Double Unloading Gas Control Technology for Fracturing Soft Coal Seams in Overlying Key Strata

Abstract

1. Introduction

2. Method

2.1. Theory

2.2. Coal Seam General Situation and Model Parameters

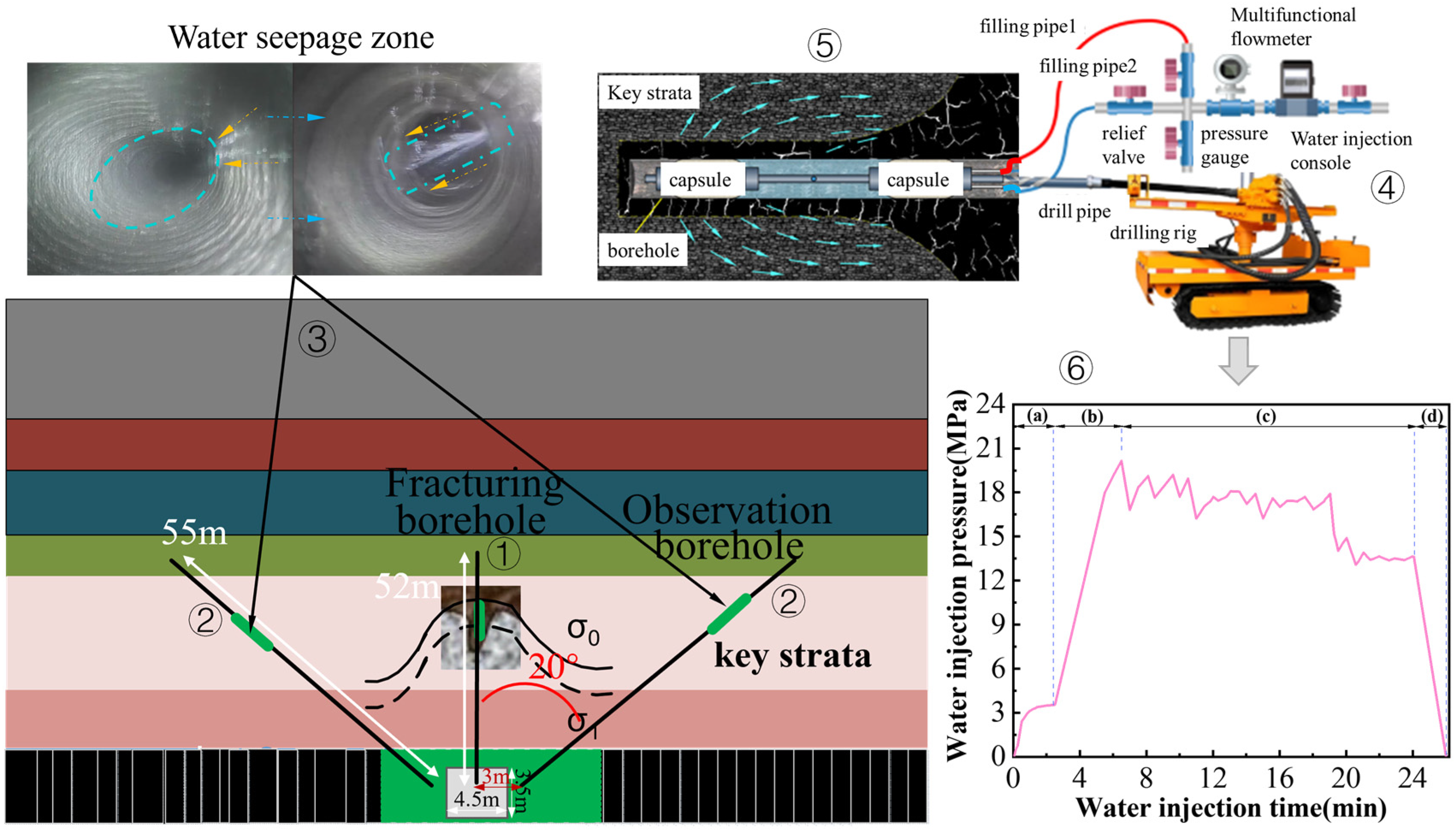

2.3. Hydraulic Fracturing Radius Determination

2.3.1. Determination of Key Strata of Overlying Rock Strata

- Determine hard rock stratum according to load

- 2.

- Calculate the breaking distance of the hard rock stratum

- 3.

- Determine the key strata according to the breaking distance

2.3.2. Determination of Crack Initiation Pressure

2.3.3. Determination of Fracturing Radius

2.4. Establishing Numerical Models

2.4.1. Mathematical Modeling

- Seepage equations of motion

- 2.

- Control equation for coal deformation

- 3.

- Other equations

2.4.2. Establishing Physical Models

3. Analysis of Simulation Results

3.1. Coal Seam Stress–Energy Change Rule before and after Key Strata Stress Removal

3.1.1. Coal Seam Stress Change Rule

3.1.2. Coal Seam Energy Change Rule

3.2. Coal Seam Permeability Change Rule

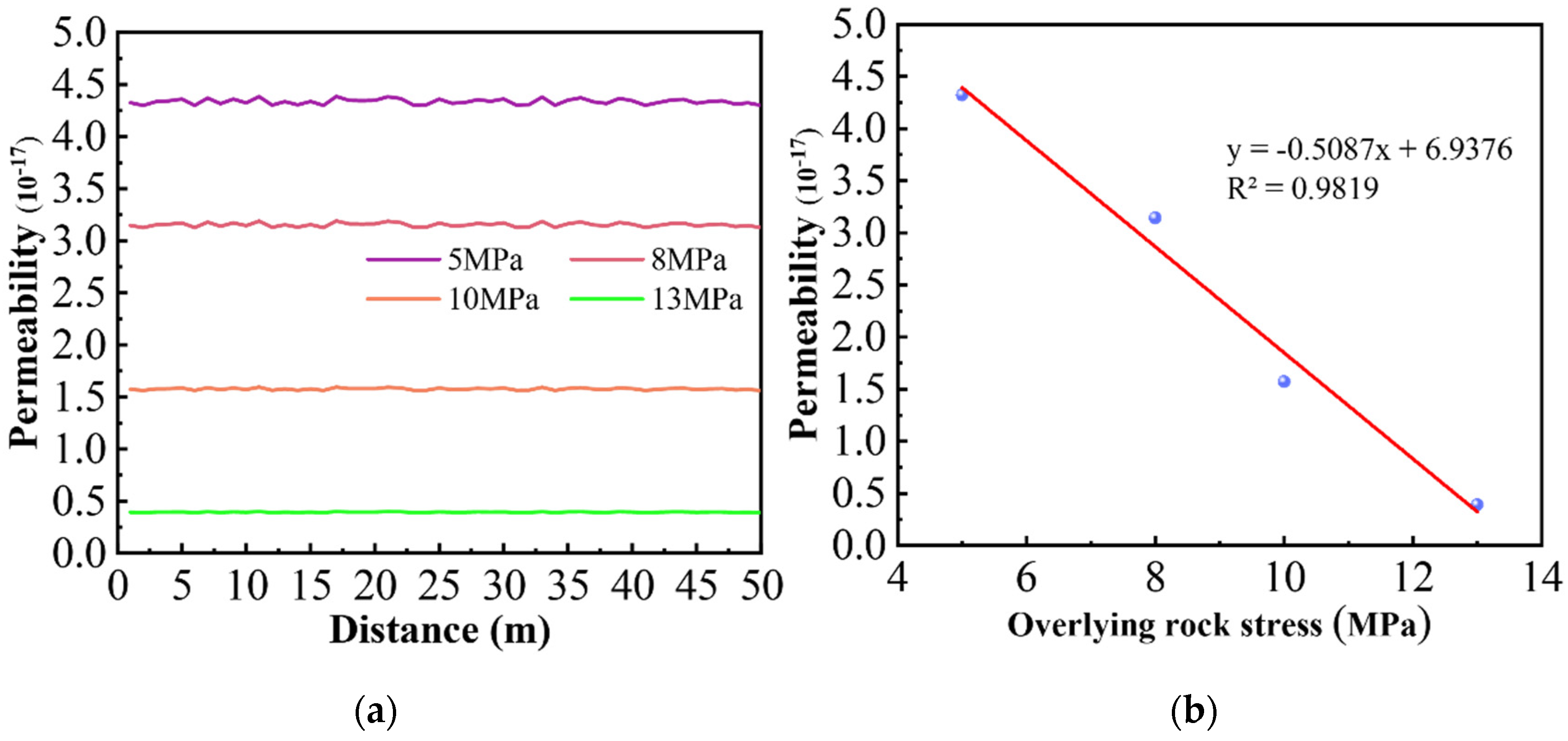

3.2.1. Change Rule of Key Strata Unloading Permeability

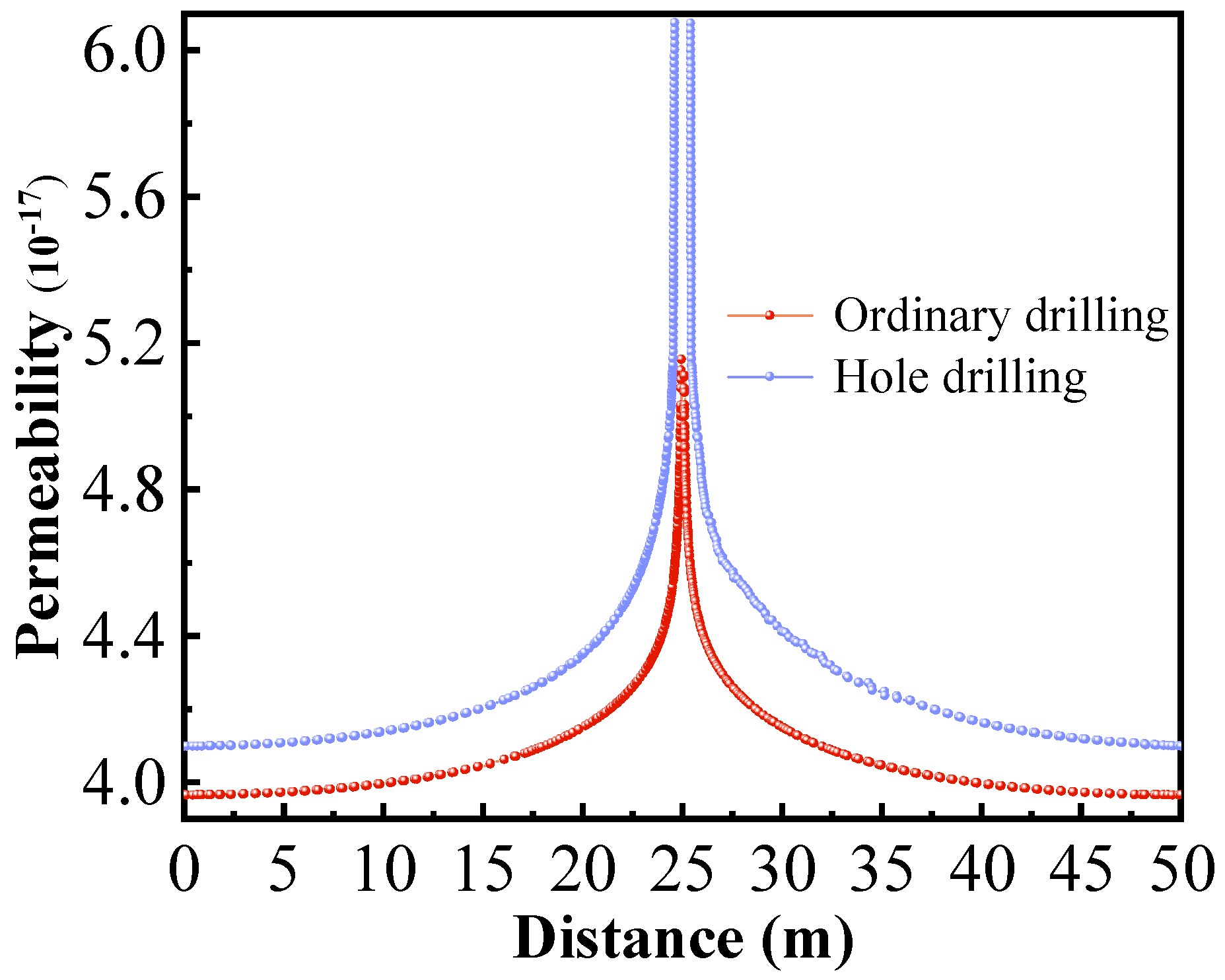

3.2.2. Change Rule in Permeability of Large-Diameter Borehole

3.2.3. Change Rule of Double Unloading Permeability

3.3. Drilling and Extraction Rules before and after Stress Relief of Key Strata

3.3.1. Gas Pressure Distribution in Extraction Boreholes

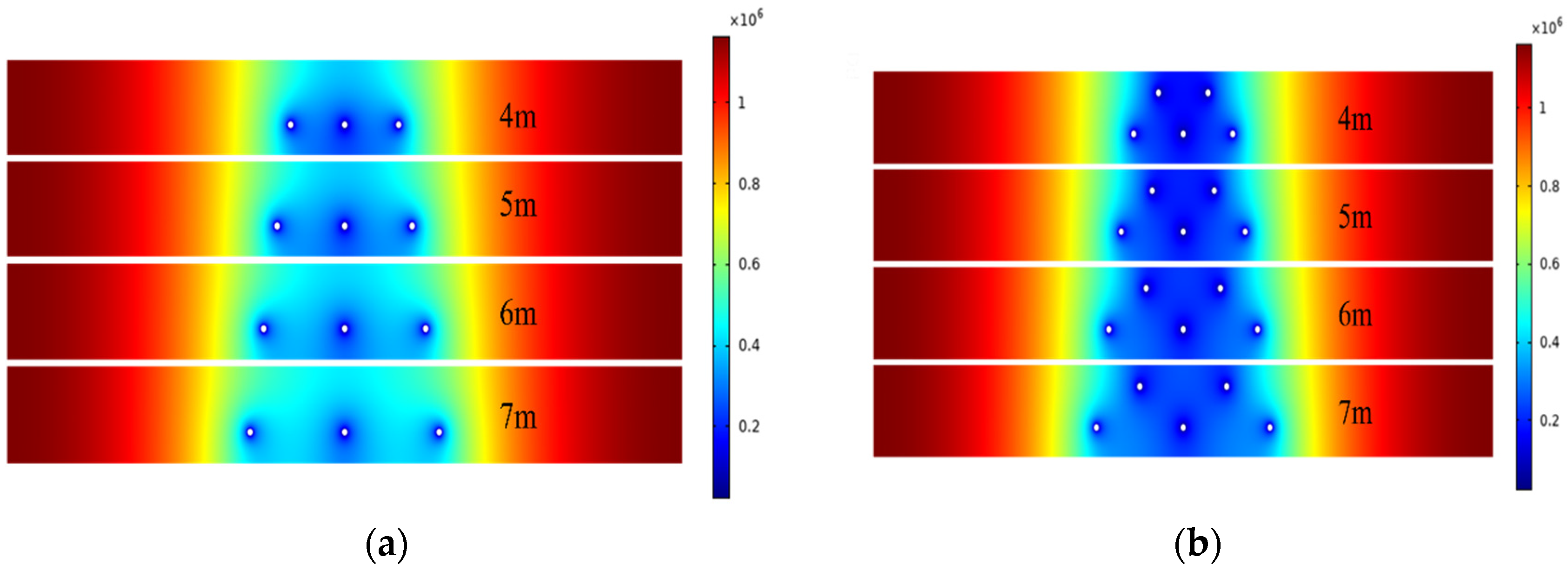

3.3.2. Effective Extraction Radius

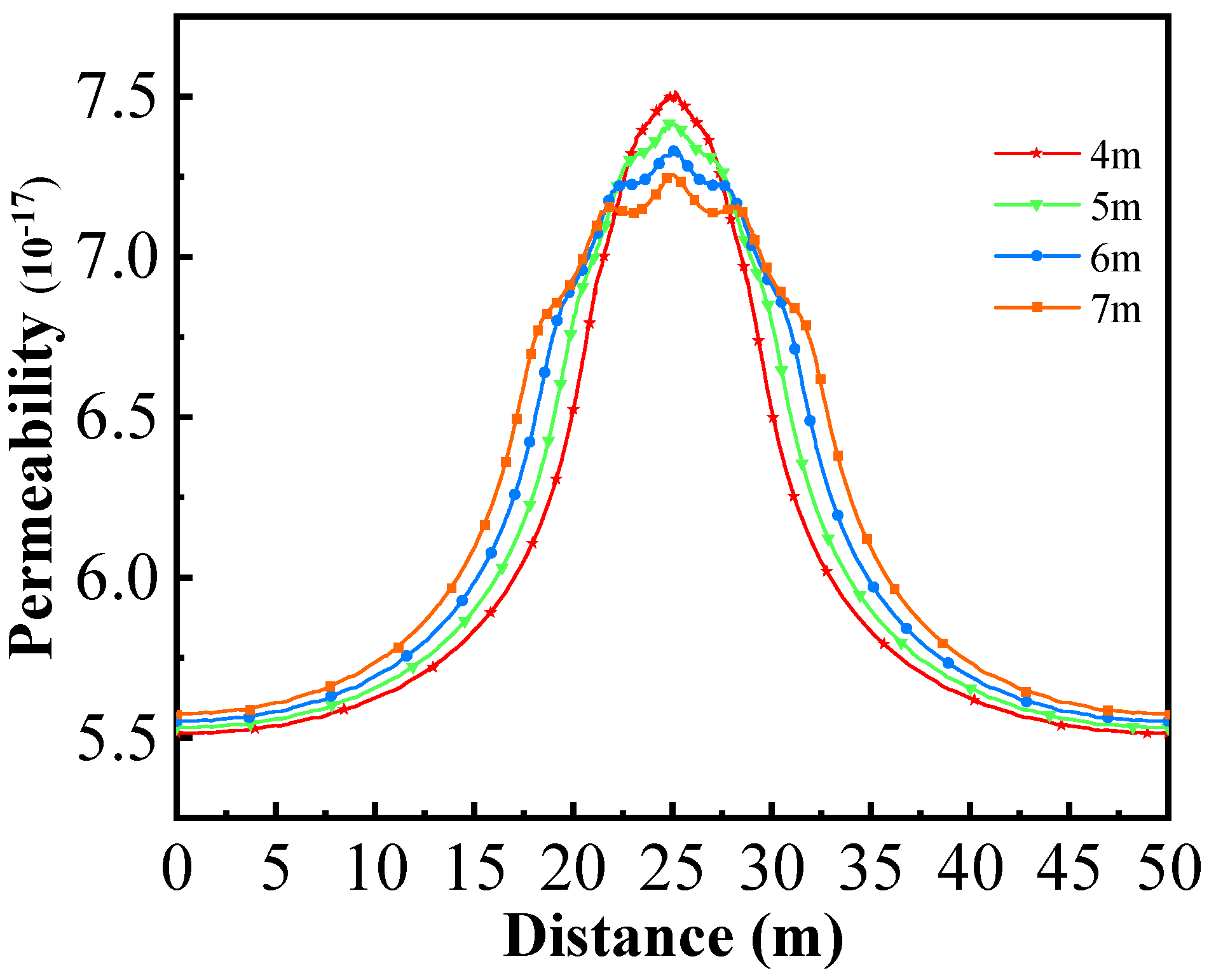

3.3.3. Optimization of Hole Drilling Arrangement Parameters

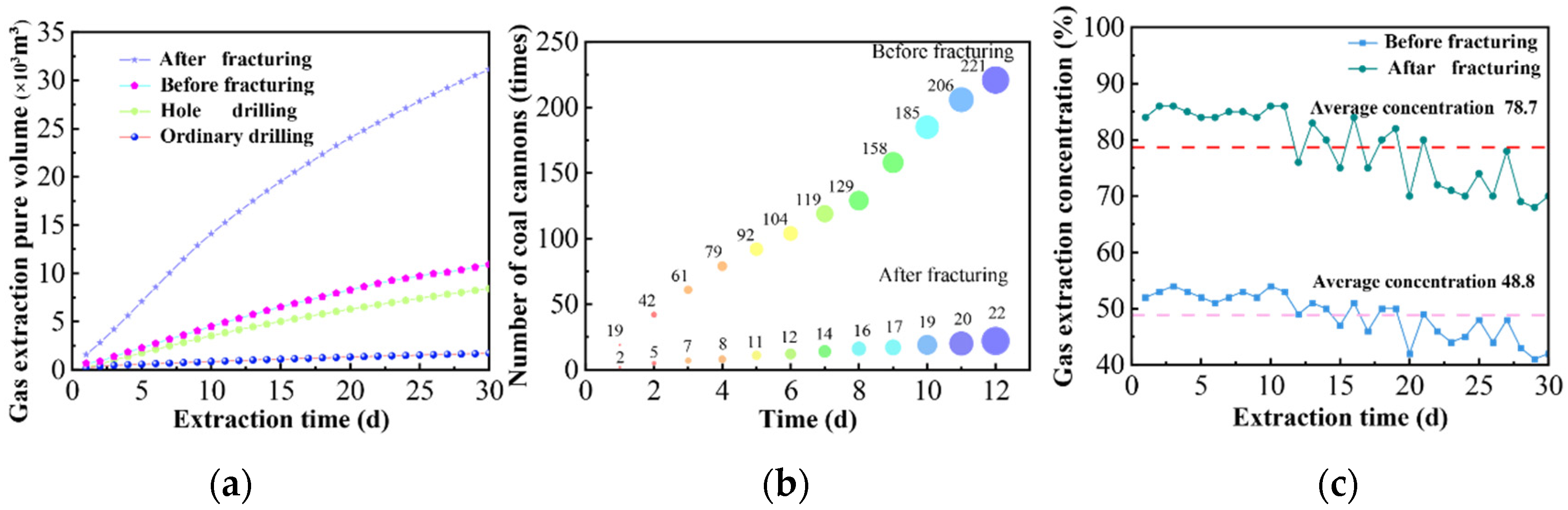

4. Field Practice Effect Analysis

4.1. Working Face Conditions and Drilling Arrangement

4.2. On-Site Implementation

5. Conclusions

- Following hydraulic fracturing of the overlying key strata, a new stress field known as the ‘three zones’ was created. The average peak stress on both sides of the coal seam roadway decreased by 3.35 MPa, with the energy peak decreasing by over 40% and the stress concentration area shrinking by approximately 2 m. These findings suggest that hydraulic fracturing of the key strata has a substantial impact on the unloading and dissipation of stress and energy within the coal seam.

- The study of stress effects on coal seam permeability revealed a significant increase in permeability through hydraulic fracturing and large-diameter cavity drilling technology. The maximum enhancement observed was up to 190 times, suggesting that reducing overlying rock stress and increasing drill hole diameter can enhance gas extraction from coal seams.

- A gas extraction model was developed to address the issue of multi-row drilling in thick coal beds, considering the impact of overburden stress. Through simulations of various hole spacing configurations and on-site validation, ‘triangular’ hole spacing of 5 m was determined as the most effective solution. This spacing successfully addressed the limitation of single-row hole spacing in influencing the coal bed longitudinally.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Cheng, Y.; Wang, L.; Guo, P.; Li, W. Safety line method for the prediction of deep coal-seam gas pressure and its application in coal mines. Saf. Sci. 2012, 50, 523–529. [Google Scholar] [CrossRef]

- Wang, L.; Liu, S.; Cheng, Y.; Yin, G.; Guo, P.; Mou, J. The effects of magma intrusion on localized stress distribution and its implications for coal mine outburst hazards. Eng. Geol. 2017, 218, 12–21. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Kursunoglu, N.; Onder, M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunn. Undergr. Space Technol. 2019, 88, 63–72. [Google Scholar] [CrossRef]

- Zhao, B.; Cao, J.; Sun, H.; Wen, G.; Wang, B. Experimental investigations of stress-gas pressure evolution rules of coal and gas outburst: A case study in Ding ji coal mine, China. Energy Sci. Eng. 2020, 8, 61–73. [Google Scholar] [CrossRef]

- Zhou, A.; Xu, Z.; Wang, K.; Wang, Y.; An, J.; Shi, Z. Coal mine gas migration model establishment and gas extraction technology field application research. Fuel 2023, 349, 128650. [Google Scholar] [CrossRef]

- Zhao, P.; Zhuo, R.; Li, S.; Shu, C.; Laiwang, B.; Jia, Y.; Suo, L. Analysis of advancing speed effect in gas safety extraction channels and pressure-relief gas extraction. Fuel 2020, 265, 116825. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.; Song, Z. Numerical simulation of surface gas venthole extraction and the effect of ventilation mode in pressure-relief mining. Processes 2022, 10, 750. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Yan, F.; Peng, S.; Gao, Y.; Li, Q.; Cheng, L. Effects of gas pressure on dynamic response of two-phase flow for coal-gas outburst. Powder Technol. 2021, 377, 55–69. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Zhang, Y.; Li, Q.; Fu, J.; Hu, Q. Rationality evaluation of production deployment of outburst-prone coal mines: A case study of nantong coal mine in Chongqing, China. Saf. Sci. 2020, 122, 104515. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, Y.; Ren, T.; Zhou, H.; Liu, Q. Permeability distribution characteristics of protected coal seams during unloading of the coal body. Int. J. Rock Mech. Min. 2014, 71, 105–116. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, K.; Zang, J.; Zhao, W.; Qin, B.; Kan, T. Effects of permeability anisotropy on coal mine methane drainage performance. J. Nat. Gas Sci. Eng. 2021, 86, 103733. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Y.; Zhou, H.; Li, W. Damage and permeability development in coal during unloading. Rock Mech. Rock Eng. 2013, 46, 1377–1390. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Chen, D.; Liu, Q.; Chu, P.; Shu, L.; Wen, Z. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 2020, 129, 104800. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, L.; Liu, H.; Kong, S.; Yang, Q.; Zhu, J.; Tu, Q. Definition, theory, methods, and applications of the safe and efficient simultaneous extraction of coal and gas. IJCST 2015, 2, 52–65. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Jiang, Z.; Wu, X. Gas flow laws in coal subjected to hydraulic slotting and a prediction model for its permeability-enhancing effect. Energy Sources Part A 2021, 7, 1–15. [Google Scholar] [CrossRef]

- Lin, B.; Yan, F.; Zhu, C.; Zhou, Y.; Zou, Q.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas Sci. Eng. 2015, 26, 518–525. [Google Scholar] [CrossRef]

- Fan, C.; Li, S.; Luo, M.; Yang, Z.; Lan, T. Numerical simulation of hydraulic fracturing in coal seam for enhancing underground gas drainage. Energy Explor. Exploit. 2019, 37, 166–193. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, W.; Chen, J.; Xiao, X.; Li, Y.; Zhao, X. Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int. J. Coal Geol. 2014, 121, 1–13. [Google Scholar] [CrossRef]

- Wang, W.; Li, X.; Lin, B.; Zhai, C. Pulsating hydraulic fracturing technology in low permeability coal seams. IJMST 2015, 25, 681–685. [Google Scholar] [CrossRef]

- Yew, C.H. Mechanics of Hydraulic Fracturing, 1st ed.; Gulf Publishing: Houston, TX, USA, 1997; pp. 39–43. [Google Scholar]

- Wang, L.; Xu, Y. Study of the law of gradual change of the influence of hydraulic punching under a rational coal output. Arab. J. Geosci. 2019, 12, 427. [Google Scholar] [CrossRef]

- Gu, B.; Wu, Y. Research and application of hydraulic punching pressure relief antireflection mechanism in deep “Three-Soft” outburst coal seam. Shock Vib. 2021, 2021, 7241538. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, T.; Guo, X. Research on gas extraction technology of directional long borehole in ultrathick coal seam. Geofluids 2022, 2022, 6957896. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Yuan, L. Gas outburst disasters and the mining technology of key protective seam in coal seam group in the Huainan coalfield. Nat. Hazards 2013, 67, 763–782. [Google Scholar] [CrossRef]

- Ni, G.; Lin, B.; Zhai, C. Impact of the geological structure on pulsating hydraulic fracturing. Arab. J. Geosci. 2015, 8, 10381–10388. [Google Scholar]

- Liu, L.; Liu, M.; Wei, J. Regional outburst-prevention technique by gas pre-drainage based on large diameter boreholes along coal seams under deep mining. Procedia Eng. 2011, 26, 623–629. [Google Scholar]

- Wang, T.; Hu, W.; Elsworth, D.; Zhou, W.; Zhou, W.; Zhao, X.; Zhao, L. The effect of natural fractures on hydraulic fracturing propagation in coal seams. J. Petrol. Sci. Eng. 2017, 150, 180–190. [Google Scholar] [CrossRef]

- Ma, Y.; Mao, X.; Yang, K.; Liu, J.; Zhao, A. Improvement on gas drainage of soft gassy coal seam with underground hydraulic flushing and fracturing: A case study in Huainan. Arab. J. Geosci. 2020, 13, 178. [Google Scholar] [CrossRef]

- Zhang, R.; Hao, C. Research on the development of hydraulic flushing caverning technology and equipment for gas extraction in soft and low permeability tectonic coal seams in China. ACS Omega 2022, 7, 21615–21623. [Google Scholar] [CrossRef]

- Lu, W.; Huang, B.; Zhao, X. A review of recent research and development of the effect of hydraulic fracturing on gas adsorption and desorption in coal seams. Adsorpt. Sci. Technol. 2019, 37, 509–529. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Peng, S.; Yan, F.; Yang, W.; Cheng, L.; Ni, G. Influence of geo-stress on dynamic response characteristics of coal and gas outburst. Rock Mech. Rock Eng. 2020, 53, 4819–4837. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, T. Environmental impacts of hydraulic fracturing in shale gas development in the United States. Petrol. Explor. Dev. 2015, 42, 876–883. [Google Scholar] [CrossRef]

- Xie, J.; Xu, J. Effect of key stratum on the mining abutment pressure of a coal seam. Geosci. J. 2017, 21, 267–276. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Huang, Y.; Gao, R. Measurement and numerical analysis of influence of key stratum breakage on mine pressure in top-coal caving face with super great mining height. J. Cent. South Univ. 2017, 24, 1881–1888. [Google Scholar] [CrossRef]

- Li, F.; Liu, H.; Wang, C.; Sun, R.; Xiang, G.; Ren, B.; Wang, G. Stress Relief and Permeability Enhancement with Hydraulic Fracturing in Overlying Key Strata of Deep and Soft Coal Seams. ACS Omega 2023, 8, 12183–12193. [Google Scholar] [CrossRef]

- Wei, P.; Huang, C.; Li, X.; Peng, S.; Lu, Y. Numerical simulation of boreholes for gas extraction and effective range of gas extraction in soft coal seams. Energy Sci. Eng. 2019, 7, 1632–1648. [Google Scholar] [CrossRef]

- Xia, T.; Gao, F.; Kang, J.; Wang, X. A fully coupling coal–gas model associated with inertia and slip effects for CBM migration. Environ. Earth Sci. 2016, 75, 582. [Google Scholar] [CrossRef]

- Hu, G.; Huang, X.; Xu, J.; Qin, W.; Wang, H. A co-extraction technology of coal and CBM based on the law of gas advanced relieving pressure of in-seam coalface. Disaster Adv. 2012, 5, 1351–1356. [Google Scholar]

| Lithology | Unit Weight kN/m3 | Modulus of Elasticity/GPa | Poisson’s Ratio/μ | Compressive Strength/MPa | Tensile Strength MPa | Internal Friction Angle ° |

|---|---|---|---|---|---|---|

| Fine sandstone | 26 | 18 | 0.22 | 100 | 10 | 42 |

| Limestone | 26 | 40 | 0.20 | 120 | 18 | 45 |

| Sandy mudstone | 25 | 15 | 0.28 | 40 | 3 | 38 |

| Coal | 14 | 0.3 | 0.34 | 10 | 0.6 | 28 |

| Parameter Name | Numerical Value | Parameter Name | Numerical Value |

|---|---|---|---|

| Initial crack rate | 0.012 | Langmuir pressure constant (MPa) | 2 |

| Initial porosity | 0.049 | Maximum value of adsorbed gas (m3/t) | 28.8 |

| Initial permeability (mD) | 0.004 | Molar mass of coal gas (L/mol) | 22.4 |

| Initial gas pressure (MPa) | 1.6 | Density of coal (kg/m3) | 1380 |

| Dynamic viscosity of gas (Pa·s) | 1.08 × 10−5 | Negative pressure (kPa) | 21 |

| Elastic modulus of coal matrix (MPa) | 8139 | Poisson ratio (υ) | 0.34 |

| Elastic modulus of coal (MPa) | 2713 | Single pore diffusion coefficient | 5.599 × 10−12 |

| Klinkenberg factor (Pa) | 1.4 × 105 | Constant amount of adsorbed gas b (MPa−1) | 0.494 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Li, F.; Yan, Z.; Huo, J. Double Unloading Gas Control Technology for Fracturing Soft Coal Seams in Overlying Key Strata. Appl. Sci. 2024, 14, 3202. https://doi.org/10.3390/app14083202

Xie J, Li F, Yan Z, Huo J. Double Unloading Gas Control Technology for Fracturing Soft Coal Seams in Overlying Key Strata. Applied Sciences. 2024; 14(8):3202. https://doi.org/10.3390/app14083202

Chicago/Turabian StyleXie, Jun, Feng Li, Zhengxu Yan, and Jingjing Huo. 2024. "Double Unloading Gas Control Technology for Fracturing Soft Coal Seams in Overlying Key Strata" Applied Sciences 14, no. 8: 3202. https://doi.org/10.3390/app14083202

APA StyleXie, J., Li, F., Yan, Z., & Huo, J. (2024). Double Unloading Gas Control Technology for Fracturing Soft Coal Seams in Overlying Key Strata. Applied Sciences, 14(8), 3202. https://doi.org/10.3390/app14083202