Abstract

This paper investigates the effects of incorporating dispersed fibrous reinforcement in hydraulically bound granular 0/16-mm mixtures. The evaluated fibrous reinforcement comprised a mixture of polypropylene and alkali-resistant glass fibers in a 1:2 weight ratio. The fibrous reinforcement was added to the mixtures in amounts of 0.05% and 0.10% by weight. The prepared mixtures utilized 1% of CEM II/B-V 32.5 R Portland cement together with 3.5%, 7%, and 14% of fly ash, characterized by a high content of reactive calcium oxide. It was found that the fibrous additives had only a small effect on the maximum dry densities and virtually none on the optimum moisture contents of the mixtures. The use of the fiber mix significantly improved the compressive strength of the reinforced samples resulting after 42 days of curing, with a performance comparable to a reference mixture bound with 8% of Portland cement. The addition of fibrous reinforcement increased the indirect tensile strength of the mixtures by up to 300%, resulting in a performance similar to that of a reference mixture with 5% of Portland cement. It was found that the use of this particular fibrous reinforcement significantly improved the performance of predominantly fly-ash-bound granular mixtures, allowing the reduction in cement content used in this type of material.

1. Introduction

The present study investigates the properties of a hydraulically bound granular mix utilizing Portland cement and fly ash as binding agents, reinforced with a mixture of polypropylene (PP) and alkaline-resistant glass fibers. We have focused on the effects of fiber reinforcement on the improvement of the compressive and tensile strength of predominantly fly-ash-bound granular material intended for road bases.

The introduction of fibrous additives is an effective way to improve the performance of paving materials subjected to compressive, tensile, and flexural stresses and strains [1,2,3]. The investigated uses include asphalt mixtures, particularly for improving fatigue life and performance properties [4,5,6,7,8]; cementitiously bound granular materials (which are otherwise not capable of bearing significant tensile loads); and unbound materials, subgrades, and soils for improving their bearing capacity [9]. On the other hand, such additives contribute to the production costs, which may vary greatly depending on the availability and demand of the fibrous additives, their type (composition), source, and other economic factors. To make such construction materials feasible, fibrous additives may be joined with other independently devised solutions aiming at decreasing the energy intensity of the production processes (such as warm and half-warm techniques in asphalt mixtures [10]) and the utilization of alternative binders in hydraulically bound materials (e.g., based on fly ash [11]).

Currently, on an industrial scale, dispersed reinforcement is primarily used in the composition of cement concrete, mainly using steel, polypropylene, basalt, or glass fibers. Depending on the type of fibrous reinforcement used in the cement concrete, it can be used to improve mechanical properties such as tensile, flexural, and shear strength, impact strength and toughness, overall durability, and to reduce the extent of plastic shrinkage cracking in fresh concrete [12]. In pavement engineering specifically, the use of dispersed reinforcement permits decreasing the thickness of concrete pavement slabs by as much as 40% [13,14].

Based on the vast experiences of concrete technology, numerous works investigating the effects of fibrous additives on the properties of cement, lime, and otherwise stabilized soils and granular mixtures have been published.

A study conducted by the US Army Corps of Engineers has shown that the addition of 0.5% of PP fibers to a 5% cement-stabilized sand and the addition of 0.3% of PP fibers to a 5% lime-stabilized clay significantly improved the service life (by up to 100%) of such test sections subjected to traffic [15]. Similar results were obtained by Santoni, Webster, and Tingle [16,17], but by using up to 1% of fibrous, tape, and mesh PP reinforcement.

Hazirbaba and Gullu [18] have evaluated the bearing capacity of fine soils stabilized using a chemical agent with the addition of PP fibers and tapes. It was found that the incorporation of dispersed reinforcement in amounts of up to 0.5% significantly improved the properties of the stabilized fine materials. Similar results were observed in the triaxial performance of cement-stabilized clay with the addition of 0.1 to 0.4% of glass fibers [19].

Shalabi et al. [20] found an up to 42% improvement in the compressive strength of cement-stabilized dune sand after adding 0.2 to 0.6% of glass fibers. Farhan, Dawson, and Thom [21] have investigated the effects of steel fibers recycled from vehicle tires on the fracture performance of cement-bound granular mixtures consisting of limestone aggregates with a size of up to 10 mm. Major increases in strains at ultimate stress, toughness, and indirect tensile strength were observed when the fiber reinforcement was used in the mixtures, with a higher efficacy being observed at higher cement contents (5 and 7%). The increases in the indirect tensile strength were up to 41%, while the material toughness was increased 2- to 5-fold. Ma et al. [22] investigated the effects of reinforcing coarse-cement-stabilized aggregate mixtures with filament PP fibers, showing increases in their flexural strength (up to 10%) and fatigue performance (up to 30%). Brasse, Tracz, and Zdeb [23] also observed a significant increase in fracture performance during bending experiments involving PP-fiber-reinforced soil–cement samples with crack mouth opening displacement measurements.

One key issue when incorporating different additives into cement-bound mixtures is their possible effect on the durability of the resulting material. Particularly, due to the alkaline nature of cement-bound materials, alkaline-resistant glass fiber should be used. The use of such fibers in pavement Portland cement concrete was investigated by Xiaochun et al. [24], who found their high efficacy in increasing the mechanical properties of the composite. Despite the corrosion of the glass fibers not being completely halted, it was found that the strength of the reinforced samples was significantly improved. It was also confirmed that, by adding 40% of fly ash (by the weight of the cement), the performance of the glass-fiber-reinforced material was improved, as shown by other researchers [25].

Other works investigating fly-ash-stabilized soils and granular mixtures were also conducted. Gailitis et al. [26] have investigated the use of 0.5% to 5% steel, polypropylene, and polyvinyl alcohol (PVA) by mass in fly-ash-bound geopolymer mixtures. This study showed that the improvement of certain mechanical properties (compressive strength, shrinkage, and creep) was possible with different fibers and their dosages—the increase in compressive strength was up to 11.4%. Kaniraj and Gayathri [27] in their work have observed significant changes in the stress–strain performance of fly ash mixtures with 0.5 to 1.0% of polyester fiber, obtaining an up to 150% increase in unconfined compressive strength. The inclusion of the fibers also provided residual strength to the material, which otherwise exhibited brittle behavior.

Based on the conducted literature review, it was concluded that different types of fibrous reinforcement materials can be used to significantly improve the performance of both low- and high-quality granular materials stabilized with different cementitious materials. Therefore, we have investigated the possibility of improving the performance of aggregates stabilized with a mixture of a small amount of Portland cement (1%) and increasing amounts of fly ash (3.5–14%) by using a mixture of polypropylene and alkali-resistant glass fibers added in amounts of 0.05–0.10%.

2. Materials and Methods

2.1. Experimental Plan

The experimental plan involved the preparation of hydraulically bound granular mixtures with dispersed fiber reinforcement composed of a mixture of two different fibrous materials—polypropylene and alkali-resistant glass fibers. We intended to use the highest possible ratio of fly ash in the investigated mixtures, supplemented with a low dosage of cement, as per the guidance of the EN 14227 standard [28]. In addition, two reference continuously bound granular mixtures (CBGMs) were produced without fibrous reinforcement. The contents of the binding agents were aligned with a goal to produce mixtures corresponding with the C1.5/2 and C3/4 classes of CBGMs intended for road bases and sub-bases.

Based on the aforementioned assumptions, two ratios of fiber reinforcement—0.05% and 0.10%—and three ratios of cement and fly ash—1-3.5, 1-7, and 1-14 (% cement–% fly ash)—were investigated. The reference CBGMs contained no fiber reinforcement, with 5% and 8% of cement as a binding agent. The designations and framework compositions of the evaluated hydraulically bound mixtures are provided in Table 1.

Table 1.

Designation of the evaluated hydraulically bound mixtures.

2.2. Materials

2.2.1. Fiber Reinforcement

The fiber reinforcement used in this study consisted of cut polypropylene (prod. Hermes Sp. z o.o., Słupno, Poland) and alkali-resistant glass fibers (prod. Rozenblat Sp. z o.o., Mosina, Poland) prepared in a 1:2 ratio by weight, which resulted in an approximately 1.5:1 volumetric ratio between the fibers. Both types of fibers had a length of 12 mm. The assumption for using the mixture of fibers was to exploit the low deformability of the glass fibers while reducing their content to mitigate the effects of their degradation in time caused by the alkali environment. The properties of the fibers used in this study are provided in Table 2. The polypropylene fibers conformed to the EN 14889-2 standard [29], and the glass fibers conformed to the EN 15422 standard [30] specifying the polymer fibers and glass fibers used in Portland cement concrete. The fiber reinforcement is presented in Figure 1.

Table 2.

Properties of the fibers used in the evaluated hydraulically bound mixtures.

Figure 1.

Fiber reinforcement used in the evaluated hydraulically bound mixtures: polypropylene fibers (A), alkali-resistant glass fibers (B), and mixture of both types of fibers (C).

2.2.2. Portland Cement and Fly Ash

The evaluated hydraulically bound mixtures used CEM II/B-V 32.5 R Portland cement (in acc. with EN 197-1 [31]). The fly ash used in the mixtures is a byproduct from the co-combustion of biomass in a cellulose processing plant. The basic properties of the used fly ash are provided in Table 3.

Table 3.

Properties of the fly ash used in the evaluated hydraulically bound mixtures.

2.2.3. Aggregate Mix

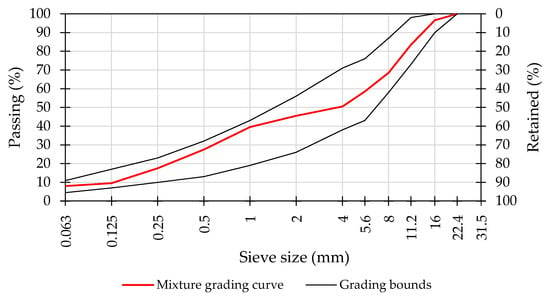

The base material for producing the hydraulically bound mixtures was a continuously graded 0/16-mm natural aggregate. The grading curve of the aggregate mix used in this study is presented in Figure 2. The coarse aggregate in the aggregate mixture was characterized by water absorption WA24 = 1.3% (WA242), flakiness index FI = 34 (FI35), shape index SI = 29 (SI40), and abrasion resistance LA = 26 (LA30), measured in acc. with EN 1097-6 [34], EN 933-3 [35], EN 933-4 [36], and EN-1097-2 [37], respectively.

Figure 2.

Grading of the aggregate mixture used in the evaluated hydraulically bound mixtures.

2.3. Methods

To evaluate the effectiveness of the fiber reinforcement on the performance of the hydraulically bound mixtures, a set of mechanical characteristics were evaluated, as follows:

- The uniaxial compressive strength of cylindrical samples (RC), in accordance with EN 13286-41 [38], after 14, 28, and 42 (only fly-ash-bound mixtures) days of curing;

- The uniaxial compressive strength after 14 freeze–thaw cycles (RC-FT) performed after full curing (28 days in cement-bound and 42 days in fly-ash-bound mixtures) in accordance with EN 13286-41. The resistance to frost (RC-FR) was calculated as a ratio of RC-FR = RC-FT/RC;

- The indirect tensile strength Rit in accordance with EN 13286-42 [39] after 28 (cement-bound mixtures) or 42 days (fly-ash-bound mixtures).

The samples for all of the tests were prepared using the Proctor compaction method in acc. with EN 13286-50 [40]. The effects of the addition of fiber reinforcement were also measured by evaluating the optimum moisture content in the compacted mixtures and their maximum dry density.

All tests were performed with 5 replicates, and the effects of the evaluated factors were presented by the calculated mean values and their 95% confidence intervals.

3. Results

3.1. Maximum Dry Density (MDD) and Optimum Moisture Content

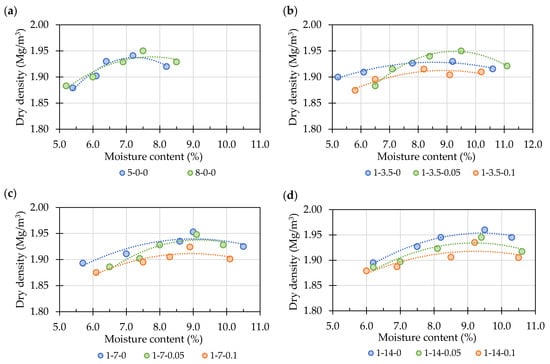

The results of the Proctor tests conducted on the investigated hydraulically bound mixtures are presented in Figure 3 (moisture content vs. dry density) and in Table 4 (optimum moisture contents).

Figure 3.

Results of the Proctor tests for evaluating the optimum moisture content in the evaluated mixtures: (a) reference CBGMs, (b) mixtures with 3.5% of fly-ash, (c) mixtures with 7% of fly-ash, (d) mixtures with 14% of fly-ash.

Table 4.

Optimum moisture content of the evaluated hydraulically bound mixtures.

The type of binder used had a measurable effect on the optimum moisture content of the mixtures. The optimum moisture contents of all of the fly ash mixtures were constrained to a narrow range of 8.75–9.25%, while the maximum dry densities of the reference cement-bound mixtures were obtained at 7.25% and 7.75% moisture content, respectively. The type of binding agent had no visible impact on the maximum dry density of the mixtures.

Regarding the effects of the fiber reinforcement content on the Proctor results, it had little-to-no effect on the optimum moisture contents of the mixtures. In the case of the maximum dry density, however, in two of three cases (Figure 3b,c), the mixtures with 0.05% of fiber reinforcement reached a maximum dry density of equal to or higher than that of the mixtures without fibrous additives, while the 0.10% addition of fibers in all cases resulted in a decrease in MDD.

3.2. Compressive Strength (RC 14d, RC 28d, and RC 42d)

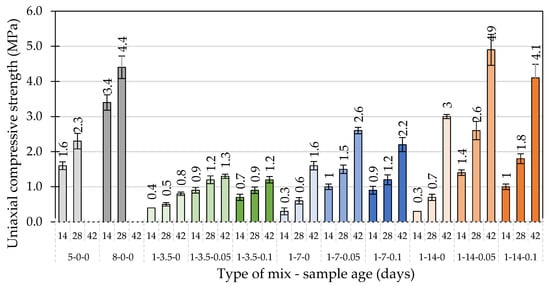

The results of the uniaxial compressive strength of the investigated mixtures after 14, 28, and 42 days of curing are presented in Figure 4.

Figure 4.

Compressive strength results of the evaluated hydraulically bound mixtures after 14, 28, and 42 days.

Based on the presented results, it can be stated that all of the evaluated factors in the analyzed mixtures had a significant impact on their compressive strength—the composition of the binder, its amount, and the amount of fiber reinforcement used. Of the two reference mixtures, the 8-0-0 mixture achieved higher strengths (RC 28d = 4.4 MPa), which corresponds to the C3/4 class of hydraulically bound mixtures, while the 5-0-0 mixture was characterized by an average strength of RC 28d = 2.3 MPa, which classifies it as a C1.5/2 CBGM. Among the mixtures containing fly ash, their compressive strength after 28 and 42 days was almost directly related to the amount of the binding agent. After 14 days, all of the non-reinforced fly ash mixtures exhibited very low compressive strengths of 0.3–0.4 MPa. The 1-3.5-0 mixture bound with fly ash was characterized by the lowest values of compressive strength of all of the analyzed mixtures (RC 42d = 0.8 MPa). Increasing the amount of fly ash to 14%, relative to the weight of the entire mixture, resulted in a significantly higher strength of the cured material. In the case of this mixture (1-14-0), its 42-day strength was 3.0 MPa, which is higher than that of the reference 5-0-0 mixture.

The evaluation of the mixtures bound with fly ash and containing dispersed fiber reinforcement showed that its use significantly improved the compressive strength throughout the mixtures’ curing periods.

Regarding the final curing period, which, for the fly-ash-bound mixtures, was considered after 42 days, the RC values obtained for the content of 0.05% fibers in the ash-bound mixtures amounted to 1.3 MPa for the 1-3.5-0.05 mixture, 2.6 MPa for the 1-7-0.05 mixture, and 4.9 MPa for the 1-14-0.05 mixture. The mixtures with 0.10% fiber content had lower compressive strengths, for which the RC 42d amounted to 1.2 MPa (1-3.5-0.10), 2.2 MPa (1-7-0.10), and 4.1 MPa (1-14-0.10). Consequently, it was found that the highest values of the Rc parameter in all cases were obtained in the fly ash mixtures containing 0.05% of fiber reinforcement, which resulted in an average of 142% higher compressive strength throughout the curing period, while the mixtures containing 0.10% of fibers had, on average, a 108% higher compressive strength than the mixtures without fiber reinforcement.

In most cases, the greatest relative increases in compressive strength due to the introduction of fiber reinforcement were observed after the first 14 days of curing, which, on average, amounted to 242% and 169% for the 0.05% and 0.10% fiber mixtures, respectively.

3.3. Frost Resistance (FR)

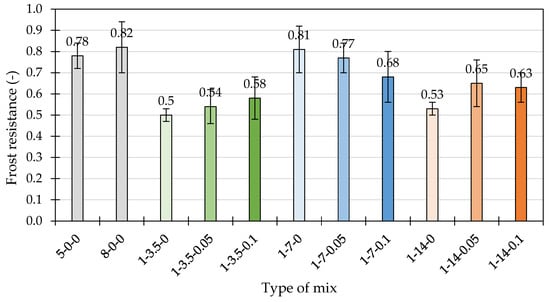

The evaluation of the frost resistance of the investigated mixtures is presented in Figure 5.

Figure 5.

Frost resistance results of the evaluated hydraulically bound mixtures.

The addition of fiber reinforcement had different effects on the frost resistance of the tested mixtures. In the mixtures containing 3.5% of fly ash, the addition of fiber reinforcement resulted in a small but consistent increase in frost resistance from 0.5 to 0.58. On the other hand, the mixtures containing 7% of fly ash, which, overall, had the best performance of the fly ash mixtures in this scope, exhibited a decrease in frost resistance after adding the reinforcement. In the mixtures containing 14% of fly ash, the 1-14-0.05 formulation performed the best. When comparing the results of the fiber-reinforced mixtures with the fly ash binder to the cement-bound reference mixtures, only the 1-7-0 and 1-7-0.05 mixtures performed similarly.

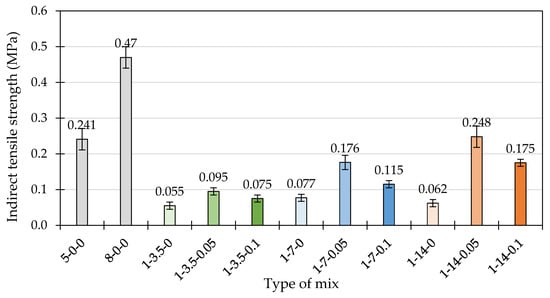

3.4. Indirect Tensile Strength (Rit)

Figure 6 presents the results of the indirect tensile strength of the evaluated hydraulically bound mixtures.

Figure 6.

Indirect tensile strength results of the evaluated hydraulically bound mixtures.

The fly-ash-containing granular mixtures without fibrous reinforcement exhibited significantly lower indirect tensile strengths than the reference cement-bound mixtures. Additionally, the Rit values observed in the non-reinforced samples of the 1-3.5-0 and 1-14-0 mixtures were comparable, and only the use of the intermediate dosage of the binding agents (1-7-0 mixture) resulted in a slight increase in the splitting strength.

The addition of fiber reinforcement significantly improved the tensile performance of the fly ash mixtures, particularly when 0.05% content of the fiber mix was used. The observed increases in the Rit values amounted to 73%, 129%, and 300% in the case of the 1-3.5-0.05, 1-7-0.05, and 1-14-0.05 mixtures, respectively. As can be seen, the changes in the indirect tensile performance were greater at the higher contents of binding agents—fly ash in this instance. Increasing the fiber content up to 0.10% did not result in a further increase in splitting strength, but the mixtures still performed better than the non-reinforced ones.

Consequently, the 1-14-0.05 mixture performed in this respect similarly to the cement-bound 5-0-0 reference mixture, which did not incorporate any fiber reinforcement.

4. Discussion

The investigated material solution was developed under a commission from an industry partner. Certain constraints were stipulated in the development of the presented mixtures regarding their cost-effectiveness, which were reflected in low contents of cement, fibrous reinforcement, and utilization of fly ash as a binder.

The specific factor in the presented study was the utilization of a mixture of polypropylene and alkali-resistant glass fibers, which has not been thoroughly investigated or presented in the literature. Additionally, the investigated mixtures contained significantly smaller amounts of fiber reinforcement than those found in the works of other researchers. The typically investigated amounts of fiber reinforcement in this type of setting range from 0.10 to 1% by mass, while the presented work used 0.05 and 0.10% of fibrous reinforcement. It should also be noted that, in most cases, other researchers investigated the use of fiber reinforcement in fine soils rather than in high-quality and controlled aggregate mixtures.

The incorporation of the fiber mixture in the hydraulically bound mixtures yielded results that were comparable to or more desirable than other similar solutions utilizing one type of fiber—polypropylene or glass. The optimum performance in both uniaxial compression and indirect tensile tests was obtained with a 0.05% fiber content, which was significantly less than the average content of fibrous reinforcement found in the literature. The obtained increases in the uniaxial compressive strength and indirect tensile strength of the tested mixtures due to the introduction of the fiber reinforcement amounted to as much as 142% and 300%, respectively.

The utilization of alternative binders, such as fly ash, may alter the rate at which the required strength of the hydraulically bound material is attained. For fly ash mixtures, the ultimate compressive strength is typically evaluated after 42 days of curing, as opposed to 28 days in cement-bound mixtures. The obtained results have not only shown that the fiber reinforcement increased the compressive strength of the fly ash mixtures, but also that the largest magnitude of this increase was seen after the first 14 days of curing. Therefore, the fiber reinforcement significantly contributed to the early strength of these mixtures and can be considered an additional advantage of such formulations.

5. Conclusions

In this study, we investigated the effects of dispersed fiber reinforcement (mixture of polypropylene and alkali-resistant glass fibers, in 1:2 ratio by mass) on the performance of hydraulically bound granular mixtures utilizing a small amount Portland cement and increasing amounts of fly ash as the binder.

The most substantial findings of the presented work include the following:

- The mixtures bound with Portland cement and fly ash with 0.05% (m/m) of fiber reinforcement yielded the most favorable compressive and indirect tensile strengths, surpassing those obtained with a higher amount of reinforcement (0.10%);

- The compressive strengths of the mixtures containing fly ash and 0.05% of fiber reinforcement exceeded those of the reference, non-reinforced CBGMs;

- In the case of indirect tensile strengths, only the mixture containing 1% of Portland cement and 14% of fly ash with 0.05% of reinforcement performed comparably to the weaker reference CBGM (bound with 5% Portland cement);

- Increasing the contents of fly ash from 3.5% to 14% in the investigated mixtures (also containing 1% of Portland cement) resulted in an improved mechanical performance; moreover, this improvement was magnified when dispersed reinforcement was used;

- The effects of fiber reinforcement on the frost resistance of the mixtures could not be clearly established because inconsistent results were obtained in mixtures containing different percentages of fly ash.

The findings suggest that it is possible to produce high-quality hydraulically bound granular mixtures, in which fly ash substitutes most of the Portland cement, by means of using relatively small amounts of fiber reinforcement composed of a mixture of polypropylene and alkali-resistant fibers. Future studies should attempt to explain these results by using more controlled mechanical tests (e.g., investigating the fracture mechanics of the material) together with imaging and analytical techniques in tests involving different compositions of fiber reinforcement. Additionally, the long-term performance of such mixtures should be evaluated.

Author Contributions

Conceptualization, A.C.-K. and K.M.; methodology, A.C.-K.; validation, A.C.-K.; investigation, K.M.; resources, A.C.-K.; data curation, K.M.; writing—original draft preparation, A.C.-K. and K.M.; writing—review and editing, A.C.-K. and K.M.; visualization, K.M.; supervision, A.C.-K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xie, T.; Ren, W.; Chen, Y.; Sheng, J.; Wang, L. Enhancing the Performance of Asphalt Mastic with Natural Fiber Reinforcement: Basalt and Bamboo Fibers. Appl. Sci. 2023, 13, 7946. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; He, L.; Guo, R.; Li, X.; Chen, Y.; Muhammad, Y.; Liu, Y. Research progresses of fibers in asphalt and cement materials: A review. J. Road Eng. 2023, 3, 35–70. [Google Scholar] [CrossRef]

- Blythe, A.; Fox, B.; Nikzad, M.; Eisenbart, B.; Chai, B.X. Stiffness Degradation under Cyclic Loading Using Three-Point Bending of Hybridised Carbon/Glass Fibres with a Polyamide 6,6 Nanofibre Interlayer. J. Compos. Sci. 2022, 6, 270. [Google Scholar] [CrossRef]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete—A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A.; Yang, X. Short- and long-term properties of glass fiber reinforced asphalt mixtures. Int. J. Pavement Eng. 2021, 22, 64–76. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A. Laboratory testing of low temperature asphalt concrete produced in foamed bitumen technology with fiber reinforcement. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 779–790. [Google Scholar] [CrossRef]

- Iwański, M.; Chomicz-Kowalska, A.; Maciejewski, K.; Janus, K.; Radziszewski, P.; Liphardt, A.; Michalec, M.; Góral, K. Stiffness Evaluation of Laboratory and Plant Produced Foamed Bitumen Warm Asphalt Mixtures with Fiber Reinforcement and Bio-Flux Additive. Materials 2023, 16, 1950. [Google Scholar] [CrossRef] [PubMed]

- Eltwati, A.S.; Enieb, M.; Al-Saffar, Z.H.; Mohamed, A. Effect of glass fibers and waste engine oil on the properties of RAP asphalt concretes. Int. J. Pavement Eng. 2022, 23, 5227–5238. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Iwanski, M.M.; Chomicz-Kowalska, A.; Maciejewski, K. Resistance to moisture-induced damage of half-warm-mix asphalt concrete with foamed bitumen. Materials 2020, 13, 654. [Google Scholar] [CrossRef] [PubMed]

- Rai, P.; Qiu, W.; Pei, H.; Chen, J.; Ai, X.; Liu, Y.; Ahmad, M. Effect of Fly Ash and Cement on the Engineering Characteristic of Stabilized Subgrade Soil: An Experimental Study. Geofluids 2021, 2021, 1368194. [Google Scholar] [CrossRef]

- Hannant, D.J. Fibre-reinforced concrete. In Advanced Concrete Technology; Newman, J., Choo, B.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2003; p. 6. [Google Scholar]

- Achilleos, C.; Hadjimitsis, D.; Neocleous, K.; Pilakoutas, K.; Neophytou, P.O.; Kallis, S. Proportioning of steel fibre reinforced concrete mixes for pavement construction and their impact on environment and cost. Sustainability 2011, 3, 965. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Ghasemzadeh, H.M.; Talari, T.B.; Ghorbani, M.A. Replacing Fibre reinforced concrete with bitumen asphalt in airports. World Acad. Sci. Eng. Technol. 2009, 58, 30–34. [Google Scholar]

- Grogan, W.P.; Johnson, W.G. Stabilization of high plasticity clay and silty sand by inclusion of discrete fibrillated polypropylene fibers (Geofibers®) for use in pavement subgrades. US Army Corps Eng. Waterw. Exp. Stn. 1993, 27–30. [Google Scholar]

- Tingle, J.S.; Santoni, R.L.; Webster, S.L. Full-scale field tests of discrete fiber-reinforced sand. J. Transp. Eng. 2002, 128, 9–16. [Google Scholar] [CrossRef]

- Santoni, R.L.; Webster, S.L. Airfields and roads construction using fiber stabilization of sands. J. Transp. Eng. 2001, 127, 96–104. [Google Scholar] [CrossRef]

- Hazirbaba, K.; Gullu, H. California Bearing Ratio improvement and freeze-thaw performance of fine-grained soils treated with geofiber and synthetic fluid. Cold Reg. Sci. Technol. 2010, 63, 50–60. [Google Scholar] [CrossRef]

- Ruan, B.; Zheng, S.; Teng, J.; Ding, H.; Ma, C. Analysis on the triaxial shear behavior and microstructure of cement-stabilized clay reinforced with glass fibers. Adv. Civ. Eng. 2020, 2020, 8842091. [Google Scholar] [CrossRef]

- Shalabi, F.I.; Mazher, J.; Khan, K.; Amin, M.N.; Alqahtani, M.; Awad, H.; Alghannam, A.; Albaqshi, H. Evaluating the Effect of Cement and ARG Fiber on the Mechanical and Microstructural Properties of Dune Sand. Adv. Civ. Eng. 2024, 2024, 5538831. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Damage propagation rate and mechanical properties of recycled steel fiber-reinforced and cement-bound granular materials used in pavement structure. Constr. Build. Mater. 2018, 172, 112–124. [Google Scholar] [CrossRef]

- Ma, Y.; Gu, J.; Li, Y.; Li, Y. The bending fatigue performance of cement-stabilized aggregate reinforced with polypropylene filament fiber. Constr. Build. Mater. 2015, 83, 230–236. [Google Scholar] [CrossRef]

- Brasse, K.; Tracz, T.; Zdeb, T. The Effect of the Type and Amount of Synthetic Fibers on the Effectiveness of Dispersed Reinforcement in Soil-Cements. Materials 2020, 13, 3917. [Google Scholar] [CrossRef]

- Xiaochun, Q.; Xiaoming, L.; Xiaopei, C. The applicability of alkaline-resistant glass fiber in cement mortar of road pavement: Corrosion mechanism and performance analysis. Int. J. Pavement Res. Technol. 2017, 10, 536–544. [Google Scholar] [CrossRef]

- Cheng, C.; He, J.; Zhang, J.; Yang, Y. Study on the time-dependent mechanical properties of glass fiber reinforced cement (GRC)with fly ash or slag. Constr. Build. Mater. 2019, 217, 128–136. [Google Scholar] [CrossRef]

- Gailitis, R.; Sprince, A.; Kozlovksis, T.; Pakrastins, L.; Volkova, V. Impact of Polypropylene, Steel, and PVA Fibre Reinforcement on Geopolymer Composite Creep and Shrinkage Deformations. J. Phys. Conf. Ser. 2023, 2423, 012030. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Gayathri, V. Geotechnical behavior of fly ash mixed with randomly oriented fiber inclusions. Geotext. Geomembr. 2003, 21, 123–149. [Google Scholar] [CrossRef]

- EN 14227; Hydraulically Bound Mixtures. Specifications. Comite Europeen de Normalisation: Brussels, Belgium, 2006.

- EN 14889-2; Fibres for Concrete. Polymer Fibres. Definitions, Specifications and Conformity. Comite Europeen de Normalisation: Brussels, Belgium, 2006.

- EN 15422; Precast Concrete Products. Specification of Glassfibres for Reinforcement of Mortars and Concretes. Comite Europeen de Normalisation: Brussels, Belgium, 2008.

- EN 197-1; Cement—Composition, Specifications and Conformity Criteria for Common Cements. Comite Europeen de Normalisation: Brussels, Belgium, 2019.

- EN 196-6; Methods of Testing Cement—Determination of Fineness. Comite Europeen de Normalisation: Brussels, Belgium, 2019.

- EN 196-3; Methods of Testing Cement—Determination of Setting Time and Soundness. Comite Europeen de Normalisation: Brussels, Belgium, 2016.

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Determination of Particle Density and Water Absorption. Comite Europeen de Normalisation: Brussels, Belgium, 2022.

- EN 933-3; Tests for Geometrical Properties of Aggregates—Determination of Particle Shape. Flakiness Index. Comite Europeen de Normalisation: Brussels, Belgium, 2012.

- EN 933-4; Tests for Geometrical Properties of Aggregates—Determination of Particle Shape. Shape Index. Comite Europeen de Normalisation: Brussels, Belgium, 2008.

- EN-1097-2; Tests for Mechanical and Physical Properties of Aggregates—Methods for the Determination of Resistance to Fragmentation. Comite Europeen de Normalisation: Brussels, Belgium, 2020.

- EN 13286-41; Unbound and Hydraulically Bound Mixtures—Test Method for the Determination of the Compressive Strength of Hydraulically Bound Mixtures. Comite Europeen de Normalisation: Brussels, Belgium, 2021.

- EN 13286-42; Unbound and Hydraulically Bound Mixtures—Test Method for the Determination of the Indirect Tensile Strength of Hydraulically Bound Mixtures. Comite Europeen de Normalisation: Brussels, Belgium, 2003.

- EN 13286-50; Unbound and Hydraulically Bound Mixtures. Comite Europeen de Normalisation: Brussels, Belgium, 2004.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).