Sensorimotor Control Using Adaptive Neuro-Fuzzy Inference for Human-Like Arm Movement

Abstract

1. Introduction

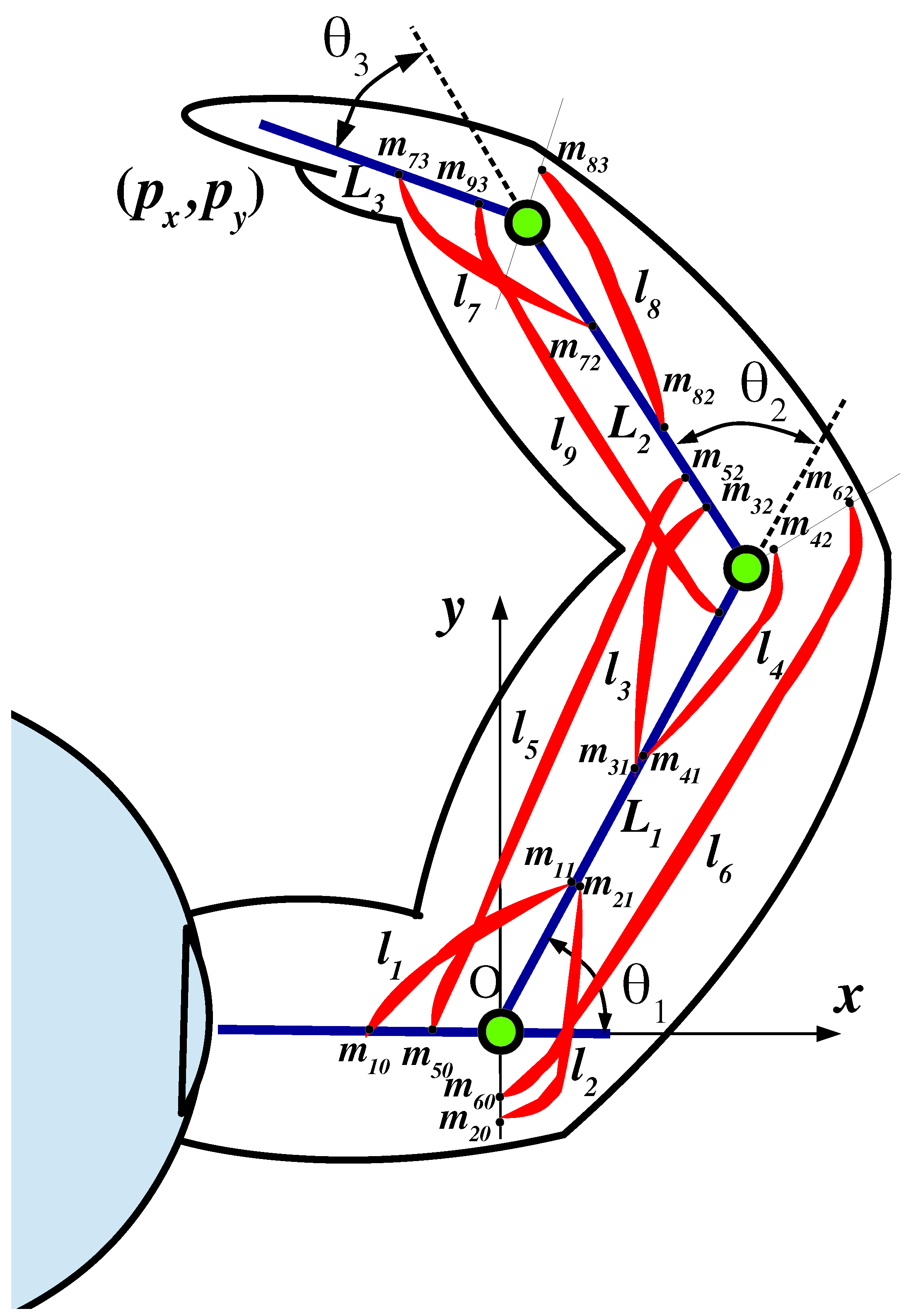

2. Musculoskeletal Modeling

2.1. Relation between Task and Joint Space

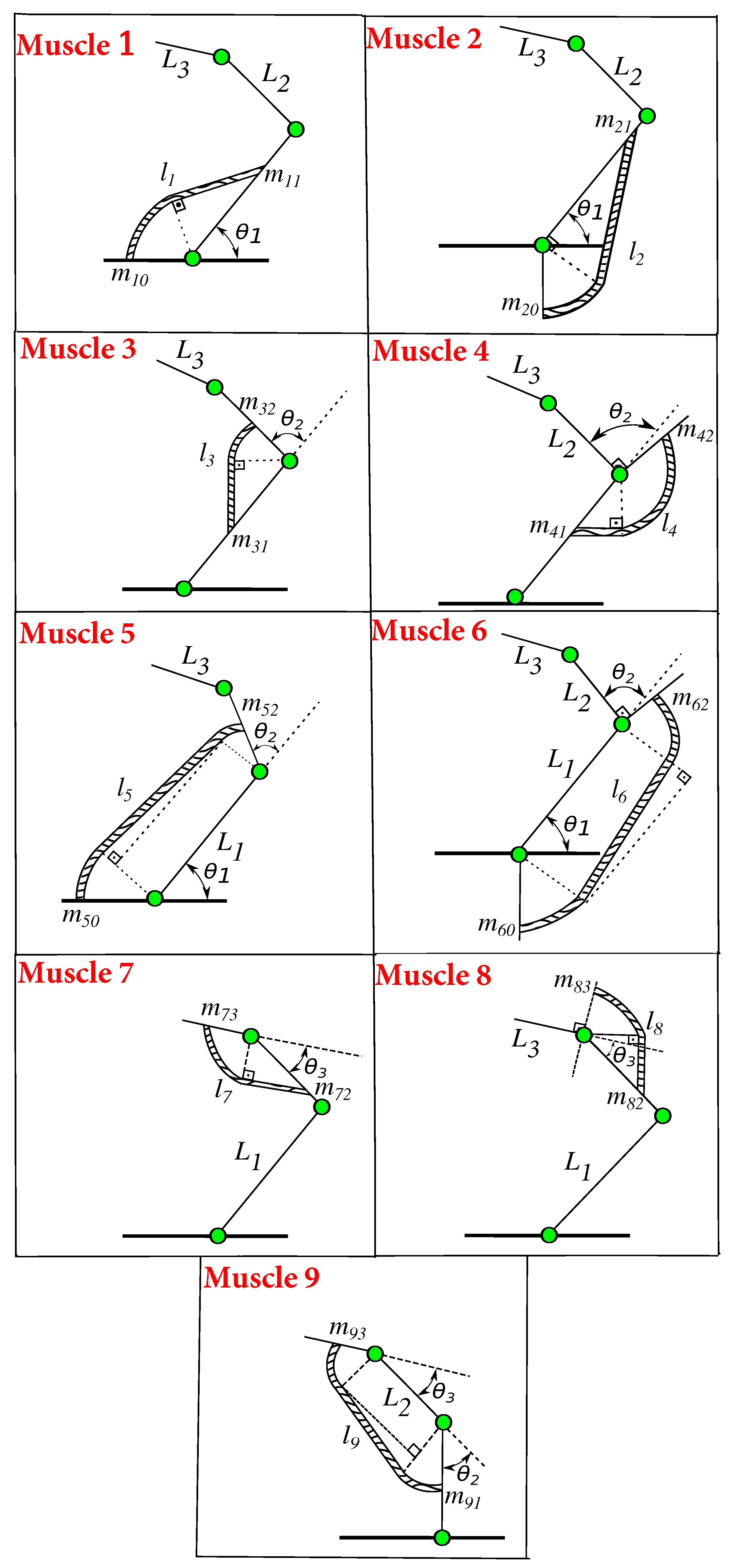

2.2. Relation between Joint and Muscle Space

2.3. Muscle Model

2.4. Robot Dynamics

3. Control Architecture for Human-Like Arm Movement

3.1. Muscle-Activation

3.2. Muscle-Force Change Cost Function

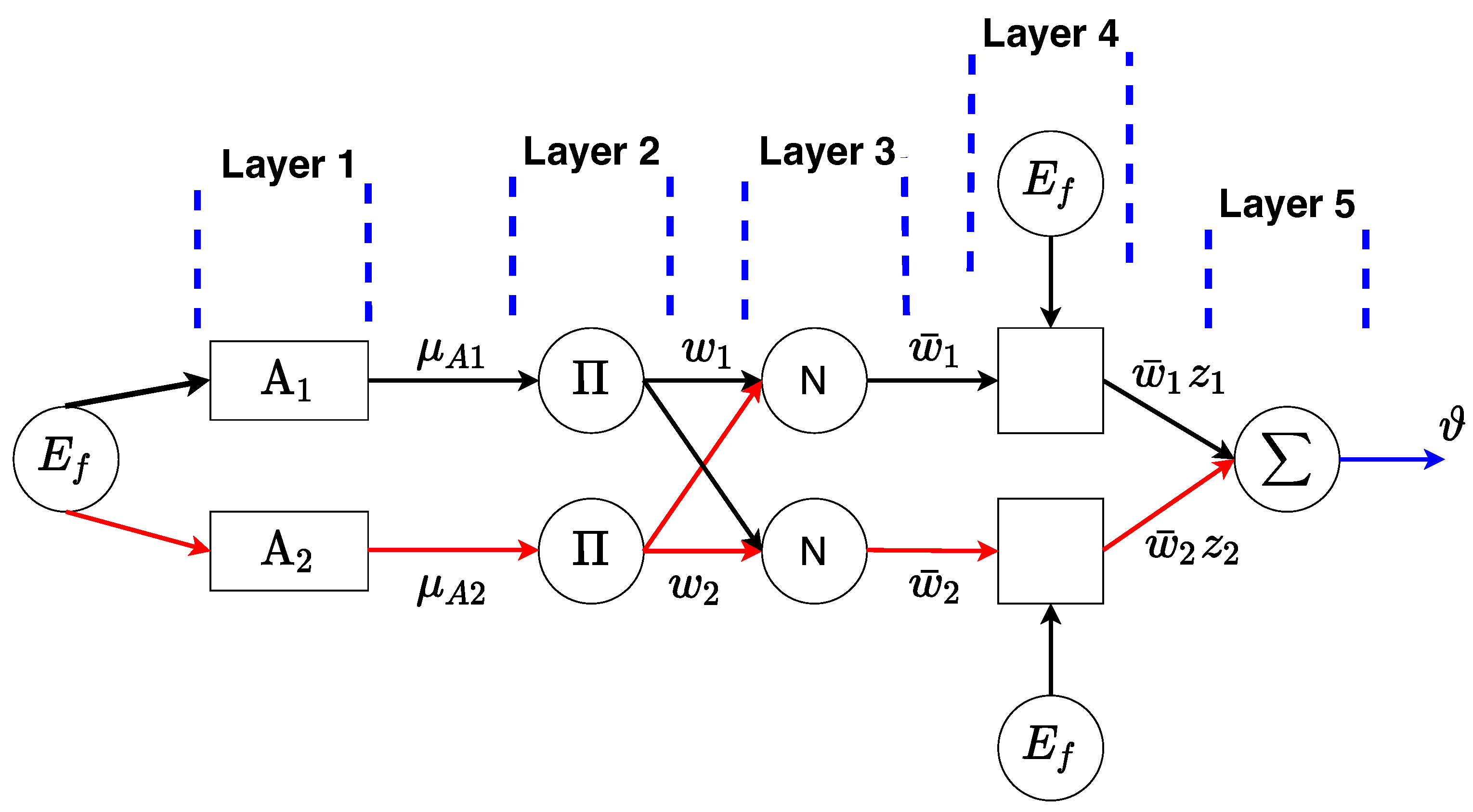

3.3. Adapt the ANFIS Architecture for Human-Like Movement Problem

4. Experimental Design and Materials and Methods

4.1. Participants

4.2. Setup

4.3. Methods

4.3.1. Offline Measurement Method

4.3.2. Online Measurement Method

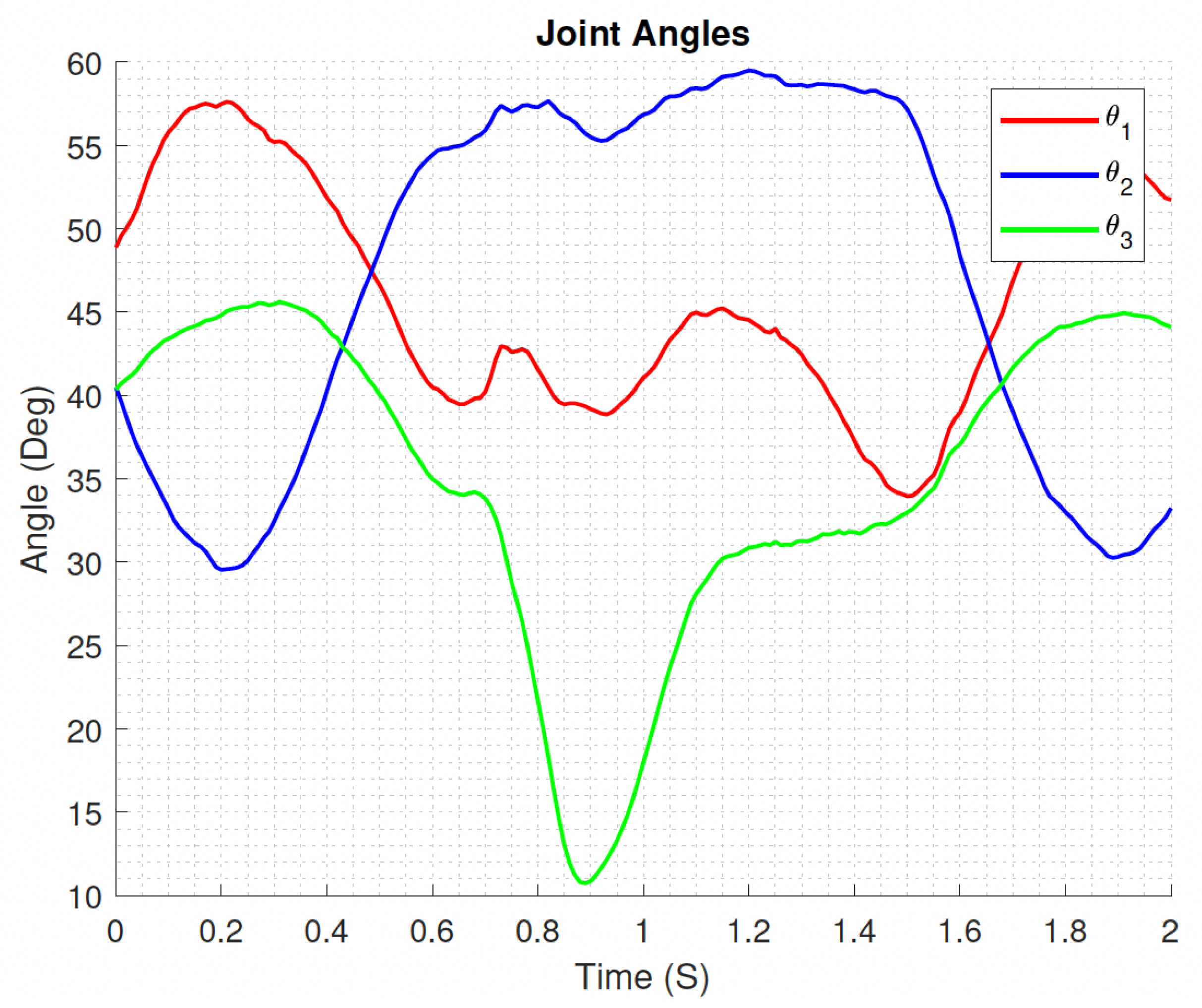

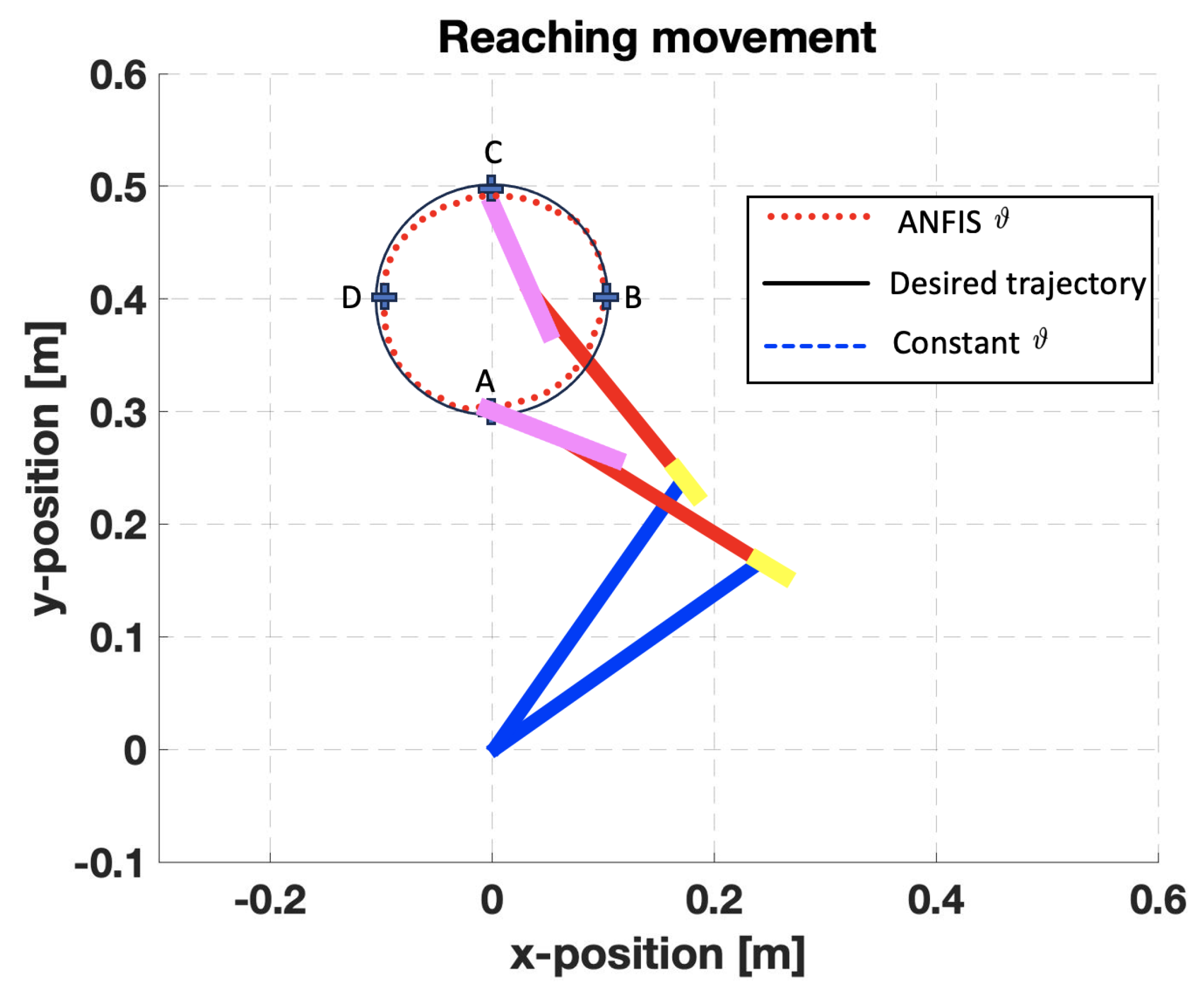

5. Results and Discussion

Measurements

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gulletta, G.; Erlhagen, W.; Bicho, E. Human-like arm motion generation: A Review. Robotics 2020, 9, 102. [Google Scholar] [CrossRef]

- Breazeal, C.; Scassellati, B. Robots that imitate humans. Trends Cogn. Sci. 2002, 6, 481–487. [Google Scholar] [CrossRef]

- Robinson, N.; Tidd, B.; Campbell, D.; Kulić, D.; Corke, P. Robotic vision for human–robot interaction and collaboration: A survey and systematic review. ACM Trans. Hum.-Robot Interact. 2023, 12, 1–66. [Google Scholar]

- Pei, S.; Wang, J.; Guo, J.; Yin, H.; Yao, Y. A Human-like Inverse Kinematics Algorithm of an Upper Limb Rehabilitation Exoskeleton. Symmetry 2023, 15, 1657. [Google Scholar] [CrossRef]

- Shin, S.Y.; Kim, C. Human-like motion generation and control for humanoid’s dual arm object manipulation. IEEE Trans. Ind. Electron. 2014, 62, 2265–2276. [Google Scholar] [CrossRef]

- Maroger, I.; Ramuzat, N.; Stasse, O.; Watier, B. Human trajectory prediction model and its coupling with a walking pattern generator of a humanoid robot. IEEE Robot. Autom. Lett. 2021, 6, 6361–6369. [Google Scholar] [CrossRef]

- Burdet, E.; Franklin, D.W.; Milner, T.E. Human Robotics: Neuromechanics and Motor Control; MIT Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Jeong, J.H.; Shim, K.H.; Kim, D.J.; Lee, S.W. Brain-controlled robotic arm system based on multi-directional CNN-BiLSTM network using EEG signals. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1226–1238. [Google Scholar] [CrossRef]

- Middleton, F.A.; Strick, P.L. Basal ganglia and cerebellar loops: Motor and cognitive circuits. Brain Res. Rev. 2000, 31, 236–250. [Google Scholar] [CrossRef]

- Wagner, F.B.; Mignardot, J.B.; Le Goff-Mignardot, C.G.; Demesmaeker, R.; Komi, S.; Capogrosso, M.; Rowald, A.; Seáñez, I.; Caban, M.; Pirondini, E.; et al. Targeted neurotechnology restores walking in humans with spinal cord injury. Nature 2018, 563, 65–71. [Google Scholar] [CrossRef]

- Mekki, M.; Delgado, A.D.; Fry, A.; Putrino, D.; Huang, V. Robotic rehabilitation and spinal cord injury: A narrative review. Neurotherapeutics 2018, 15, 604–617. [Google Scholar] [CrossRef]

- Kasukawa, Y.; Shimada, Y.; Kudo, D.; Saito, K.; Kimura, R.; Chida, S.; Hatakeyama, K.; Miyakoshi, N. Advanced equipment development and clinical application in neurorehabilitation for spinal cord injury: Historical perspectives and future directions. Appl. Sci. 2022, 12, 4532. [Google Scholar] [CrossRef]

- Averta, G.; Della Santina, C.; Valenza, G.; Bicchi, A.; Bianchi, M. Exploiting upper-limb functional principal components for human-like motion generation of anthropomorphic robots. J. NeuroEngineering Rehabil. 2020, 17, 63. [Google Scholar] [CrossRef]

- Cesari, P.; Shiratori, T.; Olivato, P.; Duarte, M. Analysis of kinematically redundant reaching movements using the equilibrium-point hypothesis. Biol. Cybern. 2001, 84, 217–226. [Google Scholar] [CrossRef]

- Bernstein, N.A. The problem of the interrelation of coordination and localization. Arch. Biol. Sci. 1935, 38, 15–59. [Google Scholar]

- Khan, N.; Stavness, I. Prediction of muscle activations for reaching movements using deep neural networks. arXiv 2017, arXiv:1706.04145. [Google Scholar]

- Nakada, M.; Zhou, T.; Chen, H.; Weiss, T.; Terzopoulos, D. Deep learning of biomimetic sensorimotor control for biomechanical human animation. ACM Trans. Graph. (TOG) 2018, 37, 1–15. [Google Scholar] [CrossRef]

- Huang, X.; Wu, W.; Qiao, H.; Ji, Y. Brain-inspired motion learning in recurrent neural network with emotion modulation. IEEE Trans. Cogn. Dev. Syst. 2018, 10, 1153–1164. [Google Scholar] [CrossRef]

- Chen, J.; Zhong, S.; Kang, E.; Qiao, H. Realizing human-like manipulation with a musculoskeletal system and biologically inspired control scheme. Neurocomputing 2019, 339, 116–129. [Google Scholar] [CrossRef]

- Arimoto, S.; Sekimoto, M. Human-like movements of robotic arms with redundant DOFs: Virtual spring-damper hypothesis to tackle the Bernstein problem. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, ICRA 2006, Orlando, FL, USA, 15–19 May 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 1860–1866. [Google Scholar]

- Tahara, K.; Kino, H. Reaching movements of a redundant musculoskeletal arm: Acquisition of an adequate internal force by iterative learning and its evaluation through a dynamic damping ellipsoid. Adv. Robot. 2010, 24, 783–818. [Google Scholar] [CrossRef]

- Tahara, K.; Kuboyama, Y.; Kurazume, R. Iterative learning control for a musculoskeletal arm: Utilizing multiple space variables to improve the robustness. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 4620–4625. [Google Scholar]

- Dong, H.; Mavridis, N. Adaptive biarticular muscle force control for humanoid robot arms. In Proceedings of the 2012 12th IEEE-RAS International Conference on Humanoid Robots (Humanoids 2012), Osaka, Japan, 29 November–1 December 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 284–290. [Google Scholar]

- Dong, H.; Figueroa, N.; El Saddik, A. Muscle force control of a kinematically redundant bionic arm with real-time parameter update. In Proceedings of the 2013 IEEE International Conference on Systems, Man, and Cybernetics, Manchester, UK, 13–16 October 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1640–1647. [Google Scholar]

- Vatankhah, R.; Broushaki, M.; Alasty, A. Adaptive optimal multi-critic based neuro-fuzzy control of MIMO human musculoskeletal arm model. Neurocomputing 2016, 173, 1529–1537. [Google Scholar] [CrossRef]

- Zhao, L.; Li, Q.; Liu, B.; Cheng, H. Trajectory tracking control of a one degree of freedom manipulator based on a switched sliding mode controller with a novel extended state observer framework. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 1110–1118. [Google Scholar] [CrossRef]

- Xiuxiang, C.; Ting, W.; Yongkun, Z.; Wen, Q.; Xinghua, Z. An adaptive fuzzy sliding mode control for angle tracking of human musculoskeletal arm model. Comput. Electr. Eng. 2018, 72, 214–223. [Google Scholar] [CrossRef]

- Qiao, H.; Chen, J.; Huang, X. A survey of brain-inspired intelligent robots: Integration of vision, decision, motion control, and musculoskeletal systems. IEEE Trans. Cybern. 2021, 52, 11267–11280. [Google Scholar] [CrossRef]

- Tahara, K.; Arimoto, S.; Sekimoto, M.; Luo, Z.W. On control of reaching movements for musculo-skeletal redundant arm model. Appl. Bionics Biomech. 2009, 6, 11–26. [Google Scholar] [CrossRef]

- Hill, A.V. The heat of shortening and the dynamic constants of muscle. Proc. R. Soc. London. Ser. B-Biol. Sci. 1938, 126, 136–195. [Google Scholar]

- Zajac, F.E. Muscle and tendon: Properties, models, scaling, and application to biomechanics and motor control. Crit. Rev. Biomed. Eng. 1989, 17, 359–411. [Google Scholar]

- Jang, J.S. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

| # Muscle | Value (m) |

|---|---|

| Wrist | Elbow | Shoulder | |

|---|---|---|---|

| Inertia (kg·m2) | 0.001 | 0.012 | 0.141 |

| Mass (kg) | 0.35 | 1.32 | 1.93 |

| Mass center (m) | 0.075 | 0.135 | 0.165 |

| Length (m) | 0.15 | 0.27 | 0.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gungor, G.; Afshari, M. Sensorimotor Control Using Adaptive Neuro-Fuzzy Inference for Human-Like Arm Movement. Appl. Sci. 2024, 14, 2974. https://doi.org/10.3390/app14072974

Gungor G, Afshari M. Sensorimotor Control Using Adaptive Neuro-Fuzzy Inference for Human-Like Arm Movement. Applied Sciences. 2024; 14(7):2974. https://doi.org/10.3390/app14072974

Chicago/Turabian StyleGungor, Gokhan, and Mehdi Afshari. 2024. "Sensorimotor Control Using Adaptive Neuro-Fuzzy Inference for Human-Like Arm Movement" Applied Sciences 14, no. 7: 2974. https://doi.org/10.3390/app14072974

APA StyleGungor, G., & Afshari, M. (2024). Sensorimotor Control Using Adaptive Neuro-Fuzzy Inference for Human-Like Arm Movement. Applied Sciences, 14(7), 2974. https://doi.org/10.3390/app14072974