | 12.7 ± 0.12 c |

| Ca | 166.8 ± 0.79 a | 186.1 ± 0.96 b | 201.27 ± 1.26 c |

| K | 1208.1 ± 17.34 a | 1298.6 ± 15.34 b | 1413.3 ± 18.58 c |

| Mg | 807.5 ± 2.16 a | 880.1 ± 2.03 b | 957.8 ±13.52 c |

| Na | 3.4 ±10.11 a | 8.5 ± 0.15 b | 9.4 ± 0.11 c |

| P | 1698.9 ± 8.52 a | 1877. 8 ± 8.21 b | 2046.4 ± 5.95 c |

| Defatted Egusi Flour 1,2 | |||

|---|---|---|---|

| Sugars | DEF1 | DEF2 | DEF3 |

| D–fructose | 2.2 ± 0.21 a | 2.4 ± 0.37 b | 1.4 ± 0.12 ab |

| D–galactose | 0.8 ± 0.00 a | 0.9 ± 0.12 a | 0.4 ± 0.05 b |

| Mannose | 0.1 ± 0.05 a | 0.2 ± 0.10 b | 0.7 ± 0.17 c |

| Glucose | 0.8 ± 0.14 a | 1.0 ± 0.19 a | 0.8 ± 0.11 a |

| Mannitol | 8.0 ± 0.37 a | 9.0 ± 1.45 a | 0.8 ± 0.13 b |

| Sorbitol | 8.2 ± 0.41 a | 9.2 ± 1.53 a | 4.0 ± 0.54 b |

| Sucrose | 106. 4 ± 75.00 a | 109.4 ± 97.54 a | 86.5 ± 13.32 b |

| Trehalose | 2.2 ± 0.75 a | 2.0 ± 0.81 a | 1.9 ± 0.29 a |

| Defatted Egusi Flour 1,2 | ||||

|---|---|---|---|---|

| Parameters (% w/w) | DEF1 | DEF2 | DEF3 | |

| WAI | 56.3 ± 2.4 a | 52.5 ± 3.7 b | 57.6 ± 3.2 a | |

| WSI | 68.0 ± 4.0 a | 65. 3 ± 6.1 b | 73.3 ± 6.1 c | |

| Defatted Egusi Flour 1,2 | |||

|---|---|---|---|

| Parameter (cP) | DEF1 | DEF2 | DEF3 |

| Peak viscosity | 386.0 ± 51.80 a | 512.0 ± 13.00 b | 398.3 ± 9.61 c |

| Breakdown viscosity | 306.0 ± 45.21 a | 373.0 ± 36.72 b | 191.3 ± 10.97 c |

| Holding strength | 53.3 ± 4.92 a | 57.7 ± 3.51 b | 49.0 ± 2.00 c |

| Pasting temperature (°C) | 92.7 ± 1.31 a | 93.0 ± 0.50 a | 93.8 ± 0.25 a |

| Final viscosity | 126.7 ± 2.30 a | 123.7 ± 2.08 a | 126.3 ± 1.15 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olubi, O.; Felix-Minnaar, J.; Jideani, V.A. Nutritional Profiling of Underutilised Citrullus lanatus mucosospermus Seed Flour. Appl. Sci. 2024, 14, 3709. https://doi.org/10.3390/app14093709

Olubi O, Felix-Minnaar J, Jideani VA. Nutritional Profiling of Underutilised Citrullus lanatus mucosospermus Seed Flour. Applied Sciences. 2024; 14(9):3709. https://doi.org/10.3390/app14093709

Chicago/Turabian StyleOlubi, Olakunbi, Joseline Felix-Minnaar, and Victoria A. Jideani. 2024. "Nutritional Profiling of Underutilised Citrullus lanatus mucosospermus Seed Flour" Applied Sciences 14, no. 9: 3709. https://doi.org/10.3390/app14093709

APA StyleOlubi, O., Felix-Minnaar, J., & Jideani, V. A. (2024). Nutritional Profiling of Underutilised Citrullus lanatus mucosospermus Seed Flour. Applied Sciences, 14(9), 3709. https://doi.org/10.3390/app14093709